The RAPEVINE G

Your Best Viniculture Information Source

See Full Story on Page 27

From Vine to Wine

Fog Crest Vineyard: Breaking Barriers While Leaving a Legacy - Pg 5

Efficiency Uncorked: Sensor Technology Empowers Modern Wineries - Pg 18

If This Was Easy, Everyone Would Do It - Pg 21

Betts Farm Case Study: Cover Cropping in Concord Grape Vineyards - Pg 49

Cover Photo Courtesy of Jensen Precast

Vice

Cyndi

Assistant

Alyssa L. Ochs

Sales

Alyssa L. Ochs

Becky

Contributing

Brad Berkman, Esq. & Louis J. Terminello, Esq.

Marketing WineGlass Marketing

Insurance Agricultural Risk Mgmt, LLC

Bricker Publishing Division of: Bricker Group, LLC 1409 13th Street North Humboldt, IA 50548

E-mail: editor@BrickerPublishing.com Website: www.brickerpublishing.com

The Grapevine Magazine targets the national viniculture market is located in Fort Dodge, Iowa. The Grapevine Magazine is printed bi-monthly & distributed to the most qualified buyers. Opinions expressed in The Grapevine Magazine are not necessarily those of the publication personnel, but of the writers who contribute stories to The Grapevine Magazine. ERROR RESPONSIBILTY: The Grapevine Magazine is responsible only for the cost of the ad for the first incorrect insertion of the ad. Each insertion of an advertisement is proof of publication and it is the responsibility of the advertiser to check the correctness of each insertion. The Publisher shall not be liable for slight aesthetic changes or typographical errors that do not lessen the intent of the ad. No adjustment can be made for advertisements not published. In the event of any error in an ad for which the publisher is liable, the liablility is limited to adjusting that portion occupied by the error in relationship to the entire value of the advertisement. No adjustments will be made 30 days after initial insertion date.

All Contents of The Grapevine Magazine are Copyright © by Bricker Group, LLC

CHANGE OF ADDRESS: Please send new address and phone number along with “The Grapevine Magazine” mailing label or email changes to editor@brickerpublishing.com

If This Was Easy, Everyone Would Do

Viticulture Experience • 24/7 Technical Support • 4 Service Trucks Across the East Coast • 4 Parts Professionals • Massive Parts Inventory • Experienced Sales Team

NEW Clemens Shootbinder NEW Clemens MultiClean

NEW Weberlane Grape Gondola NEW Clemens Single Side Radius

FOG CREST VINEYARD: Breaking Barriers While Leaving a Legacy

By: Gerald Dlubala

In 1996, Rosalind Manoogian and her husband, James, decided to purchase an apple orchard that had been neglected and in disrepair. The orchard was beyond its usefulness, and the choice was to clear it out and replace it with a vineyard that one day might sustain itself through grape and wine production. That initial vision has been realized in a big way for Rosalind Manoogian, president and current majority owner of Fog Crest Vineyards. Manoogian is the first Black female owner and operator of a winery in Sonoma County, California, producing world-renowned, ultra-premium, chardonnay, pinot noir and pinot rosé wines.

“Prior to us moving here, the land was known

for its apples. Before that, it was hops,” said Manoogian. “Grapes were just becoming the hot market when we moved here, so as the property manager, we wanted to do the right thing and follow the market, so growing grapes was a no-brainer. And let’s face it, growing grapes and making wine is sexier than the other options. Since the orchard was past its usefulness, so we spent the first year clearing, cultivating and getting the land ready for grapes. Next, we put in rootstock, then over time, we put in the vineyard, which was 10 acres evenly split between chardonnay and pinot noir vines.”

Fog Crest Vineyard was founded the following

In The Winery

year, in 1997. Located in the Russian River Valley of Sonoma County, California, Manoogian chose the Fog Crest name to pay homage to the dense fog that blankets the valley. The location and terroir of the vineyard is optimal for grape growing. Its rolling hills with a south/east exposure and sandstone-based soil offer excellent drainage and full morning sun. Combined with the cool morning fog that promotes slow ripening, The property had all the essentials for producing premium grapes.

Old-World Tradition Meets Modern Technology

Fog Crest Vineyard celebrated its first vintage in 2005. Manoogian said that while the Russian River Valley’s soils have become recognized as some of the world’s best for cultivating extraordinary chardonnay and pinot noir grapes, they complement that with a combination of old-world traditions, meticulous viticultural practices and modern technology.

“We use the most modern grape-growing techniques available while staying true to tradition in what we produce," said Manoogian. “If you try our chardonnay, you get a definite sense of the wine's traditional nature and structure. We aren’t trying to think outside the box. Our goal always has been and continues to be producing the best ultra-premium chardonnay and pinot noir wines available.”

Fog Crest Vineyard's chardonnays and pinot noirs are hand-harvested in the early mornings to keep the fruit cool. They are meticulously tended to during fermentation and bottled unfiltered after months of intentional care. The winery garnered immediate praise in its early stages. Its grapes were used by renowned winemakers and also bottled under the L’Ancien Verger Vineyard label.

Learning the Business with Help from Mentors

Manoogian admits that she initially had no idea

what she was getting into or what she should do to get started. Starting as a wife in a supporting role, she became thoroughly involved and in charge of the sales aspect by 2009. She went back and educated herself about all aspects of the wine business and the art of selling. Manoogian spent three to four years traveling around the U.S. and Canada selling wine and laughed while recalling some of her adventures while learning about and performing the various roles of the vineyard production employees.

"I was always trying to learn," said Manoogian. "Along the way, I've had, and still have, so many helpful mentors who themselves came from all different backgrounds. That was important and very reassuring as I came from a different background with no agriculture or hospitality experience. Some were mentors from the beginning; others became mentors along the way. There were people who were very kind to me, and that kindness allowed me to learn all aspects of the business, from the farm through production to the table. It was an amazing and fun process, but it was also extremely arduous. I took every opportunity to learn nearly every job within the winery, including picking grapes. And I can tell you that I have nothing but mad respect for our employees because that’s a job that I do not look forward to doing again. Honestly, I’m sure that most days, they were ready for me to get out of their way and stop holding them back. But now I know and understand how all of that works, and I’m good with it.”

A Winery Is a Business of Continuously Moving Pieces

“It’s all part of the process to be able to learn and grow, and for us, I think the last three years have brought about a happy medium of being in business,” said Manoogian. “The tasting room was a big deal for us and me personally. We opened it in 2014, and that meant that people would now travel to come into my space. Not only did they come, but they would also mention that, yes, they knew and recognized our brand and loved it. It was so exciting to hear that, and it made a huge difference in how I viewed owning not only our space, but now also owning a place for others to visit. We grew from

In The Winery

that moment.”

“Over the past years, the wildfires that affected our tourism and the pandemic have made it very challenging for us,” Manoogian continued. “We had to recommit again and figure out how to occupy this place in the way that I wanted to, including our tasting room. I had to figure out a marketing plan on so many different levels, whether it’s social media, print, or being involved in television ads for county tourism. All these pieces go together, and without utilizing all of them, I don’t feel that you're going to be successful in today's market. You have to understand that this is what is required right now. No one tells you that at the beginning. I'm at a place where I can tell people that now, but even as recently as two years ago, I wouldn't have been able to explain that to anyone. It’s not like this type of information is readily available, and frankly, it changes daily. There are a lot of grapes and tasting rooms out there, so you have to figure out how to constantly improve and up your game, no matter what size vineyard or winery you have. You’ve got to make that happen.”

Being Authentic Is Always the Right Thing to Do

“I have to be who I am,” said Manoogian. “I’m always going to focus on the things that brought us into the business and what we care about. So, if I do that, I feel like I’ve met my mission. I’m not going to be able to meet everyone’s goals and desires, but if I focus on those things, I feel like I’m reaching and occupying the space where I want to be.”

