TOOLS HEADS 2022

Golden Compass award for industrial design

made in italy

PRECISION IS OUR STRENGTH

of new products which, through advanced technological solutions, satisfy a highly

team ensures rapid execution of special projects based on

the years, the boring range has been developed to cover from manufacturing sector and an intense passion for mechanics that has now been inherited by the third generation, with the aim of responding to the increasingly stringent demands of the world of

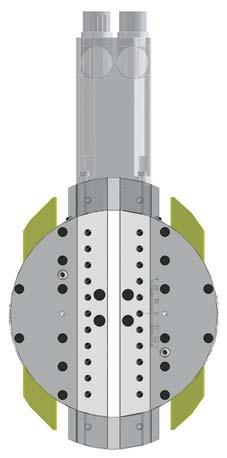

TOOLHOLDERS

RD40/16.24

RD40/25.28

RD50/16.24 RD50/20.26 RD50/25.28 RD50/32.32 RD50/40.36

RD50/16.40 RD50/20.70 RD50/25.87 RD50/32.87 RD50/40.87

RD50/16.74RAV50/16.74

RD110/80.70

RD50/20.93RAV50/20.93 RD50/25.117 RD50/32.144 RD50/40.176

RD80/50.45 RD80/63.60 RD140/80.70

RAV50/25.117 RAV50/32.144

RAV63/50.220 RAV80/63.280

TS16/16 Ø18~22

TS20/20 Ø22~28

TS25/25 Ø28~38

TS32/32 Ø35.5~50

TS40/40 Ø50~68

TS50/50-50/63 Ø68~90

TRD25 Ø28~36

TRD32 Ø36~46

TRD40 Ø46~60

TRD50 Ø60~75

TRM16 Ø18~23

TRM20 Ø22~29

TRM25 Ø28~38

TRM32 Ø35.5~50

TRM40 Ø48~63

TRM50 Ø2.5~108

TRC14 Ø14.5~18

TRC16 Ø18~24

TRC20 Ø22~30 TRC25 Ø28~40

TRC32 Ø35~53

TRC40 Ø48~66

TRC50 Ø2.5~110

TS63/63 Ø90~120

TS80/80 Ø120~200

TRD63 Ø75~95

TRD80 Ø95~160

TRM50/63-50/80 TRM63/63-80/80 Ø2.5~160

TRM80-125 Ø2.5~500

TRC63 Ø6~125

TRC80 Ø6~200

TRE Digital Heads

p.48 2μm

p.56

p.60 p.46

TRM32HSB Ø2.5~18

TRC32HS Ø2.5~18

TRM50HSB Ø2.5~22

TRE32 Ø35.5~51.5

TRE40 Ø48~64

TRE50 Ø2.5~110

TRC50HS Ø2.5~22

TRE63 Ø6~125

TRE80 Ø6~200

TRM HSB 32-50

HS 32-50

MHD’ Ød1Øm1SN·m

MHD’ 14 1410

MHD’ 16 1610

MHD’ 20 20133 MHD’ 25 25163

MHD’ 32 322047-8

MHD’ 40 4025516-18 MHD’ 50 5032630-35 MHD’ 63 6342870-80 MHD’ 80 8042870-80

MHD’ 110 1107614200-220 MHD’ 140 1407614200-220

BASE CONNECTIONS Made

69893andISO26623-1standards

groundsteel8000RPMBALANCING.

PR ForeachMHDsizethereare extensionsofdifferentlengthsthat canbeusedtoachievethedesired machiningdepths.

RD Thereductionsallowtheuseof MHDcomponentsofasmallersize ofthetoolaccordingtotheoverall dimensions.

RAV Anti-vibrationreductionsfor TS serratedsurfacesbetweenthe constantdistancebetweenthebit holderclampingscrewandthe

Thebroad boring program completes theMHDlinewitha widerangeofdouble-bit micrometricandcentesimal

TRD Double-bitheadsthatallowthe combinedhighprecisionmachining

onthevernierscaleandwhichcan alsobeperformedonthemachine.

TRM Micrometricheadsforhigh precisionmachiningwith IT6 tolerance readableonthevernierscaleandcan alsobeperformedonthemachine.

TRC Centesimalheadsforhigh precisionmachiningwith IT7 tolerancegrade.Theadjustmentis alsobeperformedonthemachine.

TRC HS e TRM HSB Centesimal (HS)andmicrometric(HSB)heads forhigh-speedmachining.

TRE headsforhighprecisionmachining with IT6 tolerancegrade.Showing oftheadjustmentontheintegrated

TREareprotectedfromtheliquids contaminationaccordingtothe IP69K gradeofprotection.

BPS Aluminiumbarsforlarge diametermachining.Usableforboth

CHUCKING TOOLS Thecomplete programofD’Andreamodular

DIN REF. CODEMHD’d1LL1•

30 DIN69871-A30 MHD’32.30 416320103020•3230110.4

30 DIN69871-A30 MHD’40.45.5 416400103020•4045.526.50.5

30 DIN69871-A30 MHD’50.60 41650010302050600.6

40 DIN69871-A40 MHD’40.45 4164001040204045260.5

40 DIN69871-A40 MHD’50.48 4165001040205048290.9

40 DIN69871-A40 MHD’50.56 4165001040705056371.1

40 DIN69871-A40 MHD’63.80 41663010402063801.5

45 DIN69871-A45 MHD’50.48 4165001045205048291.7

50 DIN69871-A50 MHD’50.48 4165001050205048292.5

50 DIN69871-A50 MHD’63.48 4166301050296348292.6

50 DIN69871-A50 MHD’63.56 4166301050206356372.8

50 DIN69871-A50 MHD’80.48 4168001050298048293

50 DIN69871-A50 MHD’80.62 4168001050208062433.4

50 DIN69871-A50 MHD’110.150 4169101050201101507.6

50 DIN69871-A50 MHD’140.160 416940105020•14016010

60 DIN69871-A60 MHD’50.50 416500106020•5050318.3

60 DIN69871-A60 MHD’63.60 416630106020•6360419.3

60 DIN69871-A60 MHD’80.65 416800106020•80654610.3

60 DIN69871-A60 MHD’110.100 416910106020•1101008110.5

60 DIN69871-A60 MHD’110.200 416910106028•11020018118

60 DIN69871-A60 MHD’140.100 416940106020•1401008112.8

60 DIN69871-A60 MHD’140.250 416940106028•14025023130

DIN REF. CODEMHD’d1LL1•

40 DIN69871-B40 MHD’50.48 4165001040215048290.9

40 DIN69871-B40 MHD’63.80 416630104021•63801.5

45 DIN69871-B45 MHD’50.48 416500104521•5048291.7

50 DIN69871-B50 MHD’50.48 4165001050215048292.7

50 DIN69871-B50 MHD’63.56 4166301050216356372.8

50 DIN69871-B50 MHD’80.62 4168001050218062433.4

DIN 69871 AD+B

DIN REF. CODEMHD’d1d 2LL1•

40 DIN69871-AD+B40 MHD’16.40 416160414021•1640210.7

40 DIN69871-AD+B40 MHD’16.63 4161606140211617.563440.8

40 DIN69871-AD+B40 MHD’16.100 4161610140211620100810.9

40 DIN69871-AD+B40 MHD’20.50 4162005140212050310.8

40 DIN69871-AD+B40 MHD’20.80 4162008140212022.580610.9

40 DIN69871-AD+B40 MHD’20.125 4162012140212025.51251061

40 DIN69871-AD+B40 MHD’25.50 4162505140212550310.9

40 DIN69871-AD+B40 MHD’25.80 416250814021252780611

40 DIN69871-AD+B40 MHD’25.125 41625121402125301251061.1

40 DIN69871-AD+B40 MHD’32.50 4163205140213250311

40 DIN69871-AD+B40 MHD’32.80 4163208140213233.580611.1

40 DIN69871-AD+B40 MHD’32.125 4163212140213236.51251061.2

DIN 69871 AD+B

DIN REF.

CODEMHD’d1d2LL1

40 DIN69871-AD+B40 MHD’40.120 4164001040284044.51201011.4

40 DIN69871-AD+B40 MHD’50.120 416500104028501201011.7

50 DIN69871-AD+B50 MHD’50.120 41650010502850601201013.5

DIN69871-AD+B50 MHD’63.150 41663010502863701501315

DIN69871-AD+B50 MHD’80.180 416800105028801801617.6

FACE CONTACT

pic.1

DIN REF.

CODEMHD’d1d2ALL1 pic. •

40 DIN69871-AD+B40 FC MHD’50.48 416500104021F50148290.9 1

40 DIN69871-AD+B40 FC MHD’50.120 416500104028F•5011201011.7 1

40 DIN69871-AD+B40 FC MHD’63.80 416630104021F631801.5 1

50 DIN69871-AD+B50 FC MHD’50.48 416500105021F501.548292.5 1

50 DIN69871-AD+B50 FC MHD’50.120 416500105028F50591.51201013.5 2

50 DIN69871-AD+B50 FC MHD’50.200 416500105027F50681.52001816.1 2

50 DIN69871-AD+B50 FC MHD’63.56 416630105021F631.556372.8 1

50 DIN69871-AD+B50 FC MHD’63.150 416630105028F6375.51.51501315.2 2

50 DIN69871-AD+B50 FC MHD’63.250 416630105027F63801.52502317.1 2

50 DIN69871-AD+B50 FC MHD’80.62 416800105021F801.562433.4 1

50 DIN69871-AD+B50 FC MHD’80.180 416800105028F801.51801616.9 1

50 DIN69871-AD+B50 FC MHD’80.300 416800105027F801.53002819.2 1

50 DIN69871-AD+B50 FC MHD’110.150 416910105021F•1101.51508 1

50 DIN69871-AD+B50 FC MHD’110.250 416910105028F•1101.525015 1

MAS 403 BT AD

BT REF. CODEMHD’d1LL1•

30 MAS403 BT30 MHD’32.32 416320103030323210.50.5

30 MAS403 BT30 MHD’40.35.5 416400103030•4035.5140.6

30 MAS403 BT30 MHD’50.60 41650010303050600.7

40 MAS403 BT40 MHD’40.45 4164001040304045180.6

40 MAS403 BT40 MHD’50.38.5 4165001040395038.511.50.8

40 MAS403 BT40 MHD’50.48 4165001040305048210.9

40 MAS403 BT40 MHD’50.56 4165001040805056291.1

40 MAS403 BT40 MHD’63.66 41663010403063661.2

45 MAS403 BT45 MHD’50.62 416500104530•5062291.7

50 MAS403 BT50 MHD’50.66 4165001050305066283.3

50 MAS403 BT50 MHD’63.50 4166301050396350123.4

50 MAS403 BT50 MHD’63.75 4166301050306375373.7

50 MAS403 BT50 MHD’80.50 4168001050398050123.8

50 MAS403 BT50 MHD’80.75 4168001050308075374

50 MAS403 BT50 MHD’110.140 416910105030•1101406.8

50 MAS403 BT50 MHD’140.150 416940105030•1401509.2

60 MAS403 BT60 MHD’110.110 416910106030•1101106311.5

60 MAS403 BT60 MHD’110.200 416910106038•11020015218.1

60 MAS403 BT60 MHD’140.100 416940106030•1401005212.9

60 MAS403 BT60 MHD’140.250 416940106038•14025020230.1

MAS 403 BT B

DIN REF.

40 MAS403 BT40B MHD’50.48

40 MAS403 BT40B MHD’63.66

50 MAS403 BT50B MHD’50.66

50 MAS403 BT50B MHD’63.75

50 MAS403 BT50B MHD’80.75

1LL1•

MAS 403 BT AD+B

BT REF. CODEMHD’d1d 2LL1

40 MAS403 BT40-AD+B MHD’16.45 4161604140311645180.8

40 MAS403 BT40-AD+B MHD’16.63 416160614031161763360.9

40 MAS403 BT40-AD+B MHD’16.100 4161610140311619.5100731

40 MAS403 BT40-AD+B MHD’20.50 4162005140312050230.9

40 MAS403 BT40-AD+B MHD’20.80 416200814031202280531

40 MAS403 BT40-AD+B MHD’20.125 4162012140312025125981.1

40 MAS403 BT40-AD+B MHD’25.50 4162505140312550231

40 MAS403 BT40-AD+B MHD’25.80 4162508140312526.580531.1

40 MAS403 BT40-AD+B MHD’25.125 4162512140312529.5125981.2

40 MAS403 BT40-AD+B MHD’32.50 41632051403132231.1

40 MAS403 BT40-AD+B MHD’32.80 416320814031323380531.2

40 MAS403 BT40-AD+B MHD’32.125 4163212140313236125981.4

MAS 403 BT AD+B

BT REF. CODEMHD’d1d 2LL1

40 MAS403 BT40-AD+B

MAS403 BT40-AD+B

MAS403 BT50-AD+B

4164001040384044.5120930.9

41650010403850120931.9

4165001050385060120824.2

50 MAS403 BT50-AD+B MHD’63.150 41663010503863701501125.8

MAS403 BT50-AD+B MHD’80.180 416800105038801801427.5

BT REF. CODEMHD’d1d 2ALL1 pic. •

40 MAS403 BT40 FC AD+B MHD’50.48 416500104031F50148210.9 1

40 MAS403 BT40 FC AD+B MHD’50.120 416500104038F•501120931.9 1

40 MAS403 BT40 FC AD+B MHD’63.66 416630104031F631661.2 1

50 MAS403 BT50 FC AD+B MHD’50.66 416500105031F501.566283.2 1

50 MAS403 BT50 FC AD+B MHD’63.75 416630105031F631.575373.7 1

50 MAS403 BT50 FC AD+B MHD’50.120 416500105038F5057.51.5120824.2 2

50 MAS403 BT50 FC AD+B MHD’50.200 416500105037F50661.52001624.5 2

50 MAS403 BT50 FC AD+B MHD’63.150 416630105038F6373.51.51501125.8 2

50 MAS403 BT50 FC AD+B MHD’63.250 416630105037F63841.52502126.1 2

50 MAS403 BT50 FC AD+B MHD’80.75 416800105031F801.575374 1

50 MAS403 BT50 FC AD+B MHD’80.180 416800105038F801.51801427.5 1

50 MAS403 BT50 FC AD+B MHD’80.300 416800105037F801.53002629.2 1

50 MAS403 BT50 FC AD+B MHD’110.150 416910105031F•1101.51508.1 1

50 MAS403 BT50 FC AD+B MHD’110.250 416910105038F•1101.525015.3 1

HSK-A REF.

