GIEDO VAN DER ZWAN

GIEDO VAN DER ZWAN

WWW.DUTCHINDUSTRY.ORG

2

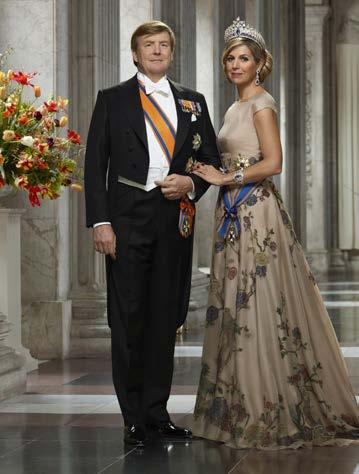

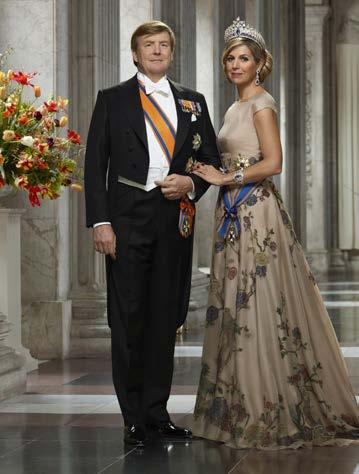

IMAGE: ARENDA OOMEN

A wise man once said, ‘The mechanics of industry is easy. The real engine is the people: their motivation and direction.’

As prime minister it’s my privilege to have regular contact with the ‘engine’ of Dutch industry. I visit companies and speak with entrepreneurs, and together we go on foreign trade missions. Time and again I’m struck by their innovative and creative mindset and their focus on cooperation, continuity and sustainability. It’s an approach that goes back decades in the Netherlands. This book showcases Dutch entrepreneurs, their companies and how they have developed over the past decades and centuries. It also describes the way they continue to operate at the forefront of the global market today, each in their own sector or niche.

Dutch businesses are popular with partners all over the globe, and no wonder. Their innovative nature and focus on continuity make them reliable. They deliver high-quality products and services. They value their knowledge base and expand it year after year by building on their own R&D activities and the input received from the first-class universities and institutes with which they form networks. Partnership between businesses, research institutes and government bodies is firmly anchored in Dutch culture, and it’s crucial to our success.

Wherever I go in the world, I find Dutch businesses active there, often helping to tackle the major challenges of our time. Challenges like producing enough food to feed the planet’s growing population, or anticipating the impact of climate change on water management, reducing greenhouse gas emissions and halt global warming. The Netherlands aims to be a world leader in smart, clean and energy-efficient technologies. Dutch industry fulfils its role as a partner by sharing its knowledge on how to increase crop yields, combat flooding or optimise communications, safety and infrastructure, to name but a few examples.

This book offers a wide-angle perspective of Dutch industry. The individuals featured talk about the competition abroad, about innovation and about the challenges they encounter in their day-to-day business. I am confident this book will give you a clearer picture of how Dutch companies operate and work towards a better, more sustainable world, as well as a better understanding of the engine behind our unique and thriving industry.

Mark Rutte Prime Minister of the Netherlands

3 DUTCH INDUSTRY

PREFACE

4

5 DUTCH INDUSTRY INTRODUCTION A NEW WORLD TOP SECTORS IN THE NETHERLANDS: 20 AGRI & FOOD 26 CHEMISTRY 32 CREATIVE INDUSTRY 38 ENERGY 44 HIGH TECH SYSTEMS & MATERIALS 50 HORTICULTURE & STARTING MATERIALS 56 ICT 62 LIFE SCIENCES & HEALTH 68 LOGISTICS 74 WATER & MARITIME INSPIRATIONAL BUSINESS STORIES FROM THE NETHERLANDS: Amgen Bejo Bosch Excess Materials Exchange Fastned Feadship Flowfirm Kaak Micreos Natural Bag OMA Port of Rotterdam Rademaker Rijk Zwaan Royal Smit & Zoon Royal Van der Most SADC Schiphol Smart Health SoluForce INVESTING IN THE NETHERLANDS PUBLICATIONS ABOUT THE AUTHOR COLOPHON Dutch Industry underwrites the international positioning strategy of the Netherlands and endorses its key philosophy of solving global challenges together. To join the conversation, visit NLplatform.com. CONTENTS 06 12 18 80 82 88 94 98 104 110 116 122 128 134 138 144 152 158 164 170 176 182 188 194 202 214 215 216

6

REASONS FOR SUCCESS

Dutch industry is of great importance for Dutch society. It employs 13% (close to 1,000,000 working years) of the Dutch labour force and generates almost 20% of the Dutch Gross National Product. As a whole the industrial sector performs as an engine for the Dutch economy by generating 75% of its exports. Being part of a broad and deeplyrooted knowledge infrastructure, of which small and medium-sized enterprises are an integral part, Dutch industry is also the main hotspot for innovation. Dutch society greatly appreciates the value-adding capacity of these industrial activities and the role that Dutch industry has played in the remarkable economic recovery of recent years.

Dutch industry also plays a significant international role. In many sectors Dutch firms, large and small, have dominated certain industrial sectors for decades.

Apart from the behind-the-scene stories of the participating companies, this volume also seeks to explore the reasons for their successes. How is it that the Dutch have managed to maintain a strong and successful industrial base, which has moved from the domestic into the wider world market? Is it a native resilience that has come from generations of battles against the sea coupled with a lack of natural resources, or the early growth of a merchant middle-class that needed trade and exploration to create prosperity? We found some answers from the companies that tell their story in this book.

A tough entrepreneurial climate

There are many reasons that explain the international success of Dutch industry. To start with, most companies have a long

7 DUTCH INDUSTRY

INTRODUCTION

history; even start-ups often have their roots in older businesses and the collective Dutch knowledge base. The Netherlands as a whole has unique and intimate knowledge of technologies and markets that have grown over the last centuries and in which companies, knowledge networks and the government continuously invest. This gives the companies involved a competitive edge. This competitiveness is also stimulated by the high costs of labour in the Netherlands, the high demands of the domestic market and both legal and quality standards. These compel companies to make only the best products in the most efficient way against the most competitive prices. As a participant said: ‘You are either the best, or not a player at all on the global market’. This tough entrepreneurial climate gets the best out of companies.

Privately owned

Another important reason for the success is the fact that most companies are privately owned, this also having an effect on other reasons for success. Without the constant pressure of shareholders, private companies have time to invest in innovation, market development, knowledge and their employees. Private ownership also seems to stimulate companies to develop their own legacy and their own ‘DNA’. This is very important for the corporate culture and cohesion within the company, especially when a proportion of the workforce operates abroad in network-style organisations that sometimes span the whole globe.

8

Many participants in this book feel that the preservation of the company DNA, or identity, is of greater importance than fast growth and higher turnover. Last but not least, private ownership makes companies resilient: a few bad years won’t scare the owners. They have been there before and survived.

Incremental innovation

Innovation in most Dutch industrial companies is incremental, although as one participant remarked ‘Incremental innovations lead to disruptive innovation’: and this is precisely what is happening. Many companies in this volume are working on, or already have developed, next-step technologies. These shed a different light on all the sectors involved: they are the result of years or even decades of incremental innovation and have led to very refined technologies such as in agriculture, chemistry or infrastructure. These innovations are always part of a greater development in which knowledge networks play an important role. Together they broaden the Dutch knowledge base and make it fit for the future. The concept of the so-called ‘Sustainable Urban Delta’, which is described in detail later in this chapter, is a good example in which many of these new technologies come together.

And innovation is not only to be found in the classic R&D department. The account manager and the technician operating ‘up front’ are often the first to signal trends in demands and technical possibilities that can be used as

input for innovations. With the typical Dutch management style in which there is room for everyone’s input, ideas quickly find their way toward the various innovative pathways.

Keen entrepreneurship

Another reason for success is the incremental way in which markets are being developed. Operating from a strong and critical home market, Dutch manufacturers and service providers dare to make next steps, firstly in neighbouring European countries and then frequently followed by newer markets in, for example, the United States, Asia or South America. In this phase the focus is on finding the right counterpart abroad, be it a manufacturer or an agent. But once settled, Dutch companies seem to be capable of acquiring a solid market position in a relatively short period, with the quality of Dutch industrial products and the companies’ pre- and after-sales activities key features. Furthermore the Dutch are also renowned for their linguistic skills, their open minds regarding different cultures, as well as good and fair trading. These all contribute to the strong position of Dutch companies abroad.

