A nationwide survey conducted by the Auto Care Association has shed light on the significant obstacles that independent automotive repair shops encounter due to restricted access to vehicle repair and maintenance data. This limitation not only hampers their operational capabilities but also leads to substantial financial losses.

technician recruitment and inflation. This data is crucial for these businesses to perform routine repairs and maintenance effectively.

Moreover, the majority of these shops face routine difficulties in servicing vehicles, with 63% encountering obstacles on a daily or weekly basis. About 51% of the shops reported being forced to

The findings support the need for the REPAIR Act (H.R. 906), a federal bill that would ensure vehicle owners and repairers of their choice have access to the vehicle data, tools and software required to maintain and repair modern vehicles.

The survey revealed 84% of independent repair facilities identify access to vehicle repair and maintenance data as their paramount concern, overshadowing other pressing issues such as

redirect up to five vehicles each month to dealerships due to these data restrictions, resulting in an estimated annual financial impact of $3.1 billion across the industry.

“This research sheds new light on the stark reality facing the 273,000 shops and 900,000 technicians in in the United States if Congress fails to take action on federal right to repair legislation,” said Bill Hanvey , president and

The Kansas Auto Body Association (KABA) and the Collision Repair Education Foundation (CREF) announced a collaborative effort to raise money for scholarships and grants provided exclusively to Kansas students and schools, while encouraging more to take advantage of those opportunities.

The organizations are also aiming to help collision repairers in the state connect with their local training programs, to ensure students are getting the best possible technical education to prepare them to ultimately join the industry.

Kena Dacus, president of KABA,

Joe Hudson’s Collision Center expanded its footprint with seven new acquisitions in Texas, Kentucky, Arkansas and its newest state, Missouri.

The most recent acquisition is that of Complete Collision, with two locations along Route 66 in St. James and St. Robert, MO. Owned and operated by Jim Smith, the Complete Collision teams have more than 120 years of combined collision repair experience.

“The vibrant communities of St.

and St. Robert present excellent opportunities for growth,” said Brant Wilson, CEO of Joe Hudson’s

On a recent episode of The Collision Vision podcast, driven by Autobody News, host Cole Strandberg spoke with Michelle Sullivan , who became CEO of Certified Collision Group (CCG) earlier this year.

The conversation touched on high level industry trends, the future of independent collision repairers, and how independent shops can stay competitive in an increasingly consolidated industry.

“There’s no sign of [consolidation] slowing down in 2024,” Sullivan said. “We’re seeing a lot of regional private equity-backed platforms coming into the industry. Yes, the consolidators are growing, no question about that. But so are the regionals and so are single-store operators.”

Sullivan said high-performing shops have multiple OEM certifications and are focused on culture.

they didn’t have a backlog, they just figured it out.”

Sullivan said she is a “huge supporter” of peer groups, like 20 Groups, and networks. CCG has built a network of nearly 800 like-minded operators across 46 U.S. states, and earlier this year announced it is expanding into Canada. Sullivan said there is power in those operators being able to connect, bounce ideas off each other and share best practices.

Sullivan’s career in the collision repair industry began about 30 years ago in Baltimore, MD, when she went to work for Superior Auto Paints. She worked in every department within the company on her way to rising to become president.

After Superior Auto Paints was sold to a national distributor, Sullivan worked for AkzoNobel and FinishMaster. In those positions, she worked as a vendor partner for CCG when it first came to the market 10 years ago.

“Industry dynamics were changing, consolidation was ramping up. And [CCG] came in with the premise of kind of leveling the playing field for the independent repairers,” Sullivan said. “Their premise was the OE certifications and really improving shop performance. How can you not get behind that?

“I was able to see firsthand what some of those affiliates were experiencing. Whether it was shop performance or performance management or the vendor programs, it was impactful,” Sullivan said. “So when the opportunity came up [to join CCG as CEO]…I was thrilled. It’s a full circle moment for me because I’m working with a lot of customers, a lot of vendors, and a lot of stakeholders that I’ve worked with at some point in my career.”

“Consolidation will continue, but so will the independents. They’ll continue to thrive,” she said. “There’s more pressure on having that exceptional customer service experience. Everyone wants that Amazon-type experience. You know, everything is easy. And our industry is no exception to that. So shops that figure that out, they’ll be successful.”

“I read this quote a long time ago and it stuck with me: ‘Your customer experience will never be greater than your employee experience.’ That’s so powerful,” Sullivan said.

The high performers are focused on their employees, Sullivan said.

“They’re creating an ownership mindset, and they’ve got people on the team that want to contribute,” she said. “They don’t have issues with retention, right? They’re keeping their teams. Their teams are engaged, and there’s something to be said for that with the employees.”

Sullivan said the first time she visited a shop that wasn’t chaotic, it was almost eerie.

“They had figured out how to create processes that minimize that chaos,” she said. “It’s not that they weren’t busy, and it’s not that

dramatically,” she said. “Not only make sure that you’re up to speed on what the trends are, what the changes are, but that your team is and that your organization is positioned for that. You’re not responsible just for yourself, but you’re responsible for those that you serve.”

Sullivan’s second takeaway is to invest in the development of others.

“We’re not fighting each other; we’re all rising together,” Sullivan said.

Sullivan said CCG looks for shops with industry-leading KPIs and OEM certifications. Then CCG’s performance management groups work with shops to help them further improve their businesses.

“One of the biggest things our affiliates really love about the network is these are highperforming operators that have really built solid reputations in their market,” Sullivan said. “They’re very much involved with the community and their name and their legacy is important to them. We have a very nonintrusive model, so you don’t have to change your name. You don’t have to give up everything that you know you’ve built.”

Sullivan said CCG’s affiliates appreciate that model.

“There’s a lot of interest in the network,” she said. “As consolidation continues, people are looking to level the playing field. The company was built on that foundation. And that still exists today.”

Sullivan said in her 30 years in the industry, she has never taken for granted the dedication and commitment of all stakeholders to performing proper repairs.

“I just want to give a shout-out to all those people out there, because they’re really the difference makers,” she said.

Sullivan said her first takeaway is to embrace being a lifelong learner.

“There is always something to learn. This industry is changing

“I read this quote a long time ago and it stuck with me: ‘Your

customer experience will never be greater than your employee experience.’ That’s so powerful.”

MICHELLE SULLIVAN CEO OF CCG

“Understand what the individuals on your team want, what their ‘why’ is, understand where they want to go, and be relentless in helping them get there,” she said. “High performers want to contribute. They love feedback and they love transparency. If you have a high performer on your team, make sure that you’re having regular career path conversations with them so you don’t ever run the risk of losing them.

“But more importantly, they lead the industry,” she added. “So again, that customer experience will never be greater than the employee experience.”

Sullivan’s third takeaway is to build your community and stay connected.

“Industry organizations are a great way to be connected to the overall industry,” she said. “You learn from the organizations and today, more than ever, there is a need for that. And you can find those 20 groups that we talked about and find a way to stay connected.”

Sullivan encouraged listeners to follow CCG on LinkedIn for an exciting announcement set to come out at CCG’s conference April 21. More information on CCG can also be found on its website, certifiedcg.com.

Listen to the full episode at www. autobodynews.com/podcasts or watch it at www.youtube.com/ watch?v=WteWcElj8kA

Ask collision repair shop owners and managers where they currently are focusing added resources, and staffing is fairly consistently at the top of the list.

“I kind of feel like the shepherd protecting my flock most of the time to guard off poaching, making sure they’re not getting enticed to go elsewhere,” said Andrew Batenhorst, manager of Pacific BMW Collision Center in Glendale, CA.

Batenhorst noted that at least in his market, it’s not just other shops looking to attract workers.

“The city has jobs with pension programs and health benefits, and they are ramping up [recruiting] efforts as they’re losing a lot of the Baby Boomer generation who have been in those jobs for 40 years,” Batenhorst said. “They’re aggressively luring people in. So that’s kind of a new threat that we’ve not really seen in this market until the last year or two.”

Scott Benavidez, owner of Mister B’s Paint and Body in Albuquerque, NM, is also focused on challenges related to human resources. He helped get a basic collision repair training program launched this year at a high school near his shop.

