From the icing on top to every bite beneath, our portfolio of superior clean label ingredients will keep your cakes, donuts, and other baked goods fresh, naturally.

Natural N Clean Label CL

Icing & Glaze Stabilizers

Replacers Sweet Goods Base Mixes K Kosher Pareve Egg Replacers

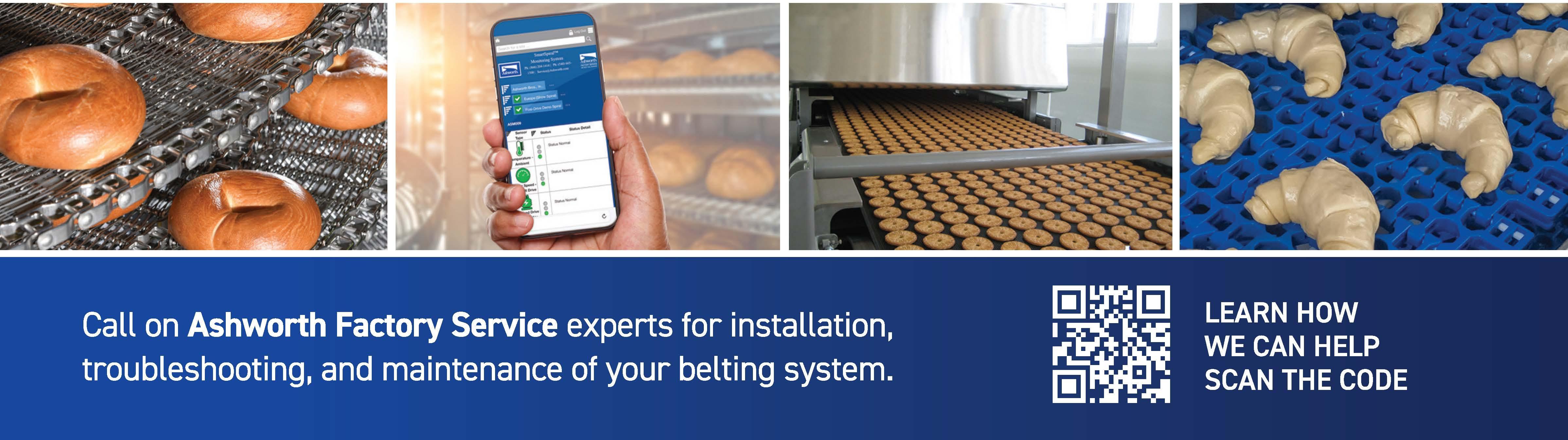

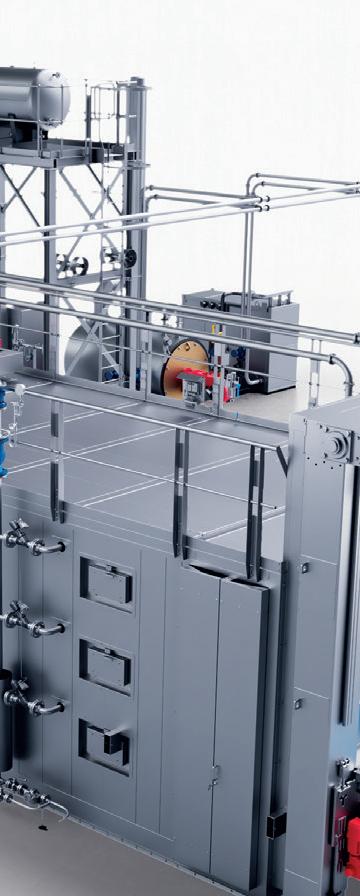

AMF's Sustainable Oven Service (SOS) transforms ovens into smart, data-driven machines that help commercial bakeries save energy and improve efficiency. By combining decades of oven-building expertise with advanced data analytics and artificial intelligence, SOS optimizes baking conditions in real time. This innovation can reduce natural gas use and CO2 emissions by up to 20%, while also enhancing product quality and consistency. Using tailored recommendations for temperature, vapor exhaust, and steady-state conditions, SOS ensures energy-efficient, top-quality baking in every batch, helping bakeries meet sustainability goals and boost performance.

www.intralox.com

Paul Lattan

President - Principal

Steve Berne

Executive Vice President - Principal

Joanie Spencer

Vice President - Partner

Paul Lattan

Publisher | paul@avantfoodmedia.com

816.585.5030

Steve Berne

Director of Sales | steve@avantfoodmedia.com

816.605.5037

Erin Zielsdorf

Account Executive | erin@avantfoodmedia.com

937.418.5557

Joanie Spencer

Editor-in-Chief | joanie@avantfoodmedia.com

913.777.8874

Mari Rydings

Editorial Director | mari@avantfoodmedia.com

Jordan Winter

Creative Director | jordan@avantfoodmedia.com

Olivia Siddall

Multimedia Director | olivia@avantfoodmedia.com

Annie Hollon

Digital Editor | annie@avantfoodmedia.com

Maddie Lambert

Associate Editor | maddie@avantfoodmedia.com

Lily Cota

Associate Editor | lily@avantfoodmedia.com

Beth Day | Maggie Glisan

Contributors | info@commercialbaking.com

Commercial Baking is published by Avant Food Media, 1703 Wyandotte St., Suite 300, Kansas City, MO 64108. Commercial Baking considers its sources reliable and verifies as much data as possible, although reporting inaccuracies can occur. Consequently, readers using this information do so at their own risk. Commercial Baking is distributed with the understanding that the publisher is not liable for errors and omissions. Although persons and companies mentioned herein are believed to be reputable, neither Avant Food Media nor any of its employees accept any responsibility whatsoever for their activities. Commercial Baking magazine is printed in the USA and all rights are reserved.

No part of this magazine may be reproduced or transmitted in any form or by any means without written permission of the publisher. All contributed content and advertiser supplied information will be treated as unconditionally assigned for publication, copyright purposes and use in any publication or digital product and are subject to Commercial Baking ’s right to edit.

Commercial Baking ISSN 2767-5319, / USPS Publication Number: 25350 is published in February, April, June, July, August, October and December, in print and digital formats by Avant Food Media, 1703 Wyandotte St., Suite 300, Kansas City, MO 64108. Periodicals Postage Paid at Kansas City, MO, POSTMASTER: Send address changes to Commercial Baking, c/o Avant Food Media, 1703 Wyandotte St., Suite 300, Kansas City, MO 64108.

Circulation is tightly controlled, with print issues sent only to hand-verified industry decision makers and influencers. To apply for a free subscription, please visit www.commercialbaking.com/subscription

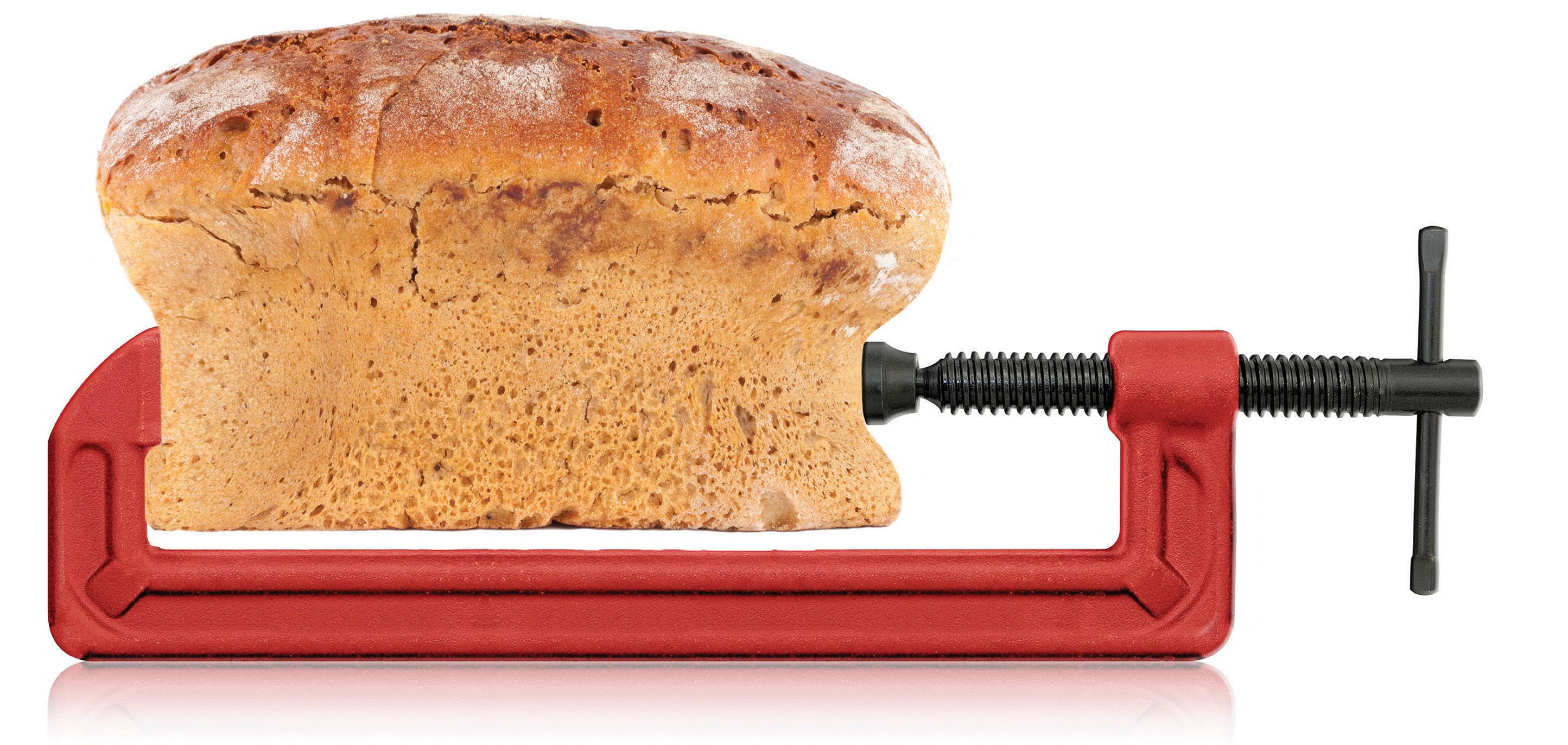

Bellarise® BellaSOFT Ever Fresh bakes the best softness, resilience, and bite into all of your breads and buns.

Oh, and it's all-natural and clean label, too.

All-new Bellarise® BellaSOFT Ever Fresh:

• Maximizes value by yielding the best softness for the longest time

Protects your breads when stacked by offering top-notch resilience

Creates a perfect bite that always reveals all the best in your breads

Our master bakers put their best into Bellarise® BellaSOFT Ever Fresh to help make your breads unforgettable. After all, you work hard at the bakery every single day, so we work hard to make sure all your efforts count.

Please contact us and order your sample today!

In addition to meeting and exceeding current production needs, we look to the future of processing.

Our experienced and knowledgeable engineers and food technologists work with you to optimize end to end solutions.

With the implementation of on-site automation, the future of facilities is rapidly changing and becoming more user-friendly and cost-effective while improving sanitation, maximizing labor, and ensuring employee safety.

JOANIE SPENCER Editor-in-Chief

| joanie@avantfoodmedia.com

WATCH NOW :

Joanie Spencer talks about the opportunities technology holds for bakeries … and their employees.

