THE VOICE OF WISCONSIN'S POTATO & VEGETABLE INDUSTRY

THE VOICE OF WISCONSIN'S POTATO & VEGETABLE INDUSTRY

Wisconsin Central Farms

THE IMPORTANCE OF Proper Potato Storage

THEY CIRCLED THEIR Wagons for Field Days WILL YOUR NEXT POTATO Sorter Be an AI Avatar?

STAR TREK OF POTATOES: McCain “Farm of the Future”

On the Cover: “I think it might be the first time this variety has been grown in the United States on the commercial side,” says Sam Ourada, this issue’s interviewee, about the McCain experimental variety of potatoes he's holding on the front cover. For McCain Foods, Ourada, of Wisconsin Central Farms, grows 600-650 acres of potatoes and 150-300 acres of sweet potatoes.

Golfers

One of only a few sweet potato growers in the state, when asked why he decided to take them on, Sam Ourada of Wisconsin Central Farms, Inc., explained that he is partnering with Shawn Bula of Signature Farms. “We saw an opportunity, and I kind of like the challenge of doing something new,” Ourada says. “He had contracts and access to labor. Labor is a big part of growing sweet potatoes, as they’re all transplanted, so each plant is touched by hand.”

Tong Stinger Hopper eases the task of unloading livebottom trucks and semis

WPVGA Board of Directors:

PreSideNT: Charlie MaTT ek

Vice PreSideNT: JohN BuSTama NT e

Secre Tary: Alex Okray

Trea Surer: WeNdy Dyk ST ra

Direc Tor S: Mike BagiNSki, Ra Ndy FleiShauer, JohN HopfeNSperger, JoSh KNighTS & J.D. Schroeder

Wisconsin Potato Industry Board:

PreSideNT: Heidi Al Sum-Ra Ndall

Vice PreSideNT: ANdy Dierck S

Secre Tary: Nicola Carey

Trea Surer: KeiT h WolT er

Direc Tor S: JohN FeNSke, Rod Gumz, Jim Okray, Eric Schroeder & Tom Wild

WPVGA Associate Division Board of Directors:

PreSideNT: MaTT SeleNSke

Vice Pre SideNT: ET ha N Ol SoN

Secre Tary: Morga N Smolarek

Trea Surer: Paul Salm

Direc Tor S: MeliSS a HeiSe, Brady PaToka, ScoTT Scheer, Sally SupriSe & Bra NdoN Taylor

Wisconsin Seed Potato Improvement

Association Board of Directors:

PreSideNT: Jeff SuchoN

Vice PreSideNT: Charlie HuSNick

Secre Tary/Trea Surer: MiTch MaTT ek

Direc Tor S: ANdy Schroeder & CloVer Spacek

Wisconsin Potato Growers

Auxiliary Board of Directors:

PreSideNT: Heidi Schleicher

Vice PreSideNT: DakoTah Smiley

Secre Tary/Trea Surer: Sama NT ha Cypher

Direc Tor S: Jody BagiNSki, MiST i KiNNiSoN, JeNN a Kuka Nich & EriN MeiST er

Mission Statement of the WPVGA: To serve the potato and vegetable industry of Wisconsin through education, research, promotion, governmental action and sustainability leadership.

Mission Statement of the WPVGA Associate Division: To work in partnership with the WPVGA as product and service providers to promote mutual industry viability by providing technology and information resources.

Badger Common’Tater is published monthly at 700 Fifth Avenue, Antigo, Wisconsin 54409

WPVGA Staff

Execu T iVe Direc Tor: Tama S Houliha N

Ma N agiNg Edi Tor: Joe KerT zma N

Direc Tor of PromoTioNS & CoNSumer

EducaTioN: Da N a Rady

FiN a Ncial Officer: KareN Ra SmuSSeN

Execu T iVe A SSiSTa NT: Julie BrauN

Program A SSiSTa NT: Ja Ne GuilleN SpudmoBile EducaT ioN a Nd Ou T reach

AdmiNiST raTor: George NeuBer

WPVGA Office (715) 623-7683 • FAX: (715) 623-3176

E-mail: wpvga@wisconsinpotatoes.com

WeBSiT e: www.wisconsinpotatoes.com

LIKE US ON FACEBOOK: www.facebook.com/WPVGA

Subscription rates: $2.50/copy, $28/year; $45/2 years.

Foreign subscription rates: $35/year; $55/2 years.

Telephone: (715) 623-7683

Mailing address: P.O. Box 327, Antigo, Wisconsin 54409

Or, subscribe free online: http://wisconsinpotatoes.com/blog-news/subscribe/

ADVERTISING: To advertise your service or product in this magazine, call (715) 630-6213, or email: Joe Kertzman: jkertzman@wisconsinpotatoes.com. The editor welcomes manuscripts and pictures but accepts no responsibility for such material while in our hands.

SEPTEMBER

10-14 POTATO BOWL USA

Grand Forks-East Grand Forks, ND & MN

27-29 HARVEST FAIR 2024

Wisconsin State Fair Grounds West Allis, WI

5 38TH ANNUAL SPUD BOWL

Community Stadium at Goerke Park Stevens Point, WI 17 5TH

Wausau Skeet and Trap Club Wausau/Brokaw, WI

Georgia

West Madison Research Station and virtual 1 p.m. on Mon., and 8 a.m. on Tues. Verona, WI

I was convinced the above image, a copy of a historic 1922 photograph, wouldn’t look good in the glossy, four-color magazine, and I even told Bob Guenthner that when he emailed it to me. But, alas, the story is too good, and the image really does speak to a time and a place, so I’m pivoting and admitting I was wrong.

Guenthner, of GP Ventures LLC, in Antigo, emailed the image and some others along with the story below, saying, “My neighbor showed me the pictures in the attachment. The writeup is part of her family history. That was a lot of people at a potato show back when traveling was difficult.”

WI

Experimental

McCormick Place Chicago, IL

Clinton Farms Bear Creek, WI

Here’s the story behind the image: “Jennie Sabina Blomberg and Gustaf Martinius Donaldson were married on Thanksgiving Day, November 30, 1911, following a courtship of about three years. Because of distance and a lack of transportation, courtship was sometimes quite lengthy in those days. They lived at least 12 miles from each other and, if they were to see one another, Gust had to either walk the distance or go by horse. Gust was a farmer at heart and soon became the largest certified seed potato grower in the state of Wisconsin …

“The county farm agent from Phillips, Mr. Ramlow, invited the state potato growers [in 1922] for a tour of the Donaldson farm [in Ogema, Wisconsin.] State dignitaries from the capitol in Madison also attended. The Prentice High School band opened the day with several selections to call the meeting to order. At noon, dinner was served to 100 dignitaries of the potato industry in the house, seated at tables. The lawn was the dining area for 500 other guests.

“Jennie had prepared 25 heavy Rhode Island Red chickens they had fattened and then dressed out the evening before. The dignitaries inside dined on southern fried chicken with cream gravy and all the trimmings. The guests on the lawn were served buffet style from an assortment of hot dishes, salads, and fresh homemade biscuits. Jennie did a great job of organizing and planning the entire production, including using the teenage girls from the area as waitresses.

Following the meal, the band took the lead, marching and playing down to the lakeshore with the 600 visitors following. They found seating room under the trees on the hillside while the speakers talked about the potato industry from a hastily erected podium right at the lakeshore.”

Please email me with your thoughts and questions. If you wish to be notified when our free online magazine is available monthly, here is the subscriber link: http://wisconsinpotatoes.com/blog-news/subscribe.

Joe Kertzman Managing Editor

jkertzman@wisconsinpotatoes.com

N1435 Cty Rd D

Antigo, WI (715) 623-2689 farm@sbfi.biz johnt@sbfi.biz

By Joe Kertzman, managing editor, Badger Common’Tater

NAME: Sam Ourada

TITLE: Partner

COMPANY: Wisconsin Central Farms, Inc.

LOCATION: Nekoosa, WI

HOMETOWN: Antigo, WI

YEARS IN PRESENT POSITION: Farm manager for 42 years, different farms

PREVIOUS EMPLOYMENT: Anthony Farms in Scandinavia, Wisconsin, and Stan Thomas Farms of Hancock

SCHOOLING: Antigo High School and Bachelor of Science degree from the University of Wisconsin (UW)-Stevens Point in soil science and chemistry

ACTIVITIES/ORGANIZATIONS: Grower member of the Wisconsin Potato & Vegetable Growers Association (WPVGA) and various ATV (All-Terrain Vehicle) clubs

AWARDS/HONORS: WPVGA Young Grower of the Year and various McCain grower awards

FAMILY: Wife, Liz, married 40 years, and daughter, Courtney, 38 years old

HOBBIES: Fishing and UTV (Utility Terrain Vehicle) riding

Raised on a potato farm in Antigo, Wisconsin, Sam Ourada had his sights set on something else—he was going to be a soil scientist or chemist. As Scottish poet Robert Burns wrote in his 1786 poem “To a Mouse,” “The best-laid plans of mice and men often go awry.”

Sam’s plans didn’t really go awry when he left his father’s farm to attend college at UW-Stevens Point. First, he earned a Bachelor of Science degree in soil science and chemistry with a minor in resource management, and then business opportunities presented themselves.