“We’ll be the first one in the nation to pilot I-CAR’s new program to start training people who may not have even touched a screwdriver,” Benavidez said. “We’re going to see how it works in my local high school here. If we can start them out from the ninth grade to the 12th grade, by the time they get out, they’re going to be beneficial to us. There’s five basic things we want them to learn: Small dent repair, R&I bolted-parts, plastic repair, prep paint and color sand and rub. If one of those kids came in my shop today with that, I’d hire them immediately.”

Benavidez said CCC Intelligent Solutions is putting an estimating system in the school to help students start learning about estimates and parts tracking.

“The Automotive Management Institute is going to do classes for these kids in how to answer the phone, how to talk to a consumer, how to see if vehicles are drivable from the get-go,” he said.

Benavidez said there’s a sizable student population in his area that are unlikely to go to college and want to begin earning right out of high school to help their families. “Hopefully this will help them and help our industry,” he said. “We’re trying to build a program where we move them in steps to get them ready to go into a shop by the time they are juniors and seniors, maybe even apprenticing during the summer. And then we can teach them the rest.”

Will Latuff, president of Latuff Brothers Auto Body in St. Paul, MN, is focusing on developing new technicians in-house.

“We have three employees who are new to us, two right out of trade school and one with little automotive experience, who we have paired up with mentor techs,” Latuff said. “We’re working on systematically increasing their skillsets so that they can become full-fledged techs. And then as we start growing those skills, we will bring on probably at least one more in the next year.”

One change that has made that more feasible to do: Latuff converted all his flat-rate technicians to hourly.

“There were more reasons behind that than just training, but that was one of the barriers to enabling a master tech to become a mentor,” Latuff said. “Because if a tech is dependent on what they produce,

“If we get that off the ground, there’d be more resources for autobody technicians throughout the state.”

— TOM RICCI BODY & PAINT CENTER

they’re not going to be focused on teaching new skills.”

One of the trainees, who is working at the shop while in his first year of trade school, didn’t have much in the way of tools, Latuff said, so the shop got him a basic set tools. “That’s not earth-breaking, but making sure he

doesn’t have to borrow our mentor’s tools is kind of key,” he said.

Also necessary, Latuff said, is having a good plan. “A lot of people

seem to think that the first thing somebody needs to learn is cosmetic dent repair, and it’s absolutely not. They need to learn organization, damage analysis, disassembly, reassembly, panel fitment.”

It’s also important to help guide the mentor techs through the process, he said. “They have a lot of knowledge but don’t always know how to translate that to a trainee,” he said. “You don’t get frustrated with a baby because they don’t know how to walk. It’s the exact same thing when

you bring in new employees. The mentors need to know those trainees don’t know what they haven’t told them. And if you tell them once, they may not remember because they’re trying to absorb so much. So you may have to tell them again and again. You have to have that empathy or that heart to transfer the knowledge.”

Like Benavidez, Tom Ricci, owner of Body & Paint Center in Hudson, MA, is also working to increase the pool of potential entry-level technicians, but he’s looking beyond local schools. He’s trying to get an auto body program established as part of rehabilitation program at a correctional institute in his state.

“I’m involved in the program that’s working to get lower-level criminals back out in the workforce, helping them with re-entry,” Ricci said. “I’ve talked to a couple of people already in regards to trying to get an auto body training program up and running. If we get that off the ground, there’d be more resources for auto body technicians throughout the state.”

State-of-the-art paint systems and the latest application recommendations open up new possibilities, but also pose new challenges for professional painters. The SATAjet X 5500 featuring the new X-nozzle system defines a completely new application standard for the future.

Revolutionary: The X-nozzles are taking atomization to a whole new level

Noticeably quieter: reduced noise level in the relevant sound frequency ranges due to optimized flow geometry of the whispering nozzle

Individual: Matches any application requirement, such as specific characteristics of the paint system, climatic conditions and application method (application speed/control)

Precise: Optimized material distribution for enhanced spraying uniformity and atomization with both spray fan shapes

Low maintenance: No air distribution ring required, which ensures a much easier and faster cleaning process

Efficient: The optimized atomization concept allows for considerable material savings

INFO

www.sata.com/x5500

SATA USA Inc.

1 Sata Drive • PO Box 46

Spring Valley, MN 55975

Phone: 800-533-8016

E-mail: satajet@satausa.com

www.satausa.com

Just saying something doesn’t make it so.

Too often I hear collision shop owners say that they’re going to do something – improve customer satisfaction, increase sales or reduce cycle, for example. But when pressed for exactly how they’re going to do that, their answers are often pretty vague.

Ladies and gentlemen, just because you say something is going to happen doesn’t mean it will. That’s a wish, a desire that something will happen, rather than a plan to make it happen. A goal is when you actually have an action plan – preferably in writing – on how to accomplish it.

A good action plan answers: What are you going to do? Why are you going to do it? How are you going to do it? Who will be involved?

Let’s take shop owner “Rob,” who wants to increase his shop’s sales by $400,000 a year. He built an action plan for accomplishing that goal.

Mike Anderson — From the Desk of Mike Anderson A

One step, he decided, is to capture more necessary but not-included labor operations the shop is already

doing, but not consistently including on estimates or final bills. He and his estimators looked through some of our “Who Pays for What?” survey reports, and decided it’s realistic they can capture one more labor on every job. At 100 jobs a month and a $63 per hour labor rate, that would add $6,300 per month (or $75,600 a year) to the shop’s annual revenue.

So how will they get that extra labor hour per job? The first Thursday of each month, Rob will have a meeting with his blueprinting and sales staff to go over two or three not-included items the shop is doing regularly that could be included on estimates. Together, they will discuss how to negotiate for those items.

Think about that plan: It lays out what is going to happen, who is involved, and when and how they are doing it. That’s a goal, not just a wish.

The other part of Rob’s action plan is to improve the shop’s closing ratio. Right now the shop has a 60% closing ratio. That means it is writing about $900,000

in estimates every month, but only capturing about $540,000 (60%) of that potential work.

Rob sets a goal of improving that closing ratio to 63%. That would mean the shop’s sales would rise to $567,000 per month (63% of $900,000) without needing to get a single additional customer through the door.

How will Rob accomplish that goal? First, he is going to bring in some after-hours sales training for

his team. And every estimate for a job not immediately scheduled by the customer will be put into a file; an estimator or customer service rep will call each of those customers the next day with a script Rob and his team develop to help get that job scheduled. If unsuccessful, that estimate will move into another file for another follow-up call a certain number of days later.

The added labor hour per job will generate an additional $75,600 in revenue over a year. The improved closing ratio will generate an additional $324,000. That puts Rob within $400 of his goal. And it’s not just a wish. He has an action plan for how to accomplish it, with specifics about what will be done and who will do it.

So enough with the wishes. Set goals. Put the plan in writing. Keep it to a manageable four or five action items. And delegate but don’t abdicate; get others involved, but don’t just dump it on them. Then regularly show them how the shop as a team is making good on that plan.

Drive profitability through efficiency, consistency, and quality repairs with OEC collision shop solutions

Solutions for the Modern Collision Repair Business

Parts Ordering

Repair Planning

Certified Repair

Coaching

Download the Repair Planning Field ReportV3

Discover the ways RepairLogic is improving repair safety by helping repairers adapt to Electric Vehicles and track OEM procedure changes.

www.OEConnection.com

What are you waiting for?

Learn more about our collision shop solutions and how the solutions can help your shop drive consistent and quality repairs.

Two federal agencies recently submitted a joint comment recommending renewing and expanding temporary repairrelated exemptions to a federal law protecting copyrighted content, to allow consumers’ and businesses’ right to repair their own products.

The Federal Trade Commission (FTC) and the Department of Justice’s Antitrust Division (DOJ) submitted the comment to the U.S. Copyright Office, which might recommend the Librarian of Congress renew and expand exemptions to the Digital Millennium Copyright Act (DMCA), passed in 1998, which prohibits circumventing measures that control access to copyrighted content.

In their comment, the FTC and DOJ said renewing and expanding repair-related exemptions would promote competition in markets for replacement parts, repair and maintenance services, as well as allow competition in markets for repairable products. Doing so would benefit consumers and businesses by making it easier and cheaper to fix things they own. Expanding repair exemptions can also remove barriers

that limit the ability of independent service providers to provide repair services.

