Fores t Produc ts

By Aislinn Sarnacki

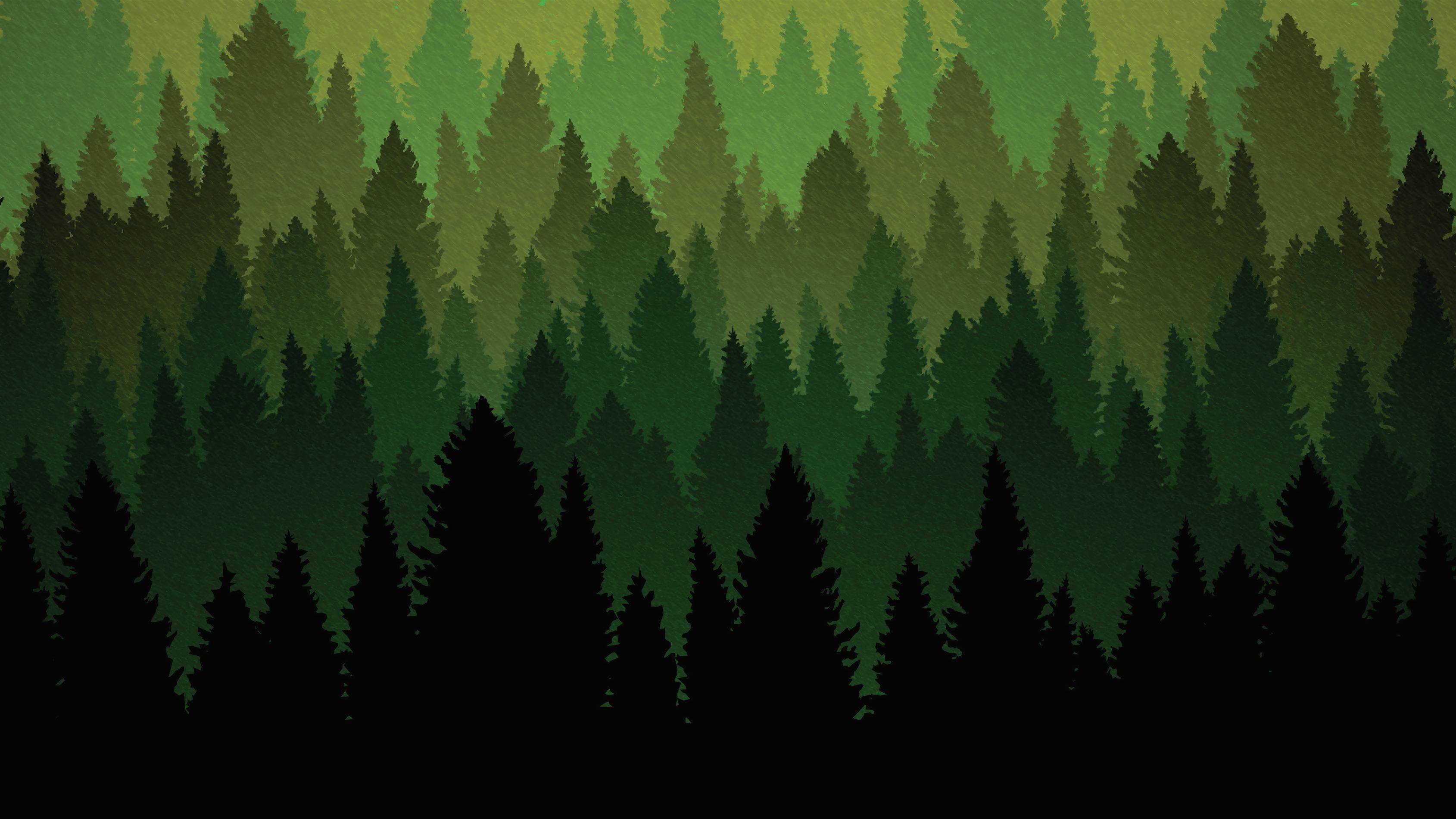

he most forested state in the nation, Maine is a land of trees. Towering pines, bone white birch, fragrant firs, and windswept spruce. The people of this area have long relied on these abundant resources.

For thousands of years, the indigenous tribes of the region have crafted birch bark canoes and brown ash baskets, sealed seams with pine pitch sap, and carved root clubs out of gray birch and poplar.

continued on page 10

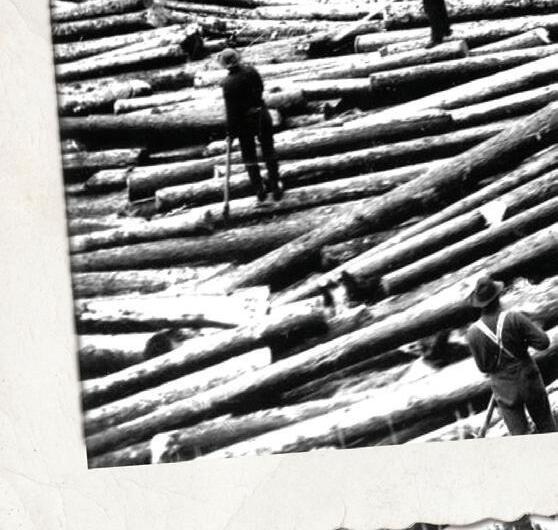

Courtesy of the University of Maine

Maine’s forest-based economy has long been a pillar of the state’s identity, providing jobs, sustaining communities, and nurturing the environment. However, as global economic and environmental challenges evolve, Maine has an opportunity to position itself as a leader in sustainable forestry innovation.