Investing in knowledge

Dutch companies dare to invest in knowledge because they know that their future depends on ‘top of the bill’ facts, information and learning. They are supported in this by the

various sector-related knowledge networks that are focussed on giving an edge to Dutch science and industry. The contemporary level of technological knowledge has its basis in the past which, in some cases, can be traced back for centuries. This knowledge has become part of Dutch DNA and is, in many respects, unique. The same applies to the companies involved: their success can be explained by their knowledge basis which, for them, requires constant expansion as part of the ‘going concern’.

Investing in people

Investing in knowledge is a corollary of investing in people as, in many ways, employees are the embodiment of knowledge. Dutch employers go a long way to engrain company knowledge in their employees and, by return, collect knowledge from them. This all contributes to the employees’ professionalism and craftsmanship. Many participating companies have in-company academies complemented by internet-based knowledge networks, as well as special expert or innovation centres where employees, clients and suppliers can contribute to the knowledge base of not only the company but themselves individually as well. In the short run the client is provided with the most up to date knowledge on, for example, how to optimize production while, in the long run, possibly obtaining new insights and development of new products. The contact between employee and client is the key to this mutually beneficial knowledge transfer. However, this is not the only reason

9 DUTCH INDUSTRY

INTRODUCTION

why investing in people is worthwhile: employees will feel more connected to the company. Such connection can create higher working satisfaction and lead to long employment relationships, thereby contributing to optimal growth and use of the collective knowledge base within the company. This knowledge base has proved to be one of the decisive factors for success.

Focus on cooperation and co design/co creation/co production

One of the unique selling points of our industrial companies is the typical ‘Dutch approach’: companies from the Netherlands are very keen on cooperation resulting in co-design and co-creation with clients. They are also willing to share knowledge, an attitude that is, in a way, unique in the world and gives companies a competitive edge. Dutch companies acknowledge that, in the overwhelming large global market, cooperation with suppliers, competitors or clients is the only way to stay successful and contribute to the strategic position of the company. Besides this, cooperation often leads to advisory and service activities thus broadening the portfolio of the company involved.

Dutch management style

The Dutch style of management is part of the larger European style of management that has created many successful companies. The

Dutch style is characterized by a free flow of horizontal and vertical communication and employee freedom within certain boundaries, by which the latter have the possibility to act without interference from their superiors. The better the DNA, or company identity, is defined, the less the boundaries have to be described, hence our earlier emphasis of this important feature. With this strong corporate culture the companies have, on the one hand, the necessary agility and, on the other, the necessary resilience by which they can move quickly and flexibly from a solid operating base. This freedom to act is especially important as many companies run complex projects abroad where important decisions have to be taken on a daily basis. Employee professionalism and the craftsmanship guarantee that the decisionmaking is in the right hands.

Knowledge networks

An important facilitating phenomenon is the so-called ‘Knowledge networks’ which significantly contribute to the competitive power of Dutch industry. This intricate fabric comprises universities, research institutes, centres of excellence, government agencies and other public authorities. Every branch has its own specific type of network and its own historical basis. The networks have broadened and deepened in past centuries so that the knowledge basis of the various branches can guarantee, and will continue to guarantee, a strong technological push. The challenge is to keep combining this push with

market demand, thereby reducing the timeto-market for innovations. For this purpose every branch has its own so called ‘Top Institute’, a public/private initiative that has the sole purpose to function as a matchmaker between the innovative ideas of researchers and the companies that might be interested in marketing them. These knowledge networks are described in the next chapters in the descriptions of what are termed ‘Top Sectors’.

Geographical position

Traditionally, the geographical position of companies explains a lot about their history. Shipyards for example are to be found along the rivers in the west and north of the Netherlands while the country’s location close to the sea and the European hinterland explain its logistical position. The precision mechanics industry is located where the old textile industries used to be and the automotive industry is found in the southern part of the country where the first cars were produced. Engineering works are often sited where iron ore was available, energy-related industry where gas is to be found, with water management-related industries in the wetlands of the west and north. Agri & Food industry and horticulture can be found anywhere in the country, but often with a region-specific profile. Knowledge networks can be found clustered around all of these industries. In this way the geographical location of a company says a lot about its history and the knowledge network to which it belongs.

10

Most of the ambitions of Dutch industrial companies come together in an integrated concept that is called ‘The Sustainable Urban Delta’. The starting point for this concept is that the Netherlands is geographically located in a delta environment with sea, rivers and water enabling food production, transport and trade.

Historically, Dutch industries have played a major role in this and, more recently, this role has evolved to make the urban delta more sustainable as, without design, engineering and manufacturing skills, it would be impossible to live, work, feed and transport people in such an area. This concept of an integrated vision and role for industries has huge potential on a global scale in the light of many international trends and developments.

Every day, about 180,000 people worldwide move from the countryside to the city. It is estimated that within 15 years over 60% of the world’s population will be living in metropolitan areas. Many of these areas are located in a delta such as the Netherlands and, just like the Netherlands, the presence of water in these foreign deltas enables food production, trade and transportation. Furthermore, these cities will need efficient energy and water flows, sustainable food production, green and clean neighbourhoods, decentralized and short supply chains, clever transportation systems and much more. Without all these conditions a certain quality of life will be unattainable for their inhabitants.

The Netherlands itself is like a city in a river delta, based on a single area of conurbation from north of Alkmaar to south of Eindhoven. With that image in mind, the Netherlands and its industry can play an important role in the development of sustainable urban deltas all over the world. In many business cases elements can be discerned that greatly contribute to this development, for example by enhancing the yield of groceries, combining energy networks, introducing organic chemistry and smart urban transport systems. Together they sketch the conceptual outlines of the future in the form of the Sustainable Urban Delta.

11 DUTCH INDUSTRY

INTRODUCTION

DUTCH DREAMS: THE SUSTAINABLE URBAN DELTA

12

TIMES OF CRISIS. TIMES OF CHANGE.

Over the past few years, the world has undergone numerous shocks. The COVID-19 pandemic, conflicts in many regions including the war in Ukraine, a cost-of-living and debt crisis, and climate related disasters are entwined through environmental, economic and social systems that created intensifying global backslides.

But as is often the case, times of crises create opportunities for change: the same interconnections that amplify the crises can generate integrated recovery strategies and address systemic risks.

In its Global Sustainable Development Report (GSDR) 2023, ‘Times of crisis, Times of change’, the UN states that if leaders are able to step up and address climate change, nature and biodiversity loss, demographic change, digitalization, economic inequalities, and violent conflict, this will help to avoid

undermining advances made in the short term and thus build resilience.

Clouds are beginning to part

In its latest World Economic Outlook (January 2024), the International Monetary Fund (IMF) said that it expects the world’s economy to pick up again in 2024 and 2025. Put another way, “The clouds are beginning to part.”

According to the IMF, there is still a risk of new commodity price spikes from geopolitical shocks and supply disruptions which could prolong tight monetary conditions. However, the global economy appears to be moving towards a ‘soft landing’, with inflation declining steadily and growth holding up.

Current disinflation and steady growth increase the likelihood of a receding ‘hard

landing’, and risks to global growth are broadly balanced. Also, faster disinflation could lead to further easing of financial conditions, while looser fiscal policies could imply higher growth and stronger structural reform momentum which could bolster productivity with positive cross-border spillovers.

New missions empowering change

In the Netherlands, with its open economy, the same shocks have disrupted the economy. Yet, at the same time, many of the same opportunities have arisen. In order to empower this positive change, entrepreneurs, scientists and the government have joined forces to strengthen the economy through innovations, capitalizing on international opportunities, improving human capital and investing in scientific research.

13 DUTCH INDUSTRY

NEW WORLD

A

Dutch policy makers, together with the representatives of ten top sectors, formulated twenty-five ‘missions’ to tackle social challenges. These missions focus on ensuring a longer and healthier life expectancy, sufficient clean water and safe food, lower greenhouse gas emissions, affordable sustainable energy and a safe environment in which to live and work. These are ambitious goals that challenge entrepreneurs and scientists to develop pioneering solutions and contribute to the global competitiveness of the Netherlands.