According to the comment, software “locks” that protect copyrighted content from theft and infringing uses can also be used to prevent third-party repair, by the owner of the product or an independent repairer.

For example, such measures can restrict access to computer maintenance hardware and software programs, leaving only the OEM able to do maintenance and repair work. The FTC and DOJ said that can be used to squash competition for replacement parts, repair and

maintenance, which ultimately limits consumers’ and businesses’ choices and raises costs.

Among the specific DMCA exemptions the FTC and DOJ support renewing is one related to the repair of vehicles. They also support adding a new one to allow vehicle owners or independent repair shops to access, store and share vehicle operational data.

In a statement, Bill Hanvey, president and CEO of Auto Care Association, said his organization supports the joint comment.

“In particular, on behalf of the entire automotive aftermarket, Auto Care Association agrees with the DOJ and the FTC that the Class 7 exemption to allow vehicle owners and repair facilities greater access to vehicle diagnostic and telematics data for monitoring purposes is critically important to lower the cost of repairs, improve access to repair services, and minimize costly and inconvenient delays,” Hanvey said.

The Auto Care Association also launched a new video campaign emphasizing the need to pass a new law, the Right to Equitable and Professional Auto Industry Repair (REPAIR) Act, which was unanimously advanced by the U.S. House Energy

and Commerce Subcommittee on Innovation, Data, and Commerce last November.

In the new campaign, shop owners from across the U.S. share their stories and shed light on the increased challenges independent repair shops are facing with accessing repair data to service their customers’ vehicles.

“You can’t do the simplest job anymore without [needing] to get into the computer system,” said Dwayne Myers, co-owner of Dynamic Automotive, an automotive repair business with six locations in Frederick County in Maryland. “If Congress doesn’t take action on the right to repair, it will only increase what it costs to fix your car. The REPAIR Act has bipartisan support because it really ties back to the American dream. It puts everyone on a fair playing field.”

“The impact to the consumer is that they have less choice and pay more for repairs that take two, three or four times longer,” said Kathleen Callahan, owner of Xpertech Auto Repair, a family-owned automotive repair shop in Englewood, FL. “I support the REPAIR Act because I want to protect my legacy, my customer’s choice, and the independent aftermarket that I’m so proud to be a part of.”

TWC/HO2S/WR-HO2S/CAC/TC/DFIU.S.

2.3L-Group:GFMXV02.3VJW

Evap:GFMXR0125NBV Noadjustments FEDOBDII ABZ

Thecombinedweightofoccupantsandcargoshouldneverexceed

TOAVOIDSERIOUSINJURYORDEATH: •Donotleanagainstthedoor. •Donotuseseatcoversthat Seeblocksideairbagdeployment. owner’smanualformoreinformation.

AVERTISSEMENT

POURÉVITERDESBLESSURES

GRAVESOUMORTELLES: •Nevousappuyezpascontrelaporte. •N’utilizezpasuncouvre-siège quipeutbloquerledéploiementdu Voircoussingonflablelatéral.lemanuelduconducteurpour deplusamplesrenseignements.

Californiaclass/stds: PC/ULEVqualified Group: FGMXV01.80111.2L

Evap:SFI/HO2S/TWCFGMXR0095805 , OBD:II

SRSSIDEAIRBAG COUSSINGONFLABLELATÉRAL (SRS)

TIREANDLOADINGINFORMATION

SEATINGCAPACITY

REAR 2

TOTAL 4 FRONT 2

Thecombinedweightofoccupantsandcargoshouldneverexceed352kgor776lbs. 240kPa,35PSI240kPa,35PSI

TOAVOIDSERIOUSINJURYORDEATH: •Donotleanagainstthedoor. •Donotuseseatcoversthat Seeblocksideairbagdeployment. owner’smanualformoreinformation.

COLDTIREPRESSURE

TIRE SIZE

215/55R1697H

POURÉVITERDESBLESSURES

FRONT REAR SPARE

GRAVESOUMORTELLES: •Nevousappuyezpascontrelaporte. •N’utilizezpasuncouvre-siège quipeutbloquerledéploiementdu Voircoussingonflablelatéral.lemanuelduconducteurpour deplusamplesrenseignements.

WARNING AVERTISSEMENT THIS VEHICLE CONFORMS TO ALL APPLICABLE FEDERAL MOTOR VEHICLE SAFETY THEFT PREVENTION STANDARDS IN EFFECT ON THE DATE OF MANUFACTURE SHOWN ABOVE .

215/55R1697H

T125/85R1699

Conformstoregulations: 2015 Fuel: Gasoline

U.S.EPAclass/stds: LDV/TIER2

SEEOWNER’S MANUALFOR ADDITIONAL INFORMATION

Californiaclass/stds: PC/ULEVqualified Group: FGMXV01.80111.2L

420kPa,60PSI

TIREANDLOADINGINFORMATION

combinedweightofoccupantsandcargoshouldneverexceed352kgor776lbs. 240kPa,35PSIPSI

VEHICLEEMISSIONCONTROLINFORMATION

Conformstoregulations:2016 MY

U.S.EPA:T2B4 LDV

TWC/HO2S/WR-HO2S/CAC/TC/DFI

FEDOBDII Fuel: Gasoline ABZ

California: Not for sale in states with California emissions standards.

2.3L-Group:GFMXV02.3VJW

Evap:GFMXR0125NBV

Noadjustmentsneeded.

A new survey conducted by WrenchWay found the average collision repair technician makes far more than the U.S. Bureau of Labor Statistics (BLS) reports, but more data is needed to be able to definitively present that positive information to young people considering a career in the industry.

WrenchWay co-founders Jay Goninen and Mark Wilson presented the results from their 2024 Technician Pay survey, which gathered data on pay and benefits from technicians across the country, in a Zoom webinar March 26: “Is BLS Data a Bunch of BS?”

median experience of 13 years.

“We were light on data for the collision side, but hopefully you guys can help us get more,” Wilson said.

The survey results are available for all to see via the Automotive and Diesel Technician Compensation Tool at wrenchway.com/pay. Users can filter the results by industry category, shop type, ZIP code and radius, and years of experience in the industry.

That is also where technicians can continue to submit their own pay data, which Wilson and Goninen encouraged everyone to do. They also asked technicians and managers to invite friends, employees and coworkers to fill out the sevenquestion survey.

According to the BLS, the average pay of an automotive technician is $46,970 per year, or $22.58 per hour, and the average pay for diesel technicians is $54,360 per year, or $26.14 per hour. The agency also cites the highest 10% earning around $75,000.

Goninen and Wilson said they already knew from the more than 1,000 shops on WrenchWay and countless others they work with that the data is simply not accurate.

Their brief, self-reported survey has been completed by about 3,000 technicians so far, which were broken down into four industry categories: automotive, diesel, collision and school, which covers high school and college instructors.

The data shows the mean salary for collision repair technicians was about $87,000 per year, and the average was $89,000.

However, of those 3,000 responses, only 43 came from collision repair technicians, with a

Wilson said the problem with the BLS statistics is that it groups so many careers under “automotive technician,” from an entry-level employee at a quick lube shop to a master technician with 40 years of experience.

BLS data also figures out annual salaries by simply multiplying hourly rates by 2,080 hours a year, but that doesn’t take into account those who work more than 40 hours per week, so a lot of technicians make more in a year than their hourly wage would indicate.

“That method just doesn’t work in our industry,” Wilson said.

The result is an average pay that doesn’t look appealing to young people considering a career to pursue.

“The problem is a high school student shows interest, they look at salary data from BLS and it s good, but not great,” Goninen said. “There’s a lot of training to keep up with and the student has to pay for their own

tools. It’s all false except the tool part. There are some really competitive salaries.”

Goninen and Wilson acknowledged the fact the responses largely came from experienced technicians, which skewed the average salary numbers higher than those for entry-level technicians with less than three years of work experience.

“A lot of people want to see the industry promoted as a great career,” Wilson said to explain why longtime technicians seemed to be more willing to participate.