CODEMHD’d1LL1•

40 HSK-A40 MHD’32.48 416321504020•3248280.4 Supplied without hole

50 HSK-A50 MHD’50.66 41650150502050660.6

63 HSK-A63 MHD’40.60 4164015063204060340.7

63 HSK-A63 MHD’50.66 4165015063205066400.9

63 HSK-A63 MHD’63.75 41663150632063751.1

80 HSK-A80 MHD’50.70 4165015080205070441.5

80 HSK-A80 MHD’63.80 4166315080206380541.8

80 HSK-A80 MHD’80.86 416801508020•80862.1

100 HSK-A100 MHD’50.72 4165015100205072432.4

100 HSK-A100 MHD’63.82 4166315100206382532.7

100 HSK-A100 MHD’80.88 4168015100208088593

VersionavailableonrequestHSK-T

HSK-A REF. CODEMHD’d1d2LL1 Supplied with coolant tube

63 HSK-A63 MHD’40.120 4164015063284046120941.4

HSK-A63 MHD’50.120 41650150632850120941.7

100 HSK-A100 MHD’50.120 4165015100285060120913.2

HSK-A100 MHD’63.150 41663151002863701501214.5

HSK-A100 MHD’80.180 416801510028801801516.5

Supplied with coolant tube Supplied with coolant tube

HSK-A REF.

HSK-A63 MHD’16.63

HSK-A63 MHD’16.100

HSK-A63 MHD’20.63

HSK-A63 MHD’20.90

CODEMHD’d1d2LL1•

63 HSK-A63 MHD’20.125 416201256320•2025125990.9

63 HSK-A63 MHD’25.63 4162506563202563370.7

63 HSK-A63 MHD’25.90 416250956320252790640.9

63 HSK-A63 MHD’25.125 4162512563202529.5125991

63 HSK-A63 MHD’32.90 4163209563203233.590641

63 HSK-A63 MHD’32.125 4163212563203236125991.2

HSK REF.

CODEMHD’d1LL1•

40 HSK-E40 MHD’32.42 4163215040253242220.5

50 HSK-E50 MHD’50.66 416501505025•50660.6

63 HSK-E63 MHD’50.66 4165015063255066400.9

63 HSK-F63 MHD’50.65 4165015063265065390.8

PSC-MHD’ ISO 26623-1

pic.1 pic.2

PSC REF. CODEMHD’d1d2LL1 pic.

40 PSC 40 - MHD’ 32.42 4163226040043242220.3 1

40 PSC 40 - MHD’ 40.45 41640260400440450.4 1

50 PSC 50 - MHD’ 50.55 41650260500550550.8 1

63 PSC 63 - MHD’ 40.50 4164026063054050280.9 1

63 PSC 63 - MHD’ 40.120 4164026063124044120981.5 2

63 PSC 63 - MHD’ 50.55 4165026063055055330.8 1

63 PSC 63 - MHD’ 50.67 4165026063065067451.1 1

63 PSC 63 - MHD’ 50.120 4165026063125054120981.9 2

63 PSC 63 - MHD’ 63.77 41663260630763771.8 1

80 PSC 80 - MHD’ 50.60 4165026080065060302 1

80 PSC 80 - MHD’ 50.120 4165026080125054120902.8 2

80 PSC 80 - MHD’ 63.70 4166326080076370402.3 1

80 PSC 80 - MHD’ 63.150 41663260801563671501204 2

80 PSC 80 - MHD’ 80.75 41680260800780752.6 1

80 PSC 80 - MHD’ 80.120 416802608012801204.3 1

100 PSC 100 - MHD’ 80.80 41680261000811080443.5 1

100 PSC 100 - MHD’ 110.120 416912610012110120845 1

KM XMZ ISO 26622-1

KMXMZ REF. CODEMHD’d1d2LL1•

63 RD KM - MHD’ 50.50 657095005063506350320.8

63 RD KM - MHD’ 63.70 657096305063•6363701.2

ANSI/CAT REF. CODEMHD’d1LL1M•

40 ANSI/CAT40 MHD’50.66 416500104040506647M161.1

40 ANSI/CAT40 MHD’63.100 416630104040•63100M161.9

45 ANSI/CAT45 MHD’50.48 416500104540•504829M201.7

50 ANSI/CAT50 MHD’50.48 416500105040504829M242.4

50 ANSI/CAT50 MHD’63.56 416630105040•635637M242.9

50 ANSI/CAT50 MHD’80.62 416800105040806243M243.2

DIN REF.

CODEMHD’d1LL1M•

30 DIN2080-A30 MHD’50.58 4165001030005058M120.6

40 DIN2080-A40 MHD’50.48 416500104000504836.5M160.9

40 DIN2080-A40 MHD’63.60 4166301040006360M161.2

45 DIN2080-A45 MHD’50.48 416500104500•504833M201.6

50 DIN2080-A50 MHD’50.48 416500105000504833M242.6

50 DIN2080-A50 MHD’63.56 416630105000635641M242.7

50 DIN2080-A50 MHD’80.60 416800105000806045M243.2

MORSE REF. CODEMHD’d1LM

4 MORSE4-A MHD’50.63 4165003004005063M160.9

4SIP MORSE4-A SIP MHD’50.63 4165003004015063M140.9

MORSE REF.

4 MORSE4-B

MORSE5-B

pic.1 pic.2

REF. CODEMHD’d1LL1d2 pic.

BR 16/16.100 65708160100116100160.15 1

BR 20/20.125 65708200125120125200.3 1

BR 25/32.35 4163208025003210035250.7 2

BR 32/50.60 4165008032005014060321 2

DIN 2079

REF. CODEMHD’d1d2d3d4d5LL1L2M•

DIN 2079-40.50 416502004000•509088.8911066.7351021M121.8

DIN 2079-40.63 416632004000•639088.8911066.7471031M122

DIN 2079-50.63 416632005000•63135128.57150101.6451231M165.4

DIN 2079-50.80 416802005000•80135128.57150101.6501236M165.3

DIN 2079-50.110 416912005000•110135128.57150101.61121298M168.4

DIN 2079-50.140 416942005000•140140128.57150101.612212108M169.5

CARBIDE BARS

REF. CODEMHD’d1d2L

BMD 16/16.110 65708160110516161100.3 BMD 16/16.140 65708160140516161400.4 BMD 16/16.170

BMD 20/20.135

BMD 20/20.170 65708200170520201700.75

BMD 20/20.210 65708200210520202100.9

BMD 25/25.160 65708250160525251601 BMD 25/25.205 65708250205525252051.3 BMD 25/25.255

BMD 32/32.195

BMD 32/32.250

BMD 32/32.315

PR

REF. CODEMHD’d1L•

PR 14.25 65690140025014250.02

PR 16.25 65690160025016250.04

PR 20.32 65690200032020320.07

PR 25.25 65690250025025250.09

PR 25.40 65690250040025400.15

PR 32.32 65690320032032320.2

PR 32.50 65690320050032500.3

PR 40.40 65690400040040400.4

PR 40.63 65690400063040630.6

PR 50.50 65690500050050500.7

PR 50.80 65690500080050801.1

PR 50.100 656905001000501001.5

PR 63.63 65690630063063631.4

PR 63.100 656906301000631002.2

PR 63.125 656906301250631252.9

PR 80.80 65690800080080803

PR 80.125 656908001250801254.6

PR 80.160 656908001600801606.1

PR 110.140 65691100140011014013.5

PR 110.200 65691100200011020014.3

PR 140.140 656914001400•14014024 PR 140.250 656914002500•14025028.5

RAV VIBRATION-DAMPING

REF. CODEMHD’d1MHD’d2d3LL1

RAV 50/16.74

RAV 50/20.93

RAV 50/25.117

RAV 50/32.144

RAV 50/40.176

RAV 63/50.220

RAV 80/63.280

EXTENSIONS -

REF. CODEMHD’d1MHD’d2LL1•

RD 16/14.25 65700160014016142519.50.02

RD 20/14.20 657002000140•20142014.50.03

RD 20/16.20 657002000160201620160.05 RD 25/14.20 657002500140•25142013.50.06

RD 25/16.20 657002500160251620150.07 RD 25/20.25 657002500200252025200.08

RD 32/14.25 657003200140•32142517.50.08

RD 32/16.24 657003200160321624180.10

RD 32/20.25 657003200200322025200.12 RD 32/25.28 657003200250322528230.14

RD 40/14.25 657004000140•40142516.50.10 RD 40/16.24 657004000160401624170.18

RD 40/20.26 657004000200402026200.2

RD 40/25.28 657004000250402528220.25

RD 40/32.32 657004000320403232270.3 RD 50/14.25 657005000140•50142514.50.25 RD 50/14.40 65700500014250144029.50.1 RD 50/16.24 657005000160501624150.34 RD 50/20.26 657005000200502026180.37

RD 50/25.28 657005000250502528210.4

RD 50/32.32 657005000320503232250.45 RD 50/40.36 657005000400504036300.5 RD 63/50.40 657006300500635040340.9 RD 80/50.45 657008000500805045361.2 RD 80/63.60 657008000630806360521.7 RD 110/80.70 6570110008001108070526 RD 140/80.70 657014000800•1408070497.8

RD

REF. CODEMHD’d1MHD’d2LL1 RD 50/63.56 6570050006305063561.1

REF. CODEMHD’d1MHD’d2LL1

RD 50/16.40 657005000162501640320.2 RD 50/16.74

RD 50/20.70

RD 50/20.93 657005000203502093850.35

RD 50/25.87 657005000252502587800.6

RD 50/25.117 65700500025350251171100.65 RD 50/32.87 657005000322503287800.75 RD 50/32.144 65700500032350321441371 RD 50/40.87 657005000402504087800.9 RD 50/40.176 65700500040350401761701.8

1.

REF. CODEØ

TS 16/16 45550160034018~220.05

TS 20/20 45550200040022~280.09

TS 25/25 45550250050028~380.2

TS 32/32 45550320063035.5~500.35

TS 40/40 45550400080050~680.7

TS 50/50 45530500100068~901.5

TS 50/63 45530630080090~1202

TS 63/63 45540630125090~1203

TS 80/80 455408001400120~1605.3

TS 40/40 Ø 50 ~ 68

MHD’40

TS 50/50 Ø 68 ~ 90

MHD’50

TS 50/63 Ø 90 ~ 120

MHD’50

TS 63/63 Ø90 ~ 120

MHD’63

TS 80/80 Ø 120 ~ 200

MHD’80

pic.1 withtwoSSCCbitholders alignedandonthesamediameter forroughingoperationswithhigh feedrate.

pic.2 pic.3

pic. 2 withoneSSCCbitholderand oneSMCCbitholderstaggeredand onadifferentdiameterforroughing operationswithhighdepthofcut.

pic.3 requiredtoprotectthecoupling surface.

PT COVER PLATES

REF.

PT

PT

PT

PT

PT

PT

PT

PT

BIT-HOLDERS SSCC.. - SSCN.. - SMCC.. - SSSC.. - SSSN.. - SSTC.. - SFSM.. - SSQC..

SSCC..-SSCN/SMCC..SSSC../SSSN..SSTC..SSSM..SSQC..

