Power in a Pandemic

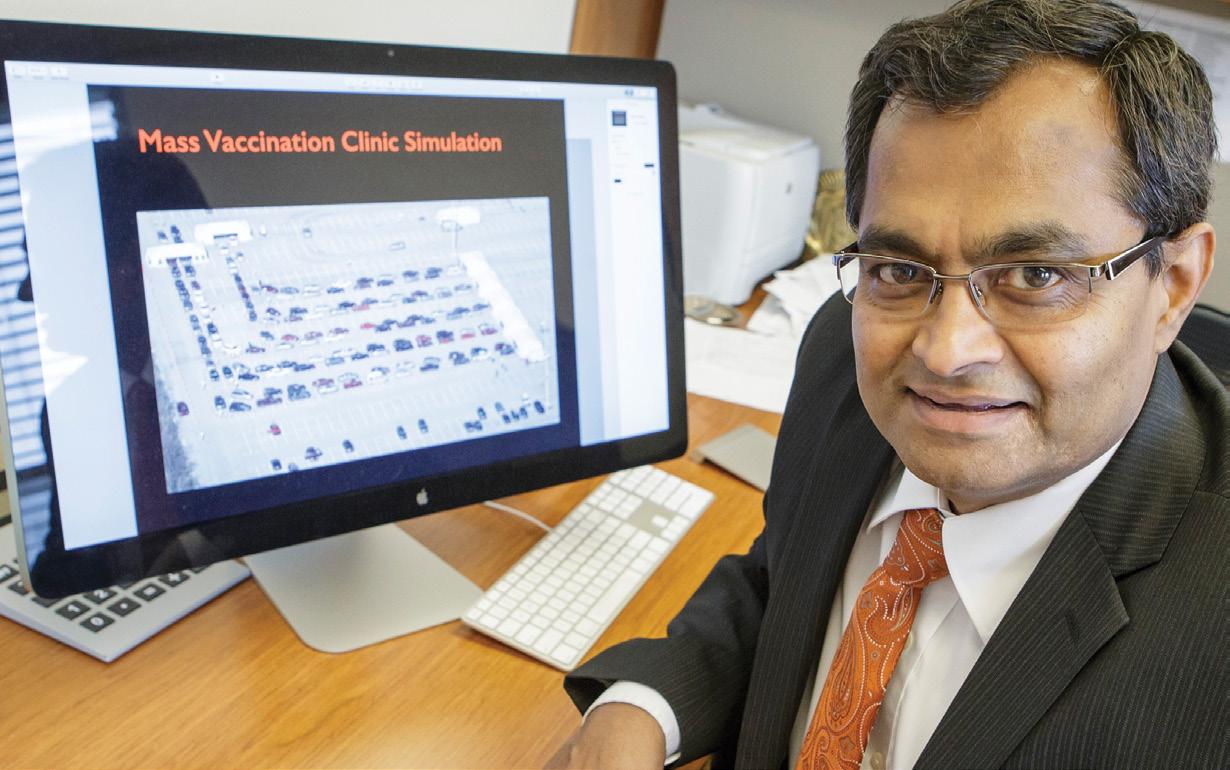

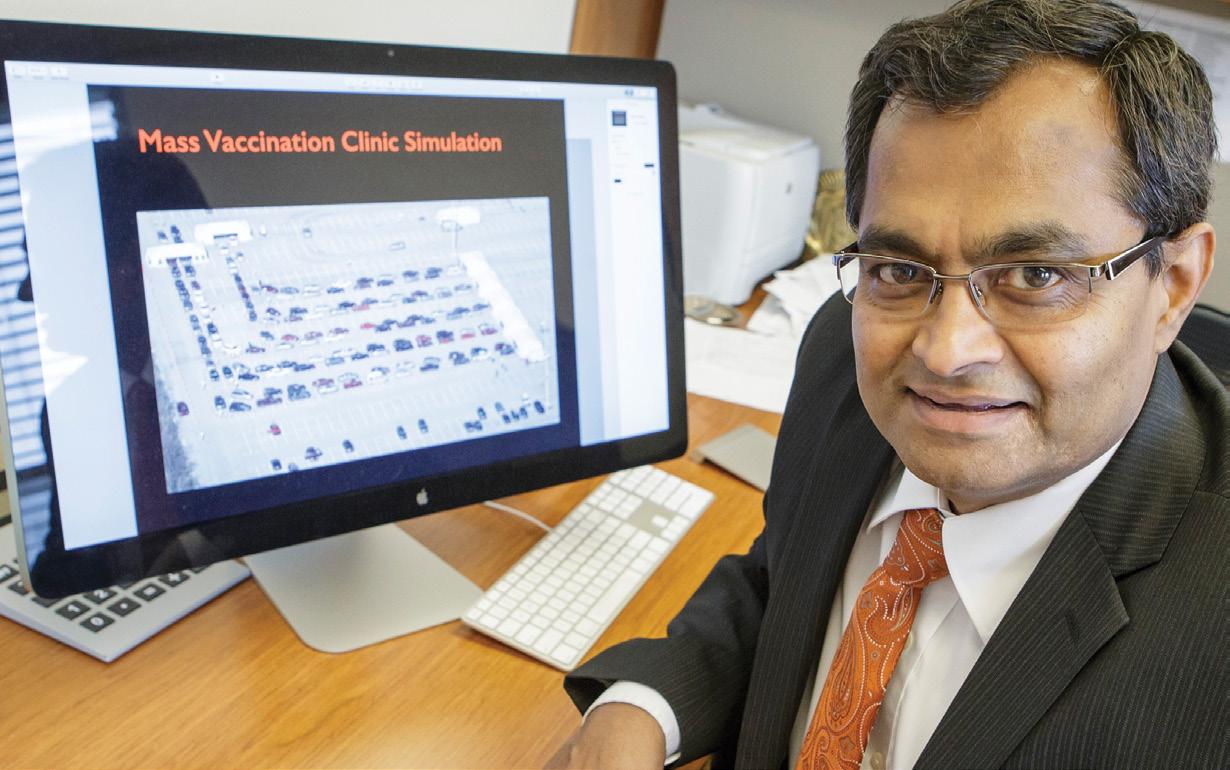

OSU’s Sunderesh Heragu leads big data project to improve public health care

2015

The official magazine of the College of Engineering, Architecture and Technology, Oklahoma State University

ON THE COVER

Dr. Sunderesh Heragu is leading research to help officials make better decisions in a major health care crisis.

GOING BOLDLY TO ROME

OSU’s study abroad program in the School of Architecture has a new home in the Italian capital city, leaving its original base of Versailles, France

A SPECTACULAR TESTING LAB

The brand-new Bert Cooper Engineering Laboratory is the largest and most advanced structures and materials testing laboratory in the region.

22

4

A CAREER OF CHALLENGES

Alumnus Ed Robben shares the secrets of his success in the ever-evolving world of technology.

18

14

EXPERIENCE IN THE CLASSROOM 36

The real-world experience of OSU’s engineering technology faculty is a key factor in preparing students for hands-on engineering careers.

CLASSES IN THE COLLEGE OF ENGINEERING, ARCHITECTURE AND

College of Engineering, Architecture and Technology

DEAN, COLLEGE OF ENGINEERING, ARCHITECTURE AND TECHNOLOGY

Paul Tikalsky, Ph.D., P.E., F.ASCE, F.ACI, EACR

SENIOR DIRECTOR OF DEVELOPMENT

Tylerr Ropp

MARKETING MANAGER AND MANAGING EDITOR

Chelsea Robinson

UNIVERSITY EDITOR

Dorothy Pugh

ART DIRECTOR

Paul V. Fleming, BCE, BFA, MS

PHOTOGRAPHY

Phil Shockley, Gary Lawson, CEAT Staff

CONTRIBUTING WRITERS

Marketa Krcalova, Ryan Doonkeen, Pam Covington, Jeff Joiner, Janet Reeder, Mallory Pence, Milissa Gofourth, Jim Self and Paige Worley

is a publication of the Oklahoma State University College of Engineering, Architecture and Technology and is designed to provide information on college activities and accomplishments while fostering communication among the CEAT family and friends. WWW.CEAT.OKSTATE.EDU

The office of publication for IMPACT is 307 Whitehurst, Stillwater, OK 74078-1024. © 2015, IMPACT. All rights reserved. Oklahoma State University, in compliance with Title VI and VII of the Civil Rights Act of 1964, Executive Order 11246 as amended, and Title IX of the Education Amendments of 1972 (Higher Education Act), the Americans with Disabilities Act of 1990, and other federal and state laws and regulations, does not discriminate on the basis of race, color, national origin, genetic information, sex, age, sexual orientation, gender identity, religion, disability, or status as a veteran, in any of its policies, practices or procedures. This provision includes, but is not limited to admissions, employment, financial aid, and educational services. The Director of Equal Opportunity, 408 Whitehurst, OSU, Stillwater, OK 74078-1035; Phone 405-744-5371; email: eeo@okstate.edu has been designated to handle inquiries regarding non-discrimination policies. Any person (student, faculty, or staff) who believes that discriminatory practices have been engaged in based on gender may discuss his or her concerns and file informal or formal complaints of possible violations of Title IX with OSU’s Title IX Coordinator 405-744-9154.

This publication, issued by Oklahoma State University as authorized by the College of Engineering, Architecture and Technology, was printed by University Marketing Services, University Printing Services, at a cost of $14,575/July 2015/job #6016.

TECHNOLOGY DRAW STUDENTS FROM ALL TYPES OF BACKGROUNDS — INCLUDING PISTOL PETE. / PAGE 46

PHOTOGRAPHY / PHIL SHOCKLEY / UNIVERSITY MARKETING

PHOTO / COLLEGE OF ENGINEERING, ARCHITECTURE AND TECHNOLOGY

INDEX DEAN’S LETTER 2 DEVELOPMENT & DONORS 56 HALL OF FAME 60 LOHMANN MEDALS 62 FACULTY CHANGES 67

The demand for practicing engineers and engineering technologists continues to rise as the world seeks new and innovative methods to manage power infrastructure, optimize energy, manufacture goods in a sustainable manner and address global challenges. The College of Engineering, Architecture and Technology (CEAT) at OSU is dedicated to providing the education and hands-on experiences necessary to prepare the next generation of engineers, architects and technologists.

CEAT continues to be one of the fastest-growing colleges on the Stillwater campus with a 42 percent increase in undergraduate engineering enrollment over the past five years. These students continually prove to be top performers, excelling in the classroom and in leading university organizations and clubs. With help from generous donations, nearly half of these students were able to graduate from CEAT without any student loan debt last year. Graduate students are also reaping the benefits of the college’s growth and excellence. Graduateprograms.com recently ranked OSU’s CEAT No. 3 in the country for career support. These successes are the beginning of where the college is headed in the coming years.

As one of roughly 120 universities in the country — and the only one in Oklahoma — that is pursuing the National Academy of Engineers Grand Challenges Scholars Program, the college is on the brink of becoming a premier leader in the nation’s leading engineering initiatives as defined by the NAE, the United Nations Millennium Goals and the White House Strategy for American Innovation. The program will empower the college to challenge students through a special program that addresses the world’s major engineering issues and allows the students to be nationally recognized as Grand Challenge Scholars.

Our students, faculty and partners are also seeing significant changes in our facilities, including the recently opened Student Excellence Center, located on the first floor of the Advanced Technology Research Center, and the Bert Cooper Engineering Laboratory, designed as a groundbreaking structures and materials testing facility. The Student Excellence Center offers students 24-hour access to study, work in groups and connect with college student services and scholarships.

