ASSOCIATE DIVISION DIRECTORY & BAGGING/PACKAGING ISSUE THE VOICE OF WISCONSIN'S POTATO & VEGETABLE INDUSTRY Vanguard Russet potatoes are sorted and graded at Midwestern Potatoes, LLC, in Plainfield, Wisconsin. Spudly is Popping up Everywhere! See “Marketplace” in this issue. USE AI TO SAVE LABOR And Help Sort Potatoes HOW EACH NUTRIENT Nourishes Your Plants COMPLETE 2023 WPVGA Associate Division Directory STEPS TO UPDATING Your Business Name $28/year | $2.50/copy | Volume 75 No. 10 | october 2023 INTERVIEW: ROD BEGGS Midwestern Potatoes, LLC

LENCO 4-ROW SELF-PROPELLED 65” AIRHEAD HARVESTER WITH TRACKS 5773 Crystal Road • Vestaburg, MI 48891 989-268-5711 • Toll Free: 877-287-5711 Check out our new website! www.lenco-harvesters.com NEW IN 2023: @AdvancedFarmEquip @Lenco Harvesters PROUDLY Rock Pickers Available in 10 ft., 7.5 ft. & 5 ft. 72” Stationary Airhead • Arrange onsite service • Stock up! Large selection of ready-to-ship wear parts

Inventory • Replenishment services • Handle all freight needs • Long-Range planning • Mike Carter CEO | John Hopfensperger COO 8 0 0 - 8 2 6 - 0 2 0 0 715-677-4533 • Fax: 715-677-4076 Rosholt, Wisconsin 8 0 0 - 8 2 6 - 0 2 0 0 Jenna Wenzel • John Eckendorf Nic Bushman • Chris Lockery Jerome Bushman (FL - WI) Mike Gatz, Jim Stefan and Chris Fleming (Milwaukee) Paul Hegewald (All fruits and vegetables) Mike Whyte (Michigan) Transportation: Matt Dobbe • Denise Moze Year-round shipping from all areas.

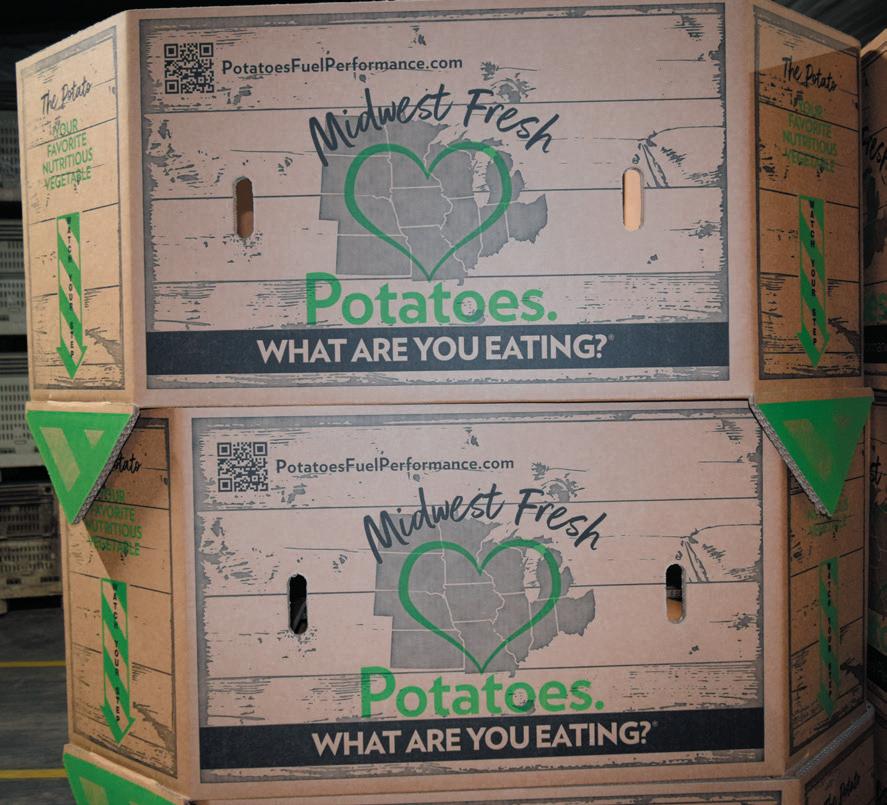

On the Cover: Technology and innovation are ever present at Midwestern Potatoes, LLC, in Plainfield, Wisconsin, where the cover image was taken of Vanguard Russet potatoes being sorted, graded, and readied for packaging. Optical sorters/graders, auto balers, and robotic stackers and palletizers are just some of the machines helping streamline the process.

FEATURE ARTICLES: ALI'S KITCHEN 66 AUXILIARY NEWS 47 BADGER BEAT 50 EYES ON ASSOCIATES ........ 59 MARK YOUR CALENDAR ..... 6 NOW NEWS ...................... 24 NPC NEWS 62 PEOPLE 56 PLANTING IDEAS ................. 6 POTATOES USA NEWS ....... 64 WPIB FOCUS ..................... 62 20 HOW EACH NUTRIENT nourishes plants and contributes to an overall healthy crop 36 INCLUDED HEREIN: your comprehensive 2023 WPVGA Associate Division Directory 60 STEPS TO CHOOSING and legally changing the name of a corporation in Wisconsin DEPARTMENTS: HOW TO BE 25% MORE EFFICIENT BY USING AI Artificial intelligence helps in potato grading & sorting 16 MARKETPLACE Print out “Flat Spudly,” let him tag along on the farm, and post it to social media

BADGER COMMON’TATER INTERVIEW:

8

NEW PRODUCTS Sunflare LiteMount solar panels do not jeopardize the integrity of old barns 32 30 4 BC�T October

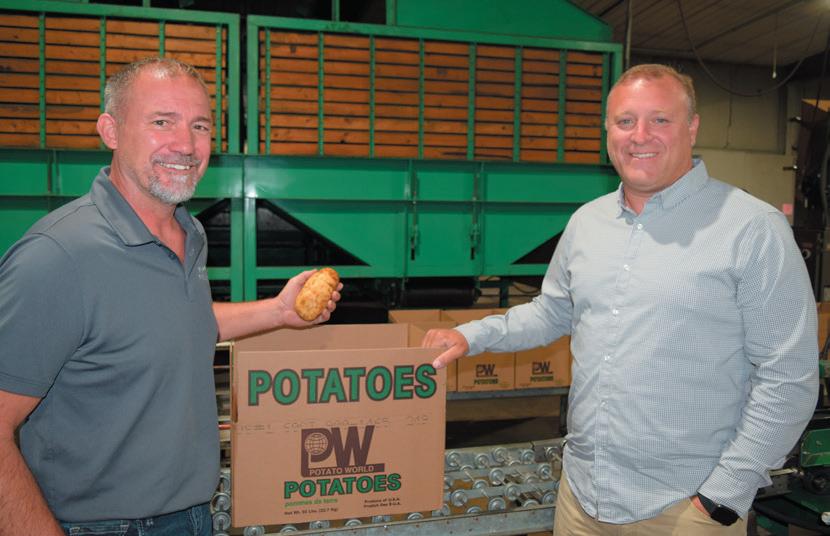

From left to right in front of the Midwestern Potatoes, LLC sign are Bushmans’ Inc. Chief Operating Officer John Hopfensperger, Rod Beggs, owner of Midwestern Potatoes, and Bushmans’ Inc. Chief Executive Officer Mike Carter. Beggs manages all operations at the packaging facility, in Plainfield, and Bushmans’ Inc., which owns one-third of the company, takes care of the sales and marketing end of the business, as well as transportation/shipping.

WPVGA Board of Directors:

PresideNt: Ra Ndy Fleishauer

Vice PresideNt: Charlie Mattek

Secretary: JohN Bustama Nte

Treasurer: Alex Okray

Directors: Mike Carter, WeNdy Dykstra, Bill GueNthNer, Josh KNights & J.D. Schroeder

Wisconsin Potato Industry Board:

PresideNt: Heidi Alsum-Ra Ndall

Vice PresideNt: ANdy Diercks

Secretary: Nicola Carey

Treasurer: Keith Wolter

Directors: JohN Bobek, JohN FeNske, Jim Okray, Eric Schroeder & Tom Wild

WPVGA Associate Division Board of Directors:

PresideNt: Matt SeleNske

Vice PresideNt: ANdy Verhasselt

Secretary: Sally Suprise

Treasurer: Paul Salm

Directors: Melissa Heise, Etha N OlsoN, Scott Scheer, Morga N Smolarek & Bra NdoN Taylor

Wisconsin Seed Potato Improvement

Association Board of Directors:

PresideNt: Matt Mattek

Vice PresideNt: Jeff SuchoN

Secretary/Treasurer: CloVer Spacek

Directors: Charlie HusNick & ANdy Schroeder

Wisconsin Potato Growers

Auxiliary Board of Directors:

PresideNt: Heidi Schleicher

Vice PresideNt: DatoNN Ha Nke

Secretary/Treasurer: Becky Wysocki

Directors: Jody BagiNski, EriN Meister, Dakotah Smiley & Misti Ward

Mission Statement of the WPVGA: To advance the interests of WPVGA members through education, information, environmentally sound research, promotion, governmental action and involvement.

Mission Statement of the WPVGA Associate Division: To work in partnership with the WPVGA as product and service providers to promote mutual industry viability by integrating technology and information resources.

Badger Common’Tater is published monthly at 700 Fifth Avenue, Antigo, Wisconsin 54409

WPVGA Staff

ExecutiVe Director: Tamas Houliha N

Ma N agiNg Editor: Joe Kertzma N

Director of PromotioNs & CoNsumer

EducatioN: Da N a Rady

FiN a Ncial Officer: KareN RasmusseN

ExecutiVe Assista Nt: Julie BrauN

Program Assista Nt: Ja Ne GuilleN

Spudmobile EducatioN a Nd Outreach

AdmiNistrator: George Neuber

WPVGA Office

(715) 623-7683 • FAX: (715) 623-3176

E-mail: wpvga@wisconsinpotatoes.com

Website: www.wisconsinpotatoes.com

LIKE US ON FACEBOOK: www.facebook.com/WPVGA

Subscription rates: $2.50/copy, $28/year; $45/2 years.

Foreign subscription rates: $35/year; $55/2 years.

