Quarro maintains a global perspective.

Goodbye 2022, Hello 2023.

Openings, closures and industry moves from across Asia.

Our eye on the international arena.

News from around the raw material sector.

Go green with ceramics.

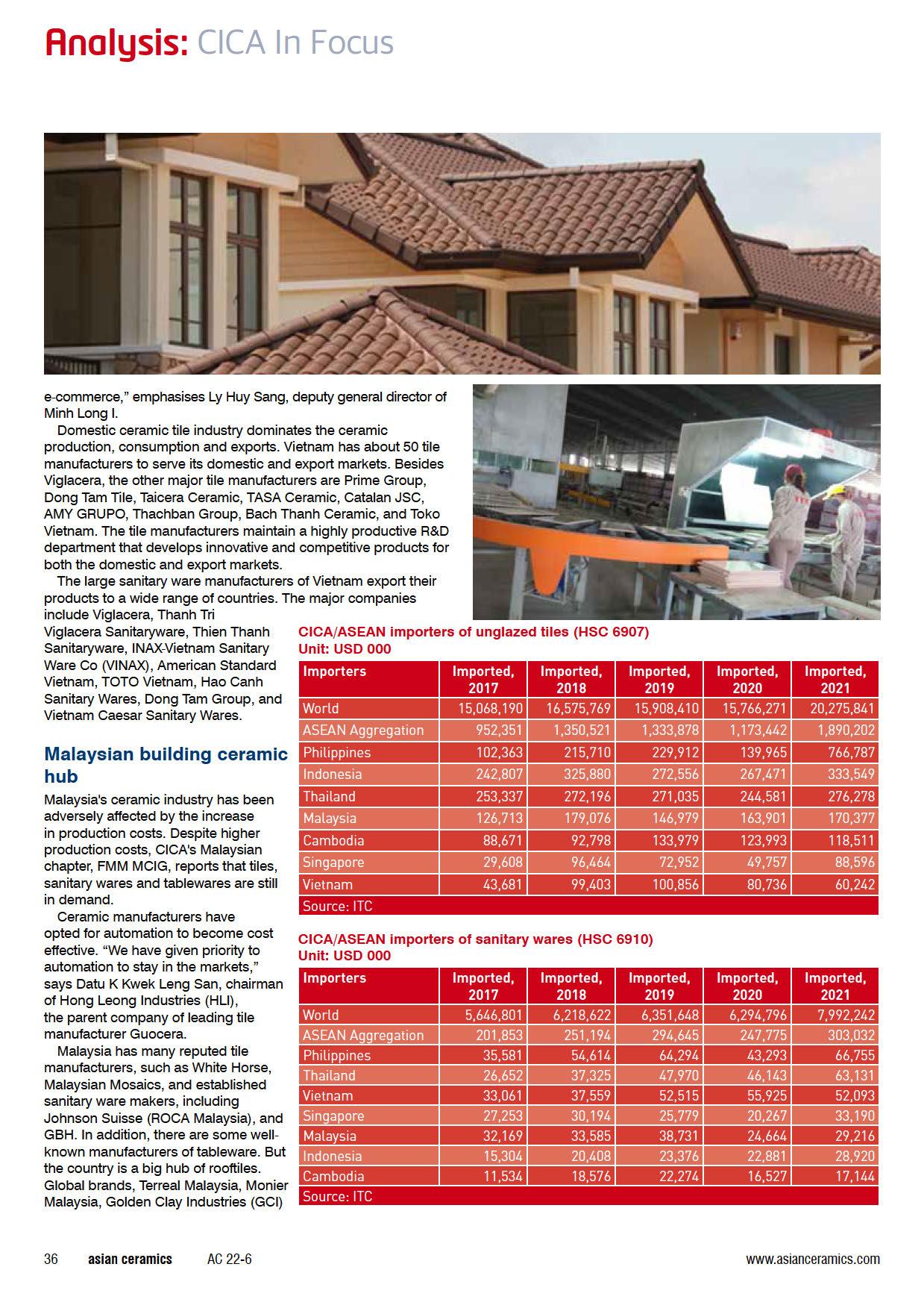

CICA, the apex ceramic manufacturers' association in ASEAN, will hold its 27th council meeting in Bali, Indonesia, on 9 December following a delay caused by the COVID-19 outbreak. The event's overview is provided by Jahir Ahmed.

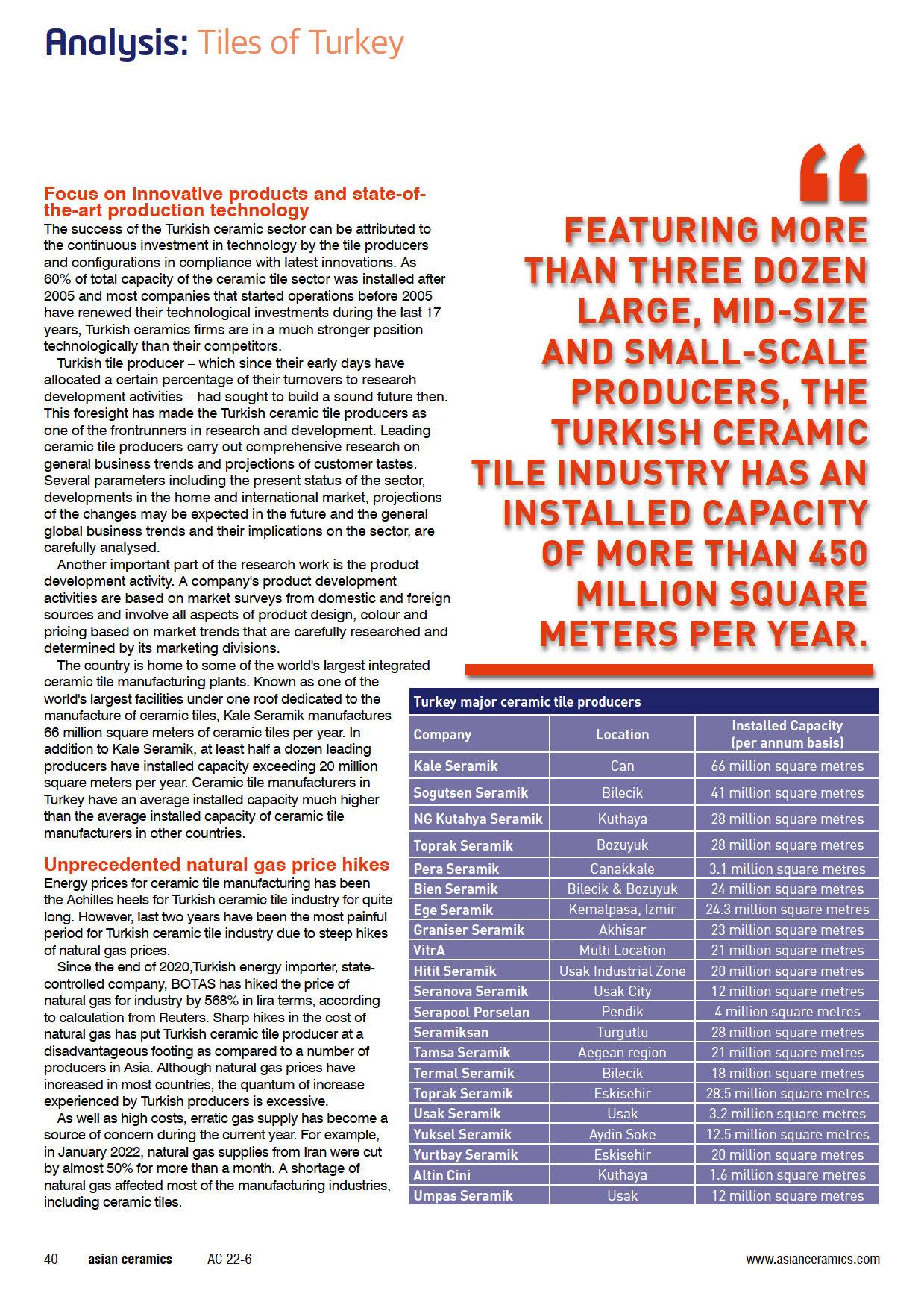

The Turkish ceramic tile industry has grown rapidly over the past 15 years. A large investment in modern technology and trend-setting designs makes Turkish ceramic tile producers some of the best in the industry, writes Yogender Singh Malik.

Bricks from traditional brick manufacturing kilns have facilitated the construction of houses, buildings, and other infrastructure in Cambodia, Laos, Myanmar, Afghanistan, India, Nepal, and Pakistan for centuries. Low-cost automated kilns and brick making machines are changing brick production traditions. Bangladesh and Vietnam paved the way, says Jahir Ahmed.