Sam’s father and brother, Ken Ourada Sr. and Ken Jr., owned Lucky Devil Farms in Antigo. “I really wasn’t into farming when I was a kid. I was going to college to get a real job,” Sam says. “I liked grading potatoes and helping ship them with my father and brother, Ken Jr., but other than that, I would have rather been fishing.”

Now, as a partner in Wisconsin Central Farms, Inc. of Nekoosa, and owner of a vacation home on Petenwell Lake, Sam can do both— grow potatoes and go fishing.

I know you worked for Stan Thomas Farms in Hancock and as a farm manager for Anthony Farms in Scandinavia. What made you branch out and start your own farming operation? I worked with Stan Thomas from 1981-1987, and at Anthony Farms from 1988-1992 before moving to B& D Farms.

Above: Sam Ourada of Wisconsin Central Farms, Inc., in Nekoosa, Wisconsin, grows potatoes, sweet potatoes and vegetables for processing. Wisconsin Central Farms has storage capacity for approximately 285,000 cwt. (hundredweight) of potatoes and another 80,000 cwt. of sweet potatoes raised for McCain Foods.

Left: Sweet potato slips are transplanted on Wisconsin Central Farms. With each plant touched by hand, a transplanter has 12 seats for workers, each of whom places the plant slips on the fingers of the planter. The farm runs six-to-eight transplanters at a time, so has close to 100 people working at once.

B&D had a manager who was nearing retirement, and I could work into ownership in an affiliated company called Wisconsin Central Farms.

B&D Farms was owned by Dar (Darwin) Blanke and Pat Daly, two bankers who had hired Chuck Von Einem as their farm manager. I knew Chuck, a great guy, and I knew how he ran a farm. To me, his way of running a business was philosophically smart.

So how did you end up as a partner in the affiliated company, Wisconsin Central Farms, Inc.? I became a shareholder in Wisconsin Central Farms when I started working there, in 1992, and gained more ownership over time.

Dar passed away in 2012, and in 2021, the B&D Farms partners wanted to exit active farming. Liz and I found a couple other partners and bought out B&D Farms’ shares or ownership in Wisconsin Central Farms.

We purchased their equipment and, for the most part, assumed their production contracts and were able to retain the employees, so it was relatively seamless. I could have retired. I was 62 years old, but I had a halfway decent standard of living and wasn’t ready for full retirement yet.

How many acres of potatoes and vegetables are you growing and on what rotation? We raise 8501,000 acres of potatoes, depending on contracts, including 600-650 for McCain Foods, 65-150 acres in other

processing varieties, and 200-300 acres of chipping potatoes.

We plant 400-700 acres of snapbeans, 200-400 in peas, and 600-900 acres of sweet corn, all depending on contracts.

Potatoes are mostly on a four-year rotation, probably 3.75 years on average.

What other crops does your farm incorporate? We plant 400-600 acres of soybeans to fill in the blanks, sort of as a glorified cover crop, and 150-300 acres of sweet potatoes for McCain Foods.

We rent out 400-500 acres for pickles and another 150 for field corn.

Left: Alternately saying he doesn’t like new equipment and admitting he’s a little too frugal to buy brand new machinery and implements, Sam Ourada refers to his trucks as “the rainbow coalition.”

Right: This view from the tractor during sweet potato harvest on Wisconsin Central Farms is drop-dead gorgeous.

So, your potatoes and vegetables are mostly going to the processing market? It’s all processing for potatoes and vegetables.

What varieties of potatoes do you grow? We raise about 500 acres of Umatilla, 50-100 acres of Russet Burbank, 80 acres of McCain experimental varieties, 65-150 acres of Goldrush, 130 of Atlantic, and 100-

150 acres of chip varieties for storage.

As far as the McCain experimental varieties, I’m trying them primarily because I want to find one that’s less expensive in chemical and fertility aspects. They supposedly have a variety that uses less fumigation, chemicals and fertility, less nitrogen primarily. I have a sustainability mindset.

We’ve been experimenting with bio-fumigation and seeing mixed results. We’re starting to figure it out, though, that piece of the puzzle, especially through longer rotation.

Like I say, we’re primarily in a fouryear rotation for potatoes, but it’s closer to three-to-four now with prices for rotational crops being in the dumpster. It’s hard to do, but you need to subsidize rotational crops with potatoes.

I don’t have any Goldrush potatoes this year, which we usually grow for Northern Star, but they had so many

left in storage, we didn’t plant any this year.

We had a lot of rain this year—how was the growing season and how did you deal with the elements? Potatoes held up pretty good. The rain makes it difficult to get stuff done on a timely basis.

It appears that the potatoes are set higher in the hill due to being saturated deep for such a long time. This will probably lead to more greening and an added risk for field frost.

The low areas are gone—washed out early in the season—so storage issues may not be as bad as some growers thought they would be.

We’ll see what August brings (with this interview conducted in late July), but if it’s relatively dry and not too hot, I think we have the potential for a decent crop.

It was extremely hard to maintain

Above and Below: Sam Ourada is in familiar surroundings at his office in Nekoosa, Wisconsin, having worked on potato farms most of his life, currently growing processing potatoes for the frozen and chip markets, and being surrounded by potato chip tins he’s collected over the years. “My daughter, Courtney, always knew she could get me a tin for my birthday or Father’s Day, but then I told her I ran out of room, and now she doesn’t know what to do,” he jokes.

fertility. If you missed a spot through fertigation, a wedge or something, it showed up. Most years, you might not even notice if you missed a spot, but this year, you saw it.

What can you do to ensure a good crop come August and September? Try not to overwater or over-fertilize. That’s easier said than done. We need cooperation from Mother Nature.

When do you start storing potatoes and how long can you store them? We usually start storage the last

week of September on potatoes, and September 15-20 for sweet potatoes. We store 100 percent of our sweet potatoes, generally until June, and most of our potato storages are empty by June.

We store about half of the potato crop with the other half shipped directly off the field to various plants, so that lightens our storage load but also puts us in a bind because of equipment and manpower limitations of trying to store and ship at the same time. We only have field trucks, and all end shipments are via customer trucks.

Harvest starts in early August and goes straight through until the 10th of October. The potatoes tell me when it’s time. I forecast, looking at the level of senescence and the condition of the crop.

Chipping potatoes are probably the most sensitive ones I store. I’m lucky—I can pick my harvest window—so our experience with storing chippers is pretty good. We might pull some equipment and manpower off sweet potatoes to harvest potatoes, and then go back to the sweet potatoes.

You’re one of only a few sweet potato growers in the state. Why did you decide to take them on?

I’m partnering with Shawn Bula. He was growing them, we saw an opportunity, and I kind of like the challenge of doing something new.

He had contracts and access to labor. Labor is a big part of growing sweet potatoes, as they’re all transplanted, so each plant is touched by hand. I had the land and some storage, and we bought our own equipment. I have two transplanters, and Shawn has five or six. Our harvest equipment is separate.

We take our transplanters out by him, and he brings his out to help with planting. A transplanter has 12 seats for workers, each of whom places the plant slips on the fingers

“When

of the planter. We run six-to-eight transplanters at a time, so we’ll have close to 100 people working at once. For the most part, sweet potatoes are also hand weeded.

What are the biggest lessons that you’ve learned over the years? When I was in my 20’s, I knew everything. Now at 64 years old, I realize how little I know. Growing crops, especially potatoes, is so dynamic. Everything can be rolling along and looking good, and then a weather event or something that can’t be explained happens and the wheels fall off. Don’t ever get too excited until the check clears.

When everything looks bad, it generally turns out better than you initially feared, and when everything looks great, it often turns out worse.

You’re in the middle of the Central Sands growing region. What do you like about working every day within

one of the largest potato-growing regions? I’m on the west side of Lake Petenwell at the edge of the Central Sands, somewhat in my own little world. Neighboring farms are owned

by the Wysocki’s and Okray’s, and they’re good neighbors.

We have a great relationship with the Wysocki’s, and they have always stepped up to help us when needed. We’ve tried to reciprocate. We trade stuff back and forth.

What are your biggest challenges growing potatoes and vegetables today? Contract availability. Vegetable processors have reduced acreage significantly because

Above: Of the many tools and machines in the Wisconsin Central Farms packing and washing shed, where most of the chipping potato varieties are washed, is a goldcolored Double L eliminator/grader that potatoes are run through before going into the red even flow hopper.

of excess inventory from large crops over the last couple of years.

Also, grain prices have dropped, so it’s difficult to show a profit with rotational crops. When you extend the potato rotation from three to four years, potatoes need to subsidize the rotational crops.

That makes it appealing to plant more potatoes, but access to profitable potato contracts is difficult, especially when you have storage capacity limitations. I’ve never been excited about the risk of growing open market potatoes.

Has technology helped you in those respects? When I started in this business 40 years ago, we would have never dreamed about how technology has changed farming—GPS Autosteer, irrigation with telemetry, remote handheld moisture sensing, cell phones, yield monitoring, and variable spreading.

These are just a few of the advancements that have increased efficiency and reduced manpower needs.