“For us, that means we honor the great history and high expectations of the Russian River Valley wineries by making ultra-premium chardonnay, pinot noir and rosé pinot noir,” she elaborated. “Some of the best pinots come out of the Russian River Valley American Viticultural Area (AVA) of Sonoma County, and we are honored to be a part of that group and its history. This space is so unique that although it gets credit from those who know, I still feel like it doesn't get the credit it should. For the rest, it's just a conversation about whether you like my wine, and that has to be enough for

me right now. It’s about finding and defining what you do best and then doing that to the best of your abilities.”

Working for Legacy

Fog Crest Vineyards is the only female Blackowned winery in Sonoma County. Manoogian is currently the majority owner and president of Fog Crest Vineyards. However, that will change by the end of this year, when she will take over 100 percent ownership of the vineyard and become president/CEO of the entire corporation. And it doesn’t end there. She has another brand that she expects to be released later this year as well.

“I also own my land,” said Manoogian. “That’s pretty much unheard of here. We were lucky enough to get here at a time when we could buy the land. But I love this project, and I have grown throughout. Through it all, I am ultimately working for my legacy. I have two daughters and two granddaughters, and I want to build something they can look at and be proud of. I want them to understand why we put in so much effort to reach this point. I do this work right now not because I want to but because I have to.”

Fog Crest Vineyard has won numerous awards in the gold and silver categories. It is located on a picturesque 30-acre plot in the Russian River Valley in Sonoma County. The vineyard is celebrated for its signature wines, including pinot noirs, chardonnays and a unique pinot noir rosé. All visits require a reservation.

To contact or learn more about Fog Crest Vineyards and their ultra-premium wines or Rosalind Manoogian’s story of breaking barriers and setting new standards in the winemaking industry, head over to:

Fog Crest Vineyard

7606 Occidental Road, Sebastopol, CA 95472

(707) 829-2006

info@fogcrestvineyard.com

www.fogcrestvineyard.com

By: Thomas J. Payette, Winemaking Consultant

I Managing pH in Wine

n a recent symposium the speaker stood at the podium. He started his talk saying “If stranded on a deserted island and the island happened to have grapes planted on it, and he were only allowed just three things he thought he could make some excellent wine.” These three items were:

• A wine glass

• An excellent pH meter

• An accurate and precise tool to measure SO2

The above statement gave each attendee at that conference an idea of how important the measurement of pH is to making wine. Understanding the relationship of pH to each wine is very important

for a winemaker to better understand how to handle a wine and to predict where a certain wine’s development may be heading. Using the experiences drawn from past winemaking developments, one will soon understand how pH is a major factor to consider when making wine.

What is pH?

pH is a numerical measurement of the acidity or alkalinity of a chemical solution. The measurement is of the hydrogen ion activity and it is logarithmic. This understanding is all the reader needs at this time. Going much beyond this understanding may only bore the readers and discourage them

In The Winery

from moving forward in their reading. For more in depth knowledge of pH – feel free to research it.

What is a normal pH Range for a wine?

Most wines range between a pH of 2.90 and 4.00 with the large majority of wines ranging between 3.20 and 3.80. Red wines will often be more near 3.40-3.80 and whites wines will normally be in the range of 3.20 – 3.58. Some wines will stretch these limits but most will conform. Winemakers must intervene, as needed or desired, to bring the wine back into the proper pH range.

What Influences the pH of a Wine?

The grape condition: how those grapes are grown, potassium levels in the grapes, maturity level and skin contact after harvest (crushing) will be some of the largest influences on the wine pH.

Grape condition: Wine grapes that have been allowed to hang will often show an increase in pH moving toward a pH of 4.00 and sometimes higher. Most winemakers get increasingly nervous as pHs near 3.70 on red wines unless the tannin and anthocyanin structure are intense enough that the wine has some protection. This protection is often from the antiseptic and oxygen scavenging properties of the tannins and deep color compounds.

How the grapes are grown: Many factors from the soil, weather, amount of water at the root zone and other factors will affect the pH of the wine. These relationships need to be studied further to be conclusive, but many factors may be controlled in the vineyard to help achieve the pH desired at harvest. Much of this is related to canopy management. Fruit that is grown in dense canopies with greater shading are more likely to come in at a higher pH than their exact same counterpart with hedging and some light exposure on the fruit zone.

Potassium Content: The potassium content of the grapes may have an influence on the pH of the wine and more importantly the ability of the winemaker to adjust the pH. When grapes are produced on a vine, research has shown only a certain amount of leaf surface area is needed to bring the

grapes to ripeness. Canopy density and leaf surface area beyond the amount for fruit maturation needed has shown to increase the level of potassium in the fruit. This potassium may result in higher pH’s in the mature fruit but more importantly offer a buffering capacity in the wine. This buffering capacity will be a challenge to a winemaker dealing with a wine that has a relatively high titratable acidity and a high ph. The winemaker may do a tartaric acid addition trial to a batch of wine then find more acid is needed than predicted to achieve the pH desired. This is a result of the buffering capacity resisting movement of the pH with each incremental addition of acid. This is one of the many reasons winemakers should find themselves in the vineyard as much as possible working with the vineyard manager to show the vineyard crew how a wine may get out of balance and not have chemical stability with the higher pH.

Maturity and Malic acid: The maturation process of most wine grapes is another factor that tends to affect the ph. As wine grapes mature, more malic acid, especially in warmer climates, will respire leaving more tartaric as the principal acid. Winemakers watching this rise in pH on the fruit are urged not to worry too much. This decline in malic acid does result in a higher pH of the fruit at harvest but it will often result in less of a shift of the pH upward after malo-lactic fermentation. The reason is there is less malic in the wine to be consumed by the malo-lactic bacteria and therefore less of a shift while converting malic acid to lactic. This principal applies mostly to red grapes but it can have applications to white wine making as well. The reader should keep in mind this malic shifting process happens in warmer climates mostly and less so in cooler climates.

Skin contact: Skin contact is another less mentioned factor when speaking of influencing the wine pH. Juice in contact with the skins after crushing will start to show a rise in the pH soon after crushing. This process will be more rapid and directly related to the temperature of the must. For this and many reasons most winemakers prefer to press just after crushing white wine grapes and some prefer whole cluster pressing.

In The Winery

pH shifts during alcoholic fermentation

When the juice is pressed off a white wine grape or red wine grapes are crushed, an alcoholic fermentation is usually started soon after with yeast. Alcohol has a higher pH than sugar so it stands to reason that as a wine ferments the pH will start to rise. Often, one will see a shift upward of about 0.15 to 0.22 in pH so a juice starting at a pH of 3.2 could result in a wine of about 3.40. This tends to stabilize while under a pH 3.65 as the tartrates precipitating out of solution will help counteract the pH shift upward from the alcoholic fermentation. Restating - the pH will rise upward during alcoholic fermentation and then drop while cold stabilizing the wine often bringing our pH back to near the original value at harvest in the juice in this example.

pH Shifts During Malo-Lactic Fermentation

After alcoholic fermentation, depending on the wine being made, the winemaker may want to induce a malo-lactic fermentation. This is often to reduce the acidity of a wine and to soften the wine by reducing the malic acid content to levels of unfermentable malic acid left over. The malic that is converted will transform to lactic and provides a pH shift upward in most cases. Many wines will shift upward by about 0.20 ph units. This is directly linked to how much malic was present prior the malo-lactic fermentation and how much was consumable by the Malo-lactic bacteria. Quantitatively measuring the malic acid prior to inducing the malo-lactic fermentation will give the winemaker a better rough idea as to how much pH shift to expect once completed.

3.62 Bifurcation

As noted in a previous addition of The Grapevine Magazine in the “Cold Stabilization article” a very interesting phenomenon does exist in grape wine when the pH of the wine is near roughly 3.62. This is more directly related to how the pH will react during cold stabilization as potassium bitartrate crystals form and precipitate out of solution. When a grape wine is below 3.62 and potassium bitartrates fall out during crystallization and precipita-

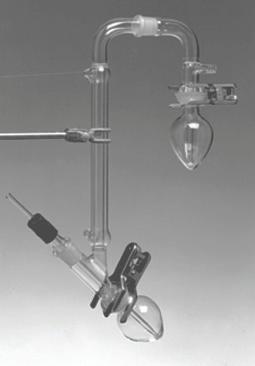

Glass Apparatus for the Wine Laboratory

Acclaimed by enologists across the continent!

