Fighting The Flu

Dr. Heather Fahlenkamp’s project aims to offer new ways to test, treat and prevent influenza and other lung infections.

2014

The official magazine of the College of Engineering, Architecture and Technology, Oklahoma State University

DEAN, COLLEGE OF ENGINEERING, ARCHITECTURE AND TECHNOLOGY

Paul Tikalsky, Ph.D., P.E., F.ASCE, F.ACI, EACR

SENIOR DIRECTOR OF DEVELOPMENT

Sandi Bliss, CQ

MARKETING MANAGER AND MANAGING EDITOR

Wravenna Bloomberg, MBA; Chelsea Robinson

UNIVERSITY EDITOR

Dorothy Pugh

ART DIRECTOR

Paul V. Fleming, BCE, BFA, MS

PHOTOGRAPHY

Phil Shockley, Gary Lawson, CEAT Staff

CONTRIBUTING WRITERS

Wravenna Bloomberg, Pam Covington, Maddy Haigh, Mallory Pence, Erin Portman, Erick Reynolds, Logan Scott, Doug Wright

is a publication of the Oklahoma State University College of Engineering, Architecture and Technology and is designed to provide information on college activities and accomplishments while fostering communication among the CEAT family and friends. WWW.CEAT.OKSTATE.EDU

The office of publication for IMPACT is 121 Cordell North, Stillwater, OK 74078-8031. © 2014, IMPACT. All rights reserved. Oklahoma State University, in compliance with Title VI and VII of the Civil Rights Act of 1964, Executive Order 11246 as amended, Title IX of the Education Amendments of 1972, Americans with Disabilities Act of 1990, and other federal laws and regulations, does not discriminate on the basis of race, color, national origin, sex, age, religion, disability, or status as a veteran in any of its policies, practices or procedures. This includes but is not limited to admissions, employment, financial aid, and educational services. Title IX of the Education Amendments and Oklahoma State University policy prohibit discrimination in the provision of services or benefits offered by the University based on gender. Any person (student, faculty or staff) who believes that discriminatory practices have been engaged in based upon gender may discuss their concerns and file informal or formal complaints of possible violations of Title IX with the OSU Title IX Coordinator, Dr. Rosalyn Green, Director of Affirmative Action, 408 Whitehurst, Oklahoma State University, Stillwater, OK 74078, (405) 744-5371 or (405) 744-5576 (fax).

This publication, issued by Oklahoma State University as authorized by the College of Engineering, Architecture and Technology, was printed by University Marketing Services, University Printing Services, at a cost of $13,920.00 8M/ Oct 2014/job #5541.

AN ASSOCIATE PROFESSOR’S PROJECT AIMS TO LEAD TO A GREATER AVAILABILITY OF LIVERS FOR TRANSPLANT SURGERIES. / PAGE 16 EXPANDING CAPABILITIES 12 A new digital fabrication lab in the School of Architecture is expanding students’ horizons. A DRONE TO DO MORE 24 An OSU doctoral student is working on an Unmanned Flying and Rolling Orb that would be able to fly, land and take off again, widening its world of possibilities ON THE COVER 8 An OSU professor is working on developing a new tool to help test and treat lung infections. THERE’S A TABLE FOR THAT 30 Construction Management Technology is incorporating an iProjectSolutions iPlanTable in some of its courses. INVESTING IN MANUFACTURING 40 The New Product Development Center has completed a $1.1 million project to help manufacturers in Oklahoma survive and thrive HALL OF FAME 58 LOHMANN MEDAL 60 TOP SENIORS 61 FACULTY CHANGES 64

PHOTOGRAPHY / GARY LAWSON / UNIVERSITY MARKETING

The engineering and technology sectors of the economy are expanding at a rate not seen in 25 years. The rapidly advancing unconventional oil and gas industry, alternative energy demand and the return of manufacturing to the United States, driven by a weak dollar and strong U.S. industrial efficiency, are creating new opportunities for the

next generation of graduates. It would have been hard to envision this change a few years ago, but the new industries and innovation in the U.S. economy require mechanical, chemical and industrial engineers.

From the Dean’s Office 1

The broader backbone of these industry changes is in our nation’s infrastructure with power, electrical, environmental and civil engineering and technology. U.S. industry is expanding its investments in pipelines, electrical distribution systems, rail transport, environmental safety and much more to support a sustainable energy future for our nation. All are supported by engineering and engineering technology. Our cities, regions and nation grow together. Innovations in sustainable and energyefficient architecture are reducing the demand for energy and bringing innovative systems to our lives.

Engaging and training students to tackle the challenges of the 21st century requires the College of Engineering, Architecture and Technology and OSU to envision and deliver the education of professionals that embraces innovation and know how both the fundamental systems and the next generation of technology work. The college is embarking on a venture to build the nation’s most advanced undergraduate laboratory building with integrated design input from leading industry experts, hands-on experimental systems and room for students to innovate and discover new ideas. We are not replacing aged labs but creating new labs that support the next generation of intellectual capital for our nation — CEAT students.

In the past year, CEAT has awarded 620 bachelor’s degrees (28 percent more than two years ago), admitted the three highest enrollments in its history and offered $2.1 million in scholarships to our students (75 percent more than two years ago). These students lead OSU in academic admissions markers, and our graduates lead OSU in starting salaries. The growth in demand for CEAT graduates and for admission to the college requires new commitments to education. CEAT is increasing its faculty size by 30 percent by 2018, and we hope to see alumni, corporations and students support a new pedagogical paradigm in next-generation, hands-on laboratories, which focus on digital control, data acquisition and evaluation, precision manufacturing and testing, communicating results, and innovating better systems.

As you read through this issue of Impact, you will see the everadvancing college. Many of you have contributed generously to support the students and programs that make OSU the great land-grant of Oklahoma. We will need your continued support. As we work toward our strategic goals, a donor has offered to match the first 150 donors that contribute at least $2,500 to the new laboratory building. Please visit OSUGIVING.COM and search for fund NO. 26-71500 ENGINEERING BUILDING FUND in order to give directly to the project. Each of these donors will be commemorated in the building and have an engineering scholarship named for them for the next academic year.

PAUL TIKALSKY DEAN, COLLEGE OF ENGINEERING, ARCHITECTURE AND TECHNOLOGY

GO POKES!

GARY LAWSON / UNIVERSITY MARKETING

Expanding Capabilities

New equipment gives students experience in digital fabrication

AT OKLAHOMA STATE UNIVERSITY, the School of Architecture established a new digital fabrication lab in the DONALD W. REYNOLDS ARCHITECTURE BUILDING last year, using a one-time allocation of student technology fee funds. This new hands-on digital fabrication equipment, consisting of 4-by-8 foot three-axis CNC MACHINES (COMPUTER NUMERICAL CONTROL), automated milling devices that make industrial components without direct human assistance, three 3-D printers, and a large-bed laser cutter, has been helping the school expand its digital design and fabrication capabilities.

“The digital fabrication tools were used by architecture students at the third-year level where they are introduced to building information modeling (BIM) as part of one of their required computer courses, ARCH 3262, an advanced computer class in conjunction with the third-year design studio work, which was coordinated with professor PAOLO SANZA,” says AWILDA RODRIGUEZ, assistant professor at the School of Architecture.

The students became familiar with tools such as the CNC and the 3-D printer for digital fabrication prototypes through digital procedures and took on responsibility for the critical aspects of design.

Working on the physical model allowed the students to quickly grasp a sense of scale while they could explore all possible changes equally quickly in the virtual environment.

FALL 2014 2

PHOTOGRAPHY / PHIL SHOCKLEY / UNIVERSITY MARKETING

continues

“The new hands-on equipment) … has infused our school with a new sense of possibility and enhanced our relationships with those outside of our discipline. It has fostered collaboration and been enjoyable.” — Nathan Richardson

3

One of the successful projects created in the fabrication lab in the ARCH 3262 course was Museo Nazionale D’Arte Romana in Rome, created by CLARISSA HOSKISON, MICHAEL MUELLER AND DREW PHILIPS. The equipment helped them create a quality design, Rodriguez says.

With students getting the opportunity to build like professionals in the field, the School of Architecture received great feedback from students who are interested in more hands-on experience with design.

The new technology provides better opportunities and education for students, making it easier to move design ideas past the drawing and modeling phase and into full-scale mock-ups of products and architectural proposals.

“There’s always a learning curve to new technology, but the new equipment works really well. Our shop manager, DAVID HORTON, has been instrumental in compressing the learning curve and helping me and others take full

advantage of the technology in our classes and research projects,” says NATHAN RICHARDSON, assistant professor in the School of Architecture.

Richardson is a part of an ongoing collaboration with the School of Entrepreneurship in the Spears School of Business and DR. CRAIG WATTERS, director of the Riata Center. In their course, they have been dealing with the issue of housing in very poor townships in South Africa, and it has expanded to the students’ research, design and building prototypes. The new equipment allows them to fabricate physical studies from their digital drawings by cutting or scoring a range of materials such as paper, plywood and aluminum.

The students from this elective Entrepreneurship and Architecture course were successful with their projects, and their intent to create housing solutions for many places of need, including Africa, was worth it.