BUILDING ON MAINE’S FOREST HISTORY: OUR FOREST OPPORTUNITY ROADMAP Faced with the challenge of declining markets and multiple papermill closures across the state, a core of collaborators across the sector including industry, communities, government, education, and non-profits came together to establish Forest Opportunity Roadmap / Maine (FOR/Maine — formaine.org). FOR/Maine developed a strategic roadmap for adapting and diversifying Maine’s sustainable forests and products to maintain a leading role in the global forest economy and support economic prosperity in the state. This roadmap focused on identifying emerging markets and opportunities in the forest sector, responsible forest management to protect ecosystem health, supported the development of forest-based technologies to market, and empowered local communities in decision-making processes. Throughout FOR/Maine, the University of Maine has served as a key partner to the state in leadership, resources, and technical expertise.

Based on the historic FOR/Maine effort, Maine was designated a Forest Bioproducts Advanced Manufacturing Tech Hub by the U.S. Economic Development Administration (EDA). This designation focuses resources and expertise within Maine to accelerate the development and deployment of forest-based biomaterials to manufacture environmentally sustainable products from our forest resource. The University of Maine serves as a key partner in this multi-collaborator effort through technology and worker upskilling in existing manufacturing facilities, developing new advanced manufacturing and product technologies, and strengthening the forest bioproduct entrepreneurship ecosystem to enable new companies to scale. These actions help serve as a catalyst for future economic growth, diversification, and place-based innovation.

Through the National Science Foundation’s recent Maine-FOREST (crsf.umaine.edu/maine-forest) and Maine-SMART awards, the University of Maine is reshaping how the state approaches economic development, bringing together diverse participants, including educational institutions, industry leaders, non-profits, Tribal communities, state agencies, and federal partners. These collaborations are not just about scientific research but about creating meaningful impacts on local communities, empowering them with the tools and technology to adapt to a changing world. The projects span every corner of the state, from the densely forested North Woods to the bustling coast, ensuring that the benefits of innovation are felt statewide. Maine is leveraging its rich natural resources, world-class researchers and facilities, and cutting-edge technologies to unlock new economic potential through these projects. By building a robust network that spans universities, businesses, and rural communities, Maine-FOREST and Maine-SMART are positioning the state as a national leader in innovative sustainable forest management and economic resilience.

From these prior, current, and new collaborative efforts, Maine is transforming its traditional forest-based economy into one rooted in advanced technologies, sustainable bioproducts, and rural resilience. These various initiatives, supported or led by the University of Maine and its partners, foster a future where the forest remains central to Maine’s economic growth, environmental stewardship, and cultural heritage.

The University of Maine is at the heart of these transformative efforts, serving as the hub for forestbased innovation and sustainability research. These

include one of the world’s leading research facilities for cellulosic nanofibers, large-scale forest biochemical and fuels production, manufacturing and evaluation on sustainable packaging and advanced wood composite building materials, the world’s largest polymer 3D printer, and the first 3D printed house made entirely of bio-based, recyclable materials. In addition, the university is home to a thriving community of scientists and engineers working on advanced manufacturing, AI, and environmental sustainability, and precision forestry to address challenges today and into the future. With its deep expertise in forestry, bioproducts, and rural development, the University of Maine is uniquely positioned to lead the state’s efforts to transform its forest-based economy.

Bioproducts Advanced Manufacturing Tech Hub, Maine-FOREST and Maine-SMART represent a bold vision for Maine’s future, one where innovation, sustainability, and economic resilience go hand-inhand. These initiatives are not just about advancing science—they are about creating real-world impacts that improve the lives of Maine’s people, protect the state’s natural resources, and address global environmental issues. By bringing together diverse partners and leveraging Maine’s unique assets, these efforts are ensuring that the state’s forestbased economy remains a vital source of jobs, innovation, and environmental stewardship for generations to come.

Join us in supporting these transformative efforts and be a part of Maine’s journey toward a more sustainable, prosperous future! Together, we can build an economy that honors Maine’s past while embracing the possibilities of tomorrow.

Courtesy of Sappi

The world has a single-use plastic problem: the majority of plastic does not get recycled, and much of it ends up in the ocean or landfills. Most consumers are in favor of reducing plastic.

In fact, 87% of customers think retailers should curb the amount of plastic packaging they use. Global governing bodies are passing sweeping environmental recommendations and regulations to reduce plastic. Congress introduced The Break Free From Plastic Pollution Act in 2021, and in 2015 all member states of the United Nations adopted the 2030 Agenda for Sustainable Development, which relies on 17 Sustainable Development Goals for global peace and prosperity. Responsible production and consumption are key components of these UN goals, and Sappi uses them as a guideline for sustainability in both our operations and our products.

Major companies, such as Estee Lauder and Unilever, are responding to the pressure with sweeping declarations to reduce plastic. Of several options to replace plastic, few are better than paperboard made from wood fiber. At Sappi, we believe wood fiber is the material of the future – and we are using it to produce alternatives to plastic in packaging.

Our innovative, fiber-based products are used in gift cards and hotel room cards, as well as in shopping bags and food-service board for paper plates, reducing or eliminating the amount of plastic in these items. Our fiber-based products are also used in luxury packaging for cosmetics, premium packaging for food and beverages and so much more.

Our flexible packaging papers come with integrated barriers against oxygen, water vapor, grease, aroma and mineral oil, which is ideal for applications such as candy wrappers, granola bars, chips and pretzel bags and even tea bag wrappers.

Unlike single-use plastics made from crude oil, wood fiber is renewable; the process of creating paperboard involves high use of renewable energy; and it can be recycled multiple times. Paper and paperboard also have the highest overall recycling rate of

all materials in municipal solid waste. Fiber-based packaging has many advantages. It is:

• Accessible: Wood fiber is one of the most commonly found materials in nature, and with sustainably managed forests, wood fiber can be responsibly harvested without damage to the environment.

• Biodegradable: Cellulose fibers are naturally biodegradable.