The RD80 Volatile Acid Still, which now is the Wine Industry standard, is an improvement on the Cash Still for determination of volatile acids in wine. It features an aspirator pump to remove the spent sample, which speeds testing, saves water, avoids repair bills and prevents cross contamination of samples.

The R&D SO2 Apparatus uses the Aeration Oxidation Method to maximize testing accuracy. It was specifically designed for this mandated test in consultation with enologists.

Flexible spherical joints and interchangeable flasks facilitate simple operation and minimize breakage.

We manufacture a full line of wine laboratory equipment, and also provide Glassware Design Engineering, Custom Fabrication & Repair Services. CONTACT US FOR OUR CATALOG

Research & Development Glass Products & Equipment, Inc.

“Suppliers of Lab Glassware to the Wine Industry since 1967” 1808 Harmon Street • Berkley, CA 94703

Phone: 510-547-6464 • Fax: 510-547-3620

Email: RD1967@aol.com • Website: http://go.to/RandD

tion the wine pH will go down. Conversely – when a wine pH is above 3.62 the pH will shift upward while the tartrates fall out. Keep in mind this may happen in portion during the alcoholic fermentation as the alcohol level goes up.

pH and Sulfur Dioxide

The use of Sulfur Dioxide is closely related to the pH value obtained on a certain wine. Wines with lower pH values will need less free sulfur dioxide added to them in order to do the job needed. Conversely wines at a higher pH may need more SO2 to protect them properly. Another interesting factor with sulfur dioxide does exist on a very small level. When sulfur dioxide reacts with oxygen it will form H2SO4 or sulfuric acid. This can have a very small effect on the pH of a wine, especially longer aging reds, in the wine production cellar.

pH and Sorbic Acid

Sweeter wines will often have potassium sorbate (sorbic acid) added to them to prevent any refermentation issues with that wine. These sorbates may be used in conjunction or the absence of sterile filtration. When using sorbates one may lower the amount used if the pH is lower. An example may be: a clean “yeast free” wine at pH 3.10 may only need 150 ppm sorbic acid to avoid a refermentation issue. This is closely linked to the SO2 value measured at bottling and post bottling. Oxygen pick up must be moderate to little in order to preserve the bottled wine. Sulfur Dioxide and Sorbic acid work together to prevent yeast fermentation.

Aging Ramifications

Wines at lower pH values will generally age slower than wines of higher pH values. This is true of wines treated the same. A red wine at a higher pH value may soften and age faster. Some reds may develop a brickish color on the edges. Try to avoid this and treat wines with a higher pH in a delicate fashion. Use protective oxygen avoidance measure to help slow the rate of oxidation. Conversely wines with lower pH may age slower yet may be handled best as well in the absence of oxygen.

pH and Micro-organisms

The higher the pH of a certain wine, the greater the chance that wine may succumb to a potential unwanted wine microbe. At higher pH’s a whole host of other bacteria may grow in the wine ranging from lactobacillus, dekkera, acetobacter, brettanomyces and Low Acid Bacteria just to name a few. So, as our wine pH values increase, we open ourselves up almost exponentially to other potential bacteria issues. Many of these can greatly change the quality of a wine in a negative fashion. When monitoring your wine pH’s in the cellar – be aware of which wines are higher and keep a special eye on those wines.

Mouthfeel

To build confidence with your palate, learn to relate how the mouthfeel is at certain pH’s. One cannot taste pH yet one can taste acidity and make general assumptions about the pH. A nice balanced wine may actually have a higher pH lending toward a broader mouthfeel. This is true with Chardonnay as well as Viognier. Many reds may do well with higher pH’s if the body, tannins and structure support to give backbone to the palate.

Measuring pH

The reader is encouraged to obtain a very nice, precise and accurate pH meter with automatic temperature compensation for his or her lab. Calibrate this unit often and most likely daily when used. This is a critical measurement in winemaking and obtaining the proper measurement is imperative to make sound winemaking decisions. Be sure the sample is free of any Carbon Dioxide during measurement because that may interfere. The meter should measure to the 100th for example 3.46. Invest in a great meter and use it often.

Summary

Keep an eye on your pH’s while growing your grapes and making wine. This tool is of greater importance than most winemakers may think. Managing the grape’s pH in the vineyards can be a first step and taking action in the cellar should be

Tom Payette, a premier hands on and analytical winemaking consultant, serves clients throughout the United States.

• Award Winning

• Wine Chemistry

• Refined Palate

• Great Communicator

• Winery Construction

• Winery Rescue

the next protocol. Get a firm understanding of how the pH’s react to each process in your cellar mentioned above to make the best wine possible.

The next issue will be on How to Raise the pH of your wine. Till then – be well.

References:

Amerine, M.A., Berg, H.W., Cruess,W.V. 1972. The Technology of Wine Making

Dharmadhikari, M.R., Wilker, K.L. 2001. Micro Vinification.

Zoecklein, B.W., Fugelsang, K.C., Gump, B.H., and Nury, F.S. 1999. Wine Analysis and Production

Verbal conversations with Jacques Boissenot, Jacques Recht, Chris Johnson and Joachim Hollerith.

I Exploring the Varieties of Oregon’s Pinot Noir Wines

n 1961, Richard Sommer planted pinot noir vines along with other varieties at the HillCrest Vineyard in Roseburg in Southern Oregon, thus establishing HillCrest as the state’s oldest currently operating estate winery and vineyard. UC Davis graduate David Lett followed suit four years later by planting both pinot noir and pinot gris at The Eyrie Vineyards in McMinnville, situated in the heart of Oregon’s Willamette Valley.

Since then, pinot noir grapes have emerged as the dominant wine grape grown in Oregon. According to the Institute for Policy Research and Development at the University of Oregon’s 2022 Oregon Vineyard & Winery Report, 26,648 acres

By: Becky Garrison

of pinot noir grapes were planted out of a total of 44,487 acres. From these plantings, the Willamette Valley produced 61,928 tons of pinot noir fruit, with the Rogue and Umpqua Valleys producing 14,490 tons. (The Oregon Wine Board underwrote and managed this report on behalf of all Oregon wineries.)

Terry Brandborg of Brandborg Vineyard & Winery (Elkton, Oregon) offers a succinct summary of this elegant grape that originated in the Burgundy region in France:

"Pinot noir has everything you could want in the glass — great red fruits, ripe cherries and raspber-

Photo Credit: Michael Alberty

ries with red plums. The color is typically not dark red, but in the mouth, it always surprises with its full body, flavors and textures. One writer once described our pinot noir as "elegant and seductive with a feminine grace." It is a great accompaniment to a great variety of foods, including cheeses, grilled salmon, lighter meats and savory brined pork".

The Growth of Oregon’s Pinot Noir Wines

As Karen McNeil reported in The Wine Bible (Workman Publishing, 2022, 3rd Edition), one of the key drivers behind the vast improvement in Oregon wine in the 2000s was the widespread implementation of so-called Dijon clones. “Named after Dijon, the city in Burgundy where France's ONIVINS plant materials laboratory is located, the numerous Dijon clones (with exciting names like 115, 667 and 777) are heralded for their complex flavors and ability to ripen fully in cool climates. In addition to Dijon clones, Willamette Valley pinot noirs are also often made from the Pommard clone, another well-suited clone from Burgundy.” Other clone varieties planted in Oregon include Wadenswil and Mariafeld.

Blending Pinot Noir Clones

The specific clones tend not to be listed on a bottle of pinot noir, though one’s skill as a winemaker can be seen based on the selection and blend of the specific clones used in a given release. On their website, WSET (Wine & Spirits Education Trust) states that the world’s greatest winemakers relish the opportunity to blend wines from different grape varieties, vineyard parcels, and barrels each year. “Masterful blending is an art form comparable to a Michelin star chef creating the perfect dish or an elite conductor crafting an exquisite symphony. It lies at the heart of the world’s greatest wines, from Bordeaux and Champagne to Rioja and Super Tuscans.”