The formulated missions are helping the top sectors to join forces, even more than before. Among the new features of this policy is also the creation of new markets, to ensure that innovations can be widely applied and made available for purchase. If necessary, the government may also act as a launch customer. By including market challengers, innovative entrepreneurs and different regions, the mission-driven policy will be applied more widely with a greater chance of success.

Focus on social challenges and key technologies

Even more extensively than before, the innovative strength of the top sectors is linked to solving social challenges. The world needs large and small solutions for a climate-proof, water-resilient, sustainable, healthy and safe environment, that range from the latest scientific insights and key enabling technologies to practical solutions in design and use. By combining the strengths of

entrepreneurs, scientists and the government, a joint effort is created to address these challenges, even when the road to the best solution has yet to be established.

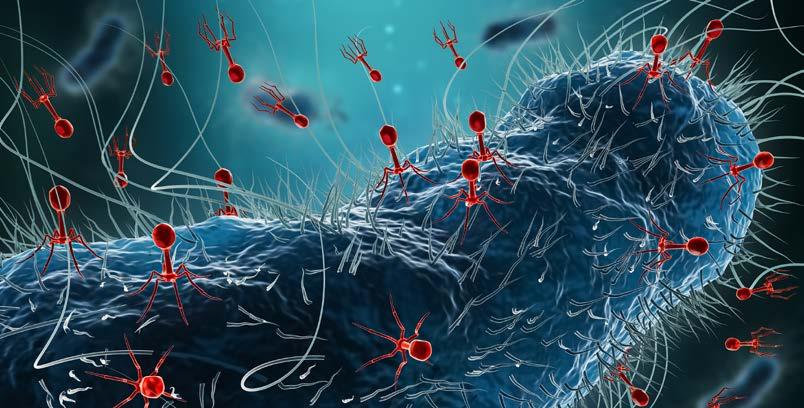

However, key enabling technologies, such as quantum, nano, photonics and digital technology, will play an important role in achieving pioneering solutions. Examples include: quantum computing which can calculate all possible options in a fraction of the time; special sensors that can determine the exact amount of water, nutrients and light needed for optimal growth; laser techniques, which enable surgeons to perform precise operations with fewer complications and a faster recovery time; or production robots that can customize any product for the best price with great precision and without waste.

A co-creation between entrepreneurs, scientists and government

The missions state a clear need for specific research and innovation. Scientists can extensively research diseases, natural resources and data, so we learn how to better treat and use them with little waste or error. Subsequently, entrepreneurs play a key role in converting innovations into concrete applications and products. They also provide employment and economic opportunities in the Netherlands as well as abroad.

The role of the government is to promote groundbreaking innovations: by investing

in research, amending laws and regulations, entering public-private partnerships, socially responsible procurement, providing financial arrangements and creating new markets.

The Netherlands have a long history of successful cooperation between entrepreneurs, scientists and the government. For example, Dutch water management, illustrated by the famous Delta Works, emerged due to national necessity. While the government played a leading role in search of inventive and pragmatic solutions, these were ultimately developed through research and made financially viable by entrepreneurs far beyond our national borders.

This collaboration between entrepreneurs, scientists and the government, generates smart solutions for global challenges. As a result, we don’t just grow older, but also enjoy a longer and healthier quality of life. We don’t just ‘keep our feet dry’, but are able to eat tasty and reliable food and produce goods durably, so that we shall still have a habitable planet in 30 years.

In addition, these innovations and solutions are also potential export products for a worldwide market. After all, other countries face many of the same challenges as we do. The Netherlands aspires to play a leading role in tackling social challenges and developing key technologies. These missions for the future should also be seen as an investment in overall progress and reinforcing economic opportunities.

14

PROMISING INNOVATIONS FROM THE NETHERLANDS

The Netherlands is an innovative and entrepreneurial country, known for many successful innovations worldwide, such as the invention of the microscope (1595), the dialysis machine (1943) and Wi-Fi (1997). The future also looks promising, thanks to the development of smart greenhouse materials that can adapt to light, climate and crops; cars that can run on sun and rainwater; an irrigation system that anticipates weather conditions and can store water for dry periods; sun-blinds made up of solar cells; a coral nursery which helps repair damaged reefs; new types of fuel; environment-friendly alternatives that protect ships, roads and machines from the elements; infinite recycling of plastic; or an artificial pancreas for people with diabetes.

These are all innovations from recent years or are currently under development.

15 DUTCH INDUSTRY A NEW WORLD

From theory to practice

The missions which were drafted in close cooperation with eight Ministries and all Top Sectors, focus on four social themes:

• Energy transition and sustainability

• Agriculture, water, food

• Health and healthcare

• Security

A Knowledge and Innovation Agenda is drawn up for each of the themes and two

separate agendas are also drawn up for key enabling technologies and projects that contribute to the earning capacity of the Netherlands. The financial resources and research capacity are specified in what is termed a ‘Knowledge and Innovation Covenant’. Subsequently, entrepreneurs and researchers can begin to develop new products, technologies and solutions for each challenge and successfully market them all over the world.

SUSTAINABLE DEVELOPMENT GOALS

16

4 themes and 25 challenges

Energy transition and sustainability

• 49% reduction of national greenhouse gas emissions by 2030, aiming for 95% lower emissions by 2050 compared to 1990.

• An entirely carbon-free electricity system by 2050.

• A carbon-free built environment by 2050.

• Carbon-neutral industry with reuse of raw materials and products by 2050.

• Zero-emission mobility of people and goods by 2050.

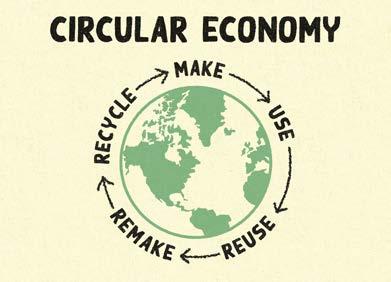

• A sustainable and completely circular economy by 2050, with resource use halved by 2030.

Agriculture, water and food

• Reduction of the use of raw and auxiliary materials in agriculture and horticulture by 2030 and creating the maximum possible value from all end products and residuals by utilizing them as fully as possible (circular agriculture).

• By 2050, the agricultural and nature system will be net carbon-neutral (Joint mission with energy transition and sustainability).

• The Netherlands will be climate-proof and water-resilient by 2050.

• By 2030, we will produce and consume healthy, safe and sustainable food, while supply chain partners and farmers get a fair price for their produce.

• A sustainable balance between ecological

capacity and water management vs. renewable energy, food, fishing and other economic activities, this balance to be achieved by 2030 for marine waters and by 2050 for rivers, lakes and estuaries.

• The Netherlands is and will remain the best-protected and most viable delta in the world, with timely future-proof measures implemented at a manageable cost.

Health and healthcare

• By 2040, all Dutch citizens will live at least five years longer in good health, while the health inequalities between the lowest and highest socio-economic groups will have decreased by 30%.

• By 2040, the burden of disease resulting from an unhealthy lifestyle and living environment will have decreased by 30%.

• By 2030, the extent of care provided to people within their own living environment (rather than in health-care institutions) will be 50% more than today or such care will be provided 50% more frequently than at present.

• By 2030, the proportion of people with a chronic disease or lifelong disability who can play an active role in society according to their wishes and capabilities will have increased by 25%.

• By 2030, quality of life for people with dementia will have improved by 25%.

Security

• By 2030, organized crime in the Netherlands will have become an excessively high-risk and low-return enterprise, thanks to a better insight into illegal activities and cash flows.

• By 2035, the Netherlands will have a navy fit for the future, which will be able to respond flexibly to unpredictable and unforeseen developments.

• By 2030, the Netherlands will have operationally deployable space-based capabilities for defence and security.

• Cyber security: the Netherlands will be in a position to capitalize, in a secure manner, on the economic and social opportunities offered by digitization.

• By 2030, the armed forces will be fully networked with other services and through the integration of new technologies, so that they can act faster and more effectively than the opponent.

• Supply and demand will come together more quickly to implement successful short-cycle innovations.

• By 2030, security organizations will be capable of collecting new and better data, so that they are always one step ahead of the threat.

• By 2030, the role of security professional will be among the ten most attractive professions in the Netherlands.

17 DUTCH INDUSTRY

A NEW WORLD

18

TOP SECTORS IN THE NETHERLANDS

The Netherlands is one of the twenty largest economies in the world and is a leading global knowledge economy. The country has a longstanding history of invention and trade with other countries, the latter built on adventurous exploration of the world’s oceans. In times of global, social and economic challenges, the Dutch find ways to ‘grow’ innovation and entrepreneurship.