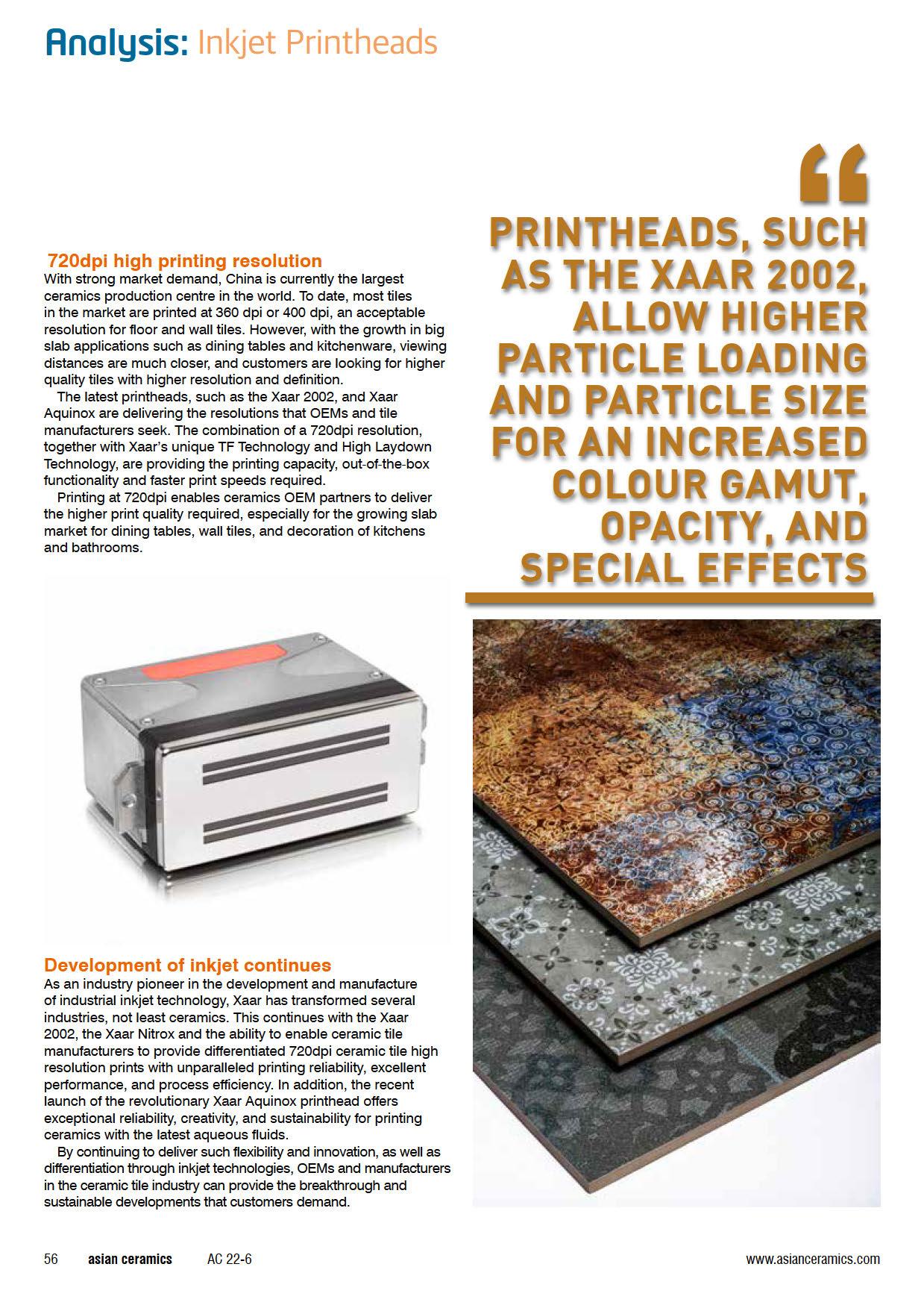

Today's brands continue to benefit from inkjet technology's latest advancements in ceramic tile decoration, says Xaar's chief product architect Michael Walsh.

Michael Hölzgen, global director ceramic auxiliaries division, Zschimmer & Schwarz, discusses his company's successful performance at Ceramitec 2022 and Cersaie 2022, and future plans.

Analysis and insight into Turkey tiles.

William Hunter addresses the after-effects of COVID-19 on world travel, as well as the economic challenges affected by the Coronavirus pandemic and the ongoing conflict in Ukraine in his farewell article for Asian Ceramics

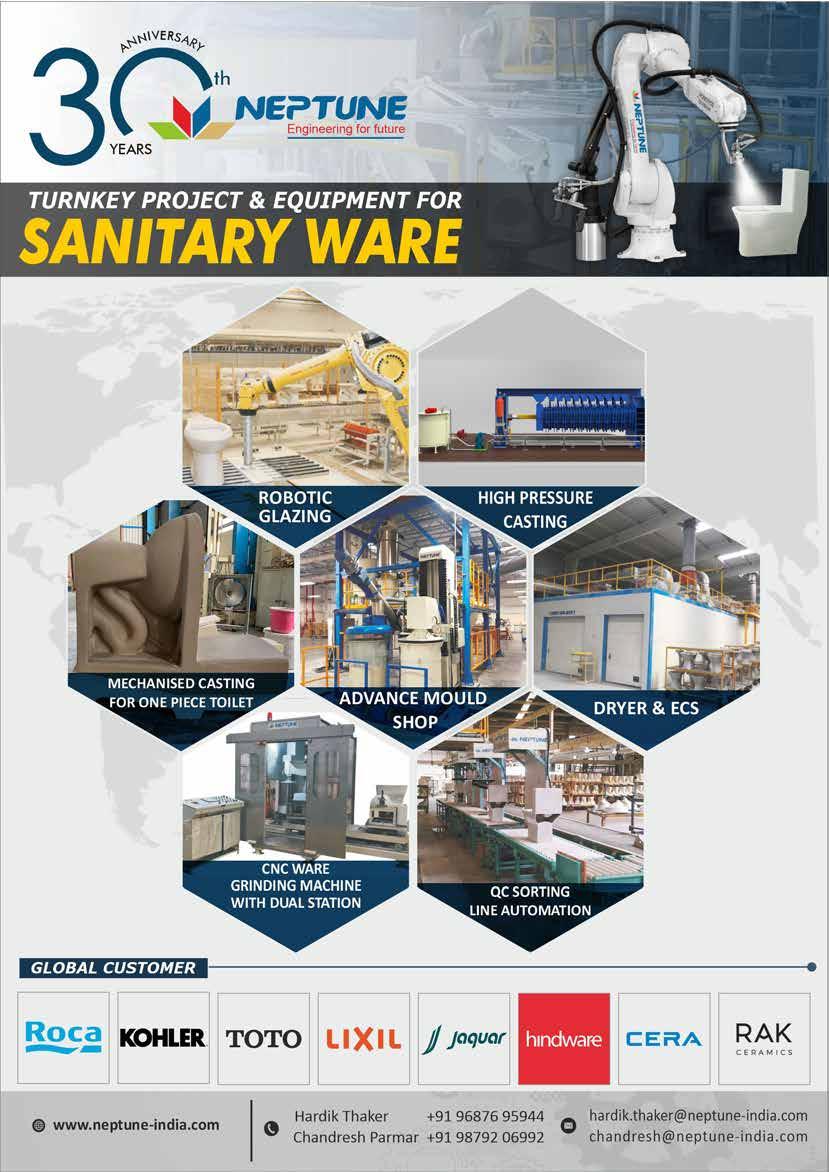

Quarro is a leading miner, supplier and exporter of Industrial Minerals and Indian Natural Stones, including Ball Clay, Kaolin Clay or China clay, Feldspar, Talc, Quartz, Gypsum, Laterite, Sandstone and Slatestone. As an importer and exporter of high-quality minerals, it has been serving several industries, including ceramics, cement, glass, glazes, paint and cosmetics. A constant focus of the company is global sourcing, as well as backward integration of its supply chain. To meet the needs of its customers, it continues to take a global perspective and look beyond geographical and regional boundaries.

With its mining operations in Rajasthan and Gujarat, which are close to three major Indian ports, Kandla, Mundra, and Dahej, Quarro supplies Ball Clay, Kaolin Clay, Talc, and Feldspar to ceramic tile plants in India, Bangladesh, Saudi Arabia, and Oman. In response to the current situation in Ukraine, it has developed a very fine substitute for ceramic clay, which it is now supplying to the Italian market as well. Its quarry produces six million tonnes of ball clay annually and more than 10 million tonnes of kaolin clay annually. Its-house infrastructure allows the company to supply any quantity of Ball Clay, Crude or Washed Kaolin Clay, Feldspar (Chips, Grains, Lumps), and Grey coloured Talc with 85+ L value.

Image Credit: Quarro Global LLP (www.quarro.in) & Minecraft Minerals Pvt Ltd.(www.minecraftminerals.com)

Image Credit: Quarro Global LLP (www.quarro.in) & Minecraft Minerals Pvt Ltd.(www.minecraftminerals.com)

Ceramic production in Turkey stretches back thousands of years, from prehistoric Anatolia's primitive sculpture to the Hitite crockery and Iznik's intricate handpainted tiles. Turkish ceramic producers-built factories to manufacture ceramics on a large industrial scale in the middle of the 20th Century, ushering in the era of mass-production.

its rich history in ceramic production. In the Anatolian region, many different civilizations have evolved and shaped these traditions. Aside from cultural history, geography has played a significant role as well. There is an abundance of natural resources in the country which ensures high quality ceramic products, as well as raw materials that are exported for ceramic production outside of Turkey. There is no doubt that Turkey is also a land for ceramics, with much to offer to the rest of the world.