CCSSCN/SMCCSSSC/SSSNSSTCSSSMSSQ

REF. CODEAA1BCL

SSCC 16 470500516201815CCMT0602..TS25TORXT080.003

SSCC 20 4705005202019.519CCMT0602..TS25TORXT080.006

SSCC 25 47050052520112.523CCMT0602..TS25TORXT080.01

SSCC 32 4705005322011532CCMT0602..TS25TORXT080.02

SSCC 33 4705005322041532CCMT09T3..TS4TORXT150.025

SSCC 40 4705005402011940CCMT09T3..TS4TORXT150.06

SSCC 41 4705005402041940CCMT1204..TS5TORXT250.06

SSCC 50 4705005502042254CCMT1204..TS5TORXT250.1

SSCC 63 4705005632012770.5CCMT1204..TS5TORXT250.2

SSCC 80 4705005802013294.5CCMT1204..TS5TORXT250.5

SSCC 90 47050059020132130CCMT1204..TS5TORXT250.7 SSCN 95 47050059520140130CNM.1906.. p. 89p. 89 0.9

SMCC 25 47050052520312.323CCMT0602..TS25TORXT080.01

SMCC 32 47050053220314.832CCMT0602..TS25TORXT080.02

SMCC 33 47050053220514.832CCMT09T3..TS4TORXT150.025

SMCC 40 47050054020318.740CCMT09T3..TS4TORXT150.06

SMCC 41 47050054020518.740CCMT1204..TS5TORXT250.06

SMCC 50 47050055020521.754CCMT1204..TS5TORXT250.1

SMCC 63 47050056320326.770.5CCMT1204..TS5TORXT250.2

SMCC 80 47050058020331.794.5CCMT1204..TS5TORXT250.5

SMCC 90 47050059020331.7130CCMT0602..TS25TORXT080.7

SSSC 32 4705005322021532SCMT09T3..TS4TORXT150.02 SSSC 40 4705005402021940SCMT09T3..TS4TORXT150.06 SSSC 50 47050055020220.554SCMT1204..TS5TORXT250.1

SSSC 63 4705005632022770.5SCMT1204..TS5TORXT250.2

SSSC 80 4705005802023294.5SCMT1204..TS5TORXT250.5 SSSC 90 47050059020232130SCMT1204..TS5TORXT250.7 SSSN 95 47050059520240130SNM.1906.. p. 89p. 89 0.9

SSTC 63 4705005632062770.5TCMT2204..TS5TORXT250.2

SSTC 80 4705005802063294.5TCMT2204..TS5TORXT250.5

SSTC 90 47050059020632130TCMT2204..TS5TORXT250.7

SSSM 25-15° 47050052521112.5231.6CCMT0602..TS25TORXT080.01 SSSM 25-30° 47050052521312.5233CCMT0602..TS25TORXT080.01 SSSM 25-45° 47050052521512.5234.3CCMT0602..TS25TORXT080.01 SSSM 32-15° 47050053221115311.6CCMT0602..TS25TORXT080.025 SSSM 32-30° 47050053221315313CCMT0602..TS25TORXT080.025 SSSM 32-45° 47050053221515314.3CCMT0602..TS25TORXT080.025

SSSM 40-15° 47050054021119392.4CCMT09T3..TS4TORXT150.06 SSSM 40-30° 47050054021319394.6CCMT09T3..TS4TORXT150.06

SSSM 40-45° 47050054021519396.5CCMT09T3..TS4TORXT150.06

SSSM 50-15° 47050055021122533.2CCMT1204..TS5TORXT250.1 SSSM 50-30° 47050055021322536.2CCMT1204..TS5TORXT250.1 SSSM 50-45° 47050055021522538.8CCMT1204..TS5TORXT250.1

SSQC 16 47050051626110162CCMT0602..TS25TORXT080.005

SSQC 20 4705005202611119.51.5CCMT0602..TS25TORXT080.008

SSQC 25 47050052526114.5242.5CCMT0602..TS25TORXT080.02

SSQC 33 47050053326117323CCMT09T3..TS4TORXT150.03 SSQC 41 47050054126121423.5CCMT1204..TS5TORXT250.08 SSQC 50 47050055026124.5573.5CCMT1204..TS5TORXT250.15

SSQC 63 47050056326128.5763.5CCMT1204..TS5TORXT250.3

SSQC 80 47050058026131.51013.5CCMT1204..TS5TORXT250.6 SSQC 90 47050059026131.51223.5CCMT1204..TS5TORXT250.8

MHD’

REF. CODEØ TRD

TRD

TRD 40 45502400090146~600.7

TRD 50 45502500086160~751.5 TRD

45502630108175~952.7 TRD 80 45502800129195~1604.8

REF. CODEAA1B

SSCC 25 D 4705005252201024CCMT0602..TS25TORXT080.008

SSCC 32 D 47050053222011.530CCMT0602..TS25TORXT080.015

SSCC 40 D 4705005402201440CCMT09T3..TS4TORXT150.03

SSCC 50 D 4705005502201954CCMT09T3..TS4TORXT150.06

SSCC 63 D 47050056322024.568CCMT09T3..TS4TORXT150.15

SSCC 80 D 47050058022029.587CCMT09T3..TS4TORXT150.3

SSCC 85 D 47050058522129.5107.4CCMT09T3..TS4TORXT150.4

SFTP 25 D 4705005250309.824TPGX0902..CS250TTORXT080.008

SFTP 32 D 47050053203011.330TPGX0902..CS250TTORXT080.015

SFTP 40 D 47050054003013.840TPGX1103..CS300890TTORXT080.03

SFTP 50 D 47050055003018.854TPGX1103..CS300890TTORXT080.06

SFTP 63 D 47050056303024.368TPGX1103..CS300890TTORXT080.15

SFTP 80 D 47050058003029.387TPGX1103..CS300890TTORXT080.3

SFTP 85 D 47050058503129.3107.4TPGX1103..CS300890TTORXT080.4

SFCC 25 D 4705005250209.824CCGT0602..TS25TORXT080.008

SFCC 32 D 47050053202011.330CCGT0602..TS25TORXT080.015

SFCC 40 D 47050054002013.840CCGT09T3..TS4TORXT150.03

SFCC 50 D 47050055002018.854CCGT09T3..TS4TORXT150.06

SFCC 63 D 47050056302024.368CCGT09T3..TS4TORXT150.15

SFCC 80 D 47050058002029.387CCGT09T3..TS4TORXT150.3

SFCC 85 D 47050058502129.3107.4CCGT09T3..TS4TORXT150.4

TRD DOUBLE-BIT

TRD

TRD

TRD

TRD

TRD

TRD

MHD’25 MHD’32 MHD’40 MHD’50 MHD’80

MHD’63

REF. CODEØ

TRM 16 45500160034118~230.05 TRM 20 45500200040122~290.1 TRM 25 45500250050028~380.2 TRM 32 45500320063035.5~51.50.35 TRM 40 45500400080048~630.7

REF.

SFCC 16 470500516002817CCGT0602..TS25TORXT080.003

SFCC 20 4705005200028.521CCGT0602..TS25TORXT080.005

SFCC 25 4705005250021026.5CCGT0602..TS25TORXT080.01

SFCC 32 47050053200211.534.5CCGT0602..TS25TORXT080.02

SFCC 40 4705005400021444CCGT09T3..TS4TORXT150.04

SFTP 25 4705005250011026.5TPGX0902..CS250TTORXT080.01

SFTP 32 47050053200111.534.5TPGX0902..CS250TTORXT080.02

SFTP 40 4705005400011444TPGX1103..CS300890TTORXT080.04

SFQC 16 47050051606210182CCMT0602..TS25TORXT080.005

SFQC 20 47050052006210.522.52CCMT0602..TS25TORXT080.008

SFQC 25 4705005250621228.52.5CCMT0602..TS25TORXT080.01

SFQC 32 47050053206213.535.52.5CCMT0602..TS25TORXT080.03

SFQC 40 47050054006216.5463CCMT09T3..TS4TORXT150.06

SFSM 25-15° 4705005250111025.51.6CCMT0602..TS25TORXT080.01

SFSM 25-30° 4705005250131025.53CCMT0602..TS25TORXT080.01 SFSM 25-45° 4705005250151025.54.3CCMT0602..TS25TORXT080.01 SFSM 32-15° 47050053201111.533.51.6CCMT0602..TS25TORXT080.02 SFSM 32-30° 47050053201311.533.53CCMT0602..TS25TORXT080.02

SFSM 32-45° 47050053201511.533.54.3CCMT0602..TS25TORXT080.02

SFSM 40-15° 4705005400111442.52.4CCMT09T3..TS4TORXT150.03 SFSM 40-30° 4705005400131442.54.6CCMT09T3..TS4TORXT150.03 SFSM 40-45°

TRM 16 Ø 18 ~ 23

MHD’16

TRM 20 Ø 22 ~ 29

MHD’20

TRM 25 Ø 28 ~ 38

MHD’25

TRM 32 Ø 35.5 ~ 51.5

TRM MICROMETRIC

MHD’32

TRM 40 Ø 48 ~ 63

MHD’40

REF. CODEØ1LL1AB

SFTP 25 4705005250011026.5TPGX0902..CS250TTORXT080.01

SFTP 32 47050053200111.534.5TPGX0902..CS250TTORXT080.02

SFTP 50 4705005500011952TPGX1103..CS300890TTORXT080.08

SFTP 51 4705005500032152TCMT16T3..TS4TORXT150.09

SFCC 25 4705005250021026.5CCGT0602..TS25TORXT080.01

SFCC 32 47050053200211.534.5CCGT0602..TS25TORXT080.02

SFCC 50 4705005500021952CCGT09T3..TS4TORXT150.08 SFCC 51 4705005500042152CCMT1204..TS5TORXT250.09

SFQC 50 47050055006220.553CCMT09T3..TS4TORXT150.1

SFSM 50-15° 4705005500111950.5CCMT09T3..TS4TORXT150.07

50-30° 4705005500131950.5CCMT09T3..TS4TORXT150.07

50-45° 4705005500151950.5CCMT09T3..TS4TORXT150.07

B3.22 57201052200122~3068TPGX0902..CS250TTORXT080.1 B5.06 5720105061056~836WCGT0201..TS21TORXT060.075 B5.08 5720105081058~1048WCGT0201..TS211TORXT060.09 B5.10 57201051010510~1260TPGX0902..CS250TTORXT080.1 B5.12 57201051210512~1472TPGX0902..CS250TTORXT080.1 B5.14 57201051410514~1684TPGX0902..CS250TTORXT080.2 B5.16 57201051610516~1896TPGX0902..CS250TTORXT080.3 B8.06 5720105061086~845WCGT0201..TS21TORXT060.065 B8.08 5720105081088~1060WCGT0201..TS211TORXT060.08 B8.10 57201051010810~1275TPGX0902..CS250TTORXT080.1 B8.12 57201051210812~1490TPGX0902..CS250TTORXT080.2 B8.14 57201051410814~16105TPGX0902..CS250TTORXT080.2 B8.16 57201051610816~18120TPGX0902..CS250TTORXT080.3

TRM

REF. CODEØ1LL1AB

SFTP 25 4705005250011026.5TPGX0902..CS250TTORXT080.01 SFTP 32 47050053200111.534.5TPGX0902..CS250TTORXT080.02

SFTP 50 4705005500011952TPGX1103..CS300890TTORXT080.08

SFTP 51 4705005500032152TCMT16T3..TS4TORXT150.09

SFCC 25 4705005250021026.5CCGT0602..TS25TORXT080.01

SFCC 32 47050053200211.534.5CCGT0602..TS25TORXT080.02

SFCC 50 4705005500021952CCGT09T3..TS4TORXT150.08 SFCC 51 4705005500042152CCMT1204..TS5TORXT250.09 SFQC 50 47050055006220.553CCMT09T3..TS4TORXT150.1

SFSM 50-15° 4705005500111950.5CCMT09T3..TS4TORXT150.07

50-30° 4705005500131950.5CCMT09T3..TS4TORXT150.07

50-45°

B3.22 57201052200122~3068TPGX0902..CS250TTORXT080.1 B5.06

B5.08

B5.10 57201051010510~1260TPGX0902..CS250TTORXT080.1 B5.12 57201051210512~1472TPGX0902..CS250TTORXT080.1 B5.14 57201051410514~1684TPGX0902..CS250TTORXT080.2 B5.16 57201051610516~1896TPGX0902..CS250TTORXT080.3 B8.06 5720105061086~845WCGT0201..TS21TORXT060.065 B8.08 5720105081088~1060WCGT0201..TS211TORXT060.08 B8.10 57201051010810~1275TPGX0902..CS250TTORXT080.1 B8.12 57201051210812~1490TPGX0902..CS250TTORXT080.2 B8.14 57201051410814~16105TPGX0902..CS250TTORXT080.2 B8.16 57201051610816~18120TPGX0902..CS250TTORXT080.3

TRM

REF. CODEØ1LL1AB

SFTP 25 4705005250011026.5TPGX0902..CS250TTORXT080.01

SFTP 32 47050053200111.534.5TPGX0902..CS250TTORXT080.02

SFTP 50 4705005500011952TPGX1103..CS300890TTORXT080.08

SFTP 51 4705005500032152TCMT16T3..TS4TORXT150.09

SFCC 25 4705005250021026.5CCGT0602..TS25TORXT080.01

SFCC 32 47050053200211.534.5CCGT0602..TS25TORXT080.02 SFCC 50 4705005500021952CCGT09T3..TS4TORXT150.08 SFCC 51 4705005500042152CCMT1204..TS5TORXT250.09 SFQC 50 47050055006220.553CCMT09T3..TS4TORXT150.1

SFSM 50-15° 4705005500111950.5CCMT09T3..TS4TORXT150.07

50-30° 4705005500131950.5CCMT09T3..TS4TORXT150.07

50-45°

B3.22 57201052200122~3068TPGX0902..CS250TTORXT080.1 B5.06

B5.08

B5.10 57201051010510~1260TPGX0902..CS250TTORXT080.1 B5.12 57201051210512~1472TPGX0902..CS250TTORXT080.1 B5.14 57201051410514~1684TPGX0902..CS250TTORXT080.2 B5.16 57201051610516~1896TPGX0902..CS250TTORXT080.3 B8.06 5720105061086~845WCGT0201..TS21TORXT060.065 B8.08 5720105081088~1060WCGT0201..TS211TORXT060.08 B8.10 57201051010810~1275TPGX0902..CS250TTORXT080.1 B8.12 57201051210812~1490TPGX0902..CS250TTORXT080.2 B8.14 57201051410814~16105TPGX0902..CS250TTORXT080.2 B8.16 57201051610816~18120TPGX0902..CS250TTORXT080.3

REF.