I just watched my teenager drive to school alone for the first time. After I cried, threw up a little and contemplated jumping in my car and following him, I got the text saying he made it just fine.

I also started wondering if the circa-2012 SUV he inherited had the necessary technology to get him safely from Point A to Point B. Oh, who am I kidding? My high school car had an FM radio, a paper map in the glove box and a driver’s side window I had to lean into if I wanted to “roll” it down.

The gaps between tech advances get smaller every day, and in our industry, technology is only as good as the workforce’s ability to keep up with it.

In the latest season of our podcast, Troubleshooting Innovation, Trina Bediako, CEO of New Horizons Baking Co., spoke about the importance of keeping teams educated and up to date on modern technology and automation. And on the pages ahead, you’ll see similar sentiments from leadership at Crown Bakeries, as well as Paula Marshall, CEO of The Bama Cos. And if that wisdom isn’t enough, we have a full feature dedicated to how upskilling through technology can create all-new opportunities for workers … while giving them more reasons to stay.

How are you tapping into technology to move your business forward? Shoot me a note and let me know. I’d love to hear your ideas (or thoughts on the feasibility of putting a 15-year-old driver in a car seat).

“Having

a mentor whom you feel connected with and an environment where you can be vulnerable is key. If you’re not going to have those difficult conversations, learning what you need to do to grow, then it won’t help you.”

the importance of mentorship

“When it comes to branding, it’s essential to make it special and meaningful. Don’t just throw something at the wall; tie it to a story that evokes emotion and passion.”

“There’s no one person doing it all. I can have a vision, and my president and I can work together and present it, but if our people aren’t prepared for it or if they’re frightened by the speed of the change, it goes nowhere.”

“As technology advances and automation has a more prominent role in food manufacturing, that will bring a higher level of sophistication in the process, including the employees, training, education and communication.”

Jon Anderson | managing consultant | BEAG

During a live recording of The Case for Safety podcast at BakingTECH 2025

“To have the best [IBIE], you have to have good energy; you have to have people in the booth excited. If your people are excited, and the people coming to your booth are excited, they will associate that excitement with your brand.”

Jeff Yankellow | director of bakery foodservice sales | King Arthur Baking Co. During a panel discussion at the IBIE Exhibitors Summit

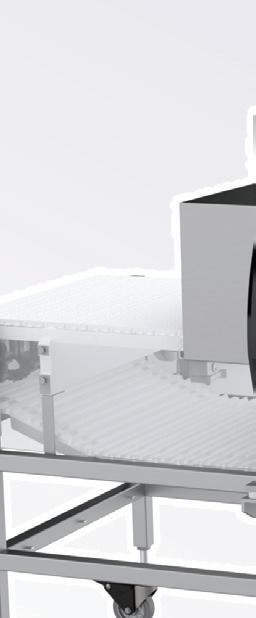

If you’re looking for a high capacity proofer that takes maximum advantage of minimum floor space, look no further. Our CapStep Proofer’s only limit … is your ceiling.

When your pans or peel boards enter the CapStep Proofer, they will be raised upward. When the pans reach the top of our system, they are gently moved over to the downward section by a transfer conveyor and lowered one level. This process continues – one Step at a time – until your product is ready to leave the proofer.

CapStep’s PLC controlled temperature and humidity HVAC and mechanical movement system is built for heavy-duty long life.

Call us today at 1.877.222.7929. We’ll help you take the next Step in automated bakery proofing systems.

“For

me, part of being a leader is having trust. People are not going to do things the way you are going to do it, but by giving them clear expectations and the freedom to execute, you can trust they’re going to get results.”

Ramon Rivera | senior VP of global operations | Grupo Bimbo

“It’s incumbent upon us as leaders to think about our company’s impact on the environment, but it’s also a business necessity if you’re connected to agriculture because of the reality of how climate change is impacting the ability to source your ingredients.”

“Big wins don’t happen overnight. Every brand that looks like they have it all figured out had a moment where they didn’t. Resilience, creativity and grit go a long way in this space, sometimes even further than deep pockets.”

Kelley

| founder and CEO | Pure Simple Foods

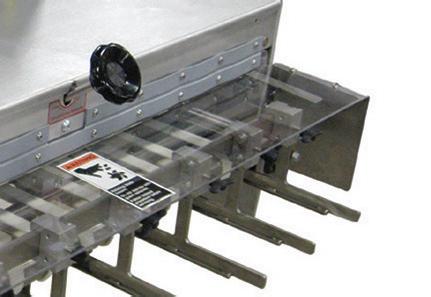

We help bakeries automate slicing and bagging by building and servicing high-tech packaging equipment. We remove manual work, improve safety and raise speed to one bag per second.

Cutting-edge slicers, baggers and sealers

Custom design and fabrication to match your specifications

Built using high-quality materials for ultimate reliability

Speeds of one bag per second with minimal manual work

Rapid replacement parts service and custom manufacturing

Fast, fastidious and committed for guaranteed satisfaction

Crown Bakeries’ Pleasant Prairie, WI, facility has it all … past, present and future.

BY JOANIE SPENCER

There’s a common mentality threaded throughout every aspect of Crown Bakeries: See what’s possible, and never stop looking.

When brothers Yianny and George Caparos, CEO and chief development officer, respectively, joined the Nashville, TN-based baking company founded by Cordia Harrington, they had a strategy to diversify the business by adding croissant and laminated dough production to the already robust bun business the original company was known for.

When these three minds came together, visionary sparks flew.

After rebranding from The Bakery Cos. to Crown Bakeries as part of the 2020 recapitalization under Arbor Investments, Crown is now ranked as the country’s largest thaw-and-sell croissant producer and 15th largest pure-play bakery in the world.

“The picture was to build a macro-level, multi-facility bakery business,” Yianny said. “We have a history in the croissant business, and we knew that once we got back into it, we’d have the right avenue for Crown to grow.”

Today, the company operates in nine facilities across the country, with premier, high-speed capabilities across croissants and laminated dough as well as bun, biscuit, bagel and English muffin production. Additionally, Crown operates several production lines that manufacture a diverse portfolio of sweet baked goods. Operationally speaking, Crown’s croissant growth has come primarily through new customer acquisition, as the addition of facilities in Pleasant Prairie, WI; Smyrna, GA; and Nashville offered the capacity needed to support marquee customers across all segments.

The Pleasant Prairie bakery might be the newest branch on Crown’s family tree, but it has a deep history for Yianny and George, as well as COO Scott Shelley. The three led the team that built this bakery and its original high-speed croissant line in 2017 as part of Chicago-based Gold Standard Baking Co., now known as 37th Street Bakery.

“This bakery was a bit personal to George, Scott and myself,” Yianny said. “We were developing plans to build another croissant factory when Pleasant Prairie became available. So, rather than having to build a new facility and generate all-new business, we were able to buy an existing asset we were familiar with and customers we already knew.”

With intimate knowledge of the operation and its capacity, starting up was just the beginning. Knowledge of the market comes into play, as well.

Current inflation and economic uncertainty are challenging QSR operators to offer consumers lower-cost menu items without compromising on quality, while other channels are also creating new competition. That calls for the forward-thinking vision and high production standards that Crown and Arbor are known for.

“Crown is evolving to meet the needs of the foodservice sector,” said Jennifer Shaw, director of marketing and communications for Crown Bakeries. “A high-quality hamburger could be as much as $18 in certain markets, and people are trading down. As these operators are becoming more margin-pressured, we’re rising to the occasion by investing in our facilities to efficiently create marginfriendly products.”

QSR is a big part of Crown’s core business, but the c-store market is stepping into growth mode as cashstrapped consumers seek out new options. When products such as croissants offer better choices like graband-go sandwiches at lower prices, that spells opportunity for Crown.

“Our business model has been built around offering a reliable sandwich carrier,” George said. “Younger people might not be making their way to QSR operators for sandwiches as much these days, but they are finding their way to the c-stores.”

With a definitive shift from simply offering gas, cigarettes and a basic fountain drink, c-stores have become destinations for easy, affordable food options.

“Food at c-stores is becoming elevated, and our products are in a great position for that market,” George added. “Breakfast sandwiches and lunch items are becoming comparable to what’s offered in QSR, and I think that will continue. I predict the landscape will eventually blend, to an extent, and our core items are well-suited for that, whether they’re made fresh or sold in a clamshell from the refrigerator case.”

Business is also picking up for in-store bakeries post-COVID, as many of them increase their breakfast offerings on the platform of quality and affordability … two factors on which consumers won’t budge, no matter if their wallets expand or contract.

“The bar for consumers will continually rise, and the onus falls on us as the manufacturer,” said Doug Bame, president of Crown Bakeries. “We have to provide a better-quality product without the cost impact. We’ve got to source our inputs at a lower price point so we can fuel that expectation for quality without [consumers] having to pay more for it.”

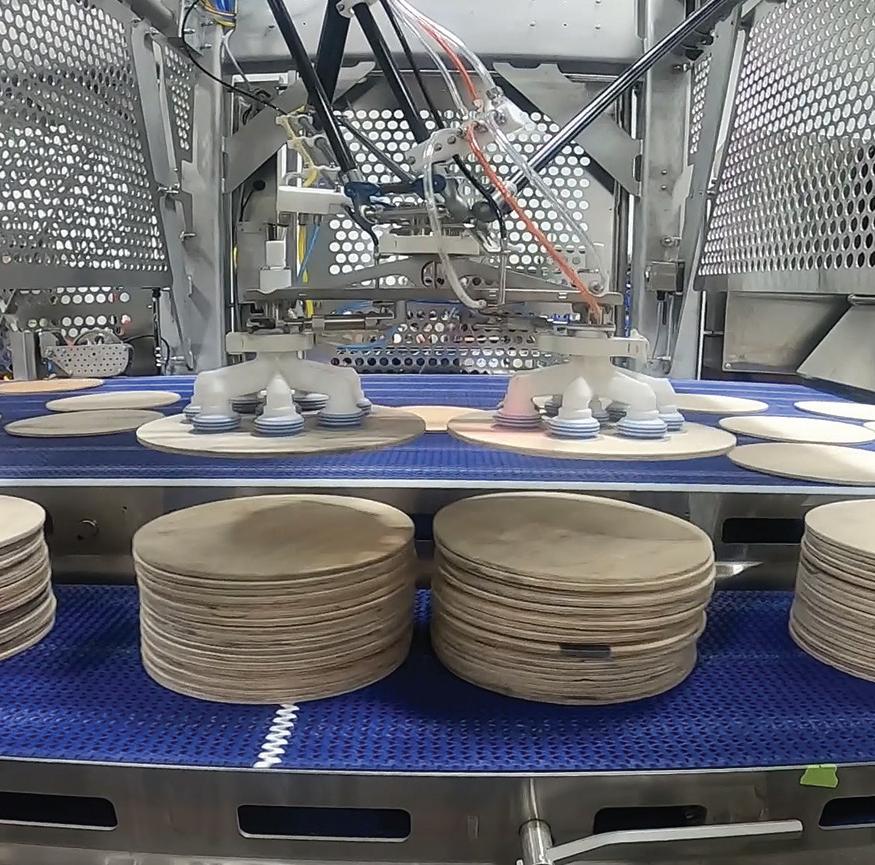

Last year, Pleasant Prairie started up its second croissant line — both high-speed and flexible — to crank out more than 86,000 croissants an hour while gearing up for a third line that will focus on high-speed, flexible bun production. Crown invested in technology to support that efficiency for producing high volumes of croissants and buns while maintaining consistent quality.