In Cambodia, Laos, Myanmar, Afghanistan, India, Nepal, and Pakistan, traditional brick manufacturing kilns have been operating for centuries, making bricks that can be used for the construction of houses, buildings, and other infrastructure. In recent years, however, automated kilns and brick making machines have radically changed brick production traditions. Bangladesh and Vietnam, according to Jahir Ahmed, have

Michael Hölzgen, global director ceramic auxiliaries division, Zschimmer & Schwarz is in conversation with us in Talking Shop. He discusses how his company has maintained its success during a challenging year for the ceramics industry as a whole. In addition, he points out how pleased he is with the company's successful outings at ceramitec 2022 and Cersaie 2022, where they were able to show off their wide range of products and services to a highly enthusiastic audience. He also discusses what the future holds for the company, which he believes will continue to deliver high quality products and services. Throughout the interview, we gain a great deal of insight into the Zschimmer & Schwarz 's history, present, and future.

As the year comes to an end, we would like to extend our gratitude to all of our readers as well as to all our advertisers, contributors, and well-wishers. We could not

EDITOR

Editor Isaac Hamza

Email: ihamza@asianceramics.com

Direct line: + 44 (0) 208 123 1540

Advertising Sales

Paul Russell

Email: prussell@asianceramics.com

Direct line: + 44 (0) 208 638 0619

Valerie Adamson

Email: vadamson@asianceramics.com

Direct line: + 44 (0) 208 133 5273

Production and design

Tim Mitchell www.piernine.co

Bangladesh

Jahir Ahmed jahir@asianceramics.com

India

Yogender Singh Malik yogender@asianceramics.com

Sri Lanka

Rohan Gunasekera rohan@asianceramics.com

Special Correspondent - China

Matthew Grandage

Research Manager

Andy Skillen

Email: andy@bowheadmedia.com

27 Old Gloucester Street, London WC1N 3AX, UK.

Directors: Valerie Adamson & Paul Russell.

Imerys inaugurates calcium aluminate plant in Vizag, India • TRA launches review of ceramic tiles from China • Monno Ceramic adds Awards • Gural Seramik's new 6M M2/year plant is now operational • Bangladesh ceramic market registers growth • Indian ceramic opens Corobrik's Kwastina Factory • Vijay Aggarwal appointed new chair at ICCTAS • Al Anwar receives new grinding plant from LB

Imerys India held a formal inauguration of its calcium aluminate plant in Vizag on 12 October to celebrate its commitment to the Indian market and the company's growth in the country. Dedicated to the refractory and infrastructure markets, it is Imerys' largest investment and site in the refractory, abrasives, and construction business sector.

The celebration was attended by key political, business, customer, employee, and community stakeholders. Among the high-profile participants in this meeting were Emmanuel Lenain, the Ambassador of France to India, and Parmod Sagar, the President of the World Refractory Association.

The event began with a plant tour of Vizag led by Emmanuel Lenain, who also delivered the inaugural address. Segi Idicula, director of Imerys Vizag, delivered a welcome address following the lamp lighting ceremony and plaque unveiling. Idicula said: “We had

been looking forward to this celebration for a long time, so it was a great feeling to finally bring everyone together to celebrate and announce in a big way to our customers and stakeholders that we are in the country.”

“The Indian government has been promoting manufacturing in India, so the commissioning of our plant has been welcome. With India’s economy growing at such a fast rate, we are securing our position at the right time, and we feel very happy to be here.”

Phillipe Bourg, Imerys senior vice-president for refractory, abrasives and construction, provided an overview of Imerys' position in India, while Sagar spoke about the importance of the refractory industry in India and around the world.

The opening of the plant was a significant achievement for a number of reasons. One of the features of the plant is that it was commissioned via remote technology during COVID-19. The Imerys Indian team was virtually

supported by colleagues in the Imerys Technical Centre in Lyon, France. Engineers in India wore helmet-mounted cameras, allowing colleagues in Lyon to view what they were seeing in real time, allowing rapid and accurate responses to problems.

A team from India, France, and the UK worked virtually over the past year to complete the project and deliver it on time, providing an example of Industry 4.0 technology in action.

Additionally, the plant specialises in the production of SECAR calcium aluminate binders and additives, which

are widely used by Imerys' customers worldwide. Prior to the Vizag plant becoming operational, Indian customers had to import products. SECAR is now produced locally, easing logistics concerns, reducing lead times to less than one week, and eliminating costs associated with customs duties.

The UK’s Trade Remedies Authority (TRA) launched a transition review into antidumping measures on ceramic tiles from China on 22 September.

These measures are among those inherited from the EU system and have been in place for 11 years. The TRA is reviewing them to establish whether they are still suitable for the UK’s needs.

The products in scope of this anti-dumping transition review include glazed and unglazed ceramic flags and paving,

hearth or wall tiles, as well as glazed and unglazed ceramic mosaic cubes – all commodity codes in scope are listed in the case’s public file. Dumping occurs when goods are imported into a country and sold at a price that is below their normal value in their country of export.

The UK imported over £382 million worth of these tiles in 2021, with 1.5% of these imports coming from China. Chinese imports of tiles to the UK currently face duty rates ranging from 14%

to 70%.

The period of investigation for this transition review will be 1 July 2021 until 30 June 2022 and the injury period will be 1 July 2018 until 30 June 2022.

The Trade Remedies Authority is the UK body that investigates whether new trade remedy measures are needed to counter unfair import practices and unforeseen surges of imports.

Trade remedy investigations were carried out by the EU Commission on the UK’s behalf until the UK left the EU.

44 EU trade remedy measures of interest to UK producers were carried across into UK law when the UK left the EU and the TRA is currently reviewing each one to establish whether it is suitable for UK needs.

CHINA/UNITED KINGDOM www.asianceramics.com

Founded in 1984 by industrialist and philanthropist Harunar Rashid Khan Monno, Monno Ceramic Industries designs, develops and markets porcelain and bone china tableware.

Exports account for a significant portion of production. Consequently, Dhaka has adopted state-ofthe-art technology, especially in regard to firing, a crucial factor in achieving high quality tableware items with great aesthetic value. In light of this, Monno recently purchased a new kiln, which has been supplied by Riedhammer, a SACMI Group company, for

glost firing porcelain products under reducing conditions.

It was successfully delivered and installed at the Dhaka facility and is said to offer all of the advantages of Riedhammer's latest generation of equipment. For example, it is equipped with advanced controls for all firing parameters (air-gas mixtures) as well as equipment for limiting and optimising the consumption of energy.

As soon as the new kiln is fully operational, Monno Ceramic will be able to fire 5,600 tons of porcelain tableware each year. The new kiln measures 56 meters long, with an effective

width of 2.1 meters and 0.6 meters high.

The kiln is characterised by excellent product quality, stability and repeatability, as well as flexibility to handle changes in load conditions. Monno Ceramic Industries purchased the kiln as part of a wider modernisation programme which, in this instance, aims to replace some older tunnel kilns. Aside from the improved kiln efficiency and the integrated heat recovery system, this investment decision was also driven by a desire to achieve environmental sustainability.

For the customer - who, in addition to the Dhaka facility, has a prestigious design studio in the heart of London - this purchase strengthens its market credentials by reinforcing its mission: to develop collections that integrate cutting-edge aesthetics, quality products and sustainability into their designs.

UNITED ARAB EMIRATES

RAK Ceramics, one of the world's largest ceramics brands, announced it was awarded Ceramics & Tiles Brand of the Year at the 2022 Design Middle East Awards. The Design Middle East Awards celebrates the best and foremost people, projects and products in the region's design and architecture industry. This year's awards honoured top architects, designers, projects, and firms.

The Design Middle East 2022 ceremony was held on Friday, 11th November in Dubai.

Commenting on the occasion Abdallah Massaad, Group CEO of RAK Ceramics said: "Since our

foundation, we have made it a priority to invest in cutting-edge machinery and technology at RAK Ceramics, and this has enabled us to create some truly remarkable products.

“We are humbled to receive this recognition for the hard work we have put into our research and development initiatives, which form the backbone of our product development strategy.

I'd like to thank the Design Middle Awards, everyone here at RAK Ceramics is incredibly grateful for this recognition.”

RAK Ceramics is one of the largest ceramics brands in the world. Specialising in ceramic and gres porcelain wall and floor tiles, tableware, sanitaryware

and faucets, the company has the capacity to produce 118 million square metres of tiles, 5 million pieces of sanitaryware, 24 million pieces of porcelain tableware and 1 million pieces of faucets per year at its 24 state-of-the-art plants across the UAE, India and Bangladesh, Germany, Austria and Hungary.

Founded in 1989 and headquartered in the United Arab Emirates, RAK Ceramics serves clients in more than 150 countries through its network of operational hubs in Europe, the Middle East and North Africa, Asia, North and South America and Australia.

RAK Ceramics is a publicly listed company on the Abu

Dhabi Securities Exchange in the United Arab Emirates and, as a group, has an annual turnover of approximately US$1 billion.