SFTP

SFTP

SFTP

SFTP

SFCC

SFCC

SFCC

SFQC

SFSM

SFSM

SFSM

TRM MICROMETRIC

CODEABCL

REF. CODEØ TRC 14 45501140030114.5~180.02 TRC 16 45501160034118~240.05 TRC 20 45501200040122~300.1 TRC 25 45501250050128~400.2 TRC 32 45501320063135.5~53.50.35 TRC 40 45501400080148~660.7

SFTP 40 4705005400011444TPGX1103..CS300890TTORXT080.04

SFQC 16 47050051606210182CCMT0602..TS25TORXT080.005

SFQC 20 47050052006210.522.52CCMT0602..TS25TORXT080.008

SFQC 25 4705005250621228.52.5CCMT0602..TS25TORXT080.01

SFQC 32 47050053206213.535.52.5CCMT0602..TS25TORXT080.03

SFQC 40 47050054006216.5463CCMT09T3..TS4TORXT150.06

SFSM 25-15° 4705005250111025.51.6CCMT0602..TS25TORXT080.01

SFSM 25-30° 4705005250131025.53CCMT0602..TS25TORXT080.01 SFSM 25-45° 4705005250151025.54.3CCMT0602..TS25TORXT080.01

SFSM 32-15° 47050053201111.533.51.6CCMT0602..TS25TORXT080.02 SFSM 32-30° 47050053201311.533.53CCMT0602..TS25TORXT080.02

SFSM 32-45° 47050053201511.533.54.3CCMT0602..TS25TORXT080.02

40-15° 4705005400111442.52.4CCMT09T3..TS4TORXT150.03 SFSM 40-30° 4705005400131442.54.6CCMT09T3..TS4TORXT150.03

40-45° 4705005400151442.56.5CCMT09T3..TS4TORXT150.03

TRC CENTESIMAL

TRC 14 Ø 14.5 ~

TRC 16 Ø

MHD’16

TRC 20 Ø

~

TRC 25 Ø

MHD’14 MHD’20 MHD’25

TRC 32 Ø

~

MHD’32

TRC 40 Ø

~

MHD’40

CODEØ1LL1AB

SFTP 25 4705005250011026.5TPGX0902..CS250TTORXT080.01

SFTP 32 47050053200111.534.5TPGX0902..CS250TTORXT080.02

SFTP 50 4705005500011952TPGX1103..CS300890TTORXT080.08

SFTP 51 4705005500032152TCMT16T3..TS4TORXT150.09

SFCC 25 4705005250021026.5CCGT0602..TS25TORXT080.01

SFCC 32 47050053200211.534.5CCGT0602..TS25TORXT080.02 SFCC 50 4705005500021952CCGT09T3..TS4TORXT150.08 SFCC 51 4705005500042152CCMT1204..TS5TORXT250.09

SFQC 50 47050055006220.553CCMT09T3..TS4TORXT150.1

SFSM 50-15° 4705005500111950.5CCMT09T3..TS4TORXT150.07

50-30° 4705005500131950.5CCMT09T3..TS4TORXT150.07

50-45° 4705005500151950.5CCMT09T3..TS4TORXT150.07

B3.11

B3.22 57201052200122~3068TPGX0902..CS250TTORXT080.1 B5.06 5720105061056~836WCGT0201..TS21TORXT060.075 B5.08 5720105081058~1048WCGT0201..TS211TORXT060.09 B5.10 57201051010510~1260TPGX0902..CS250TTORXT080.1 B5.12 57201051210512~1472TPGX0902..CS250TTORXT080.1 B5.14 57201051410514~1684TPGX0902..CS250TTORXT080.2 B5.16 57201051610516~1896TPGX0902..CS250TTORXT080.3 B8.06 5720105061086~845WCGT0201..TS21TORXT060.065 B8.08 5720105081088~1060WCGT0201..TS211TORXT060.08 B8.10 57201051010810~1275TPGX0902..CS250TTORXT080.1 B8.12 57201051210812~1490TPGX0902..CS250TTORXT080.2 B8.14 57201051410814~16105TPGX0902..CS250TTORXT080.2 B8.16 57201051610816~18120TPGX0902..CS250TTORXT080.3

SFTP

SFCC

47050055006220.553CCMT09T3..TS4TORXT150.1

B3.18 57201051800118~2263TPGX0902..CS250TTORXT080.1 B3.22

B5.06

B5.08

B5.10

B5.12 57201051210512~1472TPGX0902..CS250TTORXT080.1 B5.14 57201051410514~1684TPGX0902..CS250TTORXT080.2 B5.16 57201051610516~1896TPGX0902..CS250TTORXT080.3 B8.06 5720105061086~845WCGT0201..TS21TORXT060.065 B8.08 5720105081088~1060WCGT0201..TS211TORXT060.08 B8.10 57201051010810~1275TPGX0902..CS250TTORXT080.1 B8.12

B8.14

B8.16 57201051610816~18120TPGX0902..CS250TTORXT080.3

B5.10 B5.12 B5.14

TRC

REF.

SFTP 32

SFCC

47050055006220.553CCMT09T3..TS4TORXT150.1

B3.18 57201051800118~2263TPGX0902..CS250TTORXT080.1 B3.22 57201052200122~3068TPGX0902..CS250TTORXT080.1 B5.06 5720105061056~836WCGT0201..TS21TORXT060.075 B5.08 5720105081058~1048WCGT0201..TS211TORXT060.09 B5.10 57201051010510~1260TPGX0902..CS250TTORXT080.1 B5.12 57201051210512~1472TPGX0902..CS250TTORXT080.1 B5.14 57201051410514~1684TPGX0902..CS250TTORXT080.2 B5.16 57201051610516~1896TPGX0902..CS250TTORXT080.3 B8.06 5720105061086~845WCGT0201..TS21TORXT060.065 B8.08 5720105081088~1060WCGT0201..TS211TORXT060.08 B8.10 57201051010810~1275TPGX0902..CS250TTORXT080.1 B8.12 57201051210812~1490TPGX0902..CS250TTORXT080.2 B8.14 57201051410814~16105TPGX0902..CS250TTORXT080.2 B8.16 57201051610816~18120TPGX0902..CS250TTORXT080.3

B5.10 B5.12 B5.14

B8.10 B8.12 B8.14 B8.16

B5.06 5720105061056~836WCGT0201..TS21TORXT060.075 B5.08 5720105081058~1048WCGT0201..TS211TORXT060.09

B5.10 57201051010510~1260TPGX0902..CS250TTORXT080.1

B5.12 57201051210512~1472TPGX0902..CS250TTORXT080.1

B5.14 57201051410514~1684TPGX0902..CS250TTORXT080.2

B8.10

TRE

REF. CODEØ

455200320321•35.5~51.50.4

•

SFTP32 SFCC32SFQC32 SFSM32-15°SFSM32-30°SFSM32-45°

MHD’32

REF. CODEABL

SFCC 32 47050053200211.534.5CCGT0602..TS25TORXT080.02 SFTP 32 47050053200111.534.5TPGX0902..CS250TTORXT080.02 SFQC 32 47050053206213.535.5CCMT0602..TS25TORXT080.03 SFSM 32-15° 47050053201111.533.51.6CCMT0602..TS25TORXT080.02 SFSM 32-30° 47050053201311.533.53CCMT0602..TS25TORXT080.02 SFSM 32-45° 47050053201511.533.54.3CCMT0602..TS25TORXT080.02

REF.

SFCC 40

40

SFSM

40

40-45°

REF.

REF. CODEØ1LL1AB

SFTP 25 4705005250011026.5TPGX0902..CS250TTORXT080.01

SFTP 32 47050053200111.534.5TPGX0902..CS250TTORXT080.02

SFTP 50 4705005500011952TPGX1103..CS300890TTORXT080.08

SFTP 51 4705005500032152TCMT16T3..TS4TORXT150.09

SFCC 25 4705005250021026.5CCGT0602..TS25TORXT080.01

SFCC 32 47050053200211.534.5CCGT0602..TS25TORXT080.02

SFCC 50 4705005500021952CCGT09T3..TS4TORXT150.08 SFCC 51 4705005500042152CCMT1204..TS5TORXT250.09

SFQC 50 47050055006220.553CCMT09T3..TS4TORXT150.1

SFSM 50-15° 4705005500111950.5CCMT09T3..TS4TORXT150.07

50-30° 4705005500131950.5CCMT09T3..TS4TORXT150.07

50-45° 4705005500151950.5CCMT09T3..TS4TORXT150.07

B3.11

B3.22 57201052200122~3068TPGX0902..CS250TTORXT080.1 B5.06 5720105061056~836WCGT0201..TS21TORXT060.075 B5.08 5720105081058~1048WCGT0201..TS211TORXT060.09 B5.10 57201051010510~1260TPGX0902..CS250TTORXT080.1 B5.12 57201051210512~1472TPGX0902..CS250TTORXT080.1 B5.14 57201051410514~1684TPGX0902..CS250TTORXT080.2 B5.16 57201051610516~1896TPGX0902..CS250TTORXT080.3 B8.06 5720105061086~845WCGT0201..TS21TORXT060.065 B8.08 5720105081088~1060WCGT0201..TS211TORXT060.08 B8.10 57201051010810~1275TPGX0902..CS250TTORXT080.1 B8.12 57201051210812~1490TPGX0902..CS250TTORXT080.2 B8.14 57201051410814~16105TPGX0902..CS250TTORXT080.2 B8.16 57201051610816~18120TPGX0902..CS250TTORXT080.3

PS

REF. CODEØ1LL1AB

SFTP 25 4705005250011026.5TPGX0902..CS250TTORXT080.01 SFTP 32 47050053200111.534.5TPGX0902..CS250TTORXT080.02

SFTP 50 4705005500011952TPGX1103..CS300890TTORXT080.08

SFTP 51 4705005500032152TCMT16T3..TS4TORXT150.09

SFCC 25 4705005250021026.5CCGT0602..TS25TORXT080.01 SFCC 32 47050053200211.534.5CCGT0602..TS25TORXT080.02 SFCC 50 4705005500021952CCGT09T3..TS4TORXT150.08 SFCC 51 4705005500042152CCMT1204..TS5TORXT250.09

SFQC 50 47050055006220.553CCMT09T3..TS4TORXT150.1

SFSM 50-15° 4705005500111950.5CCMT09T3..TS4TORXT150.07 SFSM 50-30° 4705005500131950.5CCMT09T3..TS4TORXT150.07 SFSM 50-45° 4705005500151950.5CCMT09T3..TS4TORXT150.07

B5.06

B5.08

B5.10

B5.12 57201051210512~1472TPGX0902..CS250TTORXT080.1 B5.14 57201051410514~1684TPGX0902..CS250TTORXT080.2 B5.16 57201051610516~1896TPGX0902..CS250TTORXT080.3 B8.06 5720105061086~845WCGT0201..TS21TORXT060.065 B8.08 5720105081088~1060WCGT0201..TS211TORXT060.08 B8.10 57201051010810~1275TPGX0902..CS250TTORXT080.1 B8.12 57201051210812~1490TPGX0902..CS250TTORXT080.2 B8.14 57201051410814~16105TPGX0902..CS250TTORXT080.2 B8.16 57201051610816~18120TPGX0902..CS250TTORXT080.3

PS

TRE

PS

REF. CODEØ1LL1AB

SFTP 25 4705005250011026.5TPGX0902..CS250TTORXT080.01

SFTP 32 47050053200111.534.5TPGX0902..CS250TTORXT080.02

SFTP 50 4705005500011952TPGX1103..CS300890TTORXT080.08

SFTP 51 4705005500032152TCMT16T3..TS4TORXT150.09

SFCC 25 4705005250021026.5CCGT0602..TS25TORXT080.01

SFCC 32 47050053200211.534.5CCGT0602..TS25TORXT080.02

SFCC 50 4705005500021952CCGT09T3..TS4TORXT150.08 SFCC 51 4705005500042152CCMT1204..TS5TORXT250.09

SFQC 50 47050055006220.553CCMT09T3..TS4TORXT150.1

SFSM 50-15° 4705005500111950.5CCMT09T3..TS4TORXT150.07

50-30° 4705005500131950.5CCMT09T3..TS4TORXT150.07

B5.06

B5.08

B5.10

B5.12

B5.14

B5.16 57201051610516~1896TPGX0902..CS250TTORXT080.3 B8.06 5720105061086~845WCGT0201..TS21TORXT060.065 B8.08 5720105081088~1060WCGT0201..TS211TORXT060.08 B8.10 57201051010810~1275TPGX0902..CS250TTORXT080.1 B8.12 57201051210812~1490TPGX0902..CS250TTORXT080.2 B8.14 57201051410814~16105TPGX0902..CS250TTORXT080.2 B8.16 57201051610816~18120TPGX0902..CS250TTORXT080.3

BPS

BIT-HOLDERS

ISO50-60D.60

BPS

PF40-60 PSC80Linea

PF40-60 MHD’80-110-140 PF40-60MONOd’

ISO

REF. CODEd2LM

71ISO-50-DC6040•6040244.8

71ISO-60-DC6040•6040309.7

PRL

REF. CODEABC

Ø3min=(Ø2+A+1):2

A

Ø

Ø

Ø

Ø

Ø

BPS

202~302302~402402~502502~602602~702702~802802~902

BPS 200BPS

FINISHING

700BPS

A 194298394494594694794

Ø 1 200~300300~400400~500500~600600~700700~800800~900

Ø 1 PRL 100 300~400400~500500~600600~700700~800800~900900~1000

Ø 1 PRL 300 400~600500~700600~800700~900800~1000900~11001000~1200

Ø 2 202~302302~402402~502502~602602~702702~802802~902

Ø 2 PRL 100 302~402402~502502~602602~702702~802802~902902~1002

Ø 2 PRL 300 402~602502~702602~802702~902802~1002902~11021002~1202

REF.

SFTP

SFQC

Suppliedwithoutcolletsandclampingwrenches

REF. CODEMHD’d1dLL1N·m

PE 16 / ER11M 655701600110160.5~7252.50.03ER-11ME11M30 PE 20 / ER16M 655702000160200.5~103210.06ER-16ME16M40

PE 25 / ER20M 655702500200251~13402.50.15ER-20ME20M80

PE 32 / ER25M 655703200250321~16421.50.25ER-25ME25M160

PE 40 / ER25 655704000250401~164550.4UM/ER25E25200

PE 50 / ER25 655705000250501~164870.7UM/ER25E25200

PE 50 / ER32 655705000320502~205581UM/ER32E32220

PE 63 / ER32 655706300320632~2059121.3UM/ER32E32220

PE 63 / ER40 655706300400633~2664121.5UM/ER40E40250

Suppliedwithoutcolletsandclampingwrenches

REF. CODEMHD’d1d2d3LL1

FORCE 50/20 HS 65630500020550204860601 FORCE 63/32 HS 65630630032563326680802

AW WELDON WHISTLE NOTCH CHUCKING TOOLS

REF. CODEMHD’d1d2H5d3LL1L2L3 pic.

