AE-H SERIES

Volume 7.1

Multi-flute type

AE-MSS-H Multi-flute square type, 1,5 × D cutting length (Neck length 3 × D)

AE-MS-H Multi-flute square & radius type, 2.5 × D cutting length

AE-MSS-H

Square Type

AE-MS-H Square Type

Radius Type

AE-ML-H Multi-flute square type, 4 x D cutting length

Square Type

AE-HFE-H High feed type AE-CRE-H High efficiency type

AE-BM-H 4-flute ball type for high efficiency processing

AE-BD-H 2-flute ball type for high precision finishing

Long neck Type

2-flute long neck ball type for high precision finishing Exchangeable Head End Mill 1xD cutting length 4-flute radius type for high-efficiency and high precision finishing 2-flute radius type for high precision finishing

KEY FEATURES & BENEFITS

DUROREY Coating

Innovative coating that supports high-hardness steel machining

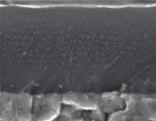

Coating Structure

Super Heat Resistant Layer

Ultra-Fine Periodic Nano-Layered Structure

Adhesion Strength Reinforcing Layer

Base Metal

Super Heat Resistant Layer

Smoothening of surface, high toughness and adhesion resistance due to the SiC containing ultra-heat-resistance material and crystal miniaturization

Ultra-Fine Periodic Nano-Layered Structure

Crystal miniaturization and improvement of mechanical properties due to the laminated structure of periodic nano-layer and wear-resistant layer

Super heat resistant layer and ultra-fine periodic nano-layered structure provide superior toughness while maintaining high heat resistance and abrasion resistance. Also suppresses chipping even in high hardness milling and achieves long tool life.

Coating Performance

Cutting data of SKD11 60 HRC

Wear comparison after milling 84 m

VAST PRODUCT LINEUP WITH DUROREY COATING

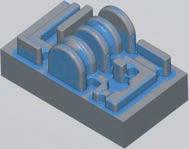

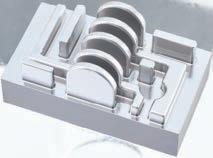

High efficiency machining of high-hardness steel (60 HRC)with a maximum depth of cut of 22 mm

Maximum

Holder: Shrink Fit

Main Spindle: HSK-A63

TO ACCOMMODATE A WIDE VARIETY OF

High efficiency direct engraving with a large depth of cut even in high-hardness steel(60 HRC)

Work Material: YXR3(60HRC)

Coolant: MQL

Machine: 5-axis Machining center

Main Spindle: HSK-A63

Maximum RPM: 25.000 min-1

1Overall 3-axis contouring line High-efficiency roughing

2Chamfer 3-axis contouring line Semi-roughing

3Groove 5-axis profilingSemi-roughing

4Ridge 5-axis turn milling Roughing Semi-roughing

5Groove 5-axis profiling High-precision finishing

6Ridge 5-axis profiling High-precision finishing

5-axis turn milling High-precision finishing

8Bottom 5-axis turn milling High-precision finishing

9Chamfer 3-axis contouring line High-precision finishing

AE-MSS-H

Stub

AE-MS-H

Short

Multi-flute square and radius type end mills for high-hardness steels

Unequal spacing teeth suppresses chattering

Optimal cutting edge specifications to enable stable machining of high hardness steels

Work Material STAVAX (52HRC)

Milling method Side Milling

Cutting Speed 100m/min (7.950 min-1)

Feed 1.250mm/min (0,039 mm/t)

Depth of Cut ap = 6mm ae = 0,2mm

Coolant Air Blow

Machine Vertical Machining Center (BT40)

DUROREY Coating

Exhibits outstanding performance in high-hardness steels due to its excellent toughness, high heat resistance and abrasion resistance characteristics.

CUTTING DATA

Long tool life

Achieves stable durability in high-hardness steel machining

Tool

Work

Milling method Side milling

Cutting

High speed milling

Demonstrates excellent durability in high-speed machining of high-hardness steel

CUTTING DATA

Stable Performance

Stable performance even in pre-hardened steel STAVAX (52 HRC)

Tool AE-MS-H Ø4

Work Material STAVAX (52HRC)

Milling method Side milling

Cutting

(7.950 min-1)

Feed 1.250mm/min (0,039 mm/t)

Depth of Cut ap = 6mm ae = 0,2mm

Coolant Air Blow

Machine Vertical Machining Center (BT40)

Long tool life

Demonstrates good cutting performance even in pre-hardened steel NAK80 (40 HRC)