Goninen said going in, they had been a little concerned only entrylevel technicians would respond, which would not show the long-term earning potential.

“We want to have realistic data,” Goninen continued. “We don t want to over emphasize the beginning salary, because it’s hard to compete with Amazon and others offering bigger starting salaries, but we can give them hope, that maybe if I can stay in this industry, I can have a very successful career.”

Looking at the rest of the survey results, a large majority – about twothirds – of all respondents said they were automotive technicians. They reported a mean experience level of 18 years, a mean salary of just over $89,000 and a median of $83,000.

Wilson said setting the results to show auto techs with zero to three years of experience returned a mean salary of $49,173, about what he expected. There were not enough collision repair respondents with the same amount of experience to generate a result.

The automotive technician data can be further broken down into those working for dealerships, either domestic or import brands; independent shops servicing all makes and models or specializing in one; fleet; service and tire chains; quick change lube shops; mobile services; or those servicing RVs or EVs.

Diesel technicians were the next-largest segment, with 644 respondents with a mean experience of 13 years, a mean salary of $83,519 and median of $77,509. They could indicate if they worked in a shop, or on construction or agricultural equipment.

The “school” category had a handful more respondents than collision repair – 50 respondents with a mean experience of 30 years reported a mean salary of $79,013 and median of $77,750.

In a follow up call, Goninen said WrenchWay is still developing its relationship with the collision repair industry. The aim is to gather enough data from technicians to be able to break it down into salaries for working in dealerships vs. independent shops and other subsets, similar to the automotive technician and diesel categories.

“We’re still very much growing the collision side of this,” Goninen said. “It’s very early in the process.”

Goninen said collision repair shops can join WrenchWay to post jobs, be searchable for technicians looking for jobs, and connect with local schools.

“The job board is like Zillow is to housing,” Goninen said. “A technician can do their due diligence on an employer, and an employer has a chance to ‘sell’ themselves to new employees.”

The School Connect program allows automotive education programs at high schools and postsecondary schools to ask for what they need to effectively teach their students – be it speakers to come to class, new equipment, or shops to place their students in apprenticeships, internships and job shadows.

For instance, one school posted to the School Connect board looking for a new brake lathe, which was donated before the end of the week by a local car dealership.

“It helps grow that program,” Goninen said. “So many schools have significant budget restrictions that lead to the program being cut. They need proper equipment and tools. The [donating] shop gets to build a relationship with that school beyond a twice-a-year advisory committee meeting.”

“I think job shadows will be critical as we move forward,” Goninen added.

For more information, visit wrenchway.com.

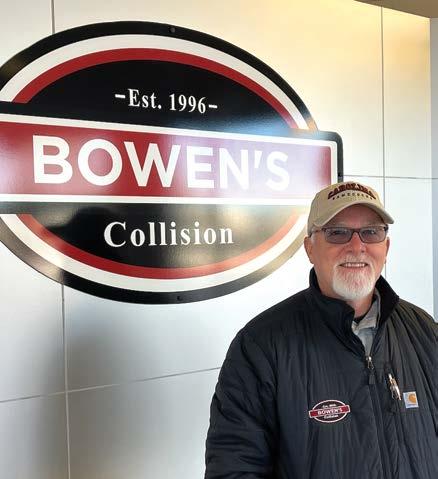

For 27 years, Bowen’s Collision has been a pillar of the Columbia, South Carolina community, but it was only in the last two years that the family-owned and operated business experienced impressive growth, adding two new locations, with plans to open more in the next few years.

General Manager Scott Austin attributes Bowen’s Collision’s success to their world-class customer service and top-quality repairs.

Putting customers first and delivering high-caliber repairs wouldn’t be possible without consistent performance, which is why Austin focused on developing more standardized routines and processes for his technicians to streamline things like diagnostic scans, which he believes gives Bowen’s Collision a competitive edge.

In fact, the decision to scan every vehicle that comes into the shop was a “no-brainer,” according to Austin, because the benefits of doing so far outweigh the drawbacks. He said most manufacturers no longer recommend scans –– they require them, yet not every shop does them consistently.

“Scans cover all the bases,” says Austin. “Pre-repair scans help us find out where the initial problems are and eliminate others right away. Documentation beats conversation and having all the information up front helps us know what we’re getting into and be prepared to have a discussion if we have to. It’s good for our customers and it’s great for our shops.”

Austin says the benefits of knowing more about vehicle damage earlier in the repair process can help save everyone time,

money, and resources, which leads to happier customers. It’s also increased revenue and profitability for his shop, he said. The cost of a brand-new scanner quickly pays for itself because the shop can bill carriers or self-paying customers for each scan, and the scans aren’t time-consuming to perform.

The problem shops often have with integrating diagnostics into their repair processes is “remembering not to forget” to scan or calibrate, sometimes even resorting to sticky notes to remind them of these critical tasks.

Austin says that’s why he uses CCC® Diagnostics Workflow, because it helps his team integrate diagnostics into every single repair plan and keep track of every scan all in one place. The result?

A diagnostics process that comes naturally to his technicians. They no longer need reminders, and they don’t even have to think about it –– it’s simply a required operation for every vehicle, every time.

“You’ve got to make sure you do it, because it’s the times you don’t that you get whistle bit,” Austin says. “We’re all about helping people –– that’s truly our mission, and if we can make a customer feel better about their repair knowing we did everything we could to diagnose the problem, well, then, we’re practicing what we preach.”

To learn more about CCC Diagnostics Workflow, visit www.cccis.com/diagnostics

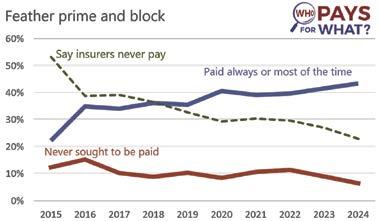

A recent industry survey found while fewer shops are successfully negotiating to be paid their higher labor rate for aluminum repair work, other new vehicle technology is adding more lines to shops’ estimates and final invoices.

Among more than 500 shops participating in a recent “Who Pays for What?” survey, the vast majority — 84% — perform aluminum repair work, and 43% hold an OEM certification for aluminum repair from one or more automakers. With the added expense of separate tools and work areas designated for aluminum work, along with training and other certification requirements, shops have seen a need for different hourly rates for aluminum repair compared to standard steel body repairs.

It appears insurers, however, have been pushing back on those higher labor rates for aluminum work. Over the past five years, fewer and fewer shops participating in the surveys are being paid the higher rates. Just 29% of those performing aluminum work reported through the survey they are being paid their aluminum rate on a regular basis (“always” or “most of the

time”) by the eight largest national insurers. That was down significantly from the same survey five years ago, when 54% of shops said they were regularly being paid their aluminum repair rates.

The average percentage of shops reporting that insurers “never” pay their aluminum rates has been slowly

grows, for example, more shops are getting paid for keeping those vehicles charged while in the shop. Nearly 2 in 5 shops (38%) say they are paid always or most of the time by the largest insurers for electric vehicle recharge. That was up nearly 13 percentage points from a year earlier. About an equal percentage

increasing over the past five years as well, rising from 25% in 2019 to 37% in late 2023.

In better news for collision repairers, however, shops are more regularly being paid for labor operations that are becoming increasingly common because of changes in vehicle technology.

As the electric vehicle population

(41%) said those insurers never pay for that procedure, but that was down from about 50% the prior year.

Given that only a small — but growing — number of automakers require a radar power test on select vehicle models, it’s perhaps not surprising that two-thirds of shops responding to the survey said they had never billed for the procedure.

But the survey, which was the first to ask about radar power tests, found more than 2 in 5 shops (42%) that have billed one or more of the eight largest insurers for the procedure said they have been paid all or most of the time.

“It’s a static function test to see if painting the bumper has reduced the power of a radar sensor too much,” said Mike Anderson of Collision Advice, who conducts the “Who Pays” surveys. “The test is needed if the system uses higher resolution radar for blind spot systems that are able to identify not just a vehicle in the blind spot, but even smaller objects such as a bicycle.

“The test uses what is essentially a metal pole on wheels, to measure, when the system is engaged, how much the bumper cover is reducing the power signal of the radar sensor,” Anderson continued. “The test is currently required for some Mercedes-Benz and Toyota vehicles but likely will be required on more makes and models in the future.”