Turkish ceramic manufacturer

Gural Seramik has begun operating its new production line at its Kutahya site in the same-named region of the country. This latest project highlights the tile market ambitions of this leading Turkish and international ceramic player, which has been a key manufacturer of sanitaryware and tableware for decades.

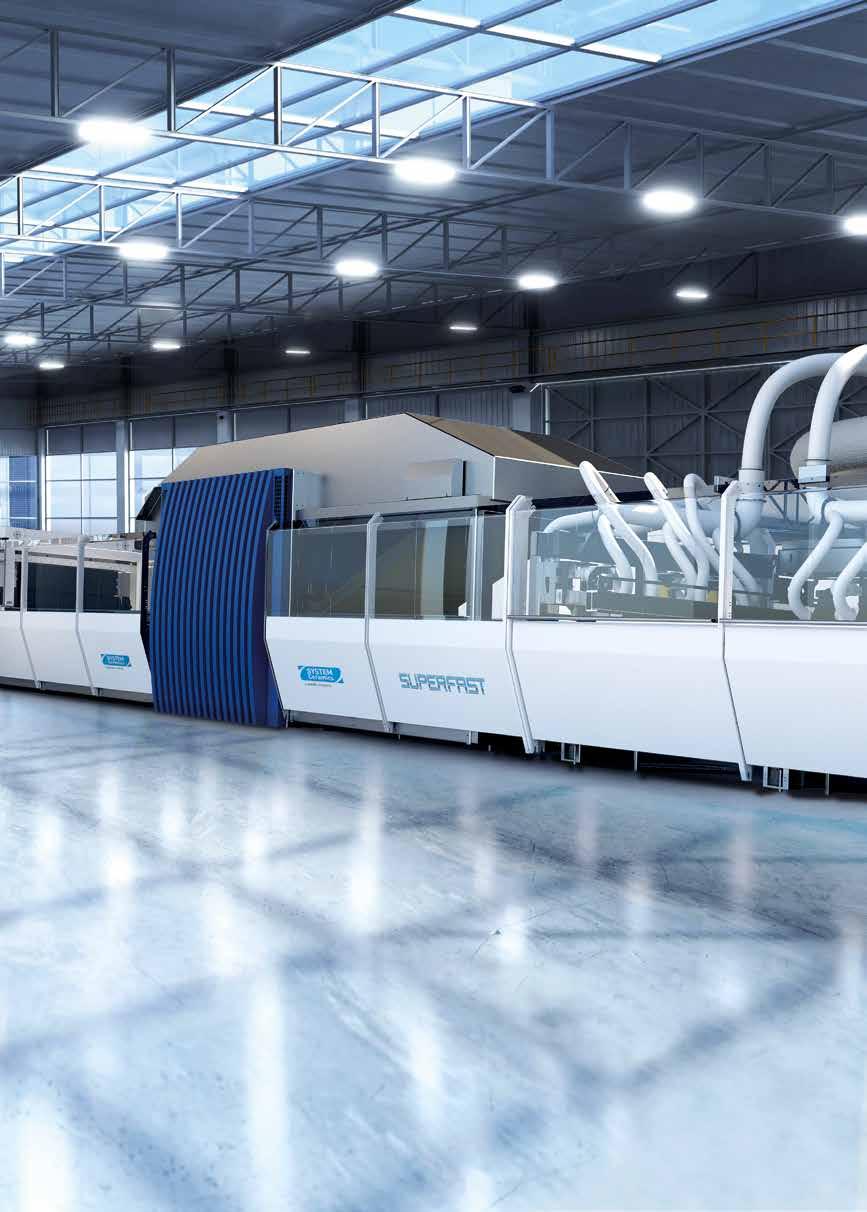

A state-of-the-art, fully automated production line for glazed and monoporosa porcelain stoneware has been created with SACMI's state-ofthe-art technology.

SACMI has provided systems

to this Turkish customer for all of its departments, including body formulation and sorting.

A MM138 modular mill and two ATM 90 spray dryers have been delivered to the company as part of its body preparation efforts.

There are two PH8200 presses used for the manufacture of the floor tiles. These presses are ideal for producing the most standard sizes available in the market (such as 60 x 60, 60 x 120, and 120 x 120cm). For the manufacture of the wall tiles, two PH5000XXL presses are used. The plant also features two 150-meter SACMI FMA295

kilns. This project is completed with Ekosort-Ekowrap sorters and a BMR-supplied finishing line.

It is anticipated that this latest plant will produce approximately six million square meters of tiles per year as a result of a diverse product

mix. Featuring full automation and outstanding flexibility, the new line demonstrates the business ambitions behind the investment.

For SACMI, this project represents another important achievement on the Turkish market.

The ceramic industry in Bangladesh has grown by 200% and has experienced a 20% increase in investment in the last ten years, said Md Sirajul Islam Mollah, President of the Bangladesh Ceramic Manufacturers and Exporters Association (BCMEA), on 19 November.

As reported by the Bangladesh Post, he was speaking at a press conference organised by BCMEA ahead of the "Ceramic

Over 90 exhibitors and 200 brands from over 15 countries, including host Bangladesh, participated in the three-day ceramic exposition held in the capital from 24 November. The organisation's general secretary, Irfan Uddin, and senior office bearers were also present.

BCMEA organised the event at the International Convention City Bashundhara, ICCB, for

Indian ceramic tile producers are increasingly shifting to LPG instead of natural gas to decrease their production costs. Though, natural gas prices have started showing some sign of softness in Q3FY23 (currently at about 60-62/SCM) after a drastic increase in gas prices over the past few quarters around 65/SCM during Q2FY23). This has prompted some of the leading ceramic tile producers to offset the increase in gas price by switching to alternatives such as LPG, which

is priced around INR 50-52.

According to Abhishek Somany, managing director of Somany Ceramics said: “Today, the gas price is approximately standard INR 65 a standard cubic meter, and if I adjust the kilo calorific value between natural gas and LPG, which is what we're using, that comes to approximately INR 50, INR 52 a standard cubic meter. It's a good INR 10 cheaper than natural gas. And it does not move in the same direction as natural gas in does not follow it. It's independent of that.”

the third time since 2017. The fair was organised to provide ceramic manufacturers and exporters with global exposure in order to increase their market share with their international standard products.

“Ceramic industry of Bangladesh is a booming sector and its growth potential in both domestic and international markets indicate it may become one of the biggest foreign exchange earners for

the country,” Mollah said.

The BCMEA president stated in the pre-event meeting that the exhibition would cover 15,000 square meters of space at ICCB and would attract over 300 delegates from different countries, thus making it the largest ceramic show in South Asia.

Five seminars were held in conjunction with the fair, as well as B2B and B2C meetings and a job fair.

India’s second largest ceramic tile producer, Somany Ceramics has increased its installed capacity by 11 million square meters per annum with the addition of three regional plants. The company has successfully commissioned its three new plants in north, west and southern region of the country.

Somany Ceramics has also announced setting up of greenfield manufacturing facility of large format tiles with an installed capacity of

4.5 million square meters per annum in Gujarat with an outlay of INR 1.7 billion ( to be funded mainly via internal accruals of the company). This plant has a revenue potential of INR 2.5 billion.

The company has placed the order for the machineries for this plant and expects the production to commence in the second quarter of 2023.

These capacity additions will take Somany Ceramics installed capacity to more than 70 million square meters per annum.

554 SACMI.COM

That’s why the SACMI Maestro kiln range guarantees minimum consumption and optimizes heat exchange by using high-speed-flame combustion. Maestro kilns let manufacturers save up to 1,108 tons/year of CO2, the equivalent of one person taking 554 Milan-New York flights. Reduce CO2 and NOx emissions while lowering energy consumption.

President Cyril Ramaphosa delivered the keynote address at the official opening of Corobrik’s Kwastina brick manufacturing factory in Driefontein, Gauteng. The stateof-the-art factory forms part of an R800 million investment, which goes hand in hand with a further R200million earmarked to expand Corobrik’s concrete operations in KwaZulu-Natal.

Corobrik is one of several local businesses that have responded to President Ramaphosa’s call on South African and international enterprises to invest in this economy. Kwastina produces clay face bricks, with its concrete operation targeting the plaster brick and block market.

The President highlighted that the fact that the company

is a local one that supports government efforts to empower and support local enterprises.

“Corobrik has made a significant contribution to our efforts to extract greater value from our natural resources, by making its bricks from raw materials extracted from South African soil. This is an important part of government’s efforts to support localisation, supplier and enterprise development, as well as empowerment.

“As we proceed with the implementation of our infrastructure plan, the demand for building materials will grow substantially. It is our intention that as much of these materials as is possible should be sourced locally,” President Ramaphosa said.

The hi-tech facility is fully automated, from mixing the raw

materials to the end product. Capable of producing 100 million bricks a year, the new factory will easily be able to meet larger-volume orders. In a first for the South African market, Kwastina will be flexible enough to produce small quantities of bespoke products for the architectural market.

Kwastina is not only one of the largest brick manufacturing plants in sub-Saharan Africa, but also one of the most modern and energy-efficient in the world. After a comprehensive analysis of Corobrik’s existing manufacturing process, the Greenfield project resulted in a new shaping plant, a new fully automatic wet side, a setting plant for direct setting, two tunnel dryers and two tunnel kilns, and a new unloading and packaging plant for dispatch

packs without pallets.