Ø3

(10.823 min-1)

(0,02 mm/t)

Depth of Cut ap = 4,5mm ae = 0,2mm

AE-MSS-H

Milling | Solid carbide

First choice in quality and performance

Carbide end mill with DUROREY coating

For hardened material up to 70HRC

Multi flute, variable helix and unequal spacing

1.5XD length of cut, long neck up to 3XD

483641994112,33451,560,9511,46°3,103,213,333,453,731 483642994213,9645361,958,19°6,656,887,137,397,991 85498304314,89454,562,855,78°9,469,8710,2310,6211,481 854983144161250663,853,59°12,6013,0913,5614,0715,211 85498324517,115607,564,851,68°15,7216,316,88--1 854983366-1880965,85------2 854983468-24901287,85------2 8549835610-3010015109,85------2 8549836612-36110181211,8------2

AE-MS-H

Milling | Solid carbide

First choice in quality and performance Square Type

2,5 × D cutting length

4-6 flutes

AE-MS-H

Milling | Solid carbide

First choice in quality and performance Radius Type

2,5 × D cutting length 4-6 flutes

CUTTING CONDITIONS

1

2

3

4

5

6

8 X 24 4.7801.8403.5801.3502.7908002.3906001.990380

10 X 30 3.8201.8302.8701.3402.2308001.9106001.590380

12 X 36 3.1801.8302.3901.3301.8608001.5906001.330380 Depth of cut

1. Use a rigid and precise machine and holder.

2. W h en chattering occurs, reduce the speed and feed simultaneously.

3. Use an air blow or a suitable cutting fluid with high smoke retardant properties.

1

2

3

4

5

6

8

10 X 30 9.5505.1607.9604.3005.1002.3004.4601.7703.1801.080

1. Tools can cause sparks. Do not use flammable fluids.

2. Use an air blow or a suitable cutting fluid with high smoke retardant properties. Caution:Sparks generated during operation or heat caused by tool breakage can cause fire. Be sure to use all proper fire - prevention measures. The conditions are for high speed / high precision machining centers.

CUTTING CONDITIONS

1

1,5

2

3

4 9.5501.5307.1701.1505.5706204.7804603.980340

4,5 8.4901.2206.3708904.9505304.2404003.540250

5 7.6401.5305.7301.1504.4606203.8204603.180360

5,5 6.9401.2205.2108904.0505303.4704002.890250

6 6.3702.2904.7801.7203.7209403.1806902.650510

1. Use a rigid and precise machine and holder.

2. W h en chattering occurs, reduce the speed and feed simultaneously.

3. Use an air blow or a suitable cutting fluid with high smoke retardant properties.

3 31.8503.82026.5403.18016.9901.63014.8601.25010.620810

3,5 27.2803.44022.7402.87014.5501.53012.7301.1809.090730

4 23.8903.82019.9003.18012.7401.63011.1501.2507.960810

4,5 21.2203.44017.6802.86011.3201.5309.9001.1807.070730

5 19.1103.82015.9203.18010.1901.6308.9201.2506.370810

5,5 17.3603.44014.4702.8709.2601.5308.1001.1805.790730

6 15.9205.73013.2704.7808.4902.4507.4301.8705.3101.210

11.9405.7309.9504.7806.3702.4505.5701.8703.9801.210

AE-ML-H

Multi-flute square type end mills for high-hardness steels

Unequal spacing teeth suppresses chattering

Improved tool rigidity by web taper geometry

The web taper geometry, where the thickness of core changes from the cutting edge to the shank, greatly improves tool rigidity, thereby prevents the machining surface from tilting

The amount of deflection of the machined surface at cutting length of 3,5m

Milling method Side milling

Cutting Speed 50m/min (1.590 min-1)

Feed Rate 668mm/min (0,07 mm/t)

Depth of Cut ap = 30mm ae = 0,1mm

Coolant Air Blow

DUROREY Coating

Exhibits outstanding performance in high-hardness steels due to its excellent toughness, high heat resistance and abrasion resistance characteristics.