The latest “Who Pays” survey, which focuses on not-included frame and mechanical labor operations, is open during the month of April; shops can click visit www.surveymonkey. com/r/9NC7D6B to take the survey.

One of the most important skills for successful collision repair estimators is a good working knowledge of the “p-pages,” or estimating reference manual, for the information system they are using, whether it is made by Audatex, CCC or Mitchell. These guides help an estimator understand what is included – and just as importantly, what isn’t included – in the labor times provided within the systems. The guides differ from one another and continue to evolve, so staying abreast of changes is important.

Danny Gredinberg of the Database Enhancement Gateway (DEG) said while the guide is generally accessible within the system itself, estimators reviewing an estimate prepared in one of the other systems may need to review that system’s guide as well. All three guides are available on the DEG’s website, degweb.org/industryestimating-systems/.

Gredinberg highlighted some of the recent changes in the guides in a presentation at an industry event earlier this year.

Audatex Solera Qapter Database Reference Manual

The latest version of the Audatex Solera Qapter Database Reference Manual, for example, spells out that “any fees related to OEM data subscriptions or information access are not included in part prices or labor values within Audatex estimating.” The same is true for any labor related to access or research of OEM service information or electronic parts catalogues.

Another new labor exclusion in section 4-2 of the document reads that “additional repair operations that are taught in an OEM training environment but aren’t included in the current OEM reference material” are not included in the system’s labor times.

“You may have to go to an OEM technical school to learn a specific repair procedure, for example,” Gredinberg said. “A lot of manufacturers may have specific information they don’t define in the actual OEM repair procedure. So it’s very important to attend the [OEM] training if it’s available because there are going to be a lot of takeaways from those for specific repairs.”

Also newly excluded from Audatex labor times is the labor to apply seam sealer on new parts that require it.

“This is an update because previously they did include seam

sealer application on bolt-on parts,” Gredinberg said.

Also excluded is assembly of new parts that come in multiple unassembled parts from the manufacturer.

“If you order a grille assembly, you may receive a box of four or five or seven different parts,” Gredinberg said. “You have to build that component to be installed. That is a not-included operation.”

Set-up of riveting equipment and

have to put a part on a stand to refinish it in a certain way,” he said. “Sometimes you have to get creative in order to get the coatings to all the nooks and crannies, the backsides and undersides. If you have to set a stand up in a unique way, that’s a notincluded operation.”

The guide now indicates repair times in the system include “one test fit of a component.” In response to a inquiry, Gredinberg said, Motor

materials, as well as test riveting, is also another new labor exclusion in Audatex.

Within the refinish guidelines in section 4-4, Gredinberg said, the blend formula wording – previously defined as 50% of the full panel refinish time –has been deleted, with Audatex stating that it “does not provide a standard labor allowance for blending panels as this requires the estimate preparer’s judgment [and] expertise, [along with] consideration of the unique requirements for each repair.”

“It allows the end-user to put whatever percentage they feel is necessary for performing the blend,” Gredinberg said.

A similar change related to the blend formula has been made in the Motor Guide to Estimating, the basis for the CCC Intelligent Solutions estimating system. Motor has eliminated blend formula, Gredinberg said, and instead states “estimated refinish times for color blending should defer to the judgment of an estimator or appraiser following an on-the-spot evaluation of the specific vehicle and refinishing requirements in question.”

Also in the refinish section, Gredinberg said, Motor has added that assembling or setting up a unique fixture or stand to hold parts for refinishing is a not-included operation.

“Many times when we’re painting parts off of the vehicle, we may

be included in that section with a labor allowance for the performance of the task if necessary.”

Gredinberg said another update notes the labor times shown for air conditioning evacuation and recharge represent “utilizing A/C servicing equipment in a collision repair environment that evacuates the system by applying vacuum that must be held by the system for a certain period of time (leak check) confirmed with an electronic leak detection equipment post refill.”

“So essentially take an electronic sniffer monitor like an A/C leak detection tool and check just the service ports, that’s included,” Gredinberg said. “But if you have to diagnose a leak within the entire system, that time is not factored into evacuate and recharge. Some vehicle manufacturers may have different routing of those lines and refrigerant type. So always follow manufacturer guidelines but, again, to leak check just at the ports is an included operation.”

clarified its labor times do not “include a second (or more) fitment of a component to the vehicle, for any reason (including verification of dimensional accuracy or adjacent part alignment),” and “if more than one component installation is required for a specific repair plan, an on-the-spot evaluation should be used for the number of fitments beyond the first one required to perform the repair.”

In the wheel section of the guide, Gredinberg said, “torque wheel to OE specifications” is now included in labor times.

“But if you look at a lot of these repair operations or repair manuals, it may tell you to retorque the wheel after so many miles of road testing the vehicle,” he said. “If you have to retorque, perform duplicate effort, it’s a not-included operation. So again, this identifies that one ‘torque wheel to specifications’ is included.”

Mitchell P-pages

Mitchell also has made recent changes to its Collision Estimating Guide P-pages. Under the labor general information section, for example, a new section on caulking indicates that “labor times…for bolton panels includes the application of caulking/seam sealer.” If Mitchell determines an OEM replacement part is not serviced consistently by a vehicle manufacturer, it will add a footnote — “does not include application of caulking” – to the specific panels, and “a headnote will

In any case, diagnosing a failed leak check test is not included, the guide states.

In terms of adhesive emblems, Gredinberg said, Mitchell says the times shown “represent installing the emblem in the correct location by performing some combination of measuring, marking and aligning to ensure proper positioning,” but “time for the fabrication of a template for emblem installation per a specific OEM procedure is not included.” Gredinberg said it’s important to check the OEM procedures for the emblems you are installing, and noted that according to the Mitchell guide, “research, retrieval, review or usage cost of OEM or other service procedural information” is a not-included operation – something all three information providers have updated to define as not-included steps.

Lastly, Gredinberg said, Mitchell has updated the guide to indicate the time to “perform weld testing or matching [including] destructive weld testing” is not included in the labor times in the estimating system.

said the idea came about when Brandon Eckenrode, executive director of CREF, mentioned no Kansas student or school had applied for a CREF scholarship or grant in several years.

“We brainstormed how to get more involvement,” Dacus said.

The result is the new KABA Collision School/Student Fund, facilitated by CREF, which will provide scholarships and grants, both only available to Kansas collision repair students and school programs.

Dacus said the deadline for the first round of student scholarship applications was March 8. KABA had only received two by that point, but it’s a good start: “As Brandon pointed out, two is better than none,” she said, adding that board members are currently reviewing the applications and expect to be able to fund both.

School programs are encouraged to apply for CREF’s annual Benchmark Grants, which award up to $25,000 each to high school and post-secondary collision repair programs to pay for tools, equipment and hands-on learning

opportunities. In 2023, CREF awarded $678,500 to more than 100 programs around the country.

The application for the 2024 awards is due June 28, and is available at collisionrepaireducationfoundation. org/schools/.

Dacus, who owns Dacus Auto Body & Collision Repair in McPherson, KS, with her husband, Chris, said Kansas collision repairers are facing the same challenges in finding enough quality technicians to run their business as their counterparts across the U.S.

“More shops are looking for students or folks you can ‘grow your own’ by giving them the training and tools.”

KENA DACUS KABA PRESIDENT

“We’re a pretty rural state,” Dacus said. “Most shops, if they’re not in Kansas City or Witchita, don’t really even have an opportunity to try to hire a tech from another shop. More shops are looking for students or folks you can ‘grow your own’ by giving them the training and tools.” To help those shops find potential

new technicians, KABA and CREF is helping them get involved with their local schools by finding volunteer and support opportunities for KABA members, including participating on a school advisory board, guest speaking at schools, donating auto parts to training, sponsoring Cintas work uniforms for collision students, or hosting students at their shops.

“We have been partnering together just to reach out to schools, and we’ve made huge progress in connecting with them so far,” Dacus said.

KABA is also organizing events to bring together Kansas industry members and collision students, while raising money for the KABA Collision School/Student Fund. The next such event is scheduled for July 13 at Top Golf in Overland Park.