In order to remain a leader in solving global challenges, the Dutch maintain what they term important ‘Top Sectors’. There are ten of these:

• Agri & Food

• Chemistry

• Creative Industry

• Energy

• High Tech Systems & Materials

• Horticulture & Starting Materials

• ICT

• Life Sciences & Health

• Logistics

• Water & Maritime

TOP SECTORS IN THE NETHERLANDS

In this chapter we will look closely at these Dutch Top Sectors, by describing recent and representative facts and figures, typical characteristics, knowledge infrastructure, and their specific challenges, objectives and ambitions. For every sector we will also highlight specific products or themes.

With the business stories in the rest of the book we give entrepreneurs a platform. We encouraged them to talk about how their own company developed during the past years, decades and sometimes even centuries. In this way we have been able to show how Dutch industrial companies continue to operate at the forefront of modern global markets, each in their own sector or niche, as well as specifically discussing how they deal with the global, social and economic challenges that confront them.

19 DUTCH INDUSTRY

20 AGRI & FOOD

The Top Sector Agri & Food is a powerful driving force for the Dutch economy.

It accounts for more than ten per cent of the country’s national income and almost 1 of every ten Dutch employees work in this sector. Every day, the sector makes an important contribution to prosperity by providing sufficient, tasty, safe, and healthy food for the population of the Netherlands and for export in Europe and worldwide.

AGRI & FOOD

The growth of the world population to 9,7 billion people in 2050 and increasing prosperity is making the sector more important, while also creating major challenges for it. These relate to areas such as sustainability, health, and food safety. The sector has a clear agenda for tackling the challenges of the future and for renewing, strengthening, and further expanding its position.

An Agrifood powerhouse

Fuelled by world-class research institutes, universities and public-private partnerships between science, industry and government, the Netherlands is a world leader in agrifood innovation – from farm to fork. As a powerhouse for food, the Netherlands is the second largest exporter of agricultural products in the world, second only to the U.S.

Fifteen out of the top 20 biggest agrifood companies have major production or R&D sites in the Netherlands. These top food companies in the Netherlands include Nestlé, AB InBev, Coca-Cola, Unilever, Heineken, Cargill, and Kraft Heinz. In addition to these food giants, the Netherlands is home to fast-growing innovators like Beyond Meat, Innocent Drinks and Lamb Weston / Meijer. Together, this vast pool of companies and innovators creates an agrifood powerhouse.

Mission driven agenda

The Netherlands faces a number of major challenges in the areas of agriculture, water and food. Together with the Top Sectors Horticulture & Propagation Materials and Water & Maritime a joint Knowledge and Innovation Agenda has been created for six

missions across the years 2024-2027. In this agenda, the three top sectors describe how they will tackle the knowledge and innovation tasks associated with the six missions:

Resilient nature

By 2050, biodiversity and resilience of nature in the Netherlands are sustainably and measurably strengthened. Both society and the economy actively contribute to this.

Sustainable agriculture and horticulture

In 2050, Dutch agriculture and horticulture will be integrally sustainable: economically future-proof, resistant against a changing climate and fitting within the boundaries of the natural environment, and contributing to the well-being of people and animals.

21 DUTCH INDUSTRY

TOP SECTORS IN THE NETHERLANDS

Vital rural areas in a climate-proof country

In 2050, the design and use of rural and urban area will fit within the preconditions of natural systems such as climate, water and soil. For both types of areas, there is a coherent perspective. This will contribute to broad prosperity for who live, work and recreate there.

Sustainable and valued food that is healthy, accessible and safe

In 2050, the Dutch food system will be ecologically, socially and economically sustainable, with an ecological footprint half as large as in 2015. Food in the Netherlands is in addition to sustainable also tasty, healthy and safe. The entire food chain is economically healthy.

Sustainable and safe use of the North Sea and other larger waters

In 2050, economic activity on the North Sea and other major Dutch waters, including energy production, food production, shipping and fishing, will fit within ecological preconditions. Sufficient fresh water of good quality is guaranteed.

Safe and resilient delta

In 2050, the Netherlands will be, despite rising sea levels, and more variable supply of river water, still a safe and resilient delta. Land and water are protected with affordable, circular, climate-neutral and nature-inclusive measures. Ports are accessible and rivers, canals and the North Sea are safely navigable.

Next to these missions key technologies will be developed that help the sectors to achieve their missions and goals more effectively, faster and/or more efficiently. The agenda builds on the previous knowledge and innovation agendas. More intensive cooperation between the three top sectors, companies, knowledge institutions and the governments (national and provincial) will ensure a more integrated approach to the topics at stake. New themes are restoration and protection of nature, biodiversity and broad prosperity in rural areas.

By working together and investing in knowledge development and innovation, a major contribution can be made to solving societal issues, both in the Netherlands and abroad. The agenda will also ensure that the Netherlands will remain as the global hotspot for smart solutions to future problems in agriculture, horticulture and the water sector.

22

AGRI & FOOD

23 DUTCH INDUSTRY

NETHERLANDS

TOP SECTORS IN THE

24 AGRI & FOOD

TOP SECTORS IN THE NETHERLANDS

Tough tasks, powerful parties, international reach

The tasks present considerable challenges for the public and private sector and knowledge institutions. In the fields of agriculture and in water and food, the Netherlands is a global leader in the development of smart, efficient solutions. This puts the top sectors Agri & Food, Horticulture & Propagation Materials and Water & Maritime in an excellent position to engage with these challenges and remain world leaders in sustainable solutions for global social issues in agriculture, water and food.

In line with national and international agendas

The development of new knowledge and innovations as mentioned above is in line with the most important international policy agendas. On a European level, there is a close link with the ambitions of Food 2030, Agricultural Research & Innovation, the Biodiversity Strategy and the Horizon Europe programme of the EU commission. On a global level, a link is being made with the Sustainable Development Goals of the UN: No Poverty, Zero Hunger, Clean Water and Sanitation, Decent work and Economic growth, Sustainable cities, Responsible consumption and production, Climate Action and Protection of bio-diversity.

25 DUTCH INDUSTRY

26 CHEMISTRY

TOP SECTORS IN THE NETHERLANDS

The Netherlands is one of Europe’s leading suppliers of chemical products and services. The Dutch Chemistry industry works methodically to find solutions for society’s great challenges, especially for the energy and raw materials transition. Chemistry companies work together on production and innovation with knowledge institutions and government organizations and take advantage of regional clustering.

CHEMISTRY

ChemistryNL is the name of this Top Sector that executes the mission-driven top sector and innovation policy of the Ministry of Economic Affairs and Climate.

The drive towards a ‘Green Chemistry Country’ for a circular economy

Like other industries the world over, the chemistry industry must deal with increasing scarcity of natural resources. The Dutch see this as an opportunity to transition to greener chemicals for sustainability and circularity. This means that environmentally friendly source materials should be utilized to develop smart materials and solutions, and new processes developed that reduce the production of unwanted by products, waste materials and CO2 emissions.

The goal by 2050 is to be recognized as the ‘Green Chemistry Country ‘– founded on sustainable resource streams and clean and sustainable production processes – and to be ranked among the top-three producers of high-tech materials worldwide.

The Dutch open and cooperative platform of chemical solutions for global challenges

Global challenges in the field of climate change, circularity, mobility, health and food provide an opportunity for the chemical industry. The Chemistry sector in the Netherlands provides a platform where various stakeholders can connect with each other and co-create new sustainable solutions. The Netherlands offers a vibrant

home to over 2,000 chemical companies, including 18 out of the 25 major chemical companies in the world. And it continues to attract investments from both major companies like SABIC, Neste, Mitsui and Teijin, as well as from innovative new foreign scale-ups.

This ecosystem of innovative chemical startups and SMEs finds public-private partnerships (PPPs), university campuses and knowledge institutes focused on finding future solutions. This Dutch chemistry network can support companies in their ambitions to contribute to solutions to global challenges, next to providing them with an ideal springboard to reach the rest of Europe and beyond.

27 DUTCH INDUSTRY

Mission driven cross sectoral impact

The chemistry sector is ideally positioned to support the Top Sectors in achieving the mission objectives of the four societal challenges “Energy transition and sustainability”, “Agriculture, water and food”, “Health and care” and “Security”. After all, chemistry produces many substances and materials that other industrial sectors use for manufacturing their products. So, where chemistry becomes more sustainable, society becomes more sustainable too.