The Cooper Lab was officially opened in April more than a decade after its namesake Bert Cooper and Gorman Gilbert, former civil and environmental school head, envisioned it. A longtime partnership between the college and the Oklahoma Department of Transportation produced the lab’s first contract, which involves moving the Highway Construction Materials Technician Training and Certification program from its Oklahoma City location to the new facility in Stillwater.

From the Dean’s Office 1

With the four largest classes in college history now enrolled at OSU, the college is focusing on developing the nation’s most advanced undergraduate laboratory building with integrated design input from leading industry experts, hands-on experimental systems and room for students to innovate and discover new ideas. Oklahoma City’s FBS in partnership with Dallas-based HKS are leading the architectural design. The conditions of CEAT’s labs have diminished over time, and the rise in enrollment and technology has made it necessary to create labs for the 21st century. While the state has not provided any direct capital funds for engineering labs, OSU has agreed to match major gifts, students have endorsed an increase in labs fees, and a donor has agreed to provide a $2,500 scholarship for every donor who provides a personal gift of $2,500 or more toward the lab building.

I urge all the alumni of CEAT to get engaged to help make CEAT’s future every bit as great as its past!

PAULJ. TIKALSKY DEAN, COLLEGE OF ENGINEERING, ARCHITECTURE AND TECHNOLOGY

GO POKES!

GARY LAWSON / UNIVERSITY MARKETING

National Scholarship Program comes to CEAT

Nearly a quarter of the country’s engineering schools have unified to establish a new, impactful scholarship program — GRAND

CHALLENGES FOR ENGINEERING

. As a member of this leadership group, THE COLLEGE OF ENGINEERING, ARCHITECTURE AND TECHNOLOGY (CEAT) is committed to graduating students who are specifically trained and educated to tackle the world’s leading engineering challenges.

FALL 2015 2

PRESIDENT BARACK OBAMA GREETS SCIENCE, TECHNOLOGY, ENGINEERING AND MATH LEADERS INCLUDING NATIONAL ACADEMY OF ENGINEERING PRESIDENT C.D. MOTE JR. DURING

THE 2015 WHITE HOUSE SCIENCE FAIR. (OFFICIAL WHITE HOUSE PHOTO BY PETE SOUZA)

PRESIDENT OBAMA endorsed the program on March 23 at the White House Science Fair, signing the letter of commitment sent on behalf of 122 higher education institutions. THE GRAND CHALLENGES PROGRAM will focus on approximately 20 engineering problems as identified by the WHITE HOUSE STRATEGY FOR AMERICAN INNOVATION, the NATIONAL ACADEMY OF ENGINEERING (NAE) GRAND CHALLENGES FOR ENGINEERING and the UNITED NATIONS MILLENNIUM DEVELOPMENT GOALS.

OSU CEAT Dean Paul Tikalsky says GRAND CHALLENGES SCHOLARS will work on innovation throughout their four years as they take on engineering challenges of the next generation.

THE PROGRAM WILL FOCUS ON FIVE AREAS THAT INCLUDE:

A hands-on research or design project connected to one of the Grand Challenges topics.

Learning with industry partners. Entrepreneurship and innovation experience.

Global and cross-cultural perspectives. Service learning.

“They will experience the global context of these challenges through study abroad and international teams,” Tikalsky says. “They will work in OSU’s New Product Development Center with our world-class faculty and industry partners to develop methodologies and prototypes.”

The developments created by the Grand Challenges students will be a first step in transforming the engineering industry’s impact on the biggest issues society faces in the modern world. Student projects will be more than experiments

— they will be tangible ideas and products that affect some of today’s most prominent and frequently used processes.

“These students will receive scholarships and support as part of our program, Tikalsky says. “They will bring the best of OSU engineering to the world.”

Many will do capstone projects and an Honors College thesis to complete the challenges. These pieces of the program will weave the practical experience into traditional textbook learning in a manner that will give students a wellrounded and unprecedented engineering education in tOklahoma.

The training model was inspired by the National Academy of Engineeringendorsed Grand Challenges Scholars Program established by ASEE’s Council of Engineering Deans in 2009 . The Grand Challenges for Engineering programs have graduated more than 160 NAE-designated scholars. OSU will be part of the expansion of this national movement aimed at boosting that number to more than 20,000 formally recognized Grand Challenges Engineers over the coming decade.

CEAT is proud to be a leader of this innovative movement and looks forward to establishing the inaugural group of scholars in the coming years.

FOR MORE INFORMATION ON THIS INITIATIVE, INCLUDING THE PRESIDENT’S LETTER OF COMMITMENT AND A MAP OF THE PARTICIPATING UNIVERSITIES, VISIT NAE.EDU

3 AN T I ONALACADEMY OFENGINEER I N G FOUN DED 1964

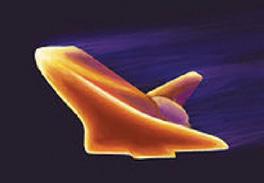

A visual representation of the existing 14 GRAND CHALLENGES FOR ENGINEERING IN THE 21ST CENTURY : (from top down) solar, carbon, fusion, nitrogen, water, infrastructure, nuclear terror, brain, medicine, health, cyberspace, personal, virtual reality, and discovery tools.

IMAGES / ENGINEERINGCHALLENGES.ORG

From France to Italy

STORY BY MARKETA KRCALOVA

Architecture’s study abroad program moves to Rome

THE SIX-CREDIT HOUR STUDY ABROAD PROGRAM IN THE SCHOOL OF ARCHITECTURE HAS ITS FIRST NEW HOME SINCE ITS BEGINNING IN 1982.

Previously based in Versailles, France, as an associated program with the University of Illinois, the program’s primary base moved to Rome in the summer of 2014.

The change was sparked by the University of Illinois program’s move to Barcelona, Spain. OSU faculty members have been going to Rome for nearly 20 years and have developed many connections in Italy’s capital city, making it a natural choice for the new home.

“Rome is just a wonderful place for architecture programs,” says Randy Seitsinger, professor and head of the School of Architecture at Oklahoma State University.

OSU professor David Hanser launched the program to provide students with real-life experience and a new perception on international architecture.

The school works with the Pantheon Institution in Rome, which helps provide housing. Students stay in Santa Maria in the Cappella student residence, a complex close to the Tiber River and just a short walk away from the historic city center, allowing students to truly experience Italy as residents.

The study abroad experience provides personal growth and accelerated architectural thinking and skills for students, who complete analysis projects, sketches and journals, as well as directed individual independent studies.

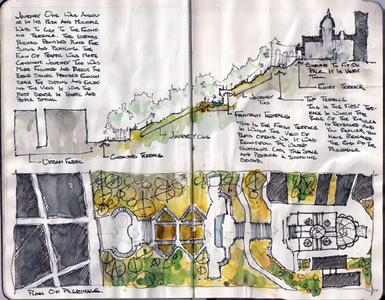

It may not sound like part of an academic study, but journals are based on a longtime tradition. For hundreds of years, architects travelling in Europe kept daily records of their experiences. The School of Architecture requires journals from its students and considers them the most valuable records of

FALL 2015 4

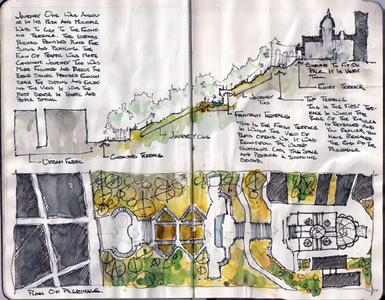

Above: A sketch from the journals kept by faculty and students on the study abroad trip.

the students’ stay in Europe — tangible evidence that can be brought back to the United States. Journals include daily records of lectures, discussions, experiences, and observations of buildings, gardens and architectural details. Since architects and engineers communicate primarily through annotated drawings, the journal is often a visual record of experiences with supplementary notes.

Students’ schedules include some free time to explore Rome. Students make multiple visits to different areas with faculty members, but the main program focus is on visual analysis and observing architecture. Most of the buildings and European architecture have been covered in classes, but students can experience the information in their textbooks in person here.

“For architects, it’s so important to be able to experience the observation,” says Seitsinger. “Your viewpoint changes, how you perceive the space changes and how you feel changes.”

Students also travel in small groups on their own, doing independent study. Faculty members assist the students on their topics, and the students record and document their experiences in their journals.

Throughout the experience, especially during their independent study weeks, students reconnect with the art of architecture. Computers are important in today’s world, but architecture students still need to learn how to draw. Rome offers a great place for learning with many historical architectural buildings that are perfect practical applications. continues

5

“For architects, it’s so important to be able to experience the observation.”

— Randy Seitsinger, professor and head of the School of Architecture

Students’ expectations are high leading into the trip. Those who’ve gone before them enjoy their time so much that they can be found sharing their experiences of this life-changing trip with their peers. Students preparing for the next summer’s trip expect to open their eyes to different perspectives and see firsthand how others live in different parts of the world.

“In our studies of architecture, we will explore the ancient neighborhoods of Rome, take in monuments like the Coliseum and try to gain new insight into the thinking behind legendary religious architecture like the Cathedral of Notre Dame in Paris,” says Cameron Patterson, an architecture student.

Patterson says he’s prepared to feel like a tourist in the beginning of his trip but knows he will start to build confidence and assimilate to the culture over time.

“Given time, we will be traveling via public transit with wind in our sails, and we will begin to see the spaces, buildings and environments in a clear, honest light,” he says.

Students pay for the six-credit class as well as the airfare; however, the School of Architecture offers many study abroad scholarship options, including the Eason Leonard Endowment and the Mike and Sharon Damore fund.

The summer study abroad trip offers a life-changing experience that will be valuable for students in their future careers.

“If I had never gone to Europe, I would have never seen the potential of the world and the potential of this profession,” says Andrew Klare, 2001 architecture alumnus. “I don’t think I would be where I am today.”

FALL 2015 6

HEAD RANDY SEITSINGER, AIA

FOCUS AREAS

Building

Computer

Commercial

Design

Digital

Environmental

Historical

Innovative

Materials

Modern

Structural

DEGREE OPTIONS

Architecture

Architecture

7 ENROLLMENT 290 undergraduates FACULTY 9 professors 9 associate professors 7 assistant professors ENDOWED POSITIONS 1 professorship

systems

architecture

building

structural concepts

and

systems

designs

architecture

designs

architecture

systems Sustainable building

design Architecture

Urban

GLANCE AT A

Engineering SCHOOL OF

Momentum is pushing undergraduate lab plans forward

The flexibility of the labs will allow instruction to adapt to evolving technologies while meeting the needs of CEAT students. Two lecture halls will offer large teaching spaces and an area for industry partners to mentor and host events. Students will be able to develop relationships with engineering-related companies by connecting real-life issues in the field to applied solutions they develop in labs through the entrepreneurial hub. This area will be open to students interested in further establishing their concepts into tangible products and services. The senior design studio and student gallery will allow students to display their work, know they are receiving a quality education that will prepare them to enter the workforce as world-class engineers.

Recently, the OSU Board of Regents approved architects Frankfurt + Short + Bruza of Oklahoma City and HKS of Dallas to assist the university in the design and construction of the new building. The project is building momentum, and several leadership gifts have already been donated. OSU has made the project a top priority and is offering capital matching funds to those making investments in the new facility. Please consider supporting the next era of engineering, architecture and technology education at Oklahoma State University.

The College of Engineering, Architecture and Technology’s success is built on a foundation of transforming math and science into ideas, devices and processes that improve the world and advance business opportunities that support society as a whole.

A new 55,000-square-foot building dedicated to undergraduate labs will further support the college’s success and add value to the quality of each degree earned from CEAT by encouraging big ideas and developing tomorrow’s innovative leaders. This plan will modernize the college’s lab spaces and give Oklahoma State a competitive edge among peer institutions.