I don’t do a lot of variable spreading, but I have, and though I don’t have yield monitoring on our harvesters, a guy who I partner with has it on his combine.

Above: Sam Ourada says the McCain Foods experimental potato varieties he’s growing require a little less fumigation. “I think this is the first time the Royal potatoes I’m shown digging are grown in the United States on commercial side,” he says. “They get processed.” The stand-alone image of potatoes is another McCain experimental variety.

I partner with everyone that I can, Dan Trzebiatowski, Shawn Bula, and Steve Kloos, a Pioneer Seeds dealer continued on pg. 14

who grows grain. How difficult is the wait for harvest, especially with all the rain, inspecting crops, and applying crop protection products? We’ve never had to wait for harvest. Most years, we start at the end of July and harvest on and off for two-and-a-half months. We’ve always pushed to get harvest equipment ready in time. I usually say we have everything ready the day we finish.

My favorite time of year is harvest. There’s always stuff happening, and it’s a lot of fun. Some days, we’ll dig 25-30 truckloads on three fields for three different plants, and our guys say we’ll never get it done. But we always do.

We have seven full-time farmworkers, and then during harvest season, we take on another 10-15 employees. Growing potatoes is fun.

What kind of storage season do you foresee, and how does the rain affect the storage quality potential for potatoes? It’s hard to predict

because we don’t know what we’ll get in August. If it’s relatively benign, not too hot or wet, we can have a decent storage season. Our low spots are already gone. We don’t have to worry about digging them.

Do you have help from experts who specialize in certain areas of crop production and storage? Well, we lean on Ron’s Refrigeration, Dale Nelson of Nelson’s Vegetable Storage

Systems, and Pest Pros for scouting. I think Dale is very knowledgeable in process potato storage.

What is your favorite part of being a potato and vegetable grower in Central Wisconsin? I like harvesting and shipping potatoes. That’s the thing I enjoy the most. I could do that year-round, and I do nearly ship year-round on and off. It’s challenging and dynamic, and there’s always

Above: Partnering with Shawn Bula on the sweet potato side (helping each other during the planting season), Sam Ourada says he likes the challenge of growing the laborintensive crop.

something different. It’s true that no two years have been the same. I cannot compare this year or last year to any other year.

The main reason I do this is to harvest and ship.

Plainfield, WI: 715-335-6368 • 800-755-0268 Beloit, WI: 608-362-0706 • 800-924-0321 www.valleynci.com

By Joe Kertzman, managing editor, Badger Common’Tater

Held exactly one week apart, the Hancock Agricultural Research Station (HARS) and Antigo/Langlade County Agricultural Research Station (LARS) field days drew nice crowds, July 11 and 18, respectively.

With the University of Wisconsin (UW) potato and vegetable research program highly respected across the country, the field days provide an excellent opportunity to share findings and results from ongoing

trials occurring at the stations.

The HARS Field Day kicked off with a welcome and introductions from two UW-Extension specialists, Guolong Liang and Natasha Paris, the latter of whom says her job is to help farmers increase sustainability and profitability. Liang is a water quality specialist.

They introduced Steven Hall, a new UW-Madison assistant professor and Extension specialist whose work in

the Central Sands is related to farmscale nitrate leaching, capturing nitrates, scaling up measurements, and tying up extra nitrogen. Hall wore a T-Shirt reading “Stop Treating the Soil Like Dirt.”

UW Storage Research Facility Manager Amber Walker gave an update on recent hires and infrastructure overhauls before sending wagonloads of field day attendees off to the research

Above: The 2024 Hancock Agricultural Research Station Field Day, July 11, was well attended, with two wagonloads of visitors taken to fields to see firsthand the results of potato trials.

Left: Kicking off the HARS Field Day, UW-Extension specialists Guolong Liang (left) and Natasha Paris (center) introduced Steven Hall, a new UW-Madison assistant professor and extension specialist whose work in the Central Sands is related to farm-scale nitrate leaching, capturing nitrates, scaling up measurements, and tying up extra nitrogen. Hall wore a T-Shirt reading “Stop Treating the Soil Like Dirt.”

plots for presentations.

UW-Madison Associate Professor Yi Wang, Department of Plant and Agroecosystem Sciences, provided a fascinating presentation on “Using Precision Agriculture Techniques in Vegetable Crop Production,” particularly in the areas of artificial intelligence, and hyper- and multispectral imaging.

Attendees enjoyed seeing a 100-pound robot that Wang’s team acquired this year that is the perfect size for scouting snap bean and green pea fields. She outfitted the droid with orange Crocs™ so its lower

Left and Above: After Wisconsin Seed Potato Certification Program (WSPCP) Associate Director Brooke Babler presented updates on planting, inspections and direct tuber testing, Antigo Field Day attendees were transported via wagon to the research plots.

appendages would’t damage the soil, and even while wearing shoes, it can hop and turn.

Wang also set up a tent at the research station so people could see a live demonstration on the newest in drone operation and imaging, including three-dimensional imaging of underground crops like beets, potatoes and sweet potatoes.

Monica Schauer, a researcher in Dr. Matt Ruark’s UW-Madison Nutrient Cycling and Agroecosystems Lab, presented preliminary results from continued on pg. 18

They Circled

the Nitrogen Optimization Pilot Program (NOPP).

Launched a year ago, the grant program is funded by the Wisconsin Department of Agriculture, Trade, and Consumer Protection and encourages growers to conduct onfarm research pertaining to the use of commercial nitrogen fertilizer.

Over 100 partners are working to update and improve nitrogen recommendations on 77 fields using three nitrogen rates and fertigation timings, and one plot with no nitrogen applied for each trial. The McCain Foods NOPP has two sites in Coloma and Plover.

Maria Caraza-Harter, a scientist and drone operator working with Dr. Jeff Endelman in the UW-Madison Department of Potato Breeding & Genetics, gave an update on the 177 breeding lines being trialed in Wisconsin, Minnesota and Michigan.

Of those, a yellow-skinned variety, purple potato and fingerling are ready for commercialization.

Dr. Russ Groves, UW-Madison Department of Entomology, provided information on insect management in potato and processing vegetables,

explaining that the pest population arrived early in 2024 and took hold.

“Some aphid species that are migrant have now overwintered here,” Dr. Groves said. “It was a mild winter with one week of below-zero temperatures and 10 inches of snow on the ground. There was no frost in the ground.”

“We’ve seen the green peach aphid colonizing in the southern half of the state since June,” he added, “and we’re between the first and second generations of Colorado potato beetles.”

Above: At the Antigo Field Day, UW Storage Research Facility Manager Amber Walker discussed her fresh market potato variety trial and an R-Leaf trial that pulls nitrogen from the air.

Below: During the HARS Field Day, Monica Schauer, a researcher in Dr. Matt Ruark’s UW-Madison Nutrient Cycling and Agroecosystems Lab, presented preliminary results from a Nitrogen Optimization Pilot Program.

UW-Madison Soil Extension Specialist Francisco Arriaga and Ph.D. student Carl Betz gave a rundown on “Challenges and Opportunities for Measuring Neonicotinoid and Nitrate

Load Losses from Potato Production in Sandy Soil.”

CHEMICAL LEACHING

The object of their study is to track water and neonicotinoid and other chemical leaching and movement through the sandy soil profile.

Jed Colquhoun, professor, UW-Madison Department of Horticulture, is an outreach specialist and Wisconsin Integrated Pest Management (IPM) program director. His presentation at the HARS Field Day entailed water quality and weed management research updates.

Regarding the wet 2024 growing season, Colquhoun remarked, “If you want to learn about herbicide solubility, this is the year. Some diluted, leached herbicides didn’t provide weed control.”

“We have a lot of huge potatoes sitting high in the hills,” he added, “and weeds pushing through. Growers might have to desiccate twice.”

Dr. Amanda Gevens, chair, professor and Extension specialist in the UW-Madison Department of Plant Pathology, provided disease and research updates in potatoes and vegetables.

“This season has been generally hot

and wet. Visiting fields this last week, there are a lot of bacterial diseases happening,” Dr. Gevens noted. “Heat and humidity push disease risk.”

“We’ve seen pectobacterium in potato, and copper is the only true

• ATLANTIC • LAMOKA MANISTEE • LADY LIBERTY MACKINAW • PETOSKEY • BLISS

They Circled the Wagons for Field Days . . . continued from pg. 19

bactericide. We’re taking a lot of calls and photos,” she said. “So far, we’re not aware of any late blight of potato or tomato in Wisconsin.”

The HARS Field Day concluded with a social hour at the outdoor pavilion and a grilled chicken dinner with sweet corn, potato salad, and refreshments provided by the Associate Division of the Wisconsin Potato & Vegetable Growers Association (WPVGA).

UW-Madison Soil Extension Specialist Francisco Arriaga (right) and Ph.D. student Carl Betz gave HARS Field Day visitors a rundown on “Challenges and Opportunities for Measuring Neonicotinoid and Nitrate Load Losses from Potato Production in Sandy Soil.” Arriaga and Betz hold up a trap that they position 24 inches deep in the soil to capture leaching neonics and other chemicals carried by water.