• Malleable: Cellulose fiber properties lend themselves to be altered to meet human needs. From a durability standpoint, R&D efforts can transform cellulose materials to be resistant to the elements, depending on packaging needs.

• Recyclable: Paperboard can be recycled multiple times, recapturing the fibers for several more uses

Sappi is renowned for its investment in R&D and modernizing its manufacturing facilities to meet market demands for innovations in consumer products. Sappi’s legacy includes ownership of the S.D. Warren mill in Westbrook, which invented coated paper in the late 1800s. We are working every day on forward-thinking, science-based innovations to replace plastic with wood fiber and cellulose solutions through our expertise in coating technology across six global research and development centers.

Wood fiber provides an intersection of sustainability and quality that brands have been searching for to fulfill their environmental pledges. With cellulose as a base for a wide variety of materials that vary in biodegradability, thickness/structure and product applications, there is no reason it cannot be widely applied as a plastic substitute. The true challenge comes not from the manufacturing floor, but from adapting wood fiber into long-standing business practices.

Here at Sappi, we are committed to helping brands understand how wood fiber can efficiently replace plastic, as well as keep businesses on track to meet customer demands and global sustainability goals.

When Europeans arrived in the 1600s, they quickly began cutting down trees to construct settlements and build ships. In fact, the King of England claimed the largest of Maine’s white pine trees as his own personal property, to be harvested as masts for sailing vessels.

“It really bothered the early settlers at the time,” said Bob Frank, Jr., a retired U.S. Forest Service forester from Hampden. “[People working for the King of England] went into the woods and they marked trees with three marks, and you were not allowed, as a pioneer, to touch those trees. If you did, I guess there was quite a penalty.”

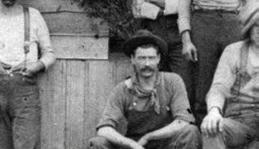

Back in the 1950s and 60s, Frank was among a group of volunteers who created the Maine Forest and Logging Museum, a nonprofit organization that preserves and shares the history of the logging industry in Maine. And what a fascinating history it is.

In just a few hundred years, timber harvesting in Maine has created communities, spurred the creation of roads, bolstered the economy, and helped shape the state’s culture.

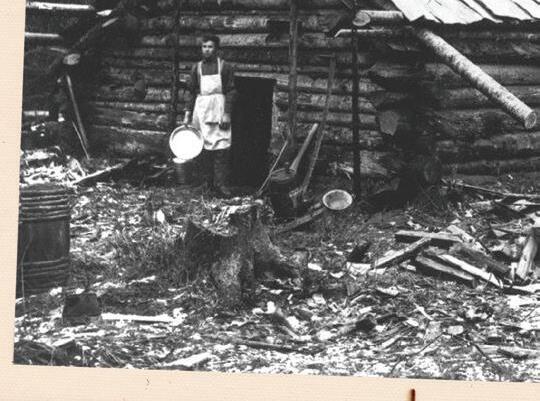

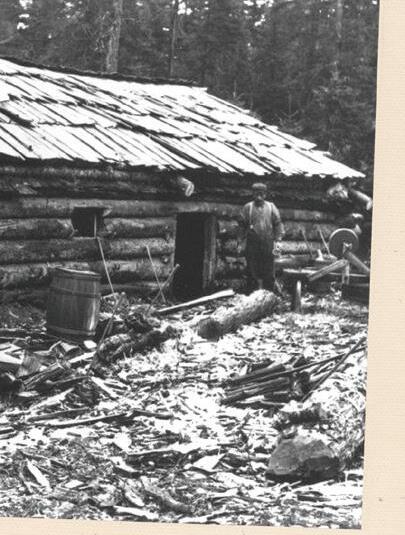

Around 1820, loggers began sleeping in primitive camps, according to the Patten Lumbermen’s Museum. Like the Maine Forest and Logging Museum in Bradley, the Patten museum’s mission is to preserve and share the state’s rich logging history. These early logging camps consisted of a 20-by-20-foot log structure built around a fire pit. This cozy abode, usually topped with a cedar shake roof, housed about a dozen men who shared a giant mattress of fragrant balsam fir needles.

“The North Woods of Maine grow all the trees you need for almost any product,” Frank said. “If you want to make pulp and paper, spruce and fir is the best. If you want to use cedar for canoes or log cabins, we grow a lot of cedar. We have a good array of hardwoods, from maple to yellow birch to white ash. It’s such a great smorgasbord of trees that any industry that wants to make something can come to Maine and find its trees here.”

With advancements in technology and an ever-changing demand for various tree products, the industry is continually changing.

who’s in her 19th season as the house, the animals, and this was back

“It was a fascinating life,” said Rhonda Brophy, who’s in her 19th season as the curator and administrator of the Patten Lumbermen’s Museum. “These men were gone from probably October until May [at the logging camps]. So it’s the women back home who had to take care of the kids, the house, the animals, and this was back before electricity. It was very hard, I think, on women.”

Some of Brophy’s favorite items at the museum are boxes made of hollow spruce that lumbermen carved sayings and scenes into, then filled with spruce gum to take home to their wives. The gum was chewed to freshen your breath, Brophy explained. Also at the museum, you can explore two replicas of the logging camps: the simple, 1820s camp and what’s known as the “double camp,” which is larger, with a kitchen area that’s separate from where the men sleep.

into, then filled with spruce gum to take

“The same men would go back to the same camps, year after year,” she said. “I’m sure they liked the comradery.”