“The School of Entrepreneurship brought a delegation of entrepreneurs from Africa, and while they were here

this spring, they toured our exhibition and the prototypes we created,” says Richardson. Entrepreneurs suggested that these proposals could actually work well throughout Africa, and these facts led to the construction of at least two of the prototypes on campus for longer-term testing in the outdoor environment and possibly deploying them abroad in the future. The construction is going to happen this summer and hopefully help with the deployment in the next few years.

The new hands-on equipment has been a success not only for professors, who appreciate the new tools helping with preparing students for their future career, but also for the students, who welcome new learning technologies that gives them more experiences, a better understanding of equipment used in the real world, and higher chance to succeed in careers.

“It has infused our school with a new sense of possibility and enhanced our relationships with those outside of our discipline. It has fostered collaboration and been enjoyable,” adds Richardson.

FALL 2014 4

ENDOWED POSITIONS

HEAD RANDY SEITSINGER, AIA

FOCUS AREAS

Building systems

Computer architecture

Commercial building

Design and structural concepts

Digital systems

Environmental designs

Historical architecture

Innovative designs

Materials

Modern architecture

Structural systems

Sustainable building

Urban design

DEGREE OPTIONS

Architecture

Architecture Engineering

5

ENROLLMENT (FALL 2013) 297 undergraduates FACULTY 9 professors 4 associate professors 6 assistant professors

1 Professorship

Architecture

GLANCE AT A SCHOOL OF

Adding Recycling to Renewable Energy

OSU research may lead to lower production costs for ethanol

AS ENERGY COSTS RISE, finding new sources for renewable energy is in great demand. OSU’s School of Biosystems and Agricultural Engineering is researching several ways to make energy production more efficient, including in nanomaterials.

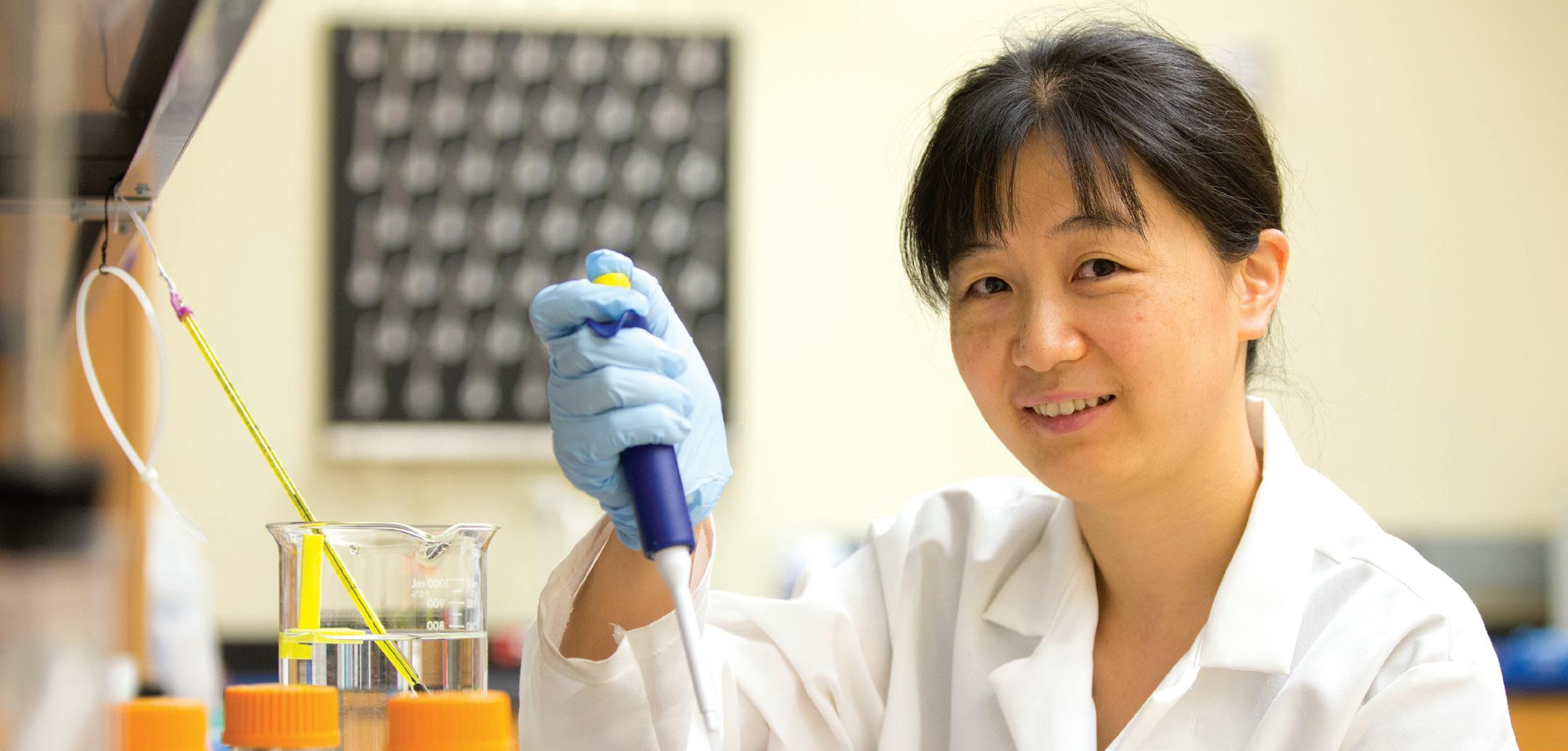

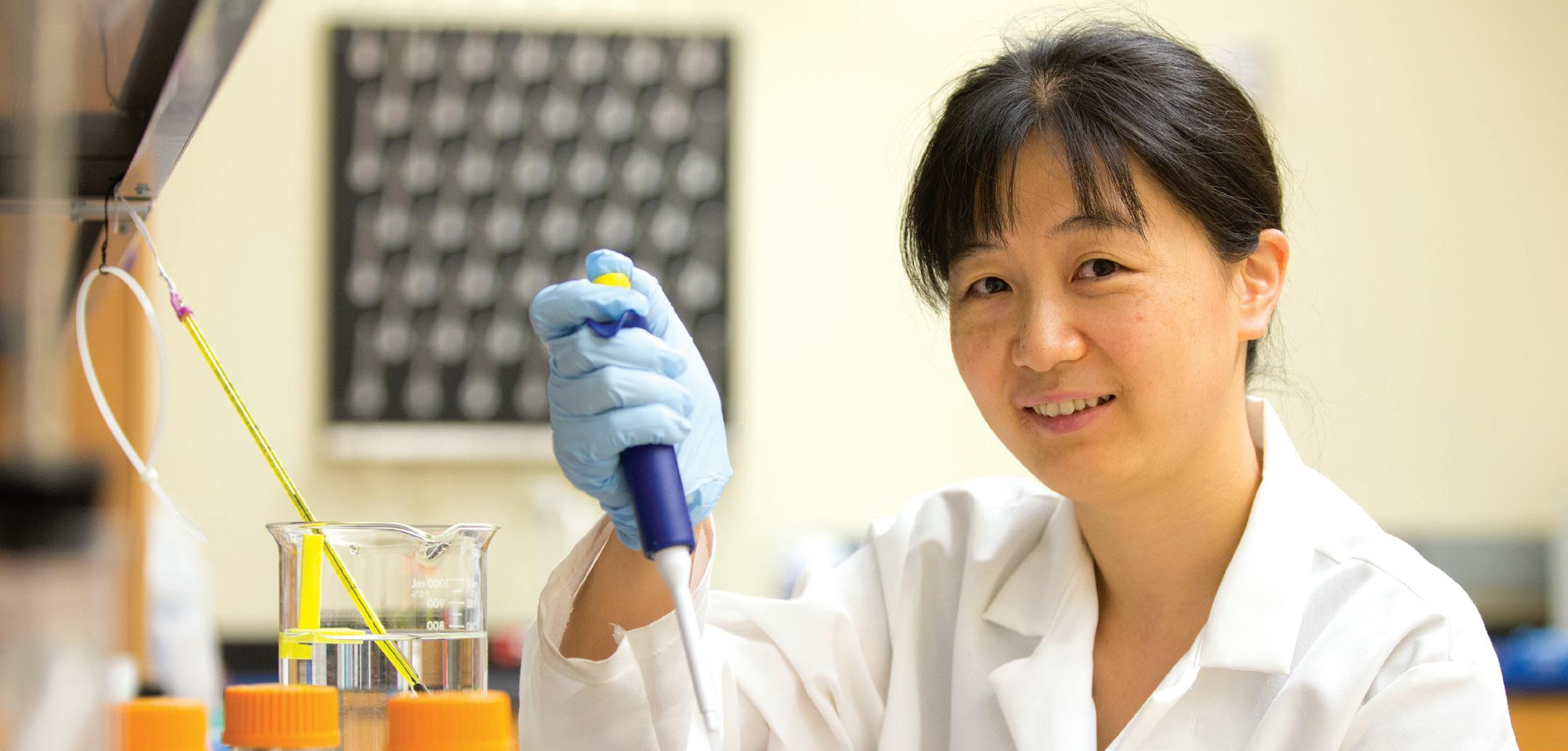

“High enzyme costs make the conversion of cellulosic biomass to ethanol economically unattractive and hinder the industrialization of cellulosic ethanol production,” says DR. DAN THOMAS , school head. “The research team led by DR. YU ‘JESSIE’ MAO is working on immobilization of cellulases on magnetic nanoparticles for quicker enzyme recycling in cellulose hydrolysis.”

