in

AI’s Impact: Exploring How Far We’ve Come & Looking Toward the Future

Three years ago, AI stormed into the public consciousness, sparking both excitement and skepticism. The apocalypse didn’t arrive, nor did we see a utopian manufacturing renaissance with flawless production and boundless efficiency. So, what’s the reality? Were the bold predictions just hype?

The truth is less dramatic but no less important. AI’s transformative potential in manufacturing requires more than algorithms—it demands hard work, perseverance, and expertise to implement solutions effectively. While the journey is ongoing, 2025 has brought significant advancements in AI, particularly in addressing long-standing challenges around privacy and capability.

For years, manufacturers hesitated to adopt AI fully due to privacy concerns. Sharing critical data—such as downtime metrics or production figures—with open-source AI platforms posed unacceptable risks. But the tide is turning. Privatized AI agents are emerging as game-changers, enabling manufacturers to harness AI’s power securely.

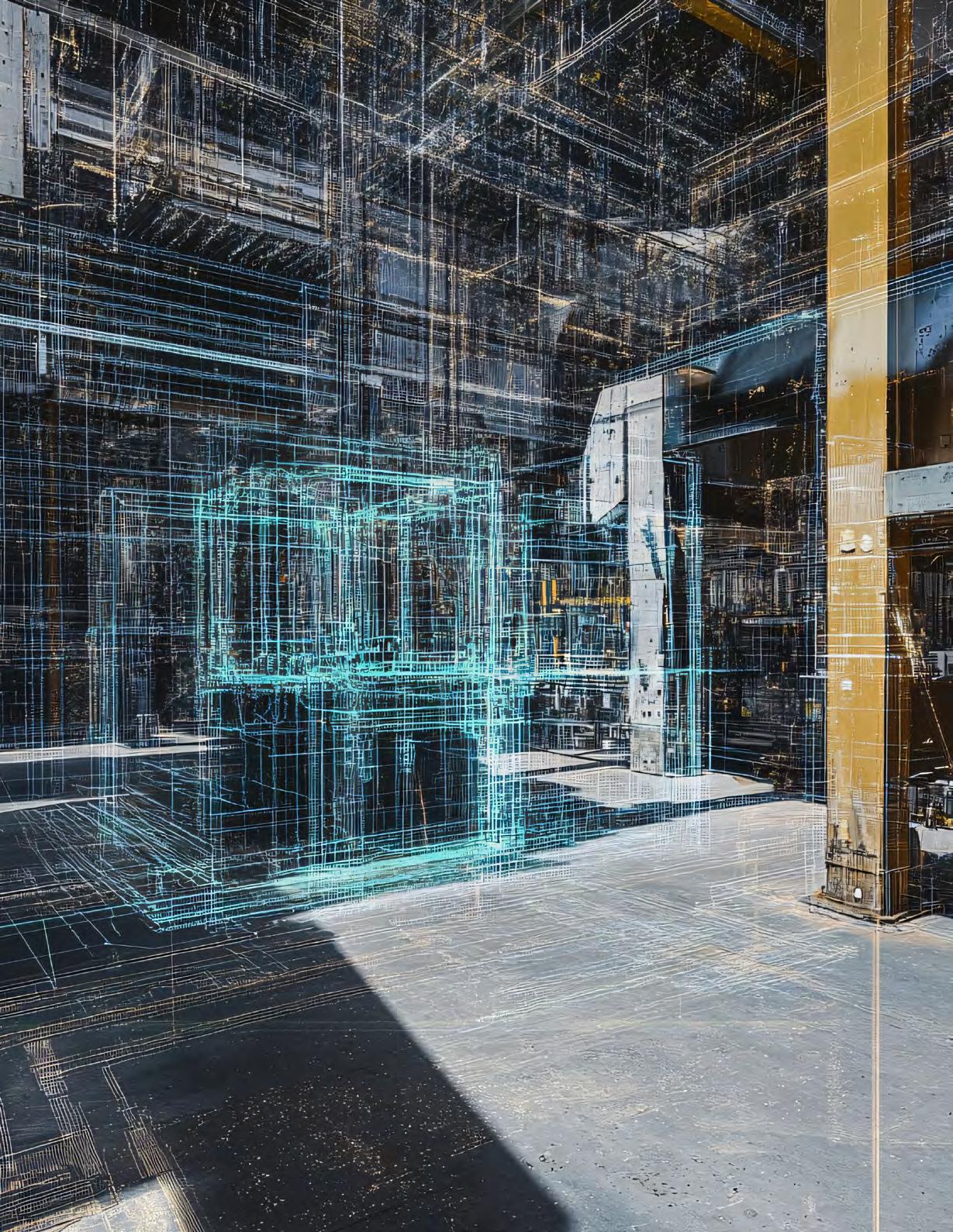

Technologies like NVIDIA’s Jetson platform are paving the way. By leveraging secure, on-premise AI systems, manufacturers can now train machines, automate programming through vision systems, and execute complex tasks without exposing sensitive data. This shift is unlocking new levels

of productivity while maintaining control over proprietary information.

As part of the 2025 Integr8 Series, we invited industry, academia and government to join us for a roundtable discussion to reflect on AI’s journey so far:

• Initial Use Cases: What early AI deployments succeeded—or fell short?

• Balancing Open-Source and Proprietary Systems: How are companies leveraging open AI tools alongside secure, closed systems? What cybersecurity and workforce training considerations have emerged?

• The Next Barrier: With the privacy hurdle largely addressed, what challenges lie ahead? Will the vast data pools AI relies on begin to dry up, stalling further innovation?