As a means of educating consumers about the blending process for pinot noir wines, Willamette Valley Estate Vineyard in Turner, Oregon decided to give consumers a very hands-on tangible blending experience through their blending machine that shows them how different wine profiles can be. The unique system was invented for Willamette Wineworks in Folsom, California, and modified by Willamette's Research & Development Manager David Markel. It was a hit at their Folsom location,

so they adapted the fun to their Salem Hills and Vancouver Waterfront locations. In their estimation, “Blending adds texture and complexity to wine and allows winemakers to balance wines with body and acid, a hallmark of Oregon wines. Blending can help to maintain consistency so wine enthusiasts can rely on flavor profiles from their favorite wine producers.”

Willamette Valley Pinot Noirs

Initially, skeptics dismissed Lett’s initial planting of pinot noir grapes. The prevailing wisdom at this time viewed this region as unsuitable for growing this particular varietal.

According to a much-touted popular myth, the Willamette Valley emerged as a premier location for producing pinot noir grapes because it sits on the same latitude as Burgundy, replete with a similar cool climate. Mallory Smith, co-founder of Sunday School Wine, debunks this myth by pointing out that the Northern Rhône is the region in France that sits at a similar latitude to the Willamette Valley, not Burgundy. Hence, it’s not the latitude but the combination of the climate, the soil and the dedicated winemakers that combine to produce world-class Willamette Valley pinot noir wines. Smith opines, “Why do we still feel the need to rely on a Burgundy story (and an untrue one at that) to validate our wines? Let Oregon be Oregon!”

This region, which stretches from north of Portland to just south of Eugene, is protected from the extreme heat via the Cascade Range to the east (and cooled by the Van Duzer winds through the corridor straight off the ocean) and the Coast Range Mountains on the east producing rainstorms with cooling breezes emanating from the Pacific Ocean. Overall, the region experiences a long and gentle growing season due to warm summers that cool down in the evening, followed by relatively mild winters and long springs. Also, most of the rains tend to fall when these vines are dormant. This slow ripening coupled is key for producing topnotch ripe and fruity pinot noir grapes. As evidence of this area’s commitment to sustainability practices, the Willamette Valley is home to the largest concentration of B Corp Certified wineries than any other region in the world.

Since the formation of the Willamette Valley AVA in 1984, this region has grown to encompass 1,116

In The Winery

wineries and 1,476 vineyards, with a total planted area of 27,202 acres out of a total area of 3,438,00. To acknowledge the unique characteristics of smaller regions within the Willamette Valley AVA, six nested AVAs were formed in 2002, and the 11th nested AVA was established in 2022. Pinot noir grapes dominate the vineyards, accounting for 70 percent of all grapes grown in the WV, followed by pinot gris (16 percent) and chardonnay (7.5 percent).

Joe Wright, winemaker for Left Coast Cellars (Rickreall, Oregon) has done 28 vintages working with fruit from both the Willamette Valley and Southern Oregon. He produced his first vintage for Willamette Valley Vineyards in 1996 before starting his winery, Belle Vallé, and transitioning to Left Coast in 2011. While the Willamette Valley produces some of the most complex and interesting wines, Wright adds that this region also presents endless challenges in the vineyard. “Winegrowers sit at the edge of our seat every week and month of the growing season anticipating the rise and fall of each vintage, ultimately embracing what's been given to us...it's not for the faint of heart.”

Wright has observed how, in the past ten years, temperatures over 90°F have increased exponentially from, on average, 12 to 20 days per growing season to 20 to 35 commonly taking place now. Also, days of over 100°F were zero to one over the growing season but are now commonly two to five days on average, occurring later into the season. In addition, precipitation has seemingly lessened in the spring and fall on average. Wright can see how these factors take a toll on fruit set and fruitfulness, fruit integrity and disease resistance.

Aaron Lieberman, Winemaker for Iris Vineyards (Cottage Grove, Oregon), has also made wine with fruit from many of the AVAs in Oregon. Beyond the normal challenges inherent to growing pinot noir, Iris Vineyards Estate is a cool site that can be susceptible to frost damage in the spring. The estate vineyard is located in the coastal mountain foothills at about 1,000 feet elevation.

Following the 2020 vintage, the price per ton of Willamette Valley pinot noir grapes increased substantially. Iris Vineyards saw an opening in the market for a Rogue Valley pinot noir that could retail between $22 to $24 and still be profitable. General manager David Cordtz looked to source fruit from

some of the finest Vineyards in the Rogue Valley. This venture allowed them to grow their overall production sustainably by sourcing fruit. “We have been sourcing fruit from all over Oregon for years. We sourced pinot noir from Rogue Valley so we could produce a different style of pinot noir, something between Willamette Valley and California, at a price point to fulfill a wholesale opportunity both in Oregon and in many of the 20 states we offer Iris Vineyards wines," commented Cordtz.

“These grapes are unique to us for their warm climate provenance. The pinot noir produced from Rogue Valley is a little fuller bodied than most of our Willamette sourced wines and has a bolder flavor profile," Lieberman observed.

Southern Oregon Pinot Noirs

Established in 2005, the Southern Oregon AVA may be known for growing warmer-weather grapes, though certain locations within the Rouge Valley and Umpqua Valley sub-AVAS have ideal microclimates for growing pinot noir and other cool-weather grapes.

For example, Stephanie Pao, winemaker for Foris Vineyards (Cave Junction, Oregon), found their location on the west side of the Rogue Valley AVA at 1400 feet elevation affords them a long, warm growing season that is ideal for early ripening varieties like pinot noir. The specific sites where their grapes are planted are in well-draining alluvial soils that are primarily gravelly or rocky, which restricts growth and tends to produce wines with greater intensity and character. Depending on the timing of phenological events, the wines tend to be fruit-forward (black or red, depending on the vintage) with lower natural acidity than the northern part of the state.

Rob Ikola of Whitetail Ridge Vineyard (Roseburg, Oregon) and Chris Hudson, Umpqua Valley Association President and owner of Lexume Wines (Elkton, Oregon), observe how the Umpqua Valley AVA enjoys enough heat degree days to fully ripen yet achieve long hang time to develop complex wines such as pinot noir. This AVA has a long frostfree growing season with light rains, a large selection of soils, and valleys with a variety of growing conditions. Small, unique microclimates (called the 100 valleys of the Umpqua) create very diverse and unique differences even though the same varietal is

grown within a few miles of each other.

According to Brandborg, pinot noir grapes and other cool varieties thrive in the northern area around the town of Elkton due to the cool, marine-influenced climate. His vineyard receives around fifty inches of annual rainfall, making irrigation unnecessary. Also, the central area to the northwest of Roseburg has a transitional intermediate climate where both cool and warm varieties do quite well.

In Brendborg’s view, site selection is very important. “Pinot noir is a thin-skinned variety and requires attention in the vineyard, with fungicide spraying as needed to avoid problems. If all of these factors work out together in harmony, world-class wine can be produced,” he reflects.

Scott Kelley, co-owner/winemaker of Paul O’Brien Winery (Roseburg, Oregon), notes how pinot noir in the Umpqua Valley is a spectacular representation of the best of Oregon. “The balance of power and elegance we showcase in Umpqua Valley pinot noir is rarely seen in other regions. There are so many

great vineyard sites yet to be planted,” he observes.

The Rise of Pinot Noir Rosé

In recent years, pinot noir rosé wines from Oregon have risen in popularity. These wines offer a cool, crisp taste with a refreshing, clean finish that stands out from the sweeter rosé wines on the commercial market. As an example of the range of wine styles that can be made from pinot noir grapes, Brandborg produces a white pinot noir, red, rosé of pinot noir, a methode Champenoise pinot noir and a port-style dessert pinot noir. “People are on a path of discovery about all pinot noir can be and bring,” Brandborg opines.

Automation systems leverage real-time sensor data to maintain precise control over critical production variables throughout the winemaking process.