Collision repairers can make a taxdeductible charitable donation to the KABA Collision School/Student Fund, by reaching out to either KABA or CREF to get a donation invoice created. Donations made to the fund will be specifically invested back into Kansas collision school programs and students.

For more information, contact Dacus at Kena@dacusauto.com or 620-803-2225, or Eckenrode at Brandon.Eckenrode@ed-foundation. org or 312-231-0258.

The Collision Industry Foundation (CIF) is delighted to announce Axalta, Enterprise and Dedoes Industries have all committed again to the CIF Annual Donor Program, each company’s fourth consecutive donation at the Urgent Care (second highest) tier.

Introduced in 2021, the Annual Donor Program was designed to bring needed recurring resources to CIF, so it can deliver on its mission to “Answer the Call” when those in the industry have been impacted by catastrophic events such as wildfires, hurricanes, tornados or flooding.

For more than two decades through the generous support of corporations and individuals, CIF has been able to assist hundreds of collision repair professionals in need after a disaster. CIF is grateful for Axalta and Enterprise’s continued support of the Annual Donor Program, which will enable CIF to continue its work for disaster relief assistance.

Metro Toyota in Brook Park, OH, was recently sold to Michiganbased Victory Automotive Group, announced Steve Corle, director of the Plains Region for the Tim Lamb Group, who brokered the sale. The dealership, located at 13775 Brookpark Road, will now be called Victory Toyota of Brook Park.

Toyota was owned by Jerry, Ken and Dan Schneider, and Barry and Jim Greenfield.

The 70,000-square-foot space includes an showroom with an attached service center. A used car showroom is located next door at 13813 Brookpark Road. The service center includes a parts and accessories department, which offers one of the largest inventories of genuine Toyota parts available in the country, as well as hard-to-find regional Toyota parts and accessories.

Corle represented both family-owned agencies in the transaction that closed March 18. The buyer and seller worked through the details quickly and without hesitation.

“The communication I had with Steve was excellent, and he provided me with timely and straightforward information,” said Ken Schneider, general manager at Metro Toyota.

moving forward, and the Victory Automotive Group helped make the process easy from the moment they were presented with the deal,” said Corle.

The importance of working closely with family every day meant a lot to the Schneiders and Greenfields, and this impacted their decision to leave their store to another family-owned company.

“Being able to speak directly with Jeff Cappo, president of Victory Automotive Group, was an enjoyable experience and one of the deciding factors in choosing a successor to take over our family business,” said Ken Schneider.

customers over the last 55 years, and we look forward to Victory Automotive Group continuing to provide our customers with excellent service and community support,” said Ken Schneider.

At the time of the sale, Metro

“Ken Schneider made quick decisions that kept the process

Throughout its 55 years in business, the Schneider and Greenfield families achieved many accolades for Metro Toyota, including being a 20-year recipient of the Toyota President’s Award. Metro Toyota also worked closely with community organizations such as The City of Brookpark, Rainbow Babies & Children’s Foundation, Wheelchair Ballet, March of Dimes, and several pet rescue organizations.

“We appreciate the loyalty of our

Victory Automotive Group is a family-owned company, started more than 25 years ago by Jeffrey Cappo, and is headquartered in Canton, MI. Cappo now works alongside his sons Eric and Michael, who are involved in the daily operations of their 50+ locations, in 11 states including Ohio, Michigan, California, Massachusetts, Florida, Texas, Indiana, Tennessee, West Virginia, North Carolina and Illinois. Victory Automotive Group represents 14 automotive brands, including 11 Toyota locations, three of which are located in Ohio.

Tim Lamb Group has worked closely with Victory Automotive Group and continues to facilitate deals with their team.

“I am honored to have assisted both families with this sale and appreciate the trust they put in the Tim Lamb Group,” said Corle. “I wish the Schneider and Greenfield families all the best in their next endeavors.”

l CONTINUED FROM COVER

Joe Hudson’S Collision

Collision Center. “This marks our first venture into the Missouri market, and we couldn’t be more thrilled. With our careful selection of strategic locations adjacent to our current footprint, we are wellpositioned to offer the operational support and oversight needed for their continued success.”

In Arkansas, Joe Hudson’s has enhanced its presence by acquiring three CARSTAR Patriot shops, in Conway, Little Rock and North Little Rock. Chase Marchese , a former U.S. Army medic who served in Iraq from 2006 to 2011, has owned the locations for the last 10 years.

“We are excited and privileged to extend a warm welcome to the CARSTAR Patriot teammates as they become part of the JHCC family. We look forward to uniting our strengths and upholding their tradition of delivering excellence in both quality and service,” said Cameron Dickson, COO of Joe Hudson’s Collision Center. “Our commitment remains steadfast in providing unwavering support to the veterans of the Little Rock community, just as Chase has done before us.”

Texas and Kentucky also saw

expansions with the acquisition of H&R Auto Body in Leander, TX, and Renfro’s Collision in Richmond, KY. Darrell and Melissa Denton have provided top-tier collision repair services to the Leander/ Cedar Park community for more than three decades. Renfro’s Collision, founded in central Kentucky by Shannon Renfro , is a 45,000-square-foot state-of-the-art repair facility known for providing quality repairs and exceptional customer service to the Richmond community since 1996.

“We’re strongly focused on retaining the valuable skills and expertise of the technicians and associates from these locations,” said Wendy Patrick , chief administrative officer of JHCC. “JHCC is committed to ensuring a smooth integration of these professionals into our organization and maintaining the exceptional standards that define Joe Hudson’s Collision Center.”

Joe Hudson’s Collision Center now operates more than 200

Eustis Body Shop is pleased to announce its Lincoln Amber Hill location has officially become a Tesla Approved Body Shop. As the first of its kind in Lincoln and one of the few Tesla-certified body shops in the state of Nebraska, Eustis Body Shop can now offer its repair expertise to local Tesla owners.

Vice President Ryan Clark. “We’re really happy to be able to provide a more convenient service option for Teslas in the area.”

With this certification, Eustis Body Shop’s Amber Hill location in Lincoln can now repair all parts of a Tesla, including the structural and battery

Previously, Tesla owners in Lincoln had to travel outside the city for major repair work. But with Eustis Body Shop’s new certification, area Tesla owners now have a local option for their repair needs.

To become a Tesla Approved Body Shop, technicians undergo specialized training to master

One of the most talked-about challenges in the collision repair industry today is the significant shortage of skilled workers. The Collision Career Institute (CCI) was established in 2015 to help solve this crisis.

“We designed a program to supercharge the growth of collision repair teams across the United States,” said Erick Bickett, co-founder and CEO of CCI. “Our team’s sole purpose is the learners’ success.”

Bickett said the genesis of CCI was rooted in necessity. Known by many in the industry as a visionary and innovator, Bickett recognized the dire need for new industry talent. With a resume including initiatives like the Collision Industry Electronic Commerce Association (CIECA), Fix Auto USA and Caliber Collision, he realized the challenges facing collision repairers.

Bickett wasn’t alone in his quest. He partnered with Charlie Robertson, a recognized authority in collision repair education with more than 25 years of experience, over the shared vision of revolutionizing the way collision repair professionals were trained.

“A lot of shops think the problem has been around a half a dozen years or so, but it has been an ongoing problem for a long time,” noted Robertson, CCI president and co-founder.

With Bickett’s industry acumen and Robertson’s educational expertise, they set out to tackle the tech shortage.

Their plans were met with an unforeseen challenge – the COVID-19 pandemic.

“Because of our dedication to the industry and future leaders, CCI pivoted during the pandemic to assist technical schools and provide curriculum support at no cost,” said Robertson.

CCI then embarked on a journey to redefine in-shop collision repair training.

“Our approach was simple yet revolutionary,” said Bickett. “We worked toward providing a comprehensive curriculum that addressed the core challenges facing the industry.”

Their efforts were supported by the addition of a new team member, Dan Dutra, vice president of business development.

“Dan’s dedication to the industry is matched only by his commitment to excellence,” said Robertson. “Together, we’re united in our mission to reshape the future of collision repair.”

Dutra said they listened to shop owners, career and technical school educators, insurers, technicians and students to refine the curriculum and support materials that deliver skills to new industry entrants.