The building will help nearly 4,000 students each year master basic engineering principles at a small scale that will later translate into larger, more complex projects and scenarios as they move into advanced education, specialization and careers. The facility will house 14-16 reconfigurable research laboratories spread strategically throughout its four floors along with lecture halls, a student gallery, an entrepreneurial hub and a capstone design studio for industry-defined projects.

WE NEED YOUR HELP TO CONTRIBUTE TO THE NEW CEAT UNDERGRADUATE LABORATORY BUILDING, CONTACT TYLERR ROPP, SENIOR DEVELOPMENT OFFICER, AT TROPP@OSUGIVING.COM OR 405-385-5664

TOP AND ABOVE: TENATIVE RENDERINGS OF THE FUTURE UNDERGRADUATE LABORATORY BUILDING FALL 2015 8

Biosystems and Agricultural Engineering

RESEARCH AREAS

Air pollution

Animal waste

Biobased products

Bioenergy

Biochemical

Biofuels

Biomass

Biomass gasification

Bioprocessing

Ecology mass

Enzymatic hydrolysis

Ethanol

Fire control

Hydraulic engineering

Manufacturing

Reactor design

Regulations

Sediment control

Sustainability

Synthesis gas fermentation

Water quality

Waste management engineering

DEGREE OPTIONS

Biomechanical

Bioprocessing and Bio-technology

Environment and Natural Resources

Food Processing

9 ENROLLMENT

FACULTY

110 undergraduates 42 graduates

9 professors 6 associate professors 3 assistant professors

HEAD DAN THOMAS, Ph.D., P.E., F.ASABE, F.ASCE

AT

SCHOOL OF GLANCE

A

FALL 2015 10

“Our motto is ‘don’t screw up.’ Students will be successful no matter what, and our job is to not demotivate them and make them lose their confidence.” — Rob Whiteley

Leaving a Legacy

STORY BY MARKETA KRCALOVA

Longtime faculty member and school head makes impact

Rob Whiteley, Ph.D., has been part of the chemical engineering program at Oklahoma State University since 1991 and school head since 2012. His contributions to OSU have helped shaped the School of Chemical Engineering and the College of Engineering, Architecture and Technology in many ways.

“Over the last two years, Dr. Whiteley has worked to transform the chemical engineering school into a world-class academic program, both at the undergraduate and graduate level,” says Paul Tikalsky, dean of the College of Engineering, Architecture and Technology.

After receiving his bachelor’s degree in chemical engineering in 1977, Whiteley worked for nearly 10 years at three different companies, concentrating on chemical engineering. Working in the industry heavily influenced his teaching and gave him a special perspective. His experience was reflected in his lectures, homework assignments, projects and exams.

He then went on to finish his master’s degree and doctorate in chemical engineering at Ohio State University.

“I am most proud of our students and faculty, both the young and the experienced, and what they accomplished academically and professionally,” says Whiteley. “I think that everybody in our faculty had major accomplishments throughout the past two years, and it’s really fun to see the success.”

Whiteley has high standards for the students, faculty and staff around him, as well as for himself. This never changed, even after he became the school head.

“His high standards were demonstrated by the fact that his classes were the toughest ones I had while in the chemical engineering program at OSU,” says Josh Ramsey, now an associate professor in the School of Chemical Engineering. “He also held himself to the same high standards, though, and this was demonstrated by the fact that his classes were some of the courses where I learned the most.”

11

continues

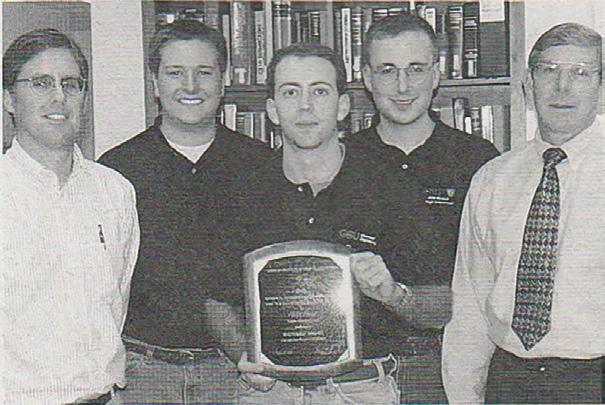

AIChE Design Contest winners, from left, Brian Callihan, Sean Hockersmith and Richard Bruce. They are flanked by design course instructors Rob Whiteley, left, and Jan Wagner.

Whiteley stresses the importance of treating everybody with equal respect. This collective attitude of working hard and treating people well brings quality results and gives everybody a chance to contribute as much as they can.

As a school head with many administrative duties, Whiteley has less direct involvement with students. The position gives him a chance to do his best work for students and faculty members, along with making sure they have the best opportunities to learn and work. He is determined to achieve the goals of the School of Chemical Engineering and OSU.

“Our motto is ‘don’t screw up,’” says Whiteley. “Students will be successful no matter what, and our job is to not demotivate them and make them lose their confidence.”

His tenure has produced significant results for the college. Chemical engineering’s enrollment has doubled since 2007, making it the second-largest school in the college of engineering. Whiteley hired three new faculty members last year, and the school is also planning on increasing the number of faculty members from 12 to 20 in the future.

“It’s been exciting to be a school head during this period,” says Whiteley. “Previous school heads didn’t have luxury of this kind of growth, and the circumstances were more difficult.”

The feedback reflects how successful Whiteley was in his dual role as a professor and school head, maximizing students’ talent and helping them to accomplish their goals. He also mentors young faculty members.

“Now that I’m a fellow Ph.D. colleague, Dr. Whiteley continues to be supportive of my research career with dynamic conversations, hosting visits to OSU, providing invaluable career advice and being an avid fan and cheerleader,” says Cassie Mitchell, a former OSU student and research engineer at Georgia Institute of Technology.

His leadership fosters a strong research environment. His positive impact on the department is not easily measured, but is definitely seen. The School of Chemical Engineering is looking at a complete renovation of the department next year, and Whiteley has hopes to design the solution for the next generation.

FALL 2015 12

Jan Wagner, Ph.D., Professor Emeritus, Chemical Engineering, left, with Rob Whitley.

A

GLANCE

HEAD

JAMES (ROB) WHITELEY, Ph.D

Chemical Engineering

ENROLLMENT

435 undergraduates

50 graduates

FACULTY

5 professors

3 associate professors

5 assistant professors

2 research assistant professors

ENDOWED POSITIONS

5 chairs

1 fellowship

RESEARCH AREAS

Adaptive filtering

Biofuels

Biomedical

Biotechnology

CFD-combustion reactor design

Fluid mechanics

Emulsion Formation and Stability

Enhanced unconventional gas recovery

Gas testing

Gene delivery

Heat transfer

Mass Transfer

Naterial science

Modeling

Nanoparticles and biomembranes

Petroleum energy and refining

Phase equilibrium

Polymeric systems

Process development

Reactor design

Sustainability

Thermodynamics and thermophysical property prediction

Tissue engineering

Viscoelasticity

Water process and ion exchange

DEGREE OPTIONS

Chemical Engineering

• Biomedical / Biochemical option

• Environmental option

• Pre-med option

13

SCHOOL OF AT

“We are committed to having the finest structures engineering program in the nation … it is also the result of a rare partnership between the private sector, the public sector and the university.” —