In plain English: Naturally occurring enzymes produce sugar and break down to cellulose. These cellulase-enhanced nanoparticles demonstrate up to 67 percent of the original enzyme activity and can be quickly separated using a small magnetic field. Thus, this can be reused — recycled — up to 10 times.

“Recovery and reuse of cellulases will significantly decrease enzyme costs for cellulosic ethanol production and positively impact the industrial conversion of cellulosic biomass to biofuels,” says Thomas.

Ethanol produced from cellulosic biomass is an exciting renewable energy source. However, current production is based on one-time use of the expensive enzyme ingredient.

“Our technology allows the enzymes to be separated using a medium magnetic field after each hydrolysis. Preliminary results showed that the enzymes can be reused multiple times,” says Mao.

OSU has been doing research in this area since 2010.

“Our long-term goal is to lower the biofuel production cost and improve the conversion efficiency of cellulosic ethanol production,” Mao says. “The objective of current research is to investigate

cellulase immobilization on magnetically separable nanoparticles for reuse in cellulose hydrolysis.”

Recycling cellulase in cellulose hydrolysis will significantly decrease the enzyme cost for cellulosic ethanol production. This will benefit starting cellulosic ethanol plants and positively impact the efficiency in industrial conversion of cellulosic biomass to biofuels.

“This research will develop a simple method to immobilize cellulase enzymes on magnetic carriers,” says Mao. “The methodology can be extended to advance the technology in immobilizing and reusing other biomass degrading enzymes in biofuel conversion.”

With exciting outcomes on the horizon, this research still faces some challenges.

Mao hopes this study will improve the efficiency of renewable energy. With increasing demands for additional energy sources, OSU biosystems and agricultural engineering is on the cutting edge of beneficial research.

FALL 2014 6

PHOTOGRAPHY / PHIL SHOCKLEY / UNIVERSITY MARKETING

Dr. Yu “Jessie” Mao is leading research at OSU that could lead to lower costs for producing ethanol.

Biosystems and Agricultural Engineering

Air

Animal

Biobased

Bioenergy

Biochemical

Biofuels

Biomass

Biomass gasification

Bioprocessing Ecology mass

Enzymatic

Ethanol

Fire

Reactor design

Regulations

Sediment control

Sustainability

Synthesis gas fermentation

Water quality

Waste management engineering

DEGREE OPTIONS

Biomechanical

Bioprocessing and Bio-technology

Environment and

Natural Resources

Food Processing

7 ENROLLMENT (FALL 2013) 115 undergraduates 43 graduates FACULTY 9 professors 6 associate professors 3 assistant professors RESEARCH AREAS

pollution

waste

products

hydrolysis

engineering Manufacturing

control Hydraulic

HEAD DAN THOMAS, Ph.D., P.E., F.ASABE, F.ASCE

GLANCE AT A SCHOOL

OF

Flu Fighter

Associate professor developing tool for testing, treating lung infections

OSU Chemical Engineering is on the forefront of tissue engineering as researchers such as DR. HEATHER FAHLENKAMP blaze new trails in modeling lung and other human tissue.

This research provides hope and opportunities for those with compromised immune systems.

“The goal of my project is to create a tissue-engineered lung model that can be used to investigate how one’s immune system responds to infectious agents,” the associate professor says. “Specifically for this project, we are focusing on influenza, commonly known as the flu.”

Lung infection from influenza is a leading cause of disease and death worldwide, says the World Health Organization. There are many strains of influenza, and some are stronger than others.

“The damaging health effects of the highly pathogenic strains are related to an excessive immune response,” says Fahlenkamp. “The lung model would provide a critical tool, making it possible to investigate some of the key aspects of influenza pathogenesis.”

Fahlenkamp’s proposed model will contain multiple human cell types within a 3-D environment that provides for cell movement and interaction.

“The results of this project will have an important positive impact because the new information on the immune response to influenza has great potential to provide new targets for preventive and therapeutic interventions in influenza infection. The lung model will be of great and continuing value for testing treatment strategies,” she adds.

FALL 2014 8

PHOTOGRAPHY / PHIL SHOCKLEY / UNIVERSITY MARKETING continues

Dr. Heather Fahlenkamp is working on creating a lung model that can be used to battle the flu worldwide.

HEAD

JAMES (ROB) WHITELEY, Ph.D

Chemical Engineering

CFD-combustion reactor design

Fluid mechanics

Emulsion Formation and Stability

Enhanced unconventional gas recovery

Gas testing

Gene delivery

Heat transfer

Mass Transfer

Naterial science

Modeling

Nanoparticles and biomembranes

Petroleum

Polymeric systems

Process development

Reactor design

Sustainability

Thermodynamics and thermophysical property prediction

Tissue engineering

Viscoelasticity

Water process and ion exchange

DEGREE OPTIONS

Chemical Engineering

• Biomedical / Biochemical option

• Environmental option

• Pre-med option

9 ENROLLMENT

395 undergraduates 59 graduates FACULTY 8 professors 4 associate professors 7 assistant professors

POSITIONS 10 Chairs 1 Professorship

AREAS

filtering Biofuels Biomedical Biotechnology

(FALL 2013)

ENDOWED

RESEARCH

Adaptive

energy and refining Phase equilibrium

GLANCE AT A SCHOOL

OF

“Being part of a research center also provides access to core facilities that would otherwise not be available to a single investigator, as well as access to a wealth of expertise from mentors and consultants associated with the center. I will have the opportunity to work with experts in the field and to build collaborations for future projects. The grant will help me take my research to the next level.”

FALL 2014 10

— Dr. Heather Fahlenkamp

A Centers of Biomedical Research Excellence grant funds supplies to carry out her experimental work and pay graduate students’ salaries to work on the project. The grant also covers a portion of her academic salary, allowing her to focus more time on the research project. She will have funds to travel to meetings and conferences to present her research findings and learn about other work being done in this area.

“Being part of a research center also provides access to core facilities that would otherwise not be available to a single investigator, as well as access to a wealth of expertise from mentors and consultants associated with the center,” Fahlenkamp says. “I will have the opportunity to work with experts in the field and to build collaborations for future projects. The grant will help me take my research to the next level.”

Fahlenkamp’s research aims to create and characterize a lung model that behaves similarly to human lung tissue. The lung model will be used to study the effect of various strains of influenza virus on key cell types that influence the immune response to the virus.

“By the end of the first year, I expect to have designed the 3-D environment for the model, which includes a porous scaffold that allows for cell migration and growth within the entire scaffold and culture conditions to maintain the multiple cell types within the model,” she adds.

Fahlenkamp received a National Science Foundation Career award for another project in tissue engineering. The goal was to create an advanced 3-D tissue model that can be used for testing and studying human allergic inflammatory responses. Over the last few decades, allergic diseases have increased dramatically in developed nations. The tissueequivalent model can be comprised of patient-specific cells in order to function as an allergy sensor to detect specific biomarkers that are expressed during an allergic inflammatory reaction.

Broader impacts of this project include a new way to test allergens and other inflammatory stimuli and evaluate sitespecific delivery of active compounds to alter the local inflammatory and immune response. This research project has the potential to provide health care providers with more information to better manage patients with allergic diseases and a better understanding of inflammation in a broader sense. Such an aggressive approach could change how immunotherapies are tested, perceived and developed against diseases associated with inflammation.

While her research in lung tissue has the potential to contribute to the future development of better flu vaccines, there are some immediate benefits as well.

“Oklahoma State University, students and I will benefit from the immediate impact of adding resources and publicity to this important area of research,” says Fahlenkamp. “The state of Oklahoma also stands to benefit with an increase of technical expertise in the research area that could serve as an incubator for startup companies with the addition of new technical jobs within the state.”

11

“We can actually show someone how much time they are able to save. It will give contractors a way to visualize the benefits of prefabrication and also perhaps identify some of the disadvantages of it.” — Phil

Lewis

Perfecting Prefab

Assistant professors lead productivity study in electrical construction

Prefabrication, long used to improve productivity in many parts of the construction industry, is gaining popularity with electrical contractors. This growing trend in the electrical industry is of special interest to ELECTRI INTERNATIONAL, which has provided a grant to an OSU research team to quantify the benefit of prefabrication in electrical construction.

Principal investigator PHIL LEWIS, PH.D., P.E., is leading the collaborative effort with co-PI YONGWEI SHAN, PH.D., P.E. Both are assistant professors in OSU’s Civil and Environmental Engineering Department. The two researchers will be working with the Oklahoma chapter of the National Electrical Contractors Association, Oklahoma City electrical contractors OESCO and Dane & Associates Electric Co., and Raleigh, N.C., contractors Carolina Fabricators, Code Electric Inc., LL Vann Electric Inc. and Strategic Connections.