Efficiency Uncorked: Sensor Technology Empowers Modern Wineries

By: Aaron Ganick, BrewOps

Using modern sensor technology in wineries enhances efficiency and consistency. These advancements allow winemakers to focus more on the creative aspects of their craft while ensuring the production of high-quality products that delight customers year after year.

Automation systems leverage real-time sensor data to maintain precise control over critical production variables throughout the winemaking process. Consistent monitoring and control are crucial for maintaining the flavor, quality, and integrity of the wine. Automation empowers operators to make data-driven decisions, enhancing efficiency and ensuring uniformity across all processes, ultimately enabling wineries of all sizes to produce

high-quality, consistent products.

In addition, automation helps wineries reduce product and material waste, minimize unexpected equipment downtime, and increase sustainability. Sensor technology optimizes the use of raw materials and energy, further reducing expenses in modern wineries and vineyards. Automated systems allow wineries to scale their operations more easily. As demand grows, these systems can be expanded or upgraded to handle increased production without a proportional increase in labor costs.

Modern sensing and automation technologies provide continuous, real-time data that was previously unavailable, capturing metrics such as

pressure, temperature, pH, oxygen, and conductivity. This wealth of continuous data allows for a deeper understanding of individual processes, which would be impossible with traditional discrete sampling. By synthesizing collected data into actionable information, winemakers can identify trends, troubleshoot issues, and make precise adjustments to optimize the winemaking process. This enhanced control over critical parameters ensures the consistent production of high-quality wine and enables continuous improvement and innovation in winemaking best practices.

Automation has expanded beyond the manufacturing floor into the cultivation and harvesting processes within agriculture and farming. What was once only available to high-tech production facilities is now ubiquitous indoors and out. Sensor technology enables continuous monitoring of soil, vegetation, and atmospheric conditions, allowing for precise regulation of irrigation and fertilization in response to environmental changes. By comparing current and historical data with predictive models, farmers can optimize the timing of the harvest season, improving yield and quality while reducing resource usage. Modern automation technologies are now accessible to wineries of all sizes, enhancing efficiency, consistency, and sustainability. These advancements allow winemakers to focus on their craft while ensuring high-quality production through precise control over critical variables. Automation reduces waste, minimizes downtime, and optimizes resource usage with realtime data, enabling informed, data-driven decisions.

Top 10 Benefits of Using Sensor Technology in Wineries

Enhancing efficiency, quality assurance, and overall operations are just a few of the benefits of using sensor technology in a winery. Here are a few specific examples of how automation benefits each step of the winemaking process:

1. Vineyard Management: Moisture sensors monitor soil water content to optimize irrigation, while weather stations track environmental conditions such as temperature and humidity. These technologies help improve yield by ensuring optimal growing conditions.

2. Harvesting: Hand-held refractometers are used to measure grape sugar levels (Brix) to determine the optimal time to harvest. Some wineries use GPSenabled tools to assist in planning and executing

In The Winery

BIG WINERY TOOLS FOR SMALL WINERY BUDGETS

VinNOW® is a complete, integrated, winery software solution! One program using one database. VinNOW® lives on your computer or in the cloud. We have the capability of hosting the database.

Unlimited FREE Live Support & Training

Easy to Use Features:

• Wine Club

• Point of Sale

• Customer Management with History

• Credit Card Processing

• Shipping & Compliance

• Inventory Management

• Extensive Reporting

• Marketing & Email Campaigns

• QuickBooks Integration

• Integrated Shopping Cart

• Bulk Wine & Custom Crush Module Also Available

VinNOW® increases productivity & helps wineries grow their business.

In The Winery

3. Sorting and Destemming: Portable optical sorting devices use cameras to sort grapes by size and quality, ensuring only the best fruit is used. Destemming machines efficiently separate grapes from stems.

4. Crushing and Pressing: Automated crushers and presses equipped with pressure sensors handle moderate volumes of grapes—ensuring efficient juice extraction while minimizing oxidation. These machines apply the optimal pressure for different grape varieties.

5. Fermentation: Temperature sensors and pH sensors monitor and control fermentation conditions. These sensors can be connected to control systems or smartphones to ensure consistent fermentation by tracking key metrics such as temperature and acidity.

6. Clean-in-Place (CIP) Sanitization: CIP systems using pressure, temperature, and conductivity sensors to ensure the thorough cleaning of tanks and equipment, reducing manual labor and minimizing contamination risks.

7. Racking and Clarification: Automated racking pumps with built-in pressure sensors precisely transfer wine between vessels, reducing oxidation and contamination risks. Filtration systems ensure clarity and stability in the final product while monitoring dissolved oxygen to reduce the risk of oxidation from leaks in the system.

8. Aging: Humidity and temperature sensors are used to monitor aging conditions in the cellar. Smart sensors send alerts if conditions deviate from desired levels, ensuring optimal aging, while providing 24/7 peace of mind for operators and owners.

9. Bottling: Semi-automatic bottling machines with sensors for volume control ensure consistent filling. Continuous quality monitoring is enabled by sensors for washing, filling, corking, labeling, and pasteurization of bottles.

10.Packaging and Distribution: Automated packaging tools like label printers and bottle cappers streamline the packaging process. Inventory management software integrated with sensors

can provide facility efficiency by tracking stock levels and automating orders to ensure reliable distribution.

Automation Empowers the Modern Winery

The options for automation technology in wineries are vast but can quickly become expensive with advanced mechanical automation and customized integration. Starting small, focusing on the ROI for each system, and quantifying repeatable metrics are critical to creating sustainable benefits. From soil moisture sensors for irrigation to drones for monitoring plant growth and blockchain for supply chain traceability from grape to glass, automation is now accessible to all. Winemakers should choose technology that is quick to install, easy to integrate, and scalable to grow with their business needs.

Using sensor technology and automation, wineries of all sizes can make data-driven decisions to enhance efficiency and processes, while creating tasty experiences that deliver year after year.

About the Author

Aaron Ganick is a serial technology entrepreneur and the founder and CEO of Preddio Technologies, the parent company of BrewOps. Aaron holds a degree in electrical engineering from Boston University and has authored dozens of granted patents in the fields of optical networking, telecommunications, and automation systems. He can be reached at aaron.ganick@brewops.com. For more information on BrewOps, the fast and easy-to-install brewery automation platform, visit www.brewops.com.

If This Was Easy, Everyone Would Do It.

By: Susan DeMatei, founder of WineGlass Marketing

Setting expectations is difficult. After all, we all want perfection and success, so isn’t it just positive thinking to predict that your campaigns will be victorious? That’s what “The Secret” tells us, anyway.

But while it can’t hurt to take a stab at manifesting abundance and contemplating gratitude, you are likely using more concrete values, such as benchmarks and previous performance, to project the results of your marketing campaigns to your management.

We submit additional data points to anticipate reasonable responses to your marketing campaigns. These data points are:

• What environment exists around this campaign?

• What workload can I reasonably handle successfully?

• What does my management consider, including the cost of goods sold?

Let’s break each of these down and include some real-life winery examples.*

CONTEXT: What Have you Done for me Lately?

Many marketing decisions are best made with data. Your database is your guidebook; you should know the segments within, their values, and their behavior. Historical data empowers you to make informed decisions. If you don’t have it, that’s fine, but then expect a low degree of certainty in your predicted response. You should test some targeting, offers, and messages to learn what your data-

Around The Vineyard Business & Marketing

base responds to.

But along with performance benchmarks, it helps to know the history of communication with your customers. Don’t expect them to wake up quickly if you haven’t talked to your database in a predictable cadence or included information about your brand, people, or location to engage them. Customer communications are like any other relationship: the dialog needs thoughtful nurturing. If you only reach out when you have something you need (selling wine), your recipients might turn deaf to your calls to order.

Take the case of a recent boutique client who, because of the current economic conditions, had cut all social media and emails out over the past two years. Without a tasting room, he felt it prudent to stop all marketing until his new vintage release. It had been a year since his last email, two years since his last social post, and he was ready to release his next vintage. We recommended warming up the audience weeks ahead with updates about the brand, the people, the vintage, and the vineyard. Why spend time on this step? Because you remind consumers who you are and why they fell in love with you in the first place. He declined, citing that he wanted to avoid spending money on any activities that were not about sales.