• Take, for example, the developments in aromatics, such as benzene, toluene, xylene and phenol, which are used by the chemical industry for the production of plastics, chemicals and coatings. To date, these have been obtained from crude oil and are therefore responsible for significant CO2 emissions. That is why the chemical industry is now working on obtaining aromatics from plant waste. This will have a serious impact, because fossil-based aromatics account for no less than 40% of all chemical ingredients in the world.

• Far more can be said about how chemistry is being made more sustainable. For example, the use of resources such as biomass, processed waste and unraveled polymers. Then there are also electrochemical processes for the conversion of hydrogen, CO2, nitrogen or biomass into fuels and resources for the chemical sector.

• And soft advanced materials should not be forgotten either. This chemical technology makes it possible to build materials from the molecular level upwards and to provide them with qualities such as safety, strength, lightness of weight, a longer durability and lower costs. All of that is done to reduce the CO2 footprint as much as possible. One application could be high-quality, fiber-reinforced thermoplastics as a plate material for superlight cars that consume less energy and produce fewer emissions.

• Another example is the chemical production of thermochromic coatings and foils for glazing that improve light reflection thus reducing the necessity for air-conditioning.

This same positive influence on industrial value chains assumes the safe design of existing and new chemical substances, materials, products and processes. Those can be (re)designed from the molecular level upwards so that highly alarming substances can be banished and emissions prevented. Then both people and the environment will no longer be exposed to toxic substances, and materials and products in a circular economy will be safe to reuse.

28

CHEMISTRY

TOP SECTORS IN THE NETHERLANDS

The future of chemistry

A collaboration between industry, research institutes, and government, ChemistryNL promotes public-private cooperation in chemical science and innovation in the Netherlands. New societal challenges and scientific developments require significant changes in education, research and innovation, globally, and to achieve them; the Dutch chemistry sector has set the following three ambitious goals:

• By 2050, the Netherlands will rank the highest in the world when it comes to green and sustainable chemistry.

• By 2050, the Netherlands will be in the global top 3 of producers of smart materials with a high added value and smart solutions.

• Thanks to high quality and ground-breaking scientific research, new areas of science and innovation will open up.

Furthermore, two cross-sectoral priorities are defined: the biobased economy and resource efficiency. To reach these green and sustainable goals, Dutch companies, scientists and knowledge institutions collaborate by way of the main thrusts below:

• Chemistry of Advanced Materials

• Chemical Conversion, Process Technology & Synthesis

• Chemistry of Energy Materials

• Chemical Sensing and Enabling Technologies

• Chemistry of Life

29 DUTCH INDUSTRY

Dutch ecosystems of

educations and R&D

At the heart of the Dutch chemistry ecosystem are world-class education, cuttingedge research and robust public-private R&D partnerships that support inter-company and public-private research.

The Netherlands hosts key R&D labs of for example DSM, SABIC, AkzoNobel, Shell, Avantium, Corbion and Arlanxeo and also has a vibrant ecosystem of innovative chemistry startups and SMEs. Public-private partnerships (PPPs), campuses, iLabs, COCI’s and tax incentives to stimulate R&D. PPPs include consortia on sustainable processing, materials, electrochemistry, biobased and novel chemicals.

Finding collaboration between research institutes, companies and government is in the genes of Dutch research and development, leading to new solutions for the chemical industry in smart manufacturing and digitalization.

DID YOU KNOW?

• The Dutch Chemical industry excels in three sustainable areas: industrial biotechnology; high-performance materials and fine chemistry.

• The Netherlands is home to world-class R&D institutes for fundamental and applied research such as TNO, Delft University, Twente University, Wageningen University and Eindhoven University.

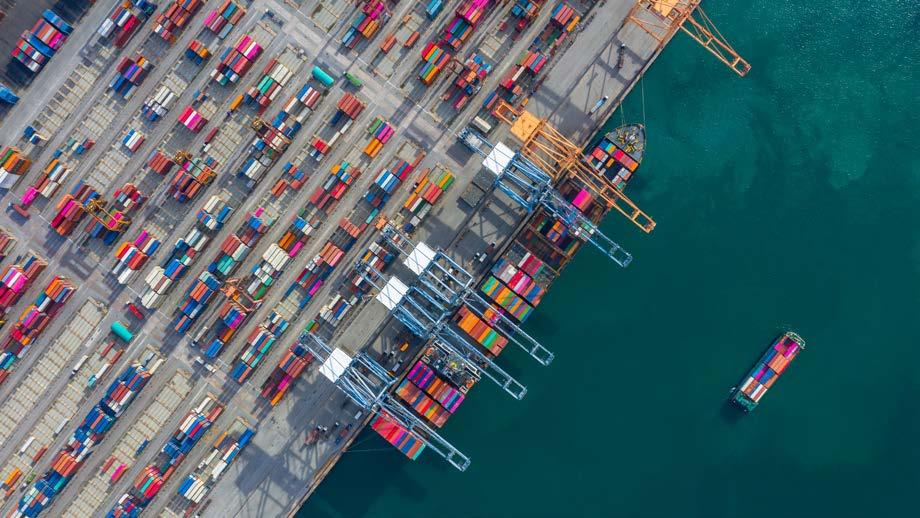

• At the Port of Rotterdam - Europe’s largest harbour - Netherlands-based chemical companies tap into one of the largest refining and chemical clusters in the world.

• Within the strong chemistry community, the Dutch cooperate via long-term publicprivate partnerships (such as the lnstitute for Sustainable Process Technology and the Dutch Polymer lnstitute) as well as through ‘open innovation’ in the seven Centres for Open Chemical lnnovation (COCI): Green Chemistry

Campus, Chemelot, Biotech Campus, Green PAC, Pivot Park, Plant One and S/Park.

• In the area of advanced materials (polymers, composites, etc.), the Netherlands consistently punches above its weight, producing worldrenowned innovation in materials and composites, such as Twaron, Dyneema, and Glare, as well as developing folding tires for the automotive industry.

• Around 80% of chemical products made in The Netherlands are exported. One-fifth of all Dutch exported goods come from the Chemistry sector.

• lnnovation is vital to achieving the industry’s ambitious goals - the Dutch Chemistry industry invests some 2.5% of its revenues to in-house R&D; around 1.4 billion euros per year.

• The Netherlands plays host to 18 of the world’s top-25 chemical Companies, including BASF, AkzoNobel, LyondellBasell, SABIC, Teijin and Dow.

30

CHEMISTRY

31 DUTCH INDUSTRY

NETHERLANDS

TOP SECTORS IN THE

32

INDUSTRY

CREATIVE

© PRADA SS2024 MENSWEAR SHOW PHOTO BY AGOSTINO OSIO

TOP SECTORS IN THE NETHERLANDS

Built on a rich artistic history including Vermeer, Rembrandt, Mondrian and Escher, the creative industry in the Netherlands is known for its entrepreneurial spirit and out-of-the-box thinking. In fact, the Netherlands generates more creative output than almost any other country in the world.

CREATIVE INDUSTRY

The Creative Industry top sector comprises various disciplines, such as architecture, design, fashion, media and ICT, gaming, and pop music. This top sector plays an important role in prompting innovation in other sectors, and in solving societal challenges in such areas as healthcare, security, and energy.

Ranked in the global top 10 for trade, jobs and brands, the Dutch creative industry fuels innovation in the Netherlands. More than 30 Dutch knowledge institutions offer Creative Arts and Design courses. Highly skilled, multilingual workers come from all over the world to find opportunity in the Netherlands’ creative agencies. Here, creatives thrive thanks to the Dutch quality of life and topranked digital and transport infrastructure. The Netherlands thus offers the ideal test market for creative companies looking to pursue innovation in Europe.

CREATIVE INDUSTRY?

The creative industry is a collective term for all designers, creators and adjacent organizations. For example, fashion design, marketing, social design, photography, events, visual arts, production houses and (pop) venues. Creative professionals often work in and for other sectors. Examples include healthcare, energy, security and construction. What binds creative professionals together is that they all use creativity as a means to create value.