“What makes this factory so exciting is that it allows us to compete anywhere in Southern Africa, landing product in regions traditionally not in Driefontein’s market as the new factory is more costeffective,” said Corobrik CEO Nick Booth. “It is going to give us an advantage in the market, not just in terms of technology, but also in quality and consistency, which are critical for specifications involving tight tolerances.”

Vijay Aggarwal, managing director of Prism Johnson, has been appointed as the new chairperson at the Indian Council of Ceramic Tiles (ICCTAS).

Aggarwal received his B Tech in electrical engineering from IIT Delhi and his PGDM from IIM, Ahmedabad, where he was awarded the Gold Medal for being the top ranker and the KV Srinivas Gold Medal for being the top allrounder. He began his career with SBI Capital Markets Limited and has several years of experience in the manufacturing sector.

He has served as managing director of the Prism Johnson Board since March 2010 after previously serving as a director. He was formerly the managing director and CEO of the erstwhile H&R Johnson (India) Limited before it was merged with the company in 1998. Besides serving on the stakeholder

relationship committee, he is also the chairman of the risk management committee, corporate social responsibility committee, and securities allotment and transfer committee.

In a statement, H&R Johnson (India) - Prism Johnson Limited stated: “We wish that under the new able leadership of Vijay Aggarwal, the tile and sanitaryware Industry is further strengthened, becomes more customer focused, and achieves new heights in International business.”

At Al Anwar, the new LB dry grinding and microgranulation line has been fully assembled and is ready for commissioning in the next few weeks.

According to LB, the client required a new factory that would be capable of producing over 22,000 square meters of double-fired tiles in

large sizes. LB's performance on the existing line has led Al Anwar to reaffirm their confidence in LB.

Al Anwar, established in 1998, is the first and largest manufacturer of ceramic tiles in the Sultanate of Oman, and the first manufacturer of dry ground tiles in the Gulf region.

The Clay Brick Association of SA (CBASA) promotes sustainable, contemporary brick architecture and building design across the built environment: commercial, residential and landscape, underpinned by ongoing research, monitoring and stakeholder engagement.

The CBA’s goal is to ensure that local property owners achieve long life, good value and sustained performance from brick walling and paving. As for most industries, the past number of years have presented

significant challenges, despite which much progress was made under outgoing president, Hendrick van Dyk.

"After the two-year pandemic, many businesses faced unprecedented challenges, followed by the looting and floods in KwaZule-Natal, but –as a country – we rose to the occasion and we’re coming back stronger,” said du Trevou in his recent inaugural speech.

“As an industry, we need to commit to creating good and fair jobs, expanding our facilities and playing a key role

in building infrastructure like schools, low-cost housing and clinics. It’s our responsibility to build cities and towns where families can be safe and warm, and to provide South Africans with the most sustainable option in clay bricks.”

Essential resources include property-owner guides and technical manuals for builders, bringing together the makers and users of clay bricks with knowledge, choices and solutions.

The CBA provides strategic direction for members through

its investment in research and educational initiatives in energy-efficiency, reduced emissions, green building and sustainable construction.

Indian ceramic tile exports are expected to touch a historic high of INR 180 billion (around $2.25 billion) in the ongoing financial year April 2022- March 2023 despite a number of headwinds.

High raw material costs, increased freight rates, and shortage of containers have resulted in a fall in demand for tiles products in the recent past mainly for export oriented Morbi

players. However, the scenario has changed in Q2FY23 with a significant fall in ocean freight rate, huge antidumping duty on Turkey by major European countries and significant rise

in electricity and gas prices in Europe. These have trigged a healthy demand revival for Indian tiles in the European territory aided by competitive price advantage.

Ferrari Stampi USA announced that it will invest $1.4 million in expanding its manufacturing operations at the company’s US headquarters in Clarksville, on Dunbar Cave Road. This project will result in 30 new jobs in Montgomery County. The company’s expansion is a direct result of its decision to purchase Poligraph USA, which will support additional production lines at its US headquarters and help grow its overall customer base, according to a state news release.

Luca Silvestrini, president, Ferrari Stampi USA, said: “The American dream is centred around the idea that if you work hard, you can ‘make it’ in the US but hard work alone isn’t always enough as sometimes you just need the help of others.

“In our case, the state

of Tennessee, especially Montgomery County, has been unbelievably supportive and hospitable in making this wonderful state our second home.”

“I thank Ferrari Stampi for its commitment to job creation in Montgomery County. I’m confident our state’s strong business climate and skilled workforce will support this company’s expansion and success in the years to come,” said Tennessee Governor Bill Lee.

“Tennessee’s central location and exceptional business climate offer international companies like Ferrari Stampi easy access to their markets around the globe. We are proud to be the home of Ferrari Stampi’s US headquarters and appreciate this company’s continued confidence in Clarksville and Montgomery County,” said Tennessee Department of Economic & Community

Development Commissioner Stuart McWhorter.

A total of nearly 3,000 jobs have been committed and $1.3 billion in capital investments have been made since 2018, thanks to TNECD's support for 15 economic development projects in Montgomery County.

Senator Bill Powers said: “I’m pleased to help announce that Ferrari Stampi is expanding at its US headquarters in Clarksville with the creation of 30 new jobs. The company’s decision to expand in Clarksville is a testament to our friendly business climate, low taxes and

great workforce. We wish Ferrari Stampi continued success moving forward.”

Ferrari Stampi USA was founded in 2014 by Italian company Ferrari Stampi to manufacture ceramic tile moulds and dies. With the addition of 30 new jobs, Ferrari Stampi will double its US headcount at their US headquarters in Clarksville.

PT Platinum Ceramics Industry (PT PCI) has been present in the ceramics industry for five decades. With the aim of establishing a closer relationship with loyal customers and bringing the newest products to the market, PT PCI and its sister company, PT Surya Multi Cemerlang (PT SMC) conducted Product Launching and Customer Gathering events in four major Indonesian cities.

After introducing Lamina Granite Titanium a few years ago, PT PCI and PT SMC have now launched a new line called Infiniti Granite Tile.

According to the company's press release, this product is positioned

as a product that is timeless and transcendent. It stated: "The dignified product can last for decades, offering granite products with a minimum load weight of 350kg / cm2 and infiltration of water less than 0.5%. Products made with Italian technology are recognised as products with the best durability in their class. For this reason, products that can be applied to both floors and walls are the most suitable products to be applied to all types of buildings that can last up to the next generation "Not only that, the latest motifs from the Lamina Granite Platinum & Ceramic Ceramics, were also introduced on this occasion.

Titanium Lamina Granite is a pioneer of big slab granite products in Indonesia that is specifically designed to answer the challenges of a design that is of the size of relief and can be a substitute for perfect natural stone. Lamina Granite Titanium has the best specifications in its class, with sizes up to 1.2x2.4m and 8mm thickness & infiltration of water below 0.5%. Excellent products from PT. This SMC is a

Florim’s new photovoltaic system is now operational on the roof of Plant 2 in Mordano (BO). This photosensitive surface area of 22,000 m2 with a nominal power of 4.5 MWp will help avoid the emission into the atmosphere of 1,400 tons of CO2 annually.

The investment is in addition to the many energy efficiency measures introduced over the years, consistent with a sustainability policy geared toward minimising the company’s impact on the environment and the local area.

When added to the two

installations already existing in Fiorano Modenese, the new system brings the total installed capacity to 12.2 MWp, amounting to 64,000 m2 of panels. This is another important step in Florim’s drive to reduce CO2 emissions and is in keeping with the amendment

solution for the needs of architects who want to bring spacious and elegant nuances in the room. All Platinum Ceramics product variants, Infiniti Granite Tile & Titanium Lamina Granite are available on the market.

to the company’s bylaws that spells out its commitment to climate neutrality.

The advanced ceramics manufacturer CeramTec is planning to expand its presence at the Marktredwitz site. The already existing manufacturing complex is to be expanded in the coming years to include, among other things, a further production hall.

Hadi Saleh, CEO, CeramTec said: "Our well-filled order books make it necessary for us to expand capacities. At the Marktredwitz site, we have already been able to count on an extremely reliable and sustainable network of employees and partners in the past. We are therefore pleased to be able to further expand our presence in Marktredwitz and thus also play an even more important role as an employer in the region in the future."

CeramTec currently employs

more than 800 people at their Marktredwitz site. Among other things, the new building is to be designed with a special focus on sustainability aspects.

"In the CeramTec Group, we introduced measures for an even more conscious use of energy some time ago and have already implemented various projects and measures. The new building offers us excellent opportunities to produce even more energyefficiently and sustainably in the future and thus make an important contribution to the energy transition in Germany," said Saleh. Subject to official approval for the project, the start of construction with initial work is planned for 2023.