“CCI has every variable covered at this point and will produce productive

with the U.S. Department of Labor.

CCI begins with a tailored assessment of the shop.

“It is critical that a shop has the right learning environment and culture to embark on this journey,” said Dutra.

In most cases, CCI recommends repair centers evaluate the company’s culture and environment before bringing in recruits. They’ve found some of the best candidates come from their own detail and parts departments, those who are already part of the team and known to be trusted and dependable.

the business’ bottom line.

“We also provide repair centers with suggested tool strategies, pay plans and resources to track and measure the transfer of skills to help apprentices produce more than they cost within 90 days of the program starting,” Robertson said.

The online program is delivered through the Canvas Learning Management system. It includes presentations, videos, handouts and skills-tracker workbooks. Students can access the materials on their smartphone, tablet, laptop or desktop computer.

“Apprentices experience every angle of the repair process in their chosen career path, as a technician, painter or repair planner,” explained Robertson.

standalone techs inside of 18 months,” he said.

Bickett emphasized that CCI’s vision extends beyond technical skills.

“It is about instilling a mindset of excellence and innovation,” he shared. “Our program focuses on teaching entry-level technicians collision repair skills so they can be successful and productive.”

The CCI team has found the holistic approach resonates with shop owners and industry professionals.

“CCI’s goal is to provide a defined career path and training for those interested in joining the industry or already working in the industry in less critical roles,” Bickett explained.

Bridging the gap between classroom theory and real-world application has had its challenges, according to Robertson.

“The challenging shop dynamics make it very difficult for a new person to learn,” he said.

To address this, CCI adopted a competency-based approach to learning, focused on mastery instead of completion.

“Rather than being time-based as with most schools, CCI’s program is competency-based,” Robertson clarified.

The program is approved by the California Division of Apprenticeship Standards and registered as a national apprenticeship program

“Ideal entry-level candidates include those who show up on time every day, are trustworthy and respectful and have excellent soft skills,” noted Robertson.

CCI helps shops match an applicant s work style and personality with their trainer to ensure it is a good fit.

“We don’t suggest using the highest-performing technician in the shop,” said Bickett. “Instead, we look for a trainer who might be a little older, needs a helper, and has the ‘teacher gene’ – someone who wants to give back to the industry.”

“We use a combination of work style and personality assessments that have been customized and tailored to our industry,” added Robertson. “Apprentices then start training using a mapped-out plan, tracking and measurement to ensure they have gained the skills needed to be successful.”

The program was designed to work with all the established processes and variables in a shop.

“We work closely with shops to transform their teams’ capabilities,” explained Dutra. “CCI guides apprentices through the skills they need to be successful through online learning and on-the-job skills development, utilizing the work assigned to their trainer.”

“We provide a road map for the in-shop trainer to allow apprentices to learn the skills they need to be successful,” added Robertson.

CCI’s process develops skilled apprentices while they contribute to

The online courses are supplemented with skills-tracker workbooks for apprentices to keep track of their developing skills. QR codes link to “how to” videos explaining how to perform each skill. The trainer guide provides step-by-step directions for trainers, helping them improve skillstransfer to learners.

As students progress, they repeat skills from previous courses so no skill diminishes during their apprenticeship.

“This ensures a learner has the skills to perform work in a live shop environment,” said Dutra.

Ultimately, he said they must contribute to the bottom-line by helping move cars through the shop during the learning process.

“With CCI’s guidance, shops can transition entry-level candidates to B-level body techs, painters and estimators,” said Dutra.

“We are inclusive, not exclusive,” said Robertson. “We don’t think we’re the only ones with the answer and are open to working with others who have a piece of the puzzle to help solve this dilemma.”

Scan this QR code to go to a playlist of informational videos on CCI’s YouTube channel.

AJ Gaston, general manager at Fix Auto Downey in California, said good technicians who know everything from A to Z are hard to find and often expensive to hire.

Gaston has worked at Fix Auto Downey, owned by Little John’s Bodyworks, for more than 38 years. Since the family-run business opened in 1960, Gaston said it has built a reputation for quality service. Most technicians are long-term employees, but some trainees have left because they weren’t part of a structured training program.

“Many times, when you hire someone new, they think they know how to do certain tasks, but they really don’t,” he noted.

Gaston recently hired two technicians after they graduated from Universal Technical Institute (UTI). They were taught how to weld and learned basic skills, but had limited knowledge working on cars.

He wanted to find an apprenticeship program that would allow him to pair the new

techs with a mentor so they could learn enough to become fullfledged technicians.

After doing research, he decided that the online apprenticeship program offered by the Collision Career Institute (CCI) was a good fit.

About six years ago, Gaston tested CCI’s program. He said it offered many benefits but took time away from a user’s daily duties.

Following the pandemic, CCI revamped its program and Gaston implemented it again.

“They told us it’s much different and we would like it a lot better,” Gaston recalled. “We really do like how things work now.”

Since implementing it, Gaston said it has helped educate technicians on how to properly repair modern vehicles.

The first step was assessing the incoming technician/ student and mentor to ensure compatibility.

He has been impressed with the program’s flexibility, which allows technicians with industry experience to start the program

at the appropriate level.

“That’s part of the beauty of the program,” said Gaston. “They don’t have to start over and waste time learning what they have already learned at another shop or technical school.”

Technicians can also input their I-CAR learning into the CCI app.

Alex has used the program for nine months and Eddie started it about four months ago.

“It is part of their daily job, other than one hour a week when they have a conference call with their CCI training manager,” explained Gaston.

“CCI is a very hands-on program and is very well designed for new techs joining the automotive collision industry,” said Alex, one of the helpers. “It’s more like an ‘in-person ASE course.’ Each module is well thought out with support from great coaches.”

and the assignments represent real-world challenges technicians would encounter in any shop, giving them confidence to do any assigned work there.

“I’m grateful for this program because it allows me to continue expanding my knowledge,” he said. “I’m also grateful for the shop where I work because it lets me continue my education in an area I’m passionate about.”

Their mentor, Larry, said CCI’s program helps him keep track of what has been taught to the student and what still needs to be presented.

Gaston said CCI’s program offers a structured approach to collision industry education and includes information to ensure technicians use the proper materials and provide the correct documentation.

Ken Ganley VW North Olmsted

Eddie agreed. “My experience with CCI has been outstanding,” he said.

Eddie has found the staff at Fix Auto Downey want to keep track of the students’ progress,

It also helps technicians and mentors stay on track by letting them know what module they should work on daily.

“Programs like CCI will help produce good techs that our industry desperately needs,” said Gaston.

Parts Direct 440-734-1076

•

Hours: M 7:30-7 T-F 7:30-6 Sat 8-4

25580 Lorain Road North Olmsted, OH 44070

jim.j@ganleywestside.com

www.kenganleyvwnortholmsted.com

Extensive Inventory of Genuine Volkswagen Parts Updated Daily

Team of Knowledgeable Wholesale Parts “ Professionals Ready to Help You

Delivery area counties: Cuyahoga, Lake, Geauga, Huron, Erie, Medina, Sandusky, Ottawa, Summit and Lorain

Fast Free Same Day, Next Day and Hot-shot Deliveries

Online ordering through

Fix Network announced the appointment of Nick Spiers as the company’s new global vice president of strategic operations, effective March 1.

In this newly created role, Spiers is responsible for overseeing and coordinating the strategic planning and execution of global operational initiatives for Fix Network and its family of brands.

Spiers joined Fix Network in 2016 as the manager of international operations, where he was instrumental in the company’s expansion into Australia, Germany and Mexico. In 2019, he was named director of strategic initiatives, where he worked globally on new business development and operations strategy, predominantly in the Middle East.

Spiers has more than 27 years’ experience in the automotive industry, where he’s held positions in sales, business development, commercial and operations. He is based in the UK.

Fix Network Names Global VP of Strategic Operations www.autobodynews.com

Kentucky Gov. Andy Beshear, backed by the International Brotherhood of Teamsters, vetoed House Bill 7 (HB7), which would have permitted the operation of driverless trucks and cars on the state’s roads, raising widespread concerns over employment and motorist safety.