These are the pressing questions we’ll explore as we analyze the past three years and look toward the future. By drawing on the experiences and insights of our trusted community, we aim to chart a path forward for AI in manufacturing.

Join us for the 2025 Integr8 Series and be part of shaping AI’s next chapter. Your insights matter, and together, we’ll continue driving progress in manufacturing’s digital transformation.

Tom Kelly Executive Director & Chief Executive Officer Automation Alley

Attendee List:

Sponsors, Supporters and Attendees

Main Feature:

Boosting Productivity in the AI Frontier

Expert Insights:

Preparing the Next Generation of AI-driven Engineers & Researchers

Michigan State University

Industry Pulse:

Ecosystem Insights at a Glance

Future Trends: The Next Wave of AI Innovation

Case Study:

Oasis Advanced Engineering

Industry Insights:

Preparing Companies and Professionals for Manufacturing’s AI-Driven Future

Michigan Manufacturing Technology Center

Key Takeaways:

Main points from Integr8 Roundtable discussions

State and National Resources:

Helpful resources for small- and medium-sized manufacturers

SPONSORS, SUPPORTERS & ATTENDEES

SPONSORED BY: Michigan State University

David Bertram - Director of Economic Development, Michigan State University, College of Engineering

Prof. Nevzat Bugdayci - Associate Professor, Michigan State University

Prof. Mohsen Zayernouri, - Associate Professor, Michigan State University, College of Engineering

STUDENT PARTICIPANTS:

Arman Khoshnevis - PhD Student, Michigan State University

Zhiyuan (Carson) Qu - PhD Student, Michigan State University

Jianxin Zhao - PhD Student, Michigan State University

SUPPORTED BY:

Ingrid Tighe - President, MMTC

Robert Scipione - Manufacturing Services Manager, MMTC

ADDITIONAL LEADERS IN INDUSTRY, ACADEMIA AND GOVERNMENT IN ATTENDANCE:

Tom Kelly - Executive Director & Chief Executive Officer, Automation Alley

Wendy Acho - Sales Associate, Farbman Group

David Alexander - Senior Director, Standards, SAE International

Brian Breuhan - Global Optimization Strategist, General Motors

Gunther Brinkman - CEO, Baking Company, LLC

Dr. Michael Brodbeck - Director – Project Management, FANUC America

Bella Brykalski - Sr. Account Executive & Search Consultant, Contract Professionals Inc.

Dan Busch - Sales Engineer, Access Michigan

Matthew Cole - Dean of College of Business and Information Technology, Lawrence Technological University

Brian Cong - Machine Learning Engineer, Liberty Robotics

Jacqueline El-Sayed - CEO, SAE International

BettyJean Hebel - Strategy Consultant, Bonal Technologies, Inc.

Patrick Hillberg - Adjunct Professor - Industrial and Systems Engineering Dept., Oakland University

Carl Hobson - President & CEO, Oasis Advanced Engineering

Brenda Jones - CEO, Ulendo Technologies, Inc.

Robert Joyce - President and Founder, FibreTuff

Gary Krus - VP of Business Development and Operations, HIROTEC AMERICA INC

Ben Lorenz - Managing Partner, Human Element

Michael Luzi - Vice President of Strategic Partnerships, BenePro/HRPro

Jason Magee - Managing Partner, Human Element

Thomas Mikulski - Chief Technology Officer, The Parsimonious Group

Samuel Pittman - Director of Strategy & BD, Leidos

Dan Radomski - CEO, Industry 4.0 Accelerator

Cody Schaub - Economic Development Director, Office of Congresswoman Haley Stevens

Tom Schneider - President & CEO, HA Industries

John Schroeder - Enterprise Account Executive & Partner Manager, imc Americas

Michael Spath - Vice President, Business Insurance, Marsh & McLennan Agency | Michigan

Courtney Steele - Director of Marketing & Communications, DeepHow

Kathleen Stillman - Senior Business Development Representative, Oakland County Economic Development

Tom Swartz - Chief Technology Officer, Detroit Manufacturing Systems

Nicholas Van Damme - Business Process Lead, Detroit Manufacturing Systems

Henry Walters - Research Engineer, Liberty Robotics

Boosting Productivity in the AI Frontier

Artificial intelligence is potentially the defining technology of this generation. According to a recent Deloitte report , 93% of organizations believe AI will be pivotal in driving growth and innovation in the coming years. That prospect is reinforced by an influx of billion-dollar investments from government and private sectors alike.

Standing on the cusp of this technological revolution, Automation Alley seeks to explore the opportunities and challenges ahead for manufacturing companies and their workers. Our most recent roundtable brought together experts from industry, academia, and government for a candid discussion on how the sector can best move forward in a world increasingly defined by AI implementation.

Opportunities

The manufacturing sector has plenty of reasons to be excited about AI. Here are some of the most common opportunities it presents:

Predictive Maintenance

AI-powered predictive maintenance systems are transforming equipment upkeep in manufacturing facilities. These intelligent systems continuously monitor machinery through sensors that track vibrations, temperature, and performance patterns. By analyzing this data alongside historical performance records, AI can identify subtle signs of wear or potential failures long before they become critical.

“Predictive maintenance is an area where you can put sensors on a lot of your equipment, aggregate that data and monitor that system in your machinery,” said Ingrid Tighe, president of MMTC. “You can see a specific point in your plant and identify when a piece of equipment is about to go down. It can also detect parts out of tolerance, helping you be more efficient and get more out of equipment.”