Telephone: (715) 623-7683

Mailing address: P.O. Box 327, Antigo, Wisconsin 54409

Or, subscribe free online: http://wisconsinpotatoes.com/blog-news/subscribe/

ADVERTISING: To advertise your service or product in this magazine, call (715) 630-6213, or email: Joe Kertzman: jkertzman@wisconsinpotatoes.com. The editor welcomes manuscripts and pictures but accepts no responsibility for such material while in our hands.

10-23 Badger Common'Tater (7.25x4.75).v1.pdf 1 2023-09-05 3:58 PM 5 BC�T October

MARK YOUR Calendar

OCTOBER

19 4TH ANNUAL SPORTING CLAYS SHOOT

Wausau Skeet and Trap Club

Wausau/Brokaw, WI

19-21 THE GLOBAL PRODUCE & FLORAL SHOW

Anaheim Convention Center

Anaheim, CA

23-24 WPVGA RESEARCH MEETING

West Madison Research Station and virtual. 1 p.m. on Monday, 8 a.m. on Tuesday

Verona, WI

JANUARY 2024

8-9 POTATOES USA WINTER MEETING

Austin Convention Center Austin, TX

10-11 POTATO EXPO 2024

Austin Convention Center Austin, TX

FEBRUARY

6-8 2024 GROWER ED CONFERENCE & INDUSTRY SHOW

Holiday Inn Convention Center

Stevens Point, WI

26-3/1 2024 NPC WASHINGTON SUMMIT

Washington Marriott at Metro Center

Washington, D.C.

MARCH

26-28 62nd ANNUAL WPS FARM SHOW

Experimental Aircraft Association grounds

Oshkosh, WI

MAY

18-21 NATIONAL RESTAURANT ASSOCIATION SHOW

McCormick Place Chicago, IL

JUNE

21 WSPIA SPUD SEED CLASSIC GOLF OUTING

Bass Lake Golf Course

Deerbrook, WI

23-26 12TH WORLD POTATO CONGRESS

Adelaide, South Australia

JULY

10 2024 PUTT-TATO OPEN GOLF OUTING

Lake Arrowhead Golf Course

Nekoosa, WI

11 HARS FIELD DAY

Hancock Agricultural Research Station

Hancock, WI

31 RARS FIELD DAY

Rhinelander Agricultural Research Station

Rhinelander, WI

AUGUST

23-26 WISCONSIN FARM TECHNOLOGY DAYS

Country/Rock Fest Grounds

Cadott, WI

6 BC�T October

Planting Ideas

Spend enough time

in the Central Wisconsin potato and vegetable industry, and you can’t help but notice that it is populated with family-focused folks who exhibit an incredible work ethic and place emphasis on morals and values. That is a good industry to be in, so when I receive images emailed to me like the one above, it makes me smile. Bob Guenthner of GP Ventures, LLC (formerly Guenthner Potato Company Inc.) sent the image of himself and his family at the Antigo Tater Trot, which the Wisconsin Potato & Vegetable Growers Association (WPVGA) sponsors. From left to right in the photo are Bill Kolb, Bob, Max McGivern, Jackie Majewski, Chase Majewski, K.K. Majewski, and Mallory McGivern.

Speaking of family, this October 2023 Associate Division Directory and Bagging/Packaging issue includes an interview with Rod Beggs, owner and manager of Midwestern Potatoes, LLC, whose dad, Denzel, was plant manager of Midwestern Farms, in Plainfield, for 35 years. Rod has held just about every job there is at Midwestern Potatoes, LLC, following in his father’s footsteps and taking the business to the next level. There were plenty of family members (roughly 150 volunteers in all) working the baked potato booth at the Wisconsin State Fair, August 3-13, in Milwaukee. The largest fundraiser for the Wisconsin Potato Growers Auxiliary, volunteers sell baked potatoes to eager fairgoers from 10 a.m. to 10 p.m. each day, and the line seemingly never stops with hungry people ready for their baked spuds. See “Auxiliary News” herein for the full story along with group photos of all the ready and willing volunteers.

“Now News” in this issue includes a story and images about the Central Wisconsin Farmers Collaborative (a Producer-Led Watershed Protection group) holding a Farmer-to-Farmer Field Day on August 3. The event included a visit to a potato field on the Worzella & Sons Farm, in Plover, to a prairie/pollinator plot on Plover River Farms, and much more. Also featured in “Now News,” the WPVGA encourages members to apply for the Member Development Program to learn about and actively participate in various facets of the Wisconsin potato and vegetable industry by exposing them to relevant information, resources, activities, and networking opportunities. Full details are in “Now News,” and the application deadline is November 3, so apply today.

Please email me with your thoughts and questions. If you wish to be notified when our free online magazine is available monthly, here is the subscriber link: http://wisconsinpotatoes.com/blog-news/subscribe.

Joe Kertzman Managing Editor

jkertzman@wisconsinpotatoes.com

Schroeder Bros. Farms, Inc. “ONLY THE BEST” Foundation & Certified Seed Potatoes REDS Dark Red Norland Red Norland RUSSETS COL 8 Norkotah Goldrush Plover Silverton TX 296 Norkotah WHITES Atlantic Hodag Lamoka Mackinaw Manistee NY163 Snowden N1435 Cty Rd D Antigo, WI (715) 623-2689 farm@sbfi.biz johnt@sbfi.biz WISCONSIN CERTIFIED SEED POTATOES

NAME: Rod Beggs

TITLE: Owner/manager

COMPANY: Midwestern Potatoes, LLC

LOCATION: Plainfield, WI

HOMETOWN: Plainfield

YEARS IN PRESENT POSITION: 10

PREVIOUS EMPLOYMENT: “I began working at Midwestern, in 1989, and worked my way up to assistant manager,” Rod Beggs relates. “In 2001, I moved to Janesville and started a painting business. Ten years later, I moved back to Plainfield and began rebuilding Midwestern. In 2013, Bob Berard and I bought out all other shareholders and formed Midwestern Potatoes, Inc. In 2015, Bushmans’ Inc. bought in, and in 2017, I bought out Berard.”

SCHOOLING: Tri-County High School, Plainfield, and U.S. Army Reserves

ACTIVITIES/ORGANIZATIONS: Member of the Wisconsin Potato & Vegetable Growers Association

FAMILY: Wife, Candy; children, Mason (Melissa), Makayla, and Jackson; and granddaughter, Penelope

HOBBIES: Spending time in the Northwoods relaxing and boating

Interview

ROD BEGGS, owner/manager, Midwestern Potatoes, LLC

By Joe Kertzman, managing editor, Badger Common’Tater

Rod Beggs didn’t know his future was already mapped out for him. His dad, Denzel Beggs, was plant manager of Midwestern Farms in Plainfield, Wisconsin, for 35 years.

Although Rod joined the U.S. Army Reserves right out of high school, in 1988, and owned his own painting business in Janesville for close to a decade, he has held just about every job there is at Midwestern Potatoes, LLC.

Primarily a packing shed when it was established by a group of Central

Wisconsin potato growers, in 1977, the storied Midwestern Farms served many potato farmers and investors over the years.

“It started back in 1966 when Godfrey and Maybelle Erickson first owned it,” Rod qualifies, “up until 1977, when there was a fire and it burned down. Then, they presented

8 BC�T October

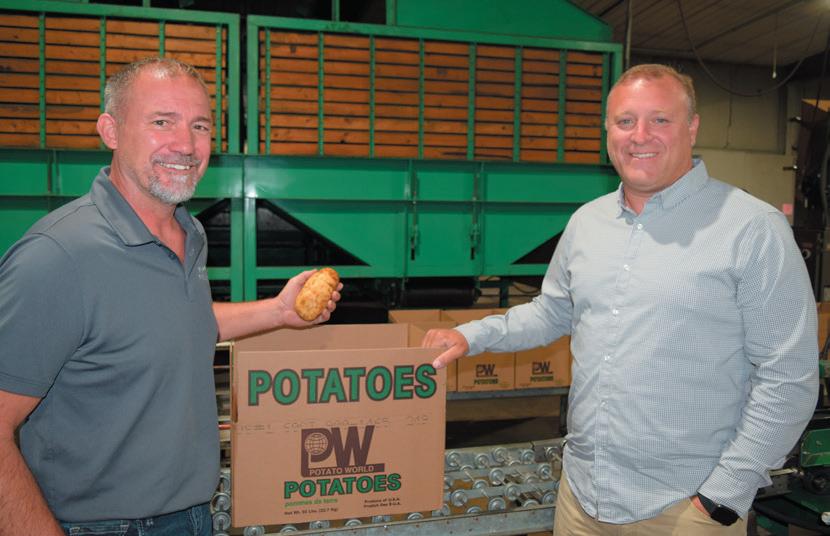

Rod Beggs, owner/manager of Midwestern Potatoes, LLC, in Plainfield, Wisconsin, says the company primarily focuses on grading, sorting, packaging and storing russet potatoes.

the opportunity for several growers to buy into the company that became Midwestern Farms.”

Denzel, Dave Beggs, Jay Erickson and Bob Berard of Paramount Farms owned and ran Midwestern until Rod and Berard bought out all other shareholders and transferred the operation to their names in October 2013. Then, Bushmans’ Inc. of Rosholt purchased one-third of the operation.

“The operation of Midwestern Farms ran up until 2015, when Bushmans’ Inc. and I formed Midwestern Potatoes, LLC,” Rod explains.

Rod, who bought out Berard in 2017, says, today, Midwestern Potatoes focuses primarily on fresh market russets.

Are you doing all the bagging and packaging of fresh market russet potatoes for Bushmans’ Inc., and how does the partnership work?

I manage all operations here at the packaging facility and Bushmans’ manages all the sales and marketing, as well as transportation/shipping from Midwestern Farms.

The two management teams at Bushmans’ and Midwestern are always in constant communication with each other, from top to bottom, from capital investment discussions on down to order needs and the dayto-day operation. It has been a great

relationship and partnership.

Is Midwestern Potatoes still packing for several growers a year, and what are your projections in that regard for this year? Yes, and looking at the current crop, I feel we are going to have a good year both in quality and quantity. As always, our goal here is to create strong returns for the grower group and provide a top-quality product for the consumer to enjoy.

Are you adding growers to the mix, and what varieties of potatoes do you bag and pack? Currently, we

are working with several growers and adding new ones every year.