Gorman Gilbert,

Gorman Gilbert,

former head of the School of Civil and Environmental Engineering

FALL 2015 14

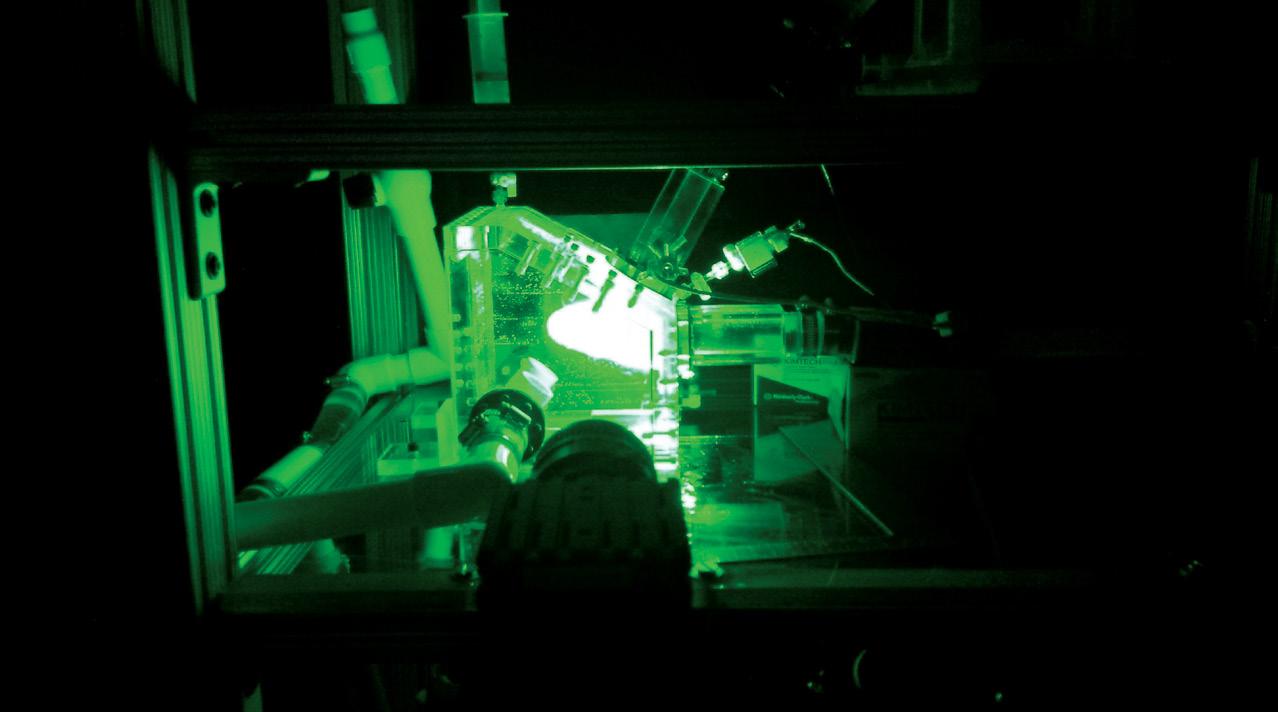

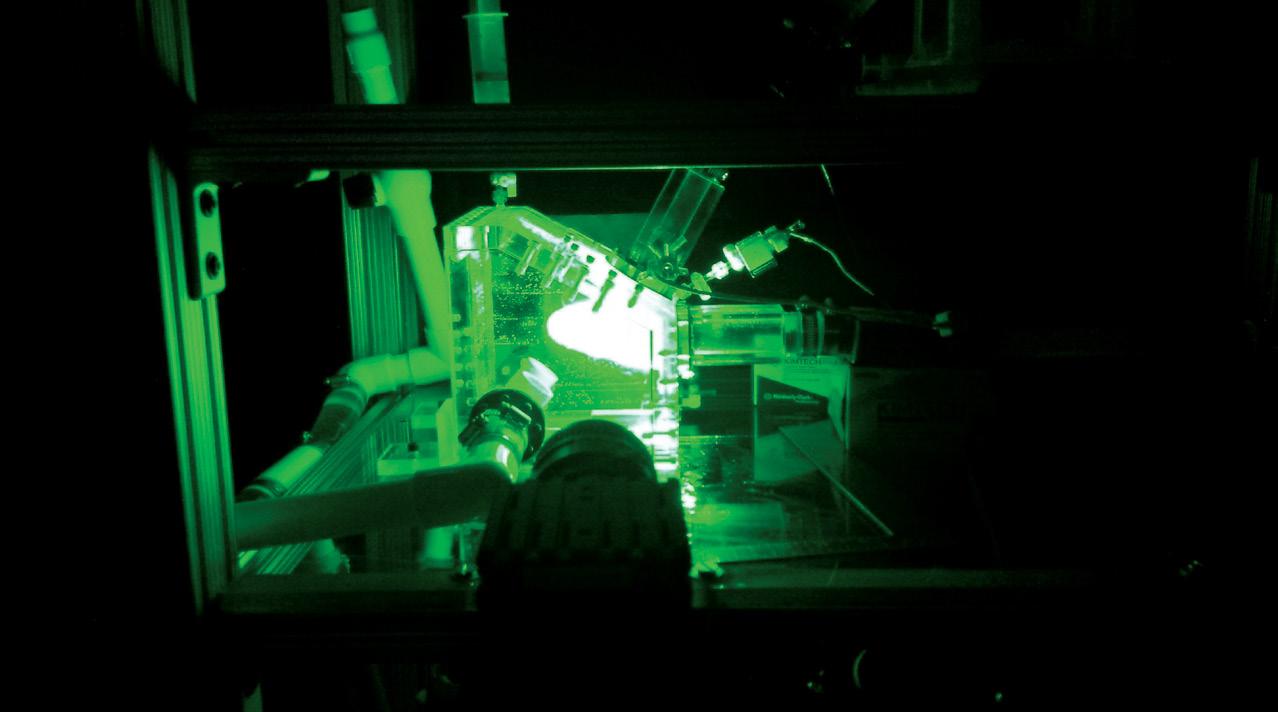

THE BERT COOPER ENGINEERING LABORATORY IS 33,000 SQUARE FEET OF SUSTAINABLE STRUCTURES TESTING FACILITY — THE BEST IN THE REGION.

Open Doors

PHOTOS BY COLLEGE OF ENGINEERING, ARCHITECTURE AND TECHNOLOGY

Cooper Lab welcomes new research and contracts in its first year

Oklahoma State’s College of Engineering, Architecture and Technology is now home to the largest and most advanced structures and materials testing laboratory in the region — the Bert Cooper Engineering Laboratory. Two of the project’s original pioneers died before they could see the building come to fruition, but they were there in spirit as the college proudly presented the lab to alumni, donors and friends at the grand opening ceremony on April 22.

ENVISIONING THE FUTURE

More than a decade ago, two engineers came together with a vision for a stateof-the-art structures and materials testing lab. Bert Cooper, former W&W | AFCO Steel CEO and OSU alumnus, and Gorman Gilbert, former head of Civil and Environmental Engineering, saw the impact that such a facility would have on the university, state and region. They set out to build momentum for the project, and in 2003, broke ground at a location near the current Fire Protection Publications building.

“This project is extremely exciting to us,” Gilbert said in 2003. “We are committed to having the finest structures engineering program in the nation and not only does this world-class lab help us attain that goal, it is also the result of a rare partnership between the private sector, the public sector and the university.”

Gilbert was instrumental in the partnership that brought the dream to life. As colleagues and friends, Gilbert worked with Cooper to create a plan that would better educate the structures engineers and produce quality employees for industry.

“Our industry’s forward momentum is dependent upon research and development of new products, and we need a facility in the state where that can

occur,” Cooper said at the original groundbreaking. “Concrete is a big competitor of ours, but we recognize that anything we can do to further the economic feasibility of concrete, steel and other construction industries in the state benefits all of Oklahoma.”

Cooper led the financial support for the building, donating all of the needed structural steel and taking a leadership role in ensuring the lab had the technology necessary to serve the college in the future.

Both men left a lasting legacy at the college, university and in their respective industries. Bert Cooper died Feb. 28, 2013, and Gorman Gilbert on Dec. 13, 2014.

BUILDING A REALITY

Fast-forward to spring 2015 at a location west of the Professional Development building north of the main Stillwater campus. Nearly 250 people arrived at the Bert Cooper Engineering Laboratory to celebrate its opening and remember those who initiated the project. The continues

15

MORE THAN 200 PEOPLE ATTENDED THE APRIL GRAND OPENING OF THE BERT COOPER ENGINEERING LABORATORY.

facility was constructed as 33,000 square feet of sustainable laboratory space with five project offices, nine labs, a graduate studio, a conference room, a 20-ton crane and a 4-foot-thick strong floor.

The lab mimics a real-world environment, providing a place to conduct groundbreaking research in structures and materials testing.

“The Cooper Lab will be home to developing the next generation of structural materials and sensor technology, and we hope to showcase the world-leading geothermal technology developed within our college,” says Paul Tikalsky, dean of the College of Engineering, Architecture and Technology. “The geothermal technology that was developed right here at OSU is now used around the world. We hope that the Bert Cooper Engineering Laboratory will provide a working example for energy efficiency and environmental sustainability in buildings.”

The facility incorporated environmentally sustainable construction methods developed by OSU faculty and researchers, from low-carbon concrete mixtures for foundations to the geothermal ground-source heat pump systems. It is

one of the first major building projects in Oklahoma to use a blended cement containing limestone flour and fly ash.

These reduce the building’s environmental footprint 40 percent. Also, 96 percent of the structural steel is made from recycled materials. In addition, the building features high-efficiency plumbing and solar shading both inside and outside.

At the time of the grand opening, materials were already being delivered for the first round of research. Steel beams provided by W&W | AFCO Steel were set up as the main stage for the event, creating a background that truly conveyed the nature of the space. A plaque dedicated to Gilbert and Cooper was installed inside the high bay area as a tribute and reminder of those who first envisioned the world-class lab.

PARTNERING WITH OKLAHOMA

Several stakeholders spoke during the grand opening ceremony, including OSU President Burns Hargis, CEAT Dean Paul Tikalsky, W&W | AFCO Steel CEO and President Rick Cooper, Civil and Environmental Engineering School Head John Veenstra and Oklahoma Department of Transportation Executive Director Mike Patterson.

Members of the OSU administration expressed gratitude to the supporters and shared their enthusiasm that the lab would begin operation immediately.

“A variety of circumstances stalled and delayed the project, but more than a decade later, the lab is more than anyone ever imagined it would be,” Tikalsky said. “The lab is as technologically advanced as any other facility in the country.”

Rick Cooper, Bert Cooper’s son and successor to the family company, expressed pride in the space his father dedicated so much time to getting started and gave a touching tribute to those who continually battled the obstacles that come with building a state-ofthe-art facility.

“Our family greatly appreciates everyone who made this a reality, it’s been worth the wait,” Rick Cooper says. “Dad shared Burns’ vision and passion for Oklahoma State; he, too, wanted it to be the best land-grant [university] in the United States, and one piece of that puzzle was for the College of Engineering to be a pre-eminent college in the country. There’s no question that goal has been achieved.”

ODOT’s Patterson announced that the Highway Construction Materials Technician Training and Certification Program would move from its Oklahoma City location to the Cooper Lab.

“A lab like this, and the research that is developed in this space, will change transportation in Oklahoma and across the country,” Patterson said. “Having a training facility and resources like this puts ODOT on the map.”

Through this partnership, ODOT begins teaching courses in fall 2015 with a combination of ODOT and OSU staff.

FALL 2015 16

CHELSEA ROBINSON

VISIT OSTATE.TV TO WATCH THE FULL GRAND OPENING CEREMONY.

THE DONOR WALL RECOGNIZES THE MANY SUPPORTERS OF THE LAB, AND ESPECIALLY RECOGNIZES BERT COOPER AND GORMAN GILBERT.

HEAD JOHN VEENSTRA, Ph.D, P.E.

Civil and Environmental Engineering

RESEARCH AREAS

Concrete

Construction

Energy

Environmental biological process

Geotechnical

GIS (geographic information systems)

Pavement construction

Pavement data systems

Recycling

Sensors and data transfer

Soil effects

Structural engineering

Steel structures

Transportation

Water quality

DEGREE OPTIONS

Civil Engineering

• Environmental option

17 ENROLLMENT

undergraduates

graduates FACULTY

professors

associate professors

assistant professors

286

81

6

5

7

chairs

professorship

ENDOWED POSITIONS 2

1

GLANCE AT A SCHOOL OF

Serial Mover

STORY BY RYAN DOONKEEN / PHOTOGRAPHY BY PHIL SHOCKLEY / UNIVERSITY MARKETING

Successful alumnus shares career and industry knowledge on OSU campus

“A journey is a person in itself; no two are alike. And all plans, safeguards, policing, and coercion are fruitless. We find that after years of struggle that we do not take a trip; a trip takes us.”

John Steinbeck could not better describe the path that Fossil Group’s Chief Information Officer Ed Robben has taken to get where he is today. Robben, a School of Electrical Engineering alumnus from Oklahoma State University, is a self-proclaimed “serial mover.” After working as an information technology executive for BNSF Railway and a consultant at the Feld Group and EDS, Robben set his sights on retail and helping J.C. Penney keep up in the evolving world of technology.

Looking for another challenge after five years, Robben became the CIO of the Fossil Group in June 2012. The company, based in the Dallas suburb of Richardson, Texas, knew that developing capabilities to engage customers and listen to their needs with a targeted, analytical approach was the only way to continue its success, and Robben would play a large role in that.

— John Steinbeck

Dealing with cybersecurity, millions of consumers’ personal information, complying with the regulations of up to 150 governments (Fossil products sell in 150 countries, and the company has locations in 27) is becoming more and more complex. Robben prides himself on being able to work daily with some of the smartest people he knows.

“The experience and being able to see all the different companies how they think about technology and how it’s applied has been great,” Robben says. “Meeting great people along the way and having great projects to work on has helped me move up in my career. I love the leadership aspect of it, and that’s why I’ve gravitated toward the position of CIO. Working with the leaders and the teams really energizes me.”

FALL 2015 18

continues

“Have a clear vision and focus and understand the risk. Be flexible and at the end of the day, remain calm.” — Ed Robben

19

OSU ALUMNUS AND FOSSIL GROUP CIO ED ROBBEN SPEAKS ABOUT HIS SUCCESS IN ENGINEERING AND THE FUTURE OF THE INDUSTRY DURING THE HALLIBURTON GLOBAL INNOVATORS SERIES ON APRIL 2.

“Today’s advances in wearable technology are exciting,” Robben says. He’s seeing it on a daily basis at fashion company Fossil, but he has always been around innovation throughout his career.

Robben worked with the global positioning system in its infancy in the early ’80s. At the time, the systems weren’t the super-compact devices of today; they were closer to the size of microwave ovens, he says. He’s seen his work on GPS systems evolve into radio frequency identification (RFID), which keeps track of everything from rail carts to shirts at J.C. Penney and now to wristwatches that can track your every move.

As an avid runner, he is excited to see this wearable technology’s impact on running. The demand to make this tightly packed technology into something that goes as well with khakis as it does running shoes is one of the challenges that Fossil and Robben are tackling.

Robben can attribute much of his success to his experience at Oklahoma State University. He says he uses the problem-solving skills he developed while getting his bachelor’s degree in electrical engineering at OSU daily in business. He participated in a co-op program that was once in place for three semesters, gaining invaluable experience. Entering the professional world with production-level programming experience under his belt kick-started his career and gave him the ability to move up the ladder very quickly.

Still, he says the best thing to happen to him at OSU was when, “I met my wife of 31 years at Oklahoma State. She’s the mother to my 3 daughters, all of whom are now a part of the OSU family.

“I met a lot of great people, and OSU does great things and continues to get better each time I visit,” says Robben. “I’m really proud of the university and everything that they’re doing.”