While many commercial bakeries build the business first and capacity second, Crown takes a more inverse approach.

“As a company, we’ve always been aggressive in terms of investing and looking ahead,” Bame said. “When we see a good opportunity, we act. We’ve had great support from our ownership group to do that.”

This way, the operational capacity is there when the business comes in. It’s a forward-thinking strategy, but it also comes with the pressure to perform. And it only works when every aspect of the business is aligned.

“With Arbor, once we create a strong, vetted business plan, they are willing to invest ahead of time within that plan,” Yianny said. “At that point, we are accountable. Working with private equity, we have a fiduciary responsibility to fill that capacity and provide the ROI in a much shorter period of time.”

To exemplify that strategy, the new croissant line at Pleasant Prairie has already filled its capacity. When the bun line starts up in August, it will likely follow suit.

Although the plant was built with space for a fourth line, Crown’s current need for speed and flexibility required a larger footprint for the bun production.

“We will sacrifice a fair bit of square footage to have that flexibility,” Shaw said. “But that’s the big differentiator for Crown: We don’t compromise on quality or flexibility, especially when different customers — regardless of the channel — need it to meet their specific needs.”

That said, quality pertains to the people as well as the products.

“You’ve got to have highly qualified people on your team,” Bame said. “You can buy the best equipment, but to be a great manufacturer, you need a quality team that works well together. That applies to everything, including leadership, training, culture, working relationships — everything.”

Over the past four years — as the Crown Bakeries workforce has grown to nearly 2,000 — Arbor has invested more than $140 million across the board, including operational installations throughout the network and building upgrades that support the “One Crown” initiative.

“You can buy the best equipment, but to be a great manufacturer, you need a quality team that works well together.”

Doug Bame | president | Crown Bakeries

The goal is for all nine bakeries to reflect the company’s brand strategy while also focusing on the workforce.

“It’s part of Cordia’s foundation,” Yianny said. “Everything we do is driven by the people. We want them to know they’re a part of the growth, so it’s important to offer something people see as a career, not just a job.”

It all folds into Crown’s mission statement: “Create opportunities, make a difference and impact lives.”

“We’ve not only focused on the look and feel coming together for all the facilities, but we also focused on amenity spaces such as lunchrooms and locker rooms,” Bame said. “We want to make coming to work every day an enjoyable experience and ensure everyone feels they’re part of the same thing. We’ve made a concerted effort to prioritize that, especially for plants that came into the network through acquisition.”

Operationally, Pleasant Prairie’s capital investments — around $32 million for building updates and additional lines — ultimately have to support a strong execution within its core capabilities.

“We always make sure it comes back to the core,” George said. “We have to focus on that execution of thaw-and-serve croissants, frozen dough croissants and freezer-to-oven croissants; the same goes for buns, as well.”

A critical component of that is having — and maintaining — close business relationships with vendors. It’s a significant part of what makes life easier for the operation, especially come commission time.

“With the second croissant line, we knew exactly what we wanted,” Yianny explained. “It was all about capturing the business this facility had been serving. We knew the vendors we trusted and the people we could work with, who understand our needs, respond promptly and treat us essentially like family.”

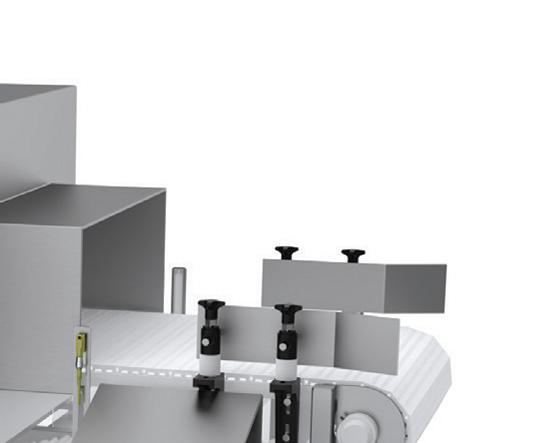

The croissant makeup lines, both built by Rademaker, mirror each other, save for any technology updates since the original installation.

Line 1 primarily runs butter-based laminated dough for QSR customers, while Line 2 focuses on margarine-based products that work well for items like microwavable sandwiches. The amount of layering, laminating and sheeting all depend on the specific customer and product type, and the Rademaker systems allow that flexibility.

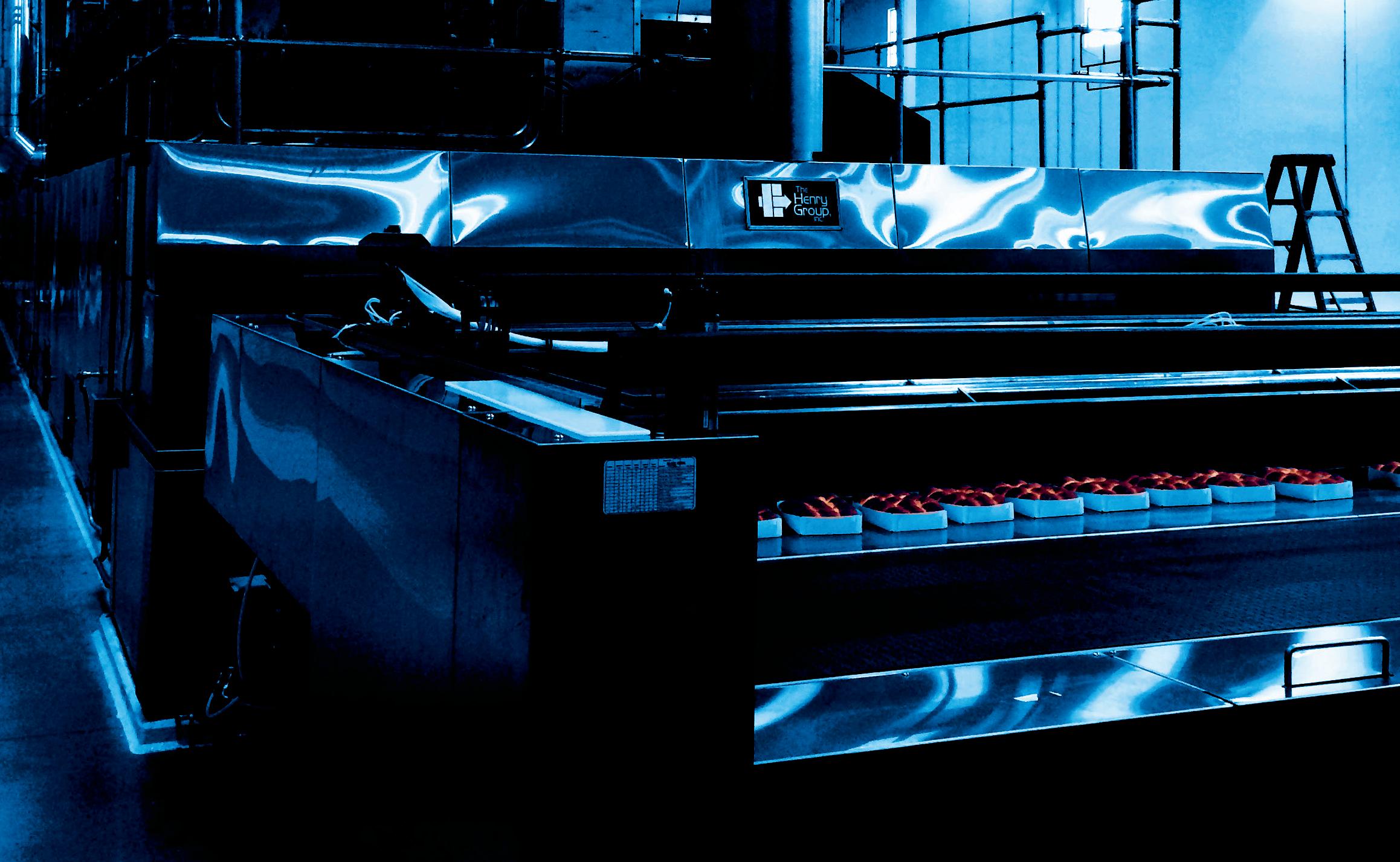

For high-speed croissant production, consistency has no room for compromise. That’s why the Crown team relied on a trusted relationship when investing in a new direct-fire tunnel oven from The Henry Group for the second line.

“The first oven Yianny ever installed was from The Henry Group,” Shelley said.

Scott Shelley talks about why Crown turned to a trusted OEM partner when it upgraded its oven technology.

“We’ve all come a long way since then, but the overall reliability and consistency of this oven is unlike any other I’ve used.”

It was a true full-circle moment.

“We didn’t pursue anyone except for The Henry Group for the new oven,” Yianny said. “We came back to them because of the equipment’s durability and reliability and the team’s responsiveness.”