Brady Patoka, who works for JayMar, Inc. and sits on the Associate Division Board, volunteered to grill the chicken and sweet corn.

LARS Station Manager Kevin Gallenberg welcomed visitors to the Antigo Field Day, thanking the Wisconsin Potato Industry Board, WPVGA Associate Division, Wisconsin Seed Potato Improvement Association, Insight FS, Quinlan’s

Left: Maria Caraza-Harter, a scientist and drone operator working with Dr. Jeff Endelman in the UW-Madison Department of Potato Breeding & Genetics, provided HARS Field Day attendees with an update on the 177 breeding lines being trialed in Wisconsin, Minnesota and Michigan.

Right: Rob Jarek from Timac Agro discussed the company’s next generation agronomy tools at the Antigo Field Day.

Equipment, Riesterer & Schnell, and Langlade County for continued

During his LARS Field Day presentation, Dr. Russ Groves, UW-Madison Department of Entomology, said it’s been an interesting year with the absence of winter and that, “We’ve had 40-50% more beetles in the Central Sands, volunteers like nobody’s business.”

donations and support.

“This year was a little challenging as far as rain goes and low spots in the field,” he said. “Nutrient runoff is a little bit of an issue.”

James Spychalla of Kohm & Spychalla, LLC addressed field day attendees, telling them about a coordinated effort to form a producer-led watershed group in Antigo.

Wisconsin Seed Potato Certification Program (WSPCP) Associate Director Brooke Babler announced Gallenberg as having joined the program and gave an update on planting and inspections.

“It’s no surprise that we’re seeing PVY,” she stated, “leading to some down-classifications. Like last year, about 9,500 acres of seed potatoes have been submitted for certification.”

Babler said the WSPCP is working with other states to get them up to speed and collaborate direct tuber testing, with no other states at this time allowed to use direct tuber testing as their post-harvest test.

Walker also attended the Antigo Field Day and discussed her variety trial at LARS.

“The WPVGA freed up funding for us to look at fresh market material generated in partnership with Dr. Endelman on potato varieties that will work for growers up here,” she

said. “We have purples and yellows that did well at Hancock last year. We’re also doing an R-Leaf trial that pulls nitrogen from the air.”

Rob Jarek from Timac Agro discussed the company’s next generation

continued on pg. 22

Left: UW-Madison Department of Horticulture Professor Jed Colquhoun’s presentation at the HARS Field Day entailed water quality and weed management research updates.

Right: UW Extension Regional Crops & Soils Educator Scott Reuss led a weed identification session for Antigo Field Day attendees.

agronomy tools such as DUO MAXX® that bonds to fertilizer and holds nutrients, not allowing them to leach. Another Timac Agro product, FERTILEADER GOLD®, was trialed on potatoes that showed no symptoms of PVY in grow-out.

Dr. Gevens gave disease updates, saying 2024 saw an earlier startup in spore production for early blight, in mid-June, and that she was anticipating lesions on the field.

“When moving sprays up earlier,

we’re seeing better control,” Gevens noted. “When you manage early, you’re doing yourself a favor.”

She gave an overview of a pink rot study at HARS, white mold studies, and variety trials with industry partners.

“We do have a common scab nursery here on this farm, and will be taking advantage of that next year,” Dr. Gevens stated.

During his LARS Field Day presentation, Dr. Groves said it’s been

Above: Antigo Field day attendees walked through a Potato Virus Y (PVY) Initiative field where treated and untreated varieties of potatoes showed varying symptoms of the virus. The PVY plots are set up as part of a Specialty Crop Research Initiative through the National institute of Food and Agriculture (NIFA), and the trials have been conducted at LARS for a few years.

an interesting year with the absence of winter and that, “We’ve had 4050% more beetles in the Central Sands, volunteers like nobody’s business. A mass of adult beetles moved from corn fields to potato fields.”

“Another insect I fear has done well this year is the green peach aphid,” Groves remarked, and then, pointing to a suction trap at LARS, continued, “We captured our first green peach aphid in that trap on May 25. It could have been from elsewhere, but I don’t think so. I think they overwintered here.”

“If you have colonizing species in the field, you should do something about it now,” he added.

Groves also discussed figuring out a way to manage without neonicotinoids (if they someday become regulated), which he estimates provide half to two-thirds

UW Extension Regional Crops & Soils Educator Scott Reuss led a weed identification session for field day attendees.

“Knowing what you’re dealing with or killing is important,” Reuss said. “Is the weed an annual, biannual or perennial?” He then held up examples of each from a variety of weeds he had gathered and brought with him to LARS.

“Identification—that’s where scouting comes into play,” he said, “preventing weeds from taking root.”

Field day attendees then exited the wagons to walk a Potato Virus Y Initiative field where treated and untreated varieties of potatoes show varying symptoms of the virus. Recombinant strains don’t show as many symptoms, making it difficult to see PVY in potato.

The PVY plots were set up as part of a Specialty Crop Research Initiative through the National institute of Food and Agriculture (NIFA), and the trials have been conducted at LARS for a few years.

Following the presentations, food and refreshments were provided by Insight FS and the WPVGA Associate Division at East City Park in Antigo.

Don’t take the time and effort to grow a near-perfect crop only to lose it in a day

By Joe Kertzman, managing editor, Badger Common’Tater

Consultation with one of the industry’s stewards of potato storage could be the key to overcoming any obstacles brought on by Mother Nature, thus ensuring a healthy, attractive, stable, and sellable crop.

No one needs to tell growers,

shippers, packers, or brokers there was a lot of rain in Wisconsin this year or mention that the heat of summer and fall could factor into storage quality of the 2024 potato crop.

You certainly don’t have to tell Dale Nelson, co-owner of Nelson’s Vegetable Storage Systems, in

Above & Left: Dale Nelson of Nelson’s Vegetable Storage Systems stands next to one of two built-in BTU control panels in his laboratory that are outfitted with iPads and remote connection so he can monitor his customers’ 300 storage buildings from his iPhone and immediately tell them when something is amiss. “It’s a godsend,” he says. “Every morning, I can look to see who’s down and give customers a courtesy call, or I just go take care of it myself.”

Plainfield, your concerns about trying to maintain a healthy potato crop after a steamy season.

Nelson’s name came up during a recent visit to the Wisconsin Potato & Vegetable Storage Research Facility in Hancock, Wisconsin, where Amber Walker, facility manager, thanked him specifically for the volunteer work in maintenance and storage-bin research he’s conducted there over the years.

His name was also mentioned by this issue’s main interviewee, Sam Ourada, as someone whose advice and consultation the grower seeks out when it comes to maintaining potatoes in storage.

With decades of experience in the

ventilation and refrigeration business, Nelson was involved in the planning stages of the Wisconsin Potato & Vegetable Storage Research Facility and awarded the contract to design and install its air system.

“I have a good working relationship with the staff. When the Storage Research Facility was initially built, there really was no one to manage it. I wasn’t going to let it fail, so for the first two or three years, I lived down there,” Nelson relates.

“They struggled getting managers until Mary LaMere came aboard, and I think she brought Amber into the fold,” he says. “Now, my time is only on an as-needed basis to fix things. Their maintenance budget is not big, but Amber and her team do a good job of maintaining the facility on a minimum budget.”

“We do donate CIPC applications to them, equating to about $6,0008,000 a year,” he remarks.

continued on pg. 26

Above: Dale Nelson invested in two $30,000 machines that calibrate humidity sensors so that customers who store potatoes and vegetables can bring their equipment to him to have it calibrated. Nelson’s Vegetable Storage Systems designs and assembles their own humidifiers, insulated doors, HDPE cell tanks, galvanized fans, and has a custombuilt cooler that holds 30 buckets for testing different sprout inhibitors and disinfectants.

Nelson appreciates the Storage Research Facility being in Hancock.

“It’s good for the industry,” he says, “and for a lot of reasons, like variety development, and researchers having all those lockers where they can conduct multiple experiments. There might be 10-15 or more experiments going on in one locker.”

“I think it’s a valuable tool,” Nelson says, “and good for the Wisconsin

industry. It gives us a leg up.”

Nelson specializes in agri-ventilation sales and service, potato sprout inhibiting, humidification, computerized controls, custom designs and consulting.

There are two things he would like growers to remember about minimizing stress before potatoes go into storage: 1. Harvest temperature—Only harvest potatoes at 65 degrees Fahrenheit or below

for process potatoes, and 60 degrees or below for fresh potatoes, to 50 degrees Fahrenheit; and 2. Hydration in the field—Keep potatoes hydrated even after vine kill.

“Care must be taken not to overwater. All we are trying to do is keep moisture from leaving the potato and losing it into the soil,” Nelson says. “A dehydrated potato is very susceptible to black spot bruising, even if proper handling procedures are followed.”

Pressure bruising is more of a field problem than a storage problem, although proper storage practices need to be followed.

“To avoid pressure bruising, keep potatoes hydrated and don’t harvest them hot,” Nelson imparts. “For the first 20 years or so that I was in this industry, the top temperature

Left: Nelson’s Vegetable Storage Systems specializes in agri-ventilation sales and service, potato sprout inhibiting, humidification, computerized controls, custom designs and consulting.