AI’s effectiveness in this area is widely recognized. According to Capgemini, maintenance projects account for 32% of AI implementation efforts. This proactive approach allows maintenance teams to schedule repairs during planned downtimes, significantly reducing unexpected breakdowns and extending the equipment’s lifespan.

Facility and Workforce Management

AI is reshaping how manufacturing facilities operate daily, creating more efficient and safer working environments by managing environmental controls, worker scheduling, and equipment oversight. AI-powered computer vision systems can monitor production quality while ensuring workplace safety. The technology also helps optimize resource allocation, manage energy use, coordinate maintenance activities, and adjust staffing levels based on production demands.

These applications form the foundation of smart manufacturing, where AI, sensor technology, and advanced analytics work together to create more efficient, flexible, and productive environments. As these technologies evolve, they are expected to unlock even more possibilities for innovation in manufacturing.

Open vs. Closed-Source AI Environments

As manufacturers evaluate AI adoption, one of the most fundamental decisions is whether to leverage open-source or closed-source AI environments. Each approach offers distinct advantages and trade-offs that impact scalability, security, and innovation.

Open-Source AI

Open-source AI platforms offer transparency, flexibility, and cost savings. Because their source code is publicly available, manufacturers can customize models to fit their specific needs and benefit from a global community of developers contributing to continuous improvements. Open-source AI also fosters innovation by enabling cross-industry collaboration.

However, Dr. Michael Brodbeck, director of project management at FANUC, emphasized the importance of data integrity. “With open-source environments, when so many people input into the system, it runs the risk of people inputting bad data. With garbage in comes garbage out,” he said.

Mohsen Zayernouri, associate professor of mechanical engineering at MSU, added that open-source products are often used for creativity and general ideation, whereas closed-source products are preferred for proprietary information and targeted research and development.

VSClosed-Source AI

In contrast, closed-source AI solutions—such as those from Google Cloud AI, Microsoft Azure AI, and IBM Watson—offer built-in support, enterprise-grade security, and proprietary algorithms tailored for specific use cases. These platforms often integrate seamlessly with existing enterprise systems, making them attractive for manufacturers with limited AI expertise.

“The information is trusted with good sources in a closed system. It is more transparent and traceable,” Tighe said. “However, it is more limited inside the sandbox. Also, you must have strong cybersecurity in a closed-source environment.”

Brodbeck likened open vs. closed AI environments to their discussion setting. “A closed-source approach is like keeping our roundtable conversation within this table, but an open-sourced one is sharing it.

Making the Right Choice

For manufacturers, the decision between open- and closed-source AI depends on factors such as budget, security requirements, and technical capabilities. Many companies adopt a hybrid approach—leveraging open-source tools for experimentation and innovation while integrating closed-source AI for mission-critical applications that require reliability and support.

Challenges

Making AI mainstream won’t be easy. Several challenges require forethought and effort from manufacturers and employees, including:

Workforce Readiness

While business leaders recognize AI’s potential, not all companies have the resources or in-house skills to deploy it. Expertise in AI is scarce, and salaries for data science and AI talent range from $100,000 to more than $300,000, according to the World Economic Forum.

“Workforce readiness is the biggest barrier to AI reaching its full potential for manufacturing,” said Courtney Steele, marketing and communications director at DeepHow. “This is relevant to frontline workers all the way to the decision-makers and executives. Each of those folks are going to struggle with all the changes affecting workforce readiness today—culture, generation gaps, and the general public understanding of AI.”

AI also raises questions about education and training. “The next generation will still need to be savvy enough and have the acumen to critically assess the information they are looking at,” Steele said. “AI can’t do that for us. We need the human factor. Education is still relevant. There are no shortcuts.”

Zayernouri agreed, emphasizing that making AI successful requires collaboration between human and artificial intelligence. “We need highly trained engineers who understand the underlying physical processes and the economic mathematical way to incorporate such data into AI platforms,” he said.

Data Quality and Management

AI systems rely heavily on high-quality, consistent data. Many facilities struggle with data collection standardization, storage infrastructure, and real-time processing. Maintaining data integrity while handling massive volumes of information from multiple sources can overwhelm traditional IT systems, requiring significant upgrades to data management infrastructure.

Cost and Infrastructure Barriers

The cost of AI remains a significant hurdle, particularly for small and mid-sized manufacturers. “The cost for a small to medium-sized company is a large barrier to entry,” Tighe said.

Brodbeck raised concerns about subscription-based AI models, asking: “Is it worth it to pay to put your data into these platforms so the software gets smarter?”

Additionally, AI’s growing energy demands present a challenge. “There will be huge competition in securing power for AI,” Brodbeck said. “The other barrier is people. Younger generations can move in and implement AI easier.”

Cody Schaub, economic development director at the U.S. House of Representatives, emphasized the importance of establishing AI standards for wider adoption. “From a federal perspective, we as a country need to determine how AI will affect our national security,” he said.

ensuring operational security while keeping systems accessible presents a complex challenge for manufacturers implementing AI solutions.

Workforce

How Companies and Employees can Brace for Change

AI is often feared as a job killer, but it has the potential to create many skilled roles essential for its effective operation. From prompt engineers to data scientists and programmers, demand is surging for professionals who can understand and implement AI.

However, experience and education remain critical barriers. A study by National University found that 77% of AI-related job openings require a master’s degree in a relevant field, while only 8% accept applicants with just a high school diploma—widening the gap between those who can deploy AI and those who cannot.