The investigators will identify the best practices in prefabrication using on-site interviews with the electrical contractors. Productivity data will be collected from different electrical construction projects and differences between conventional approaches and those using prefabrication will be compared at the Oklahoma NECA chapter’s training facility.

Using the data, a building information model will be created to simulate the impact of prefabrication on productivity. Instead of a 3-D model, the BIM will be a 4-D model since it will add the fourth dimension of time.

“We will use this concept to do a side-by-side comparison of traditional methods and prefabrication methods to compare how much benefit you can get in terms of productivity in prefabrication in electrical construction,” says Shan.

“We can actually show someone how much time they are able to save,” says Lewis. “It will give contractors a way to visualize the benefits of prefabrication and also perhaps identify some of the disadvantages of it.”

Electrical contractors use prefabrication in precut conduit, precut electrical cable, prewired raceway and box and bracket assemblies, to name a few. According to Lewis, industry consultants estimate that electrical contractors could improve their average productivity 30 percent by using at least some prefabrication practices. Lewis and Shan’s yearlong study for ELECTRI International will provide real-world data to quantify the impact of prefabrication on electrical labor productivity.

“We’re doing this for the electrical industry, but it would certainly apply to other trades in construction, particularly mechanical and plumbing, and maybe even other areas that you wouldn’t consider candidates for prefabrication,” Lewis says. “This could get people thinking outside the box about how to be more productive.”

FALL 2014 12

PHOTOGRAPHY / GARY LAWSON / UNIVERSITY MARKETING

Yongwei Shan (left) and Phil Lewis are leading a study on the usage of prefabrication in electrical construction.

HEAD JOHN VEENSTRA, Ph.D, P.E.

Civil and Environmental Engineering

RESEARCH AREAS

Concrete

Construction

Energy

Environmental

Geotechnical

GIS

Pavement

Pavement data systems

Recycling

Sensors and data transfer

Soil effects

Structural engineering

Steel structures

Transportation

Water quality

DEGREE OPTIONS

Civil Engineering

• Environmental option

13 ENROLLMENT (FALL 2013) 269 undergraduates 79 graduates FACULTY 5 professors 8 associate professors 9 assistant professors

POSITIONS 1 Chair 3 Professorships

ENDOWED

biological process

(geographic information systems)

construction

GLANCE AT A SCHOOL OF

Going Up

New Cooper Lab Building to expand civil engineering

A NEW LAB BUILDING

under construction will benefit OSU civil engineering students once it’s finished in November. Students will be able to broaden their education with the state-of-the-art lab space.

This 35,000-square-foot building, to be called the COOPER LAB BUILDING, is a creative learning environment that will prepare students for a future of innovation and leadership. It will offer a hands-on environment for multiple educational, research and outreach opportunities with its industry leading technology.

The only facility of its kind in the Midwest, it will feature capabilities nearly unmatched in the nation. A 5,000-square-foot strong floor capable

of testing full-scale bridge components, multistory structural assemblies and next-generation building materials will be the central focus of the research laboratory.

This facility also includes an advanced construction materials laboratory focusing on simulating different environmental exposures from the initial construction throughout the material’s life. The materials laboratory incorporates large environmental chambers that can simulate extreme heat, extreme cold and adverse drying conditions. In addition, the lab building features state-ofthe-art capabilities for testing structural assemblies in case of fire, blast and other extreme environmental conditions. The envisioned live fire chamber will be able to measure the heat produced by fires in real time and to measure gas discharges.

The new building lab will offer unmatched collaboration between structural research, fire protection and safety testing.

The lab also features equipment and spaces to advance the development of sensors to measure, monitor and assess the performance of construction materials. The facility includes instrumentation and equipment capable of exploring phenomena that control the formation of new materials at the microscopic level. Additionally, the lab includes experimental and analytical instrumentation for viewing the formation of composite materials and new ceramics at the micro and nano scales. This aids scientists and research engineers in understanding, predicting and developing innovations that will lead the construction industry into the next several decades.

FALL 2014 14

FRANKFURT SHORT BRUZA

Above rendering shows the finished Cooper Lab Building.

Expanding a Mission by Advancing Careers

Professional Development offers non-credit adult education programs and professional development services through strong partnerships with the College of Engineering, Architecture and Technology and industry leaders. For nearly 90 years, this outreach and extension unit has enhanced careers and extended OSU’s mission both locally and abroad through:

Customized courses that offer training simulation of real-world scenarios. Hands-on experience that translates seamlessly into worksite application. A long-standing tradition of exceeding industry standards.

Thank you to our alumni and current clients for your continuing support, and we welcome all who have never experienced America’s Brightest Orange.

Go Pokes!

Professional Development ceatpd.okstate.edu 1812 Tyler | Stillwater, OK 74078 | 405-744-5714

Life-Saving Engineering

Liver transplant research might sound like something you’d be more likely to see at a medical school, but DR. DAQING PIAO, associate professor in the School of Electrical and Computer Engineering, is focusing on biomedical research that he hopes can expand the availability of livers for transplants.

In one of his current research projects, he is working to help develop a technology to objectively evaluate whether one specific condition of a donor’s liver will make it unacceptable for transplantation.

“There are always more patients waiting for a transplant than there are donor organs that are available,” says Piao, who joined the school nine years ago. “There are about 6,000 liver transplants being done annually in the United States, and patients on the waiting list can be about 17,000.”

IT’S ALWAYS A LIFE-OR-DEATH SITUATION.

“Because of the growing demand for liver transplantation with a concomitant shortage of donor livers, livers of marginal quality, such as with fatty changes, sometimes will have to be used for transplant,” he notes. “None of the fatty changes of liver is healthy;

however, when there is only a fatty liver available, using it could save lives, but not without serious risk.”

Both the extent and the type of the fatty changes affect the functioning of the liver after transplant. The less fatty changes a donor liver has, the less risk it brings.

Piao says there are basically two types of fatty changes that are relevant to his work. One type occurs when a large single fatty particle is formed in a liver cell, squeezing and deforming the normal material within the liver cell. This type of fatty change significantly risks the functioning of the organ after being transplanted, so it should not be used for transplantation. The other type occurs when numerous small fatty particles are formed in a liver cell, making space among but not deforming the normal material there. This type of fatty change doesn’t affect the functioning of the organ after being transplanted, so the liver is usually acceptable for transplantation.

Piao is developing a fiber optic probe that can fit in a small needle in order to evaluate the extent and possibly the type of fatty changes.

“The need of an evaluation technology like this one we are developing was actually suggested by a doctor whom I know personally,” Piao says. “Liver transplant surgeons are in need of a fast and reliable method to know about the interior conditions of the donor liver. If a very small fiber can be placed to probe the donor liver deeply, and there are some optical signals or images that can show if the tissue has low-extent and low-risk fatty changes, the doctors can make a better decision for the patient.”

Piao says the fatty condition is only one of many things that can affect the viability of a donor liver.

“Eventually, we would like to see our method helping the surgeons determine if a donor liver cannot be used because it has become too fatty or it has a highrisk type of fatty change,” Piao says. “To do that, we will need to have a tool for them to evaluate objectively how much fatty change has occurred in the liver, and possibly which kind of fatty particles, bigger one or smaller ones, is more prevalent in the fatty change.”

The Oklahoma Center for the Advancement of Science and Technology funded the three-year research project, which began in 2011.

FALL 2014 16

Research project could lead to more liver transplants

continues

17 PHOTOGRAPHY / GARY LAWSON / UNIVERSITY MARKETING

“There are always more patients waiting for a transplant than there are donor organs that are available.” — Daqing Piao

“This

“We are right now on the third year, and we have already developed the prototype and continue to optimize the algorithms,” Piao says. “We have started developing a rat model of fatty liver to test if our system can at least tell the extent of the fatty changes and then can potentially tell the different types of the fatty changes.

“Over the past year, we have completed the measurement phase of the study on 18 rats, and in the remaining six months, we have 12 more rats to go,” he says. “This study is not possible without the collaboration with an exceptionally devoted team of investigators from the OSU Center for Veterinary Health Sciences.”

Experts assisting with this study include:

DR. KENNETH E. BARTELS, DVM, MS, McCasland Foundation Laser Surgery Professor and Kerr Chair for Biophotonics; DR. G. REED HOLYOAK, DVM, Ph.D., head of Department of Veterinary Clinical Sciences, professor and Bullock Professorship in Equine Theriogenology; DR. JERRY W. RITCHEY, DVM, Ph.D., professor, diplomate, American College of Veterinary Pathologists; DR. COREY R. WALL, DVM, assistant professor; and JILL K. MURRY, veterinary technician III. Additional staff members from Lab Animal Resources are involved as well.

“The workhorse of this study is Ph.D. student NIGAR SULTANA,” says Piao. “She has done a marvelous job by keeping her head out of tons of data needing her careful acquisition and analysis.”

Piao says he’s confident the project will benefit liver transplant patients if it’s successful.

“We will be hopeful,” Piao says. “The state agency also thinks this may be useful as we predicted, but we need to test it out.”