RIght: Dale Nelson was involved in the planning stages of the Wisconsin Potato & Vegetable Storage Research Facility and awarded the contract to design and install its air system.

consultants said you should harvest potatoes was 60 degrees down to 50 degrees. Somewhere along the line, the gauge moved up to 65 degrees down to 50 degrees.”

“A fresh market potato should not be harvested above 60 degrees,” he stresses. “The respiration curve once it gets to 60 degrees goes straight up, and after that weight loss and dehydration are significant.”

This adds to pressure flattening/ bruising. This is probably unrealistic but needs to be added to the overall management, as potatoes harvested warm should probably not be those designated as long-term storage potatoes.

For the most part, Nelson says growers are conscious about not bruising potatoes in the field or shed by using the correct conveyor belts, liners and implements, and not allowing tubers to drop long distances or at high heights from one implement to the next along the line.

“They spend all this time and money growing the near perfect crop, and come harvest, forget all about sticking to temperature parameters for harvest,” he says.

“I realize some of the largest farms don’t have the luxury of harvesting every field at the ideal temperature,” Nelson allows, “but we have to realize the consequences of the action.”

The same care expressed in a conversation with him reemerges when taking a quick tour of Nelson’s Vegetable Storage Systems. His passion manifests itself within the offices, shop, lab, and storage facilities he’s built and added onto over the years in Plainfield.

There are the two $30,000 machines that calibrate humidity sensors so that customers who store potatoes and vegetables can bring their relative humidity sensors to Nelson’s to have them calibrated.

“To avoid pressure bruising, keep potatoes hydrated and don’t harvest them hot.”

– Dale Nelson, Nelson’s Vegetable Storage Systems

• Maximizes nutrient release from crop residues and the soil

• Extends existing nutrient availability later into the season

• Supports easier plantability in the spring

• Promotes more even crop emergence

• Optimizes yield potential for the next crop

Importance of Proper Potato Storage. . . continued from pg. 27

He walks through a sterile lab where he developed systems to clean and calibrate the humidity sensors.

“The remote computerized controls are a godsend,” Nelson says. “Every morning, I can look to see who’s down and give customers a courtesy call, or we just go take care of it. Sometimes, they call us for service as the service guys are pulling into their driveway.”

Other customers who want to do as much as they can themselves download the app, troubleshoot, and it tells them what sensors they need to replace and will even send them a text or email.

“Computerized controls have gotten a lot more dependable,” Nelson states. “If we didn’t have computerized controls right now, I’d have to hire one or two more service guys.”

“The equipment in general has become more reliable,” he adds. “Using underground floor systems also allows a little increase in air volume. We’ve advanced to going away from aboveground culverts to underground culverts or below-

ground floor systems.”

“The underground floor systems are a lot more expensive,” Nelson admits, “but you don’t need people onsite to move pipes around.”

DESIGN & ASSEMBLY

Nelson’s Vegetable Storage Systems designs and assembles their own humidifiers, insulated doors, HDPE cell tanks, galvanized fans, and has a custom-built cooler that holds 30 buckets for testing different sprout

inhibitors and disinfectants.

The company carries a large inventory of parts and machines to include 10 different kinds of refrigeration compressors, and shelves filled with 7 ½- to 25-horsepower fan motors.

“We cannot expect our customers to wait on our suppliers,” he says.

“When something stops working, you can’t tell them you’ll check into ordering the parts or units they need. The customer has a very valuable crop and Nelson’s tries to get them running as quickly as possible.

“We are 100% agriculture related,” Nelson stresses, “and probably 80% of that is in potatoes. While we were concentrating on ventilation, refrigeration and sprout control, we started getting involved with products to help minimize potato disease in storage that took us into a whole new area that has been good for us and the industry.”

Nelson says there is no substitute for CIPC when it comes to sprout

inhibitors for potatoes. “For many years, our main goal was to cut back on the amount of CIPC I was using. I don’t believe it’s a harmful chemistry,” he notes, “but we need to be stewards of our own industry.”

“So, we started blending CIPC with surfactants and found it was very beneficial to sprout control and reducing the amount of CIPC. Finding the correct surfactants was a challenge,” Nelson says.

“One hundred percent of our applications have a surfactant blended with the CIPC,” he stresses. “Probably 50 percent of applications blend some sort of green chemical with CIPC to get a synergistic affect that aids in sprout control and lowers the amount of CIPC used.”

Green blending agents include clove oil, mint oil, essential oils, and Smart Block. Each of these and 1,4-dimethylanphthalene can be used as a standalone product for sprout control.

“The amount of chemicals needed to treat potatoes and control sprouting is directly related to the

and more chemical application is necessary to keep sprouting under control.

When asked if he thinks CIPC will be regulated or outright banned in the United States like it has been in Europe, Nelson replies, “I hope not.”

“Last year was a perfect example of a much-stressed crop,” Nelson points out, “including a hot growing season, and a hot, dry harvest. We did have some quality issues in storage, but if we tried to control the sprouts without CIPC, it would have been a disaster.”

“Here’s the difference,” he says. “We’re a big country. In Europe, using fresh market potatoes as an example, they take them out of storage, put them on store shelves, and in a very short time, maybe even three to four days, they’re throwing them away because they have such a short shelf life.”

“There’s no way we could survive like that,” Nelson states. “It may take potatoes in the U.S. three weeks or more before they reach the shelf.”

VALUABLE TOOLS

alternatives,” he says, “blending them with CIPC, or in certain circumstances, using them as standalone tools. But it’s going to cost the growers. The cost of each comparable product is prohibitive and could be 5-10 times the price compared to CIPC.”

“If we’d be forced someday to live without CIPC, the grower cost would be very high, and quality of the product for the most part would not be what we’d consider acceptable,” Nelson imparts.

There is more to storing potatoes and minimizing stress than what is talked about in this article, but it is a start and hopefully gives some growers something to think about, and if they want, ask more questions.

In the meantime, being in such a small industry, Nelson says people who need help or consultation with potato storage know who he is and how to find him.

“We’re a one-stop shop and follow

As revealed at the 2024 Grower Education Conference & Industry Show, Buch Fencil, formerly of Fencil Urethane Systems, is partnering with Zander Solutions, introducing the company to Central and Northcentral Wisconsin potato and vegetable growers and associated businesses.

Zander Solutions, which has 50 years of experience in the spray foam industry, expanded its operations to include the location in Wisconsin Rapids where Fencil Urethane Systems operated for many years. Butch is the former owner of Fencil Urethane Systems.

“We purchased our first urethane spray foam machine in 2022 and felt that it was part of what we needed to insulate full wall cavities for air barriers,” explains Frank Acker, president of Zander Solutions.

“The spray foam acts as an air barrier on the outside of buildings.”

“We were into the waterproofing of entire buildings, from the foundations on up, coming up out of ground and doing air barriers on

walls. That’s primarily why we got into urethane spray foam insulation,” Acker explains.

Through one of his vendors, Acker heard there was equipment for sale in Wisconsin Rapids from Fencil Urethane Systems, which was closing its business. Nick Laudenbach wanted to sell all the equipment, so Zander Solutions purchased everything (not the business, but the assets), including the trucks, some scissors lifts, and scaffolding.

“After talking to Butch, we decided to keep the business and clientele intact up there, operating as our business, not Fencil Urethane Systems. There was a market in the Wisconsin Rapids and Central Sands area that needed to be filled,” Acker says. “Butch was

Above: With 50 years of experience in the spray foam industry, Zander Solutions has expanded its operations to include the old Fencil Urethane Systems location in Wisconsin Rapids, partnering with Butch Fencil as a semi-retired liaison. Standing from left to right in the Zander Solutions booth at the 2024 Industry Show, in Stevens Point, are Frank Acker, president of Zander Solutions, Butch, and then Shawn Klingforth and Jason Pavloski of Zander Solutions.

the catalyst who got us up there and interested in the urethane spray foam end of the business.”

With operations in Verona and Waukesha, Wisconsin, Zander Solutions made the decision to expand its operations, which now include the central part of the state all the way to the peninsula of Green Bay in the east, and La Crosse to the west.

“I had no idea the potato and onion operations were as big as they are in Central Wisconsin,” Acker admits. “I knew it was an area where they grew a lot of produce, but I didn’t have any idea about the sizes of their storage buildings and equipment sheds. They insulate the heck out of those buildings for climate control and storability.”

A SPRAY FOAM ICON

“Butch is an icon up there when it comes to spray foam,” Acker continues. “I looked at retaining Butch as maintaining contacts and a certain level of experience. The knowledge he has in the industry is a real asset to us up there.”

“When this all came about, I realized quickly that Butch’s way of doing business and how I operate are weirdly identical, a great fit,” Acker says. “He’s a semi-retired liaison for me, my eyes and ears up there, looking at jobs and issues as they arise.”

Though Zander Solutions offers drain tile services, foundation crack repairs, basement waterproofing, structural building repairs, subpumps and exterior waterproofing, plus more, most of those services are not available through the Wisconsin Rapids location.