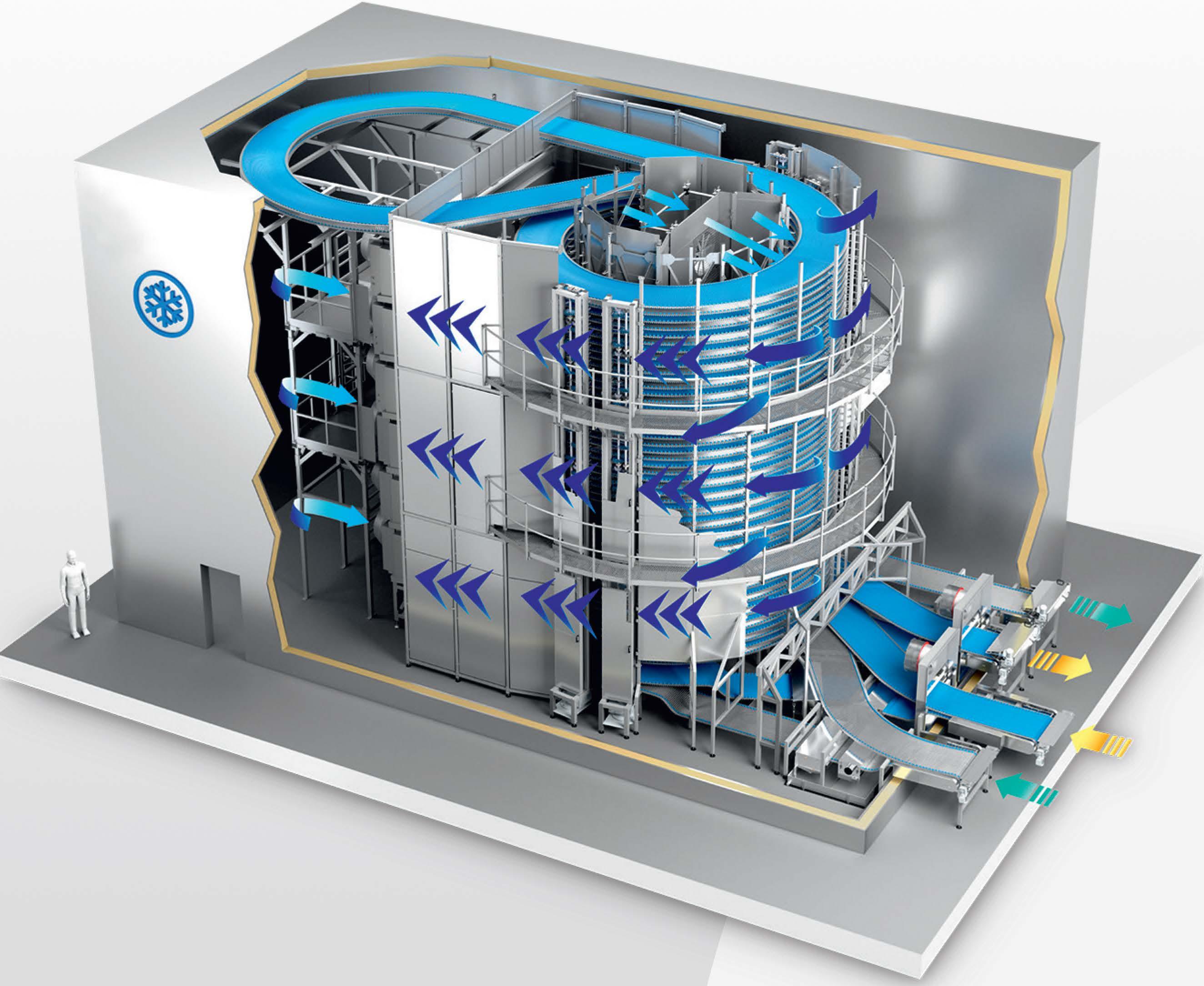

Cooling and freezing on both lines represent technology that enables speed, efficiency and flexibility. Still working like a charm since the bakery opened, the original Tecnopool cooling tower on Line 1 — discovered at the 2016 International Baking Industry Exposition — was Yianny’s must-have when the first operation began.

Meanwhile on Line 2, a hybrid cooling-freezing spiral from Coastline enables flexibility without changing lines.

“We first installed a Coastline spiral at our Norcross [Georgia] plant in early 2020,” Shelley said. “When we built the croissant line in Nashville, we installed one there, as well. It’s robust from a construction standpoint, and it’s very sanitary. It’s a great solution for us to supply customers such as sandwich makers with commissaries.”

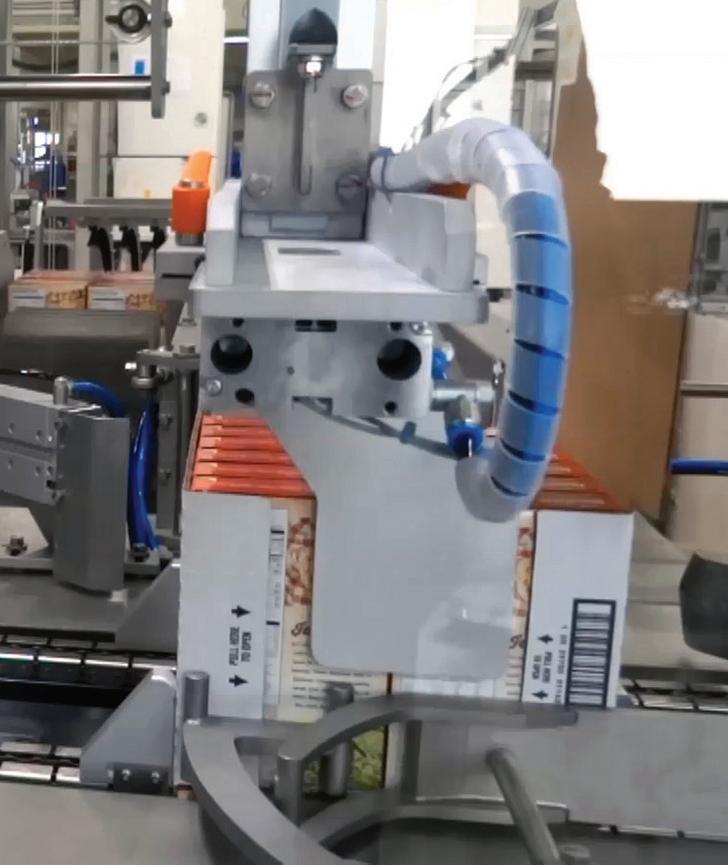

The final touch on Line 2 is a Pattyn packaging system, designed to streamline controls for bulk case packing. The system bags, fills, shakes and seals each case quickly and efficiently.

Scott Shelley explains how technology advances at the end of the line keep croissant production running smoothly at Crown Bakeries’ Pleasant Prairie, WI, facility.

“It runs incredibly fast, but it’s also very smooth,” Shelley said. “I think Yianny says it best: ‘We’re running so fast, yet it’s all very calm.’”

With an additional 10,000 square feet of space on the building’s second floor, Crown has an opportunity to extend its office space or add R&D and product demo capabilities. For now, the focus is on making those croissants and commissioning the bun line.

“The entire infrastructure of this facility was built with the intention of filling it up,” Shelley said. “When we came in, we knew we had great bones in this building. And now, the bun line is going to fulfill that original vision. You could say it all comes back to leadership at Crown and Arbor. There’s a total expectation to be the best.”

Sometime in the future, growth might require expansion for additional freezer space. That’s a long way off, but for a company always planning ahead, one just never knows. Building codes for the Pleasant Prairie facility dictate that it can only be as wide as it is tall … for a team that’s already come full circle, perhaps there’s nowhere to go but up. CB

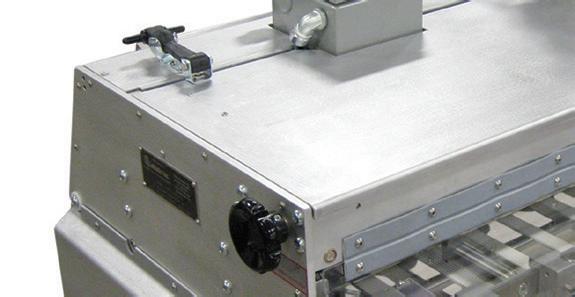

At Crown Bakeries’ 220,000square-foot facility in Pleasant Prairie, WI, state-of-the-art systems enable high-speed, yet flexible croissant production on two lines. While croissant business is booming, the operation is gearing up for bun production to start in August. Below is a list of innovations that can be found on the bakery floor.

AMF Workhorse Automation pan storage and retrieval

Babbco oven

CBF proofers

Coastline spiral cooler/freezer

Contemar indoor silos

Coperion | Shaffer mixers

Coperion | Shick Esteve ingredient handling

The Henry Group oven

LeMatic pillow pack

Pattyn bulk packaging system

Rademaker laminators and croissant makeup lines

Tecnopool spiral cooler

AMF mixers, divider/Accupan system, proofer, oven, spiral cooler

HaF Equipment liquid brew and ingredient handling

LeMatic pillow pack

Lenexa Manufacturing baggers

As Bama Cos.’ CEO, Paula Marshall has built a global operation through care, accountability and a keen eye for long-term gains.

BY JOANIE SPENCER

Life has a funny way of giving gifts that are packaged as challenges. For Paula Marshall, CEO of Tulsa, OK-based The Bama Cos., everything is a gift if one has faith … and the courage to dig deep enough to find it.

As a granddaughter of Cornelia Alabama “Bama” Marshall — Bama Cos.’ matriarch and co-founder — Marshall has the proverbial flour running through her veins. Her grit, determination and unwavering high standards are inherent in her DNA as well.

“My dad nicknamed me ‘Bama Two,’” Marshall recalled. “He saw characteristics like determination and [my grandmother’s] work ethic in me. Those were the things he loved about his mom, and he loved seeing me exhibit them in the plant. I’ve heard so many stories about her, and from what I hear, I think I carry on a lot of her traits. What she stood for are the things I stand for too, though maybe in different ways.”

Life changes steered Marshall down a path that led her to work in the bakery instead of traveling the world and learning about new cultures, as she’d once dreamed of doing when she was younger.

“You dream of things when you’re 16 or 17, and then life changes,” she said. “But I look back now, and I see divine intervention.”

In Marshall’s career, the turning points are where she leaves her mark.

The opportunity to step into leadership of the business came sooner than she’d expected. In truth, it may be more accurate to say it was unexpected. But Marshall’s grit comes from treating challenges not as something to push back on but something to face head on, and when thrown toward the top of the ladder, she landed on her feet.

“That’s how it is for me,” she said. “I try to tell people I work with or mentor that you have to take every assignment. You can’t just pick and choose because you’ll never know if you chose the right thing.”

That mentality came in handy as she dabbled in nearly every aspect of the business, from operations to sales. The company — which is known for being McDonald’s first pie manufacturer — also dabbled in different business markets including retail CPG. Marshall learned through experience that taking every project doesn’t mean keeping every project. Oftentimes, it simply provides the context for knowing which jobs are the right ones for the business.

Although pie production is highly specialized, the core competency — high-speed dough production — lends itself to creating a diverse lineup of other baked goods. Identifying that led to Marshall’s first sales pivot: selling off the CPG business and diversifying production of dough-based items.

“In 1997, we had an opportunity to delve into frozen dough for pizza, and it became my account,” she said. “I knew it had potential to really grow the business, and I told my dad we just needed the capital and the space to build.”

“When you put caring with accountability, it brings a balance … To me, it makes perfect sense, and it’s how we’ve been able to retain talent, sometimes for 20 or 30 years.”

Paula Marshall | CEO | Bama Cos.

From there, Marshall has taken Bama Cos. from high-speed pie production to one of the most highly rated bakery suppliers to the QSR market, both domestically and abroad, for customers including McDonald’s, the Yum! Brands portfolio and more.

Identifying new opportunities based on operational excellence is where growth begins, but maintaining relationships is how the business lasts. In foodservice, relationships are the brand.

“To be a good partner, there has to be a relationship,” Marshall said. “Everything’s built around a four-, five-, six-year relationship. And within that, we’ll spend time developing new products, talking about different things we can make, investing in new ingredients, efficiency gains, or even entire production lines. It’s a trusted relationship that builds those types of discussions.”

WATCH NOW: Paula Marshall explains how strong customer relationships lead to opportunities for long-term innovation.

Steering away from retail and leaning into foodservice was not only pivotal in Bama’s growth and expansion, but it also illuminated ways Marshall and her teams have been able to innovate with the customer base.

“Making product and packaging it in beautiful boxes for retail shelves is difficult to execute,” Marshall said. “In my business, we’re putting frozen products in a box — we’re talking 50,000 to 75,000 pies an hour — and shipping it to an end customer who can then bake it. These are the companies that are growing.”

“We’re seeing innovation coming from customer input around what they want to see coming off the lines,” she said.

Over the years, Marshall has seen several iterations of apple pie innovation, ranging from the baked pie of the ’90s to the more modern lattice-topped pies with larger fruit chunks. Above all, demand for clean-label products has driven innovation that could not be achieved without trust and open dialogue between Bama and its customers.

As technology and consumer access to information progress, the rapidity of trend cycles is tighter than ever. For Marshall, it means not only being willing to listen to customers but also being ready to act.

Much of Bama’s customer base is focused on clean-label products, enabling the company to stay ahead of the game, so to speak. But Marshall knows that things happen quickly these days, and the product developers who are in tune with — and stay in front of — the pendulum swings will remain successful.