FALL 2014 18

Dr. Daqing Piao (right) adjusts light as Dr. G. Reed Holyoak runs tests on a lab rat involved in the project on fatty changes in the liver.

study is not possible without the collaboration with an exceptionally devoted team of investigators from the OSU Center for Veterinary Health Sciences.” — Daqing Piao

INTERIM HEAD

JAMES WEST, Ph.D.

Electrical and Computer Engineering

ENROLLMENT (FALL 2013) 417 undergraduates

Communications systems and signal processing

Computational intelligence, perception and neuroscience

Computer simulations

Digital and embedded systems

Pattern recognition and machine learning

Photonics

Plasmonics

Robotics and embedded computing sensors

12 associate professors

5 assistant professors

ENDOWED POSITIONS

1 Chair

3 Professorships

RESEARCH AREAS

Laser spectroscopy

Biomaterials

Biophotonics/biomedical optics

Classical optics

Electronic materials and devices

Energy and renewable energy sources

Image processing and computer vision

Intelligent systems and control

Laser optics

Medical imaging

Microelectromechanical systems

Metamaterials

Nanomaterials

Optical imaging

Solar hydrogen Systems theory and instrumentation

Terahertz photonics

Thermoelectric

Tissue engineering

Ultrafast femtosecond lasers

Very large scale integration

DEGREE OPTIONS

Electrical Engineering

Computer Engineering

19

206 graduates FACULTY 10 professors

GLANCE AT A SCHOOL OF

Emergency Aid

OSU team developing apps for use in crises

FALL 2014 20

USER INTERFACE FOR AMBULANCE DISPATCH ASSISTANT

Making sure needed resources are in the right places during an emergency can be a daunting task for officials. Oklahoma State University and the University of Louisville are developing mobile apps and support tools for a real-time, decision-support system to help personnel with decisions on allocating scarce resources in a pandemic influenza or other viral attack.

The $3.3 million project development is funded by the U.S. DEPARTMENT OF HOMELAND SECURITY’S SCIENCE AND TECHNOLOGY DIRECTORATE, through a technology development and deployment program managed by the National Institute for Hometown Security. At OSU, DRS. SUNDERESH S. HERAGU, Donald and Cathey Humphreys Professor and head of the School of Industrial Engineering and Management, CAMILLE DEYONG AND MANJUNATH KAMATH are leading the project.

Emergency officials, concerned about the impact of the next pandemic attack, need a real-time decision support system to assist decision-makers during and immediately after a pandemic outbreak.

With studies suggesting that up to 40 percent of the population could be affected by an influenza virus, the Department of Homeland Security wants to upgrade current health care systems for the most efficient and effective response to the next pandemic. These tools support that.

A web portal would help strategic national stockpile coordinators and emergency medical services coordinators know what is where, with live data from multiple sources. Not only can that help, for example, in storing and distributing vaccines, it can also help in dispatching emergency medical services in response to new patient calls and changing conditions such as hospital diversion, ambulance unavailability, road closures and other factors.

A fully deployed system should be able to optimally solve resource allocation problems in real-time and display the information on a map or in a format that’s easy to use by novice users.

Camille DeYong (left) and Manjunath Kamath are on the School of Industrial Engineering and Management’s team developing mobile apps to help officials in cases of emergency.

21

PHOTOGRAPHY / GARY LAWSON / UNIVERSITY MARKETING

SELECTION OF THE POINTS OF DISPENSE (PODS)

Analysis to Impress

Team led by engineering student shows off expertise in data mining

An OSU team led by JUAN MA , a doctoral student in industrial engineering and management, finished second out of more than 50 teams competing in the SAS ANALYTICS SHOOTOUT COMPETITION at the 2012 Analytics Conference in Las Vegas.

Ma’s team, SHIRMEEN VIRJI, MATTHEW DALE RUMSEY AND ISAAC PISORS, demonstrated their expertise in data mining in the competition.

Ma received a data mining certificate through the SAS and OSU certificate program (offered in three levels: data mining, predictive analytics or marketing data science). This program produces capable and analytic understanding managers who will be a great fit at leading teams of IT, marketing and strategy personnel in any organization, and by analyzing data, they will be able to solve business problems. This course was designed with help from SAS, a leading provider of business analytics and data mining software and services. Any current OSU graduate student with a technical background is eligible to receive this certificate by completing course requirements.

Ma joined the SAS and OSU datamining program to learn about data analysis, predictive modeling, model deployment and other related topics.

ANALYTICAL DATA MINING LOOKS AT WORDS AND THEIR CONTEXTS TO ANALYZE THEIR MEANINGS.

Keywords

Language

choosing a model that carefully looks at when to distribute the vaccine and how to market it, you can reduce the impact of these viruses in the coming flu season.” — Juan Ma

Analytics

SIMULATED

She led a team consisting of business and industrial engineering students, who answered all the questions the competition demanded:

Which virus to include in vaccine?

Which promotion program to apply?

What amount of vaccine to produce?

How to predict influenza impact?

Students had an access to data from California, Michigan, New Jersey and Washington that included details on the number of people infected by influenza, hospitalizations and deaths, along with details on marketing plans. Teams had to choose a promotional plan; to ensure they chose the right one, students analyzed data that showed the percentage increase in vaccination (the lift rate) for each plan.

“By choosing a model that carefully looks at when to distribute the vaccine and how to market it, you can reduce the impact of these viruses in the coming flu season,” Ma says. “When we looked at the literature, no one had really tested this type of prevention model.”

The team discovered marketing the vaccine is ineffective until enough is available to meet the demand.

“In some sense, the value of the research was to solve a complicated, large-scale, real-world problem, which has a good potential to yield a plan of reducing influenza impact,” Ma says.

Ma calls this program a great opportunity for students. OSU teams have consistently placed in the top three in the shootout for the last seven years.

FALL 2014 22

“By

Latin

Submit Clear

Enter text (up to 5k words

or 50k characters)

Donec

pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. In enim justo, rhoncus ut, imperdiet a, venenatis vitae, justo. Nullam dictum felis eu pede mollis pretium. Integer tincidunt. Vivamus elementum semper nisi. Aenean leo ligula, porttitor eu, consequat vitae, eleifend ac, enim. Aliquam lorem ante, dapibus in, viverra quis, feugiat a, tellus. Phasellus viverra nulla ut metus varius laoreet. Aenean imperdiet. Etiam vel augue. Curabitur ultricies nisi. Etiam rhoncus. Maecenas tempus, tellus eget condimentum rhoncus, sem quam semper libero, sit amet adipiscing sem neque sed ipsum. Nam quam nunc, blandit vel, luctus pulvinar.

INTERFACE

Industrial Engineering and Management

DEGREE

23 ENROLLMENT (FALL 2013) 132 undergraduates 116 graduates 115 engineering and technology management graduates FACULTY 8 professors 8 associate professors 2 assistant professors ENDOWED POSITIONS 1 Chair 2 Professorships RESEARCH AREAS Algorithms Applied probability Cognitive ergonomics Energy operations Information systems Logistics and supply chain management Management and decision analysis Manufacturing systems Modeling Motorcycle safety Quality management Robotics Sensors Supply chain Sustainability Transportation

SUNDERESH HERAGU,

HEAD

Ph.D.

Industrial Engineering and Management SCHOOL OF GLANCE AT A

OPTIONS

PHOTOGRAPHY /

/ UNIVERSITY MARKETING FALL 2014 24

PHIL SHOCKLEY

“This exciting research puts OSU on the leading edge of unmanned systems.” — Ben Loh

Flying’s Just the Beginning

Doctoral student works on a safer and more versatile UAV

Search and rescue, military tactics and observation in potentially dangerous situations are all possibilities that current research in Aerospace Engineering at OSU could benefit. Doctoral student BEN LOH has been perfecting his UNMANNED FLYING AND ROLLING ORB since 2011.

“Imagine a survivor is trapped inside a building under a pile of rubble. The UFRO can land in any orientation and roll towards the survivor without imposing propeller hazard to the survivor,” says Loh.

This device was developed at OSU as a multifunctional spherical robotic vehicle designed for search and rescue that combines hovering, forward flight and ground mobility. The latest prototype consists of a single propeller controlled by eight vanes enclosed in a spherical frame reinforced with carbon fiber.

“This exciting research puts OSU on the leading edge of unmanned systems,” says Loh. “The ability to return to flight is one of the unique features. The UFRO can land on the ground without any landing coordination, roll on the ground to get away from obstacles and self-upright using propeller slipstream before returning to flight. This is a recovery feature that is not available in any other platforms such as ducted fan, multi-rotor, fixed wing [aircraft] or helicopter.”

The UFRO has a GPS module for autonomous flight control and proximity sensors for altitude hold and object avoidance purpose.

“An operator can use a smartphone or tablet to control the UFRO using Bluetooth,” says Loh.

25

continues

Open-tip propellers on hand-tossed fixedwing unmanned aerial vehicles and multirotor platforms can present safety hazards to the operator and are likely to get damaged upon contact with an object. The need to avoid these problems has led to the development of several shrouded-fan vehicles with robust control systems.