He offers advice for today’s students: “If you’re in the field of change or driving to create change, believe it can be done,” says Robben. “Have a clear vision and focus and understand the risk. Be flexible and at the end of the day, remain calm.”

FALL 2015 20

HEAD JEFFERY YOUNG, Ph.D.

Electrical and Computer Engineering

ENROLLMENT

401 undergraduates

235 graduates

FACULTY

13 professors

7 associate professors

4 assistant professors

1 visiting assistant

ENDOWED POSITIONS

2 chairs

3 professorships

RESEARCH AREAS

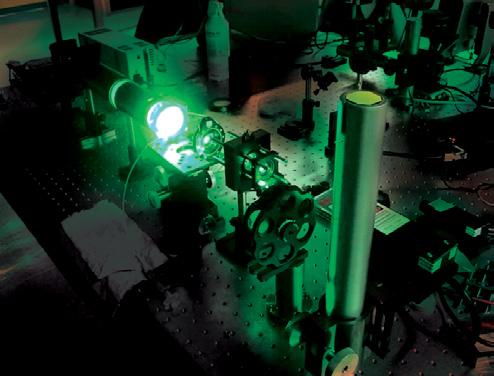

Laser spectroscopy

Biomaterials

Biophotonics/biomedical optics

Classical optics

Communications systems and signal processing

Computational intelligence, perception and neuroscience

Computer simulations

Digital and embedded systems

Electronic materials and devices

Energy and renewable energy sources

Image processing and computer vision

Intelligent systems and control

Laser optics

Medical imaging

Microelectromechanical systems

Metamaterials

Nanomaterials

Optical imaging

Pattern recognition and machine learning

Photonics

Plasmonics

Robotics and embedded computing sensors

Solar hydrogen Systems theory and instrumentation

Terahertz photonics

Thermoelectric

Tissue engineering

Ultrafast femtosecond lasers

Very large scale integration

DEGREE OPTIONS

Electrical Engineering

Computer Engineering

21

GLANCE AT A

SCHOOL OF

Using Data in Health Care

STORY BY PAM COVINGTON

OSU industrial engineering faculty, students unite on innovative projects

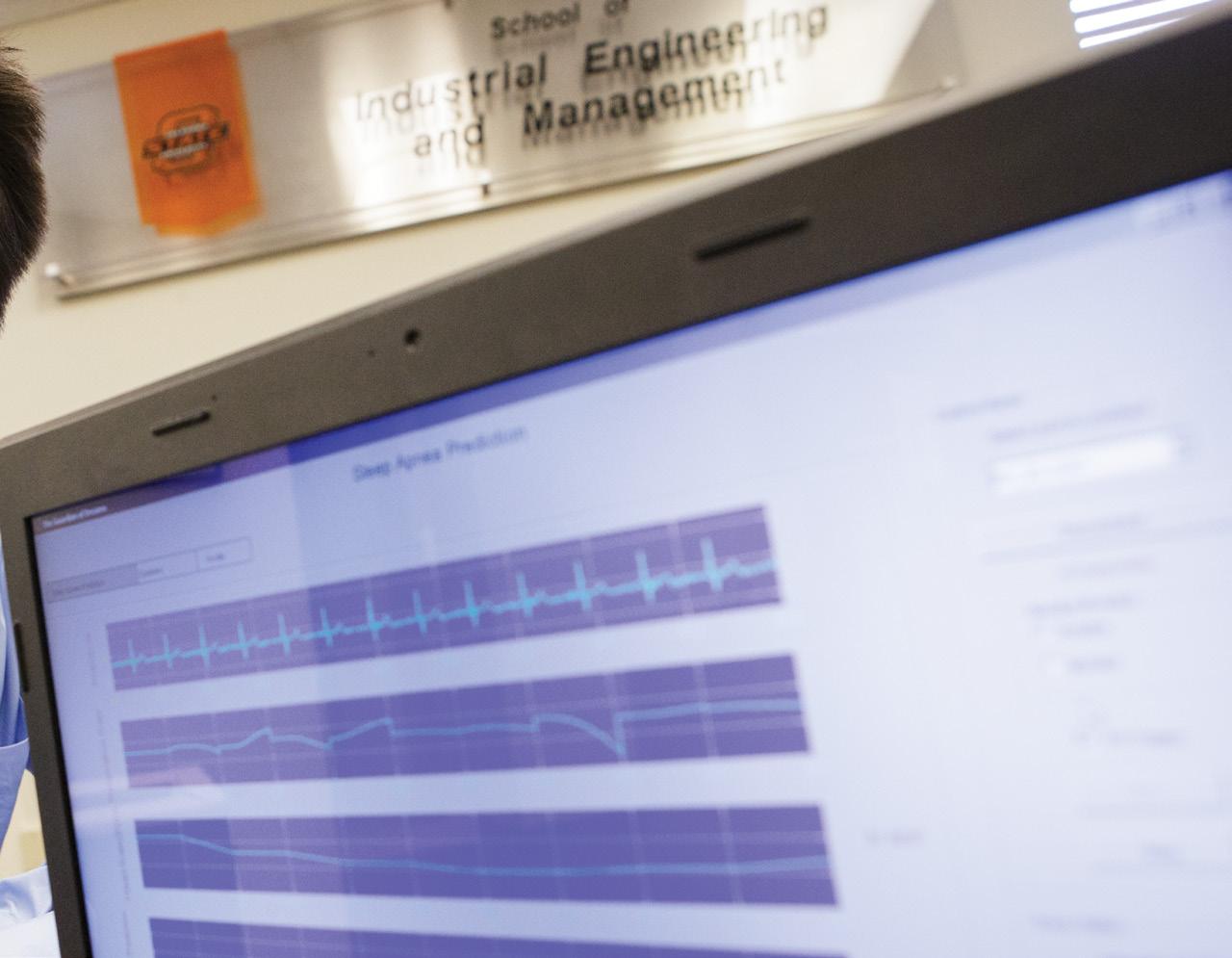

Several OSU industrial engineering faculty members and students are involved in research aimed at improving public safety and health with big data analytics.

Sunderesh Heragu, Ph.D. and head of OSU’s School of Industrial Engineering and Management, is the lead investigator in an ongoing project to develop a decision support system for a pandemic influenza response. This system takes the guesswork out of making decisions during a public health emergency by pulling together information. For example, the system can determine which airport in a state or which routes would be best to receive shipments of aid.

A system like this can determine the quickest, most efficient way to deliver vaccinations or other treatments, taking into account minute details such as the capacity of each vehicle, speed limits on the selected routes, traffic conditions, road repairs and weather conditions. It can even send the vehicle drivers pictures from DOT cameras on highways so that drivers en route can judge traffic tieups.

FALL 2015 22

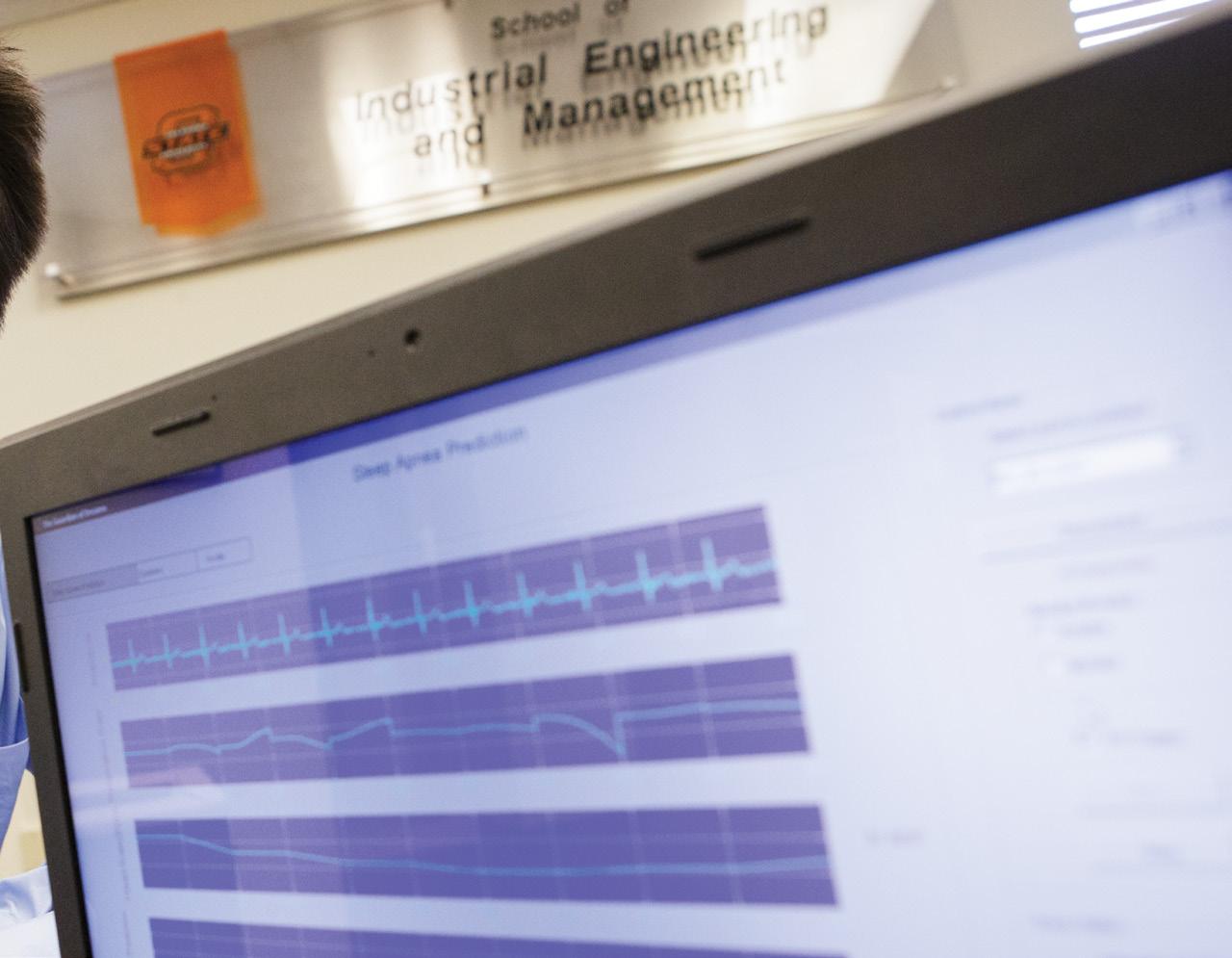

WORANAT

PATIENT IS AT HOME —

EVEN

PHOTOGRAPHY / GARY LAWSON / UNIVERSITY MARKETING

WONGDHAMMA IS WORKING ON A WIRELESS, WEARABLE MULTISENSORY SYSTEM THAT CAN DETECT SLEEP APNEA WHILE

A

AND

PREVENT SUCH ATTACKS.

About 50 experts in health care, industrial engineering and computer science have been involved in developing the pandemic decision support system over the past three years. The system is now in the process of being commercialized and has already been used in drills in Georgia, Kentucky, Alabama, Florida, North Carolina, South Carolina, Tennessee and Mississippi.

Heragu says decision support tools have been developed for public health officials, first responders and hospitals. One module has been used in a realworld mass vaccination clinic. In 2009,

19,000 vaccines were administered in 1½ days in a mass drive-through clinic in Louisville, Ky., a world record.

Apps have also been developed for resource allocation. For example, as soon as a ventilator becomes available in a hospital, a nurse could swipe the ventilator bar code, and the database would be updated to show that the resource is available.