We also recommended we launch a low-level advertising program to gather new mailing list signups from Meta for a few hundred dollars. Why? We know that databases naturally decay at a rate of about 2% a month, and with such a long hiatus between touchpoints, there would likely be a fair amount of database degeneration. Meta is the most efficient channel for adding contacts to a database without a tasting room. He also declined this recommendation, insisting we send the email to his database to launch the new wine. It was a beautiful email. He obsessed over every line of copy and took time in the design. It was perfect.

The database did not return with one single order. It did result in a 10.5% bounce rate (wrong addresses), a meager 6% open rate, and zero clicks. He had expected sales to be like previous years before he cut out all consumer communication. He learned marketing isn’t a faucet you can turn on and off, and one single channel is only part of the story. The sales may come in from an email, but each transaction is influenced by social media

posts, emails about the brand, texts on events, or other communications that keep your consumers interested and engaged with your winery. Without hearing from the winery in almost a year, the response was silence when the time came for the new release.

The parable? Keep up with your marketing –especially now. When you need sales post more, communicate honestly and resist the urge to shrink back into a shell to wait out the storm. Over time, if you share information of value on a consistent schedule with consumers, they will become reliable buyers. This ongoing two-way communication is a responsibility and a commitment, but it’s worth it in the long run. How long, you ask? In our experience, it takes six to nine months of repetition and best practices to train a database to open and click on your emails to the benchmark standards we share here.

WORKLOAD:

If We Could Hold Time in a Bottle.

It is possible to do everything right, and still be disappointed. Another client recently came to us wanting to use Enolytics for email segmentation. Typically, they had launched one mass email each quarter to their entire database and wanted to learn if breaking it up into segments would bring in more sales. They were specific about the goals – they wanted 4x the cost (our fees) in sales. We dove in, quickly outlined a half dozen segments we wanted to try with email offers, and began the program. From the first week of May to the first week of July, we executed eight emails to micro-segments and brought in over $60,000 in

sales – almost 5x our fees. When we paused for a mid-program touch base, we were surprised when the program was canceled.

Why? They explained that executing eight emails instead of one was a lot of work for their team, which was not set up to work with an agency daily, reviewing copy and images and supporting the resulting sales and customer queries the campaigns created.

This highlights our second expectation variable— time. Yes, segmentation is effective, and yes, best marketing practices take time and thought, so prepare for that. Set reasonable internal expectations for the time and effort it takes to support smart marketing.

COGS:

Rhymes with Dogs, but not as Awesome.

What your winery considers costs can vary. Typically, the Cost Of Goods/production costs aren’t up for debate. The cost for grapes by ton, barrels, and storage are documented and outlined in the COO’s spreadsheets. However, the Cost Of Goods Sold is another number entirely, as when marketing gets involved, it becomes less defined. A tasting room is likely the most expensive channel to sell if you add up the mortgages or rent, staff, overhead, groundskeeping, utilities, etc. But few wineries consider that. Why are wineries quick to ignore some costs but then obsess about advertising dollars or outsourcing fees?

Our third example is on this topic, which we battle with frequently. We worked with a substantial Napa Winery, which, seeing tasting room traffic wane, wisely wanted to test whether they could attract consumers to buy wine over $100 purely online. Up for the challenge, we outlined Meta and Google ads and set up for a three-month test. We aimed to sell a three-pack of wine online to brandnew people outside their database.

At the end of the test, we had spent $7200 and brought in $21k in sales—or a ROAS of 2.89. We were thrilled as the average Return on Ad Spend is around 1.5 for Google and 1.7 for Meta. But we were up for a surprise when our client did not consider the campaign a success. Why? Because they included our cost along with the ad spend, which made it closer to breaking even.

There are a couple of breaks with logic when including outsourcing fees in your cost of goods sold, and I’m not just saying this to defend our costs. (Ok, maybe I am a little bit.) First, when your employees execute programs internally, it isn’t free. There is still a cost to having employees. You need to include or exclude consistently. The second flaw is that you don’t take a break and go home early when adding outsourced support. No, you are freeing yourself or your team to do other critical tasks of value. So instead of considering outsourcing as just a drain on funds, look at it as paying to accomplish a goal.

Another point this winery missed was lifetime value of these customers. Remember that the future value of these 42 new consumers is still being determined. Two months later, seven ordered again, and now are a total value of $30k and 50 orders.

BRING IT HOME

I will leave you with a last cautionary tale combining all three above areas into one misadventure. This involves a very successful central California winery with multiple locations. They intensely focused on traffic to their tasting rooms but needed to create a thoughtful remarketing email program. Since the last marketing manager left, they had not routinely emailed their database in over 18 months. As predicted, the database was sluggish in responding initially, but as our segmentation and repetition continued, we saw sales increase more readily. We micro-targeted groups of 300 – 1000 based on recency and product choice. The client was dubious, and we routinely had to remind him that with small lists come small sales. (After all, a 5% response on a list of 350 recent buyers of a certain SKU is only about two orders). After two and a half months, we had made back the money spent on our retainer and were just starting to see the database respond, but the client pulled the plug, saying the test was “a disaster.” Why? From his point of view, he said he could have done nothing and been in the same spot. I’m sure that is true, but it’s unclear how they’d ultimately succeed sitting on cases of unsold wine with no customers!

Since they hadn’t done much online sales before, I inquired about his internal barometer for online sales success, to which he replied 4x our retainer

Around The Vineyard Business & Marketing

cost. I asked him if he included his own employees’ costs when evaluating the tasting room channel, to which he replied, “That’s none of your business.”

This example combines so many mistaken assumptions about marketing. First, a conjecture that marketing performs immediately at full steam. Second, an lack of understanding that regular segmented emails do bring a higher % of conversions, but realizing the lists are smaller so the number of sales might seem small. (But, they add up.) Third, the inconsistency of including manpower cost in one channel but not another. Finally, unrealistic metrics for success. I have heard some creative KPIs before, but never that marketing shouldn’t cost anything – that the benchmark was comparing any marketing costs to the cost of doing nothing. Doing nothing will always be cheaper. And easier.

What’s the point of my rant? Well, I got to vent, so if you made it this far, thanks for that. But know there are no tricks. There is no silver bullet. There is no magic tool, database, or platform that will bring you thousands of dollars. Like all things in life, selling your wine takes thought and focus. Marketing is a process that takes time – assume 6-12 months. And money – assume 5% of your gross sales. And effort – sometimes yours, sometimes others. But if you set reasonable expectations and communicate your goals, you can succeed by improving over time.

Ultimately, the cost of not doing marketing is assuredly failure, which is a far greater cost than anything you might risk with a few ads or emails.

Susan DeMatei founded WineGlass Marketing; the largest full-service, award-winning marketing firm focused on the wine industry. She is a certified Sommelier and Specialist in Wine, with degrees in Viticulture and Communications, an instructor at Napa Valley Community College, and is currently collaborating on two textbooks. Now in its 12th year, her agency offers domestic and international wineries assistance with all areas of strategy and execution.

WineGlass Marketing is located in Napa, California, and can be reached at 707-927-3334 or wineglassmarketing.com

By: Brad Berkman and Louis Terminello, Greenspoon Marder

A The Contract Packaging Agreement

few times on these pages, we’ve written about contracts of various types to assist brand owners in proper planning for brand manufacture, introduction and distribution. In this article, we’ll take something of a deeper dive into production agreements in a contract package or custom crush arrangement.

First, building a winery, and perhaps developing a vineyard, is an extraordinarily time-consuming and expensive process. Returns on investment may take many years to see back. In addition, winemaking (as well as brewing and distilling), is a manufacturing process that requires great deals of expertise, technological know-how and a deep appreciation for the art form. Taking a brand to market and getting placed on wine lists and by-the-glass programs require a very different set of skills. Enter: the brand owner and the contract package relationship.