AW 50/6 655805000060506254432.5720.5 1 AW 50/8 655805000080508284433720.5 1

AW 50/10 65580500010050103552421130.7 1 AW 50/12 65580500012050124257481130.8 1 AW 50/14 65580500014050144257481130.8 1 AW 50/16 65580500016050164867611741.1 1 AW 50/20 655805000200502051671641.2 1 AW 50/25 655805000250502563802241.8 2

AW 63/16 65580630016063164864531441.4 1 AW 63/20 65580630020063205266561441.5 1

AW 63/25 655806300250632564741642.1 2

AW 63/32 655806300320633272761442.5 2

AW 80/40 655808000400804080831243.2 2

DISC AND FACING CUTTER HOLDERS REF. CODEMHD’d1d2d3d4MLL1 pic.

PF 40/16 65590402016540163217150.3 1

PF 40/22 65590402022540224019130.4 1

PF 50/16 65590500016050163217150.5 1

PF 50/22 65590500022050224019150.5 1

PF 50/27 65590500027050275021150.6 1

PF 50/32 65590500032050326024150.7 1

PF 63/22 65590630022063226019150.9 1

PF 63/27 65590630027063276021151.1 1

PF 63/32 65590630032063326324151.2 1

PF 80/32 65590800032080328024241.7 1

PF 80/40 65590800040080408466.7M1227241.9 2

PF 80/50 65590800050080509030242.0 2

PF 80/60 6559080006008060128.5101.6M164031.53.5 2

PF 110/40 655911000400110408866.7M1227204.2 2

PF 110/60 65591100060011060128.5101.6M1640366 2

PF 140/40 •655914000400140408866.7M1227266.2 2

PF 140/60 •65591400060014060140101.6M1640267.8 2

MHD’ FORCE ULTRA-TIGHT TOOLHOLDER FORCE

CM MORSE TAPER CHUCKING TOOLS

MT DIN 228-A. follows:a.Driveinscrew1;b.Removeexpandingpin2andsleeve3to allowtheAllenwrenchtobeintroducedfromtherear;c.Fitthetooland

MT DIN 228-B.

withDIN228-Btooth.

REF. CODEMHD’d1MORSEd2d3LL1M CM 50/1 6560050000105012012.0658068M60.6 CM 50/2 6560050000205023017.78010086M100.7 CM 50/3 6560050000305033623.825120110M121 CM 63/3 6560063000306333623.825120108M121.3 CM 63/4 6560063000406344831.267150133M162

REF. CODEMHD’d1WFLKLL1d2d3a AM 50/M3-12 65650500010050WFLK115B/A308M3~12726019367.50.9 AM 50/M8-20 65650500020050WFLK225B/A308M8~20106315312.51.2 AM 63/M3-12 65650630010063WFLK115B/A308M3~12705819367.51 AM 63/M8-20 65650630020063WFLK225B/A308M8~2010493315312.51.3

WCGTL

CARBIDE REF. dsr DP300DK100DC100DC100T WCGT 020102 L 3.971.590.2TS21*-TS211*TORXT06•••• WCGT 020104 L 3.971.590.4TS21*-TS211*TORXT06••••

*TS21:B...06/*TS211:B...08

CCGTL

CARBIDE

REF. dsr DP300DK100DC100DC100T

CCGT 060200 L10° 6.352.380TS25TORXT08••••

CCGT 060202 L 6.352.380.2TS25TORXT08•••• CCGT 060204 L 6.352.380.4TS25TORXT08•••• CCGT 09T302 L 9.5253.970.2TS4TORXT15•••• CCGT 09T304 L 9.5253.970.4TS4TORXT15••••

CARBIDE REF. dsr DP300DK100DC100DC100T TPGX 090200 L10° 5.562.380CS250TTORXT08•••• TPGX 090202 L 5.562.380.2CS250TTORXT08•••• TPGX 090204 L 5.562.380.4CS250TTORXT08•••• TPGX 110300 L10° 6.353.180CS300890TTORXT08•••• TPGX 110302 L 6.353.180.2CS300890TTORXT08•••• TPGX 110304 L 6.353.180.4CS300890TTORXT08••••

TPGX

DIAMOND CUBIC BORON REF. dsr D20 MDCD20 CBND25 CBN TPGX 090202

TPGX 090204 5.562.380.4CS250TTORXT08••• TPGX 110302

TPGX 110304

CCMT

CARBIDE REF.

CCMT 060202

060204

CCMT 09T304

09T308

CCMT 120404

120408

DP300DP100 R

DP100R

Finishing.

Finishing.

Finishing.

Finishing.

Finishing.

REF.

TS

TS

CS

TS

TS

TS

REF.

TORX TO6 101500900600

TORX TO6 101500900600

TORX TO8 101500900800

TORX TO8 101500900800

TORX TO8 101500900800

TORX T15 101500901500

TORX T25 101500902500

The PSC coupling

Coupling PSC ISO 26623-1/2

PSC

S

MHD boring line

PSC SN·m

PSC 32 845 PSC 40 855 PSC 50 1095 PSC 63 14170 PSC 80 14170 PSC 100 17380

DIN-AD / PSC DIN 69871 / ISO 26623-2

DIN REF. CODELL1

40 DIN69871-AD40 PSC 40.30 41PS040140204030110.8

40 DIN69871-AD40 PSC 50.40 41PS050140285040210.9

40 DIN69871-AD40 PSC 50.50 41PS050140225050311.1

50 DIN69871-AD50 PSC 50.30 41PS050150205030112.7

50 DIN69871-AD50 PSC 63.30 41PS063150286330112.8

50 DIN69871-AD50 PSC 63.50 41PS063150226350313

50 DIN69871-AD50 PSC 80.70 41PS080150208070513.7

HSK-A / PSC DIN 69893 / ISO 26623-2

HSK-A REF. CODELL1

63 HSK-A63 PSC 40.80 41PS040563204080541.1

63 HSK-A63 PSC 50.90 41PS050563205090641.5

100 HSK-A100 PSC 50.100 41PS0505992050100713

100 HSK-A100 PSC 63.110 41PS0635992063110813.6

100 HSK-A100 PSC 80.120 41PS0805992080120914.7

125 HSK-A125 PSC 80.130 41PS08059520801301016.5

Supplied with coolant tube

MAS BT-AD / PSC MAS 403 BT / ISO 26623-2

BT REF. CODELL1

40 MAS403 BT40-AD PSC 40.30 41PS04014030403030.9

40 MAS403 BT40-AD PSC 50.50 41PS050140325050231.2

50 MAS403 BT50-AD PSC 50.40 41PS05015030504023.4

50 MAS403 BT50-AD PSC 63.50 41PS063150326350123.5

50 MAS403 BT50-AD PSC 80.70 41PS080150308070324

CAT-AD / PSC ANSI B5.50 / ISO 26623-2

CAT REF. CODELL1L2M

40 CAT40 AD PSC 40.40 41PS040140454044.540215UNC5/8-110.95

40 CAT40 AD PSC 50.50 41PS05014045505031UNC5/8-111

50 CAT50 AD PSC 50.40 41PS050150455069.940215UNC1/82.5

50 CAT50 AD PSC 63.50 41PS063150456370503112.5UNC1/83

50 CAT50 AD PSC 80.100 41PS080150458010081UNC1/84.6

REF.

EXTENSIONS -

CODEL

PR PSC 32.60 656PS0320600032600.35

PR PSC 32.80 656PS0320800032800.45

PR PSC 40.60 656PS0400600040600.55

PR PSC 40.80 656PS0400800040800.7

PR PSC 40.100 656PS0401000040100

PR PSC 50.80 656PS0500800050801.1

PR PSC 50.100 656PS05010000501001.4

PR PSC 63.100 656PS06310000631002.2

PR PSC 63.140 656PS06314000631403.2

PR PSC 80.100 656PS08010000801003.6

PR PSC 80.125 656PS08012500801254.5

REF.

CODELL1

RD PSC 40/32.70 657PS04003200403270120.6

RD PSC 50/32.60 657PS0500320050326034.80.65

RD PSC 50/40.65 657PS05004000504065450.7

RD PSC 50/40.85 657PS05004001504085121

RD PSC 63/32.70 657PS06303200633270391.1

RD PSC 63/40.80 657PS0630400063408051.41.3

RD PSC 63/50.80 657PS0630500063508051.51.5

RD PSC 63/50.110 657PS063050016350110123.4

RD PSC 80/32.60 657PS0800320080326029.31.8

RD PSC 80/40.70 657PS0800400080407036.51.9

RD PSC 80/50.80 657PS0800500080508049.32.2

RD PSC 80/63.80 657PS0800630080638053.12.5 RD PSC 80/63.120 657PS080063018063120123.9 RD PSC 100/80.100 657PS100080001008010058.25

REDUCTIONS TO MODULAR

PSC REF.

PSC

PSC

- MHD’

-

pic.

41640260400440450.4 1

50 PSC 50 - MHD’ 50.55 41650260500550550.8 1

63 PSC 63 - MHD’ 40.50 4164026063054050280.9 1

63 PSC 63 - MHD’ 40.120 4164026063124044120981.5 2

63 PSC 63 - MHD’ 50.55 4165026063055055330.8 1

63 PSC 63 - MHD’ 50.67 4165026063065067451.1 1

PSC 63 - MHD’ 50.120 4165026063125054120981.9 2

63 PSC 63 - MHD’ 63.77 41663260630763771.8 1

80 PSC 80 - MHD’ 50.60 4165026080065060302 1

80 PSC 80 - MHD’ 50.120 4165026080125054120902.8 2

80 PSC 80 - MHD’ 63.70 4166326080076370402.3 1

80 PSC 80 - MHD’ 63.150 41663260801563671501204 2

80 PSC 80 - MHD’ 80.75 41680260800780752.6 1

80 PSC 80 - MHD’ 80.120 416802608012801204.3 1

100 PSC 100 - MHD’ 80.80 41680261000811080443.5 1

100 PSC 100 - MHD’ 110.120 416912610012110120845 1

PSC REF.

•

CODEMLL1

40 PSC 40 PF22.25 71PSC-040PF2202•2225190.3

50 PSC 50 PF22.25 71PSC-050PF22022225190.5

PSC 50 PF27.25 71PSC-050PF2702•2725210.6

PSC 63 PF27.25 71PSC-063PF27022725210.8

PSC 63 PF32.25 71PSC-063PF3202•3225240.9

80 PSC 80 PF32.30 71PSC-080PF3203•3230241.8

80 PSC 80 PF40.45 71PSC-080PF4004•408466.7M1245272.4

80 PSC 80 PF60.60 71PSC-080PF6006•60128.5101.6M1660405.2

pic.1pic.2

PSC REF. CODEHLL1L2 pic.

63 PSC 63 - MF 12.70 71PSC-063MF120712284670480.9 1

PSC 63 - MF 12.100 71PSC-063MF1210122831.5461007829.51.4 2

PSC 63 - MF 20.80 71PSC-063MF200820486080581.3 1

63 PSC 63 - MF 20.120 71PSC-063MF2012204860120981.9 2

63 PSC 63 - MF 32.100 71PSC-063MF32103266801002.1 1 63 PSC 63 - MF 32.140 71PSC-063MF32143266801403.1 2

80 PSC 80 - MF 20.80 71PSC-080MF200820486080503.7 1 80 PSC 80 - MF 20.125 71PSC-080MF2012204860125954.1 2

80 PSC 80 - MF 32.100 71PSC-080MF3210326680100704.4 1

80 PSC 80 - MF 32.160 71PSC-080MF32163266801601304.9 2

SEMIFINISHED CHUCK HOLDERS

PSC REF.

CODELL1 HRC

40 PSC 40 - NS 50.160/140 H.28 71PSC040Z20501450201402.4 28

40 PSC 40 - NS 50.160/140 H.42 71PSC040Z40501450201402.4 42

40 PSC 40 - NS 63.160/140 H.28 71PSC040Z20631463201403.6 28

40 PSC 40 - NS 63.160/140 H.42 71PSC040Z40631463201403.6 42

40 PSC 40 - NS 80.160/140 H.28 71PSC040Z20801480201405.7 28

40 PSC 40 - NS 80.160/140 H.42 71PSC040Z40801480201405.7 42

50 PSC 50 - NS 63.160/140 H.28 71PSC050Z20631463201403.8 28

50 PSC 50 - NS 63.160/140 H.42 71PSC050Z40631463201403.8 42

50 PSC 50 - NS 80.160/140 H.28 71PSC050Z208014802014010.2 28

50 PSC 50 - NS 80.160/140 H.42 71PSC050Z408014802014010.2 42

50 PSC 50 - NS 100.180/160 H.28 71PSC050Z210016100201605.9 28

50 PSC 50 - NS 100.180/160 H.42 71PSC050Z410016100221605.9 42

63 PSC 63 - NS 80.162/140 H.28 71PSC063Z20801480221406.2 28

63 PSC 63 - NS 80.162/140 H.42 71PSC063Z40801480221406.2 42

63 PSC 63 - NS 100.182/160 H.28 71PSC063Z2100161002216010.4 28

63 PSC 63 - NS 100.182/160 H.42 71PSC063Z4100161002216010.4 42

63 PSC 63 - NS 120.202/180 H.28 71PSC063Z2120181202218017 28

63 PSC 63 - NS 120.202/180 H.42 71PSC063Z4120181202218017 42

80 PSC 80 - NS 100.190/160 H.28 71PSC080Z2100161003016011.5 28

80 PSC 80 - NS 100.190/160 H.42 71PSC080Z4100161003016011.5 42

80 PSC 80 - NS 140.210/180 H.28 71PSC080Z2140181403018023.4 28

80 PSC 80 - NS 140.210/180 H.42 71PSC080Z4140181403018023.4 42

MONOforce

MONOforce represents

of

Builtintheversionformachine spindlesHSK63and100,ISO 26623-1PSC63and80,as wellasDIN69871andMASBT 40and50,itallowstheuseof reductionbushingsofØ12mm, Ø20mmandØ32mm.Itis availableintheentirediametral rangecompatiblewiththese housingdiametersforclamping fromØ3mmtoØ25mm, alsoSEALED.