As another example, the resource allocation system could determine how many vehicles of different types are needed to evacuate patients from a hospital in the

path of a hurricane and how to allocate these patients to other hospitals in unaffected areas. Other countries such as China are also interested in a resource allocation tool, which can be used for transporting resources such as grain during a famine or earthquake, a mobile hospital, pallets of food or any number of other resources.

“That’s what big-data analytics is all about — taking large amounts of data, mining through it, processing it, and then using the processed information to make real-time decisions,” Heragu says.

23

continues

Industrial engineering faculty member Tieming Liu is also working to improve health care. Liu is using his data analytics skills with the large database of OSU’s Center for Health Systems Innovation, analyzing strategies to predict and prevent diabetes.

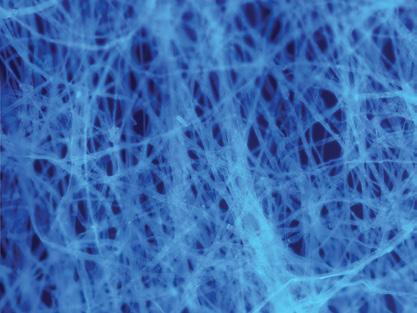

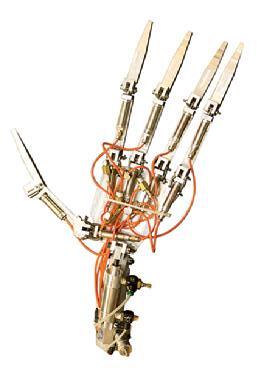

Industrial engineering doctoral student

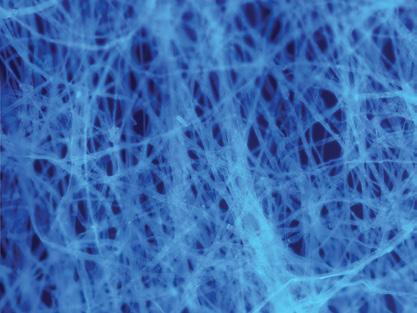

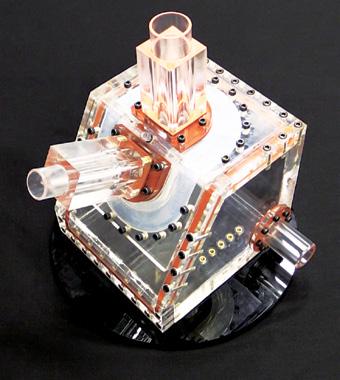

Woranat Wongdhamma, who worked with former faculty member Satish Bukkapatnam, Ph.D., is also conducting health care-related research. Wongdhamma and his research group have developed a wireless wearable multisensory system to detect sleep apnea.

Currently, the primary way to diagnose sleep apnea is through a sleep study performed overnight in a sleep lab. According to Wongdhamma, the waiting period for a sleep study could range from two to 10 months and could cost around $2,500.

Wongdhamma’s wireless wearable multisensory system uses an armband to record a patient’s EKG waves while the patient is sleeping in his own home. Using advanced statistical analysis and data mining techniques, the system analyzes the EKG patterns and determines whether or not a patient has sleep apnea, and if so, the degree of severity. The wireless wearable multisensory system is so precise that it can determine if a person is going to have a sleep apnea attack within the next minute.

Because of the advance warning the system provides of an impending attack, the research project can be taken to a new level. Since sleep apnea is caused by upper-airway obstruction during sleep, a stimulus could be provided directly to the target muscles to prevent the obstruction before it actually happens.

Wongdhamma says he feels good about working on a research project that will eventually be used to help people and could save lives.

Heragu also mentioned another industrial engineering student who is in the early stages of working on a similar idea for predicting and diagnosing bipolar disorder.

According to Wongdhamma, future health care is likely to be more personalized and less costly. The cost will be lower because the diagnosis process could be carried out at the patient’s home with the help of the Internet and wearable sensors. In addition, the health care analytics will help diagnose conditions before damage is done to a body’s systems, thus eliminating the need for costly medical procedures.

FALL 2015 24

PHOTOGRAPHY / GARY LAWSON / UNIVERSITY MARKETING

“That’s what big-data analytics is all about — taking large amounts of data, mining through it, processing it, and then using the processed information to make real-time decisions.” —

Sunderesh Heragu

Industrial Engineering and Management

DEGREE OPTIONS Industrial

25 ENROLLMENT 132 undergraduates 240 graduates FACULTY 3 professors 7 associate professors 4 assistant professors 1 lecturer ENDOWED POSITIONS 1 chair 1 professorship 1 fellow

AREAS Algorithms Applied probability Cognitive ergonomics Energy operations Information systems Logistics and supply chain management Management and decision analysis Manufacturing systems Modeling Motorcycle safety Quality management Robotics Sensors Supply chain Sustainability Transportation

RESEARCH

HEAD SUNDERESH HERAGU, Ph.D.

Engineering and Management SCHOOL OF GLANCE AT A

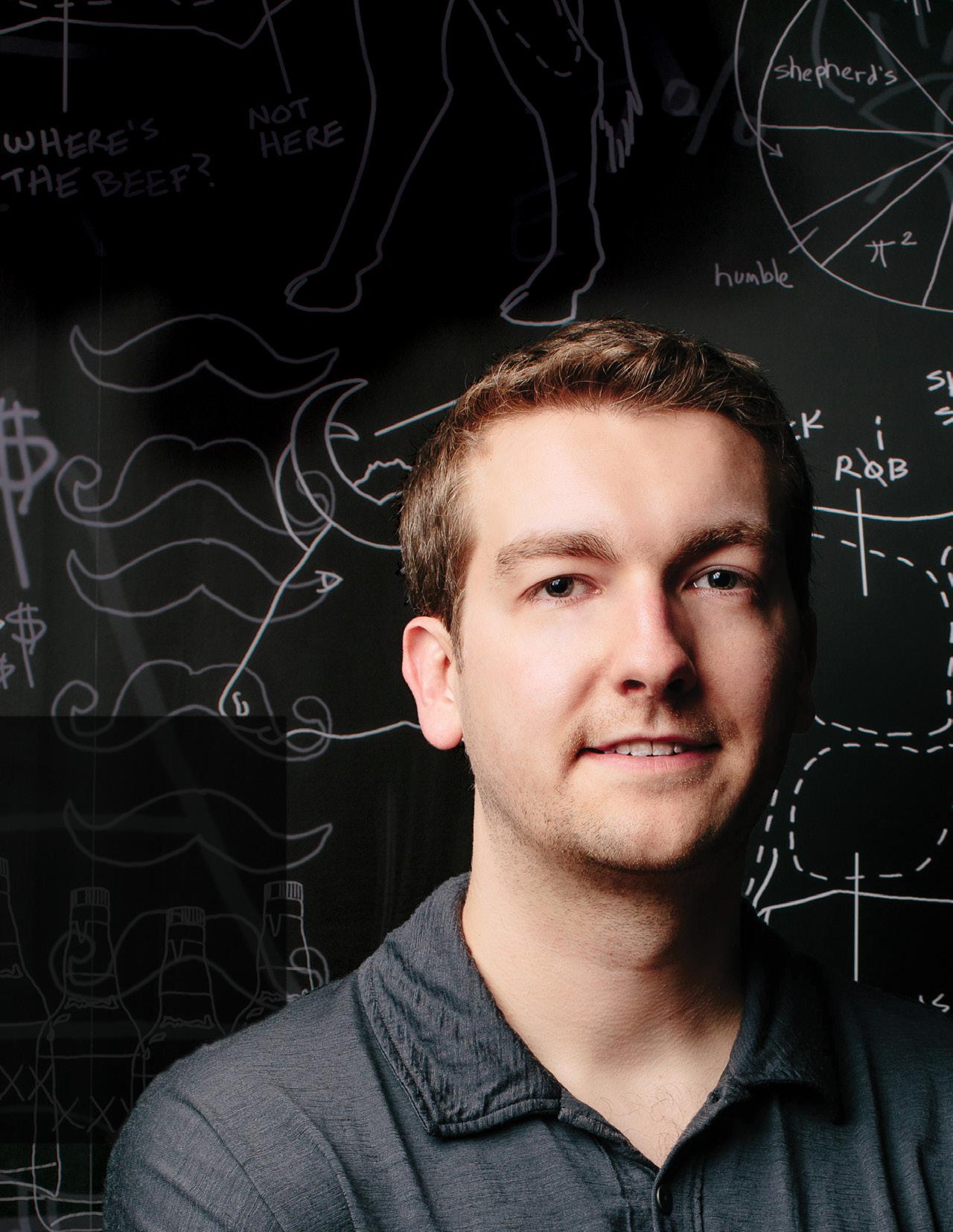

Making It to ‘30 under 30’

STORY BY JEFF JOINER

Mechanical engineering alumnus receives national attention for his entrepreneurship

“My experiences as an undergraduate, and in graduate school, made me realize I wanted to continue to learn, and that all began with opportunities at OSU.” — Brett Walker

FALL 2015 26

AT FIRST GLANCE

it might look like Walker’s success has been as much luck as anything else. After all, the 29-year-old entrepreneur started a successful company that has enjoyed rapid growth, launched a consumer product with a wildly successful Kickstarter campaign and won recognition for his accomplishments by Forbes magazine. But crediting luck alone overlooks years of hard work, painstaking research and an education that began at Oklahoma State University.

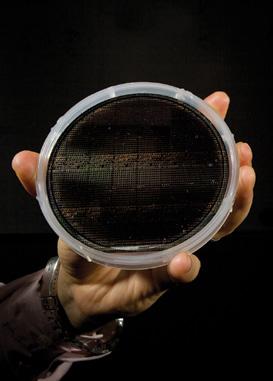

Walker is a co-founder and CEO of Electroninks, which develops electricity conductive inks widely used in consumer electronics. But Electroninks is best known for Circuit Scribe, a rollerball pen he and colleagues invented that allows users to draw functioning electrical circuits by doodling on paper. The pen caused a sensation in 2013 when Walker launched it with a Kickstarter campaign that raised $675,000 from more than 12,000 backers, many of whom were teachers who use the pen to demonstrate how circuits work in the classroom.

“It uses a high-performance, conductive ink that’s nontoxic, dries quickly at room temperature and allows you to draw a circuit on paper and get immediate feedback if it’s working by connecting it to a battery,” Walker says.

Walker and his company have garnered a lot of attention in just a few short years. In 2013, Scientific American magazine named Walker’s ink one of nine materials that will change the future of manufacturing. And earlier this year, Forbes named Walker to its “30 Under 30” list in industry and manufacturing. Each year the magazine selects up-and-coming leaders under the age of 30 in a variety of fields, described as “disruptors and innovators” who are modernizing the way things are made in a greener, tech-savvy world.

Walker traces the roots of his success to OSU, where he graduated in 2004 with a bachelor’s degree with honors in mechanical engineering. The Edmond, Okla., native then went straight into a materials science engineering doctorate program at the University of Illinois at Urbana-Champaign.

As an undergrad in the College of Engineering, Architecture and Technology, Walker first experienced research and the foundations of mechanical and materials engineering that changed the course of his career. Walker says working with engineering faculty in the lab was a formative experience that led to his passion for materials science.

“There is really a lot of research going on at OSU that is widely available as long as you’re open to the experience,” he says. “As an undergrad, I got my feet wet in the practical applications in a number of areas.”

Walker worked with Jim Smay, Ph.D. and associate professor of materials science and engineering, who was working with 3D printers to make dental composites from printed ceramic materials. He also did research with Lorenzo Cremaschi, Ph.D. and associate professor in mechanical and aerospace engineering, assisting him with thermodynamic experiments, with mechanical and aerospace engineering professor Jamey Jacobs.