Creative launchpad of Europe

The Netherlands is a global hub for media and broadcasting, housing many of the industry’s biggest players. In particular, Amsterdam and Hilversum are hotbeds for media and entertainment companies, including NEP Group, Netflix, Discovery and Disney. On top of that, the Dutch have a knack for reaching audiences.

Creativity and sustainability are woven into the Dutch fashion and apparel sectors. Companies like Tommy Hilfiger, Asics, and Patagonia are drawn to this unique combination and have established European headquarters in the Netherlands. In Amsterdam, Denim City is pioneering the future of the jeans industry. Providing access to most European countries by road transport, the Netherlands is a strong logistics

33 DUTCH INDUSTRY

CREATIVE INDUSTRY

base for fashion and apparel companies, including Crocs, Michael Kors and Decathlon. World-class institutions like Design Academy Eindhoven, Amsterdam Fashion Institute and Arnhem Academy of Art & Design produce some of the best and brightest talent in the field. From high-quality design, to headquarters and logistics, to sales and marketing, the Netherlands is the place to be for fashion companies.

As a result, the creative industry is growing faster than the rest of the Dutch economy. In addition, it makes a significant contribution to employment and the growth of new companies in the Netherlands. The sector pursues innovation in other sectors and helps to find solutions to social challenges. To keep the sector top of the bill, state of the art knowledge is essential. Thus, the Dutch creative industry also holds a top position in the international arena.

CLICKNL

CLICKNL – is the TKI of the Top Sector Creative Industry, and formulates what knowledge and methods are required to achieve a resilient and relevant creative sector. In addition, it drives the agenda of the creative sector to make an important contribution to the mission driven innovation policy and the missions from other top sectors.

Knowledge

Together with creative professionals and researchers, CLICKNL draws up the agenda for the creative industry named KIA Resilience. This describes how the creative industry contributes to (social) challenges and what knowledge the creative professional needs to be able to do this. With this agenda they influence and steer subsidy schemes, programs and projects. They also look at the application and development of key methodologies/KEM: methods that help to tackle issues. They inspire and encourage the use of previously acquired knowledge in practice, by sharing inspiring content (including cases and news) with both online and physically (events).

Collaboration

CLICKNL builds programs and projects around (social) challenges in which the creative industry plays an important role.

Creativity challenges

The endless streams of technological developments impact the way people interact, live and work together. Creative professionals flourish in these conditions: being in the business of connecting, enticing and mobilizing people by providing different insights and portraying panoramic views, often out of more than sheer occupational interest. From a cultural and societal perspective, but also with regard to economic value, creative professionals in broad partnerships develop solutions that bring support for change. The sector is thriving, also internationally. To maintain this position and to be able to face the challenges now and in the future, creative professionals are investing in new knowledge, methods and techniques supported by an agenda which offers the vision and ambition for that crucial knowledge base.

Knowledge and Innovation agenda

Society is the creative professional’s playing field. Due to the major transitions that are currently happening in society, the way in which the professional works and collaborates is changing. The role of the creative professional has become more fluid than before. At the same time, more is expected of the rationale behind developed interventions, and the complexity of issues and solutions is increasing. To support the creative professional in this, partnership between the creative industry and knowledge institutes is crucial.

34

TOP SECTORS IN THE NETHERLANDS

35 DUTCH INDUSTRY

© COUNTRYSIDE | PHOTOGRAPH BY LAURIAN GHINITOIU COURTESY

CREATIVE INDUSTRY

Creative industry and Key enabling methodologies (KEM’s)

It is widely recognized in the approach and discussions surrounding the mission-driven innovation policy that all Top Sectors are pursuing, that a multidisciplinary approach is required. Investments must not be made only in technology, but also in social and cultural aspects. The approach to this complex problem, working multidisciplinary and the themes of the missions fit the creative industry well.

Affordable healthcare, conservation of resources and nature, reduced greenhouse gas emissions, affordable and sustainable energy. These are just a small sample of the many social challenges we face today. Innovative solutions are needed to take targeted action. But how do we develop these solutions and ensure the right societal impact? That’s where key methodologies, or KEMs, are needed. KEMs (Key Enabling Methodologies) are methods, strategies, tools and practices that give you tools to realize innovations. KEMs are relevant to anyone working on a complex, societal puzzle: business, education/knowledge institutions, thinkers, makers, policy makers, consultants, clients, nonprofit organizations and civic initiatives.

For this reason, CLICKNL, in close cooperation with the creative industry and knowledge community, has drawn up its research agenda for the KEMs. This agenda was created, on the one hand, to improve our knowledge about KEMs and stimulate their development.

36

© MUSEO EGIZIO | PHOTOGRAPH BY OMA

37 DUTCH INDUSTRY

IN THE NETHERLANDS

TOP SECTORS

38 ENERGY

The Dutch energy sector enjoys a strong global position. This success is founded on a typically Dutch quality: the willingness to share knowledge within tight-knit alliances of business, research, NGOs, and government. This has made the sector a front-runner in public-private research and open innovation partnerships and it is exemplary for how it approaches complex energy issues.

ENERGY

Energy Innovation NL is a public-private partnership for energy innovation financially supported by the Ministry of Economic Affairs and Climate. Energy Innovation NL encourages new initiatives that accelerate the transition to a sustainable energy system. In this way new activities are being created while strengthening the Dutch international competitive position. Energy Innovation NL also contributes to the specific missions needed for the energy transition, which have been formulated by the Dutch government.

Drive towards a climate neutral energy system

Our fossil fuel-based energy system is making way for a renewable and more decentralized energy supply. Acceleration of this energy transition contributes to a

sustainable economic growth and a healthy society which includes economic and social justice and a clean environment. It is through the power of Dutch energy innovations that we can transition to an affordable, reliable and sustainable energy system. The Netherlands has made substantial strides in the areas of renewable energy and energy efficiency, attaining a leading position in offshore wind, deployment of solar panels, and development of sustainable heating solutions for buildings. The energy sector contributes substantially to Dutch national revenue, exports and employment, both directly and indirectly.

Close collaboration is key

Cooperation is especially important when it comes to developing and rolling out technological, social and institutional

innovations. From boosting energy efficiency to enabling energy transition, while also building a circular economy, ‘cleantech’ companies will have a decisive impact on the future of our planet. In the Netherlands, we are proud to have a large and sophisticated technology sector, with hundreds of companies focusing on sustainable solutions in many key areas: from renewable energy production to biobased technologies and energy-efficient process technology. If anything characterizes their portfolio of clean technologies as ‘typically Dutch’, it is probably that many of them bear the stamp of close collaboration.

Strong in fundamental research

The Netherlands has a strong backbone of internationally renowned research groups, both at universities and independent

39 DUTCH INDUSTRY

TOP SECTORS IN THE NETHERLANDS

ENERGY

knowledge institutes. These have, for decades, been conducting groundbreaking research in such diverse areas as Solar-PV technology and biobased materials. Knowledge has been built up, in some cases facilitated by the the Dutch Research Council (NWO), by several university groups as well as by the Netherlands Organization for Applied Scientific Research, (TNO) which together comprise one of Europe’s largest energy research organizations. Research in the field of energy technology in the Netherlands is held in high regard. For university research this is apparent from the high score on the citation index on which the Netherlands ranks fourth after Switzerland, Denmark and Singapore. Energy Innovation NL facilitates close collaboration between these research groups, NWO and TNO and government agencies and the private sector.

Driving energy innovations

Within this top sector, four ‘Top Consortia for Knowledge and Innovation’ (TKIs) work with governments, the business community, knowledge institutes, partnerships, NGOs and regions. They focus on the entire innovation chain: from fundamental energy research via applied research to demonstration and exploitation:

TKI Offshore Energy: Offshore energy is an essential component for a successful energy transition in the Netherlands. This TKI stimulates and facilitates offshore innovations through research, development and demonstration on three themes: cost reduction

and optimization, integration into the energy system and integration into the environment. The aim of this is to enable offshore wind energy to make a major contribution to the energy transition in the Netherlands and beyond, and to strengthen the competitive position of the relevant companies in the international export market.

EXAMPLE: NEW STANDARDS IN THE WIND TURBINE INDUSTRY

The Haliade-X prototype in the Port of Rotterdam has set several new standards in the field of sustainable wind energy. This wind turbine is 248 meters and has blades of 107 meters. It produces the largest energy yield ever from a single wind turbine. Annually, the Haliade-X can generate 46.3 GWh of electricity: as a consequence, CO2 emissions are reduced by 28.1 kilotons.