CUTTING DATA

High precision milling

Achievesstablemillingaccuracyinhigh-hardnesssteelmachining

Tool

Work Material

Milling method

Cutting Speed

Feed Rate

Depth of Cut

AE-ML-HØ106flutes

SKD11(60HRC)

Sidemilling

30m/min(955min-1)

260mm/min (0,045mm/t)

ap=30mm ae=0,05mm

Coolant AirBlow

Machine Horizontal MachiningCenter (HSK63)

Comparisonoftheamountofdeflection ofthemachinedsurface

Atcuttinglengthof3.5mAtcuttinglengthof42m

Long tool life

Achievesstabledurabilityinhigh-hardnesssteelmachining

Tool

Work Material

AE-ML-HØ106flutes

SKD11(60HRC)

Milling method Sidemilling

Cutting Speed

Feed Rate

Depth of Cut

30m/min(955min-1)

260mm/min(0,045mm/t)

ap=30mmae=0,05mm

Coolant AirBlow

Machine HorizontalMachiningCenter (HSK63)

102030405060708090100

Millingm Length Breakage

AE-ML-HConventionalCompetitorACompetitorB

CUTTING DATA

Stable Performance

Achievesstabledurabilityinhigh-hardnesssteelmachining

Tool AE-ML-HØ3 4flutes

Work Material SKD(60HRC)

Milling method Sidemilling

CompetitorA 4flutes CompetitorB 3flutes

Cutting Speed 40m/min(4.250min-1)

Feed 460mm/min (0,027mm/t) 345mm/min (0,027mm/t)

Depth of Cut ap=9mmae=0,03mm

Coolant AirBlow

Machine VerticalMachiningCenter(BT40)

Wearconditionofouterperipheralcuttingedgeandcorneredge

AE-ML-HCompetitorACompetitorB

MillingLength CuttingedgeCorneredge

AE-ML-HCompetitorACompetitorBAE-ML-HCompetitorACompetitorB

High efficiency CUTTING DATA

Highly efficient machining of hot working die steel DH31-S, which requires superior tool performance

Work Material: DH31-S (50HRC)

Machine: Vertical Machining Center

Main Spindle : HSK-A63

Maximum RPM: 20.000 min-1

Coolant : Air Blow

Holder: Shrink Fit

AE-ML-H

CUTTING CONDITIONS

1. Use a rigid and precise machine and holder.

2. W h en chattering occurs, reduce the speed and feed simultaneously.

3.

AE-CRE-H

High efficiency radius type carbide end mill for high-hardness steels

Multi-flute and unequal spacing teeth specifications for high efficiency

- Achieves high-efficiency milling with multi-flute specification

- Unequal spacing teeth suppresses chattering to enable stable machining

2-stage gash shape

Prevents chipping of center cutting edge

Large chip pocket Improved chip evacuation

Cutting edge specifications

KEY FEATURES & BENEFITS

Direct engraving of hardened steel

Tool

AE-CRE-H Ø10 X R2

Work Material SKH51 (65HRC)

Milling method Contour milling

Cutting Speed

80m/min (2.550 min-1)

Feed Rate 2,230mm/min (0,17 mm/t)

Depth of Cut ap = 0,1mm ae = 3mm

Coolant Air Blow

Machine Vertical Machining Center (HSK-A63)

*Please refer to page 23 for cutting condition details

Realization of resource circulation and a sustainable manufacturing environment by regrinding

Cutting edge specification that minimizes shape change after regrinding

Strong back taper

Stable machining by preventing contact with the wall surface

Straight specification with consideration of regrinding

Outer diameter φ5 or above

Regrinding, recoating, and cemented carbide recycling contribute to resource circulation and a sustainable manufacturing environment.

CUTTING DATA

Stable Performance

Stable wear transition in 60 HRC high-hardness steel machining

Tool

Work Material SKD11 (60HRC)

Milling method Frontal milling

Cutting Speed

100m/min (3.180 min-1)

Feed Rate 3.820mm/min (0,24 mm/t)

3.820mm/min (0,3 mm/t)

Depth of Cut ap = 0,1mm ae = 3mm

Overhang Length 30mm (L/D=3)

Coolant Air Blow

Machine Horizontal Machining Center (HSK-A63)

Wear comparaison of the cutting edge

Long Tool Life

Exhibits excellent durability even in die-cast mold steel

Tool

Work

Cutting

(6.900 min-1)

Feed Rate 1.700mm/min (0,049 mm/t) 1.700mm/min (0,062 mm/t)

Depth of Cut ap = 0,18mm ae = 2,4mm

Overhang Length 24mm (L/D=4)

Wear comparaison of the cutting edge

CUTTING DATA

Direct engraving of forging dies out of right-hardness steel (65 HRC)

Work Material: SKH51 (65HRC)

Machine: Vertical Machining Center

Main Spindle : HSK-A63

Maximum RPM: 20.000 min-1

Coolant : Air Blow

Holder: Shrink Fit

3

AE-CRE-H NEW

First choice in quality and performance

Type

efficiency type 4-5 flutes

CUTTING CONDITIONS

AE-CRE-H

Frontal Milling

(m/min)

Depth of cut

apae 0,1RE0,3D

apae 0,1RE0,3D

apae 0,05RE0,3D ap Max = 0,2mm ap Max = 0,2mm ap Max = 0,1mm

1. Use a rigid and precise machine and holder.

2. These milling conditions are based on milling with circular interpolation at corners. For milling without circular interpolation (such as right angle corners), reduce the speed to 50-70% and the cutting depth to 50-80% of the above conditions.