We are running all russet varieties and all pack sizes. We also try to run as close to year-round as possible. This year, we were only down for two weeks during the summer.

Above: Midwestern Potatoes, LLC has the capacity to store 450,000 hundredweight (cwt.) of potatoes and tries to keep a yearround supply. The company can pack up to 10,000 cwt. of potatoes a day, which equates to 18 or 19 semi-loads or roughly 10,000 bags. continued on pg.

9 BC�T October

10

How many different brands and labels to you bag and pack for? We pack several different brands, but most retailers want their own labels. Therefore, we accommodate their requests.

Our main carton label is the iconic

Potato World Brand, also known as PW Brand.

What type of bagging and packaging machines do you have? We utilize Volmpacks for all our consumer brands and a five-lane Hagen with X-rays for all carton sizes.

Quality

We also just added a custom-built bin filler codesigned with Chris Anderson of Thunderstruck Farms, in Plainfield. This filler allows us to fill the bins

Yellows:

Colomba

Whites: Superior

Reds: Red Norland Modoc

Growers of

Foundation

and Certified Seed Potatoes for Over 50 Years!

Russets: Norkotah #8 Burbank Gold Rush Mercury Silverton Plover

We handle our own line of clean and dependable late model trucks for all of your delivery needs.

Interview. . . continued from pg. 9

Above: Automation such as this Volmpack Auto-Baler saves Midwestern Potatoes time, labor and money.

N3502 Hwy H • Antigo, WI 54409 Office: 715-627-7753 • Fax: 715-623-5412 • mike@baginskifarms.com

Featuring Colomba An early maturing and high yield potential yellow variety. 10 BC�T October

as fast as one every 1 minute, 20 seconds, which will help during the holiday rushes.

Anderson designed and fabricated a new bin-filling line for us meeting Wal-Mart’s new packaging requirements and box specifications. Now we’re the envy of a lot of people, and I just sold the prototype to the Soiks.

Anderson is also building a box stacker and pallet feed now, and currently making upgrades to the filler line with a few more efficiencies.

Do you pack in bulk bins, bales, or what are your smallest bags/ packages? We pack nearly all consumer sizes with a few off-grade bulk loads for processors. We’re going to start packing 40-pound bales for Wal-Mart as part of our new Midwest Fresh bin program.

Do you work with specialty packs of potatoes, and if so, in what sizes? Currently, we are not packing any specialty packs. With our large cooler space, we utilize other facilities and cross-dock the items here for distribution to our customers.

Are you the sales/marketing end of it to retail or wholesale, or do you simply do the bagging and packaging and not sales? I manage all aspects of the operation here at the facility. I leave the sales and marketing to Bushmans’, Inc.

What is Midwestern Potatoes’ potato storage capacity, and how

long do you typically store potatoes? Midwestern has the capacity to store 450,000 hundredweight (cwt.) of potatoes, and we try to keep a yearround supply.

This year, we stored to the end of June and then ran outside potatoes to finish off the rest of the year.

CHROME ALLOY WEAR PARTS

R & H Machine manufactures wear resistant Chrome Alloy parts for planting, fertilizing, cultivating, ripping, and harvesting.

You can count on our signature high Chrome Alloy to give you extremely long life. Our wings maintain their original width throughout the life of the point.

Our shin guards are designed to protect your shank from wear. We make it our business to help reduce your downtime when preparing your fields for next year’s crops.

difficult wear problems!

& H Machine . 115 Roedel Ave . Caldwell, ID 1-800-321-6568

Solving

R

www.rhmachine.com

Proudly made in the USA

on pg. 12

continued

11 BC�T October

Rod Beggs (left) and Bushmans’ Inc. Chief Operating Officer (COO) John Hopfensperger (right) pose by a box of Vanguard Russet potatoes. The main carton label for Midwestern Potatoes is the iconic Potato World Brand.

Do you have a shipping arm of the operation? We don’t have any trucks. Bushmans’ arranges all the transportation for truck loading out of Midwestern and we utilize many local carriers. Some are sourced truck broker relationships.

Do you have any new bagging/ packaging machines using the latest technology? Palletizers? We just added a custom-built bin filler, and we also ordered a new A5 Tomra optical auto grader. We expect that installation to be complete before the end of the year.

How about X-ray capability, and what are you trying to detect with the machines? We currently have three X-ray machines looking for hollow heart in the potatoes.

How much time do you think automated palletizers and bagging/ packaging machines save you? It’s not so much the time as it is labor savings. Palletizing is hard work,

Interview. . . continued from pg. 11

Above:

“It’s not so much the time as it is labor savings,” says Rod Beggs regarding the necessity for such machines as the Fuji-Ace EC201 robotic stacker. “Palletizing is hard work, and it makes it much easier to hire and retain employees when that is not part of the job description.”

Rod Beggs’ son, Mason (left), works for Midwestern Potatoes as Rod’s right-hand man. “I kind of pulled him through the system like my dad pulled me through,” Rod says.

“Palletizing is hard work, and it makes it much easier to hire and retain employees when that is not part of the job description.”

12 BC�T October

– Rod Beggs, Midwestern Potatoes, LLC

and it makes it much easier to hire and retain employees when that is not part of the job description.

As far as bagging, is there a push for you to use more eco-friendly

packaging, and if so, how are you handling that? We pack whatever the retailer is demanding, and we will adjust as they do. However, all the cardboard we use is made from some percentage of recycled material.

Above: The Lockwood VACS Mobile potato handling and cleaning system takes a lot of manual labor out of the equation for Midwestern Potatoes and ensures rocks and debris stay outside of the packing facility.

continued on pg. 14

We're committed to helping you through each and every season. Valley® service teams are trained to prepare your machine for any weather conditions, and know what your irrigation system needs to stay ready.

Schedule your Valley-certified preventative maintenance check today. valleyirrigation.com

WINTER IS COMING. ARE YOU READY FOR IT?

CA1121 DEALER LOGO Address | Phone Number | Website suggested font: Arial 4 COLUMN x 5” 7.708” x 5” MAINTAIN TO SUSTAIN. valleyirrigation.com DA1271 Ensure your irrigation equipment will be ready for the growing season and avoid mid-season breakdowns. Valley® Preventative Maintenance goes beyond Valley machines as we can maintain all pivot brands and provide drive train, electrical, control panel and sprinkler upgrades. VALLEY® PREVENTATIVE MAINTENANCE North Central Irrigation Plainfield, WI: 715-335-6368 • 800-755-0268 Beloit, WI: 608-362-0706 • 800-924-0321 www.valleynci.com

13 BC�T October

You said you’ll be busy from now (late August) straight through to December because of harvest and potatoes coming in. What is your daily production capacity? We can run up to 10,000 cwt. a day, which equates to 18 or 19 semi-loads or roughly 10,000 bags.

I enjoy the challenge and like being busy. I’d rather have 11 orders going out the door than three. I can tell you

Above: Chris Anderson of Thunderstruck Farms, in Plainfield, fabricated a bin-filling line for Midwestern Potatoes that meets Wal-Mart’s new packaging requirements for boxing 5-pound bags of potatoes. Octagonal-shaped boxes allow them to be triple-stacked without being crushed from the weight above.

Interview. . . continued from pg. 13

| mrice@mcgowanrice.com | COMMITTED TO QUALITY SERVICES Master Planning Design/Engineering Potato Storage Consulting General Contracting United States and Canada PROJECT TYPES Potato Storage: - Air Envelope - Straight Wall - Arch Buildings - Bin Storage Truck/Maintenance Shops Wash/Grading Facilities Packing Sheds Building Maintenance Remodels PLAN BETTER BUILD BETTER MAINTAIN BETTER mcgowanrice com 14 BC�T October

Mark Rice, Owner | Cell: 208.863.7242

that in all honesty.

What technologies or changes do you see on the horizon for Midwestern Potatoes and other plants like yours? Automation is the number one technology we see coming down the pipe, as well as

better storage techniques to allow for long-term quality storage.

What do you hope for the future of Midwestern Potatoes? I plan to continue expanding the company with top-tier growers, those who raise quality potatoes. My son,

Mason, works for us as my right-hand man. I kind of pulled him through the system like my dad pulled me through.

SNOWDEN • ATLANTIC • LAMOKA HODAG • MANISTEE • LADY LIBERTY MACKINAW • PETOSKEY • NY163 Contact: Jim or John

Above: While Bushmans’ Inc. Chief Executive Officer Mike Carter (left) looks on, John Hopfensperger, COO of Bushmans’, inspects Vanguard Russets at Midwestern Potatoes, LLC.

15 BC�T October

Using AI to Help Sort Potatoes

How to be 25% more efficient in quality control by implementing artificial intelligence

Submitted by Dominique Jobin, business development manager, Vooban

Patates Dolbec is the largest potato producer in eastern Canada. The company cultivates nearly 10,000 acres of land in the Portneuf region and has vertically integrated itself over the years.

The Saint-Ulbade company markets to retailers such as Costco, Metro, and Sobeys, as well as distributors like Cage aux Sports, for example. Today, Patates Dolbec cultivates,

transforms and packages a wide variety of potatoes destined for the North American market.

Patates Dolbec had a problem with potato sorting in its factories, which required extensive manpower.

Potatoes can exhibit many types of imperfections, with some becoming green because of sun exposure in the field, or others exhibiting black spot, which is caused by fungi, and more.

In all, Patates Dolbec identified 25 types of defects to consider, as well as size, with some customers wanting small potatoes and others preferring medium or large spuds.

Through the labor-intensive task of manually sorting potatoes, workers were accidentally removing healthy potatoes or missing those that had defects.

ARTIFICIAL INTELLIGENCE

In automating the task with optical sorting machines and cameras, Patates Dolbec initially achieved a 70 percent efficiency rate, which meant that the remaining 30% of potatoes were not sorted correctly.

Above: Patates Dolbec was not satisfied with the performance (30% error rate) of its legacy potato optical sorting machine, which required laborers to manually remove the remaining defective potatoes and avoid losing good potatoes and the profits associated with them.