To bridge this divide, companies like Coursera are offering AI certifications for all skill levels. The Coursera Generative AI Academy, in partnership with Amazon, IBM, and ADP, teaches ethical and responsible AI use. One course of particular value to manufacturing is the DeepLearning.AI Data Engineering Professional Certificate, which provides skills in AI data trend analysis, methodology, and collection. With a six-month completion time, it offers a faster, more accessible path to AI proficiency than traditional academic routes.

Yet, the biggest challenge to building an AI-ready workforce may not be the workers themselves, but the organizations they hope to join.

The Infosys AI Readiness Report , which surveyed over 1,500 organizations and interviewed 40 top CEOs, found that only 2% of companies are prepared to deploy AI effectively across talent, strategy, governance, data, and technology. Just 9% have the technological infrastructure to support AI, and only 10% have accessible data for AI analysis. Worse still, only 12% offer AI training to their workforce.

These findings highlight how AI is disrupting the corporate model, with most organizations unprepared to capitalize on its potential. To fully realize AI-driven productivity gains, businesses must invest in workforce training and modernize their data infrastructure. Success will require a company-wide effort—from the C-suite to the factory floor—to understand and embrace AI’s transformative power.

The Path Forward

The manufacturing sector stands at a critical juncture heading into 2025. The promise of AI-driven innovation meets the reality of implementation challenges, from technological adoption to buy-in from industry leaders. Success requires a holistic approach that balances technological advancement with human considerations.

“AI is a gamechanger,” Zayernouri said. “No matter how hard, risky or costly, change is inevitable in our industry. The question is: How do we make it happen? AI is not about cutting jobs, but making new opportunities and choices in the job market.”

Looking ahead, manufacturers must embrace AI while maintaining a focus on sustainable practices, workforce development, and competitive advantage. The road forward may be complex, but the rewards for those who successfully navigate this transition are substantial.

Preparing the Next Generation of AI-driven Engineers & Researchers

AProf. Mohsen Zayernouri, PhD1, PhD2

Associate Professor

Michigan State University

Department of Mechanical Engineering

Department of Statistics and Probability

s Artificial Intelligence (AI) continues its rapid integration into global industries, the role of academic institutions in leading AI-driven innovation has never been more pivotal. Michigan State University (MSU), through its College of Engineering, is uniquely positioned to contribute to this transformation by advancing physics-based/informed AI applications in revolutionary material/meta-material and thermo-fluid systems, advanced manufacturing, AI-enabled workforce development, and cutting-edge research tools.

As AI adoption accelerates, research institutions must also serve as innovation hubs to explore emerging AI applications, evaluate new technologies, and align industrial advancements with societal imperatives.

By leveraging its expertise in AI-enabled engineering, MSU is poised to address critical industrial challenges, foster technological innovation, and prepare the next generation of AI-driven engineers and researchers with cutting-edge capabilities.

It is envisioned that the fusion of both natural and artificial intelligence will create unprecedented new opportunities in industry. The industrial landscape is being reshaped by AI, with applications spanning predictive maintenance, process optimization, intelligent automation, and real-time decision-making.

AI-driven methodologies such as Machine Learning (ML), digital twins, and robotics are revolutionizing manufacturing by streamlining production, minimizing waste, and enhancing efficiency. As AI adoption accelerates, research institutions must also serve as innovation hubs to explore emerging AI applications, evaluate new technologies, and align industrial advancements with societal imperatives.

Key AI applications in industry include predictive maintenance, where AI algorithms analyze equipment performance to preempt failures and reduce operational downtime, and intelligent automation, wherein AI-powered robotics optimize assembly lines, minimize human error, and maximize efficiency. Additionally, AI is revolutionizing supply chain management through advanced analytics, improving demand forecasting, inventory control, and logistics, thereby enhancing supply chain resilience. Moreover, AI fosters Human-AI collaboration/supervision by augmenting well-educated/trained human decision-making with intelligent assistance, boosting productivity and innovation, hence giving rise to new job opportunities.

MSU’s College of Engineering, particularly its Department of Mechanical Engineering, is at the forefront of these AI-driven transformations. With expertise spanning thermo-fluid sciences, high-speed imaging, integrative design, advanced manufacturing, dynamic control systems

and robotics, MSU is well-positioned to pioneer AI research and industrial applications. The university is actively engaged in AI-powered digital twins, which facilitate real-time simulation, testing, and optimization of manufacturing systems. Advanced robotics is another critical focus area, where AI enhances robotic adaptability, precision, and safety in industrial environments. Additionally, MSU is leveraging AI in materials engineering to design and evaluate new multi-functional materials with new/improved performance and sustainability. Through these initiatives, MSU is driving AI adoption, promoting industry competitiveness, and stimulating sustainable industrial practices.

Collaboration between academia and industry is also essential for translating AI research into practical solutions. MSU serves as a conduit between theoretical AI research and its industrial implementation, fostering partnerships with manufacturers to test AI-driven solutions in real-world settings. The university also plays a pivotal role in technology incubation, supporting startups and established enterprises in adopting and commercializing AI innovations. Furthermore, MSU is establishing inter-disciplinary/multi-disciplinary

Collaboration between academia and industry is also essential for translating AI research into practical solutions.

AI research centers that integrate expertise across Mechanical Engineering, manufacturing science, and AI. These collaborations position MSU as a leader in AI-driven industrial transformation, contributing to massive job creation, enhanced productivity, and the advancement of key sectors such as energy, manufacturing, and supply chain management, hence maintaining the USA’s leadership in AI-driven industry with many new possibilities and choices for investments and collaborations.