“Over the past few years, I’ve maintained an awareness for how the trend cycles are changing,” she said. “I think there’s going to be a lot of information coming out about different ingredients, and we’re going to see more change coming. Obviously, an apple pie has to taste like an apple pie, and it has to be delicious, but we have to be ready to adapt based on demand around how products are made.”

While consumers are mostly the ones driving the speed of change in terms of product development, Marshall is also keeping a close eye on how the labor landscape has evolved. With workforce woes still permeating the industry, she believes that automation is only part of the solution.

“The technology we, as an industry, have invested in to solve the people shortages still requires people who know how to run it,” she said. “Innovation is happening really fast in that regard, and we need to be careful not to outstrip the technical capabilities of our people. If technology outpaces people’s ability to know how to use it, then it’s no longer solving the problem we needed it to solve.”

Training on the machines is incredibly important, but for Marshall, there’s no substitute for having people in the plant who are not only knowledgeable but who also care about what they’re doing.

That’s where the hard and soft skills intersect, and it’s inherent in the Bama Cos. mission: “People helping people be successful.” That’s accomplished through care and accountability, and for Marshall, these are the two most critical factors in bringing the mission to life.

In the baking industry — and the business world — Marshall has a reputation for

building Bama’s culture into a place where people not only want to work but they’re also inspired to give their best.

“When you put caring with accountability, it brings a balance,” she said. “As humans, we need accountability; otherwise, things can go off the rails pretty quickly. But caring is not a sign of weakness. We take a big interest in what’s going on with our people. If we see they’re stumbling, we’re there for them.”

With more than 1,000 employees in the US and abroad, Marshall sees every team member as an extension of the family.

In fact, through a collaboration with Marshall’s daughter and stepson, Bama transformed an underutilized building into the Bama Caring Center (BCC), equipped with classrooms and HR offices, as well as a counseling center, medical clinic and legal aid, to assist with a range of personal challenges employees might be facing. Other benefits also include tuition reimbursement and profit sharing

Marshall can often be found sharing her leadership insights at speaking engagements. She always advises the people she mentors to take every opportunity that comes their way.

for manufacturing team members, but the BCC yields the best intangible ROI.

“For what I consider to be not a huge financial investment, this has been considered the No. 1 team member benefit,” Marshall said. “Whenever I ask a team member, ‘What do you love most about Bama?’ They always say the BCC and the clinic.”

Make no mistake. Care is not charity, and the resources available in the BCC are considered an exchange for work well done. Guard rails are in place to keep the operation running smoothly.

“There are things that have to be done,” Marshall said. “You have to be here; you have to be on time. We are a crew, and we need everyone on the line supporting one another. If there’s a problem, we’ll help you get through it, and we encourage open conversations. But working here and enjoying those benefits means meeting expectations.”

Through the care and accountability philosophy, Marshall maintains a long-term view of the Bama workforce.

“When we are willing to help them, they’re willing to do their jobs at a high level and make great products for our customers,” she said. “To me, it makes perfect sense, and it’s how we’ve been able to retain talent, sometimes for 20 or 30 years.”

Growing up with the stories of Cornelia Alabama’s matriarchy, Marshall might not have imagined being a matriarch of change herself. Nonetheless, she’s carried on a legacy that was passed down from her grandmother to her father and on to her with grace, compassion and an unyielding commitment to quality through innovation.

Perhaps Cornelia Alabama never imagined her handheld pies becoming a global company, either. But here it is, supporting foodservice operators with pies, pizza crust, breads and more through its US operation and Bama Europa — the recent UK acquisition — as well as operations in China and Poland.

“We put Bama on the map,” Marshall said. “That has been pretty amazing to accomplish for my family.”

For her, in fact, it’s the greatest gift of all. CB

THEWORLD'S LEADING TRADE FAIR FOR THE BAKING AND CONFECTIONERY INDUSTRY

MAY 18-22, 2025, D0SSELDORF

POSIDRIVE SPIRAL®

Increase capacity while minimizing maintenance and downtime in the most demanding applications.

SMARTSPIRAL®

Flexible belt stackers that deliver cost-effective, high quality food processing solutions.

SMARTOVEN®

Monitor key metrics that are tracked and trended to identify changes in the equipment's operating parameters.

SPIRALSURF®

Customize to meet individual requirements for cooling and freezer applications. Perfect for tight transfers and small products.

Embracing a better-for-everyone philosophy, Lexington Bakes raises the bar for indulgent treats.

BY MADDIE LAMBERT

“Treat yo’ self” may have been coined by the popular sitcom Parks and Recreation, but the phrase has become more than just a comical tagline. The concept is now part of everyday consumer language, and more significantly, often used to permit indulgent snacking.

Los Angeles-based Lexington Bakes (LXB) started as an Instagram post showing off homemade organic brownies, and it turned into a brand that had demand before it even had a name.

Most entrepreneurial origin stories start with the same formula: develop a product, create the brand and seek out customers. LXB — perhaps akin to its founder and CEO — did things a little differently. Lex Evan is nothing if not warm, eccentric and wildly creative. No stranger to entrepreneurial adventures, he’s a principle-driven risk taker.

After moving from New York to Los Angeles to pursue a graphic design career, Evan baked as a hobby, not a gig. That was, until he posted his brownie creations on Instagram, triggering an influx of direct messages from acquaintances in New York. Those messages suddenly turned into requests for him to package and ship his brownies across the country.

Could it have been that easy?

“I wasn’t sure if people would pay $10 for a brownie, let alone more than one, plus

two-day cross-country shipping,” Evan said. “It was $50 to ship four brownies. I didn’t believe people would actually pay for that.”

Yet, to his surprise, he received $5,000 in Venmo payments to ship 500 brownies across multiple orders.

Recognizing the potential and shifting into an entrepreneurial mindset, Evan planted the seeds of a luxury dessert CPG company. He shipped his first batch of brownies in December 2021 and used the holiday break to build out the brand’s website and complete product formulations.

A month later, LXB officially had an online storefront through Shopify. Assuming brownies would take center stage, the lineup included the original Fleur De Sel flavor, with a later addition of a Hazelnut Crunch variety. The launch also included an organic and fair-trade cookie.

Originally, Evan formulated 10 versions of a chocolate chip cookie. After local taste-testing, the fifth recipe was the crowd favorite. Eventually, batch five, now known as Choc Chip No. 5, made the permanent lineup.

“It’s funny that the brownies started the company, but now Choc Chip No. 5 is taking over,” Evan said. “It has become our number one bestseller.”

At its core, LXB’s trademarked “Radical Ingredient Transparency” and “No Naughty Ingredients” make up the brand’s foundation. All products are made with three standards: real, organic and fair. And everything is made without artificial sweeteners, flavors, preservatives, dyes, sugar alcohols, soy, gums, corn syrups, bleached flour or hydrogenated oils. With the exception of baking soda, LXB is committed to using only organic ingredients.

“I take pride in sourcing real, organic and fair-trade ingredients with respect for people and the planet,” Evan said. “It’s not the easiest thing to do, but there’s always a solution to work around the obstacles. That’s what our brand is all about: doing the hard things that are challenging to do at scale.”

For example, the Cosmic Forest cookie — the brand’s second cookie variety and first vegan and nut-free offering — showcases LXB’s dedication to flavor while remaining faithful to its roots. Wanting the cookie to have the flair of sprinkles without palm oil and artificial coloring, Evan troubleshot various substitutions to find an ingredient that was wholly organic, fair-trade and didn’t compromise on taste.

The final product is made with tahini and coconut oil, applesauce and a dusting of shredded coconut covered with blue spirulina and pink dragon fruit powders to mimic the traditional look of sprinkles … but baked with a twist. The “sprinkles” are added after the cookie comes out of the oven. While typically an untraditional way to incor-

“That’s what our brand is all about: doing the hard things that are challenging to do at scale.”

Lex Evan | founder and CEO | Lexington Bakes

porate ingredients, this proved to be the workaround LXB was searching for.

“[Finding workarounds] has been one of the greatest hurdles since going all organic,” Evan said. “Of course, we’re going to encounter limitations, but we rise above them and find new ways to do what makes this brand so special.”

In February 2022, LXB released its limited-edition trademarked Raspberry Velvet brownie for Valentine’s Day. The take on a red velvet brownie was developed using jam made from Skagit Valley heirloom raspberries instead of food coloring. The product sold out in its first two weeks, and today, Raspberry Velvet is LXB’s most anticipated brownie flavor of the year, with consistent sellouts during the two-week pre-sale.

Building a diverse product portfolio — with an ambition to continuously innovate — LXB formulated limited-edition recipes of its brownies and cookies in partnership with other artisan brands. The seasonal brownie lineup includes two flavors: Pumpkin Spice Espresso, made with Equator Coffees’ Jaguar Espresso, and Raspberry Velvet. The seasonal cookie offerings include Peanut Butter Chip, Maple Pecan Chip and Snickerdoodle Tahini, using French Squirrel Peanut Butter, Raaka Maple Dark Baking Chocolate, and Seed + Mill Organic Tahini, respectively.

Offering transparency and traceability, LXB showcases those specific partner brands on its packaging to ensure consumers can trace every ingredient to its origin and ethical sourcing.

While growing the business, Evan bootstrapped it for the first year and took out an SBA loan for $100,000 and matched it with another $100,000 of his own.

Today, he is in the first round of raising capital with investors. The funds will be used for co-manufacturing equipment and to build a stock of raw ingredients.

Finding a co-manufacturer that not only understood but also respected LXB’s production process proved to be easier said than done. To keep the dense, fudgy taste and texture, the batter must stay warm before entering the oven. This factor created an obstacle when manufacturing at scale. The initial days of co-man collaboration consisted of multiple trials to pinpoint the right time and temperature.

Looking back, if Evan had to do it over again, he probably would have sourced a co-manufacturer sooner than 2023 rather than starting up his own production in a commercial kitchen.

“I wish I would have known to go to a co-manufacturer from the very beginning,” Evan shared. “The most challenging thing is finding the right manufacturer and making sure they have the right equipment because every little detail

matters. I’m charging for premium ingredients but also a premium experience. If any part of that experience is subpar, the brand doesn’t live up to the promise.”

Production output averages about 2,000 units over two eight-hour shifts in an environmentally conscious operation. While some sustainable production efforts might seem unorthodox, Evan does everything with purpose. For example, not only do the brownies and blondies come in the traditional square format, but so do the cookies, and for good reason.

“Square cookies take up less energy, water and air space for storage,” Evan explained. “Inherently, they’re more eco-friendly because of their shape. We can maximize how much product can fit on a pallet, which eliminates emissions and uses less energy overall.”

As part of its mission to deliver quality in all aspects — from branded packaging to uncompromised taste — LXB is exploring new flowwrapper technology that can ensure perfectly flat seams with transparent packaging material.

“The reason our packaging is transparent is I don’t want people to see this as just another CPG brand,” he said. “I want them to think fresh-baked. The package is clear because that’s how they would see it in a dessert case in a bake shop.”

While LXB products are sold in certain major retail outlets, as well as local shops and pop-up markets throughout the country, expansion is a top priority for the brand. To grow its reach — and product portfolio — LXB recently added Chilled Oat Bars in Maple Brown Butter and Raspberry Crumble flavors. Marketed as “oatmeal on the go,” the brand is breaking into the breakfast and snacking markets while staying true to its mission of being real, organic and fair.