TKI Urban Energy: This TKI stimulates the development of innovations for a sustainable, reliable and affordable energy system in the built environment. It supports partnerships with small businesses, larger companies, research institutes, universities, potential customers and other stakeholders active in the energy innovation sector. Over 450 innovation projects have been started in the last few years, on topics ranging from solar power technology, reduction in energy consumption, sustainable heating and cooling systems, and smart IT solutions.

EXAMPLE: ENERGY-EFFICIENT AND CLIMATE-FRIENDLY AIR CONDITIONING

The air conditioning ICECUBE comes without harmful refrigerants. It is made of recycled plastic and is competitive with its traditional counterparts. Because it uses ‘dew point cooling’ it uses 80% less energy. The operating costs remain low because time-consuming registration and expensive control of harmful refrigerants are not required.

TKI Hydrogen: Hydrogen, Green gases, CCUS (Carbon Capture, Utilization and Storage) and Geo-energy, the last focusing on the use of the sub-surface for the energy transition, are the main focus areas of this TKI. In doing so, it builds on the traditionally strong position of the gas sector in the Netherlands, by helping knowledge institutions and companies to develop, demonstrate and apply sustainable and innovative technologies. These also include the optimal use of existing knowledge, expertise and assets such as pipelines, locations and gas storage. New Gas has more than 400 cooperation partners such as Green Gas Netherlands, the CATO CCS consortium, the GEO Energy consortium and the Dutch Hydrogen Platform.

TKI Energy and Industry: Dutch industry is responsible for approximately 40% of the greenhouse gas emissions in our country. This demands that the efficiency of the energy use in this sector is increased and the

40

41 DUTCH INDUSTRY

NETHERLANDS

TOP SECTORS IN THE

42

ENERGY

sources for the required energy are shifted to sustainable ones. The aim of this TKI is to realize a sustainable and inclusive industry that operates within the space of climate and environment. With about a hundred projects in their portfolio, the TKI sees that the Dutch process industry is gradually becoming a cradle for innovation and its application.

EXAMPLE: REDUCING ENERGY COSTS AND CO2 EMISSIONS IN THE DUTCH PROCESS INDUSTRY

Dow Benelux B.V. developed the steam recompressor, which considerably reduces CO2 emissions. The recompressor can sometimes reuse energy produced from steam up to five times, for example in the main process of cracking molecules, thus enabling production of more new chemical compounds.

The Intersecting Themes

The tremendous challenges associated with the global energy transition require new innovations and new ways of working. Often these are not sector-specific but rather touch on essential insights and challenges across multiple sectors. Therefore Energy Innovation NL works on several intersecting themes:

System integration: System integration in the context of the energy transition means

the coordinated integration of chains of different energy carriers and end-use sectors into one sustainable, reliable, affordable, and safe energy system, with broad societal support. An energy system encompasses the entire energy value chain, including everything necessary to bring energy from generation to consumption. This integrated energy system operates at different spatial and temporal scales, from local to Northwestern European scale and from seconds to several decades.

Socially Responsible Innovation in Energy:

The aim of the programme is to stimulate other innovation programmes to work in a more integrated, co-creative manner on innovations that contribute to a more sustainable society. Several interests are weighed up to discover where possibilities arise for multiple-value solutions. For example, these might include wind parks, built and operated in such a way that underwater ecosystems are restored and biodiversity flourishes, leading to a healthier fish population.

Human Capital Agenda:

Tens of thousands of additional workers are needed to achieve climate goals. Energy Innovation NL is making efforts to pass on knowledge and organizing capacity through skills building. Due to the energy transition, education and the business community will have to cooperate even more closely on regional levels to achieve this, in what are termed

‘Learning Communities’. This approach will ensure that future staff is trained in the right way and shortages in personnel will not hamper the implementation of the energy transition.

Digitalization: This programme aims to utilize the potential of digitization towards achieving a sustainable energy system. Digital developments create new possibilities and change the way people live and work. In addition to sustainable sources and changing energy networks, the energy transition also entails a changing society, in which digitization enables us to deal with energy in a whole new way. Digitization provides a compass for the desired energy solutions of the future.

Financing Desk: Finding the right finance is essential for successfully developing the energy innovations. This is seen by entrepreneurs from Energy Innovation NL as the main challenge for valorizing such innovation. To prevent innovation from failing prematurely and/or valuable time being lost, the Financing Desk offers help to SME entrepreneurs who are struggling with a financing issue.

43 DUTCH INDUSTRY

TOP SECTORS IN THE NETHERLANDS

44 HIGH TECH SYSTEMS & MATERIALS

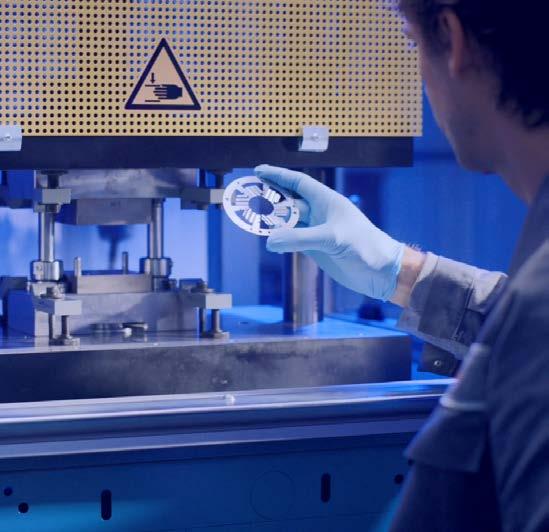

From satellites the size of a milk bottle to micro-chips processing megabits of information, innovations play a key role in our fast-moving high-tech world. Dutch innovations are intelligent, accurate and efficient. They are utilised worldwide in medical equipment, semi-conductor manufacture, cars, logistics systems, aeroplanes, satellites and energy systems. By creating the right framework and conditions, the Netherlands supports innovation at all levels, be it big or small; or even tiny.

HIGH TECH SYSTEMS AND MATERIALS

Today, the Netherlands continues to pioneer new technology to help solve major challenges. Holland High Tech (HHT), the Top Sector High Tech Systems and Materials, unites industry, academia and government to play a crucial role the urgent transitions that are necessary: the energy transition, the development of a circular economy and the development of digitalisation including smart industry and key enabling technologies.

The ‘ecosystem’ of Holland High Tech comprises 100,000 enterprises where more than 500,000 professionals work. Multinationals, SMEs, start-ups as well as scale-ups. This industry creates 166 billion euros in production value, and 70 billion euros in export. Annually, it invests 6.1 billion euros in R&D, of which over 500 million euros is in collaborative programmes with academia

and government, both within and outside the Netherlands. More than half of all private R&D in the Netherlands is invested by hightech companies.

This ecosystem develops key enabling technologies (KETs) for solutions to the grand societal challenges of our time, by realising products and services that make these solutions economically feasible. Key enabling technologies are omnipresent in consumer and business applications ranging from telecommunication, the internet and energy supply through to medical instrumentation, automobiles, airplanes and satellites. Holland High Tech is the largest top sector by some distance in terms of production, added value, exports, and employment.

Success in our top sector critically depends on the availability of qualified personnel. Knowledge workers in technology continue to be scarce. Education and training in applied and application- oriented science are essential, as is access to the international labour market. The industry and research organisations operate in a global value chain. HHT actively collaborates with international innovation attachés to enlarge the global Dutch network.

The urgent transitions

With fifteen innovation roadmaps and a coordinating role in the Knowledge and Innovation Agendas (KIA’s) Key Enabling Technologies and the Agenda Security, Holland High Tech targets the urgent transitions with a focus on economic and societal impact. In a

45 DUTCH INDUSTRY

TOP SECTORS IN THE NETHERLANDS

HIGH TECH SYSTEMS & MATERIALS

continuously changing landscape of financing support for research and innovation, Holland High Tech strives for ways to add value to both the sector and current transitions. This framework provides the connection between the bottom-up programming of the HTSM technology roadmap teams and the top-down programming in the Dutch mission-driven top sector and Innovation Policy.

• Circular economy

The Netherlands wants a completely circular economy by 2050. Holland High Tech recognizes that the circular economy is becoming an ever more important topic for the high-tech manufacturing industry. We are devoted to this theme, because we are convinced that the high-tech sector must provide an essential contribution to achieve the objectives of a circular economy as well as develop the inventions that make it possible.