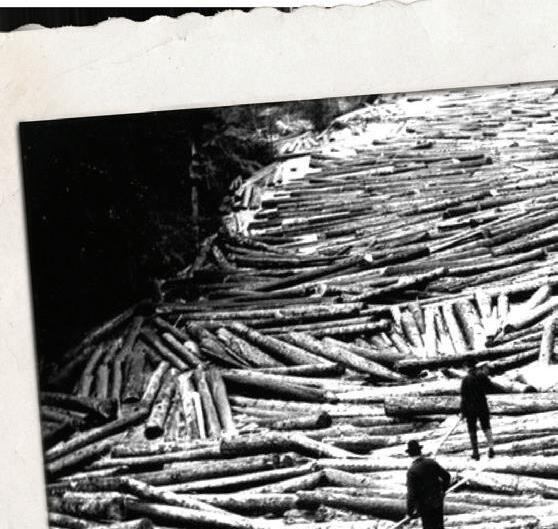

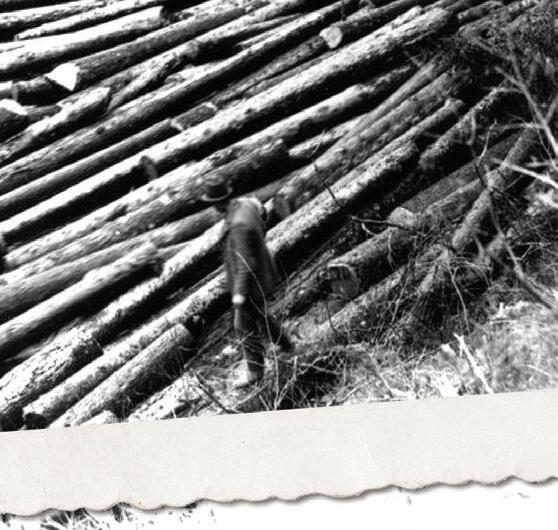

Logging was done primarily in the winter because it was easiest to transport timber over the snow in horse-drawn sleds. As the land thawed each spring, logs were dumped into streams and rivers that were swollen with spring run-off. The water would then carry them to ports that connected to the ocean, such as Bangor.

By 1832, Bangor had become the largest shipping port for lumber in the world, with as many as 3,000 ships anchored at any given time. Each spring, logs harvested farther north were floated down the Penobscot River to Bangor-area mills. These massive log drives were the most efficient way of transporting the wood to the ocean, where it could be shipped far and wide.

“This was before the roads were created,” Brophy said. “So they used the rivers as roads. And if a log got hung up, they had to keep them moving.”

Log drivers wore caulk boots, which were covered with metal spikes that helped them walk across floating logs. They also used a long, wooden tool called a peavey to move the logs and break up jams. With a metal spike and hook on the end, the peavey was invented in 1858 by Maine blacksmith Joseph Peavey.

This method of moving timber persisted for many years. Maine’s last log drive was in 1976 on the Kennebec River.

Today, log rolling and other traditional lumberjack skills are celebrated throughout the Northeast and Canada. The University of Maine, for example, organizes a co-ed “woodsmen team” to compete against other universities in lumberjack skill events.

Aspects of the log drive days also permeate Maine’s culture, with peaveys and old crosscut saws displayed in restaurants and sporting camps, and bean-hole beans a favorite dish for community dinners.

“For bean-hole beans, the cook would go ahead of the men on the drive and get their meals ready for them,” Brophy explained. “They cooked the beans in the ground because they didn’t have any real stoves. It would act like a slow cooker.”

By 1846, Maine was home to about 1,500 sawmills. In 1868, Maine’s first mill to produce pulp commercially was up and running in Topsham. And in 1883, large pulp mills were established in Old Town.

As technology advanced, logging and the production of wood products changed.