LXB was founded on high expectations, and it plans to maintain its growth by delivering on every single one. From transparent packaging to 100% ingredient traceability, this better-for-everyone brand is poised to flourish in any “treat yo’ self” market. CB

The STA Servo Topping Applicator Handles It All With Precision And Speed.

FROM SWEET TO SAVOURY

The STA Servo Topping Applicator is engineered to meet the high demands of industrial bakeries with its robust versatility, making it a standout choice for innovative and reliable topping solutions while promoting efficiency and reducing waste.

Diverse Topping Compatibility

Multi-Mode Functionality

Telescopic Height Adjustment

Servo-Driven for Precision and Speed

12” to 60” Customizable Widths

Recipe Driven with Touch Screen

Quick-Change Roller System

All Stainless Construction Easy to Clean

Available in Three Standard Models

Any baker will say that when it comes to their craft, precision is the secret ingredient. From perfect texture to consistent flavor, every detail in production counts.

One critical component of this process is the accurate and consistent metering of micro-ingredients, which can be add-ins such as dough conditioners, flavor enhancers, or inclusions.

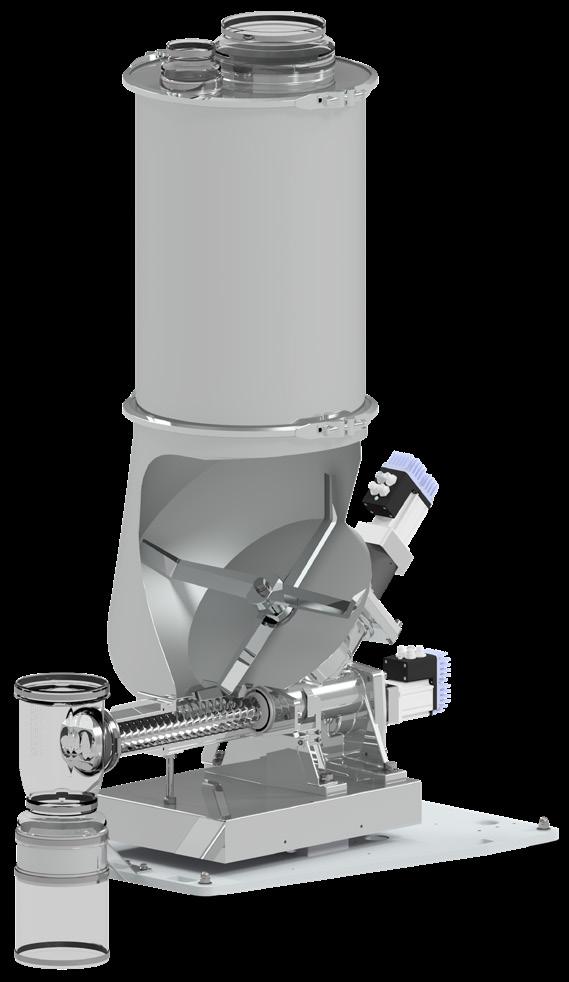

Kubota Brabender Technologie is at the forefront of metering technology, with automated feeding solutions that make ingredient handling easier, more reliable and cost-effective.

Many consumers will argue that there’s no such thing as too many chocolate chips in a cookie. But for bakery manufacturers, the reality is that imprecise metering of any ingredient will lead to inconsistencies in texture, taste and, ultimately, the bottom line.

Too much? It can throw off the formula and lead to waste. Too little? The product falls short of customer or consumer expectations. Kubota Brabender feeding systems ensure every batch hits the mark.

With ingredient costs rising and labor shortages straining operations, automated metering systems provide game-changing solutions:

• Consistent Quality: Every batch meets the highest standards.

• Less Waste, More Savings: Optimized ingredient use keeps costs down.

• Faster, Smoother Production: Automation streamlines workflow and reduces downtime.

• Labor Efficiency: Reliance on manual labor is reduced.

• Safe Processing: Hygienic design minimizes contamination risk and ensures compliance with food safety regulations.

Whether ingredients are free- or poor-flowing, Kubota Brabender offers tailormade solutions for precise, reliable metering. Gravimetric feeders (also known as loss-in-weight feeders) provide real-time weight monitoring for maximum accuracy, while volumetric feeders are ideal for applications where batch delivery/recipe makeup times are flexible, and gain-in-weight systems provide effective cost of ownership. Each distinct feeder type integrates seamlessly into production lines.

Take the Next Step

As the baking industry evolves, staying competitive while improving operating costs means optimizing every aspect of production.

Automated micro-ingredient feeding systems help maintain quality, reduce waste and boost efficiency, all while simplifying operations.

Precision you can trust. Service you can count on.

In the age of Industry 4.0, upskilling is essential to maintaining a competitive edge.

BY MARI RYDINGS

Disruption via innovation takes many forms: a new product that satisfies an unmet consumer need, a first-of-its-kind business model, technology that significantly increases productivity. It’s the latter, often in partnership with AI, that’s driving disruption in manufacturing across all industries.

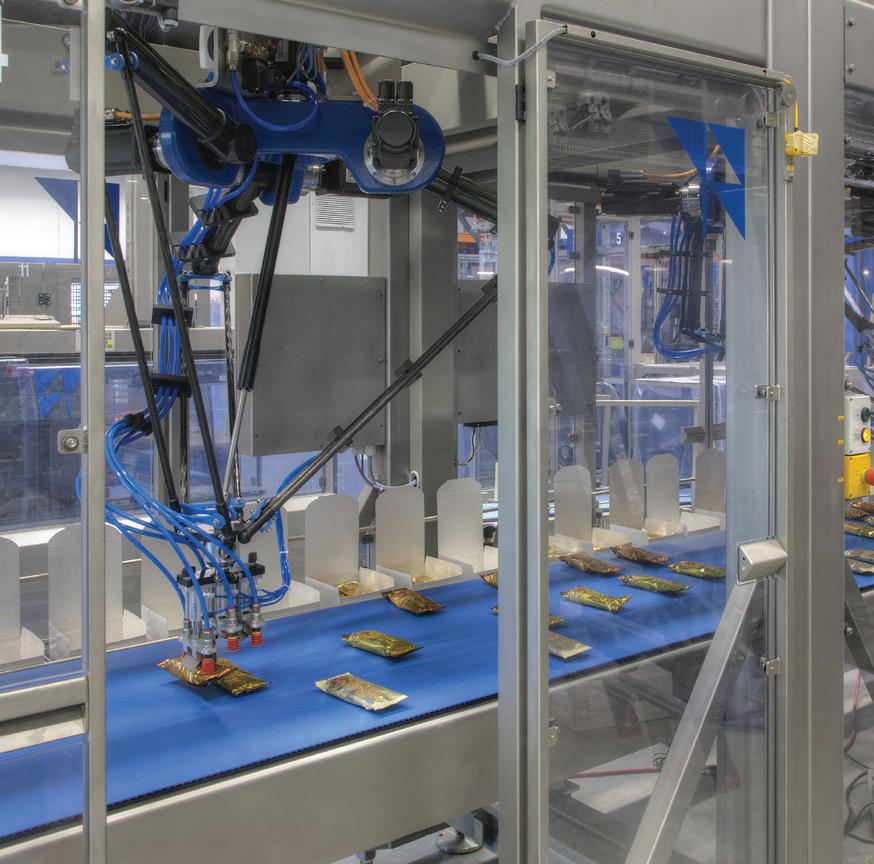

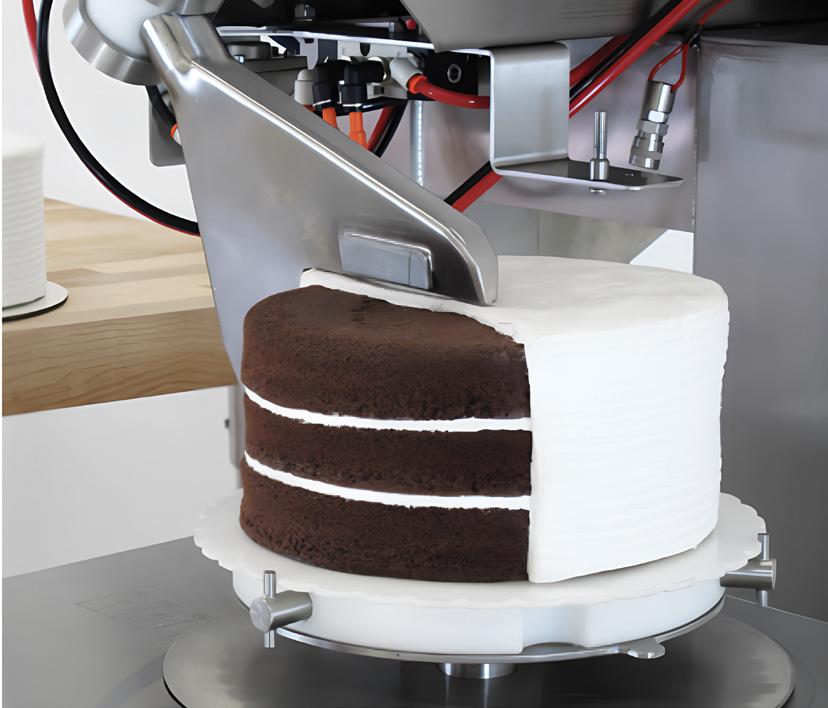

Automation has advanced to the level that machines can now perform many of the manual, repetitive tasks traditionally handled by humans, and they can do so faster, more efficiently and often at a lower cost than people. Robotic technology, in particular, has progressed to the point where robots can analyze data, learn from it and adapt accordingly to optimize operations.

While some companies view investing in automation strictly as a way to reduce their workforce, others — industry disruptors — embrace automation as an opportunity for job evolution vs. elimination. They know how vital it is to have employees who can understand, manage and troubleshoot these advanced, often complex, systems. That’s why when they allocate

capital to automation, they also invest in upskilling resources that can help employees gain the skills and knowledge needed to future-proof the business.

“Investing in workforce training ensures employees remain valuable contributors in an evolving industry while improving workplace safety, efficiency and innovation,” said Thomas Bailey, director of government relations at the American Bakers Association (ABA). “Automation creates a growing need for upskilling, allowing workers to develop valuable skills in data analysis, predictive maintenance and supply chain optimization.”

Walmart is an example of a company that embraces advanced technology in its supply chain network — and the need for educating its workforce — with open arms. The company’s wide range of upskilling programs creates new types of jobs, enhances the associate experience and strengthens its ability to deliver for its customers.

“Walmart is paving the way for good jobs and great careers in our supply chain,” said Tim Cooper, senior VP of supply chain operations for Walmart U.S. “This is more than an investment; it’s a commitment to our associates, our communities and our future.”

The intangible benefits related to upskilling can be just as impactful as the tangible ones: reduced employee turnover; increased morale, job satisfaction and engagement; higher productivity as a result of having people who are better equipped to do their jobs; the development of an innovative and creative culture; and a future-ready business.