It’s worth noting that brand owner, though a common term in the industry, is also a term of art in the beverage law. Since the writers of this article are striking their keyboards in Florida, we’ll refer to Florida Beverage Law for quick analysis.

561.42 FL. Stat. makes the first reference to “brand owner” in the Florida Beverage Law. The statute is Florida’s tied-house evil statute prohibiting direct and/or indirect interests between upper-tier industry members and retailers. Brand owners are lumped in and treated similarly to manufacturers, distributors, importers, primary American sources of supply, registrants, and/or any broker or sales agent or salesperson. By this definition, brand owners, absent the presence of a statutory exception, are treated as upper-tier industry members and subject to tied-house laws and restrictions. This is generally true in all states.

Brand owners, when appropriately licensed, are permitted to enter into contract packaging agreements with manufacturers. Both are upper-tier industry members and certain tied-house restrictions are inapplicable. Prior to finalizing the production agreement, a federal wholesalers permit is required, as issued by the Alcohol Tax and Trade Bureau (TTB), and in many instances, state permits are required as

well. The reader should keep in mind that an alternative licensing paradigm exists called an “Alternating Proprietorship” arrangement where the brand owner, via a different licensing scheme, acts as a tenant of the winery and produces its own product on the winery’s premises. This article will focus on the former arrangement.

Negotiating and finalizing the terms of a production agreement can be a daunting task. The brand owner and manufacturer share a common goal, but agreeing on the terms which will lead to the goal of a final product could be challenging generally because of the bargaining positions and goals of the parties.

What follows is a look at some of the essential terms of a contract package or custom crush agreement that both parties to the contract should consider carefully. By no means is this an exhaustive list, and competent alcohol beverage contract attorneys should be retained to assist.

• Quantities and Pricing: Total quantities produced under the agreement require careful consideration, and for the brand owner in particular. There must be a meeting of the minds on production levels prior to focusing on other areas. Brand owners should be careful not to enter into agreements where production quantities and commensurate pricing/costs are higher than anticipated sales over the same time period. Managing brand building resources against production costs is essential. Phrased another way, brand owners should carefully manage their production dollars to ensure the required monies are available for marketing and sales spends.

On the flip side, manufacturers must consider the volume expectations of the brand owner. They must consider whether they can meet the production requirements of the brand owner. In the alternative, they must carefully consider allocating valuable production time to brand owners whose volume requirements are too low, which ultimately cuts into revenue potential.

• The Juice: Manufacturing services need to be

Around The Vineyard Business & Marketing

clearly stated. The parties need to determine whether the winery will actually be producing and supplying the wine to be used or if it will be outsourced from a different winery and bottled at the contract packer’s premises. Quality specifications need to be determined and assurances need to be made that the end product will comply with quality standards established by the parties. By extension, provisions should be included for how to deal with a finished product that does not comply with agreed upon quality standards.

• Raw Goods and Production Material:

Any ingredient specifications, if required, should be determined, agreed to, and set forth in the agreement. As with the above, finished product assurances (as to quality) should be included, as well as methods for dealing with materials not in compliance with quality standards.

The same should be considered with production materials. Bottles, caps, labels, cases and other constituent parts must be considered. Central issues such as how these items will be procured, that is whether the winery will procure these items and build their costs into the finished product or whether the brand owner should source them out and supply these items as required. Quality assurances need to be addressed as well, and in particular, how to manage materials that do not comport with quality standards.

Another seemingly innocuous issue is storage fees associated with the storing of raw goods and production materials at the packager’s location. Associated costs for storage services should be memorialized in the agreement. Hidden or undetermined fees may add up quickly, causing revenue issues for the brand owner and could potentially lead to disputes among the contracting parties.

• Exclusivity and Production and Supply Goals:

Serious consideration must be brought to the issue of exclusivity by both parties. Brand owners need to determine early on whether a potential contract packager has the ability to supply all the requirements of the brand owner. Conversely, the packager must also make honest inquiries as to its ability to produce and pack according to the brand owners’ requirements. Generally, the preferred approach is the middle ground. That is to say, a reasonable production number

based on the brand owners’ requirements and the contract packer’s ability to produce should be agreed upon and memorialized in the contract packaging agreement. Under this scenario, both parties have a reasonable expectation as to their respective performance requirements under the agreement and an understanding of the benefits incurred. The issue of exclusivity could become moot, if the production and supply numbers are agreeable to both parties.

• Production Forecasting and Scheduling: Another area for the parties to agree upon prior to execution of the agreement, is anticipating production needs over time to ensure that the packer can produce according to a set schedule and the brand owner can rely on goods being ready according to their sales and marketing needs. Anticipated variances and procedures for adjusting product forecasts and scheduling should be memorialized as well.

• Recall: A system and procedures for recall should be established and memorialized as well, with allocation of costs based upon the reasons for recall. Recalls may occur for myriads of reasons, and when addressing this issue parties to an agreement should devise a method for determining the cause that led to recall. It should be clear that determining cause guides the parties in allocating costs for the same.

Contract packaging agreements can be complicated agreements to negotiate and draft, requiring many more provisions than those stated above. Ultimately, agreeing on terms that satisfy the operational requirements of both parties is ideally supported by the legal protections required by both parties. As a word of warning, take care in proceeding forward with these types of agreements. Having experienced legal counsel involved is the most prudent course of action.

Common Trellis Systems and Choosing the Right One

By: Alyssa L. Ochs

In the modern vineyard, trellis systems consist of posts, wires or other structures used to support grapevines and help them grow. The concept of a trellis is relatively simple, but choosing the right one could mean the difference between a successful harvest and plants struggling to survive. We connected with industry experts and vineyards with effective trellis strategies to share insights about the options available and how to choose the best one for your vineyard.

The Importance of Trellises

Trellises provide structural support for the vines and fruit in a way sturdy enough to sustain signifi-

cant wind. They also help vines get adequate sunlight for photosynthesis while ripening and developing sugars for high-quality fruit. An effective trellis system helps circulate the air around plants and reduce disease risk without excessive use of herbicides and pesticides.

Meanwhile, trellises help reduce the labor needed for weeding because the vines are lifted off the ground, making weeding tasks easier. Spraying the vines with a trellis is easier because the structural support shapes the canopy. At harvest, a trellis makes it easier to pull grapes by hand, reducing labor needs and costs.

Photo Credit: Jensen Precast

Around The Vineyard

Overall, a trellis is essential to effective vineyard design and can ensure a vineyard's success or failure. By supporting the vine and fruit in a way plants cannot naturally do, trellises help vineyard owners produce healthy fruit and improve the quantity and quality of their grapes.

Types of Trellis Systems

Vineyards can experiment with various trellis systems based on conditions and personal preferences. Vertical shoot positioning (VSP) involves a single-curtain system with movable catch wires and a stationary cordon wire. This system trains the vines to grow vertically and is ideal for narrow-row spacings. VSP systems often have four to six wire levels, making pruning and harvesting easier. However, installing them can be costly and require maintenance beyond other trellising methods.

Another trellis option is the Geneva double curtain (GDC), which incorporates a double canopy system and canopies with bilateral cordons. This method ensures the vines get adequate light and canopies are divided horizontally for shoot positioning.

Vineyards can also try the four-arm kniffin (FAK) method for trellising, which involves a four-arm, quadrilateral cane system with equal spacing on the wire. Fruit canes grow between the arms, making it ideal for small vineyards. A FAK with a three-wire trellis system is easy to build and cost-effective. It is also versatile and can adapt to various row spacings.

Top wire cordon (TWC) trellis systems work for flat sites and have cross arms, posts and top wires strung from the post's bottom to the arms' ends. This design can accommodate row spacings from about three to 10 feet and is ideal for vines growing downward. However, they offer less overall support and can damage wind and sun.

There’s also the umbrella kniffin (UK) method, which uses two wires at 45-degree angles to grow vines between them. Vineyards in warm climates with high winds often find success with this method. It's simple and easy to install but takes up more space than other systems, and weed control can be an issue.