“A flipped vehicle without self-upright capability has no further operational benefit,” says Loh. “To operate in an urban environment or even indoors, a search and rescue oriented UAV should consider functionalities such as object detection and avoidance, hover, small landing footprint and self-recovering in an undesirable environment.”

This need in search and rescue led to the UFRO.

“The UFRO can also carry payloads such as alarms, GPS modules, light beacons to help rescuers locate the survivors quickly,” says Loh.

A few direct areas that could benefit from this research include:

MILITARY APPLICATIONS

Search and rescue

Proximal reconnaissance, indoors or outdoors

Damage assessment in urban and military environments

Mine detection in war zones

Formation flying of hovering air vehicles for multiple mission objectives

Deployment of multiple micro air vehicles by a central command for distributed monitoring

CIVILIAN APPLICATIONS

Inspecting electrical transmission lines, oil and gas pipelines

Police surveillance, interdiction, SWAT; border patrol (immigration and drug)

Search and rescue over disaster area

Riot monitoring system

“We have five patents on this vehicle,” says Loh. “OSU Cowboy Technology is helping us to create a startup company to commercialize the UFRO.”

FALL 2014 26

HEAD DAN FISHER, Ph.D.

Mechanical and Aerospace Engineering

ENROLLMENT (FALL 2013)

1, 244 undergraduates

161 graduates

FACULTY

11 professors

5 associate professors

14 assistant professors

ENDOWED POSITIONS

3 Chairs

5 Professorships

RESEARCH AREAS

Acoustics

Aerospace

Aircraft

Automation

Building systems

Cardiovascular

Coatings

Computational fluid dynamics

Design systems

Dynamics

Electromagnetics

Fire

Fluids

Heat pump

Heat transfer

Image processing

Lasers

Material science

Mechanics

Polymers

Precision engineering

Refrigeration

Robotics Systems

Thermal systems

Tissue engineering

Unmanned aerial systems

Vehicle stability and control

Winding

Wrinkling

DEGREE OPTIONS

Aerospace Engineering

Mechanical Engineering

• Biomedical option

• Pre-med option

27

SCHOOL OF GLANCE AT A

The Diamond Answer

body

Research being done at Oklahoma State University on ways to deliver drug treatments inside the body could lead to diamonds becoming everyone’s best friend.

How can this elegant material be used to administer healing agents to the human body?

“Due to its low chemical reactivity and unique physical properties, diamond nanoparticles may be useful in a variety of biological applications such as carriers for drugs, genes or proteins; novel imaging techniques; coatings for implantable materials; and biosensors and biomedical nanorobots,” says DR. CHUCK BUNTING, associate dean of research and sponsored programs in the College of Engineering, Architecture and Technology.

OSU is on the cutting edge of research in nanomaterials, and diamond nanoparticles — also referred to as DNPs — promise an exciting future with possible usage in bio-sensing applications, catalysis, electrochemical applications, quantum computing and quantum optics.

The research into using DNPs for drug delivery is taking place in the School of Material Science and Engineering at OSU by DR. RAJ SINGH in collaboration with DRS. RASHMI KAUL AND ANIL KAUL at OSU’s Center for Health Sciences in Tulsa. DNP is just one piece of research that could help millions that’s being conducted in the Helmerich Advanced Technology Research Center.

“The most important aspect of this research will be to use diamond nanoparticles as agents of drug delivery,” says Singh. “In order to achieve this, we have to find new ways of attaching drug molecules to diamond surfaces.”

For example, DNPs could be used in treating urinary tract infections, considered the second most common infectious disease in the United States and resulting in more than $6 billion in health care costs. The high recurrence rate of UTIs shows a significant need for better treatment options.

The research for DNP found persistent UTIs are caused by a virulent form of bacteria known as Dr + E. coli , which invades and survives in tissues for extended periods of time by binding

to a known host cell receptor. Rashmi and Anil have been working with this specific type of bacteria and its specific receptors for more than 20 years and have a variety of patents dealing with urinary tract infection pathogenesis.

Traditional methods of treating UTIs involve high dosages of antibiotics such as amoxicillin. However, the widespread use of such high-dosage antibiotics leads to the evolution of antibiotic-resistant pathogens and unwanted side effects, which is where using DNPs becomes more appealing.

“If successful, the drug-loaded nanoparticles can be more effective in treating the infections without the adverse side effects of antibiotics,” says Singh. “Prevention and more effective treatments can also lead to cost savings for health delivery systems.”

Diamond nanoparticle research lays the foundation for targeted, low-dosage antibiotic treatments. It demonstrates that DPNs are viable platforms for efficient delivery of drugs, such as amoxicillin to kill Dr + E. coli in cells.

“This research requires the use of new approaches to modify and control diamond surfaces using chemical means so that drugs can bind/attach and keep the drugs there until released at select locations to treat infections,” says Singh. “This will help in administering a lower amount of drugs to treat the diseases and prevent the proliferation of the drug-resistant bacteria.”

FALL 2014 28

OSU researchers say precious mineral may be used to pinpoint drug delivery in

“This will help in administering a lower amount of drugs to treat the diseases and prevent the proliferation of the drugresistant bacteria.”

— Raj Singh

RAJ SINGH, Ph.D.

Materials Science and Engineering

LAUNCH DATE

Fall 2013

FACULTY

2 professors

3 assistant professors

ENDOWED POSITIONS

3 Chairs

RESEARCH AREAS

Biomechanics/biomaterials in medicine

Biomechanics/biomaterials in tissue engineering

Biomimetic photothermal hydrogen production

Electric eel bio-mimicry

Filament winding

Fuel cell

In vitro/in vivo studies

Ion channel arrays

Lipid multilayer assemblies

Liposomal drug delivery

Manufacturing

Nanomaterial for medicine

Natural gas

Nonotubes/nanorods

Polymer composite

Processing

Properties of nanostructured materials

Scaffold design

29

HEAD

AT A

SCHOOL OF GLANCE

iPlanning for the Future

Construction Management Technology adds ‘giant wide-screen tablet’ to courses

Some big technology is being used at Oklahoma State University’s College of Engineering, Architecture and Technology — and not just in size.

OSU’s Construction Management Technology department is incorporating an iPROJECTSOLUTIONS iPLANTABLE in some of its courses for hands-on learning.

“It’s essentially a giant wide-screen tablet, and it allows you to work with blueprints, or what we would consider prints,” says DR. HEATHER YATES, interim CMT department head and associate professor.

The 55-inch screen iPlanTable functions as a normal computer as well. It can compile all types of documents, allowing those working on projects to visually change the documents as well as add details. Links can also be added.

The iPlanTable makes construction sites run more efficiently by eliminating large paper blueprints and heavy construction specification books.

“On a construction project, we’ve got the big set of blueprints, and then we’ve got the huge spec book,” says Yates. “You can actually link them together on the iPlanTable, so when you touch the concrete, or whatever, you essentially link it to the spec book just by clicking concrete. It can be fully integrated, eliminating the need to flip through 570 pages.”

This technology is relatively new to construction management. In fact, only a few other universities offer this type of training technology. Pittsburg State University was the first to purchase the iPlanTable in December 2012.

This modern technology places OSU in an elite group to equip the next generation of construction management professionals. The department’s goal is that every student will be comfortable with the iPlanTable by graduation.

FALL 2014 30

PHOTOGRAPHY / GARY LAWSON / UNIVERSITY MARKETING

Students in Construction Management Technology work with the iProjectSolutions iPlanTable.

DANA HOBSON, Ph.D., P.E.

DIVISION

OF

Engineering Technology

RESEARCH AREAS

Concrete design and law

Construction design and management

Construction

Data acquisition and control

Development equipment design

Electrical infrastructure

Embedded microcontrollers

Engineering technology

Environmental building

Fire control

Fluid power

Geotechnical engineering

Ground source heat pump

Hazardous material incident

Industrial hygiene

Instrumentation development

Manufacturing systems

Materials science

Safety

Security in emergencies

Systems process and management

DEPARTMENTS AND DEGREE OPTIONS

Construction Management

• Building option

• Heavy option

Electrical Engineering Technology

• Computer option

Fire Protection and Safety Technology

31

756 undergraduates FACULTY 6 professors 7 associate professors 11 assistant professors

ENROLLMENT (FALL 2013)

ENDOWED POSITIONS 6 Professorships

materials testing and inspection

INTERIM HEAD

Mechanical Engineering Technology GLANCE AT A

Supporting Success

$2.1 million of CEAT scholarships help ease students’ worries, enhance their paths

FALL 2014 32

PHOTOGRAPHY / GARY LAWSON / UNIVERSITY MARKETING

IN THE UPCOMING 2014-15 ACADEMIC YEAR, OKLAHOMA STATE UNIVERSITY’S COLLEGE OF ENGINEERING, ARCHITECTURE AND TECHNOLOGY WILL AWARD MORE THAN 980 SCHOLARSHIPS TO STUDENTS WORTH $2.1 MILLION. IT’S AN INVESTMENT IN STUDENTS AND THE FUTURE.

These scholarships would not be possible without the help and support of generous donors who give back to the school. Because of their generosity, this $2.1 million helps students reach their financial and career goals.