“My plan is to offer a lot of those services there,” Acker says. “We work with Findorff and Scherrer Construction, each of which has a lot of guys up in that area. Having crews up in that area allows us to serve people quicker and easier. Over time,

we will develop more of what we do down here in the Rapids area.”

“In this industry, it’s a challenge making sure we keep up on schedules. No matter what you do, schedules are tight,” Acker says. “The next crew can’t come in and put catwalks up in the barn or finish electrical until we’re done spray foaming. It’s like 911, we’ve got to go.”

Acker says the keys are to offer a product that performs well, stay on time, back it up with service and knowledge gained from years of experience, offer low costs and efficiencies, build relationships, and maintain schedules.

“We stand behind our work no matter what it is; it’s pretty simple,” Acker states. “Price your job fairly and stand behind your work. It’s a lost art in business now. Being passionate about you do—it bleeds through the company and determines what is acceptable and what is not. Be fair and good things will happen.”

“I’m hooking my horses to Butch’s wagon,” he concludes. “He will help us open doors through his knowledge and relationships.”

The Central Wisconsin Farmers Collaborative, a group of eight WPVGA-member farms in the Little Plover River/Wisconsin River Watershed, hosted a Producer-Led Field Day on July 30, in conjunction

with Wisconsin Department of Agriculture, Trade and Consumer Protection (DATCP) specialists.

The field day included stops at Plover River Farms and Isherwood Farms to

view on-farm practices designed to protect the watershed. Dan Walsch, agronomist at Plover River Farms, described several initiatives including potato and sweet corn inter-seeding, planting green into living rye with sweet corn, companion cropping clover and sweet corn, and the use of pollinator plantings.

The field day also included a stop at Isherwood Farms in Plover to view their Nitrogen Optimization Pilot Project, which involves using humic acid to prevent leaching.

Above: Dan Walsch (left), agronomist at Plover River Farms Alliance, Stevens Point, describes inter-seeding practices in a corn field as part of a Producer-Led Watershed Protection Grant program tour of the farm, on July 30.

Left: Isaac Isherwood (third from right) of Isherwood Farms, Plover, discusses the farm’s Nitrogen Optimization Pilot Project aimed at preventing the leaching of nitrogen into groundwater. There was an excellent turnout at the Producer-Led Field Day, with over 25 individuals attending.

Dutch machine builder is reliable partner for any agricultural entrepreneur

After decades of working together with North American clients, Dutch machine builder Eqraft now opens a branch on American soil. Operating from Tri-Cities, Washington, Eqraft Inc. is a reliable partner for any agricultural entrepreneur looking to future-proof their business.

Eqraft focuses on future-proofing agricultural business, offering stateof-the-art machinery and software, as well as consultancy based on extensive technical and practical knowledge built up since the 1980s.

The Dutch tech company designs and builds processing lines and factories for onions and potatoes worldwide. Many of those clients are in North America.

For instance, Eqraft has longstanding

collaborations with Target Ag, Bybee Produce, Hartley Produce, Blue Sky Management, and Sunset Produce, all in Washington; Northwest Onion of Oregon; Baker & Murakami and Treasure Valley Farms of Idaho; Onions Etc. in California; Onions 52

continued from pg. 33

(Utah); Torrey Farms (New York); and Nova Agri (Nova Scotia).

Eqraft started out as a repair and construction company for agricultural machines. The company made a name for itself with the closed onion topper, which turned out to be a great success and is still part of the portfolio.

Later, weighing and packing machines were added to the mix. Now, one of Eqraft’s most important machines is the Eqrader. It sorts produce automatically and at a high rate of speed by quality, size, weight, shape, and color, separating each into a dozen or more different boxes.

Thanks to the cameras and infrared technology, rot on the inside of produce can be detected easily.

To design and build efficient and reliable agri-factories, Eqraft works

together with dust extraction expert Modesta and palletizing specialist Symach. Together, they form the Onion Tech Alliance to guarantee an integrated approach, from reception, grading, dust extraction, internal logistics and storage to packing, palletizing and the handling of

residual flows.

In recent years, Eqraft has grown rapidly, both in the number of projects and new employees. This continuous growth led to a brand new headquarters, which opened earlier this year in Emmeloord, the Netherlands.

Founding Eqraft Inc. and having permanent representation in the United States was a logical next step. The new facility in Tri-Cities, Washington, is within one of the country’s prime agricultural regions, allowing Eqraft to better serve the North American market.

Eqraft Inc.’s service center is operational and features a warehouse, workshop, office space, service truck, and a diverse blend of American and Dutch employees. Most common spare parts are in stock to make sure installation and maintenance can be done quickly and efficiently.

We can’t wait to welcome existing and new North American partners at Eqraft Inc.

Contact Eqraft, Inc. for service or parts at (509) 420-4472, or email support.na@eqraft. com / parts.na@eqraft.com. For sales or other inquiries, call +31-527-256-130, or email info@eqraft.com. Eqraft: 2513 Logan St., Unit 101, Richland, WA 99354, https://www.eqraft.com.

Joint venture focuses on optical sorting technology for potatoes and onions

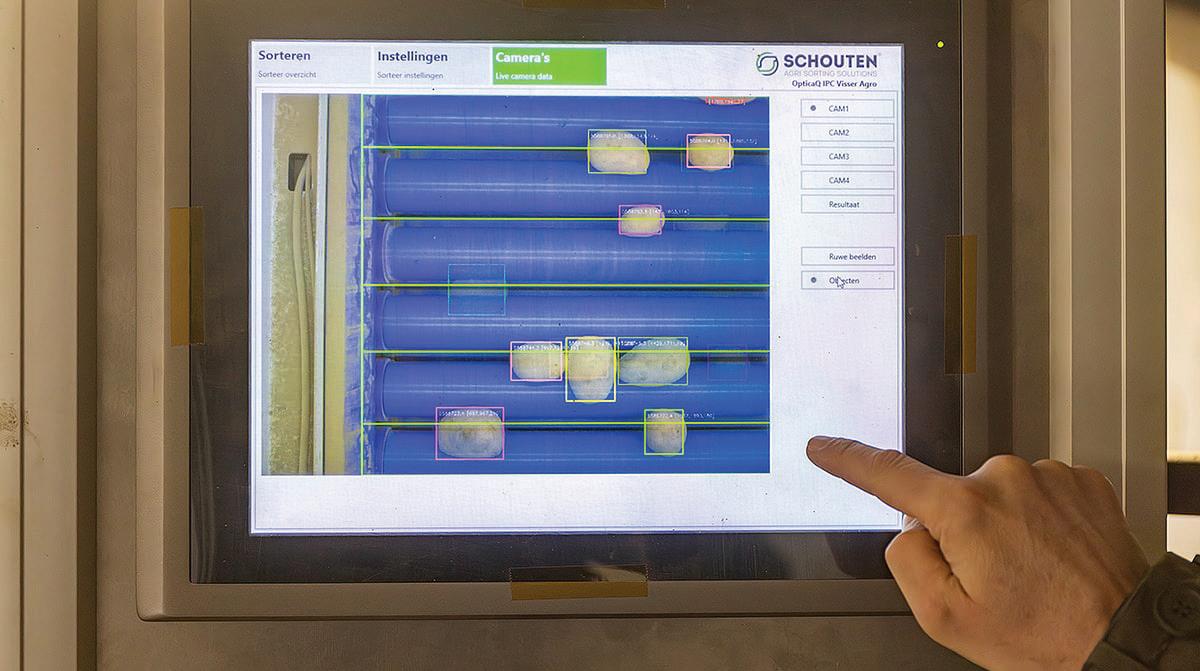

As of May 1, 2024, Tolsma-Grisnich and the Invaro Group (Schouten) will be joining forces in the field of optical sorting of potatoes and onions.

The partnership means that TolsmaGrisnich and the Invaro Group are embarking on an intensive collaboration. As part of this collaboration, Tolsma-Grisnich will take on all commercial and service activities of the Schouten Optica Q and Optica CS globally. The Invaro Group will continue to focus on the development and production of Optica technology and machinery.

As leaders in the agricultural and horticultural sector, both companies

Together, they will offer innovative solutions that simplify the work of

The Schouten Optica Q and Optica CS are a valuable addition to Tolsma-

By Dana Rady, WPVGA Director of Promotions and Consumer Education

Wisconsin potatoes and Healthy Grown program highlighted in episode

Sustainability: Years ago, that term didn’t mean much and certainly didn’t resonate with most of the population. As time has passed, however, so have consumers’, and specifically younger consumers’, perceptions and understanding of that word, especially as they search for and become more educated about the origins of their food and how it’s produced.

In fact, while many agree to the core components of sustainability and what it encompasses, the term itself

is often synonymous with phrases like “regenerative agriculture,” “conservation practices,” etc.

Regardless of the way you refer to sustainability, the fact remains that Wisconsin potato and vegetable farmers take it seriously and practice it regularly in all aspects of their organizations.

This is why sustainability and Wisconsin’s Healthy Grown program were featured in the latest Mad Dog and Merrill television episode.

Mad Dog and Merrill are a grilling duo who take Wisconsin potatoes to a new culinary level. Now if you already grill Wisconsin potatoes on a regular basis, then you might be one step ahead of the game. Or you might watch their show and get inspired!