However, a critical impediment to widespread AI adoption in industry is the shortage of skilled professionals capable of implementing and managing AI systems. MSU’s College of Engineering is addressing this challenge through comprehensive AI workforce development initiatives. The university is expanding AI-focused curricula especially within Mechanical Engineering, encompassing ML, industrial automation while considering AI ethics yet in a non-confining manner. Hands-on training is a core component of this effort, with AI-integrated manufacturing labs providing students with real-world experience in AI applications.

MSU is also strengthening industry engagement through internships and cooperative education programs, ensuring that students gain direct exposure to AI-driven industrial environments. Additionally, the university is offering AI upskilling programs for current professionals (online programs), equipping the existing workforce with the necessary skills to thrive in an AI-powered industry. By prioritizing AI education and workforce development, MSU is cultivating a talent pipeline that will lead the next wave of AI-driven industrial transformation.

Of particular interest, the Department of Mechanical Engineering is leading AI-driven research and development (R&D) initiatives that tackle complex industrial challenges across advanced manufacturing, thermo-fluid processes, materials engineering, nanotechnology, and thermal management. In AI-driven manufacturing and thermo-fluid processes, deep learning is enhancing multi-scale modeling, improving predictive accuracy in fluid dynamics, and optimizing process efficiency and thermal management, which are abundant in industry. AI-driven optimization is also refining scan strategies in Laser Powder Bed Fusion (LPBF), enhancing additive manufacturing

(AM) precision, improving material properties, and reducing defects. Additionally, MSU is developing a novel AM system that integrates stereolithography (SLA) and binder jet printing (BJP) principles with a digital light projection (DLP) engine, enabling rapid, high-resolution large-surface-area printing. These are only a few examples of many.

In materials engineering and nanotechnology, AI is revolutionizing semiconductor fabrication through plasma-assisted synthesis, optimizing plasma conditions to enhance electronic and optoelectronic material properties. AI-driven simulations are accelerating material discovery by predicting nanostructure behavior during gas-phase processing, facilitating advancements in energy and sensor applications. Furthermore, AI-driven analysis is refining aerosol deposition processes to enhance the properties of thin films used in energy-efficient devices. AI-enhanced in-situ experimental techniques are also providing real-time insights into the mechanical and electrochemical behavior of batteries, significantly improving energy storage efficiency and longevity.

The aforementioned research initiatives underscore MSU’s commitment to advancing AI applications in industry, fostering innovation in energy storage, and developing the next-generation of manufacturing technologies.

In summary, as AI continues to redefine industrial paradigms, MSU and specifically the College of Engineering is strategically positioned to lead this transformation maintaining the US’s leadership in AI technology. Through pioneering research, industry collaborations, and workforce development, MSU is and will be further driving AI innovation in manufacturing while addressing pressing challenges. By harnessing its expertise, infrastructure, and partnerships, MSU will reshaping the future of AI-driven industrial advancements, ensuring a more efficient, sustainable, and technologically advanced future for key sectors such as energy, health, defense, and manufacturing.

Industry PULSE

We polled leaders in industry, academia and government for their input on these questions many face. Here’s what they said: Where do you find AI most useful?

Exponential Growth

In manufacturing, change often comes incrementally while the power of computing doubles every 18-24 months, bringing rapid changes to AI. Industry must be prepared to meet the technological challenges associated with using AI efficiency and cost-effectively.

Future Trends for AI

Increased integration in the manufacturing process

As AI reaches into manufacturing systems - such as predictive maintenance, quality control, automation, and supply optimization - companies must be proactive, not reactive. Industry leaders who are cognizant of this rapid change will be ready, and those who are not will be left behind.

Emphasis shifting to IP development

Manufacturing has traditionally been about conceiving a product and figuring out how to make that product. Often, the manufacturers don’t own the designs they build the products. As AI makes the manufacturing process less expensive, companies will need to shift to creating and owning their own designs.

Human collaboration

As influence expands, humans become the X-Factor. With AI, people have to become more adept at mastering concepts just tolerated in the past. Humans must respond with enthusiasm and confidence to the technology. Proceed down their own individual path to mastery.

Changing mindsets and cultures

New technologies can be learned, so leaders must create a culture of acceptance of AI while alleviating the fear that it will “eliminate jobs.” AI is another tool, and educating employees on its value and embracing the technology will enable workers to remain competitive in an international workforce.

A navigator, not a driver

Too many people are asking AI what to say instead of asking it to help with what they want to say. It’s not about “human or AI,” it’s about “human and AI,” with the technology assisting with creative ideas, concepts, and designs.

Oasis Advanced Engineering uses AI to assist in business and engineering design processes and enhanced product capabilities

Carl Hobson is no latecomer to Artificial Intelligence (AI). He began studying the technology in college in the 1980s and in 1985 was hired by General Dynamics Land Systems to lead up their Artificial Intelligence Lab in support of their Defense Advanced Research Projects Agency program to transition evolving robotic vehicle technology to a combat vehicle.

During this period, he understood the potential for AI but also understood its limitations, not due to the basic research and theory, but to the limitations of processing technology.

“Everyone overpromised, and as a result AI appeared to lose favor for a period of time, but basic research continued. Today we see the results of the basic research and the advancements in computing power, sensor technology, advanced language models, and search engines that have resulted in everyday tools such as Alexa and Siri and semi-autonomous and autonomous driving capabilities,” Hobson said.

Today, AI has resurfaced and will forever change the way we live and do business. “Unfortunately, I hear the same hype I heard four decades ago, and caution my colleagues and friends to understand that AI is simply another game changing tool in our toolbox and will not solve all of the world’s problems,” Hobson emphatically stated.