The money is awarded through 101 different departmental scholarship funds and 58 CEAT scholarship funds to incoming freshman, transfer and continuing students within CEAT. The 58 scholarships supporting these students include awards such as the DOLESE SCHOLARSHIP, as well as programs such as the PHILLIPS 66 SHIELD SCHOLARS PROGRAM

The Dolese Scholarship provides aid to undergraduate students who are majoring in engineering and in good academic standing. About 60 percent of the Dolese funds support students that have significant financial need. This scholarship will be awarded to more than 350 CEAT students for the 2014-2015 academic year, and funds range from $1000 to $3000 per student.

ZACHARY DEMARCO, a civil engineer senior, received a Dolese scholarship for the 2013-1014 school year.

“My biggest goal, is to graduate without student loans,” DeMarco says. “So every time I get a scholarship, I’m one step closer to meeting that. I have one year left, and it’s looking good.”

For most of these students, a scholarship means more than money; it means time. Without financial aid, many

students would be forced to take out loans or work part-time or full-time jobs. Scholarships allow students to focus on their education and not stress about its cost.

JORDAN THOMAS, a chemical engineer senior who qualified for the Dolese Scholarship for the upcoming 20142015 year, already sees the benefits of this financial support in her life.

“I currently work three jobs,” says Thomas. “With the help of this scholarship, I will only need to work two. This is a huge stress off of my shoulders, and a huge financial burden lifted.”

Donors also support several scholars programs such as the Phillips 66 SHIELD Scholars Program. This program supports 10-12 CEAT students each year who are interested in the energy industry and are majoring in chemical engineering, civil engineering, computer engineering, electrical engineering, fire protection safety technology, industrial engineering, mechanical engineering or materials engineering.

It offers a $3,500 scholarship, plus mentorship, professional development, enrichment activities, community service and cultural events. The program explains it best with its full name, Students Heightening Involvement in Education, Learning and Development Students must be involved in community service and activities that focus on leadership and service learning while maintaining a 3.5 or greater GPA in sophomore — through senior-level classes.

ALEXANDRA POND, a mechanical engineer senior and SHIELD Scholar, has benefited from the program in many ways.

“I have had several opportunities arise since I received this scholarship,” Pond says. “Not only have I been able to

attend several cultural and community events with other scholarship recipients, but I have also accepted a summer internship with Phillips 66 at its refinery in Ponca City.”

ANTHONY GASKILL, an electrical engineer senior and SHIELD Scholar, has seen the program enrich his college experience.

Part of the SHIELD’s program includes mentorship and interaction with Phillips 66. Last spring, Gaskill attended a leadership seminar at the SHIELD Scholars’ forum, where he learned about the history of Phillips 66 and networked with current employees.

The scholarships provided to these students create a path, both directly and indirectly, to help them achieve their dreams.

DeMarco works as an intramural sports supervisor. Because of his Dolese Scholarship, he was able to work less and spend more time with various organizations. This past year, he was president of Oklahoma State Officials Association, which further trains OSU student officials in intramural sports, and joined the American Society of Civil Engineers. Both of those helped prepare him for his future career, where he would someday like to be a project manager.

“I think my leadership experience has set in place a management position in my future career,” says DeMarco. “Any time not spent working [to pay for school], I can spend in these associations, which will help me get the job I want.”

Thomas hopes her degree takes her to South America, where she wants to do mission work through water purification. Ultimately, she wants to give back to the world she lives in by helping people who are less fortunate than herself. By having a Dolese scholarship, she can get there with less stress and more money.

33

continues

“This scholarship helps me because it allows me to be less stressed and stay in better health,” Thomas says. “It will also help me graduate with fewer loans, so I can afford to do mission work when I graduate.”

Pond hopes to stay in Oklahoma after graduation and find a job working as a proposal or applications engineer. She also has plans outside the engineering world. Being a SHIELD Scholar is helping her start out with less debt.

“I’d also like to run a business and own a boutique,” Pond says. “This scholarship is helping me reach my goals by providing funds for my undergraduate degree.”

Gaskill has seen a large need for young engineers in the electrical utility field and hopes to fill that need with his innovation. He hopes to help design the next generation of power grids in the U.S. Through the SHIELD program, he’s been able to connect with engineers who can help him get where he wants to be.

“I hope to help make the grid smarter and more adaptable for new energy sources such as solar, wind and hydroelectric,” Gaskill says. “This scholarship has allowed me to interact with other engineers in the power field. This has allowed me to expand my network of fellow engineers.”

Without the support of the donors who generously give to CEAT scholarship funds, these students would not have experienced countless opportunities. Donors help create the future by allowing students to pursue education without the stress of worrying about how they will pay for it. Every dollar given helps students reach their dreams of providing water to third-world countries, improving eco-friendly energy, training future supervisors and creating new businesses.

“I always make sure to come across grateful for everything,” says DeMarco. “I hope one day, I can return that favor and help someone else accomplish their educational goals through scholarship support.”

FALL 2014 34

PICTURED ARE 22 OF THE MORE THAN 350 CEAT SCHOLARS WHO RECEIVED SCHOLARSHIPS OF $1,000-$3,000 FUNDED BY DOLESE. THE GIFT WAS THE LARGEST DONATION MADE TO AN ACADEMIC UNIT AT OSU.

Dolese gift helps college expand

The largest gift ever made to an OSU academic unit has increased support for engineering students, expanded the rolls of aspiring engineers and fostered innovation in the College of Engineering, Architecture and Technology.

DOLESE BROS. CO. split a stock gift worth approximately $210 million among OSU, Kansas State University and the University of Oklahoma. In addition to gaining shares worth about $70 million, the schools became a nonvoting majority shareholder in Oklahoma’s largest supplier of ready-mix concrete, crushed stone, gravel and sand.

The gift was rolled out privately at OSU in 2010 and has since contributed to a 30 percent enrollment spike in engineering disciplines. It has also led to a commitment to hiring more faculty.

CEAT DEAN PAUL TIKALSKY says Dolese’s generosity will help OSU meet the needs of the state, region and nation.

“These graduates are the intellectual capital for growing companies throughout the nation and building a strong economy,” Tikalsky says.

“Young engineers are leading the next generation in building a more sustainable world, creating new entrepreneurial business, improving medicine, securing our nation, advancing new energy resources and efficiencies and developing systems that deliver goods and services to every nation,” he says. “This gift will benefit engineering students generations to come by funding new scholarships each year to help students succeed.”

FOR MORE INFORMATION ABOUT HOW YOU CAN HELP THE COLLEGE OF ENGINEERING, ARCHITECTURE AND TECHNOLOGY, CONTACT SANDI BLISS, SENIOR DIRECTOR OF DEVELOPMENT, AT SBLISS@OSUGIVING.COM OR 405-564-4378

“This gift will benefit engineering students for generations to come.”

— CEAT Dean Paul Tikalsky

35

National Conference Comes Home

CEAT Student Council welcomes representatives from 44 schools to OSU

“STAKE YOUR CLAIM” This theme came to embody a host of emotions and accomplishments for the Oklahoma State University College of Engineering, Architecture and Technology’s Student Council during the 2014 National Association of Engineering Student Councils National Conference, held in April in Stillwater.

NAESC is the official overarching body for all engineering student councils throughout the nation. The head organization provides individual resources and developmental advice for nearly 50 undergraduate councils nationwide. The annual national conference draws members of those councils, sponsors and volunteers.

In planning the conference, the OSU executive team hoped to showcase the current works of OSU CEAT as well as the economic prosperity, rich history and cheerful nature of the entire state of Oklahoma. Oklahoma and OSU have a storied legacy of innovation coupled with an immense melding of cultural perspectives. The aim was to inspire all attendees to respect the beauty and the pride we as Oklahomans have for our heritage while recognizing the vast frontier awaiting the next generation of leaders.

The 2014 conference drew more than 250 students, sponsors and volunteers from 44 different institutions from the United States and abroad. The CEAT Student Council opened the festivities with a unique rendition of the state song “Oklahoma!” to an audience radiating the same excitement that the settlers did long ago. The opening ceremony also included an engineering rap by the CEAT Freshman Council and a keynote address by Assistant Dean Ed Kirtley.

Members of engineering student councils from across the country gather at a banquet in the Chase Building hosted by the Oklahoma City Petroleum Club as part of the 2014 National Association of Engineering Student Councils National Conference.

FALL 2014 36

The culmination of the conference on Saturday evening embodied the resurgent and vibrant culture of Oklahoma on the dawn of a new horizon in downtown Oklahoma City.

Attendees immersed themselves in various council chats and informational sessions to collaborate and brainstorm ideas about council development. Attendees also learned professional development skills from some of the most renowned industry leaders. Corporate sponsors interacted with students and conveyed advice about effective communication skills, career building strategies and professional ethics.

Attendees also experienced the rustic and western culture that Oklahoma is known for. Nightly functions allowed the attendees to meet and connect with each other in more colloquial settings. Friday evening took the entire group to the White Barn Estates in Stillwater, where a traditional Cowboy barbeque was held. Former CEAT Student Council President Brian Engelman spoke about the balance between personal and professional life with personal anecdotes and witty demonstrations. Following that keynote address, the banquet hall was cleared and members of OSU’s council demonstrated another invaluable life skill: country two-step dance lessons. The group danced deep into the Oklahoma evening.