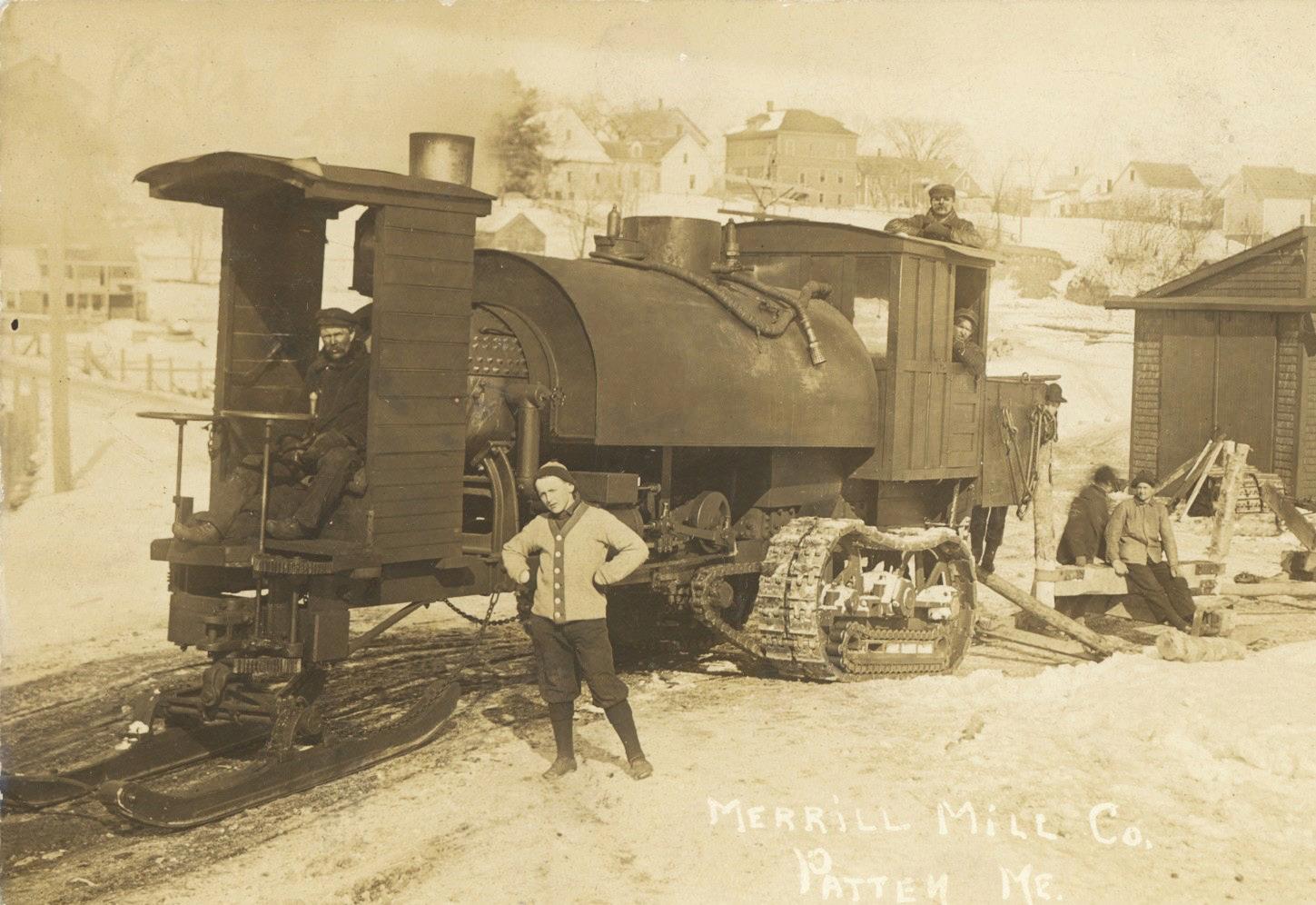

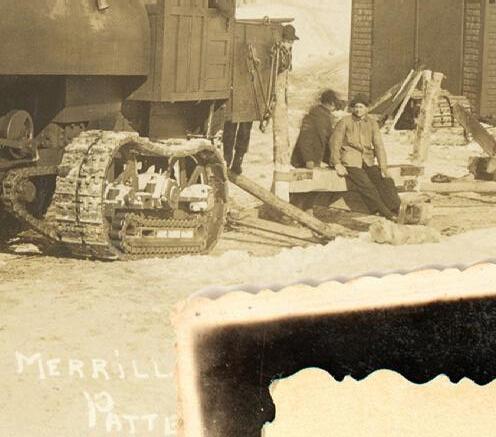

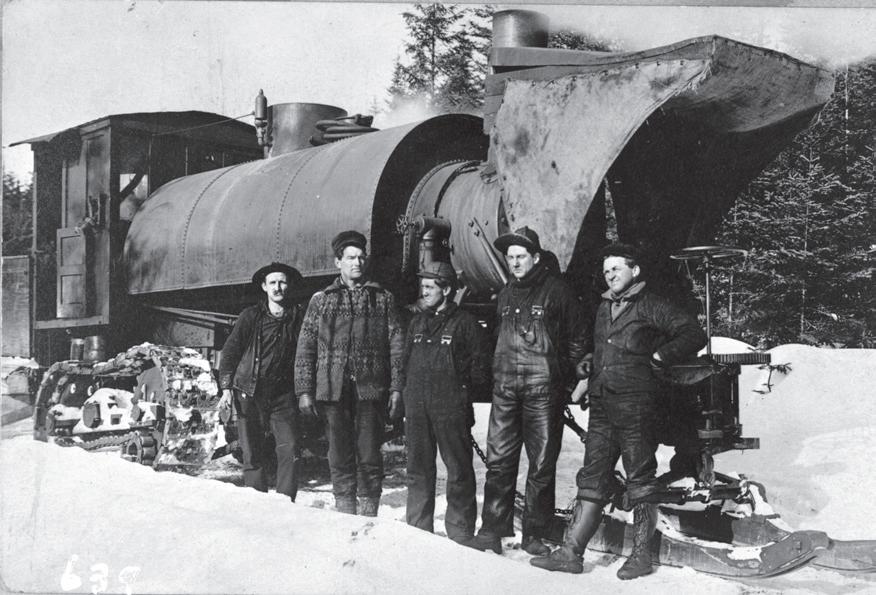

Perhaps the greatest of these changes was at the turn of the century. Patented in 1901, the

Lombard steam log hauler was designed by Waterville blacksmith Alvin Orlando Lombard. Now featured in the Mechanical Engineering Hall of Fame, this steam-powered machine transported logs through the forest in place of horses and sleds.

“He had the first patent for a cleat track, which is what you see on tanks and bulldozers today,” Brophy said.

More machinery followed, with gasoline log haulers, tractors, and power saws coming into use.

“I remember being invited to go look at [the Beloit tree harvester] because it was the first big machine to eliminate human effort to cut trees,” Frank said. “That was the first of many machines.”

Ongoing scientific research also impacts how logging is done in Maine. In the Penobscot Experimental Forest, where Frank worked for over 30 years, a number of experiments have been in the process for decades.

“I don’t care what year it is, there’s always some kind of pathogen, usually an insect, that’s bothering a species of trees that’s in the Maine forest, whether it’s softwood or hardwood,” Frank said. “I don’t know of any [tree] species that’s insect-proof.”

Spruce budworm. Hemlock wooly adelgid. Emerald ash borer. Beech bark scale. These pests challenge foresters to come up with new ways to keep forests healthy. Though times have certainly changed, Maine people continue to work in the woods, harvesting trees and creating products to ship around the world. Yet Maine remains the most forested state in the nation, with 89 percent of the land covered by forest.

“Thank God that trees grow,” Frank said with a laugh.

Courtesy of Professional Logging Contractors of the Northeast

The Maine Forest Service (MFS) has announced results of its 2022-2023 study on the implementation and effectiveness of Best Management Practices (BMPs) in timber harvesting across the state. According to MFS, the 2022-2023 results are consistent with previous years, showing a solid commitment to BMPs within Maine’s forestry and logging community.