3. We suggest using air blow or MQL (mist).

4. Please adjust the speed, feed and cutting depth according to actual cutting conditions.

5. These milling conditions are for overhang length of less than 4 × D. For longer overhang length, reduce the speed, feed rate, and the cutting depth in accordance to the respective coefficients to prevent chattering. It can also be used by lowering the cutting speed and adjusting the ae.

Cutting Condition Guide for Changes in Overhang Length

Maximum Ramping Angle (E°)

When ramping or helical milling, after adjusting the cutting condition by changing the overhang length, set the feed rate to 50% or less. DC x RE

KEY FEATURES & BENEFITS

AE-HFE-H

High feed radius type carbide end mill for high-hardness steels

Composite radius shape capable of high feed

Unique radius shape reduces cutting resistance High-feed machining possible even at overhang length of L/D = 7

Unequal spacing teeth suppresses chattering

Achieves stable and highly efficient machining

gash shape

Bottom edge R

Incline cutting edge

Corner R

Achieves both cutting edge strength and good chip evacuation 2-stage

Prevents chipping of center cutting edge

Large chip pocket

Improved chip evacuation

KEY FEATURES & BENEFITS

High-speed,

high-feed machining at overhang length of L/D = 7

Unique radius shape reduces cutting resistance

■ Cutting resistance in the feed direction is reduced due to the small cutting angle, suppressing vibration and deflection of the tool.

■ By reducing the chip thickness, cutting heat is easily transferred to the chip, making it more difficult for heat to remain on the tool cutting edge and work material.

Stable machining made possible by reducing cutting resistance

Realization of resource circulation and a sustainable manufacturing environment by regrinding

Cutting edge specification that minimizes shape change after regrinding

Strong back taper

Stable machining by preventing contact with the wall surface

Straight specification with consideration of regrinding

Outer diameter φ5 or above

Regrinding, recoating, and cemented carbide recycling contribute to resource circulation and a sustainable manufacturing environment.

CUTTING DATA

Stable Performance

Achieves stable machining in STAVAX (53HRC)

Tool AE-HFE-H Ø10 X R0,7

Work Material

Processing Shape

STAVAX (53HRC)

Milling method Pocket milling

Pocket Shape 172mm x 31mm x 10mm Depth

Cutting Speed 100m/min (3.180 min-1)

Feed Rate

3.180mm/min (0,2 mm/t)

3.180mm/min (0,17 mm/t)

Depth of Cut ap = 0,2mm ae = 4mm

Overhang Length

50mm (L/D=5)

Coolant Air Blow

Machine Horizontal Machining Center (HSK-A63)

Long Tool Life

Tool

Work Material

4

SKD61 (50HRC)

Milling method Pocket milling

Pocket Shape 171mm x 31mm x 13,5mm Depth

Cutting Speed 75m/min (2.390 min-1)

Feed Rate

3.590mm/min (0,3 mm/t)

3.590mm/min (0,38 mm/t)

Depth of Cut ap = 0,2mm ae = 4mm

Overhang Length 70mm (L/D=7)

Coolant Air Blow

Machine Horizontal Machining Center (HSK-A63) Machining

Wear comparaison of the cutting edge

High-feed machining with excellent durability in SKD61 (50 HRC) at L/D = 7

Processing Shape

Wear comparaison of the cutting edge

AE-HFE-H NEW

Milling | Solid carbide

4flutes5flutes

First choice in quality and performance

Radius Type

High Feed type

4-5 flutes

8550019410,10,360,10,48812,63600,460,8511,33°3,163,333,53,6641 8550020420,20,730,150,97513,66600,861,88,46°6,296,566,827,077,631 8550021530,31,10,21,46314,79601,362,75,95°9,369,710,0410,411,221 8550022540,351,50,21,9515,812701,663,63,71°12,4212,8513,313,7814,871 8550023550,41,870,22,43816,91580264,51,74°15,516,0216,59--1 8550024560,452,240,22,925-18902,565,4------2 8550025580,652,990,33,9-241003,587,2------2 85500265100,73,830,34,875-301104,5109------2 85500275120,84,590,35,85-3613551211------2

CUTTING CONDITIONS

AE-HFE-H

Frontal Milling L/D≤4

Frontal Milling 4<L/D≤6

Depth of cut

1. Use a rigid and precise machine and holder.

2. The values listed above are for reference. Please set the cutting condition in accordance with the actual machining environment.