Mad Dog and Merrill have made appetizers, main dishes and even desserts using Wisconsin potatoes, and all on the grill.

During this episode, while grilling, Mad Dog and Merrill learned from Conservation Agronomist Seth Olson,

of Alsum Farms & Produce, about sustainability and conservation efforts on the farm, which are practices other potato and vegetable growers across the state implement as well.

The episode was filmed directly in front of a field that experienced a prescribed burn in the spring and is now showing beautiful signs of

regrowth and beneficial habitats for native plants, animals and insects.

Left: A compass plant blooms on a restored prairie at Alsum Farms & Produce following a Spring 2024 prescribed burn.

Prompted by Mad Dog’s inquiries, Olson discussed things such as the significance of biodiversity in prairies and the fact that the term includes grass and wildflowers. He also mentioned the importance of prairies when it comes to flora like the compass plant, animals such as birds, reptiles, amphibians and mammals, and insects like the rusty patched bumble bee.

Right: Mad Dog flips Wisconsin potatoes on the grill in preparation for making a delicious and hearty potato soup during the July 23 “Midwest Grill’n” episode shoot at one of the fields, in Arena, owned by Alsum Farms & Produce.

continued on pg. 38

Olson also touched on the importance of prescribed burns in promoting the vitality of a prairie, noting that “all native prairie plants are adapted to withstand fire.”

Most prescribed burns in the Wisconsin potato and vegetable industry occur through participation in the state’s Healthy Grown program, with some growers conducting a burn

While Olson was helping to educate the audience about sustainability efforts in Wisconsin, Mad Dog and Merrill kept busy making potato soup, which they thickened with a separate serving of mashed potatoes, and open-faced tuna melts using Wisconsin potato “planks” instead of bread.

It was the perfect way to include all the nutritional benefits Wisconsin potatoes naturally provide while also indulging in the full flavors of comfort food.

The episode began airing the week of August 11 and will repeat throughout the months ahead. Visit https://www.maddogandmerrill.com/ midwest-grilln-tv-show.html for a list of stations and times based on your area.

Left: Silky-smooth Wisconsin potato soup was featured on the Mad Dog and Merrill episode filmed on a restored prairie owned by Alsum Farms & Produce.

Right: Fast Freddie, piano player for Mad Dog and Merrill’s “Midwest Grill’n” television series, gives his hands a break as Alsum Farms & Produce Conservation Agronomist Seth Olson (shown) surprises the group and takes over, sharing his talent at the July 23 episode shoot.

Potato packers from across North America exceed their expectations with Ellips grading technology

Do you want to increase your grading capacity? Are you facing challenges related to labor issues and inconsistent product quality? The world of potato packers is challenging. Batch qualities vary, but customer demands remain consistently high. With our industry leading grading technology, you can optimize your operational performance while better addressing your customers’ needs.

Get the most value from every potato After a season of hard work, you want to be rewarded with maximum harvest value. Regardless of weather conditions or batch quality, you can always deliver consistent quality with the Elisam Potato Grading Machine (powered by Ellips grading technology).

What are the main powerful benefits of grading technology?

4 Meet any demand;

4 Powerful defect detection;

4 Maximize throughput;

4 Consistent quality;

4 Less labor requirements.

Already dozens of U.S. potato packers use the Ellips-Elisam grading machine daily. What challenges did they face? What results have they achieved?

Discover the customer stories from Wada Farms, Folson Farms, Pioneer Potatoes and O.C. Schulz & Sons in this article.

1. Wada Farms surpasses its ROI in the very first year using optical grading technology

“This project exceeded our expectations from the initial planning phase through the final production results, including surpassing our return-on-investment objectives in the very first year. All our objectives related to capacity, efficiency, quality and cost reductions were achieved. In fact, within the first 30 days of operation, we hit our first production milestone, reaching the throughput rate (i.e., pounds per hour) that we had established for year end. The early successes boosted our confidence and enabled us to rely on the system to meet expanded production and quality goals.”

Kip Yeates - Wada Farms

Main challenges Wada Farms:

1. Enhance production efficiency considering labor and costs.

2. Deliver consistently sized and graded quality products.

3. Improve grading accuracy to avoid false positives and increase returns.

4. Hand sorting is prone to human error and oversight.

5. Mechanical sizing and manual sorting struggle with grading, handling, capacity, and market demands.

Achievements Wada Farms:

4 Labor related to manual sizing and sorting was reduced by 75%.

4 Improved quality consistency and operational flexibility to respond to customer demands

4 Increased grading capacity by over 20%.

2. This is how Folson Farms guarantees superior potato quality

“Folson Farms works to produce quality potatoes in the rich soils of the Red River Valley. Our focus is to provide customers with a consistently quality product. Ellips-Elisam stood out for its gentle potato handling, unmatched quality consistency and throughput. Our operations are now more efficient with fewer labor requirements and higher capacities.”

Casey Folson – Folson Farms

Main challenges Folson Farms:

1. You sometimes have difficult batches.

2. The type of defects that affect potato quality vary from year to year.

3. With hand grading it’s difficult to achieve the quality you want.

4. Labor is hard to find.

5. The throughput per hour was not sufficient to handle the potential volumes.

Achievements Folson Farms:

4 Increased quality consistency

4 Improved production capacity to expand business potential.

4 Created a reliable, efficient operation that is less dependent on labor.

3. Smaller-scale grower Pioneer Potatoes achieves big results with grading technology

“Pioneer Potatoes understands the fundamentals of effectiveness and efficiency in grading and provisioning potatoes. Despite smaller acreage, we prioritize delivering topquality potatoes. We maximize our harvest, producing a high percentage of A-size, premium potatoes. I am happy and proud that we, as a relatively small family farm, have been able to effectively deploy and utilize Ellips-Elisam’s potato grading and packing technology. I know that I am the customer, but I am grateful that I can use this grading technology every day.”

Wylie

Thulen – Pioneer Potatoes

Main challenges Pioneer Potatoes:

1. Difficulty in finding and retaining workers year-round.

2. Rising labor costs and competitors investing in automation.

3. Manual grading can’t compete with advanced grading technology.

4. Inconsistent defect detection with manual sorting.

5. Difficulty in quickly changing grading standards with manual processes.

Achievements Pioneer Potatoes:

4 Monumental cost savings by reducing our workforce by 50%.

4 Improved product quality through powerful defect detection and consistent grading.

4 Accurate classification across all grades optimizes crop value and minimizes waste.

4. This is how O.C. Schulz & Sons takes customer satisfaction to perfection

“The customer is always right” is our motto at O.C. Schulz & Sons. We understand the importance of customer satisfaction and strive daily to exceed expectations. We ensure consistent quality and on-time delivery. Our high-quality red and yellow potatoes are renowned for their clear skin and outstanding taste. In the past, we faced limitations in meeting all customer needs. It’s hard to put the transition in words since the installation of the Ellips solution has changed our operation so significantly. Everything is much easier now. We have a peace of mind because we can respond to any customer demand - we never have to say no anymore”

Dave and Andy Moquist - O.C. Schulz & Sons

Main challenges O.C. Schulz & Sons:

1. Labor shortages occasionally disrupt operations.

2. Seasonal weather variations make consistent quality delivery challenging.

3. Manual sorting is inconsistent and tiresome.

4. Hand sorting leads to misclassification of potatoes.

5. Labor shortages and quality issues limit potato processing and packing capacity.

Achievements O.C. Schulz & Son:

4 Reduce dependency on labor by eliminating virtually all manual grading.

4 Improved quality consistency to increase customer satisfaction.

4 Increased production capacity to improve on-time deliveries and expand business opportunities.

Are you looking into optical grading technology and machinery?

Your potato business is unique. It’s why every partnership we have with customers is different. With complex individual needs, business pressures, harvest characteristics and more. Our aim is to work closely with you to focus on what will work for your specific packhouse and maximize your return on investment.

Anticipated annual Associate Division tournament raises funds for research, scholarships and industry priorities

By Joe Kertzman, managing editor, Badger Common’Tater

The ag industry was just glad it wasn’t raining, something they’ve had enough of this growing season, during the 2024 Putt-Tato Open at Lake Arrowhead golf course in Nekoosa, Wisconsin. The day of the tournament, July 10, dawned with blue skies and comfortable temperatures.

Forty-two teams of four players each (some with three) hit the course for the annual four-person scramble tournament, the biggest fundraiser of the year for the Associate Division of the Wisconsin Potato & Vegetable Growers Association.

Thanks to their support and that of sponsors and donors, the 2024 PuttTato Open reached its fundraising goals, with proceeds going toward agricultural research, college scholarships and other industry causes to be determined by the Associate Division throughout the coming year.

A perfect mid-season opportunity for

Above: It was such a beautiful day at Lake Arrowhead golf course for the 2024 PuttTato Open, July 10, even the deer were playing through.

Below: Playing for the T.I.P., Inc. team, Mark Nichols smashes one off the tee.

the Wisconsin potato and vegetable growing community to gather before harvest for camaraderie, networking, and fun, the annual tournament is a favorite among industry players.