Notably, there was a 5% decrease in sedimentation associated with crossing structures since the 2020-2021 report, with the report stating, “Sediment entry to the waterbody was observed at 29% of all crossings, a decrease from an average of 34% reported between 2020 and 2021.” Historically, sedimentation is most often linked to crossing structures.

This positive result coincides with a dramatic increase in recent years in BMP workshops conducted by the Northeast Master Logger Certification Program® in Maine and neighboring states. Master Logger is the only organization providing true hands-on BMP training to contractors and their employees in the region.

The Professional Logging Contractors of the Northeast (PLC) encourages all loggers who are not Master Logger certified to consider certification as a way to improve and market their business and access quality training opportunities. PLC members who are Master Logger certified also receive a dues discount.

The Professional Logging Contractors (PLC) of the Northeast raised a record $287,691 for Children’s Miracle Network (CMN) Hospitals in Maine in 2023 through its annual Log A Load for Kids fundraising efforts.

The total shattered the previous record set in 2022 of $262,403, with the PLC’s two Log A Load golf tournaments and the Log A Load live auction at the PLC’s annual membership meeting performing strongly while funds raised at the American Loggers Council (ALC) annual meeting in Bethel also contributed to the total.

“It is truly inspiring that despite the many challenges facing the Northeast’s logging industry, PLC’s Members, Supporting Members, friends, and families rallied once again in 2023 to raise a record amount for Children’s Miracle Network hospitals,” Dana Doran,

Executive Director of the PLC, said. “No matter what the conditions in the industry are, this group always reaches deep for the kids and their families.”

On Jan. 19, Doran presented a check for the funds to representatives from Northern Light Eastern Maine Medical Center in Bangor and The Barbara Bush Children’s Hospital at Maine Medical Center in Portland. The check was presented at PLC’s office in Augusta. Those accepting the check on behalf of the hospitals were Victoria Sorrentino, Philanthropy Officer for the Eastern Maine Medical Center Children’s Miracle Network Hospital program at Northern Light Health, and Kate Richardson, Children’s Miracle Network Senior Philanthropy Manager for Barbara Bush Children’s Hospital (BBCH).

“It’s difficult to properly express the gratitude that we feel for this community. We continue to be in awe of

the ways the bar is raised each year and how this community rises to the challenge every time,” Richardson said. “We were also thrilled to welcome loggers from across America this year who helped us achieve this incredible fundraising total during the ALC’s annual membership meeting. It certainly proves that the generosity of the logging community extends far beyond Maine’s state lines.”

“I’d like to echo Kate’s sentiments. The words thank you don’t seem enough to express how grateful we are to folks in the logging and forest products industry,” Kelly Pearson, Director of the Children’s Miracle Network Hospital program and Corporate Engagement at Northern Light Health, said. “Each year they dig deeper to ensure that kids who need care have access to the very best in Maine. From the bottom of our hearts, thank you.”

The PLC’s Log A Load efforts have now raised more than $2.4 million since 1995.

The PLC raises the majority of Log A Load funds during an auction at its annual membership meeting in the spring and at golf tournaments in Lovell and Lincoln in August and September. Some additional funds are raised through the sale of items

including holiday ornaments and through end of year donations.

The PLC and the Northern Light Health Foundation have partnered in the Log A Load fund-raising effort since 1996. Donations have gone to support research and training, purchase equipment, and pay for uncompensated care, all in support of the mission to save and improve the

lives of as many children in Maine as possible. Eastern Maine Medical Center in Bangor is a CMN hospital and includes a Neonatal Intensive Care Unit that has received support for years from the PLC’s Log A Load efforts. The PLC partners with The Barbara Bush Children’s Hospital at Maine Medical Center in Portland for the southern tournament.

ICourtesy of the Maine Forest Service

n the spring of 2013, in response to observations in Canada, representatives from the University of Maine, the Maine Forest Service and Maine’s forest industry met to develop “ The Spruce Budworm Task Force.” They brought together an impressive cadre, crossing many agencies and organizations, to formulate a spruce budworm response plan. Published in 2016, the plan recommended several measures, including adaptive harvest to reduce budworm impacts, expanded monitoring of populations, policy changes to allow landowner control of the response, and continued communication (sprucebudwormmaine.org). In Atlantic Canada, scientists were preparing for a novel response to this insect’s buildup (healthyforestparnerships.ca). 2020 was memorable to some because it was the first time since the early 1990s that spruce budworm caterpillars were seen in Maine by people working in the woods—the birds, small mammals, wasps, and other insects that consume this native species had been finding them all along. Still, they were so uncommon that many would think they had disappeared altogether. It was later than biologists initially thought they’d be spotted, and some had begun to question whether the changing climate, particularly warmer temperatures in late summer and fall, meant Maine had seen its last budworm outbreak.

A

Defoliation

severity is evaluated based on the percentage of missing foliage on the last three years of growth.

In another turning point, heavy spruce budworm feeding damage was seen near the Canadian border in 2024. In some places, all the needles that had developed this spring were stripped. During aerial survey flights, Maine Forest Service surveyors mapped almost 3000 acres of this damage. If the wind and the

People who spent time in the north woods of Maine in the late 70s remember smelling Christmas in July, not at a craft bazaar but due to the damage caused by spruce budworm feeding.

sun were right and you were in the right spot, you could smell Christmas in July.

Meanwhile, scientists in Atlantic Canada were in year ten of using an Early Intervention Strategy that targets building spruce budworm populations to suppress outbreak development. The strategy is a landscape-scale approach that requires precise, annual monitoring of spruce budworm overwintering populations, surgical applications of insecticides to augment natural mortality factors where populations show signs of growth, and a high cost before damage is evident.

of using an Early Intervention Strategy that targets building requires precise, annual monitoring of spruce budworm damage is evident.