CeramTec is a global medtech platform focused on high-performance ceramics

(HPC) solutions, which develops, manufactures, and markets ceramic parts, components, and products. The company has over a century's experience developing and producing advanced ceramic materials for a wide range of uses in the HPC industry. Its HPC products are used in a variety of applications, including medical applications such

as hip replacements, orthopaedic implants, dental implants, and medical equipment, as well as industries such as mobility and electronics. Its manufacturing and distribution centres are located in Europe, North and South America, as well as Asia and its headquarters are located in Plochingen, Germany.

International bathroom brand VitrA is celebrating 30 years of supplying bathrooms in the UK.

Due to what the company describes as its quality manufacturing, strength in domestic market leadership, and innovative production capabilities, VitrA was one of the first European manufacturers to be successful in the domestic market, which at the time was dominated by British names.

When VitrA entered the UK market in the early 1990s, the company already had 30 years’ experience in ceramic manufacturing and 10 years’ experience in brassware manufacturing, as well as an enviable portfolio of products. While VitrA brought new design styles into the UK, products were always produced according to UK plumbing systems. It also designed products suited specifically to the British market, such as the Chelsea and Chartwell ranges. The company was also one of the first non-British manufacturers to become a member of the

Bathroom Manufacturers Association, reflecting its sense of duty to the UK industry.

Building on the success of the retail market, VitrA started to supply to the commercial market over 20 years ago. Within the first five years, the company won the contract for the new Heathrow T5 terminal and created the K basins specifically for this project. It has also nurtured relationships within the hospitality sector including IHG & Hilton, leveraging the company's global presence.

In the early 2000s, VitrA launched a collaboration with Welsh designer Ross Lovegrove. The range, called 'Istanbul', (freestanding basin pictured below) was and still is unlike anything else on the market. For the UK, this was the start of a long history of designer collaborations, culminating in the launch of Liquid with British designer Tom Dixon last year. (The Liquid collection below at VitrA London, the company’s new flagship showroom in London)

Today, VitrA operates over 2,000 sqm of warehouse space in

Oxfordshire and a team of over 60 people. The company continues to grow from strength to strength, addressing the industry's new challenges and changes in buyer behaviour.

Last year VitrA opened a showroominLondonforarchitects, designers, and specifiers, marking a new milestone in the company's journey. VitrA London is not only a space to showcase products, but also to engage with the community through events, workshops, and installations

Rapid post – pandemic recovery for kiln furniture: Please note that IMERYS current open operation for its Ceramics Kiln Furniture activities are in Hungary and Spain

The National Ceramic Industries Australia (NCIA) is reducing the costs associated with its energy costs with the help of OFS, a Melbourne-based manufacturer performance software company.

In addition to being the country's largest tile producer, NCIA is one of the largest users of natural gas at a single site.

As a result of the current energy crisis, the company contacted its data and technology partner OFS to find out if it could measure its energy usage in real time, joule by joule. As part of its performance management solution, OFS already provides its services to NCIA, which uses sensors to monitor the performance of

its production in real time. The company installed new sensors to track energy consumption against production accurately.

This provided NCIA with the data necessary to predict with pinpoint accuracy how much energy is required to produce each product. As a result of the insights gained, the company was able to negotiate the best possible deal with its gas suppliers because its production schedule could be matched with its energy requirements. This has resulted in an average monthly savings of $40,000 and a yearly saving of approximately half a million dollars.

NCIA factory manager Craig Oliver said: “Forecasting penalties and trying to manually count energy usage is incredibly expensive. OFS

has automated that entire process and positioned us to mitigate the surges in energy prices and optimise how we buy our gas.”

OFS CEO James Magee said: “NCIA should serve as industry best practice to absolutely minimise the cost impact of energy on the sector – you can’t manage what you can’t measure.

“The energy trauma facing Australia’s manufacturing sector is immense, and it’s disheartening that it’s come at a time of such renewed confidence in, and hope for, the sector. But manufacturers are resilient, and I hope the current crisis will spur more to leverage digital transformation to optimise their operations.”

OFS is an Australian company that provides productivity and efficiency

improvement software (OEE software) to global manufacturing industries. The company's customers include Kraft/Cadbury, Coca-Cola Amatil, Electrolux, AstraZeneca, Heinz, Orora, Dulux Group, Unilever, Food Plastics Co, PACT Group, Labelmakers, Visy Industries, Murray Goulburn, Tatura, Sanitarium, HB Fuller, Standard Can and NCI.

CIMAC, the Italian Ceramic Machinery Manufacturers' Association, participated in two important events in Asia, the first in Bangladesh and the second in Thailand.

From 24 to 26 November, the third edition of Ceramic Expo Bangladesh was held in Dhaka's International Convention City Bashundhara and Acimac sent a delegation that included ICF & Welko, Officine SMAC, Sacmi, System Ceramics, and Tecnoferrari. The exhibition was last held in 2019 and brought together more than 300 ceramic

manufacturers and suppliers from over 20 countries around the world. The event was particularly significant since Bangladesh produced 100 million square metres of tiles last year but has the potential to produce more than 150 million. Further, the fact that the country is an emerging economy with a large ceramic industry, a skilled workforce, and adequate natural gas supplies makes it a strategic partner for Italian suppliers of ceramic machinery, ACIMAC said.

Next, the Italian delegation travelled to Asean Ceramics Thailand, an international

Mohawk Industries has entered into an agreement to purchase Brazilbased Elizabeth Revestimentos. When combined with Eliane, which became part of Mohawk in 2018, the company will be the largest producer of ceramic tiles by revenue in Brazil, which is the second largest ceramics market in the world.

exhibition held at the IMPACT Exhibition Centre from 30 November to 2 December at which ACIMAC organised a joint Italian participation in collaboration with the Italian Trade Agency. Five Italian companies were in the delegation namely, Essepienne, Expert Lab Service, Keran, Officine SMAC and Tecnocer Italia.

As per ACIMAC, Thailand is another rapidly growing market that produced 148 million square metres of tiles in 2021 but has the potential of producing more than 180 million square meters in the future. Thailand's construction sector

has seen strong growth since the government introduced economic packages in 2020 with the goal of raising GDP and bolstering consumer and investor confidence.

Since both countries are part of Southeast Asia, Italy's second largest export market outside the EU, these two exhibitions are important events for ceramic machinery suppliers. It is estimated that the region imported €272 million worth of machinery from Italy in 2021, accounting for 17.6% of Italy's total ceramic machinery exports (a rise of 68.6% over the previous year).

Elizabeth produces porcelain and ceramic tiles and sells mainly to the retail, home centres and constructors channels. Founded in 1984, it has four manufacturing units strategically located to optimise distribution. Coupled with Eliane's manufacturing strengths, Elizabeth's advanced manufacturing assets will enhance the product offering, operational efficiencies and

service capabilities of the combined business.

Mohawk Industries is a global flooring manufacturer that creates products to enhance residential and commercial spaces around the world. Its vertically integrated manufacturing and distribution processes provide competitive advantages in the production of carpets, rugs, ceramic tiles,

laminate, wood, stone and vinyl flooring. Its brands include American Olean, Daltile, Durkan, Eliane, Feltex, Godfrey Hirst, IVC, Karastan, Marazzi, Mohawk, Mohawk Group, Pergo, QuickStep and Unilin. Over the past decade, Mohawk has transformed its business from an American carpet manufacturer into the largest flooring company in the world.

Italcer has won the second edition of the 2022 Sustainability Award, an important recognition reserved for Italian companies addressing today's challenges with ingenuity and excellence.

The ranking compiled by the Credit Suisse Team, Kon Group and Forbes places Italcer at the top of the sustainable companies list, all of which have received an ESG rating issued by Altis Università Cattolica and Reprisk.

In the rating, the propensity for innovation in governance and

social media was particularly examined. The award is also the recognition of the path of continuous improvement in terms of sustainability and efficiency of the production processes of the company, which constantly tends to be more efficient in using materials, saving energy, reducing pollution, and managing water and waste more responsibly.

Italcer considers this as an important recognition confirming its attention to

sustainability, an area in which over €10 million was invested in 2021 in order to meet the needs of an increasingly greener customer base.

Graziano Verdi, CEO of Italcer Group said: "We design our products in a sustainable way using over 50% recycled raw materials and we are now able to recover 99.6% of production waste destined for recovery activities.

“Italcer is also the first factory in the sector to have installed, in August 2021, a new press,

equipped with innovative solutions for the hydraulic circuit, in order to optimise and speed up each production phase with the lowest energy consumption. And let's not forget the beating heart of our Group, our employees.”

Among the brands of the Italcer Group that produce ceramic products for interiors and exteriors are: Fondovalle, La Fabbrica, AVA, Elios Ceramica, Devon&Devon, Ceramica Rondine, Cedir, Bottega and Equipe.

analytica and ceramitec have been rescheduled. The world’s leading trade fair for laboratory technology, analysis and biotechnology and the world’s leading trade fair for the ceramics industry will now be held two weeks earlier than scheduled. A new date for the exhibitions has been set 9-12 April 2024, and once again both events will take

place simultaneously.