MAX.RPM 15.000

MAX.40

solution

is

precision

loads.

DIN 69871 AD

403 BT

DIN REF.

Withoutclampingwrench-Chipprearrangement

CODEd1d2d3HLL1L2kg pic.

40 DIN69871-AD40 MF12.50 71DIN-A40MF120512284650310.8 1

40 DIN69871-AD40 MF12.100 71DIN-A40MF1210122832461008129.51.2 2

40 DIN69871-AD40 MF20.60 71DIN-A40MF200620486360411.1 1

40 DIN69871-AD40 MF20.100 71DIN-A40MF2010204863100811.4 2

40 DIN69871-AD40 MF32.95 71DIN-A40MF3209326680951.6 1

40 DIN69871-AD40 MF32.140 71DIN-A40MF32143266801402.0 2

50 DIN69871-AD50 MF20.80 71DIN-A50MF200820486380612.3 1

50 DIN69871-AD50 MF20.125 71DIN-A50MF20122048631251062.7 2

50 DIN69871-AD50 MF32.75 71DIN-A50MF320732669075562.8 1

50 DIN69871-AD50 MF32.160 71DIN-A50MF32163266901601413.2 2

MAS 403 BT AD

Withoutclampingwrench-Chipprearrangement

BT REF. CODEd1d2d3HLL1L2kg pic.

40 MAS403 BT40-AD MF12.60 71MBT-A40MF120612284660330.9 1

40 MAS403 BT40-AD MF12.100 71MBT-A40MF1210122832461007329.51.4 2

40 MAS403 BT40-AD MF20.65 71MBT-A40MF200720486365381.3 1

40 MAS403 BT40-AD MF20.100 71MBT-A40MF2010204863100731.9 2

40 MAS403 BT40-AD MF32.90 71MBT-A40MF3209326680902.1 1

40 MAS403 BT40-AD MF32.140 71MBT-A40MF32143266801403.1 2

50 MAS403 BT50-AD MF20.85 71MBT-A50MF200820486385473.7 1

MAS403 BT50-AD MF20.125 71MBT-A50MF2012204863125874.1 2

50 MAS403 BT50-AD MF32.95 71MBT-A50MF320932669095574.4 1

50 MAS403 BT50-AD MF32.160 71MBT-A50MF32163266901601224.9 2

Withoutclampingwrench-Chipprearrangement

BT REF. CODEd1d2d3HALL1L2kg pic.

40 MAS403 BT40-AD FC MF12.100 71MBF-A40MF12101228324611007329.51.4 2

MAS403 BT40-AD FC MF20.65 71MBF-A40MF2007204863165381.3 1

MAS403 BT40-AD FC MF32.90 71MBF-A40MF32093266801902.1 1

50 MAS403 BT50-AD FC MF20.85 71MBF-A50MF20082048631.585473.7 1

MAS403 BT50-AD FC MF32.95 71MBF-A50MF32093266901.595574.4 1

Supplied with coolant tube - Withoutclampingwrench-Chipprearrangement

HSK-A REF. CODEd1d2d3HLL1L2kg pic.

63 HSK-A63 MF12.70 71HSK-A63MF120712284670440.8 1

HSK-A63 MF12.100 71HSK-A63MF1210122832461007429.51.1 2

HSK-A63 MF20.85 71HSK-A63MF200820486085591.2 1

63 HSK-A63 MF20.125 71HSK-A63MF2012204860125991.7 2

63 HSK-A63 MF32.105 71HSK-A63MF32103266801052 1

HSK-A63 MF32.140 71HSK-A63MF32143266801402.6 2

100 HSK-A100 MF20.95 71HSKA100MF200920486095662.8 1

100 HSK-A100 MF32.110 71HSKA100MF3211326680110813.1 1

100 HSK-A100 MF32.160 71HSKA100MF32163266801601313.6 1

125 HSK-A125 MF32.120 71HSKA125MF3212326680120915.3 1

PSC REF.

PSC

PSC

PSC

PSC

-

-

- MF

-

PSC 63 - MF

PSC 63 - MF

PSC 80 - MF

PSC 80 - MF

PSC 80 - MF

PSC 80 - MF

Withoutclampingwrench-Chipprearrangement

CODEd1d2d3HLL1L2kg pic.

1

2

71PSC-063MF2012204860120981.9 2

71PSC-063MF32103266801002.1 1

1

2

2

71PSC-080MF32163266801601304.9 2

1

1

DINREF. CODEkg

KIT K01 MONOFORCE 12.50 DIN40AD 7KDIN-A40MF12051.5

KIT K01 MONOFORCE 20.60 DIN40AD 7KDIN-A40MF20062

KIT K01 MONOFORCE 32.95 DIN40AD 7KDIN-A40MF32094.4

KIT K01 MONOFORCE 20.80 DIN50AD 7KDIN-A50MF20084.6

KIT K01 MONOFORCE 32.75 DIN50AD 7KDIN-A50MF32076.2

BTREF. CODEKg.

40 KIT K01 MONOFORCE 12.60 BT40AD 7KMBT-A40MF12061.5

KIT K01 MONOFORCE 20.65 BT40AD 7KMBT-A40MF20072.3

KIT K01 MONOFORCE 32.90 BT40AD 7KMBT-A40MF32094.6

50 KIT K01 MONOFORCE 20.85 BT50AD 7KMBT-A50MF20085.4

50 KIT K01 MONOFORCE 32.95 BT50AD 7KMBT-A50MF32097.5

HSK-AREF. CODEKg.

63 KIT K01 MONOFORCE 12.70 HSK63 7KHSK-A63MF12071.5

KIT K01 MONOFORCE 20.85 HSK63 7KHSK-A63MF20082.3

KIT K01 MONOFORCE 32.105 HSK63 7KHSK-A63MF32104.5

MONOFORCE 32.110 HSK100 7KHSKA100MF32116.7

PR CT N SHRINK FIT EXTENSIONS

REF. CODEd1d2d3Lkg

PR.CT.N D12.03.160 49DC1161203038121600.09

PR.CT.N D12.04.160 49DC1161204048121600.09

PR.CT.N D16.03.160 49DC11616030310161600.14

PR.CT.N D16.04.160 49DC11616040410161600.14

PR.CT.N D16.05.160 49DC11616050510161600.15

PR.CT.N D16.06.160 49DC11616060612161600.16

PR.CT.N D16.08.160 49DC11616080814161600.16

PR.CT.N D20.05.160 49DC11620050514201600.27

PR.CT.N D20.06.160 49DC11620060614201600.26

PR.CT.N D20.08.160 49DC11620080814201600.26

PR.CT.N D20.10.160 49DC116201001016201600.21

PR.CT.N D20.12.160 49DC116201201218201600.22

PR CT R SHRINK FIT EXTENSIONS WITH AXIAL ADJUSTMENT

REF. CODEd1d2d3LL1kg

PR.CT.R D16.06.130 49DC213160606101613022/360.18

PR.CT.R D16.06.160 49DC216160606101616022/360.17

PR.CT.R D20.06.130 49DC213200606142013022/360.20

PR.CT.R D20.08.130 49DC213200808142013022/360.25

PR.CT.R D20.06.160 49DC216200606142016022/320.33

PR.CT.R D20.08.160 49DC216200808142016026/360.32

PR.CT.R D25.10.130 49DC2132510010202513031/410.40

PR.CT.R D25.12.130 49DC2132512012202513036/460.37

PR.CT.R D25.16.130 49DC2132516016222513039/490.32

PR.CT.R D25.08.160 49DC216250808192516026/360.53

PR.CT.R D25.10.160 49DC2162510010202516031/410.51

PR.CT.R D25.12.160 49DC2162512012202516036/460.48

PR.CT.R D25.14.160 49DC2162514014222516036/460.47

PR.CT.R D25.16.160 49DC2162516016222516039/490.43

PR.CT.R D25.08.200 49DC220250808192520026/360.67

PR.CT.R D25.10.200 49DC2202510010202520031/410.64

PR.CT.R D25.12.200 49DC2202512012202520036/460.60

PR.CT.R D25.16.200 49DC2202516016222520039/490.52

PR.CT.R D32.16.160 49DC2163216016273216039/490.78

PR.CT.R D32.18.160 49DC2163218018273216039/490.77

PR.CT.R D32.20.160 49DC2163220020273216041/510.67

PR.CT.R D32.16.200 49DC2203216016273220039/491.81

PR.CT.R D32.20.200 49DC2203220020273220041/510.87

Supplied with the axial setting screw

MONOd’

Monolithic tool-holders are the ideal solution to equip any type of machine tool with HSK 63 and 100, DIN 69871 and MAS BT 40 and 50 spindle, guaranteeing the advantages of high quality and precision, at a highly competitive market price.

TheMONOd’programincludes ERcolletchucks,Weldon, shell-millholders,morsetaper.

All the tool-holders are balanced by design, G 6.3 at 8,000 rpm. MONOd’ ER G 6.3 at 15,000 rpm.

0.003

MAX.RPM 15.000

DIN 69893 HSK DIN 69871 MAS 403 BT

DIN 69893 HSK-A COLLET CHUCK HOLDER - ER DIN 6499

Supplied with coolant tube

HSK-A REF. CODETYPEd1d2d3d4LL1L2L3kg 63 HSK-A63 ER16.80 71HSKA063ER1608ER16M0.5~1022328054411.1 63 HSK-A63 ER16.120 71HSKA063ER1612ER16M0.5~102231120941.9 63 HSK-A63 ER25.80 71HSKA063ER2508ER251~164280541.3 63 HSK-A63 ER25.140 71HSKA063ER2514ER251~164247.5140114461.7

63 HSK-A63 ER32.90 71HSKA063ER3209ER322~205090641.6

63 HSK-A63 ER32.160 71HSKA063ER3216ER322~20501601342.2

100 HSK-A100 ER16.100 71HSKA100ER1610ER16M0.5~10222545100716141.52.3

100 HSK-A100 ER16.160 71HSKA100ER1616ER16M0.5~102234.5441601311262.5

100 HSK-A100 ER25.100 71HSKA100ER2510ER251~164245.510071472.6 100 HSK-A100 ER25.160 71HSKA100ER2516ER251~164249.5160131473.2

100 HSK-A100 ER32.120 71HSKA100ER3212ER322~20505512091523.1

100 HSK-A100 ER32.160 71HSKA100ER3216ER322~205056.5160131523.7

100 HSK-A100 ER40.120 71HSKA100ER4012ER403~266371.512091603.5

DIN 69893 HSK-A WELDON - WD DIN 1835-B

Supplied with coolant tube

HSK-A REF. CODEd1H5d2d3LL1L2kg 63 HSK-A63 WD06.60 71HSKA063WD060662360340.8 63 HSK-A63 WD08.65 71HSKA063WD080682665390.9 63 HSK-A63 WD10.70 71HSKA063WD1007103070441.1 63 HSK-A63 WD12.70 71HSKA063WD1207123470441.2 63 HSK-A63 WD16.80 71HSKA063WD1608164280541.4 63 HSK-A63 WD20.80 71HSKA063WD2008205080541.5 63 HSK-A63 WD25.110 71HSKA063WD251125631102.3 63 HSK-A63 WD32.110 71HSKA063WD321132701102.5 100 HSK-A100 WD10.90 71HSKA100WD1009103045906153.52.3 100 HSK-A100 WD12.100 71HSKA100WD12101234451007165.52.4 100 HSK-A100 WD16.100 71HSKA100WD16101642100712.6 100 HSK-A100 WD20.110 71HSKA100WD20112050110813.1 100 HSK-A100 WD25.120 71HSKA100WD25122563120913.9 100 HSK-A100 WD32.120 71HSKA100WD32123270120914.3 100 HSK-A100 WD40.120 71HSKA100WD40124080120914.8

DIN 69893 HSK-A MILL HOLDERS - PF

Supplied with coolant tube

HSK-A REF. CODEd1d2d3MLL1kg 63 HSK-A63 PF16.50 71HSKA063PF1605163250171.1 63 HSK-A63 PF22.50 71HSKA063PF2205224050191.2 63 HSK-A63 PF27.55 71HSKA063PF2705275055211.4 63 HSK-A63 PF32.60 71HSKA063PF3206326060241.8 100 HSK-A100 PF22.65 71HSKA100PF2265224065192.3 100 HSK-A100 PF27.65 71HSKA100PF2765275065212.5 100 HSK-A100 PF32.70 71HSKA100PF3270326070242.9 100 HSK-A100 PF40.70 71HSKA100PF4070408866.7M1270273.3 100 HSK-A100 PF60.75 71HSKA100PF607560128.5101.6M1675404.2

DIN 69893 HSK-A MORSE - CM DIN 228 AB

HSK-A REF. CODEMORSEd1d2LL1kg 63 HSK-A63 CM2.110 A-B 71HSKA063CMB211217.78032110842 63 HSK-A63 CM3.130 A-B 71HSKA063CMB313323.825401301042.2 63 HSK-A63 CM4.155 A-B 71HSKA063CMB415431.267481551292.6

DIN REF. CODETYPEd1d2d3LL1L2kg pic.