Fortunately, the insecticides available today for spruce budworm management are targeted. For successful early intervention, they need to be. The insecticide applications must add to the mortality caused by the diversity of insects, diseases and other organisms living on spruce budworm. They cannot reduce the impacts of insect natural enemies. Researchers are seeing success in the approach. Economic models show that the upfront costs are considerably less than the anticipated revenue loss from an outbreak. Ecological research shows a robust insect natural enemy community in the treated forests. Carbon sequestration and storage and greenhouse gas mitigation outlooks are also positive.

Whether an early intervention approach will be applied across Maine’s landscape remains a question. For some, it is the only logical response, and the resources to make it happen will be found for the forests they steward. For others, resources, ownership objectives, and other factors may influence plans. Although the response to spruce budworm in Maine may include many approaches, what is certain is that spruce budworm populations in Maine have been in a building phase since 2012 and, currently, at least two broad areas of northern Maine have budworm populations poised for continued growth that meet the Early Intervention Strategy action threshold identified by Canadian scientists. The Maine Forest Service and Spruce Budworm Task Force partners remain engaged in monitoring spruce budworm populations and communicating options for preparation and response.

Stay updated about spruce budworm and other forest stressors, subscribe to our newsletters at maine.gov/foresthealth, or scan this QR code. For information specific to spruce budworm, visit sprucebudwormmaine.org.

Courtesy of Treeline, inc.

In an era where large corporations often dominate the commercial landscape, family-owned businesses like Treeline make a real difference in the communities they serve.

Maine’s Forest Products Industry (MFPI) is a rich tapestry of independent contractors, sole proprietors, and small businesses who contribute to their communities in unique ways: providing secure employment, boosting local economies, and stewarding the forests they call home.

These companies make up the backbone of the state’s traditional rural economy. According to a 2019 report from the University of Maine, the MFPI contributes nearly 32,000 full and part-time jobs within the state.

These jobs offer our neighbors, friends, and family members quality employment. Given the chance to build careers close to home, these hardworking people support other local businesses — creating self-sustaining ecosystems in rural areas with limited economic opportunity.

Every year Treeline is evolving and growing, creating jobs and better supporting its community. In 2023, Treeline’s new sawmill came online, creating up to ten jobs and providing much desired rough sawn timbers and lumber for camps, barns, sheds, decks, and more.

Meanwhile, Treeline’s Service Center has also been expanding. Adding services and product lines such as SP Tools, a lifetime warranty line of hand tools; high-quality, cost effective Vitillo hydraulic hoses and fittings, and others. Check us out at: treelineinc.biz.

Other MFPI businesses in our area and throughout the state are also positively impacting their communities. At Lincoln’s former LP&T mill site, work continues repurposing the area to support plans for a future biofuel plant, creating new jobs converting wood waste into heating fuel.

Down the road in Enfield, Standard Biocarbon’s plant has come online to convert sustainably harvested forest materials into high quality biochar and is employing even more community members. The manufactured biochar offers many beneficial uses to agricultural and environmental activities around the northeast.

Just completing their first year of production, we want to give a SHOUT OUT to TimberHP’s continued success converting wood fiber to quality building insulation in Madison, Maine!

The Professional Logging Contractors of the Northeast (PLC), an organization of over 200 small family businesses (including Treeline), provides a voice for the timber harvesting and trucking companies within the industry. They also give back, raising $2.5 million since 1995 through the Log A Load for Kids program for Children’s Miracle Network Hospitals in Maine, including Northern Light Eastern Maine Healthcare in Bangor.

The industry’s readiness to give back doesn’t stop there. Treeline is committed to our own philanthropic efforts, as illustrated by our non-profit charity: Treeline Making a Difference, which helps support various community needs.

Treeline staff members along with compassionate community members have been instrumental in supporting the Northern Penobscot Activities Council (NPAC), a local 501c3 supporting our communities through education, outreach, personal and community development.

It is clear that Maine would not be the great place it is to live if not for the family businesses that make up the Forest Products Industry!

FAIRFIELD, ME – The Mechanized Logging Operations and Forest Trucking (MLOFT) Program, a unique 20week certificate course providing unmatched training and preparation for careers in logging and forest trucking, is now underway for its eighth straight year.

The program is an expanded version of the original logging operations certificate program created in 2017 by the Professional Logging Contractors (PLC) of the Northeast, the Maine Community College System, and industry partners, that now includes Commercial Driver’s License (CDL) training.

The MLOFT program is being hosted by Kennebec Valley Community College (KVCC) at its Alfond Campus on U.S. Route 201 but is administered by Northern Maine Community College (NMCC) in Presque Isle.

A dozen students began classwork and safety training in late June at the Alfond Campus before progressing to hands-on training with mechanized

logging machines at an active timber harvest on the campus in late July.

“This remains the only program of its kind in our region, and it is critical to addressing Maine’s shortage of qualified logging operators and forest truckers in an efficient and affordable way,” PLC Executive Director Dana Doran said. “We could not offer this unique opportunity to students without the support of Maine’s Congressional delegation, which secured Congressional Directed Spending (CDS) support for it, or our industry partners, who ensure we have the equipment to offer a top-notch training experience.”

The opportunity to earn a CDL-A permit and receive preparation for the state driving exam was a significant addition to the program in 2023 and has expanded opportunities for graduates while increasing benefits to Maine logging employers who need more mechanized logging operators and truck drivers.

Students enrolled in the post-secondary training

program harvest timber and operate trucks using sophisticated state-of-the-art machines like those they will encounter in the logging industry. The hands-on experience students gain operating equipment is an opportunity unavailable anywhere else in Maine and neighboring states and will prepare them for indemand careers with logging contractors throughout the state of Maine. A report released by the University of Southern Maine in 2019 forecast up to 2,000 positions in timber harvesting and trucking will be available over the next decade.

The program includes a strong emphasis on safety as well as giving students an understanding of the variables of timber growth, tree species, and markets. Students pay no tuition or fees, and the program provides all personal protective equipment (PPE).