The new dates are expected to offer both trade fairs greater opportunities to utilise the facilities and rooms at Messe München. This change also ensures that both of the world’s leading trade fairs will be held at the same time in 2024, a decision that will create synergies for exhibitors and visitors.

analytica is the world’s leading

trade fair for laboratory technology, analysis and biotechnology as well as for their users in research and industry. Held every two years in Munich since 1968, the trade fair is complemented by the analytica conference, a gathering that attracts members of the international scientific elite and serves as a platform for discussions about the latest chemical, bio-chemical and

laboratory-medicine issues. ceramitec is the leading trade fair for the ceramics industry. The exhibition covers all areas of the ceramic industry, such as classical ceramics, raw materials and industrial ceramics, as well as technical ceramics and powder metallurgy. ‘ceramitec: Technologies ∙ Innovations ∙ Materials’ is held every three years.

Two years after the launch of its communication project focused on teaching, training, and sharing of skills, Zschimmer & Schwarz Ceramco brings together the several actions put in place over time by gathering them today in a single virtual space, thus offering its interlocutors an easyto-use and always available tool.

For the leading chemical company and specialist in the formulation of solutions for the ceramic industry, September 2022 coincided with the first release of the app named ‘Apparently Invisible. The Chemistry of Ceramics.’

The two key words around which the different sections of the new device revolve –available immediately in Italian and by the end of the year in the

corresponding English version – are as usual chemistry and ceramic production.

With a simple language that is accessible even to non-experts, the APP addresses issues related to chemistry applied to ceramic tiles’ production, mostly from the perspective of manufacturers and therefore with the intention to explore the issues of greatest interest for those who daily work along the production lines. A method that is largely configured according to the logical ‘problemcauses-solutions’. A journey in stages with a focus on products, applications, and processes.

Through its different sections and its heterogeneous educational approaches, the tool tries to shed light on the mechanisms

that lie behind the scenes of one of the most fascinating industrial production processes, while offering glossaries, nuggets of information, quizzes, and calculation tools through which to expand their knowledge or have confirmation of what you already know.

Process problems or technical and aesthetic critical issues can in many cases be solved, or at least contained, thanks to the intervention of chemistry or by means of actions that involve and imply a deep knowledge

of what happens along the production lines.

For this reason, the APP, which has been downloadable for free on Apple Store or Google Play Store from September 26th, contains sections that, with different levels of depth, range from front lessons to quiz.

Imerys CEO Alessandro Dazza announced the launch of ‘EMILI’ (Imerys' Lithium mica mining project) at the Beauvoir site on 24 October. A number of government officials and local authority representatives attended the event: Valérie Hatsch, the prefet of the Allier region; Claude Riboulet, the regional council president; and Stéphanie Dupuy-Lyon, the head of the department for development, housing, and nature (DGALN), under the Ministry for Ecological Transition and Regional Unity.

Several elected representatives, including the mayors of Echassières and its surrounding communes, were also present, as was Véronique Pouzadoux, president of the intercommunal structure, and various Imerys partners, including the BRGM (the geological and mining research bureau). An introduction to the project was already conducted over the last month, and the consultation phase will begin shortly.

The launch of the EMILI project establishes Imerys as a key player in the energy transition. This major lithium mining project at the Beauvoir site in the Allier region will enable 34,000 tonnes of lithium hydroxide to be produced annually from 2028 onwards. The EMILI project will also help improve France's and Europe’s

Brick producer Vandersanden and the Dutch company 2Return are launching a pilot project together on a return service for wooden pallets in Belgium and the Netherlands. With this, the brick producer reduces the disposable use of materials, commits fully to circularity, and moves ever closer to its goal of being CO2 neutral by 2050.

Vandersanden, the largest family-owned brick producer in Europe, has started a pilot project for a pallet return service. This service is a collaboration between Vandersanden, its customers (contractors and traders) and the Dutch logistics company 2Return.

After use, 2Return collects disposable pallets from the customer on behalf of Vandersanden, checks them for reusability, carries out relevant repairs and then ensures that the brick producer’s pallets end up back with Vandersanden. This way, wooden pallets can be reused with ease, allowing Vandersanden to reduce the disposable use of materials. Moreover, Vandersanden offers this service completely free of charge.

The first phase of this pilot project will be rolled out to a limited number of selected customers in Belgium and the Netherlands. In

industrial sovereignty by playing a part in creating an integrated battery production sector at a time.

Bruno Le Maire, France's minister for the economy, finance and industrial and digital sovereignty, said: “This project is exemplary from an environmental and climate perspective and will drastically reduce our lithium import needs. It will enable us to produce daily 700,000 electric car batteries per year. It will help us meet the target set by Emmanuel Macron of producing two million electric vehicles in France by 2030 and as such will be supported by the government.”

Dazza said: “Drawing on our expertise in extracting and transforming minerals, on our operational excellence and on our ability to deliver projects responsibly and sustainably, we are building, here in Beauvoir, one of Europe's main lithium mining projects.”

He then went on to share details of the project's timeline , which should enable – subject to the necessary permits being obtained and consultation with stakeholders – commercial operation to commence in 2028. This will involve investments of more than €1 billion and the creation of more than a thousand direct and indirect jobs.

the second phase, Vandersanden will evaluate the project and tighten the processes where necessary, before launching the collection service on a large scale in Belgium and the Netherlands.

Raf Jansen, COO at Vandersanden, said: “With this return service, we are taking the next step in our sustainability story. We are tackling waste by reusing pallets.”

“In addition, we feel it is important to offer our customers the best possible service and making life easier for them. In fact, this return service will remove a big weight from the customers’ shoulders. With the use of the data and insight we’ll gather during this pilot project, we want to ensure we’ve connected the dots by the time of the major launch.”

The project aligns with Vandersanden’s Collective Well-being vision, the term used by the company to bundle all its initiatives relating to sustainability, among others.

“Everything we do as a company is aimed at focusing on a better future together. This new project also reinforces this ambition,” added Jansen.

The pilot project on returnable pallets is a subsequent step in the ambition to be completely CO2 neutral by 2050.

Michelmersh has announced its successful bid to the Department for Business, Energy & Industrial Strategy (BEIS) UK Government, Industrial Fuel Switching competition to conduct a feasibility study to replace natural gas with hydrogen in the brick making process.

The project represents a global flagship physical study to replace natural gas with hydrogen in brick manufacturing. Phase 1 of the project will demonstrate the viability of fuel switching and will see hydrogen used in the clay brick production process at Michelmersh’s Freshfield Lane site.

The project aims to inspire radical change across the sector and present opportunities and evidence-based research to support manufacturers on their journey to heavily decarbonise the production processes.

The programme is part of the £1 billion Net Zero Innovation Portfolio (NZIP) which aims to provide funding for low-carbon technologies to decreasing the costs of decarbonisation.

In a press statement, the company said it is excited to inspire radical change across the sector and present new opportunities and research to support manufacturers on the journey to massively decarbonise the production process.

Commenting on the new development, Frank Hanna, Joint CEO of Michelmersh, said: “The Group is proud to stand at the

forefront of such evolution for our industry. While we have seen energy costs rise due to environmental and political factors, this incredible application of technology and innovation allows the Group to reduce its costs considerably, improve its resilience and welcome new products that take sustainability to a whole new level.

“While we look forward to the challenges ahead of us, we are optimistic about the change we can inspire within the manufacturing sector. With decades of experience producing high-quality products and with the aid of our industry-leading partners, the Group is well suited to lead the UK with this flagship global first.

“The Group has set ambitious 2030 Sustainability KPIs which include 100% of our electricity provided by green suppliers and renewable sources from October 2022, with other onsite renewable energy sources already on the ground at Michelmersh sites.

“The team understands the impact this project could have if successful, however, it also recognises there is a long journey ahead before hydrogen is fully tested throughout the multiple different production processes or is financially viable to expand to all our sites.”

Altilium Group (Altilium) and New Generation Minerals (NGM) will form a new legal entity to promote, market and licence the DNi Process, Altilium’s ground-breaking, patent-protected method for extracting nickel, cobalt and other constituent metals in laterite ore, in Western Australia.

The race to switch to electric vehicles (EVs) and an underinvestment in ore processing plants have led to a diminishing supply of critical battery metals. Significant action is urgently required to develop more processing facilities which are powered by clean technologies.

There is an opportunity to increase production of sustainably produced nickel and cobalt and unlock currently stranded laterite ore bodies. Such additional capacity would be highly complementary to existing and planned production, such as from NGM’s nickel-cobalt deposit near Kalgoorlie, as global supply gaps are forecast over the coming decade.

As a first step, the partnership will collaborate to commence scoping study economics to build the first DNi Process plant in Western Australia. This plant will be designed to produce not less than 16,000 tpa of nickel and cobalt in the form of mixed hydroxide product (MHP), although the plant may be designed to deliver nickel and cobalt sulphates.

Chris Gower, CEO of Altilium, said: “We are very pleased to partner with NGM in Western Australia as we see our DNi Process as being able to unlock nickel and cobalt deposits such as NGM’s in one of the most sustainable mining districts in the world.

“We see huge value in being able to provide the EV industry with a clean, sustainable supply of nickel and cobalt, and help Australia increase its role as a top player in the worldwide transition to EVs.”

Arthur Darivas, CEO of New Generation Minerals, said: “We see Altilium’s DNi ProcessTM as the key enabler to unlock laterite ore extraction close to infrastructure for us, with our Lake Yindarlgooda deposit near Kalgoorlie, and partners with similar deposits.