40 DIN69871-AD40 ER16.60

71DIN-A40ER1606ER16M0.5~102260410.9 1 40 DIN69871-AD40 ER16.100 71DIN-A40ER1610ER16M0.5~102229.510081411 2 40 DIN69871-AD40 ER16.160 71DIN-A40ER1616ER16M0.5~102238160141412 2 40 DIN69871-AD40 ER25.60 71DIN-A40ER2506ER251~164260411.1 1 40 DIN69871-AD40 ER25.100 71DIN-A40ER2510ER251~16424710081461.6 2 40 DIN69871-AD40 ER25.160 71DIN-A40ER2516ER251~164250160141462.1 2

40 DIN69871-AD40 ER32.70

71DIN-A40ER3207ER322~205070511.2 1

40 DIN69871-AD40 ER32.110 71DIN-A40ER3211ER322~2050110911.7 1

40 DIN69871-AD40 ER32.160 71DIN-A40ER3216ER322~20501601412.7 1 40 DIN69871-AD40 ER40.80 71DIN-A40ER4008ER403~266380611.3 1 40 DIN69871-AD40 ER40.120 71DIN-A40ER4012ER403~26631201012.3 1

50 DIN69871-AD50 ER16.100 71DIN-A50ER1610ER16M0.5~102229.510081412.5 2 50 DIN69871-AD50 ER16.160 71DIN-A50ER1616ER16M0.5~102232.5160141413.3 2 50 DIN69871-AD50 ER25.110 71DIN-A50ER2511ER251~16424811091462.8 2

50 DIN69871-AD50 ER25.160 71DIN-A50ER2516ER251~164250160141463.6 2 50 DIN69871-AD50 ER32.70 71DIN-A50ER3207ER322~205070512.9 1 50 DIN69871-AD50 ER32.110 71DIN-A50ER3211ER322~20505511091523.4 2 50 DIN69871-AD50 ER32.160 71DIN-A50ER3216ER322~205057.5160141524 2

50 DIN69871-AD50 ER40.100 71DIN-A50ER4010ER403~26636510081553.8 2 50 DIN69871-AD50 ER40.160 71DIN-A50ER4016ER403~266370160141554.3 2

DIN REF. CODEd1d2d3MLL1kg pic. 40 DIN69871-AD40 PF16.35 71DIN-A40PF1603163235170.9 1 40 DIN69871-AD40 PF22.40 71DIN-A40PF2204224040191 1

DIN69871-AD40 PF27.45 71DIN-A40PF2704275045211.2 1

DIN69871-AD40 PF32.50 71DIN-A40PF3205326050241.7 1

DIN69871-AD40 PF40.55 71DIN-A40PF4005407055272.1 1

DIN69871-AD50 PF16.40 71DIN-A50PF1604163240172.4 1

DIN69871-AD50 PF16.110 71DIN-A50PF16111632110172.8 1

DIN69871-AD50 PF22.45 71DIN-A50PF2204224045192.6 1

DIN69871-AD50 PF27.50 71DIN-A50PF2705275050212.7 1

DIN69871-AD50 PF32.55 71DIN-A50PF3205326055243.2 1

DIN69871-AD50 PF40.60 71DIN-A50PF4006408866.7M1260274.3 2

DIN69871-AD50 PF60.70 71DIN-A50PF600760128.5101.6M1670406.6 2

DIN 69871 AD WELDON - WD DIN 1835-B

DIN REF.

CODEd1H5d2LL1kg pic. 40 DIN69871-AD40 WD06.50 71DIN-A40WD060562350310.8 1 40 DIN69871-AD40 WD08.50 71DIN-A40WD080582650310.9 1 40 DIN69871-AD40 WD10.50 71DIN-A40WD1005103050311 1 40 DIN69871-AD40 WD12.35 71DIN-A40WD1203123435161 2 40 DIN69871-AD40 WD12.110 71DIN-A40WD12111234110911.4 1 40 DIN69871-AD40 WD16.35 71DIN-A40WD1603164235161.1 2 40 DIN69871-AD40 WD16.110 71DIN-A40WD16111642110911.7 1 40 DIN69871-AD40 WD16.160 71DIN-A40WD161616421601412.2 1 40 DIN69871-AD40 WD20.35 71DIN-A40WD2003204435161.2 2 40 DIN69871-AD40 WD20.110 71DIN-A40WD20112050110912.1 1 40 DIN69871-AD40 WD20.160 71DIN-A40WD201620501601412.6 1 40 DIN69871-AD40 WD25.35 71DIN-A40WD2503254435161.3 2 40 DIN69871-AD40 WD25.100 71DIN-A40WD25102563100652 3 40 DIN69871-AD40 WD25.160 71DIN-A40WD251625631601253.2 3 40 DIN69871-AD40 WD32.100 71DIN-A40WD32103270100652.5 3 40 DIN69871-AD40 WD32.160 71DIN-A40WD321632701601253.9 3 50 DIN69871-AD50 WD10.63 71DIN-A50WD1006103063442.5 1 50 DIN69871-AD50 WD10.160 71DIN-A50WD101610301601412.9 1 50 DIN69871-AD50 WD12.63 71DIN-A50WD1206123463442.6 1 50 DIN69871-AD50 WD12.160 71DIN-A50WD121612341601413.2 1 50 DIN69871-AD50 WD16.110 71DIN-A50WD16111642110913.2 1 50 DIN69871-AD50 WD16.160 71DIN-A50WD161616421601413.7 1 50 DIN69871-AD50 WD20.110 71DIN-A50WD20112050110913.6 1 50 DIN69871-AD50 WD20.160 71DIN-A50WD201620501601414.2 1 50 DIN69871-AD50 WD25.80 71DIN-A50WD2508256380613.5 1 50 DIN69871-AD50 WD25.110 71DIN-A50WD25112563110914.1 2 50 DIN69871-AD50 WD25.160 71DIN-A50WD251625631601415.1 2 50 DIN69871-AD50 WD32.100 71DIN-A50WD32103270100814.6 2 50 DIN69871-AD50 WD32.160 71DIN-A50WD321632701601416 2 50 DIN69871-AD50 WD40.100 71DIN-A50WD40104080100814.8 2

DIN 69871 A MORSE - CM DIN 228 AB

DIN REF. CODEMORSEd1d2LL1kg

DIN69871-A40 CM2.50 A-B 71DIN-40-CMB205217.7803250311

DIN69871-A40 CM3.70 A-B 71DIN-40-CMB307323.8254070511.1

DIN69871-A50 CM2.60 A-B 71DIN-50-CMB206217.7803260412.6

DIN69871-A50 CM3.60 A-B 71DIN-50-CMB306323.8254060412.7

DIN69871-A50 CM4.80 A-B 71DIN-50-CMB408431.2674880612.9

BT REF. CODETYPEd1d2d3LL1L2kg pic.

40 MAS403 BT40-AD ER16.60 71MBT-A40ER1606ER16M0.5~102260331 1

40 MAS403 BT40-AD ER16.100 71MBT-A40ER1610ER16M0.5~10222810073411.1 2

40 MAS403 BT40-AD ER16.160 71MBT-A40ER1616ER16M0.5~102236.5160133412.1 2

40 MAS403 BT40-AD ER25.65 71MBT-A40ER2506ER251~164265381.2 1

40 MAS403 BT40-AD ER25.100 71MBT-A40ER2510ER251~164245.510073461.7 2

40 MAS403 BT40-AD ER25.160 71MBT-A40ER2516ER251~164249.5160133462.2 2

40 MAS403 BT40-AD ER32.70 71MBT-A40ER3207ER322~205070431.3 1

40 MAS403 BT40-AD ER32.110 71MBT-A40ER3211ER322~2050110831.8 1

40 MAS403 BT40-AD ER32.160 71MBT-A40ER3216ER322~20501601332.8 1

40 MAS403 BT40-AD ER40.80 71MBT-A40ER4008ER403~266380531.4 1 40 MAS403 BT40-AD ER40.120 71MBT-A40ER4012ER403~2663120932.4 1

50 MAS403 BT50-AD ER16.100 71MBT-A50ER1610ER16M0.5~102226.510062413.6 2

50 MAS403 BT50-AD ER16.160 71MBT-A50ER1616ER16M0.5~102231160122414.3 2

50 MAS403 BT50-AD ER25.110 71MBT-A50ER2511ER251~164245.511072463.8 2 50 MAS403 BT50-AD ER25.160 71MBT-A50ER2516ER251~164248.5160122464.6 2

50 MAS403 BT50-AD ER32.80 71MBT-A50ER3208ER322~205080423.9 1 50 MAS403 BT50-AD ER32.110 71MBT-A50ER3211ER322~205052.511072524.4 2

50 MAS403 BT50-AD ER32.160 71MBT-A50ER3216ER322~205056160122525 2 50 MAS403 BT50-AD ER40.100 71MBT-A50ER4010ER403~2663100624.8 1 50 MAS403 BT50-AD ER40.160 71MBT-A50ER4016ER403~266368.5160122555.3 2

BT REF. CODEd1d2d3MLL1kg pic.

40 MAS403 BT40-AD PF16.40

71MBT-A40PF1604163240170.9 1

MAS403 BT40-AD PF22.40 71MBT-A40PF2204224040191 1

MAS403 BT40-AD PF27.45 71MBT-A40PF2704275045211.2 1

40 MAS403 BT40-AD PF32.50 71MBT-A40PF3205326050241.7 1

40 MAS403 BT40-AD PF40.55

71MBT-A40PF4005407055272.1 1

50 MAS403 BT50-AD PF16.50 71MBT-A50PF1605163250172.4 1

MAS403 BT50-AD PF22.50 71MBT-A50PF2205224050192.6 1

MAS403 BT50-AD PF27.55 71MBT-A50PF2705275055212.7 1

50 MAS403 BT50-AD PF32.55 71MBT-A50PF3205326055243.2 1

MAS403 BT50-AD PF40.60 71MBT-A50PF4006408866.7M1260274.3 2

50 MAS403 BT50-AD PF60.80 71MBT-A50PF600860128.5101.6M1680406.8 2

MAS 403 BT40 AD WELDON - WD DIN 1835-B

BT REF.

CODEd1H5d2LL1kg pic.

40 MAS403 BT40-AD WD06.50 71MBT-A40WD060562350230.8 1 40 MAS403 BT40-AD WD08.50 71MBT-A40WD080582650230.9 1 40 MAS403 BT40-AD WD10.56 71MBT-A40WD1005103056291 1 40 MAS403 BT40-AD WD12.35 71MBT-A40WD120312343580.9 2 40 MAS403 BT40-AD WD12.110 71MBT-A40WD12111234110831.4 1 40 MAS403 BT40-AD WD16.35 71MBT-A40WD160316423581 2 40 MAS403 BT40-AD WD16.110 71MBT-A40WD16111642110831.7 1 40 MAS403 BT40-AD WD20.35 71MBT-A40WD200320503581.1 2 40 MAS403 BT40-AD WD20.110 71MBT-A40WD20112050110832.1 1 40 MAS403 BT40-AD WD25.35 71MBT-A40WD250325633581 2 40 MAS403 BT40-AD WD25.100 71MBT-A40WD25102563100732 3 40 MAS403 BT40-AD WD32.100 71MBT-A40WD32103270100672.5 3

50 MAS403 BT50-AD WD10.70 71MBT-A50WD1007103070323 1 50 MAS403 BT50-AD WD10.160 71MBT-A50WD101610301601223.4 1 50 MAS403 BT50-AD WD12.70 71MBT-A50WD1207123470323.1 1 50 MAS403 BT50-AD WD12.160 71MBT-A50WD121612341601223.6 1 50 MAS403 BT50-AD WD16.80 71MBT-A50WD1608164280423.3 1 50 MAS403 BT50-AD WD16.110 71MBT-A50WD16111642110723.5 1 50 MAS403 BT50-AD WD20.80 71MBT-A50WD2008205080423.5 1 50 MAS403 BT50-AD WD20.110 71MBT-A50WD20112050110723.8 1 50 MAS403 BT50-AD WD25.100 71MBT-A50WD25102563100624.5 2 50 MAS403 BT50-AD WD25.125 71MBT-A50WD25122563125875 2 50 MAS403 BT50-AD WD32.100 71MBT-A50WD32103270100625.6 2 50 MAS403 BT50-AD WD40.110 71MBT-A50WD40114080110725.8 2

403 BT40 A MORSE - CM DIN 228 AB

BT REF.

CODEMORSEd1d2LL1kg

40 MAS403 BT40-A CM2.50 A-B 71MBT- 40- CMB205217.7803250231 40 MAS403 BT40-A CM3.70 A-B 71MBT- 40- CMB307323.8254070431.1 50 MAS403 BT50-A CM2.60 A-B 71MBT- 50- CMB206217.7803260222.6 50 MAS403 BT50-A CM3.60 A-B 71MBT- 50- CMB306323.8254060222.7

50 MAS403 BT50-A CM4.80 A-B 71MBT- 50- CMB408431.2674880422.9

ACCESSORIES

ISO

REF. CODEISOd1d2d3d4LL1a pic.

ISO 7388/2 A DIN 69872 201430250401401914M1617542615° 1

ISO 7388/2 A DIN 69872 201430250451452317M2021653015° 1

ISO 7388/2 A DIN 69872 201430250501502821M2425743415° 1 ISO 7388/2 A DIN 69872 201430250400401914M1617542615° 2 ISO 7388/2 A DIN 69872 201430250500502821M2425743415° 2

ISO 7388/2 A DIN 69872 201430250600604030M3032904015° 2

ISO

- ANSI B.5

1

pic. 2 pic. 2

REF. CODEISOd1d2d3d4LL1a pic.