“We work diligently on continuous enhancements to the capabilities, quality, reliability, and maintainability of our training systems to provide our warfighters with unrivaled training. AI will assist in this on-going continuous improvement process as it will enable personnel to evaluate a greater number of alternative designs.

In 1993, Hobson founded Oasis Advanced Engineering, located in Lake Orion, MI, a company that designs and produces advanced simulation and combat vehicle training systems for the United States military. The company is a pioneer and innovator in embedded gate-to-live fire gunnery training technology and in the development of software reuse that enables combat vehicle software to be used in high-fidelity simulations and training devices.

Hobson anticipates that AI will play a significant role in all facets of his company’s business practices and the products that they develop and manufacture.

“We are already seeing AI make significant inroads in the mechanical and electrical engineering design tools we use. The incorporation of AI enables the CAD tools to assist the engineers in verifying completeness and validity of their designs, thereby reducing the labor hours required throughout the various phases of checker, lead review, and QA process,” he said.

“We work diligently on continuous enhancements to the capabilities, quality, reliability, and maintainability of our training systems to provide our warfighters with unrivaled training. AI will assist in this on-going continuous improvement process as it will enable personnel to evaluate a greater number of alternative designs,” Hobson said.

Areas of AI use at Oasis-AE

Hobson anticipates that AI will assist the company in reaching a new level of productivity and innovation in the products it develops. A sampling of areas that Oasis-AE is using AI and has begun to explore its use include:

Cybersecurity:

One of the most critical areas in which Oasis-AE is using AI is in the protection of its Information Technology infrastructure. The company is working diligently to enhance its cybersecurity protection by leveraging AI-powered Monitoring, Detection, and Response tools. The company is also using AI-based tools to assist in cybersecurity compliance management and in streamlining their security posture. The company is committed to meeting U.S. Department of Defense cybersecurity NIST SP 800-171 and Cybersecurity Maturity Model Certification 2.0 requirements by July 1, 2025.

Engineering design:

Oasis-AE began using model-based design tools two years ago and has committed to their use throughout company programs and projects. The company is beginning to see real benefits in the use of AI-powered tools such as Cameo Systems Modeler to capture the system design and data flow analysis tools developed by Georgia Tech Research Institute that enable systems engineers to analyze the completeness and verify the system design. It is a new way of capturing the design process that was previously well intended but at times a bit ad hoc and lacked the ability to verify and validate against system requirements. Hobson stated “This system design process coupled with AI-enhanced CAD systems will result in superior product designs and reduce redesign efforts once the product has moved to the manufacturing phase.” Oasis-AE is also in the early stages of exploring the capabilities of using AI-powered coding assistant tools, such as Aider, Github Copilot, and SonarQube that transform the way developers interact with their codebase and verify reliability, security, and maintainability of their code.

Document preparation and review: Engineers are not the most gifted writers and often have to work together across disciplines to create a proposal or training system user and maintenance manuals. In order to turn the documents into acceptable proposals and products that are comprehensible by the reader/user requires multiple days of collaborative review that is time consuming and costly. The company anticipates using newly released AI-based language modeling tools to assist in the review process to create superior products and significantly reduce the labor cost and time in their development.

Product feature enhancements:

Combat vehicle designs and capabilities are going through significant changes due to rapidly evolving technology and battlefield tactics. Crews are being reduced from 3-4 person crews to 2 person crews at the same time workload is increasing. Information overload and decreasing time to make life-dependent decisions is a challenging problem. AI-based sensor fusion and decision-making capabilities are essential to address the problem. Oasis-AE is now incorporating the same AI-based capabilities into their training devices to prepare the crew personnel to become accustomed to the stress of combat engagement. The company is also taking it a step further by designing their trainers to be used for human-factor analysis to evaluate alternatives to combat vehicle crew-interface designs and alternatives to determining when crew personnel have decreased cognitive ability to make proper life-dependent decisions.

AI will be a

game changer for Oasis-AE

Oasis-AE is a small business with 50+ employees with less than 20% currently involved with AI. Despite not having a large contingent dedicated to the technology, the company is moving forward with its plans to increase its use throughout the company and expand its knowledge base by working with educational institutions such as the University of Michigan and Michigan State University.

Hobson is confident that the selective use of AI-powered tools throughout the company will enable Oasis-AE to continue to be a pioneer and leader in the field of advanced simulation and combat vehicle training systems for the United States military. Hobson stated.

“The goal is not only to be the best in the United States, but the best in the World at what we do,” Hobson said.

Oasis Advanced Engineering is an essential member of Automation Alley and a participant of Project DIAMOnD. They are located in Lake Orion, Michigan.

®

The goal is not only to be the best in the United States, but the best in the World at what we do.

“ “

Integrity, camaraderie, innovation, and quality are the cornerstones upon which Oasis was founded in 1993. The employees take great pride in their work and place the welfare of the Armed Forces personnel above all else. Their dedication to doing things the right way sets the company apart and has set the bar for others in the industry.

Oasis has decades of experience in the development and production of complex, vehicle-centric, high-fidelity training systems. Oasis has extensive experience working with actual combat vehicles in the development of common embedded training capabilities. Oasis is all about commonality, a true pioneer in the field.