“Your locally owned and family operated Insurance Agency. Offering: Multi-Peril, Crop Hail, Farm & Agri-Business Insurance. Call US today for all your farm insurance needs!” Chad Glaze Owner/Agent Chad Glaze www.vinevestnorth.com 3300 County Road WW • Wausau, WI 54401 888-675-1829 • 715-675-1829 An Equal Opportunity Employer CROP AND FARM INSURANCE We Protect Those Who Provide for the World. Let Us Insure Your Farm or Agribusiness. Call Today! 1-888-675-1829 16 BC�T October

Having always relied on innovation to improve performance, Potatoes Dolbec sought the help of Vooban, a Quebec-based company, to streamline its quality assurance process using artificial intelligence.

Vooban not only specializes in the application of artificial intelligence (AI), but also helps companies navigate the Cloud and Internet of Things (IoT), as well as performing Web and mobile device development.

The challenge was to significantly improve Patates Dolbec’s existing equipment with the help of AI, among other technologies, without completely changing the machines. One change was to the preexisting system of cameras, which was older or more traditional, replacing them with newer, more effective models.

Vooban also developed a deep learning algorithm with a whole new dataset made from thousands of pictures of potatoes taken by the cameras.

Commands were created according to the algorithm’s results to effectively sort the potatoes.

DETECTING IMPERFECTIONS

Patates Dolbec’s objective was to enlist Vooban to help detect all types of imperfections affecting the potatoes’ quality and to provide a solution that would allow freedom in choosing the quality level of product according to the varying needs of customers (restaurants, grocery stores, etc.).

An additional challenge was to surpass the performance and detection algorithm of its industrial sorting machine, which is the market benchmark for this sort of task.

Patates Dolbec was not satisfied with the performance (30% error rate) of its legacy optical sorting machine, requiring laborers to manually remove the remaining defective potatoes to avoid losing good

continued on pg. 18

Need

stacking power?

Discover the ultimate potato stacking & palletizing solutions.

Do you need the ability to accumulate boxes with multiple SKUs? Scan the QR to watch our flagship machine VPM-VHV stack pallets at blistering speeds or visit verbruggen-palletizing.com

“Not only did AI help a local company optimize its processes, but it also helped counter food waste.”

17 BC�T October

– Hugues Foltz, executive vice president, Vooban

potatoes and the profits associated with them.

In an industry with chronic labor shortage, a better solution was crucial.

The company did eventually reach a 95% efficiency rate by retrofitting its optical sorting machine with high-definition cameras and a state-of-the-art, deep-neuralnetwork model to leverage recent developments in AI and computer vision.

To allow for periodic retraining of the model, a machine learning pipeline was developed in the AWS (Amazon Web Services) Cloud.

From datastore, labeling, and training to model registry and edge deployment, the AWS Cloud is the foundational backbone of the upgraded sorting machine.

25% GAIN IN EFFICIENCY

In the end, the implementation of AI in the quality control process had allowed Patates Dolbec to gain no less than 25% in efficiency, as the error rate went from 30% to 5% in just a few months.

“Simply with the implementation of artificial intelligence, we managed to avoid the loss of at least 15% of healthy potatoes that would have been thrown out otherwise,” says

Hugues Foltz, executive vice president of Vooban. “That amounts to roughly 500,000 pounds of potatoes a year.”

“Not only did AI help a local company optimize its processes,” he adds, “but it also helped counter food waste.”

Patates Dolbec, with the help of the AWS Cloud, is now fully autonomous in its capacity to retrain and deploy new models developed using knowledge from the company’s own workforce.

This allows Patates Dolbec to adapt the model to new varieties or changes in the base product. Furthermore, the company can customize the behavior of the sorting to a level unattainable by its legacy machine.

Patates Dolbec can now precisely tune the sorting characteristic to address the needs of different customers.

Using AI to Help Sort Potatoes. . . continued from pg. 17

Contact Pete Schroeder • 715-623-2689 Email: farm@sbfi.biz • Web: https://binfront.biz/ BINFRONT BARRIERS …a better barrier IDEAL FOR BULK STORAGE Barrier system walls off potatoes in bulk storage.

Patates Dolbec eventually reached a 95% efficiency rate by retrofitting its optical sorting machine with high-definition cameras and a state-of-the-art, deep-neural-network model to leverage recent developments in AI and computer vision.

BinFronts can be placed in tight circumferences for corners or circles, eliminating the burden of ordering corner pieces.

• Interlocking Design for Stacking

18 BC�T October

• Angled Barrier Ends Allow for 90-Degree Turns Using Three Barriers WHEN THERE’S A NEED FOR SEPARATION.

North Dakota Certified Seed Potatoes • Minto, ND Contact John Miller: (701) 248-3215 Dryland Grown…Northern Vigor! We are now offering shipments in 2,000 lb. totes and contracting for the current year and beyond if interested. Silverton Goldrush Chieftain Dark Red Norland Red Norland Modoc Lamoka Ranger Russet Dakota Russet Reveille Russet Viking Dakota Pearl ND7799C-1 Waneta All Lots PVX, PVY & Non-GMO Tested www.johnmillerfarms.com

How Each Nutrient Nourishes Plants

What is the plant equivalent of a protein shake for humans?

If a plant decided to go on a diet, what do you think it would choose to be as healthy as possible? It turns out that plants, like humans, rely on essential nutrients to maintain a healthy and balanced lifestyle.

So, what’s the plant equivalent of a protein shake you might be wondering? Probably an N-P-K shake comprised mostly of nutrients like nitrogen (N), phosphorus (P), and potassium (K).

These are referred to as plant macronutrients. Then you can add some “shots” of smaller amounts

Above: Macronutrients such as nitrogen, phosphorus, and potassium aid plant growth along with smaller amounts of calcium, magnesium, and sulfur, as long as not overapplied. The green bean field appears healthy. Image courtesy of TriEst Ag Group

Left: A comparison of common nutrients and what they do for plants and humans.

Source: “Agronomy: Grow with It!,” Ateh, et al., 2016, page 73.

Provided by the Soil Science Society of America and Amanda Ramcharan of Bayer Crop Science

Provided by the Soil Science Society of America and Amanda Ramcharan of Bayer Crop Science

20 BC�T October

of calcium (Ca), magnesium (Mg), and sulfur (S), which are essential for plant health. These are plant micronutrients.

Nitrogen (N)

Nitrogen is used by plants to create amino acids, the building blocks of proteins. Proteins are essential for all our human and plant cells.

Amino acids are needed to form protoplasm—the site for cell division. That makes nitrogen crucial to plant growth and development. All plant enzymes used in biochemical reactions are also made of proteins. Besides the creation of amino acids and proteins, nitrogen is also a necessary component of the chlorophyll molecule. So, nitrogen influences the photosynthesis process.

Nitrogen can improve the quality and quantity of dry matter in leafy vegetables and protein in grain crops. Nitrogen deficiency results in stunted growth, and pale green or yellowing of older leaves, the latter as the plant tries to scavenge nitrogen from older leaves and give it to younger tissues. You might be thinking, “Well, I’m going to pour on the fertilizer, then,” but hold that thought. Plants can also have toxic levels of nutrients.

Nitrogen toxicity also results in stunted growth, with plants looking dark green. It can also result in vegetative bud formation (more plant leaves or stems) instead of reproductive bud formation (more flowers or crops), which isn’t very good for yield.

Phosphorus (P)

Another big player in plant nutrition is phosphorus. It is very important in plant metabolism. Phosphorus is used in plant photosynthesis and respiration, as it is needed for energy storage and transfer.

It’s also part of ribonucleic acid (RNA)

and deoxyribonucleic acid (DNA), the stores of genetic information of living things. Seeds usually have large stores of phosphorus available for young cells in shoot and root tips where growth is rapid.

If the plant lacks phosphorus, it will result in stunted growth as cell division gets compromised. Luckily, phosphorus can be mobilized in a plant and transferred to sites of

new growth. However, if a plant does this, it causes older leaves to appear dark or blue-green and even purple in severe cases.

Phosphorus deficiency thus causes slow development and low seed and fruit quality. But be cautious about applying too much phosphorus to a plant; excess amounts can cause iron and zinc deficiencies.

2731 Maple Drive • Plover, WI 54467 • 715-344-3401 • Toll Free: 1-888-696-4019 www.bigironequipment.com New & Used Sales Service • Repair Proud Dealer of: eyor Belt Mulchers Rock Crushers Customizing equipment to fit your needs for over 25 years!

SPUDNIK Harvester

Used - 2004 SPUDNIK 9060 Hiller

Used - SPUDNIK 8046 7-Row Potato Bed Planter. Includes Fertilizer Tanks and Tubing.

3 Available! continued on pg. 22 21 BC�T October

Used - 2009 GRIMME M odel GL38T-2 8-Row Planter, 36”Row Spacing.

How Each Nutrient Nourishes Plants . . .

Potassium (K)

Potassium is a bit different from nitrogen and phosphorus. It doesn’t become part of any organic compounds in the plant. It’s more like the ultimate assistant to many processes happening in a healthy, growing plant.

For example, potassium assists in the regulation of water use in the plant by controlling the opening and closing of stomata, allowing the plant to cool itself.

At sites of energy production, potassium maintains the balance of electrical charge. It has even been shown to improve disease resistance of the plant, improve the size of

seeds and grains and improve quality of fruits and vegetables.

But too much potassium can also result in toxic levels in the plant, leading to calcium, magnesium, and nitrogen deficiencies.

Calcium (Ca)

Now on to those smaller essential nutrient “shots.” Calcium is needed in smaller amounts in the plant, but it’s not mobile in the plant. This means that if adequate amounts of calcium aren’t available, symptoms of deficiency will first appear on young leaves as growth is stunted.

Growing points of the stem and roots also stop developing with notable

Magnesium deficiency is evident in this canola plant leaf. Notice the vein area remains green, while the rest of the leaf is turning yellow. Image courtesy of Ivan Izgagin

deterioration of the root system before the above-ground parts of the plant. Again, on the flip side, high calcium in a plant can cause magnesium and boron deficiencies.

Magnesium (Mg)

Magnesium is an important component of the chlorophyll molecule and therefore needed for photosynthesis.

It is mobile in the plant, therefore when there’s a deficiency, chlorosis first occurs on older leaves in the leaf tissue between the veins.

Leaves can start to look yellow, bronze, or reddish, while leaf veins remain green. High magnesium levels can cause a calcium deficiency.

Sulfur (S)

Finally, sulfur is used by the plant to create some amino acids and is essential for chloroplast growth and function (the part of the cell where photosynthesis occurs).