“That was it,” Walker says. “I decided this is for me. This is what I wanted to do.

“In undergrad mechanical engineering courses, I studied the failure of materials and material science and a lot of the chemical fundamentals to mechanical engineering that really interested me,” he says. “That sort of melding of mechanical engineering and the chemistry and fundamentals of materials really appealed to me and led me to do graduate work in materials science.”

27

continues

Brett Walker, a 2004 OSU mechanical engineering graduate, was named one of Forbes magazine’s ‘30 under 30’ for his company, Electroninks.

Walker was also a member of the American Indian Science and Engineering Society, where he served as president his senior year, and a student scholar with the Oklahoma Louis Stokes Alliance for Minority Participation (OK-LSAMP), which supports underrepresented students studying science, technology, engineering and mathematics (STEM).

Fueled with a passion to continue studying, Walker joined the University of Illinois research team of renowned materials engineer Jennifer Lewis, PhD., and began working with conductive inks. His optimized ink improved conductivity, and the formulation was more costeffective to manufacture and easier to use than existing products. The project, Walker’s doctoral thesis, resulted in the development of the silverbased conductive ink, which created a buzz when published in journals and highlighted in science publications. In 2012, Walker won second place in the graduate student category of the National Collegiate Inventors Competition.

The buzz resulted from a realization that this was a game changer for manufacturers of printed electronics. Most inks for printed electronics rely on suspended metal particles in the ink to conduct electricity. But the inks are expensive to make and difficult to use. Walker’s ink uses a dissolved solution of silver acetate and ammonia. Once the ink is laid down, the liquid evaporates, leaving the conductive silver behind. The ink also dries faster at lower temperatures and can be used in inexpensive printers. Walker and his fellow researchers knew the ink had potential to be commercialized.

In January 2013, Walker and Lewis launched Electroninks to make and market the improved conductive ink to consumer electronics manufacturers. The buzz did translate into demand as sales grew rapidly. Additional students joined the partnership to help propel an idea for a consumer product that used similar inks in a simple rollerball pen that would appeal to educators, students and do-it-yourself types interested in prototyping electronic circuitry. That pen became Circuit Scribe. Walker and his partners believed the product would be popular but had no idea how much so until their December 2013 Kickstarter campaign.

“I think it is so popular because it’s so accessible,” Walker says. “You don’t need an instruction manual for a rollerball pen. Kids who don’t know how to write yet can doodle with Circuit Scribe and make functional circuits.”

Since its launch, Circuit Scribe pens, which sell for $20, and accessories, have generated more than $1.5 million in revenue. Sales of industrial inks remain the company’s largest revenue producer, but Circuit Scribe has become the “cool” face of Walker’s company.

“I feel like the educational market has the brightest future,” he says.

The company is expanding its line of pens and accessories and recently introduced Circuit Scribe Microcenter national computer and electronics chain. Walker is pushing to see the pen sold in more retail locations and directly to educational outlets and schools.

Walker also just finished moving the company’s headquarters from Illinois to Austin, Texas, where Electroninks also develops and makes its inks. A group in Boston develops educational content, while its customer service is in Phoenix.

Walker will tell you that starting a successful business is as much about passion as it is about having a great product to sell.

“I’m passionate about learning and understanding the fundamental reasons why things work,” he says. “My experiences as an undergraduate, and in graduate school, made me realize I wanted to continue to learn and that all began with opportunities at OSU.”

FOR INFORMATION ABOUT WALKER’S COMPANY, VISIT WWW.ELECTRONINKS.COM

“Undergraduate research really prepared me for the research world. It was a lot of hard work but it was exciting,”

FALL 2015 28

— Brett Walker

HEAD

DAN FISHER, Ph.D.

Mechanical and Aerospace Engineering

ENROLLMENT

1,333 undergraduates

134 graduates

FACULTY

10 professors

5 associate professors

10 assistant professors

5 lecture/clinical

ENDOWED POSITIONS

6 chairs

3 professorships

RESEARCH AREAS

Acoustics

Aerospace

Aircraft

Automation

Building systems

Cardiovascular

Coatings

Computational fluid dynamics

Design systems

Dynamics

Electromagnetics

Fire

Fluids

Heat pump

Heat transfer

Image processing

Lasers

Material science

Mechanics

Polymers

Precision engineering

Refrigeration

Robotics Systems

Thermal systems

Tissue engineering

Unmanned aerial systems

Vehicle stability and control

Winding

Wrinkling

DEGREE OPTIONS

Aerospace Engineering

Mechanical Engineering

• Biomedical option

• Pre-med option

29

SCHOOL OF GLANCE AT A

Building Partnerships

STORY BY BY PAIGE WORLEY / ARTWORK BY OSU-TULSA

OCAST advances Oklahoma service with Helmerich Research Center

OKLAHOMA STATE UNIVERSITY’S 27-year relationship with the OKLAHOMA CENTER FOR THE ADVANCEMENT OF SCIENCE AND TECHNOLOGY (OCAST) is becoming even stronger.

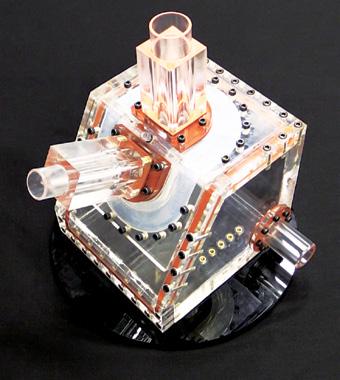

OCAST will be using office space in the Helmerich Research Center (HRC), a state-of-the-art research facility on the OSU-Tulsa campus. OCAST works with entrepreneurs and small to medium-size businesses on innovation and manufacturing to advance science and technology in Oklahoma through funding for projects from grants. It also assists business owners with integrating innovative techniques into manufacturing.

“We sponsor manufacturing activity, particularly in support of advanced manufacturing processes and techniques,” says Michael Carolina, executive director of OCAST. “Our universities, specifically OSU and the New Product Development Center, are an integral part of what we do because of the focus on manufacturing processes and techniques.”

“The HRC has high-quality equipment that OCAST can utilize to advance its research,” says Robert Taylor, director of the New Product Development Center.

FALL 2015 30

THE OKLAHOMA CENTER FOR THE ADVANCEMENT OF SCIENCE AND TECHNOLOGY WILL SOON BE USING OFFICE SPACE IN THE HELMERICH RESEARCH CENTER AT OSU-TULSA.

OSU has also offered to hire a full-time design engineer and several students to work with OCAST in the HRC to support the business community in Tulsa. OCAST will use space available in the HRC to meet with Tulsa-area clients.

“Our goal is to expand our services in Tulsa, and OCAST has welcomed the idea of having that increased support,” says Taylor.

The HRC was created to allow development, testing and education to fulfill the commitment made to the residents of Tulsa for Vision 2025. In its mission statement, the HRC is meant to “positively impact the economy and quality of life for the region and provide opportunities for OSU students and faculty to work hand-in-hand with industries.”

“This partnership is the HRC’s mission at its finest. OCAST has worked with OSU and the Oklahoma Manufacturing Alliance (OMA) to connect OSU

specialists and researchers with companies that need assistance with a problem,” Taylor says.

“OCAST brings us a lot of business, in terms of companies that need support work,” Taylor says. “A lot of our proposal writing comes through OCAST, and it will identify someone who is looking for funding that is specifically qualified for a Small Business Innovation Research grant. We will support that company in writing those proposals.”

The relationship involving OSU, OCAST and the OMA cultivate the teaching, outreach and innovation needed to help businesses grow.

“The collaboration also gives these students on-the-job problem-solving training while they are still in school,” Taylor says. “The easy problems have been solved; the hard problems will come out of these programs.”

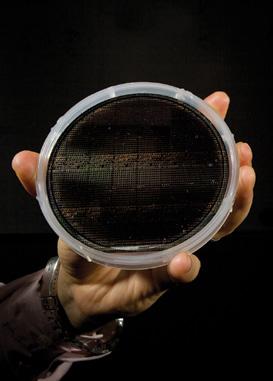

The HRC’s 123,000 square feet of space can house up to 40 faculty and researchers and 100 graduate students. The center also has specialized laboratories, a clean room, an imaging suite and advanced information technology equipment. The HRC’s core lab is its biggest asset to OCAST, Taylor says.

“A core lab has equipment that most of us can’t really afford to go buy unless we have a high-value need for it, and the HRC will allow us to use this equipment or give us students who are trained on the equipment,” Taylor says.

OCAST and other businesses using the technology and researchers in the core lab pay a small fee.

“The fees are really small compared with the cost of the equipment,” he says. “It’s been a wonderful move for some of

our manufacturing companies that want to try something out without buying a large piece of equipment.”

The primary research conducted in the HRC is on material science, a program on the OSU-Tulsa campus. Ed Kirtley, assistant dean of Outreach and Extension, says the program is doing cutting-edge research.

“For example, it has developed a new wrap for natural-gas storage cylinders for cars that are natural-gas fueled,” he says. “The research they are doing is state-of-the-art; it’s current, ground breaking science.”

The variety of opportunities and resources at the HRC will serve as a collaborative space for OSU, CEAT, Tulsa and Oklahoma.

“One of the primary contributions that CEAT can make to the Oklahoma economy is to help small and medium-sized manufacturing and businesses overcome technical problems,” Kirtley says. “We can bring the latest research, science and engineering technology to help solve common, everyday problems.”

According to OSU’s experts, researchers and students helping businesses and industries with problems, allows the companies to be competitive and the industry to grow.

“That’s really the land-grant mission we talk about at its best,” Kirtley says. “This is what the founding fathers of the land-grant mission university meant with research, teaching and outreach all represented.”

31

“This is what the founding fathers of the land-grant mission university meant with research, teaching and outreach all represented.” — Ed Kirtley, assistant dean of Outreach and Extension

SINCE THIS ARTICLE WAS WRITTEN, THE OKLAHOMA SMALL BUSINESS DEVELOPMENT CORP. HAS ALSO MOVED INTO THE HRC.

HEAD RAJ SINGH, Ph.D.

HEAD RAJ SINGH, Ph.D.

Materials Science and Engineering

8 graduates FACULTY

1 associate professor

2 assistant professors

1 research assistant

ENDOWED POSITIONS

2 chairs

1 research assistant professor

RESEARCH AREAS

Biomechanics/biomaterials in medicine

Biomechanics/biomaterials in tissue engineering

Biomimetic photothermal hydrogen production

Electric eel bio-mimicry

Filament winding

Fuel cell

In vitro/in vivo studies

Ion channel arrays

Lipid multilayer assemblies

Liposomal drug delivery

Manufacturing

Nanomaterial for medicine

Natural gas

Nonotubes/nanorods

Polymer composite

Processing

Properties of nanostructured materials

Scaffold design

33

ENROLLMENT

GLANCE AT A

SCHOOL OF

Avoiding the Brain Drain

STORY BY MALLORY PENCE / PHOTOS BY CEAT

STORY BY MALLORY PENCE / PHOTOS BY CEAT

Students and industries benefit through New Product Development Center internship program

THE NEW PRODUCT DEVELOPMENT CENTER at Oklahoma State University has a rich history of supporting the Oklahoma business and manufacturing community and working with student interns from an array of disciplines. Much of the center’s accomplishments can be traced to how it connects the business and manufacturing communities with student interns.

For the last several years, funding from state, federal and industry sources has supported this student-industry interaction.

Robert Taylor, a research professor who serves as the NPDC director, says improving the student-industry interaction helps keep graduates in Oklahoma.

“We want to connect the right students to professionals in their desired fields, so they can begin to network and get their foot in the door,” Taylor says.