3. When the depth of cut ap exceeds the table above, set it so that it does not exceed the maximum depth of cut ap Max. Please adjust the cutting condition according to the actual machining environment.

4. Please reduce the feed rate when the depth of cut is greater than specified.

5. We suggest using air blow or MQL (mist).

6. Please adjust the speed, feed and cutting depth according to actual cutting conditions.

7. If the pick amount is DCF or more, cusp may occur on the machined surface.

CUTTING CONDITIONS

Frontal Milling 6<L/D≤7

Maximum Ramping Angle (E°)

* For ramping and helical milling, set the feed rate to 50%.

Edge shape definitions for the purpose of creating a program

Maximum depth of cut

AE-BM-H

4 flutes high efficiency Carbide ball end mill for high-hardeness steel

R1 ~ R6

total 8 items

Center 2 flute specification

Controls tear when milling flat areas to improve surface accuracy.

Secures chip pockets with the center 2-flute specification to control the clogging of chips.

Sharp spiral curve

Reduces cutting resistance and enables stable performance with extended tool life.

Superior ball R precision

Suitable for a wide range of processes, from roughing to semi-roughing.

Unequal flute spacing

Controls harmonic vibration commonly generated during milling with multiple flutes to enable high-efficiency milling.

KEY FEATURES & BENEFITS

Main Features

Variable negative spiral gash

High accuracy

finishing, 2 flutes

R0,5 ~ R6

total 17 items

Unequal spacing

High performance 4 flutes type

R1 ~ R6

total 8 items

Strong negative point to suppress chipping & negative outer cutting edge angle for excellent surface finish

Core thickness

Improved core thickness suppresses cracks and chipping

Excellent radius accuracy

Wide variety of finishing applications

Also available as short shank type for shrink fit holders

DUROREY coating

Excellent wear resistance for machining high hardness materials

Smooth surface

High coating surface smoothness for improved work material surface

Multiflute type to suppress vibrations

Strong spiral geometry

Low cutting resistance, high efficiency machining

2 flutes center cut

- large chip pocket for improved chip evacuation

- improved surface quality even on flat surfaces

Excellent radius accuracy

High versatility from roughing to semi-finishing

DUROREY coating

Excellent wear resistance for machining high hardness materials

Newly developed DUROREY coating enables superior heat resistance and high toughness optimized for

Super heat resistant layer and ulra-fine periodic nano-layered structure provide superior toughness while maintaining high heat resistance and abrasion resistance. Also suppresses chipping even in high hardness milling and achieves long tool life.

Ultra-Fine Periodic

AE-BM-H

Milling | Solid carbide

First choice in quality and performance

For high hardness materials

4 flutes, ball nose

CUTTING DATA

Long tool life

Exhibits superior endurance in high-hardness steel milling.

Work Material SKD11 (60HRC)

Milling method Pocket milling

Cutting Speed 55m/min (1.750 min-1)

Feed Rate 875mm/min (0,125 mm/t)

Depth of Cut ap = 0,75mm Pf = 2,25mm

Coolant Air Blow

Machine Vertical Machining Center (BT40)

Milling

Pocket milling

Depth of Cut ap = 0,3mm Pf = 1,2mm

Coolant Air Blow

Machine Horizontal Machining Center (HSK63)

Low cutting force

Effects of sharp spiral curve and unequal flute spacing enable stable milling with low resistance.

Work

Milling method Corner R milling

Cutting Speed

(2.550 min-1)

Feed Rate 2.000mm/min (0,196 mm/t)

Depth of Cut ap = 5mm Pf = 0,1mm

Coolant Air Blow

Machine Vertical Machining Center (BT40)

CUTTING CONDITIONS

AE-BM-H

Roughing

The machining path is on condition of contouring line operation

1. Use a rigid and precise machine and holder.

2. We suggest using air blow or MQL (mist).

3. These milling conditions are for an end mill where the tool extension length is 4 times the diameter of the end mill. When length of the tool extension from the machine is

and milling depth.