High-wire cordon trellis systems work well with cold-hardy grapes and require minimal labor and investment. This system involves one to three wires,

Around The Vineyard

with the top wire four to six feet from the ground. Pruning is easy with this system, which allows for vineyard mechanization more than more complex trellis systems.

What Vineyards Are Using

Four Daughters Vineyard in Spring Valley, Minnesota uses two different trellis systems in its vineyard, primarily a mid-wire cordon with VSP-trained vines and some lyre trellis. Four Daughters is a winery, cidery, restaurant and event center on a sprawling estate with a six-acre vineyard in rural southeastern Minnesota.

“We are working to retrain the vines on the lyre system to VSP and convert the trellis as well,” Hannah Hanlon, Four Daughters’ winemaker and vineyard manager, told The Grapevine Magazine. Hanlon said that the mid-wire cordon with VSP works well for the vineyard and the vines.

“Many vines are best suited to a high-cordon; however, working on high-cordon systems is really hard on the back, and those vines may not be as perfect

as VSP, but they will produce and grow just fine,” Hanlon said. “Similarly, the lyre system we have is hard to hedge and hard to penetrate the center of the canopy with sprays; VSP would solve those issues. We feel fortunate that our site is on limestone and less vigorous than most in Minnesota, and we can grow a double cordon VSP vine without unmanageable vigor. Vines are incredibly versatile and resilient. Finding perfection is not my goal in the trellising and training in the vineyard; my goal is to keep the vines happy enough and keep them easy to be worked on.”

Concerning trellis-related supplies, Hanlon from Four Daughters Vineyard shared, “I use grow tubes from MDT to grow up vines when I need to retrain trunks or replant; this protects them from herbicide and rabbits. With these, I use bamboo poles to hold them in place. I use rubber black ties to hold the vines onto the trellis system, a Maxtapener for the growing season tying and Felco pruners, saws and loppers for pruning. We net our vines and use clips to hold those nets in place to protect them from birds. I have an herbicide sprayer, fungicide sprayer and tractor. We have a tractor-mounted hedger. For

Around The Vineyard

repairing the trellises, I have a crimping tool, strainer handle, hammer and extra trellising supplies.”

Hanlon recommends the Minnesota Grape Growers Association's book Growing Grapes in Minnesota (available for free download) to compare the costs of different trellis systems.

Meanwhile, in New Haven, Vermont, Lincoln Peak Vineyard has most of its vineyard trained on Geneva double curtain (GDC) but also has some high wire. Kevin Bednar and his wife, Nichole Bambacigno, own Lincoln Peak and took over management of the vineyard earlier this year.

“In these systems, the fruiting wire is six feet off the ground, and we encourage the shoots to grow downwards as the season progresses,” Bednar told The Grapevine Magazine. “These systems typically are spur-pruned and lay down cordons for multiple years, but we opt for cane pruning, replacing the canes on the fruiting wire every year. This allows us to eliminate potentially diseased or cold damaged wood.”

Bednar shared that the systems they use now at

Lincoln Peak allow vigorous hybrids plenty of room to grow, balancing the vegetative and reproductive growth. He explained that these varieties struggle to grow upright, so their trellis system fits their tendencies more than VSP and allows the vine to support a heavier crop load.

“The downward growth pattern of the shoots leads to great sun and wind exposure in the fruit zone, leading to better ripeness and good development of fruiting buds,” Bednar said. “I certainly think VSP and other upright trellis systems are nicer to look at, and, having had more experience working with VSP, it seems to me that you have more control over undervine growth and fruit zone exposure throughout the season.”

Bednar from Lincoln Peak explained that a vineyard needs to purchase end posts and anchors, row posts, wire, crossbars and a post hole digger to construct a trellis.

“All trellising systems have the same number of posts, so it really comes down to wire and crossbars,” Bednar said. “The more wires, the more expensive the system. High wire is typically just one

wire, GDC is two and VSP can be up to seven.”

Recommended Vineyard Trellis Products

One company specializing in vineyard trellis systems is Jensen Precast, based in Reno, Nevada and one of America’s largest, independently-owned precast concrete businesses. George Kehagias, Jensen’s director of product management, told The Grapevine Magazine that their most popular products for vineyards are the Harvest Pillar brand 3”x3”x8’ concrete line posts, 4”x4”x8’ concrete end posts, wire clips and end post bracketry.

“Our wire clips are popular because they’re very quick to install,” Kehagias said. “We also offer a variety of easy-to-mount cross arm bracketry, depending on the type of trellising in the vineyard.”

Kehagias explained that the method for trellising determines what supplies are required, but concrete posts require similar components to wood and steel.

“The vineyard will need clips to attach the wire to the post, which Harvest Pillar supplies, and then wire to attach the fruit to,” Kehagias said. “In general, vineyards use anchors to secure the fruiting wire to the ground. With Harvest Pillar, the anchors and wire used are interchangeable between wood, steel and concrete. The wire clips used on concrete are similar in function but slightly different in form from clips used on wood and steel. Our customers also typically attached irrigation drip lines to the trellis. With concrete, this method can be done using the same accessories as used on wood and steel trellis.”

He shared that concrete posts are the most cost-effective solution when you factor in the replacement costs of damaged posts and optimized spacing for strengths. Jensen Precast has a calculator on its website that compares wood, steel and concrete costs per acre.

Headquartered in Aurora, Illinois, Gripple, Inc. is the leading manufacturer of wire joiners and tensioners for the agricultural market. Its highest-selling products in the vineyard market are the GP Medium, GP1 and GPak kits.

“While the GP Medium is our best-seller, it is available in a range of sizes starting with small to medium, then large, and we even carry a jumbo option," Rick Hermosillo, campaign marketing manager for

Around The Vineyard

Around The Vineyard

Gripple, told The Grapevine Magazine. “The GP Medium is most often used for joining 13.5-to-10gauge smooth trellis wire together, repairing broken or cut wires and often used at termination points around the end post. The medium is popular for its ease of use and speed of installation without drawbacks. It has an 880-pound working load and is designed with corrosive-resistant materials to last the life of the trellis wire.”

Hermosillo explained that GP1 is another termination end option. It is designed with a flat edge, creating extra stability when using metal end posts. While the GP1 has a high load strength equivalent to the GP Medium, there is also a GP2 option for larger wire with a stronger hold at 1,320 pounds.

“Lastly, our GPak kit — again, this comes in a range of sizes, but the most common is our GPak 3,” Hermosillo said. “It’s a ready-to-use kit with a pre-cut fused cable and a joiner. The GPak is designed as a quick installation tieback to connect your end post to your ground anchor.”

Gripple manufactures 95 percent of the components in all its products and has released three new products to the vineyard market in the past two years. The GP90 is a cross-wire joiner, the D8 works with a 5/16-inch cable that provides a load rating of 6,170 pounds and the Anchor 5 is the largest anchor of its series to fit the most demanding trellis systems.

Finger Lakes Trellis Supply is another company that can help if you're in the market for a new trellis system. Based in Williamson, New York, it offers trellises, fencing, posts, wires, harvest supplies, irrigation supplies, tools, equipment and wildlife solutions.

For vine training, Finger Lakes Trellis Supply offers a lightweight and durable MAX Tapener, four-inch KlipOn Trellis Ties and 1/4-inch stake-to-wire clips. These products provide a stable foundation for growing vines and help you save time while setting up trellises. This company also sells metal and wooden posts and accessories, plus earth anchors in various styles.

Final Words of Advice

Hanlon from Four Daughters Vineyard & Winery advised vineyards, "Think about standing at that vine and pruning it, training it, working on it, driv-

ing down the row and harvesting the grapes. What tools you plan to use to do all of that? Choose something that is amiable to your tools and body. Bending down or reaching up to do a task for one vine is manageable, but can you do it for 1,000?”

Bednar from Lincoln Peak advised, "Do your research and be realistic with yourself! There's no right answer, so figure out what your short-term and long-term goals are. What's your labor budget and access? How much mechanization do you want to do? What are your goals for fruit yield, quality and vine longevity?”