Student interns get to put their university-acquired skills to use, learn good communication skills and get a jump start on for future employment. Industry clients discover the value student interns bring to their companies.

Many of the small manufacturing businesses interacting with the NPDC do not have a degreed engineer or business professional on staff. For these manufacturers to compete in hiring recent graduates, they must offer a competitive salary, which can be difficult. Those businesses in rural areas also find location to be an issue with hiring. Many graduates prefer a big city. Oklahoma and its universities have seen science, technology, engineering and math (STEM) students leave the state for other jobs with higher pay and better benefits — the “brain drain.”

Within Oklahoma, many communities and companies have launched programs to entice local students to return home after graduation. These efforts have been effective to counter the brain drain, yet there are still some problems reducing the effect in specific STEM fields such as engineering.

FALL 2015 34

“Advantages of working in rural manufacturing are that manufacturers have uniquely experienced workforces availability of raw materials, and low-cost space for expansion and water,” Taylor says. “This allows for less money and resources to be used and spent for shipping, materials and recruiting, but these advantages are sometimes not enough to make engineering graduates stay.”

Tulsa and Oklahoma City are striving to improve their attractiveness to recent college graduates. Bloomberg Businessweek’s “Best Cities for New College Grads” list recently placed Tulsa at No. 13 and Oklahoma City at No. 14 in the nation for entry-level career opportunities with good pay and a low cost of living.

According to the National Center for Education Statistics, Oklahoma had a “brain gain” overall in all educational disciplines in 2008, with 2,039 students leaving and 4,734 arriving.

However, engineering data tell a different story.

In 2014, the College of Engineering Architecture and Technology graduated 434 students. Of those who responded to surveys regarding employment location after graduation, 55 percent were staying in Oklahoma. The OSU Career Services system, however, found in a 2014 survey that out of more than 245 post-graduation respondents, only about 70 went to work for Oklahoma companies.

“There have been improvements in attracting engineering students to work in rural areas of Oklahoma but major changes have yet to occur,” Taylor says. “The statistics show that our efforts at the NPDC and other departments have helped the students and the Oklahoma companies. We need these students to stay in order to help our economy; we have invested the effort to train them, let’s try to keep them here.”

Six recent NPDC student interns accepted positions, thanks to the NPDC’s efforts.

Tyler Worden is a perfect example of the success of the student-industry interaction program. Worden found his job after graduate school because of the NPDC and its integrated program.

“As a graduate intern at the NPDC, I assisted on a project that was for a company called Wilco,” Worden says. “Upon approaching graduation, the faculty of the NPDC put a large foot in the door by initiating communications with the company, giving excellent referrals and providing guidance throughout the interviewing and job application process. Without the NPDC, I almost assuredly would not have landed such a rewarding position at a successful and growing Oklahoma manufacturing company.”

Worden’s experience and professional guidance from the NPDC also provided him with helpful insights for his future as an engineer.

“Working at the NPDC opened my eyes to the importance of not only keeping manufacturing and engineering in Oklahoma but also striving to make it stronger,” Worden says. “I felt it was my duty to apply my Oklahoma-learned skillsets here in Oklahoma, in a way, to give back.”

Many people may find Oklahoma lacks specific industry opportunities or the job markets they want to pursue. It also depends on the degree program from which the student is graduating; some degree field options are not available in Oklahoma. Other students prefer to stay in the state because it is their home and recent improvements make it a more attractive place to live.

Stuart Wood, a current NPDC intern and soon-to-be Webco employee, believes Oklahoma manufacturers are taking important, early steps toward connecting with students.

“Webco works with local high schools around the Tulsa area to allow students to visit their facilities, which helps get younger students interested in manufacturing and design,” Wood says.

Business and manufacturing companies are improving their student interaction to boost their appeal to recent graduates, but guidance from professional advisers also benefit the student-industry interaction.

“The staff at the NPDC was extremely helpful when it came to answering questions about potential employers, how to handle professional communication, résumé review and any other questions I had about the hiring process and the interviews,” Wood says.

35

An IndustryAppreciated Education

STORY BY PAM COVINGTON PHOTOGRAPHY BY PHIL SHOCKLEY / UNIVERSITY MARKETING

Faculty members bring decades of real-life experience to engineering technology classrooms

The real-world experience of OSU’s engineering technology faculty is a key factor in preparing students for handson engineering careers. More than 90 percent of OSU’s engineering technology faculty members have at least five years of industry experience, says Dana Hobson, interim head of the Division of Engineering Technology.

Oklahoma State’s Engineering Technology Division includes four degree programs: construction management technology, electrical engineering technology, fire protection and safety engineering technology, and mechanical engineering technology.

With nearly 950 students and 23 faculty positions, the Engineering Technology Division is the second-largest school in OSU’s College of Engineering, Architecture and Technology.

Most of the engineering technology faculty spent long careers in the industry before teaching at OSU. Antone Kusmanoff, Ph.D., a faculty member in

Electrical Engineering Technology, is one example. He served 20 years in the Air Force as a communications systems officer. After retiring from the Air Force, Kusmanoff earned his doctorate at OSU and took a job at at the Southwest Research Institute working on multiple contracts associated with computer and information systems for NASA’s Johnson Space Center, and other government and defense organizations.

Kusmanoff worked as a principal systems engineer for major defense industry contractors: E-Systems, Raytheon and L-3 Communications. Altogether, he worked in the industry for 24 years after he retired from the Air Force. Although the two fields overlap, electrical engineering technology is more applied whereas electrical engineering is more theoretical. Kusmanoff says that even though he has a doctorate in electrical engineering, he spent most of his time in the industry doing applied engineering, such as building parts for a new communication system in the Johnson Space Center.

FALL 2015 36

continues

ELECTRICAL ENGINEERING TECHNOLOGY FACULTY MEMBER ANTONE KUSMANOFF (LEFT) IS JUST ONE EXAMPLE OF PROFESSORS IN THE DIVISION OF ENGINEERING TECHNOLOGY WHO BRING DECADES OF INDUSTRY EXPERIENCE TO THE CLASSROOM.

37

“There’s a lot of demand for people who have that applied engineering skill set,” Kusmanoff says.

Kusmanoff puts his senior design students in industry-like experiences. The students work in teams to build microprocessor-based projects suited for the needs of customers.

“I’m making them experience it, not just telling them about it,” Kusmanoff says.

Senior Jeff Johnson says he is using what he learned in his electrical engineering technology classes in his internship with Hewlett-Packard.

“Mainly what I do is programming. We learned the different languages throughout the program courses, and I’ve actually used every single language to do multiple projects,” says Johnson.

More Experience

Other faculty members who bring years of professional experience to the Engineering Technology Division, according to interim department head Dana Hobson, are:

ROB AGNEW — a senior manager in the defense sector who worked for 15 years in the environmental, health and safety field.

RICHARD BEIER — 18 years of industrial experience with companies such as Conoco, DuPont and Factory Mutual Research.

DANA HOBSON — 20 years in the construction business. For 13 of those years, Hobson owned and managed his own contracting company, designing and constructing over 600 projects in 38 states.

RACHEL MOSIER — oversaw numerous large construction projects during six years as a civil engineer for Oklahoma City.

MARK PRUITT — over 15 years of designing and building homes for several design and construction companies, resulting in the construction of more than 2,000 homes.

Hobson says there are several reasons why OSU engineering technology students are capable of solving realworld application problems: First, the technology program attracts students with a desire to work with their hands and their minds to physically make things work. Second, the fact that the faculty members have been truly successful gives validity to what they say. The third reason is that the entire technology curriculum is hands-on rather than theoretical.

As an example of the curriculum, Hobson says that two 400-hour internships are required in construction management technology — one between the sophomore and junior years and the second between the junior and senior years.

“They have to put in the hours, or they don’t graduate,” Hobson says. “We realize how important it is to get out there.”

The engineering technology division maintains close relationships with the industry, helped by the faculty members’ successful backgrounds.

“Our relationship with the industry, with our recruiters and with our donors is based upon a common respect. Although we are educators now, our alums, our donors and the employers of our students see us as people capable of doing their jobs. Most of us have been successful in our field and chose to go another direction, so we are successful with raising funds, placing our students and giving recommendations for our students,” says Hobson.

Through continued recruitment of faculty with successful industry experience, OSU’s Engineering Technology Division is providing students with the hands-on training needed to allow them to hit the ground running when they enter the workforce.

FALL 2015 38

ANTON KUSMANOFF

HEAD GOURANGA BANIK, Ph.D.

Engineering Technology

761 undergraduates FACULTY

5 professors

6 associate professors

10 assistant professors

1 visiting assistant

ENDOWED POSITIONS

1 chair

RESEARCH AREAS

Concrete design and law

Construction design and management

Construction materials testing and inspection

Data acquisition and control

Development equipment design

Electrical infrastructure

Embedded microcontrollers

Engineering technology

Environmental building

Fire control

Fluid power

Geotechnical engineering

Ground source heat pump

Hazardous material incident

Industrial hygiene

Instrumentation development

Manufacturing systems

Materials science

Safety

Security in emergencies

Systems process and management

DEPARTMENTS AND DEGREE OPTIONS

Construction Management

• Building option

• Heavy option

Electrical Engineering Technology

• Computer option

Fire Protection and Safety Technology

Mechanical Engineering Technology

39

ENROLLMENT

DIVISION

GLANCE AT

OF

A

Economic Impact

PHOTOS BY CEAT OUTREACH AND EXTENSION UNITS

CEAT’s Outreach and Extension units improve the lives of Oklahomans

Land-grant universities are tasked with educating and informing the communities that surround them. As part of the College of Engineering, Architecture and Technology, Outreach and Extension has been pursuing that mission and reaching its goals since the early 1900s. The department is made up of nine outreach units that include:

Applications Engineers Program (AEP)

Center for Local Government and Technology (CLGT)

Distance Education

Fire Protection Publications (FPP)

Fire Service Training (FST)

International Fire Service Accreditation Congress (IFSAC)

International Ground Source Heat Pump Association (IGSHPA)

New Product Development Center (NPDC)

Professional Development

Together, these units serve all 77 counties of Oklahoma, multiple states and countries to improve people’s lives by sharing their best practices.

“Our college represents the best in technology, science and innovation,” says Ed Kirtley, assistant dean of Outreach and Extension for CEAT. “Outreach and Extension takes that knowledge and those skills, and they serve as the delivery system that sends it out in a way that it can be used.”

All areas of the Outreach and Extension units serve the state of Oklahoma whether it’s in manufacturing, processes, sustainability, safety or other areas. Several extend into the surrounding region, including the NPDC through its work with companies throughout the southeast, and Distance Education with students located across the country. Three units in particular offer resources

CEAT Outreach and Extension has programs that assist the state, region and nation with all types of engineering and technology issues, including road maintenance and fire trainings.

around the world, including IFSAC through its international accreditation programs, FPP with publications in more than 12 languages, and IGSHPA with members in Canada, India, China and Australia.

From small manufacturing companies to international organizations, Outreach and Extension units provide services to all facets of industry. AEP and the NPDC improve processes and equipment for local manufactures while FPP, FST and IFSAC make up some of the largest governing and education groups in fire safety. Distance Education and Professional Development each offer courses for industry workers looking to continue their education, and groups like IGSHPA serve as global partners to the world’s most innovative sustainability efforts.

FALL 2015 40

While the units maintain working relationships with the academic side of the college, Outreach and Extension operates largely on its own as an arm of CEAT. However, this has not always been the case. History has shown that nearly all the units were formed by faculty who knew the college had something practical to offer the citizens who supported it and made an effort to connect those stakeholders with information and services that could benefit the state, region and country as a whole.