Oasis Advanced Engineering Military Training Equipment in Action

Preparing Companies and Professionals for Manufacturing’s AI-Driven Future

Ingrid Tighe President

Michigan Manufacturing Technology Center

The rise of Industry 4.0 technology in manufacturing may end up being as impactful to our industry as the industrial revolution, and artificial intelligence (AI) is at the heart of the movement. While tools like robotic arms and autonomous carts are more visible advanced technologies on a shop floor, AI is integrated throughout the production process, gathering and analyzing crucial data and influencing operations. AI helps companies monitor equipment and perform predictive maintenance to reduce downtime, track inventory, demand, and logistics needs to support the supply chain, improve the efficiency and accuracy of production processes, and even simplify the process of adopting other advanced technologies by enhancing interoperability.

AI’s ability to gather and process data and initiate responsive action is streamlining work and helping large and small manufacturers adapt to increasing demand and workforce challenges. AI tools are more accessible than ever, and a recent State of AI in Manufacturing survey reported that 77% of manufacturers had already adopted some form of AI, and 82% planned to increase their budgets for AI technologies over the next 12-18 months. Manufacturers and professionals must prepare to work and compete in an increasingly AI-powered industry, and access to upskilling and reskilling programs is crucial to securing their futures.

Recent studies have shown that integrating AI can have positive effects on both workers and companies, but employers and employees alike must plan for a successful integration. Widespread AI adoption may accelerate or expand existing skills gaps occurring in various manufacturing sectors. A Manufacturing Institute survey revealed that roughly 65% of company leaders agreed that filling vacancies is difficult because of the evolving skills and competencies necessary for the job, and 82% were seeking new ways to invest in their employees’ careers. The message is clear—as technology advances, our industry will move beyond the days where a certain hard skill or certification will guarantee success. The manufacturing workforce—

and companies—that grow and thrive today and tomorrow will be adaptable and flexible enough to pivot along with our changing technology. Manufacturing organizations and stakeholders must provide comprehensive programs to support these companies, especially the small and midsize businesses that often have limited resources yet comprise the majority of manufacturing employers in the US. To maximize their impact, these programs should:

“ “

AI tools are more accessible than ever, and a recent State of AI in Manufacturing survey reported that 77% of manufacturers had already adopted some form of AI, and 82% planned to increase their budgets for AI technologies over the next 12-18 months.

Prioritize Learning:

Professionals need access to quality continuous education opportunities that help them stay abreast of the developments in their sectors. Companies need strong training programs that upskill employees as AI changes manufacturing processes, especially in cases where the need for human work is reduced. One survey indicated that more than 60% of manufacturers planned to expand or augment their internal training programs in the near future to tackle skills gaps that are growing as technology impacts roles and responsibilities. Establishing a learning-focused culture will ensure companies and workforces have the resources necessary to stay ahead of the curve as AI influences more manufacturing processes.

Explore Adaptive Skills:

Some specific technical skills will always be in demand in the manufacturing industry, and a foundational knowledge of AI-enabled technologies will be useful to manufacturing professionals in a range of sectors. However, adaptive skills are the latest trend to ensure future-ready workforces. The ability to learn quickly, analyze information, use creative reasoning, apply systems thinking, and leverage social and emotional intelligence will be beneficial no matter how AI impacts operations. Training and reskilling programs must focus on developing these “softer” skills in a variety of contexts, and must help companies develop similarly adaptive cultures where employees and teams are empowered to problem solve and apply new skills to real-life scenarios. A combination of cutting-edge training and workplace culture insights can give professionals in-demand competencies, promote recruitment and retention among manufacturers, and spur innovation across the industry.

Center Technology:

Technology must be a focal point for upskilling and reskilling programs industry wide. The growth in technology adoption means that, even if an organization or role does not require a high level of technical knowledge today, tomorrow’s process or job could look very different. Integrating AI adds another layer of complexity by vastly expanding capabilities, generating significant data, and, as a result, modifying the skills needed to sustain operations at every level. As more machines and processes leverage AI, a basic understanding of how these new technologies work, what information they collect, how to store and protect critical data, and other capabilities will be fundamental to manufacturing professionals’ success. Keeping technology at the forefront of every program promotes continuous improvement within companies, identifies key trends that may impact specific jobs and sectors, and helps professionals understand their work in the context of a larger, ever-evolving industry.

Inspire Further Innovation:

AI’s flexibility in creating solutions and enhancing work can be tailored to a company or process’s unique needs, and training programs must encourage professionals to explore its vast possibilities and how it supports further technology integration. For example, AI tools can identify inefficiencies in current processes that new technologies may address. AI-enabled digital twin modeling can demonstrate the potential impact of a new technology before it is physically incorporated into a production environment. Finally, using machine learning and other capabilities, AI can translate data between systems and promote interoperability, streamlining previously disparate processes and ultimately making it easier for organizations to adopt new technologies.

AI brings myriad opportunities to the table for manufacturers and professionals, but comprehensive support and training is necessary to promote successful integration. Giving manufacturing professionals the skills they need to excel in AI-driven environments will ensure they continue to see manufacturing as a viable career path with significant growth potential. Helping companies create adaptable and learning-focused cultures will further mitigate workforce challenges and provide opportunities for professionals to develop new skills, innovate, and enhance operations.

Stakeholder organizations like MMTC (www. the-center.org) are committed to continuing Michigan’s manufacturing legacy and supporting the professionals and companies driving our industry forward. Together, we can embrace AI and Industry 4.0 technology to promote manufacturing growth and stability, improve the quality and safety of manufacturing jobs, and enhance our processes and outputs.

Since 1991, Michigan Manufacturing Technology Center (MMTC) has assisted Michigan’s small and medium-sized businesses to compete and grow. Today, we are celebrating 30 years of building super highways of competitive success for our clients, where there were once only slow and lonely dirt roads. Now, we stand ready to face the future with bountiful optimism, focused purpose, strong determination, legions of support staff and inspired creativity.