Sulfur is not mobilized in a plant,

pg. 21

continued from

22 BC�T October

Besides the creation of amino acids and proteins, nitrogen is also a necessary component of the chlorophyll molecule. So, nitrogen influences the photosynthesis process necessary for such healthy plants as the cucumbers shown here.

so symptoms of deficiency first show on new plant growth where there is a uniform yellowing of new plant tissue. Growth is stunted and maturity is delayed, which lowers yield.

Toxic levels of sulfur are hard to create, so a plant likely won’t suffer from this problem.

So now you know the list of essential nutrients a plant needs to have a healthy diet. With these nutrients, plants can make the most of the water and sunlight available, which results in a high-yielding crop!

If you are growing vegetables in your own garden, it’s best to have a periodic soil test to determine if the soil contains the correct amounts of each nutrient. You don’t want to create toxic levels of any one nutrient, nor do you want those nutrients getting into stormwater systems.

The Soil Science Society of America (SSSA) is a progressive international scientific society that fosters the transfer of knowledge and practices to sustain global soils.

Based in Madison, Wisconsin, and founded in 1936, SSSA is the professional home for 6,000+ members and 1,000+ certified professionals dedicated to advancing the field of soil science. The Society provides information about soils in relation to crop production, environmental quality, ecosystem sustainability, bioremediation, waste management, recycling, and wise land use.

Follow SSSA on Facebook at https://www.facebook.com/SSSA. soils, or Twitter at SSSA_Soils. SSSA has soils information on www.soils.org/discover-soils, for teachers at www.soils4teachers.org, and for students through 12th grade, www.soils4kids.org.

“With these nutrients, plants can make the most of the water and sunlight available, which results in a high-yielding crop!”

23 BC�T October

– Amanda Ramcharan, Bayer Crop Science, and Soil Science Society of America

Now News

Central WI Farmers Collaborative Hosts Field Day

Producer-Led Watershed Protection group holds farmer-to-farmer gathering

The Central Wisconsin Farmers Collaborative (a Producer-Led Watershed Protection group) held a Farmer-to-Farmer Field Day on August 3.

The event included a visit to a potato

field on the Worzella & Sons Farm, in Plover, Wisconsin, to hear about research being conducted that helps potato growers measure and monitor crop water use with highly accurate evapotranspiration (ET) calculations

using an Eddy Covariance Flux Tower. The field day also featured a visit to a prairie/pollinator plot on Plover River Farms. Without the actions of pollinators, agricultural economies, our food supply, and surrounding

Above: Nick Somers of Plover River Farms (center, facing camera) describes the prairie/pollinator plot on his farm, which is adjacent to a vegetable production field in Plover, Wisconsin. Plover River Farms’ pollinator plantings are one component of the Wisconsin Potato & Vegetable Growers Association’s Healthy Grown high-bar sustainability program.

Left: The first stop of the Farmer-to-Farmer Field Day, August 3, was at a potato field on the Worzella & Sons Farm in Plover. Pictured are (left to right) Jonathan Thom with the University of Wisconsin (UW) Atmospheric and Oceanic Sciences Department, and potato growers Nick Somers, Curtis Gagas, Curt Soik and Scott Worzella; and Karla Lochman, program leader of the Boston School Forest. Thom describes the research that is helping potato growers measure and monitor crop water use with highly accurate evapotranspiration (ET) calculations using an Eddy Covariance Flux Tower.

24 BC�T October

landscapes would collapse. During the Farmer-to-Farmer Field Day, Curt Soik of Myron Soik & Sons Inc., Stevens Point, explained how his farm makes use of The CropX system, which aggregates data from soil to sky and transforms it into useful information, helping farmers monitor the health of fields and crops.

Farmer-to-farmer and producerled initiatives such as the field day showcasing recent technologies and research help growers change public

perception, become better stewards of the land and learn new, more sustainable ways of producing quality, high-yielding crops.

Above: Potato grower Curt Soik (left) explains how his farm makes use of The CropX system. This system aggregates data from soil to sky and transforms it into useful information, helping farmers monitor the health of fields and crops. The information is easy to access and provides a holistic overview of field conditions, providing guidance for successful and sustainable farming. From left to right next to Curt are

potato growers Scott Worzella and Andy Diercks; Guolong Liang, outreach specialist in UW-Madison’s Extension Ag Water Quality Program; and Portage County Ag Agent Ken Schroeder.

Above: This image of a bee and a butterfly was taken on the prairie plot at Plover River Farms. Without the actions of pollinators, agricultural economies, our food supply, and surrounding landscapes would collapse. Pollinator plots also sustain our ecosystems and preserve our natural resources by helping plants reproduce.

VARIETIES Reds • Russets • Yellows CUSTOM PACKING Bales • Boxes • Loose Tray Packs Individual Wraps CONTACT Brian, Mark, or Alex to place your order 715-344-2526 Proudly selling potatoes since 1905! Plover, Wisconsin • www.okray.com continued on pg. 26 25 BC�T October

Allied and ProVision Announce Merger

that just fits.”

TRANSITIONING LOGOS

The co-op has been transitioning the logos on their facilities, vehicles, and marketing materials to reflect the Allied Cooperative brand.

Allied Cooperative (Adams, Wisconsin) and ProVision Partners Cooperative (Marshfield) announce the merger of their cooperatives, which officially took place in March 2023.

In a recent letter to their members, they also announced the name of their new cooperative—ProVision Partners Cooperative, doing business as (dba) Allied Cooperative.

Believing that the co-ops already had two strong names, the boards made the decision to forego the expense of rebranding and trademarking a new name, and instead utilize their existing names in the new company.

The name ProVision Partners Cooperative will be used on legal documents. The name Allied Cooperative will be used for all marketing purposes and is the name that the public will see.

“We believe this is a win-win for both cooperatives. Each cooperative’s name is represented with significant savings for our organization as a whole,” says Rob Larson, ProVision Partners Cooperative chief executive officer (CEO), who is set to take the helm of the new cooperative.

“The name Allied Cooperative has an active registration with the U.S. Trademark Office and is a strong representative of who we are moving forward,” says Tim Clemens, Allied Cooperative CEO. “The word ‘Allied’ means connected or joining together by compact or treaty. It’s a definition

“Regardless of what name is on the facility or vehicle, we are moving forward as one cooperative. This company is owned by our members, and we look forward to growing an even stronger co-op as we come together,” Larson says.

The combined co-op has over 600 employees and will serve customers from east to west across Central Wisconsin. Cooperative business leaders estimate that the combined organization’s sales will be approximately $570 million. Allied Cooperative’s roots date back to 1918. Its services include agronomy, grain, LP (liquid petroleum) gas, refined fuels, hardware, tires, auto parts, country stores and convenience stores. It currently has operations in Adams, Blair, Galesville, Mauston, Melrose, Mindoro, Necedah, Plainfield, Plover, Tomah, West Salem, and Wisconsin Rapids.

ProVision Partners’ roots date back to 1912. Its services include agronomy, feed, grain, LP, refined fuels, country stores, convenience stores, a tire and service center, and lawn care.

It currently has operations in Arpin, Auburndale, Black Creek, Black River Falls, Chili, Colby, Fairchild, Granton, Hixton, Humbird, Luxemburg, Manitowoc, Marshfield, Merrillan, Northfield, Pittsville, Seymour, Stratford, Unity, Warrens, and West Salem.

Now News. . . continued from pg. 25

Boards forego expense of rebranding and trademarking new cooperative name 1-800-236-0005 WWW.RONSREFRIGERATION.COM 24 HOUR EMERGENCY SERVICE YOUR ONE CALL STORAGE SOLUTION Computerized Control Systems Refrigeration • Humidification • Ozone Electrical Design & Installation Potatoes • Onions Sprout Inhibiting: Sprout Nip® • Amplify® • Shield® & Air Conditioning R R on’s efrigeration 26 BC�T October

Food + Farm Exploration Center Launches Website

All aspects of the Foundation and Center are under one new responsive website

The Food + Farm Exploration Center in Plover, Wisconsin, is excited to announce the launch of a new website, www.explorefoodandfarm. org. The new website is the culmination of several months of work by the staff and the website developer, Detonator.

Previously, the organization was operating two separate websites, fftf. us, which was the Farming for the Future Foundation website focused on the capital fundraising campaign initiatives, and foodandfarm. us, focused on the Food + Farm Exploration Center and featuring the educational and programming initiatives.

All aspects of the Foundation and the Center are under one new responsive website that is easily navigable on all

devices and built to showcase all that the Food + Farm Exploration Center has to offer.

Visit www.explorefoodandfarm.org to learn about the immersive exhibits, educational offerings, and meeting space rental opportunities. The Exploration Center is projected to open in late fall of this year.

About Food + Farm Exploration Center

The Food + Farm Exploration Center is an extension of Farming for the Future Foundation, a 501(c)(3) nonprofit dedicated to educating current and future generations about agricultural innovation and sustainability.

Its goals are to promote agricultural literacy, to increase the understanding of the origins of our food and to deepen the relationship between farmers and consumers.

continued on pg. 28

27 BC�T October

Join WPVGA Member Development Program

Objective: It is only by preparing members to be effective that the future success of the organization and industry will be realized.

The purpose of the Member Development Program is to provide members of the Wisconsin Potato & Vegetable Growers Association (WPVGA), WPVGA Associate Division and Wisconsin Potato Growers Auxiliary with the opportunity to learn about and actively participate

Right: As part of the February 2022 “Promotions and Marketing” session of the WPVGA Member Development Program, participants made potato donuts. From left to right are Jared Suchon, John Bustamante, Mike Johnson and Samantha Konkol.

Now News. . . continued from pg. 27

potato

vegetable industry

Apply to learn about and participate in facets of the

and

Compeer Financial can provide assistance with financing and operations based on historical data and industry expertise. Compeer Financial does not provide legal advice or certified financial planning. Compeer Financial, ACA is an Equal Credit Opportunity Lender and Equal Opportunity Provider and Employer. © 2023 All rights reserved. DEFINE YOUR SUCCESS WITH US COMPEER.COM/YOU OR CALL (844) 426-6733 Ag Loans & Leases | Crop Insurance | And More A true partner is defined by those they support. That’s why at Compeer Financial we’re defined by you — your hopes for the future as well as your needs today. As a member-owned cooperative, our clients help shape the direction we go and how we serve them. And as agriculture continues to evolve, so will we, together. So whether you need an experienced lender or a trusted financial services provider you can count on, we’re ready. DEFINED BY Cathy Schommer, VP Food & Agribusiness (608) 370-6792 | Cathy.Schommer@compeer.com Dan Kendall, Insurance Officer (608) 370-6825 | Dan.Kendall@compeer.com 28 BC�T October

in the various facets of the Wisconsin potato and vegetable industry by exposing them to relevant information, resources, activities and networking opportunities.