“The technology offers the prospect of more sustainable production of battery metals, and we believe this will be very attractive to down-stream buyers, the Australian Government, and other companies we may partner with holding laterite ores.”

Altilium is a British company established in 2019, however its operating business dates back to 2008. NGM is a postdiscovery gold and battery metals exploration company with prime location projects in Western Australia.

Sibanye-Stillwater announced that, subsequent to securing an effective controlling interest of approximately 85% in Keliber Oy (Keliber) as announced on 3 October 2022, the Board of Sibanye-Stillwater has approved capital expenditure of €588 million for the Keliber lithium hydroxide project (Keliber project), beginning with the construction of the Kokkola lithium hydroxide refinery (the Kokkola refinery).

The Kokkola refinery will be located at the Kokkola industrial park in Finland, a world-class industrial and logistics hub, strategically positioned to supply the growing European battery sector.

The construction of the Kokkola refinery marks the first phase in the development of Keliber’s wholly owned, advanced, Keliber project, located in the Central Ostrobothnia region of Finland, one of the most significant lithium-bearing areas in Europe.

Four initial open cast and three underground, highly mechanised mining operations, (primarily Syväjärvi and Rapasaari, with Emmes, Outovesi, and Länttä towards the end of the project life), situated across three municipalities (Kaustinen, Kokkola and Kronoby), are planned to supply ore to the Päiväneva concentrator which will be situated close to the Rapasaari mine.

Concentrate produced at the Päiväneva concentrator is planned to be trucked approximately 66 kilometres to the Kokkola refinery. The Kokkola refinery is forecast to produce an average of 15,000 tonnes of battery grade lithium hydroxide monohydrate per year.

Keliber is emerging as a scalable district opportunity and Sibanye-Stillwater is committing further exploration capital with the aim of extending the resource potential of the area.

Neal Froneman, CEO of Sibanye-Stillwater, said: “We are delighted to advance and grow our presence in the European battery metals industry through Keliber, which we expect will be the first fully integrated European lithium hydroxide producer supplying the European market and is expected to have one of the lowest carbon emission footprints in the industry.

“We look forward to working with all stakeholders to deliver this exceptional project which will contribute to the Finnish battery metals ecosystem as well as to the growth of our unique portfolio of green metals that reverse climate change.”

Sibanye-Stillwater is a multinational mining and metals Group with a diverse portfolio of mining and processing operations and projects and investments across five continents.

Modern exploration and marketing techniques can help Pakistan become a top feldspar exporter, according to a report published in the New Nation.

The Mingora and Buner districts of Khyber Pakhtunkhwa province have been estimated to have over six billion tonnes of deposits of potassic and sodic feldspar. Despite having a great potential, a substantial import bill is paid for this commodity, the publication said.

The value of Pakistan's exports of feldspar in the fiscal year 2020 was $11.2 million, which was the 19th largest exporter in terms of value, and it was the 177th highest export item in the country. In the same year, Pakistan imported $1.31 million worth of the same commodity as the 53rd largest importer and the feldspar was the 831st most imported item.

By the year 2027, the global feldspar market is expected to reach $755.1 million at a compound annual growth rate (CAGR) of 6.9% from $517.4 million in 2021. Around 55% of the world's feldspar is produced by China, Turkey, and Italy. It is estimated that there are feldspar resources in more than 70 countries

around the world. Feldspar is valuable in industrial applications due to its high alkali and alumina contents. Fluxes are widely used as glazing agents for Chinaware and other ceramics, for fillers in paints, adhesives, plastics, sealants, rubber, glassmaking, and enamels.

Muhammad Yaqub Shah, Principal Geologist at Global Mining Company and former General Manager Geology at Pakistan Mineral Development Corporation (PMDC), told WealthPK:

“Feldspars are found in almost every section of the rock cycle. Many feldspars are igneous as they commonly make a solid solution series from magma as it cools.

“Two combinations of feldspar are the dominant ones i.e., potash feldspar and soda feldspar. Potash feldspars have more commercial value than the other feldspars as they are widely used as basic raw material in the manufacturing of ceramic wares both as value and glaze material. Soda and potash feldspars are also interchangeably used as fluxing material as well as in the glazes.”

United Lithium (ULTH) announced it has increased the land position of the Liberty Lithium Project in the southern Black Hills of South Dakota near the town of Pringle and south east of Custer by additional staking. The new claims are contiguous to those previously staked and announced in May and September this year.

The company has staked more than 200 additional unpatented lode claims covering more than 6.5 square miles (nearly 17 square kilometres) in the south part of the Black

Hills. This extends the ‘Liberty Lithium Project’, and the new claims cover numerous pegmatite bodies, most of which have not seen much exploration or production aside from historical and current quarrying of potassium feldspar and mica. A reconnaissance rock chip sampling programme was carried out by the company in conjunction with each of the staking programs to identify new areas for detailed field work. Samples have been submitted to the laboratory and assays are awaited.

By Isaac Hamza

By Isaac Hamza

It is no secret that the ceramic industry is one of the most energy-intensive manufacturing industries due to the need to fire at high temperatures.

This sector is also extremely diverse and comprises manufacturers of heavy clay construction products (such as bricks, blocks, roofing tiles, and drainage pipes); whiteware (tableware, giftware, sanitary ware, wall tiles); refractories (essential in all high-temperature processes); advanced ceramics (for a wide range of applications in electronic, medical, aerospace, environmental, military and structural fields); as well as suppliers of raw materials and equipment to the industry.

Since ceramic businesses compete on global markets that are fiercely competitive, their success is fundamentally dependent on energy and climate costs that are internationally competitive.

Despite this, if you look around the world, you can increasingly see the ceramics sector becoming increasingly committed to decarbonising in accordance with global decarbonisation targets.

As an example, decarbonisation projects and initiatives were prominent at the inaugural 'Delivering Net Zero for British Ceramics' conference, hosted by the British Ceramic Confederation in early December.

The purpose of this conference was to promote and celebrate best practices, research, and collaboration within the ceramic industry, as well as to promote initiatives that will enable the ceramic industry to attain net zero emissions by the year 2050. An estimated 150 delegates from various sectors of the ceramics industry and its stakeholders attended the event held in the heart of Britain, indicating its importance and relevance.

Speaking at the event, Rob Flello, CEO, the British Ceramic Confederation, said: “This is our first conference to focus on decarbonisation and we are delighted that it has been so well received.

“It provides a great opportunity for people to network, share ideas and discuss collaborations and has showcased the exceptional work and investment companies are undertaking as the ceramic sector strives to do its bit in the push for net zero by 2050.”

There are efforts being made throughout the world to 'Go Green', and ceramic businesses are doing their best to ensure they deliver on their environmental promises.

For instance, the GCC region has one of the most active construction markets in the world, with the UAE as the region's most active construction market, followed by Saudi Arabia and Qatar.

Over 10,000 projects are currently under construction or in the design and planning stages in the GCC. There is a constant demand for large volumes of construction materials in this region as a result of the largescale construction projects in this region. The ceramic tiles and sanitary ware market is one of the fastest growing markets in the GCC building materials industry. There are also significant imports in the GCC market for ceramic tiles and sanitary ware; almost 40% of the region's total demand is imported from countries such as China, Spain, Italy, Egypt, and India. The area is characterised by a high level of ceramic activity and construction, all of which may have a negative impact on the environment.

In spite of this, care and consideration for the environment and investing time and energy in sustainability initiatives remain top priorities in these rapidly

expanding economies with their burgeoning construction industry. Oman, for example, is establishing new joint ventures and projects as part of its vision to achieve a low carbon economy. This translates to the ceramic sector in that country as well. Initiatives such as Oman Sustainability Week, a national platform aimed at highlighting Oman's commitment to sustainability leadership through innovative strategies aligned with the UN Sustainable Development Goals (SDGs), as well as engaging national development stakeholders to present Oman as a new model for sustainable development, are gaining traction and drawing business and state attention to the issues of not only decarbonisation but also sustainability. In September this year it was announced that Oman Investment Authority (OIA) and Abu Dhabi-based ADQ had identified preliminary investments of more than AED 30 billion ($8.16 billion/€8.42 billion) in new projects in Oman that include hydrogen, solar energy, wind power, aluminium, and steel. Especially commendable was the commitment by the two parties to conduct feasibility studies on the targeted projects. It will have a significant impact on the environment while allowing business to continue in the area. Nearly 90% of all construction activities in the UAE are carried out in Dubai and Abu Dhabi, for example. There is an inextricable connection between these activities and the ceramics industry in the region. There is no doubt that these and other initiatives underway throughout the world indicate a promising future. It also demonstrates yet another endeavour on the part of the government and businesses, such as ceramics, to maintain a commitment to climate change and the environment.

The new high-pressure slip casting system type BTDG has been designed for production of cups incl. handles with higher output in one production step. Automatically fettling of pressure casting seams can be carried out by direct connection to the automatic fettling machine.

significantly higher production quantities (up to 400 pieces/h)

cost-effective article production

compact design: low space requirement

production: large batch size, high output

excellent service by Lippert expertise team