The culmination of the conference on Saturday evening embodied the resurgent and vibrant culture of Oklahoma on the dawn of a new horizon in downtown Oklahoma City. Following a presentation by Oklahoma City’s City Council, a walking tour covered the developing modern downtown district.

That evening, the Oklahoma City Petroleum Club hosted a banquet at the Chase Building. An industrial panel comprised of engineers throughout their careers, ranging from new hire to senior project manager, provided perspective and advice on how to navigate a path through one’s professional career. Purdue University and the University of Pittsburg were recognized as the Best Overall Large and Small Council (respectively) at the conference awards ceremony.

37

“… I want to make sure people know that geothermal is a great unbelievable heating and cooling system when it is used in the right application.”

Nationwide Notice

STORY BY JANET F. REEDER / PHOTOGRAPHY BY KEVIN O’CONNOR / THIS OLD HOUSE

OSU technology highlighted on ‘This Old House’

Ground-source heat pump installations in homes in the colder reaches of the American Northeast, has been popular, though not widespread, for years. The technology and its outstanding energy savings are both already established. But getting notice from a national television program of the caliber of PBS’ This Old House for a geothermal project is definitely new. And it is just exactly the kind of public exposure and credibility the technology, as well as the industry, needs to help spread the word.

The energy-efficient technology advocated by the Environmental Protection Agency and supported by the International Ground Source Heat Pump Association is gaining in popularity around the world. IGSHPA provides training nationwide; Geo Outlook , a quarterly trade magazine; and a national conference annually to promote, train and educate about the technology.

FALL 2014 38

A COTTAGE OUTSIDE ESSEX, MASS., WAS RETROFITTED WITH A GEOTHERMAL HEAT PUMP SYSTEM ON THIS OLD HOUSE .

— Ross Trethewey

A geothermal project in Massachusetts that involved IGSHPA members and the show cast from the popular home improvement television show brought the association, the industry and the technology to weekend television. It also placed an important footprint for geothermal technology online at www. thisoldhouse.com. The show originally aired in February 2013 but is still being rerun in different regions of the country. Episodes can be seen at the show’s website.

This Old House crewmembers included regulars NORM ABRAM, TOM SILVA, RICHARD TRETHEWEY, ROGER COOK and show host KEVIN O’CONNOR .

This project covers the transformation of an English-style cottage from neglected to an accessible, stylish and energyefficient home. The quaint 1935 cottage belongs to John and Julie Corcoran, who purchased it to remodel into an aging-in-place residence for Julie’s parents. The home renovation, which included a geothermal retrofitting, is in the Cape Ann area near Essex, Mass.

All of this fell in place because Richard Trethewey of the Emmy Award-winning series had worked on other projects with IGSHPA member and marketing chair JACK DIENNA. DiEnna, a long-term geothermal advocate, is also executive director of the Geothermal National and International Initiative and always looking for ways to promote the geothermal industry.

He called on and recommended other IGSHPA members to make the project happen. ROGER SKILLINGS, an IGSHPA dealer/contractor and accredited installer and driller out of Amherst, New Hampshire, was contracted by the show for the heat-exchange work. DiEnna also sought a heat pump manufacturer that would donate the system. IGSHPA Advisory Council member and CEO of Enertech Global LLC STEVE SMITH stepped up.

An Enertech heat pump, a Hydron twostage 3-ton, water-to-water unit using 410A refrigerant, was selected for the project. Radiant floor heat is used to heat the home.

Richard Trethewey’s son, renewable energy specialist ROSS TRETHEWEY, consulted on the geothermal installation and designed the geothermal system from the ground loop heat exchanger to the loop manifolding and pump.

“The system is a perfect match for that type of house, and it is going to work great,” Ross Trethewey says.

Skillings and Sons Inc. put in two 350-foot closed loops for the cottage and another for the carriage house in its most unusual drilling project. Roger Skillings says the experience added some notoriety to his crew and challenged them daily with all of the stopping and reshooting to capture the video of the drilling. He says his crew is used to staying “hard at it” to get the drilling done. He had to coach them to be patient.

and well system and think about how we were going to heat and cool the building,” he says, explaining that information drives the mechanical system planning.

“You have to do a heating and cooling load on a building to know how much energy it is going to need to heat it and how much energy it is going to take to cool it. Otherwise, you are just guessing,” Trethewey says.

“Computer systems are very smart these days. Controlling is very sophisticated,” he says. “You put that all together, and with all the right inputs from the architect, from the homeowner, from the builder — and you can basically come up with the game plan and direction on how that building can be heated and cooled.”

“[Radiant floor heat] is a perfect fit for a water-to-water heat pump. You can’t get much better than hydronic floor heat matching up radiant and water-to-water for heating,” Trethewey says. “That is why I want to make sure people know

“Filming is different. They are never satisfied with the first shoot and have to repeat it,” Skillings says. He says geothermal is still in its infancy in the heating and cooling world in the Northeast. “The neat thing is that this gives geothermal some real publicity.”

Ross Trethewey first needed to establish a heating and cooling load. “Once we got that, then we could design the geo system

that geothermal is a great unbelievable heating and cooling system when it is used in the right application.”

The This Old House Essex project did a great job of bringing ground-source technology to a huge audience by spotlighting the project. It gave homeowners and contractors real information about applying the technology in residential remodeling projects. And it all came back to IGSHPA and OSU.

39

THE SKILLINGS AND SONS CREW WORKS TO GET IT RIGHT FOR THIS OLD HOUSE CAMERAMAN STEVE “DINO” D’ONOFRIO. DOUG SKILLINGS IS ON THE TRUCK, AND PAT CHAMBERLAIN IS HANDLING THE LOOP COMING OFF THE REEL.

Investing in Oklahoma Manufacturing

New Product Development Center teams up on $1.1 million project

Manufacturing plays a key role in Oklahoma’s economy, boosting the state’s revenue, creating new jobs and enhancing capital investment. In turn, that boosts the national manufacturing industry.

Teams such as the OKLAHOMA MANUFACTURING ALLIANCE, THE OKLAHOMA STATE UNIVERSITY NEW PRODUCT DEVELOPMENT CENTER AND THE OKLAHOMA CENTER FOR THE ADVANCEMENT OF SCIENCE AND TECHNOLOGY strive to improve Oklahoma’s manufacturers through economic development initiatives and manufacturing improvement programs.

The OMA and NPDC completed a National Institute of Standards and Technology ECAR project in September 2013. The project was a three-year, $1.1

million grant proposal funded by NIST, which grants awards to manufacturing extension partnership teams that provide the biggest impact and technological change.

In 2010, an ECAR award was granted to the OMA and the OSU NPDC for its proposal for sustainable manufacturing innovations and designs and how these teams focus on the practical technology needed in the manufacturing industry.

CHUCK PRUCHA, president of the OMA, fully supports the work of the OMA and NPDC and its innovations through ECAR.

“Much of what we do at the Oklahoma Manufacturing Alliance improves a company’s bottom line by increasing efficiency through Lean Manufacturing

concepts,” Prucha says. “But that’s only half the solution. For a firm to be successful, it must expand its markets and innovate. That improves the top line and that is the role of the NPDC.”

The NPDC is a multidisciplinary organization working with small and medium-size manufacturers across Oklahoma. The center’s goal is to improve the economic development and product innovation for rural manufacturers, so companies can become more competitive.

Through the ECAR program, NPDC design engineers assisted manufacturers in developing proposals for state and federal funding, helped with the introduction of new products and provided process innovation support for small manufacturing companies in Oklahoma.

FALL 2014 40

PHOTOGRAPHY / GARY LAWSON / UNIVERSITY MARKETING

“Using the resources of NPDC, Oklahoma companies can survive and thrive when they otherwise might not have.”

— Chuck Prucha

These ECAR-funded initiatives helped revolutionize productions and processes to keep manufacturers competitive in the marketplace.

JENNIFER VINYARD, a senior design engineer for NPDC, was leading this product revolution.

“ECAR helped Oklahoma manufacturers hire more individuals, increase profit margins and capital, and keep money in Oklahoma,” Vinyard says.

In addition to keeping money in Oklahoma, the ECAR grant created and improved 79 projects; 64 companies were positively affected by ECAR. The program created 117 jobs and retained 90 jobs. Additionally, the grant generated capital investment of more than $3.3 million and avoided unnecessary investments by more than $6.8 million.

The program also resulted in a change in sales of more than $34 million and retention of sales of $31 million. Overall, ECAR had a cost savings of more than $9 million over the three-year program.

The ECAR program was instrumental in the NPDC’s growth to five, full-time employees and 30 students. Student interns gained real-world experiences by helping develop products and solve problems. The students brought creative, fresh ideas and positive energy to new product or process development for the manufacturer. The program created an

environment where students from engineering and business disciplines were working directly with Oklahoma companies on manufacturing innovation projects. This gives the students a level of on-the-job training while still in school.