Program Design: Designed as a fivemonth program, one session will be held each month between November and March. Sessions will be offered in-person (with some available virtually).

Participants will be expected to attend all five sessions, with each being approximately five to seven hours in length and focusing on a particular topic, skill or issue relevant to the potato and vegetable growing industry.

Preparatory material will be provided prior to each session to enhance the value of the associated relevant experience. Dates and locations for the sessions will soon be announced.

Program Participants: Ten to 20 candidates for the Member Development Program will be selected by the WPVGA from submitted applications based on their potential as active participants and future leaders in the potato and vegetable growing industry.

Candidates should represent one or more of the following segments of the industry: chip grower, seed grower, process grower, fresh grower/marketer, vegetable grower, farm worker or farm office worker, any facet of the Associate Division category or the Auxiliary.

Candidates should also exhibit a willingness to commit time and effort to prepare for sessions and actively participate in all aspects of the program. There are no age requirements or restrictions.

Program Costs: Program participants will pay nominal fees ($250) for

participation and will be expected to make their own personal arrangements to attend sessions and related activities (including transportation, meals outside of the sessions, and lodging if necessary).

Costs associated with conducting the program will be borne by the WPVGA with aid provided by the WPVGA

Associate Division in keeping with its mission to support the growth and development of the Wisconsin potato and vegetable growing industry. Most sessions will include a lunch/meal along with snacks and refreshments. The application deadline is November 3, 2023.

Biocatalyst for Nutrient Release BENEFITS

Maximizes nutrient release from crop residues and the soil • Extends existing nutrient availability later into the season • Supports easier plantability in the spring • Promotes more even crop emergence • Optimizes yield potential for the next crop Plainfield, WI | 715-335-4900

•

29 BC�T October

“Flat Spudly” Debuts on Social Media

WPVGA mascot loves to be out and about, and now he can be many places all at once

By Dana Rady, WPVGA Director of Promotions and Consumer Education

By Dana Rady, WPVGA Director of Promotions and Consumer Education

The Wisconsin Potato & Vegetable Growers Association mascot, Spudly, loves to be out and about!

He has certainly had his share of fame over the last year after being featured as a main character in a series of online videos showing him

not quite understanding what to do in the kitchen.

He’s provided a level of good-natured humor, appeal and brand awareness to Wisconsin potatoes, thereby taking knowledge of the product to a new level.

While the videos showcased Spudly in the kitchen, a “flat Spudly” concept is beginning on social media. The idea originally known as “flat Stanley” is the notion of taking a computer file or printout of a particular image, in this case, of Spudly, and putting it in everyday situations.

In other words, you can print out an image of Spudly and put him in your harvester or at your computer desk. You can take a picture of him and post it to social media with a caption explaining the photo and include hashtag Spudly (#Spudly).

It’s an easy and seamless way to gain a following for Spudly that ties in with his kitchen videos and is sure to gain the WPVGA mascot even more of a fan base.

It’s also an effort that requires teamwork to implement. Anyone involved in the industry is able, welcome and encouraged to

Marketplace

Above: Spudly happily stands in the fertile soil of a Wysocki Family of Companies field, within the Wisconsin Central Sands production area, after planting.

Spudly enjoys a UTV ride in the fields around Bancroft. He even makes sure his seatbelt is fastened!

30 BC�T October

incorporate Spudly into their professional and personal social media platforms.

Wysocki Family of Companies, in Bancroft, has already taken advantage and made Spudly travel around the farm.

LAMINATED SPUDLY

A laminated image of the Wisconsin potato mascot has been appearing in UTV’s (Utility Terrain Vehicles), in potato fields, on a pile of potatoes and on the side of farm equipment as part of RPE Inc.’s social media efforts.

In each image, he shows off his studly physique and the health benefits that he has gained through regularly consuming Wisconsin potatoes.

He also sports the “Powered by Wisconsin Potatoes” logo on his jersey to feature how far Wisconsin potatoes go in powering performance for any activity level.

It’s an effort that will go a long way in spreading word of Wisconsin potatoes and their health benefits online.

Spudly has become increasingly popular since debuting the four videos of him in the kitchen, to the point where WPVGA’s consumer website (https:// eatwisconsinpotatoes.com/spudly/)

saw significant increases in traffic. So, the more the industry can help him gain a greater fan base across its networks, the more successful our promotional efforts will be.

Visit https://eatwisconsinpotatoes.

and scroll down the page to download images of Flat Spudly and start including him in your social media efforts!

com/spudly/

Spudly shows his support for foundation seed potatoes from Eagle River Seed Farm, in Eagle River, Wisconsin, as he stands in front of a beautiful field of blooming spuds.

The most popular varieties of these world-class hybrids are going fast. Wisconsin’s Highest Yielding Corn and Soybean Varieties Are At Visit with Wayne, Ann, Julie, Sammi, Mike and Brady today to secure the top performing hybrids. Don’t delay, these seeds are growing fast! www. Jay-Mar.com Plover (715) 341-3445 800-236-2436 31 BC�T October

Spudly is so proud to stand in the sun on a pile of Wisconsin potatoes. If we’re being honest, is there any better place to be?

New Products

Old Barn Roofs Get a New Purpose

Sunflare LiteMount60 solar panels do not jeopardize the integrity of older buildings

Farms and ranches have been hard hit by inflation, and skyrocketing fuel and energy costs this year. Going to solar power can help cut electricity costs, but installing traditional silicon solar panels on 100-yearold barn roofs is impossible due to weight issues without an entire roof restructure.

Instead of rebuilding barns and outbuildings, there is now an alternative to traditional silicon solar panels that is lightweight, and more weatherproof and efficient in lowlight, shaded or cloudy conditions— Sunflare LiteMount60.

LiteMount60 panels proved to be the ideal solar option for a 100-yearold barn at Hopeful Hollow Farm, in Rockingham County Virginia.

The installation consisted of 50 185W (watt) LiteMount60 modules with an installed capacity of 9.25kW (kilowatts). One of the biggest

reasons this farm owner chose Sunflare was because the 100-yearold roof was not strong enough to hold traditional silicon modules without an entire reworking of the structure.

Instead of putting that time, money and effort into a barn that has been owned by the same family for generations, the owner opted to install the LiteMount60 modules that would not jeopardize the integrity of the building.

Another benefit of the LiteMount60 panels was realized during the installation process. The slope of the roof was quite steep, and having light modules that were not prone to cracking made placing and moving the modules around much easier.

Two installers were easily able to manipulate module placement compared to using a traditional silicon module.

Above: The Hopeful Hollow Farm in Rockingham County Virginia is 100 years old, and while the roof structure could not support the weight of a standard solar installation, the lightweight Sunflare solar panels were the ideal match.

LESS THAN 1 LB./SQ. FT.

Sunflare LiteMount60 195W panels weigh less than a pound per square foot and are installed using standard S-5! roof clamps for standing metal seam roofs. Custom 20mm (millimeter) high S-5! Pvkit 2.0 Module clamps are also an option and have the benefit of grounding each module when installed.

LiteMount60 is the only lightweight module that seamlessly integrates with every existing metal roof attachment system.

Sunflare Chief Executive Officer Philip Gao says, “Our mission is to reduce CO2, so it’s imperative to find innovative ways to go where

32 BC�T October

traditional solar can’t. At almost 4 pounds per square foot, silicon is too heavy to be installed on many metal roofs.”

LiteMount60 panels have a wind load of 42 lbs./sq. ft. (pounds per square foot) and a snow load up to 33 lbs./sq. ft. They also have no glass covering, so are shatterproof. That means there’s no waste due to broken panels.

Sunflare panels are all tested to withstand extreme weather conditions, in temperatures ranging from 40-185 degrees Fahrenheit, and impact resistance tested to withstand 25mm (1 inch) diameter hail at 52 miles per hour.

LiteMount60 also has bypass diodes at every cell. That means shading doesn’t affect the unit as much as most silicon panels that have a bypass diode for every string. It would take full shade to shut down a LiteMount60 panel, whereas silicon panels can be shut

down if shade falls across one cell.

For more information, contact Sunflare, 1693 Yeager Ave., La Verne, CA 91750, 888-577-9935,

info@sunflaresolar.com, https:// sunflaresolar.com, or contact Laura Baumgartner, lbaumgartner@ asylumpr.com.

33 BC�T October

Built on a thin and flexible stainless-steel backing, Sunflare solar panels are more durable and weather resistant than traditional units that utilize glass substrates and can be prone to micro-cracking. continued

on pg. 34

Fan Efficiency Equals Effective Airflow

Tolsma ACM fan is driven by a permanent magnet synchronous motor

Reprinted with permission from Paul van Eijck of PotatoPro.com

Ventilation takes a lot of electricity and has become pricy now that energy prices are going through the roof. One stroke of luck is that the latest generation of fans is much more energy efficient.

Fans come in all shapes and sizes. But every fan has an optimal control range in terms of rpm (revolutions per minute), airflow and energy consumption.

Modern fans with a direct current motor (EC type) achieve an efficiency of 30 to 60 percent effective airflow. In addition, the back pressure in Pascal (Pa) determines what type of fan is best for which application.

For example, with a pressure difference of 150 Pa in box storage, this requirement is different from bulk onion storage with pressure differences of up to about 350 Pa.

a fan blade would suffice with fewer blades.

In the latter case, the fan blade needs more blades and higher power. Therefore, the most optimal setup is chosen for each application, allowing

Come

With Us!

The fan consists of a fan housing with mounting brackets on which the electric motor is mounted. Remarkably, the shape and placement of the motor supports determine a significant part of the ambient noise.

The Tolsma ACM fan is driven by a permanent magnet synchronous motor, or PM motor.

In these motors, the speed control (an electronics box) is placed outside the motor, thus not exposing the technology to vibration.