Key Takeaways on

Opportunities

Predictive Maintenance – AI-driven systems monitor equipment, predict failures, and optimize repairs, reducing downtime and extending machine lifespan.

Modular Manufacturing – AI enables flexible, reconfigurable production lines, allowing for rapid adaptation to market demands.

Facility & Workforce Management – AI optimizes resource allocation, ensures workplace safety, and improves production efficiency.

Path Forward

Investment & Accessibility – As AI technology becomes more affordable, SMEs will increasingly adopt AI-driven solutions.

Human-AI Collaboration – Success depends on integrating AI while supporting workforce development and sustainable manufacturing practices.

AI in Manufacturing Challenges

Technical Integration Complexity – Legacy equipment lacks AI compatibility, requiring costly upgrades and careful implementation.

Data Quality & Management – AI relies on high-quality data, but many manufacturers struggle with standardization and infrastructure.

Security & Privacy Concerns – AI-driven manufacturing systems are vulnerable to cyber threats, requiring strong security measures.

Adoption & Buy-In – While AI potential is recognized, actual implementation remains low due to cost, expertise shortages, and infrastructure limitations.

Workforce Adaptation & Training – AI shifts job roles, demanding retraining, upskilling, and strategies to ease worker concerns about automation.

Michigan Resources

Michigan Economic Development Corporation offers a variety of resources for small-to-medium-sized businesses, including an Industry 4.0 Implementation Grant that provides 50% reimbursement for technology costs, including AI. There are eligibility requirements. To learn more about these grants, visit michiganbusiness.org/industry4-0/grant/

The Michigan Small Business Development Center (michigansbdc.org) has several webinars answering technology questions, including one that introduces AI with tips and tools. For more information, visit lms.michigansbdc.org/course/ artificial-intelligence-and-small-businesses

The Smart Manufacturing: Leveraging AI for Competitive Advantage Course is designed for manufacturers of all levels and hosted by the Michigan Manufacturing Technology Center (MMTC). Enhance your AI expertise to optimize manufacturing operations through hands-on learning in predictive maintenance, quality control, and supply chain optimization. This course also covers ethical considerations, ensuring responsible AI implementation for increased efficiency, innovation, and competitiveness. To register, visit https://www.the-center.org/Classes/Industry-4-0/Smart-Manufacturing-Leveraging-AI-for-Competitive

Funding Resources for MMTC Smart Manufacturing Training

• Going PRO Talent Fund https://www.the-center.org/Resources/GoingPRO

• STC Grant https://www.the-center.org/Resources/STC-Grant

• MDRC Grant https://www.the-center.org/Resources/Michigan-Defense-Resiliency-Consortium

Ann Arbor Spark provides networking opportunities with businesses, universities, and technology experts, as well as workshops and training sessions. For more information about technology workshops and other opportunities, visit annarborusa.org/

National Resources

U.S. Small Business Administration offers information, tools, and other aids to help start or develop a small business, including loans to improve infrastructure and technology. For more information, visit sba.gov

The National Institute of Standards and Technology promotes AI innovation, development, and safety. In collaboration with the private sector, the NIST has created an AI Risk Management Framework (nist.gov/itl/ai-risk-management-framework). For more information, visit nist.gov/

Coursera partners with learning institutions, companies, and other organizations that offer online AI certifications with courses that vary in length and cost. For more information, coursera.org

Automation Alley is a nonprofit technology business association and Digital Transformation Insight Center focused on driving the growth and success of businesses in Michigan and beyond through innovation and automation. With a global outlook and a regional focus, we foster a vibrant community of innovators, entrepreneurs, and business leaders through opportunities for collaboration and learning. Our programs and services help businesses develop the skills and expertise needed to effectively jumpstart or accelerate digital transformation. By bringing together industry, academia, and government, we aim to create a dynamic ecosystem that drives innovation and growth across Michigan.

At Automation Alley, our mission is to help businesses thrive in the rapidly changing digital economy. We equip them with the knowledge, insights, and tools to develop a software-first mindset that leverages the power of automation, AI, and other cognitive technologies. We believe that by working together, we can build a stronger, more innovative, and more competitive economy for the future.

Wealth, prosperity and equality through technology.

To

SOURCE LIST

Deloitte - Survey on AI Adoption in Manufacturing https://www2.deloitte.com/cn/en/pages/consumer-industrial-products/ articles/ai-manufacturing-application-survey.html

Capgemini - Manufacturing Operations Needs to Embrace AI https://www.capgemini.com/us-en/insights/research-library/manufacturing-operations-needs-to-embrace-ai/

World Economic Forum - How we can bridge the AI divide with accessible AI data scientists https://www.weforum.org/stories/2024/11/bridge-ai-divide-with-data-science-agents/

TechTarget - 10 top AI jobs in 2025 https://www.techtarget.com/whatis/feature/Top-AI-jobs

Forbes - Coursera Launches Several New Certificate Programs Focused On AI https://www.forbes.com/sites/michaeltnietzel/2024/09/17/coursera-launches-several-new-certificate-programs-focused-on-ai/

DeepLearning.AI - Professional Certificate https://www.deeplearning.ai/

InfoSys - While only 2% are ready, most companies expect productivity gains of 10-40% with Enterprise AI: Infosys Research https://www.infosys.com/newsroom/press-releases/2024/enterprise-ai-readiness.html

Publication Credits

Editorial: Nicole Kampe, Dennis Burck, Joseph Gray

Graphic Design: Laura Gearhart

Photography: Sean Healey and Corey Sims