This year, via sponsorships, donations and raffle ticket and mulligan sales, the event raised more than $23,000 to go toward several worthy causes. The total includes $1,130 in mulligan sales and $2,180 in raffle ticket sales to golfers.

The golf outing is a major undertaking, with Associate Division board members gathering outside the clubhouse the morning of the event to check in groups and sell mulligans to golfers who always prove generous in their support of the industry.

WPVGA Executive Assistant Julie Braun and Financial Officer Karen Rasmussen once again coordinated the golf outing, setting up a booth at the fourth hole to sell raffle tickets and engage golfers throughout the day.

Progressive Ag, Rural Mutual

Insurance—the Zinda Insurance Group of Plover, and Jim Wehinger, Adams—and Volm Companies, Inc. sponsored lunch hot off the grill outside the clubhouse.

GENEROUS SPONSORS

McCain Foods donated appetizers for the awards banquet, while AgCountry Farm Credit Services, and Sand County Equipment/ Lemken/Lockwood were Gold Dinner Sponsors, helping provide a delicious supper at the course.

Nichino America stepped up as the Premier Event Sponsor this year, and Silver Sponsors included Big Iron Equipment/Spudnik and Compeer Financial. See the Putt-Tato Open

“Thank You” ad in this issue for a full rundown of all the generous companies helping make the event a success.

Associate Division Board President Matt Selenske announced the tournament winners after dinner

during the awards banquet, and, with the help of WPVGA staff, awarded prizes to individual hole winners, and drew names and gave out raffle and door prizes.

Prize money was given for top scores and some impressive, donated items went to those whose names were

drawn for raffle and door prizes. The industry support was impressive

as always, and everyone who participated in the Putt-Tato Open contributed to a good cause and walked away winners.

Nearly all segments of the potato and vegetable growing industry contributed, including growers, researchers, potato brokerages, processors, insurance companies, banks and lending offices, real estate agents, fertilizer and chemical plants, implement and equipment dealers,

and irrigation, refrigeration, trucking, storage and construction companies.

Hole sponsors hosted games and contests, and gave out prizes, gifts, and refreshments on the course, providing fun at each stop along the way.

In addition to raffle and door prizes each year, the Putt-Tato Open includes hole awards for longest drives and putts and being closest to

the pins, as well as monetary prizes up for grabs to golfers with the best shots.

In addition to providing a muchneeded break during the growing season, the Putt-Tato Open generates significant funds that are put right

Above: Nick Hayes of Roberts Irrigation chips one out of the rough at Lake Arrowhead golf course in Nekoosa.

Above Right: Nabbing Second Place at the Putt-Tato Open with a score of 58 was one of two Sand County Equipment teams, here represented by, from left to right, Jay Halbert, Joe Dahlen, Jeff Lauritzen, and Pauly Cieslewicz.

Bottom: Jeff Sommers of Wysocki Family of Companies tees off at the 2024 Putt-Tato Open.

continued on pg. 44

Eyes on Associates . . .

continued from pg. 43

back into the industry.

2024’s sold-out tournament is a testament to the dedication and generosity of the Wisconsin potato and vegetable industry. Look for the 2025 Putt-Tato Open to be at The Ridges Golf Course, in Wisconsin Rapids, and in the surrounding area for years to come.

Above: Chad Heath of Family Insurance Center won a Blackstone griddle door prize donated by Pest Pros, a Division of Allied Cooperative.

Left: The good group of guys making up the BMO Bank team includes, from left to right, Paul Salm, Jason Blenker, Nate Knutson, and Lucas Wysocki.

Above: Frank Acker of Zander Solutions chips a marshmallow toward a hula hoop at the Vista Financial Strategies sponsored hole as his teammate, Dale Sankey, Prevail Bank, looks on in amusement. If a player landed a marshmallow in the hoop, their name was entered into a drawing for a chance to win both a bottle of Polish vodka and one of potato vodka.

Top Left: Kelsi Mueller of Nichino America, Inc. had the support of her teammates Austin Headlee (left) and Brayden Montgomery (right) when attempting a long putt.

Bottom Left: All smiles, the Wysocki Family Farm team includes, from left to right, A.J. Bussan, Keith Glodowski, Andrew Pribramsky, and Dakotah Smiley.

PREMIER EVENT SPONSOR

Nichino America, Inc.

GOLD DINNER SPONSOR

AgCountry Farm Credit Services

Sand County Equipment | Lemken | Lockwood

SILVER SPONSORS

Big Iron Equipment/Spudnik

Compeer Financial

LUNCH CO-SPONSORS

Progressive Ag

Rural Mutual Insurance:

Zinda Insurance Group, Plover, WI & Jim Wehinger, Adams, WI

Volm Companies, Inc.

APPETIZER SPONSOR

McCain Foods USA

GOLF BALL SPONSOR

Sand County Equipment

RAFFLE PRIZE SPONSORS

• Blackstone 28” Griddle

– Pest Pros & Allied Co-op

• Pedal Tractor

– Swiderski Equipment

• Decorative “HOME” Sign

– Jay-Mar, Inc.

• RTIC Cooler with Beverages

– BMO Bank

• Fishing Gift Basket & Beverage Gift

Basket – EXIT Realty CW

• Gift Certificate for Rounds of Golf

– Lake Arrowhead

• Custom Bean Bag Toss Set

– Vista Financial Strategies, LLC

• Kayak & Paddle

– C & D Professional Insurance

Services & Adventure Outfitters

• Cooler with Beverages

– Green Bay Packaging

• Variety Gift Basket

– Food + Farm Exploration Center

HOLE SPONSORS

Adams-Columbia Electric Cooperative

Allen Supply Company, Inc.

Anderson O’Brien, LLP

Ascendance Truck Centers

Bayer

Blenker Construction

Compeer Financial

EXIT Realty CW

Express Employment Professionals

Food + Farm Exploration Center

Gowan USA

Green Bay Packaging, Inc.

Jay-Mar, Inc.

Keller, Inc.

McCain Foods USA

MetLife Agricultural Finance

Modern Produce Equipment

Nelson’s Vegetable Storage Systems

Phospholutions

Portage County Bank

Prevail Bank

Progressive Ag

Riesterer & Schnell

Roberts Irrigation Company

Soiltech Wireless

T H Agri-Chemicals, Inc.

T I P, Inc.

The Little Potato Company

Thorpack LLC

Trace Genomics

TriEst Ag Group

Vista Financial Strategies, LLC

Warner & Warner, Inc.

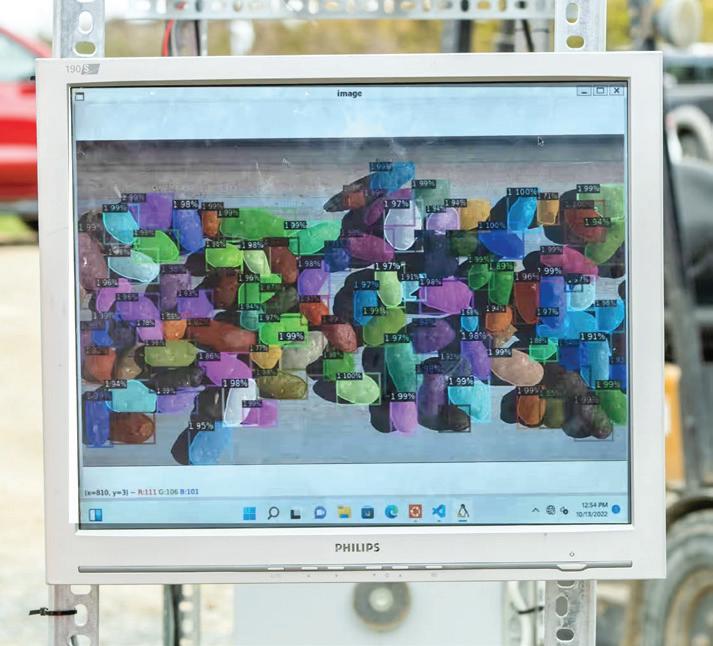

It’s a fascinating concept quickly becoming a reality in potato sheds worldwide

By Scott A. Parrott, business development, Smart Vision Works

Imagine an assistant who can understand 70 languages, manage dockside grading and payout, continuously monitor production performance, adjust as needed, and perform all quality control functions and shipping.

Moreover, this employee could provide you with production status reports and sales information 24/7 upon request.

Technologies like the SiftAI™ Artificial Intelligence (AI) Platform from Smart Vision Works (a KPM brand) continuously monitor a sizer’s infeed and adjust sizer kickers to keep them in time.

Technologies such as these incorporate human-defined AI models to rapidly assess potatoes for product size and defects with impressive accuracy and efficiency.

Sheds relying completely on manual potato sorters have a typical recycling rate of 20-40%. Sheds with active lane monitoring have a recycling rate of about 4%. This difference translates to hundreds of additional

Above: Multiple AI (Artificial Intelligence) camera systems are positioned over sorting lines at a potato facility.

Below: An AI model automatically calculates the “old bruise” defect percentage on a potato moving at full-line speed.

sacks produced per shift without additional labor costs.

An AI model can also identify mechanical issues with kickers and instantly communicate with the maintenance team for needed repairs.