Another feature of this PM electric motor is its flat shape and lower maximum speed. This type of motor is on average 30 percent more economical than a standard asynchronous induction motor.

THE CURVED

BLADE

Tolsma’s latest development is the curved blade. This contributes to higher efficiency in air movement and

The blade is wide at the point where it sits against the fan blade shaft because it is at the tip. However, the

New Products. . . continued from pg. 33

• Grower-owned operation • Operation packs many varieties of potatoes year-round for retailers, wholesalers & foodservice companies • Scoop-up purchasing • Pool participation • Multiple grading options • Temperature & humidity controlled storage available • Direct marketing For more details on how to grow with us, contact Mike Hayes at 715-572-6366 or mike.hayes@wfc.ag

34 BC�T October

Grow

Eagle River Seed Farm Seed Operations Wysocki Produce Farm Farming Operations Paragon Potato Farms Plant Operations

position of the blade varies with the radius.

That means the blade is more twisted close to the shaft than far from the drive shaft. As a result, the fan close to the shaft moves about as much air as it does at the end of the blade, where the turnover rate is much higher.

You could say that the modified blade angle compensates for the lower turnover rate near the shaft. Furthermore, the blade has the external characteristics of an airplane wing, which helps the airflow. An additional advantage of an ACM fan is that it can easily rotate backwards, so the fan sucks instead of blows.

Saving energy (reducing costs) is an important criterion in ventilation. A possibly even greater effect is ventilating at the right time, as this can reduce ventilation time.

A quieter fan means gain for the environment, but also for the wallet.

At current energy rates, the payback period of modern fans with a PM motor is shortened. Moreover, the purchase of energy-efficient fans is fiscally attractive.

For more information, contact Tolsma-Grisnich, attn: Cameron Folmer, 208-519-6421, cameronfolmer@tolsma.com, https://www.tolsmagrisnich.com.

35 BC�T October

2023 WPVGA Associate Division Directory

ACCOUNTING

OMERNIK & ASSOCIATES INC

MICHAEL OMERNIK

PLOVER, WI

(715) 341-9036

mike@accounting-offices.com www.accounting-offices.com

AERIAL SPRAYING

AGRICAIR FLYING SERVICE INC

JIM PERRIN

BANCROFT, WI

(715) 335-4470

agricair@uniontel.net www.agricairflyingservice.com

REABE SPRAYING SERVICE INC

CURT MEISTER

PLOVER, WI

(715) 341-9393 office@reabesprayingservice.com www.reabesprayingservice.com

AG CONSULTANTS

AGRI-PEST CONSULTING INC

TIM GROSS MILTON, WI (608) 208-5049

agripest89@gmail.com

AGSOURCE LABORATORIES

COLE BRODIN BONDUEL, WI

(715) 758-2178

cole.brodin@agsource.com www.agsource.com

ALLIED COOPERATIVE

KARMEN BERNACCHI

ADAMS, WI

(608) 339-3394

info@allied.coop www.allied.coop

CLA (CLIFTON LARSON ALLEN LLP)

JIM HALVORSEN

MARSHFIELD, WI

(715) 221-3037

jim.halvorsen@claconnect.com www.claconnect.com

ELLINGSON COMPANIES

SIMONE STEISKAL

WEST CONCORD, MN (507) 527-2294

ssteiskal@ellingsoncompanies.com www.EllingsonCompanies.com

FOCUS ON ENERGY

LAURA LANE

CHIPPEWA FALLS, WI (800) 762-7077

business@focusonenergy.com www.focusonenergy.com/agribusiness

GZA GEOENVIRONMENTAL INC

JAMES F DROUGHT

BROOKFIELD, WI (414) 831-2540

james.drought@gza.com

www.gza.com

INSIGHT FS

CASEY KOBACK

ANTIGO, WI

(715) 627-4844

antigo@insightfs.com

www.insightfs.com

MID-STATE TECHNICAL COLLEGE

ALEX LENDVED

MARSHFIELD, WI

(715) 389-7011

alex.lendved@mstc.edu www.mstc.edu

MOERKERKE CONSULTING

BOB MOERKERKE CORNELIUS, OR (715) 360-7975

bob.moerkerke@gmail.com

NELSON'S VEGETABLE STORAGE SYSTEMS

HOLLY NELSON

PLAINFIELD, WI (715) 335-6660

holly@nelsonsveg.com

POSSIBILITIES UNLIMITED

ELLIE WOMELDORF

STEVENS POINT, WI

(715) 281-1743

ellie_womeldorf@yahoo.com

ROCK RIVER LABORATORY INC

DUSTIN SAWYER

WATERTOWN, WI (920) 261-0446

dustin_sawyer@rockriverlab.com

www.rockriverlab.com

SYNAGRO LLC

MATTHEW MIELKE

WISCONSIN RAPIDS, WI

(715) 421-1866

mmielke@synagro.com

www.synagro.com

AG INSPECTIONS

AG WORLD SUPPORT SYSTEMS LLC

BRYAN HENNINGER

MOSES LAKE, WA (509) 765-0698

bhenninger@aginspections.com

www.aginspections.com

AGRICULTURAL CHEMICALS

AMVAC CHEMICAL CORP

RALPH FREDERICK

DULUTH, MN (218) 340-1609

ralphf@amvac.com

www.amvac.com

ANALYTICAL LABORATORY

A & L GREAT LAKES LABORATORIES INC

DAVID HENRY

FORT WAYNE, IN

(260) 483-4759

dhenry@algreatlakes.com

www.algreatlakes.com

BAG COMPANIES

FOX PACKAGING AND FOX SOLUTIONS

VICTORIA LOPEZ

MC ALLEN, TX (956) 682-6176

victoria.lopez@foxbag.com

www.foxbag.com

THORPACK LLC

MARTIN KOLPACK

BRYANT, WI

(715) 627-7333

mkolpack@thorpack.com

www.thorpack.com

36 BC�T October

VOLM COMPANIES INC

MARSHA POZZA

ANTIGO, WI

(715) 627-3626

marsha.pozza@volmcompanies.com

www.volmcompanies.com

WARNER & WARNER INC

JAY WARNER

PLOVER, WI

(715) 341-8563

jay.warner@warnerpackaging.com

www.warnerpackaging.com

CHAIN

BROEKEMA BELTWAY USA INC

JEFF EILERS

PINE CITY, MN

(320) 629-3900

jeff.eilers@broekema.us www.broekemabeltway.com

CHEMICALS

GOWAN USA

BECKY HECK

BARNEVELD, WI

(715) 450-1291

bheck@gowanco.com

www.gowanco.com

SYNGENTA CROP PROTECTION

KEN CLEVELAND

MARATHON, WI

(608) 642-3717

ken.cleveland@syngenta.com

www.syngenta-us.com

CHEMICALS/FERTILIZERS

ALBAUGH LLC

KEITH MILLER

TROY, IL

(314) 306-7444

keithm@albaughllc.com

www.albaughllc.com

ALLEN SUPPLY COMPANY INC

JASON ALLEN

STEVENS POINT, WI (715) 341-7635

jason.allen@allensc.com

ALLIED COOPERATIVE

KARMEN BERNACCHI ADAMS, WI (608) 339-3394

info@allied.coop

www.allied.coop

AQUA YIELD

ROY ZELLMER

BARABOO, WI (608) 393-4120

roy@aquayield.com

www.aquayield.com

BASF JUSTIN TUSS

APPLETON, WI

(920) 570-2686

justin.tuss@basf.com

BAYER

ADAM VANDENPLAS

CROSS PLAINS, WI

(608) 640-9810

adam.vandenplas@bayer.com

CONTREE SPRAYER AND EQUIPMENT

DAVID VONBEHREN

BEAVER DAM, WI (920) 356-0121

davev@contree.com

www.contree.com

CORTEVA AGRISCIENCE

ROBERT HAUS

JOHNSTON, IA (515) 535-6290

robert.j.haus@corteva.com

www.corteva.com

COUNTRY VISIONS COOPERATIVE

BRIAN MADIGAN

BRILLION, WI (920) 754-4321

bmadigan@cvcoop.com

www.countryvisionscoop.com continued

on pg. 38 37 BC�T October

2023 WPVGA Associate Division Directory. . . continued from pg. 37

DRAMM CORP

JUSTIN ELLIS

MANITOWOC, WI (920) 684-0227

jellis@dramm.com www.dramm.com

GREENLIGHT BIOSCIENCES

CATIE LEE

LEXINGTON, MA (617) 616-4258

clee@greenlightbio.com www.greenlightbio.com

HELIAE MARK IMMEL

PESHTIGO, WI (715) 923-5550 mimmel@heliae.com www.PhycoTerra.com

HGS BIOSCIENCE

TOM BALLINGER

ONALASKA, WI (507) 273-4095 tom.ballinger@hgsbioscience.com www.hgsbioscience.com

ICL

JUDSON MOORE

GARRETSON, SD (605) 215-2876 judson.moore@icl-group.com www.icl-sf.com/us

JAY-MAR INC

TONY GRAPSAS PLOVER, WI (715) 341-3445

tonyg@jay-mar.com www.jay-mar.com

MIDWESTERN BIOAG HOLDINGS LLC

PATRICK HOLVERSON

BLUE MOUNDS, WI (608) 437-4994

patrick.holverson@midwesternbioag.com www.midwesternbioag.com

MILLER CHEMICAL

KAYLA SMITH

ATLANTA, GA (715) 591-1921 kaylasmith@millerchemical.com www.millerchemical.com

NACHURS

SIMON LARSON MARION, OH (800) 622-4877 silarson@nachurs.com www.nachurs.com

NICHINO AMERICA INC

TIM SCHRANK

ST JOHNS, MI (989) 763-3506

tschrank@nichino.net www.nichino.net

NUTRIEN AG SOLUTIONS

JIM BEACH BELOIT, WI (970) 518-2685 jim.beach@nutrien.com www.NutrienAgSolutions.com