ISO 7388/2 B ANSI B.5 50 2014302514014018.9512.95M161744.5016.4045° 1 ISO 7388/2 B ANSI B.5 50 2014302514514524.0516.30M20215620.9545° 1

ISO 7388/2 B ANSI B.5 50 2014302515015029.1019.60M242565.5025.5545° 1

ISO 7388/2 B ANSI B.5 50 2014302514004018.9512.95M161744.5016.4045° 2 ISO 7388/2 B ANSI B.5 50 2014302515005029.1019.60M242565.5025.5545° 2

MAS 403 BT - 30° - 45°

REF. CODEISOd1d2d3d4LL1a

MAS 403 BT 30° 20143025230130117M1212.5432330°

MAS 403 BT 30° 201430252401401510M1617603530°

MAS 403 BT 30° 201430252451451914M2021704030°

MAS 403 BT 30° 201430252501502317M2425854530°

MAS 403 BT 30° 201430252601603224M30311156530°

MAS 403 BT 45° 20143025230230117M1212.5432345°

MAS 403 BT 45° 201430252402401510M1617603545°

MAS 403 BT 45° 201430252452451914M2021704045°

MAS 403 BT 45° 201430252502502317M2425854545°

MAS 403 BT 45° 201430252602603224M30311156545°

HSK

ET-1- ER TAPPING COLLETS WITH AXIAL COMPENSATION

-

ER - GB TAPPING COLLETS WITHOUT AXIAL COMPENSATION

REF. CODEdD1LE

ET-1-ER25 (M2~M12)

ET-1-ER25 (M2~M12)

ET-1-ER25 (M2~M12) 4960861254504.526348100451012500

ET-1-ER25 (M2~M12) 496086125600626348100451012500

ET-1-ER25 (M2~M12) 496086125700726348100451012500

ET-1-ER25 (M2~M12) 496086125900926348100451012500

ET-1-ER32 (M4~M16) 4960861324504.5334310100451033200

ET-1-ER32 (M4~M16) 4960861326006334310100451033200

ET-1-ER32 (M4~M16) 4960861327007334310100451033200

ET-1-ER32 (M4~M16) 4960861329009334310100451033200

ET-1-ER32 (M4~M16) 49608613211011334310100451033200

ET-1-ER32 (M4~M16) 49608613212012334310100451033200

ET-1-ER40 (M8~M20) 4960861406006415413100451034000

ET-1-ER40 (M8~M20) 4960861407007415413100451034000

ET-1-ER40 (M8~M20) 4960861409009415413100451034000

ET-1-ER40 (M8~M20) 49608614011011415413100451034000

ET-1-ER40 (M8~M20) 49608614012012415413100451034000

ET-1-ER40 (M8~M20) 49608614014014415413100451034000

ET-1-ER40 (M8~M20) 49608614016016415413100451034000

On request

REF. CODE(dxc)DIN 371 DIN 374-376D1L

ER 16-GB (M4~M10) 4960851160454.5x3.4M4M61627.5100451011600

ER 16-GB (M4~M10) 4960851160555.5x4.3M71627.5100451011600

ER 16-GB (M4~M10) 4960851160606x4.9M5M81627.5100451011600

ER 16-GB (M4~M10) 4960851160606x4.9M6M81627.5100451011600

ER 16-GB (M4~M10) 4960851160707x5.5M6M101627.5100451011600

ER 25-GB (M4~M16) 4960851250454.5x3.4M4M62534100451012500

ER 25-GB (M4~M16) 4960851250555.5x4.3M72534100451012500

ER 25-GB (M4~M16) 4960851250606x4.9M5M82534100451012500

ER 25-GB (M4~M16) 4960851250606x4.9M6M82534100451012500

ER 25-GB (M4~M16) 4960851250707x5.5M102534100451012500

ER 25-GB (M4~M16) 4960851250909x7M122534100451012500

ER 25-GB (M4~M16) 49608512511011x9M142534100451012500

ER 25-GB (M4~M16) 49608512512012x9M162534100451012500

ER 32-GB (M4~M20) 4960851320454.5x3.4M4M63240100451033200

ER 32-GB (M4~M20) 4960851320555.5x4.3M73240100451033200

ER 32-GB (M4~M20) 4960851320606x4.9M5M83240100451033200

ER 32-GB (M4~M20) 4960851320606x4.9M6M83240100451033200

ER 32-GB (M4~M20) 4960851320707x5.5M103240100451033200

ER 32-GB (M4~M20) 4960851320909x7M123240100451033200

ER 32-GB (M4~M20) 49608513211011x9M143240100451033200

ER 32-GB (M4~M20) 49608513212012x9M163240100451033200

ER 32-GB (M4~M20) 49608513214014x11M183240100451033200

ER 32-GB (M4~M20) 49608513216016x12M203240100451033200

ER 40-GB (M10~M27) 4960851400707x5.5M104046100451034000

ER 40-GB (M10~M27) 4960851400909x7M124046100451034000

ER 40-GB (M10~M27) 49608514011011x9M144046100451034000

ER 40-GB (M10~M27) 49608514012012x9M164046100451034000

ER 40-GB (M10~M27) 49608514014014x11M184046100451034000

ER 40-GB (M10~M27) 49608514016016x12M204046100451034000

ER 40-GB (M10~M27) 49608514018018x14.5M224046100451034000

ER 40-GB (M10~M27) 49608514018018x14.5M244046100451034000

ER 40-GB (M10~M27) 49608514020020x16M274046100451034000

On request

BFC QUICK CHANGE TAP HOLDERS WITHOUT TORQUE CLUTCH(M3

(M3

(M3 ~ 12)

(M3 ~ 12)

(M3 ~ 12)

BFC1 (M3 ~ 12) 4950610700557x5.5M10M10301917721.5

BFC1 (M3 ~ 12) 4950610900709x7M12M12301917721.5

BFC2 (M6 ~ 20) 4950620600496x4.9M5M8M84831301135

BFC2 (M6 ~ 20) 4950620600496x4.9M6M8M84831301135 BFC2 (M6 ~ 20) 4950620700557x5.5M10M104831301135

BFC2 (M6 ~ 20) 4950620900709x7M12M124831301135

BFC2 (M6 ~ 20) 49506211009011x9M14M144831301135

BFC2 (M6 ~ 20) 49506212009012x9M16M164831301135

BFC2 (M6 ~ 20) 49506214011014x11M18M184831301135

BFC2 (M6 ~ 20) 49506216012016x12M20M204831301135

BFC3 (M14 ~ 33) 49506311009011x9M14M147048441455.5

BFC3 (M14 ~ 33) 49506312009012x9M16M167048441455.5

BFC3 (M14 ~ 33) 49506314011014x11M18M187048441455.5

BFC3 (M14 ~ 33) 49506316012016x12M20M207048441455.5

BFC3 (M14 ~ 33) 49506318014518x14.5M22M227048441455.5

BFC3 (M14 ~ 33) 49506318014518x14.5M24M247048441455.5

BFC3 (M14 ~ 33) 49506320016020x16M27M277048441455.5

BFC3 (M14 ~ 33) 49506322018022x18M30M307048441455.5

BFC3 (M14 ~ 33) 49506325020025x20M33M337048441455.5

BFS QUICK CHANGE TAP HOLDERS WITH TORQUE CLUTCH

REF. CODE(dxc)DIN 371 DIN 374 DIN 376D1D2L1L2L3

BFS1 (M3 ~ 12) 4950710350273.5x2.7M3M5M53219172521.5 BFS1 (M3 ~ 12) 4950710400304x3M3.53219172521.5 BFS1 (M3 ~ 12) 4950710450344.5x3.4M4M6M63219172521.5 BFS1 (M3 ~ 12) 4950710550435.5x4.3M7M73219172521.5 BFS1 (M3 ~ 12) 4950710600496x4.9M5M8M83219172521.5 BFS1 (M3 ~ 12) 4950710600496x4.9M6M8M83219172521.5 BFS1 (M3 ~ 12) 4950710700557x5.5M10M103219172521.5 BFS1 (M3 ~ 12) 4950710800628x6.2M83219172521.5 BFS1 (M3 ~ 12) 4950710900709x7M12M123219172521.5 BFS1 (M3 ~ 12) 49507110008010x8M103219172521.5 BFS2 (M6 ~ 20) 4950720600496x4.9M5M8M85031303435 BFS2 (M6 ~ 20) 4950720600496x4.9M6M8M85031303435 BFS2 (M6 ~ 20) 4950720700557x5.5M10M105031303435 BFS2 (M6 ~ 20) 4950720800628x6.2M85031303435 BFS2 (M6 ~ 20) 4950720900709x7M12M125031303435 BFS2 (M6 ~ 20) 49507210008010x8M105031303435 BFS2 (M6 ~ 20) 49507211009011x9M14M145031303435 BFS2 (M6 ~ 20) 49507212009012x9M16M165031303435 BFS2 (M6 ~ 20) 49507214011014x11M18M185031303435 BFS2 (M6 ~ 20) 49507216012016x12M20M205031303435

BFS3 (M14 ~ 33) 49507311009011x9M14M147248444555.5 BFS3 (M14 ~ 33) 49507312009012x9M16M167248444555.5 BFS3 (M14 ~ 33) 49507314011014x11M18M187248444555.5 BFS3 (M14 ~ 33) 49507316012016x12M20M207248444555.5 BFS3 (M14 ~ 33) 49507318014518x14.5M22M227248444555.5

BFS3 (M14 ~ 33) 49507318014518x14.5M24M247248444555.5 BFS3 (M14 ~ 33) 49507320016020x16M27M277248444555.5 BFS3 (M14 ~ 33) 49507322018022x18M30M307248444555.5

BFS3 (M14 ~ 33) 49507325020025x20M33M337248444555.5

On request

3-2496080116030496080120030496080125030496080132030

4-3496080116040496080120040496080125040496080132040496080140040

5-4496080116050496080120050496080125050496080132050496080140050

5.5-5496080111055

6-5496080116060496080120060496080125060496080132060496080140060

6.5-6496080111065

7-6496080116070496080120070496080125070496080132070496080140070

8-7496080116080496080120080496080125080496080132080496080140080

SET

SET

SET

SET

SET

SET

1~16496080125000

2~20496080132000

RANGECODE

3-2.5496080016030496080025030496080032030

3.5-3•496080016035496080025035496080032035

4-3.5496080016040496080025040496080032040496080040040

7.5-7•496080016075496080025075496080032075496080040075 8-7.5496080016080496080025080496080032080496080040080 8.5-8•496080016085496080025085496080032085496080040085 9-8.5496080016090496080025090496080032090496080040090 9.5-9•496080016095496080025095496080032095496080040095 10-9.5496080016100496080025100496080032100496080040100 10.5-10•496080025105496080032105496080040105

SYSTEM MHD’

REF. CODEd1d2CODE1CODEORL pic.

MHD’ 14 38172500116114101015001002502 2 MHD’ 16 38172500116116101015001002502 2

MHD’ 50 RD 50 / ..

MHD’ 20 38172500120120131015001003002.5 2 MHD’ 25 38172500125125161015001003003 2 MHD’ 32 38172500132132201015001004001012540075103.55 2 MHD’ 40 38172500140140251015001005001012540100104 2

TRD - TRM - TRC - TR-E 38172500150150321015001006001012540130104.2 2

TS

pic. 1 pic. 1

pic. 2 pic. 2

MHD’ 50 381725001001503210150010060010125401301012.2 1 MHD’ 63-80 38172500100263-804210150010080010125100207513.85 1 MHD’ 110 - 140 381725001003110-1407610150010140010125100311210 1

REF. CODE1CODE2CODE3 pic.

TS 16/16 201430110008100051030014100231030004 1

TS 20/20 201430110009100051040015100231030005 1

TS 25/25 201430110010100051040020100231030008 1

TS 32/32 201430110011100051050025100231040012 1

TS 40/40 201430110012100051060030100231050014 1

TS 50/50 201430110013100051080035100231050012 2

TS 50/63 201430110014100051100040100231060016 2

TS 63/63 201430110014100051100040100231060016 2

TS 80/80 201430110015100051120045100231080025 2

TRD

REF. CODE1CODE2CODE3CODE4CODE5

TRD 25 100231040008200100150411201430110024101500800200100271040004

TRD 32

TRD 40

TRD 50 100231060014200100150820201430110021101500800300100271060008

TRD 63 100231060016200100151026201430110026101500800300100271060008

TRD 80 100231060020200100151230201430110022101500800300100271060012

TRM

pic. 2

pic. 1 pic. 3 pic. 4 pic. 5 pic. 6

REF. CODE1CODE2CODE3CODE4CODE5 pic.

TRM 16 200100190301100051030006101500800150 1 TRM 20 200100190301100051040008101500800150 1 TRM 25 100271040004100051050010101500800200 1 TRM 32 100231040006100051060012101500800200 1

TRM 40 100271050006100051080014101500800250 1

TRM 50 100271050008201041015002100231100016100051100025101500800250 1

TRM 50 200100150501100051100020100051100025101500800250 2 TRM 50 100271050008200560116082100231100016101500800250 3-4

TRM 63 100251060010100051100018101500800300 5 TRM 80 100251060014100051100018101500800300 5 TRM 125 100251060020100051100025101500800300 5

TRM 63 100251060010100231050006100231100010101500800300 6 TRM 80 100251060014100231050006100231100010101500800300 6

TRM

HSB

REF. CODE1CODE2CODE3

TRM 32 HSB 100271040005100231050008-100231050012

TRM 50 HSB 100271050008200560116082100231100010

TRC

REF. CODE1CODE2CODE3CODE4CODE5 pic. TRC 14 200100190302100051030006101500800150 1 TRC 16 200100190301100051030006101500800150 1 TRC 20 200100190301100051040008101500800150 1 TRC 25 100271040004100051050010101500800150 1 TRC 32 100271050005100051060012101500800250 1 TRC 40 100271060006100051080014101500800300 1 TRC 50 100271060008201041015002100231100016100051100025101500800300 1

TRC 63 100271060008100051100020101500800300 1