• Energy transition

The energy transition is an important theme in the mission-driven innovation policy. The Netherlands wants to be completely climate-neutral by 2050. Before 2030, the target is to achieve a 55% reduction in CO2 emissions compared with 1990. We will achieve this through making the electricity system and built environment more sustainable and through realising a climate-neutral and competitive industry, emission-free mobility and climate-neutral agriculture.

EXAMPLE: BREAKTHROUGH IN QUBIT TECHNOLOGY

Engineers from Intel and scientists from QuTech have delivered the first qubit made in the very same industrial manufacturing facilities that mass-produce conventional computer chips. This advancement has been a long-standing goal due to its promise of scalability. The breakthrough is a crucial step towards scaling to the thousands of qubits that are needed for practical quantum computation.

The industrial manufacturing of a single qubit device is now a fact. Parallel efforts are geared towards controlling multiple spin qubits and improving the quality of the qubit control. Combined, these advances will build a solid foundation to realize full-scale quantum computing integrating millions of qubits.

• Digitalization & Smart Industry

Digitalization including smart industry are changing global economies and societies at breakneck speed. New digital technologies act as a catalyst for the development of the circular economy, the energy transition as well as worldwide (cyber)securtity and quality of living. We stimulate new digital technologies and innovations, examples include quantum computing and laser satellite communication.

EXAMPLE: EARLY WARNING SCAN FOR BREAST CANCER USING 3-D TECHNOLOGY

Breast cancer is the world’s most prevalent cancer. The lives of many women could be saved if screening could be done more cheaply, less invasively and could better detect malignant cells earlier on. A collaboration between 3-D photographer Tom Sanders, the Jheronimus Academy of Data Science in Den Bosch, Holland High Tech and medical equipment supplier Demcon, have started to develop the Early Warning Scan using 3-D technology which measures changes in the movement of breast tissue.

46

TOP SECTORS IN THE NETHERLANDS

• Key enabling technologies

The Dutch high-tech sector develops solutions for societal challenges, based on key enabling technologies, through realising products and services that are economically viable and where the Netherlands play a key role in the international field. Examples are integrated photonics, Quantum technologies, Imaging technologies, Mechatronics and opto-mechatronics, Artificial Intelligence, Data science, Energy materials, Micro-electronics and Cybersecurity.

ELECTRIC FUEL CELL / HYDROGEN

The Netherlands wants to achieve zero-emission mobility for people and goods by 2050. This calls for decisions to be taken now on implementing smart and sustainable systems in the near future. The Netherlands is among the leaders in the standardisation and rollout of smart charging infrastructure and renewable energy storage. After introducing EV in 2010, the country has one of the densest charging networks in the world with hundreds of fast-charging stations and tens of thousands of regular charging stations. By 2030, an estimated annual average of 400,000 electric vehicles will take to Dutch roads.

47 DUTCH INDUSTRY

48 HIGH TECH SYSTEMS & MATERIALS

A NEW APPROACH TO COMPONENT DESIGN AND MANUFACTURING

Independently of the energy source, the weight of a transportation system always has negative effects on system efficiency and eventually on the environment. Many of the components of transportation systems are single material products and are often overdesigned to meet a wide range of possible applications and conditions. Conventional manufacturing methods (casting, forging and machining from solid blocks) cannot produce locally tailored properties and are thus inefficient and wasteful.

Additive manufacturing (AM) has already revolutionized the way we approach product design and manufacturing. The next paradigm shift is in Multi-Material AM, which allows for simultaneous printing of different materials with functional properties, thus enabling component design with “pre-programmed” site-specific properties. Combining light weight with optimal local properties is the holy grail of the transport sector. Reducing a car’s weight by 100 kg triggers a reduction in CO2 emissions of 7.6 g/km. For the Netherlands alone, this would create a reduction of 830.000t of CO2 per year!

TOP SECTORS IN THE NETHERLANDS

These urgent transitions are enabled ‘bottom-up’ by the HHT technology roadmaps. Each roadmap is managed by a dedicated team of experts from enterprises, institutes and universities, with roadmaps largely overlapping with the key enabling technologies (KETs) defined by the European Commission. All technologies in the top sector are intimately connected with information and communications technology (ICT). KETs are knowledge intensive and associated with high R&D intensity, rapid innovation cycles, high capital expenditure and high-skilled employment. They are multidisciplinary, cutting across many areas, and assisting leaders in other fields to capitalise on their research effort.

Building bridges

HHT actively partners with government ministries and regional public organisations to realise long-term alignment of scientific research, technological innovation, and societal challenges. Value is added by building top-down bridges with the bottomup HHT roadmaps. Cross-over collaboration with other top sectors is increasingly important for enhanced partnership, with explicit involvement of ICT.

As HHT competes in a global market, participation in joint European R&D is a priority for both science and industry. Results gained from European projects leverage the top sector’s national contribution.

Technology transfer and go-to-market Process innovation and digitisation are essential in the deployment of new manufacturing technologies. Smart Industry Fieldlabs, of which there are over thirty in the Netherlands and in which companies can test new solutions, have created a basis or joint experimentation and learning. Government policy and instruments are put in place to support SMEs through smart manufacturing assessment and individual stimulation. Market introduction of products and services that directly serve innovation in societal challenges does not come automatically. Public procurement, as in Small Business Innovation Research (SBIR), can bridge the gap between R&D results and the creation of economic value, especially for SMEs. Successful implementation requires systemic improvement, as well as processes for structural alignment with the involved ministries and funders in the Netherlands as well as worldwide.

49 DUTCH INDUSTRY

HORTICULTURE & STARTING MATERIALS

50

The Dutch Horticulture & Starting Materials sector is among the best in the world today in all fields, whether this concerns entrepreneurship, a capacity for innovation, the level of knowledge or craftsmanship. The corporate community, research institutes and the government join forces to ensure that this top sector remains among the highest-ranking in the world.

HORTICULTURE & STARTING MATERIALS

The economic opportunities and prospects for Horticulture & Starting Materials are excellent. They are powered by global societal challenges such as population growth and ageing, climate change, economic and social inequality, and urbanisation. Horticulture & Starting Materials offers solutions that contribute to food security, safety and quality as well as health, the sensible use of raw materials and the protection of our environment and biodiversity.

About the sector

The business activities of the Top Sector Horticulture & Starting Materials are varied. Horticulture covers greenhouse construction, horticulture production, logistics and collections, such as at auctions and trade,

in order to supply to consumers via the retail sector. Starting materials range from breeding to supplying young plants, for both agricultural and greenhouse crops.

Dutch horticulture enjoys an excellent national and international position due to technological innovations and strong business know-how. This economically healthy sector is growing year on year in terms of production, adding value, exports, job creation and R&D expenditure. Companies in the horticultural chain are investing almost 1 billion euros annually in research & development, 5 percent of the entire R&D expenditure in the Netherlands. Approximately 75% of this R&D expenditure in the horticultural chain is realised by companies active in seed breeding, plant propagation, horticultural technology and the wholesale of horticultural products.

The Dutch golden triangle

The Dutch horticulture & starting materials sector integrates a network of economic clusters and regions where various horticultural chains, services and knowledge institutions work together. Their goal is to foster continuous innovation, such as in robotics and plant monitoring, plant safety or nutritional value. The Netherlands is home to universities and institutes that are best in their field, such as Wageningen University & Research in food and agriculture and TU Delft, and TNO in high-tech solutions. They cooperate in public-private partnerships with the six regional Greenports and world-leading seed, supply and tech-companies. This way we can develop super-efficient greenhouses that make the best of limited water and resources.

51 DUTCH INDUSTRY

TOP SECTORS IN THE NETHERLANDS

HORTICULTURE & STARTING MATERIALS

The sector is characterized by five branches. Vegetables and fruits: Dutch vegetable production is focused strongly on export, especially to EU markets. Including reexport, the Netherlands has been the largest exporter of vegetables in the world for three consecutive years.

Flower bulbs and trees/shrubs: the Dutch bulb sector has a leading position in the world market. Approximately 60% of production and more than 90% of trade is realized via the Netherlands.

Plant breeding and propagation: this subsector includes the development of breeding material, propagation material, cultivation, and the trade of seeds and young plants. Cut flowers and plants: the Netherlands, with 60% of the world trade passing through Dutch companies, is the international commercial centre for flowers and plants.