PRECISION GROUND APPLICATIONS LLC

DOUGLAS BENNETT NEKOOSA, WI (715) 315-9728 aerocrop@hotmail.com

ROVENSA NEXT

KEVIN BOEHM DEERFIELD, WI (608) 697-5949

kevin.boehm@oroagri.rovensa.com www.oroagriusa.com

STOLLER

CARLA MILLARES

HOUSTON, TX (800) 539-5283 cmillares@stollerusa.com www.StollerUSA.com

T H AGRI-CHEMICALS INC

ROBERT ZIMPEL PLAINFIELD, WI (715) 335-6343

robertz@thagrichemicals.com www.thagrichemicals.com

T I P INC

STEVE TATRO CUSTER, WI (715) 592-4650

tip@tipinc.net www.tipinc.net

TELEOS AG SOLUTIONS

MELODY CRISP

HAMLET, NC (619) 592-0858

mcrisp@teleosagsolutions.com www.teleosagsolutions.com

TRIEST AG GROUP INC

TONY BELCHER

GREENVILLE, NC (844) 878-5178

tbelcher@triestag.com www.triestag.com

UPL

TYLER PALM

EAU CLAIRE, WI (763) 325-5502

tyler.palm@upl-ltd.com

www.upl-ltd.com/us

VALENT USA LLC

BRAD GUNNINK

SUN PRAIRIE, WI (608) 213-7309

brad.gunnink@valent.com

www.valent.com

VIVE CROP PROTECTION

ROB VINCENT MISSISSUAGA, ON, CANADA (416) 260-8889

rvincent@vivecrop.com

www.vivecrop.com

WILBUR-ELLIS COMPANY LLC

KURT DEPORTER

ALMOND, WI (715) 366-2500

kdeporte@wilburellis.com

www.wilburellis.com

COMMUNICATION

FOX VALLEY TECHNICAL COLLEGE

NICK SCHNEIDER

APPLETON, WI (920) 831-4369

nicholas.schneider2990@fvtc.edu

www.fvtc.edu

UNITED POTATO GROWERS COOP OF WI DANA RADY

ANTIGO, WI (715) 610-6350

drady0409@gmail.com

www.unitedpotatousa.com

WDATCP-SAFE WISCONSIN PRODUCE KRYSTAL MARTIN

MADISON, WI (715) 216-0379

safeproduce@wi.gov

www.safeproduce.wi.gov

CONSTRUCTION

ALTMANN CONSTRUCTION COMPANY INC

TAMMY MEYERS

WISCONSIN RAPIDS, WI (715) 421-2550

tmeyers@altmannconstruction.com

www.altmannconstruction.com

BLENKER CONSTRUCTION

MELISSA ELLINGSON

STEVENS POINT, WI (715) 824-5665 EXT 140

melissa.ellingson@blenkerco.com

www.blenkerco.com

38 BC�T October

CENTRAL DOOR SOLUTIONS

CHRIS BROOKS

PLOVER, WI (715) 342-4153

cbrooks@centraldoorsolutions.com

www.centraldoorsolutions.com

COUNTY READY MIX

SCOTT BEHNKE

MARATHON, WI (715) 848-1365

scott.behnke@countymaterials.com

www.countymaterials.com

ENERGY EDGE LLC

BEN RUDIN WAUSAU, WI (715) 551-5945

ben@energyedge.info

www.energyedge.info

HIXWOOD METAL

BOB KORTBEIN STANLEY, WI (715) 206-7027

bobk@hixwood.com

www.hixwood.com

KELLER INC

KATIE BAUKNECHT

KAUKAUNA, WI (920) 766-5795

kbauknecht@kellerbuilds.com

www.kellerbuilds.com

MCGOWAN RICE CONSTRUCTION

MARK RICE

MERIDIAN, ID (208) 863-7242

mrice@mcgowanrice.com

www.mcgowanrice.com

MIDLAND GARAGE DOOR MFG CO

DOUG LARSON

WEST FARGO, ND (701) 282-8136

dougl@midlandgaragedoor.com

www.midlandgaragedoor.com

M.P.B. BUILDERS INC

DOYLE POKORNY

RIPON, WI (920) 748-2601

doyle@mpbbuilders.com

www.mpbbuilders.com

RHINEHART METAL BUILDINGS INC

CHAD RHINEHART ADAMS, WI (608) 547-1523

chadr@rhinehartmetalbuildings.com

www.rhinehartmetalbuildingsinc.com

CONSUMER EDUCATION

FOOD + FARM EXPLORATION CENTER

ANDY REITZ

PLOVER, WI (715) 459-3535

areitz@fftf.us

www.fftf.us

DIESEL REPAIR

K&S FUEL INJECTION INC

JASON MAKI

WESTON, WI (715) 359-1000

jmaki@ksfuel.com

www.ksfuel.com

ELECTRICAL

ADAMS-COLUMBIA ELECTRIC COOPERATIVE

JEREMY HUHNSTOCK

FRIENDSHIP, WI (608) 339-5428

jhuhnstock@acecwi.com

www.acecwi.com

on pg. 40 39 BC�T October

continued

2023 WPVGA Associate Division Directory. . . continued from pg. 39

MOTORS AND CONTROLS OF WI LLC

KEVIN KONOPACKY

PLOVER, WI (715) 344-0010

sales@macowi.com www.macowi.com

RON'S REFRIGERATION & AIR CONDITIONING LLC

EUGENE MANCL

WISCONSIN RAPIDS, WI (715) 421-1525

emancl@coolsys.com

www.ronsrefrigeration.com

EXIT / SUCCESSION PLANNING

VISTA FINANCIAL STRATEGIES LLC

SCOTT D SCHEER

APPLETON, WI (920) 731-4572

scott@vistafinancialstrategies.com www.vistafinancialstrategies.com

FARM EQUIPMENT

BADGER PLASTICS & SUPPLY

MAX BERGEN

PLOVER, WI (715) 345-0009

mbergen@badgerplastics.com www.badgerplastics.com

CROP IMS LLC

BARRY BEWLEY

EFFINGHAM, IL (217) 347-5959

bbewley@cropims.com www.cropims.com

FALL CITY IMPLEMENT

ROLLIN METZGER

GRAND MARSH, WI (715) 505-5188

rmetzger@cvbean.com www.cvbean.com

FERTILIZER DEALER SUPPLY

PAUL MCQUILLEN

MILON, WI

(800) 462-6670

paulmc@fertilizerdealer.com www.fertilizerdealer.com

LEMKEN USA

JAY HALBERT

LANGFORD, SD

(507) 951-2494

j.halbert@lemken.com www.lemken.com

PESHTIGO NATIONAL BANK

MICHAEL JAJE

PESHTIGO, WI

(715) 582-4512

mjaje@peshtigobank.com www.pnbwi.com

PICKETT EQUIPMENT

BRADY OLSON BURLEY, ID (208) 678-0855 bolson@pickettequipment.com www.pickettequipment.com

RIESTERER & SCHNELL INC

HEATHER RIPP MARION, WI (920) 358-3801 marketing@rands.com www.rands.com

SAND COUNTY EQUIPMENT PAUL CIESLEWICZ paul@sandcountyequipment.com

BANCROFT, WI (715) 335-6652

cheryl@sandcountyequipment.com www.sandcountyequipment.com

SERVICE MOTOR COMPANY

KRISTEN WONDRA

DALE, WI 920-779-4311

kristen.wondra@servicemotor.com www.servicemotor.com

SWIDERSKI EQUIPMENT INC

MELISSA HEISE

MOSINEE, WI (715) 693-3015

mheise@sei247.com www.swiderskiequipment.com

VANTAGE NORTH CENTRAL INC

SEAN TIMM

PLAINFIELD, WI (715) 335-6368

sean@vantage-northcentral.com www.vantage-northcentral.com

WILCOX AGRI-PRODUCTS

ALAN WILCOX

WALNUT GROVE, CA (916) 776-1784

awilcox@wilcoxap.com

FERTILIZERS

BIO-GRO INC

BRUCE ANDERSEN

CEDAR GROVE, WI (608) 354-1123

bruce@biogro.com www.biogro.com

CALCIUM PRODUCTS

DENA RESECH

AMES, IA

(800) 255-8196

dena.resech@calciumproducts.com

www.calciumproducts.com

DRAMM CORP

JUSTIN ELLIS

MANITOWOC, WI (920) 684-0227

jellis@dramm.com

www.dramm.com

INSIGHT FS

CASEY KOBACK

ANTIGO, WI (715) 627-4844

antigo@insightfs.com

www.insightfs.com

NEW CHESTER DAIRY

AVI STERN

FREEDOM, WI (920) 759-4673

astern@milksource.net

www.milksource.com

FERTILIZERS - CONVENTIONAL AND ORGANIC FARM FIXATION LLC

MARK J KLISH

MOSINEE, WI (715) 347-0545

mark@farmfixation.com

www.farmfixation.com

FINANCIAL ABBYBANK

NATALYN JANNENE

ABBOTSFORD, WI (715) 223-2345

marketing@abbybank.com

www.abbybank.com

AGCOUNTRY FARM CREDIT SERVICES

MARK GROHOLSKI

STEVENS POINT, WI (715) 321-2970

mark.groholski@agcountry.com

www.agcountry.com

BAKER TILLY

DANIEL EHR

APPLETON, WI (920) 739-3392

daniel.ehr@bakertilly.com

www.bakertilly.com

BANK FIRST

BRAD RAHMLOW

TOMAH, WI

(715) 299-9809

brahmlow@bankfirst.com

www.BankFirst.com

40 BC�T October

BMO

PAUL SALM

ALTOONA, WI

(715) 726-0718

paul.salm@bmo.com www.bmoharris.com

CLA (CLIFTON LARSON ALLEN LLP)

JIM HALVORSEN

MARSHFIELD, WI

(715) 221-3037

jim.halvorsen@claconnect.com www.claconnect.com

COMPEER FINANCIAL

CATHY SCHOMMER

PRAIRIE DU SAC, WI (608) 370-6792 cathy.schommer@compeer.com www.compeer.com

COVANTAGE CREDIT UNION

STEPHANIE BARTLETTI

ANTIGO, WI

(715) 627-4336

sbartlet@covantagecu.org www.covantagecu.org

I

FIRST STATE BANK

BRENDA HANSEN

NEW LONDON, WI (920) 531-2857

bhansen@bankfirststate.com www.bankfirststate.com

INCREDIBLE BANK

ROB WYMAN WESTON, WI

(715) 584-4203

rwyman@incrediblebank.com www.incrediblebank.com

METLIFE INVESTMENT MGMT AG FINANCE

TROY FISCHER

ROCKFORD, IL (815) 494-4349

tfischer@metlife.com

www.metlife.com/ag

NICOLET NATIONAL BANK

CRAIG ROGAN