“Automation has improved my quality of life,” said Chance Bayless, an automation equipment operator in one of Walmart’s high-tech regional distribution centers who completed one of the retailer’s upskilling programs. “Before, I was doing manually intensive labor: 85 percent manual labor and just a small fraction of that was mental. Now, I’m doing 85 percent mental and about 15 percent physical. I’m using my mind to solve problems instead of my body. It’s increased my quality of life, but it’s also increased my job longevity.”

It’s impossible to talk about automation without mentioning AI. According to ABA’s 2024 AI in the Commercial Baking Industry study, nearly 70% of the commercial baking industry has adopted or plans to adopt AI in some capacity, including via pilot programs in the next 12 months, with the top areas of

29%

of workers don’t feel optimistic about the opportunities they have for training to learn new skills or upskill.

Source: University of Phoenix Annual Career Optimism Index 2022

focus being marketing and sales, supply chain management and manufacturing.

“AI presents significant opportunities to enhance the existing workforce and improve the job quality of individuals on the manufacturing floor,” Bailey said.

A well-rounded upskilling program, one that builds technical, digital and soft skills simultaneously, is essential as employees transition from manual tasks to ones that demand more interaction and critical thinking.

“Knowledgeable operators who can maximize runtime, minimize downtime, manufacture high-quality packaged products and handle a variety of tasks are productive, satisfied, self-sufficient, and typically the employees with the lowest turnover rate,” said Cliff Fitzgerald, technical training manager for Harpak-Ulma Packaging. “Learning how to operate and maintain automation requires digital skills, but the success of companies also depends on people who can communicate, cooperate and collaborate with others.”

Solve your toughest secondary packaging challenges with our automated solutions

You make it. We pack it. End-of-line packaging solutions for the bakery, snack and tortilla industries. BPA loads your packaged and naked products into cases and various secondary containers including your hffs machines, wrapper chain in-feeds and indexing thermoform machines.

In a recent study of c-suite executives, Boston Consulting Group found that 75% see talent retention and development as significant areas of investment and allocate as much as 1.5% of their budgets to upskilling resources.

On the other hand, according to the University of Phoenix’s Annual Career Optimism Index 2022, 52% of workers said they needed to learn new skills within the next year to continue their careers, and 46% of those employees indicated they were not as skilled as they needed to be. That same study also found that nearly one-third (29%) of workers said they don’t feel optimistic about the opportunities they have for training to learn new skills.

This dichotomy may be the result of high employee turnover in industries such as commercial baking, which makes some companies hesitant to invest in upskilling.

“We hear across the industry that employee turnover is a huge issue,” said Sarah Day, director of education for the American Society of Baking (ASB). “The issue becomes, ‘How much do I invest in training up front?’ because bakeries are losing employees at three, six, nine months. It’s about striking that balance.”

Day believes ASB’s Education Hub, which includes online training and access to options such as ABA’s Bakers Manufacturing Academy courses, is a viable, cost-effective resource for bakers and their employees.

“One of the reasons our training is so useful is because the cost is relatively low entry, and it’s online, so there’s no travel involved,” she said. “It’s much less of an investment up front for the company, but it’s enough to ignite that interest. We

know that if people are educated about something, and they understand how it works, they’re more invested.”

The key to getting results that match the upfront investment is to meet employees where they are. For younger generations, most of whom are digital natives, that may mean online learning platforms featuring interactive videos combined with hands-on learning and simulations.

“The nature in which upskilling and training are delivered makes a difference — especially as you bring in younger workers — in terms of consumption, knowledge and understanding,” said Nate Walts, CEO of WorkForge, a company that creates digital learning and development solutions, including custom content. “We have micro-modules, which are small, consumable pieces of content that consist of five to seven minutes of training time on a specific subject area versus asking someone to sit for an hour and explore a training binder.”

The ROI of meeting employees where they are when it comes to upskilling can outweigh the upfront costs in terms of increased productivity and employee engagement, especially when a company integrates resources into its processes, starting with onboarding.

“One of our food industry clients was having a problem with its employees not really understanding how to maximize the productivity on one of their packaging lines,” Walts said. “We created a video showing the optimal output for that line, and the company began using it during onboarding and training. Over time, they doubled their productivity in terms of the number of bags the line could pack.”

Industry 4.0 is here, and investing in automation, AI and other smart manufacturing technologies can help companies remain relevant and competitive ... but only if they’re also willing to invest in cultivating a future-ready workforce through upskilling. CB

Removing eggs from a formula can not only remove an allergen, but also save on costs, make raw material storage easier and simplify the production process.

Brolite’s egg replacers can work as a total egg replacement in yeast raised products and up to 30% in cakes. Even with a partial replacement, a baker can have more consistent costs of ingredients and more supply stability.

Lose the eggs, keep the functionality, supply and cost savings of an egg replacer.

Women are homing in on what best fuels them at every life stage, and baking companies should take note.

BY MAGGIE GLISAN

Crash test dummies, the full-scale model bodies used to test for car safety, have been in use since the ’70s. But up until 2003, those crash tests relied almost exclusively on male-sized dummies. By failing to account for differences in height, weight, muscle distribution and seating posture, women were 17% more likely to die in crashes compared to men. It wasn’t until researchers pushed for the inclusion of female crash test dummies and adjustments to airbag deployment that safety measures began to improve for women.

The automotive industry isn’t alone in overlooking women’s specific physical needs — the food and beverage industry has also been slow to adapt. However, it is beginning to recognize health interests particular to women and responding with new products and marketing strategies tailored to their nutritional needs.

The women’s global health industry is valued at more than $35 billion and growing at a CAGR of 3.2%, per Fortune Business Insights, and it’s one that appears to be evolving as consumers broaden their definitions of health. Hormones, gut health, mood and cognition are just a few areas women are increasingly focusing on for overall wellbeing.

“Throughout history, there’s an overarching theme that women have been thought about interchangeably with men in terms of physiology, and that’s just not accurate,” said Jane Dummer, food consultant and registered dietitian. “There have been inroads in the past two decades or so in terms of research, but we still have a way to go.”

Women make up approximately 50% of the global population. Traditionally, when the food and beverage industry has paid close attention to women’s health issues, it’s focused on needs related to reproductive health, pregnancy, postpartum care and weight loss. A recent surge in funding for women’s health research indicates a shift toward a more comprehensive view of women’s needs and experiences at each stage of life.

“Nutrition plays such a pivotal role in women’s health, influencing everything from fertility and pregnancy outcomes to the management of menopause symptoms and the prevention of age- related diseases,” said Charlotte Martin, a registered dietitian and consultant for the Grain Foods Foundation. “Whole and enriched grains help women meet their daily needs for these essential nutrients. They are vital at every stage of life, yet bread isn’t really marketed as a product to support women’s health, despite the fact that it clearly does. Bakers have a huge opportunity here.”

On the coattails of recent pushback against “diet culture,” there has also been a market shift away from a generic or prescriptive idea of health to one that addresses individual motivations.

Tastewise, a generative AI platform for the food and beverage industry, highlighted “hyper-personalized nutrition” as one of its most disruptive food and beverage trends in its “2025 Trend Predictions” report, and Innova called “precision wellness” one of its top 10 food and beverage trends for 2025, noting consumers are seeking functional foods tailored to their life stage, lifestyle and health needs.

Female-specific experiences such as menstruation and menopause are also receiving more attention and are more openly discussed than in the past. Each day, approximately 6,000 women in the US enter menopause, and with that transition comes a shift in nutritional needs for balancing hormones and keeping up energy levels, among other things. According to Tastewise, menopause support through food and beverage is the biggest growth category within women’s health.

“The challenge of women’s health is that the taboo surrounding so much of what women experience has impacted not only how products are marketed toward women but also how women have felt discussing these sorts of things,” said Miriam Aniel Oved, head of integrated marketing for Tastewise.

Oved said she sees seed cycling as one area of opportunity for bakers to market their existing products specifically to women. Seed cycling is an ancient practice that involves eating different seeds at specific times to balance estrogen and progesterone. It’s gained popularity recently thanks to niche nutrition social media influencers, but it’s becoming more mainstream as women consume nutritional content that supports what their bodies need at any specific moment.

“If you are already including seeds — sesame, pumpkin, flax, etc. — in your products, be sure to call that out on pack,” Oved said. “Make sure to market to this large number of women consumers who are already looking for that.”

Gut health is another area in which women are increasingly interested. According to Grand View Research, the gut health market is valued at more than $51 billion with a projected CAGR of 8.3%.

“Women are very interested in gut health, probably more so than men,” said Julie Miller Jones, a member of the Grain Foods Foundation Scientific Advisory Board. “In terms of formulation, bread manufacturers might consider heatstable pre- and probiotics as well as postbiotics.”

By calling out ingredients and nutrients that contribute positively to a healthy gut — whether that’s a high-fiber cracker made with whole grains or a naturally fermented sourdough bread — bakers can capture the attention of women who are actively seeking out these nutrients.

“Fiber is finally having its well-deserved moment,” Martin said. “Particularly for women, fiber plays a crucial role in supporting digestive health. It also aids in weight management and reducing the risk of chronic diseases like diabetes and heart disease. Plus, a fiber-rich diet may help promote healthy estrogen regulation and protect against breast cancer.”

Recent trends in women’s health reflect a broader need for positive nutrition, such as adding ingredients that support health vs. eliminating ingredients for both immediate and long-term benefits.

“We’re currently seeing a more holistic nutrition approach that focuses on an

increase in nutrient-dense foods rather than one that isolates specific ingredients,” Dummer said.

Despite the shift to a more additiveapproach to diet, there’s one ingredient women in particular see as a red flag: refined sugar. According to Tastewise, people are 12 times more likely to talk about sugar-free or free from refined sugar when it comes to women’s health applications.

“I see the term ‘refined sugar-free’ as an emerging consumer need around diet in relation to women’s health,” said Lee Brymer, head of marketing communications for Tastewise.

Consumer interest in hormone balancing has grown 150% since 2022.

Source: Tastewise

“Refined sugars, which are often used in baked goods, are known to have negative effects on women’s health, specifically as it relates to reproductive cycles, hormone balancing, and many of the things women are seeking from their food products. [Bakers] want to make sure that the other ingredients in their products are not negating the benefits of what they’re trying to achieve.”

Brymer also suggested seeking out sugar alternatives such as date syrup or Manuka honey and creating products that speak to the full needs of women.

It’s not just ingredients women care about. They are also increasingly looking to support brands created by women for women. One such brand is Mena, a UK-based food company founded by Charlotte Blacker that makes breads, cereals and bars that incorporate plantbased, estrogen-rich ingredients formulated to support women experiencing perimenopause and menopause symptoms. Blacker, who has a background in pharmaceuticals, was inspired to create the products during her struggles with menopause-related joint pain.

There’s a similar story behind MenoWell, a brand of menopause-focused energy protein bars created by founder and CEO Julie Gordon White that carries the tagline “Power food for the pause.” White developed the bars when struggling with her own menopause symptoms, including sugar cravings and weight gain.

With ingredients such as organic maca, prebiotic fiber, plant-based protein, flaxseed, spinach and kale, MenoWell bars pack a nutritional punch without crushing a woman’s calorie budget for the day.

“Our bars aim to handle the sugar cravings, reduce visceral fat and make it easy

to get fiber and protein, even on the go,” White said. “They address women in midlife and meet them where they are.”