“This bill and others like it are written by and for Big Tech, and Gov. Beshear made the right call by vetoing it,” said Teamsters General Secretary-Treasurer Fred Zuckerman. “We encourage every lawmaker who supported this dangerous piece of legislation to reconsider their support for it, given the devastating impact it will have on middle-class jobs and motorist safety throughout the Commonwealth. The Teamsters are asking elected officials in every state to support good union jobs, to protect public safety, and to stand against these deadly autonomous vehicle proposals wherever they pop up.”

Recent polling showed the majority of Kentucky voters oppose the idea of driverless vehicles on their roads, with more

than 80% less likely to support legislators endorsing such measures. These findings echo a broader national apprehension, as a study from the American Automobile Association revealed more than 91% of U.S. drivers harbor fears or uncertainties regarding autonomous vehicles.

public safety.”

“There are tens of thousands of good-paying careers that could be jeopardized by HB7,” said John Stovall, president of Teamsters Joint Council 94. “The Teamsters strongly encourage working people across Kentucky to contact their lawmakers and tell them to let Gov. Beshear’s veto stand.”

“Elected officials need to listen to their constituents – not lobbyists – and let bills like HB7 die,” said Avral Thompson, Teamsters Central Region International vice president and president of Teamsters Local 89. “Voters recognize this bill for what it is –a threat to middle-class jobs and

In California, a bill was introduced in February that would mandate human operators in selfdriving trucks weighing more than 10,000 pounds. The bill, AB 2286, is a resurgence of a similar bill introduced in 2023 that passed both the Assembly and Senate with bipartisan support but was ultimately vetoed by Gov. Gavin Newsom Polling of voters in California showed similar results to the one conducted in Kentucky; nearly three-fourths of Californians across party lines, gender, geography and all other demographics supported the legislation.

Unlock savings and precision fit with genuine parts

• Save time and money: reduce returns by up to 16%

• Faster ordering process

• More accurate orders

• Easier invoice processing

• Live information

• Seamless fit

• Competitive pricing

Order now on CCC ONE®

Please contact these dealers for your Honda or Acura Genuine parts needs.

Honda of Lisle

Lisle

866-874-6632

630-437-5299

Dept� Hours: M-F 7-5 WholesaleParts@HondaofLisle�com

INDIANA

Bob Rohrman Honda

Lafayette

765-588-9984

765-448-1000

Dept Hours: M-F 7:30-5:30; Sat 8-3

Brho partsmgr@rohrman com

Suburban Honda

Farmington Hills

248-427-7996

Dept Hours: M, Thu 7-8; Tue, W, F 7-6; Sat 8-3 nowiesny@suburbancollection com

Victory Honda

Plymouth

800-824-4646

734-453-3600

Dept� Hours: M-F 7:30-7; Sat 8-4

Robert rosenau@victorytoyota com

McGrath Acura of Morton Grove

Morton Grove

847-470-2308

Dept Hours: M-F 7-7; Sat 7-4 acparts@mcgrathag com

Jay Wolfe Acura of Overland Park

Overland Park

913-648-2287

Dept Hours: M-F 7-5; Sat 8-4 wozburn@jaywolfe com

Ziegler Honda

Kalamazoo

855-513-4477

269-585-5812

Dept� Hours: M-F 8-6; Sat 8-2 glenloubsky@ziegler�com

Brookdale Honda

Brooklyn Center

800-899-8900

763-331-6880

Dept Hours: M-Thu 7-9; F 7-6; Sat 8-6 parts@lutherbrookdalehonda com

Luther Hopkins Honda

Hopkins

800-328-6016

952-908-8585

Dept Hours: M-F 7-6; Sat 8-4 parts@hopkinshonda com

Richfield-Bloomington Honda

Richfield

800-328-2703

612-866-8197

Dept� Hours: M-Thu 6:30-7; F 6:30-6; Sat 6:30-5 parts@rbhonda�com

Acura of Troy

Troy

800-935-0923

248-643-0900

Dept Hours: M-F 8-6

parts286@acuraoftroy com

parts287@acuraoftroy com

Luther Bloomington Acura

Bloomington

800-451-5078

952-887-0600

Dept Hours: M 6:30-6; Tue-F 6:30-9; Sat 8-4

parts@bloomingtonacura com

Bommarito Honda

Hazelwood

800-731-8270

314-731-8270

Dept� Hours: M-Sat 7-6 cmelvin@bommarito�net

Ed Napleton Honda

St Peters

800-875-4190

636-928-4400

Dept Hours: M-F 7-6; Sat 7-5 gethondaparts@napleton com

Columbia Honda

Columbia

573-818-3650

Dept� Hours: M-F 8-5:30; Sat 8-4 gropp@columbiahonda com

Honda of Tiffany Springs

Kansas City

816-452-3221

Dept Hours: M-Fri 7-6; Sat 7-2 parts@hondats com

Superior Honda Omaha

Omaha

402-408-1100

Dept Hours: M-F 7-5:30; Sat 7-5

Columbia Acura

Cincinnati

844-677-4902

513-530-0698

Dept Hours: M-F 8-5:30; Sat 8-12 columbiaparts@email com

Jay Honda

Bedford

800-509-9057

440-786-3363

Dept� Hours: M-F 7:30-6; Sat 8-4 jayhondaparts@gmail�com

In today’s collision industry environment, many shop owners and managers are finding competent staff are becoming a scarce and valuable commodity. In response, progressive companies are looking for ways to differentiate themselves to be the “employer of choice” in their marketplace, according to Tim Ronak, senior services consultant at AkzoNobel.

One option is to implement a fourday workweek.

“A four-day workweek can be a powerful recruiting tool that positively impacts facility morale, helping to foster an environment to becoming an ‘employer of choice,’” he said.

Ronak and Tony Adams, a business services consultant at AkzoNobel, discussed the potential benefits and challenges of this alternative structure during the AkzoNobel Acoat Selected North American Performance Group event in Orlando, FL, in March. They also presented the idea during a presentation held as part of the Society of Collision Repair Specialists (SCRS) Repairer Driven Education Series at the SEMA Show in Las Vegas, NV, in November 2023.

“It typically involves reducing the workweek from five days to four while maintaining the same number of weekly working hours,” explained Ronak. “However, it can mean different things to different stakeholders.”

In the European Union (EU), for example, the alternative structure can imply four eight-hour days, resulting in a 32-hour workweek. However, in the U.S., Ronak said businesses typically work four 10-hour days to maintain a 40-hour workweek.

Ronak shared information about an EU study conducted in June 2022 that evaluated the merits of a fourday work week. Over six months, 61 organizations reduced their work hours by 20% with no pay decrease.

“They found that it boosted employee well-being without comprising productivity,” he said.

Participating companies reported a 65% reduction in sick days and a 57% decrease in staff turnover. At the same time, 71% of employees reported lower levels of burnout and 39% said they were less stressed compared to the beginning of the trial. This resulted in 92% of the companies planning to continue with a four-day work week; 18 companies said it would be a permanent change in their business.

Ronak noted the work schedule variations implemented by the organizations. While some stopped work entirely for a three-day weekend, others staggered a reduced workforce over a week. A selection of participants designated fewer holiday days and others set an agreement that staff could be called in at short notice. Some decided that a “conditional” four-day week would only continue while performance targets were met.

with the same amount of output, Ronak said they would need to work at 156% efficiency for 50 hours of output and 187% efficiency with six hours of output.

With one less day of coffee or lunch breaks during the week, Ronak said there are fewer stop-and-start intervals, potentially allowing for more productivity.

“The fewer breaks and the longer days seem to drive efficiency,” he said.

Adams then talked about the pros and cons of the alternative work schedule. Potential advantages for employers include increased employee retention and productivity, cost savings, a positive impact on company culture and enhanced employee morale, and a reduced carbon footprint with less commuting.

scheduling complexities.

“It’s a hard shift for some of us serial entrepreneurs who are trying to figure out how to maximize the efficiency of our facilities,” said Adams.

Challenges for employees include longer workdays, the potential for burnout, difficulty adjusting and reduced opportunities for overtime pay.

Adams said there is no one-sizefits-all scenario and encourages owners and managers to consider the pros and cons before deciding what is best for the facility.