This project is funded 100% by a $1M grant from the U.S. Department of Labor, Employment and Training Administration.

Approximately 95 percent of logging in Maine now relies on mechanized equipment. The industry also relies almost exclusively on heavy trucks to move wood. With the majority of logging operators and forest truckers at or near retirement age, the demand for new workers in the logging industry is high and most students in the previous certificate program have had job offers before graduating.

Anyone with an interest in the program should contact Holly Grant at Northern Maine Community College at 207-768-2856 or visit www.nmcc.edu to apply. Additional information may be found online at plcloggers.org

Maine’s economy and many local communities depend on the forest products supply chain, which starts in the woods. Decades before a tree can be harvested for lumber, paper, fuel, or countless other products, it begins as a seedling or sprout in someone’s forest. Over the years, it grows, spreading its crown, and taking its place in the canopy. At some point, it may be cut as part of a thinning, to promote growth, forest health or habitat, or to make way for new trees. Once cut, it continues along the supply chain — yarded to the log landing, loaded onto a truck, and transported to a mill where it’s transformed into various products.

Despite over three centuries of logging and land-use changes, Maine’s forests remain resilient. These forests continue to provide the raw materials that fuel the forest economy while delivering ecological benefits like wildlife habitat and clean water, as well as recreation and nature-based tourism. Mainers and visitors alike participate in activities ranging from hiking and leafpeeping to hunting and snowmobiling. With forests covering 89% of the state, Maine’s identity and culture are inextricably tied to its woodlands.

The Maine Forest Service (MFS) plays a key role in sustaining the forest, working alongside landowners, foresters, loggers, truckers, and mills to ensure informed decisions about forest management. MFS’s District Foresters spend much of their time in the field, meeting with landowners to guide them through the complexities of woodland management. They collaborate with loggers and foresters to implement sustainable practices and provide valuable educational resources like workshops, field tours, and classes.

Maine’s forests touch everyone in the state — not only woodland owners, loggers, and foresters, but also towns, schools, community groups, and businesses. MFS works to reach all these audiences, ensuring that Maine’s forests endure for future generations.

The Maine Forest Service also plays a key role in monitoring and reporting on the health and productivity of the forests and industry. Through timber harvesting reports, wood processor data, forest inventory, and analyses, MFS provides critical information guiding public and private decisions. These data help secure the future of Maine’s forests, allowing participants in the

forest economy to make choices today that will sustain the forests for generations.

The challenges facing Maine’s forests are increasing. Invasive insects, diseases and plants threaten tree health, while storms, flooding, and wind damage further stress the woods. Perhaps the greatest single challenge is climate change, which exacerbates many of these issues, from pests to severe weather events.

The trees harvested today began their journey decades ago. Every decision made about the forest must consider this timeline, ensuring that thoughtful management today results in continued benefits long into the future. Maine’s forests have weathered centuries of change, and with careful stewardship, they will continue to grow and provide for the state, its economy, and its people.

Contact MFS for assistance, education, and support in making informed decisions that protect and preserve our forests for future generations, call (207) 287-2791 or visit maine.gov/dacf/mfs.

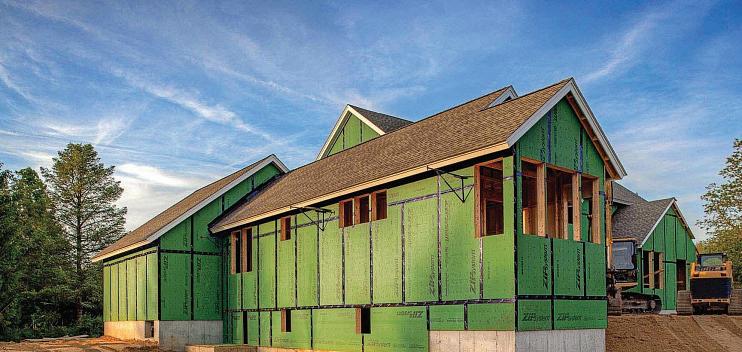

Courtesy of passivhausMAINE

Maine’s aging housing stock and a reliance on inefficient technologies are key challenges for the state’s residents. With many homes built decades ago, often using now-outdated materials, the need for energy-efficient upgrades is more pressing than ever. Enter low-carbon retrofitting — a push for sustainability tied directly to Maine’s forest industry, which offers a unique opportunity for both the economy and our statewide workforce.

Many of Maine’s homes are stick-built structures, lacking modern insulation, and often powered by expensive and polluting heating oil. This combination not only increases energy costs for homeowners but also leaves homes with poor energy efficiency and a larger carbon footprint. Retrofitting these homes with materials like high-performance insulation, energy-efficient windows and renewable wood-based products reduces our state’s carbon footprint while making homes more comfortable and healthier… and it saves money.

But upgrading homes will require more than just materials. Maine has a chance to fuel future economic growth by investing in local economies and workforces. At passivhausMAINE, their programming is bringing needed training directly to Mainers, wherever they are.

Maine’s forests can be a solution to both the housing and workforce challenges. Sustainable wood products, like cross-laminated timber (CLT) and other

engineered wood materials, are increasingly replacing traditional materials like steel and concrete in construction.

The University of Maine’s Advanced Structures and Composites Center has been at the forefront of these developments, advancing wood composites and even 3D-printed homes using forest products. But for these innovations to make a meaningful impact on the state’s housing crisis, they must be used in our industries.

Mainers are forward thinking, and our state must continue investment into training programs to equip builders, contractors and tradespeople to work with advanced wood products and high-efficiency construction techniques. By focusing on workforce development, Maine can grow its forest products industry and make strides toward upgrading its housing stock. Sustainable building isn’t just about materials — it’s about empowering people with the tools and skills to implement them.