“Whole and enriched grains help women meet their daily needs for these essential nutrients ... yet I don’t really see bread being marketed as a product to support women’s health … Bakers have a huge opportunity here.”

Charlotte Martin | registered dietitian and Grain Foods Foundation consultant

She cautions bakers, however, about trying to simply jump on the women’s health bandwagon without doing the proper research.

“You have to be authentic, because if you’re a ‘me too’ kind of company or you’re just putting a pink wrapper on something, [women] are sniffing that out in a big way and will call you out in a second,” White said. “Women will invest in their health and pay more for premium products, especially if it’s created by a woman or if there’s a really personal story connected to it. They are prioritizing that.”

Whether it’s functional ingredients that support hormonal balance, gut health, mental wellbeing or a commitment to female-founded brands, the demand for innovations that address women’s needs is growing, and it’s important for bakers to be a part of the conversation. CB

Our bread bags made with cast film provide:

•Superior clarity and low haze

• Sho'paque® finishing technology

• Matte and gloss finishing options

ptions eatures

•Excellent durability and machine performance

• Reclosability features Scan here to learn

Gaining new insights from the 2025 Baking Expo is easier — and more accessible — than ever.

BY ANNIE HOLLON

Professional development is the crux for growth in the baking industry, and through robust educational offerings, the International Baking Industry Exposition (IBIE), powered by the American Bakers Association and BEMA and supported by the Retail Bakers of America (RBA), makes it possible for attendees to learn from industry experts and celebrity chefs. With each show cycle, this content adjusts to the needs of industry members, and 2025 is no different.

While people can still expect quality content tailored to the industry, what is different is that IBIEducate — the lineup of educational sessions and demos offered at the triennial event — is now included in the overall registration cost, a change from previous show cycles.

“The demand for education has increased almost exponentially since the inception of IBIE,” said Mark Hotze, IBIE 2025 Planning Committee member,

chair of IBIEducate and VP, North America for Corbion. “Including all IBIEducate sessions with registration makes budgeting and the checkout process more convenient.”

This change makes it easier for baking industry members to engage in educational offerings — including the dedicated day of education on Saturday, Sept. 13 — before the show starts, and take advantage of all the show’s benefits.

IBIEducate includes sessions for bakers of all disciplines.

Registration for the largest baking tradeshow in the Western Hemisphere includes more access than ever before. This year, attendees can access the Baking Expo, show floor demos and IBIEducate, including the dedicated day of education on Saturday, Sept. 13, as part of their registration.

Visit the IBIE website to register and to find education sessions sorted by product categories, industry segments and pavilions.

“We want people to get as much out IBIE as they possibly can, and a part of the experience is education and idea sharing,” said Marissa Sertich Velie, executive director of RBA, IBIE planning committee member and co-manager of IBIEducate. “Offering more IBIEducate sessions than ever and including all-access with registration was a natural next step in terms of homing in on that mission of the betterment and advancement of the baking industry.”

Members of the baking industry, including those in adjacent areas, are increasingly looking for ways to share their knowl edge on labor and supply chain shortages, inflation and generational consumer shifts. All of these changes make it integral for baking leaders to stay in the know with the latest thought leadership. The record number of speaker applications submitte d for the upcoming event follows that trajectory, marking continued interest from experts to impart their insights at the largest baking industry event in the Western Hemisphere.

of IBIEducate, noted that the uptick in speaker submissions is also a testament to the positive experience speakers have had in previous cycles.

“The reputation of the show draws a lot of traffic,” Bowers said. “People want to come back, which says they’re having a great experience as a content provider at IBIE, so they’re returning with new topics.”

From QuickBITES presentations to hands-on workshops, the Baking Expo offers dozens of curated sessions that cover the essential information baking industry members seek.

“We were very specific about the type of content that we wanted to elevate for the industry, and this came from feedback from attendee surveys as well as IBIE planning committee members, who are bakers and suppliers,” Bowers said. “We have curated a program aimed at tackling the industry’s most pressing challenges and opportunities, and more than doubled the number of education offerings at IBIE.”

Scan the QR code for the most up-to-date education lineup.

“The increased offerings from the IBIEducate program points to the growing demand and mindset throughout the industry that IBIE is the premier one-stopshop for all segments of the grain-based foods industry,” Hotze said. “In addition to experiencing the equipment and ingredient innovations throughout the show floor, companies can bring a variety of team members who will have access to a diverse offering of professional development that is unmatched at other events. With sessions and demos galore, attendees have a wealth of content to explore, tailored to their specific industry segment and job function.”

Emily Bowers, VP of education and operations at BEMA and co-manager

Key presentations in this year’s lineup include the essential topics bakers and suppliers need to know, as well as hot-button issues including regenerative agriculture, sustainability, e-commerce, automation, AI, succession planning and workforce management.

“With a new generation of bakers coming in, and technology advancements, the workplace has changed,” Velie said. “Managers, owners and operators are taking steps to better support and retain talent, and investing in upskilling and professional development can make a huge impact.”

In addition to leadership insights, participants can also gain knowledge from

Experience a game-changing way to control sugar and enhance your baking process.

Essential ® FSA Benefits:

► Manage Sugar Levels in Bakery Formulations

► Accelerate Fermentation and Proofing Times

► Reduce or Replace Sugar

other segments of the baking industry. Thanks to smaller-scale operations, retail bakers have the flexibility to create new products on the fly. Commercial bakers can gain valuable insights by dropping by retail-oriented education sessions for CPG innovation.

“The retail industry can pivot based on trends and availability of products, so it’s always helpful and insightful for commercial bakers to see what’s happening at a quicker pace of adoption on the retail side,” Velie said.

On the show floor in the West Hall, the Artisan Village, formerly known as the Artisan Marketplace, and the Wholesale Bakers Center, a new show feature in 2025, will offer opportunities to tap into industry insights between booth visits. The area will feature two stages that will serve as the base for more than 50 presentations throughout the course of the show.

“The wholesale topics being presented cover many different aspects of not only the science of baking but also the fundamental principles of running a manufacturing facility,” Hotze said. “The retail-focused offerings will showcase top trends and techniques in baked goods, as well as business best practices. Ensuring that both wholesale and retail audiences are provided that breadth in programming has always been a strong suit for IBIE, and this year we’re taking it even further with consideration to multilingual offerings.”

The retail side of the show’s educational program is also receiving a revamp. As a result of recent North Hall renovations, IBIE participants can attend education sessions without trekking between the two halls.

With attendees traveling from more than 105 countries for the triennial event, making the educational program more accessible was also top of mind for the task force as it planned this year’s event. During the IBIEducate application process, speakers had the opportunity to express if they’d like to present in English and/or Spanish.

“IBIEducate will offer more sessions in Spanish, and some will be available for translation in several different languages,” Hotze said. “This reflects IBIE’s ongoing commitment to the development of our industry’s global workforce and supporting the advancement of our grain-based foods industry worldwide. We also expanded our partnership with Mexipan, the leading bakery trade fair in Mexico and Latin America, to bring their Chef Talks program featuring

distinguished bakers from Latin America to IBIE 2025.”

In addition to more Spanish-language content, the show is also partnering with Wordly, an app that translates and transcribes live audio into 64 languages on a smartphone. This app will be free to all attendees via QR codes on display throughout the show.

“It’s a lot easier for people to learn and comprehend in their native language,” Bowers said. “We feel like it will be a real added benefit for attendees.”

With more than 250 sessions , demos and workshops lined up for the event, this year’s IBIEducate program offers bakers from every corner of the industry vast access to valuable insights they can take back to their operations. CB

BY BETH DAY

Crackers Dollar Share

Creative product innovation and the perception of crackers as a better-for-you snacking option are driving growth.

Crackers resonate with consumers across demographics. Creative product innovation and the perception of crackers as a better-for-you snacking option are driving growth, while limitless versatility opens the door to expanded occasions and uses.

The category’s dollar sales increased 1.8% to $10.98 billion, according to Circana data for the 52 weeks ending Jan. 26, 2025.

“For crackers, key strategies for growth center around innovation,” said Sally Lyons Wyatt, EVP and chief advisor, CPG and foodservice for Circana. “I think some brands are already engaging with innovation around new flavors and formats, and some are embracing healthier labels with functional claims or cleaner and fewer ingredients.”

Private label shows growth momentum, and it is not only due to inflation, according to Mintel’s “US Crackers Market Report 2024.” Circana data revealed private label All Other crackers grew 5.3% in dollar sales and 4.8% in units, and increases for private label occurred in most other cracker segments. That growth may be attributed to a combination of innovation and pricing.

“We have seen some innovation with new formats, flavors and multi-packs for other cracker segments,” Lyons Wyatt said, “And that may be influencing private label growth.”

Crackers are versatile and can be delivered as a snack, a meal or both. Mintel’s report found that while more than half of cracker buyers tend to use them

in the same way, two-thirds are interested in pairing ideas. Highlighting creative combinations of flavors and formats paired with cheese, dips, meats, spreads or fruit will engage consumers. Crackers play across the dayparts for everyday uses and micro-occasions, such as Galentine’s Day or the Super Bowl.

“Consumers do not buy categories, they buy for occasions fueled by categories,” Lyons Wyatt said. “Whenever they buy something, it ladders up to an eating occasion, a social gathering or celebration. Cracker producers can and do spur growth by showing multiple uses.”

Expanded snacking and other eating occasions create innovation opportunities for flavor, texture and better-for-you perceptions, according to Mintel. Lyons Wyatt noted that some health claims such as natural, non-GMO, gluten-free, vegan/vegetarian and no, low and less fat are driving growth.

All Other crackers remained steady in unit sales at 1.89 billion vs. a year ago.

Source: Circana

Thomasville, GA-based Flowers Foods’ Simple Mills and Loves Park, IL-based TH Foods’ Crunchmaster brands are seeing gains in dollars and units. Simple Mills showed 13.4% dollar and 21.1% unit growth, while Crunchmaster increased 4.7% in dollars and 3.3% in units, according to Circana.

Considering what constitutes overall wellbeing for consumers could be a strategy for innovation. Products that market how they impact physical health and contribute to overall mental and social wellbeing may also drive growth.

“While health is top of mind, even products not positioned as better for you may be part of the wellbeing journey for consumers,” Lyons Wyatt explained. “More indulgent snacks eaten as a reward make you feel good, which can improve mental wellness. Products that can be shared with family and friends appeal to the social aspect of food.”

BoothS #3500 & #3801

The sanitary SNAX Double Sigma Arm Mixer by AMF Fusion delivers exceptional flexibility and reliability for a wide range of snack foods including wire-cut cookies, energy bars, pie doughs, granola, pretzels and other specialty snacks. For reduced maintenance, a simplified mechanical dual-tilt system enables easy ingredient incorporation and seamless integration with many dough handling solutions. The DuraBowl™ refrigeration jacket ensures ideal process consistency and complete control over your final dough temperature. High performance, reliable mixing and dough handling

Circana data indicated crackers with fillings posted $1.73 billion dollar sales, a 10.4% dollar increase vs. a year ago, but showed 1% unit declines. Even with 11.5% price increases, Lyons Wyatt observed that filled crackers and select other crackers are found in 44% of households, with two-thirds of consumers repeating purchase for this format.

Crackers with fillings showed the largest dollar sales growth vs. a year ago at

10.4%

Source: Circana