4. The above condition shows an approximate standard for contouring operation (side milling) with a low machining load. If abno rmal cutting sounds, vibration or chattering occur depending on the machining shape, cutting amount, rigidity of the machine or work holding condition, etc., please adjust the speed, feed and the depth of cut.

5. When the radius of curvature is less than 1.5 times the tool diameter, please reduce the speed to 50-80%, the feed rate to 50-80%, and the pick feed to 20-60% of the above shown cutting conditions.

6. When the machining incline angle (β) is more than 15° , please reduce the speed to 40-60%, the feed 30-50%, and the axial cutting depth to 30-60% of the above shown cutting conditions.

7. If the cutting depth is small, it is possible to further increase the speed and feed.

AE-BM-H

Finishing

The machining path is on condition of contouring line operation

CUTTING CONDITIONS

AE-BM-H

High Speed Roughing

The machining path is on condition of contouring line operation

1. Use a rigid and precise machine and holder.

2. We suggest using air blow or MQL (mist).

3. These milling conditions are for an end mill where the tool extension length is 4 times the diameter of the end mill. When length of the tool extension from the machine is long, reduce the speed and feed and milling depth.

4. The above condition shows an approximate standard for contouring operation (side milling) with a low machining load. If abno rmal cutting sounds, vibration or chattering occur depending on the machining shape, cutting amount, rigidity of the machine or work holding condition, etc., please adjust the speed, feed and the depth of cut.

5. When the radius of curvature is less than 1.5 times the tool diameter, please reduce the speed to 50-80%, the feed rate to 50-80%, and the pick feed to 20-60% of the above shown cutting conditions.

6. When the machining incline angle (β) is more than 15° , please reduce the speed to 40-60%, the feed 30-50%, and the axial cutting depth to 30-60% of the above shown cutting conditions.

7. If the cutting depth is small, it is possible to further increase the speed and feed.

AE-BM-H

High Speed Finishing

The machining path is on condition of contouring line operation

1. Use a rigid and precise machine and holder.

2. We suggest using air blow or MQL (mist).

3.

milling

When

milling depth.

4. The above condition shows an approximate standard for contouring operation (side milling) with a low machining load. If abno rmal cutting sounds, vibration or chattering occur depending on the machining shape, cutting amount, rigidity of the machine or work holding condition, etc., please adjust the speed, feed and the depth of cut.

5. When the radius of curvature is less than 1.5 times the tool diameter, please reduce the speed to 50-80%, the feed rate to 50-80%, and the pick feed to 20-60% of the above shown cutting conditions.

6. When the machining incline angle (β) is more than 15° , please reduce the speed to 40-60%, the feed 30-50%, and the axial cutting depth to 30-60% of the above shown cutting conditions.

7. If the cutting depth is small, it is possible to further increase the speed and feed.

KEY FEATURES & BENEFITS

AE-BD-H

2-flute high-precision finishing Carbide ball end mill for high hardness steel

R0,5 ~ R6

total 17 items

Variable negative spiral gash

Controls chipping with larger negative angle at tip of cutting edge.

While securing cutting quality by making the negative angle weaker near the outer periphery, chipping resistance is enhanced in combination with the weaker helix angle specification.

Thickness at the center

Thickening of the center core to prevent deformation of the ball tip and improve control of chipping.

Superior ball R precision

Secures stable R accuracy across 180°

Superior shank accuracy

Supports h4 tolerance (0/-0.004)

Ideal for shrink fit holders

Lineup of short-shank type suitable for shrink fit holders are also available.

Smooth Surface Treatment

Improves surface accuracy by smoothening the coating surface.

Milling | Solid carbide

First choice in quality and performance

For high hardness materials

2 flutes, ball nose

3042001-210,52500,87,640,9511,71°2,05°2,1°2,16°2,22°2,35°1 3042002-21,50,753501,27,841,4510,03°3,13°3,25°3,35°3,44°3,65°1 3042003-2214501,611,961,9510,64°4,22°4,44°4,65°4,85°5,25°1 3042004-231,56602,411,862,858,15°6,25°6,49°6,72°6,94°7,36°1 3042005-2428-4603,2-43,85------2 3042006-2428703,21263,855,65°8,32°8,62°8,9°9,15°9,71°1 3042007o2428-S453,21263,855,65°8,32°8,62°8,9°9,15°9,71°1 3042008-252,51080412,164,802,92°10,36°10,69°10,99°11,3°-1 3042009o252,510-S50412,164,802,92°10,36°10,69°10,99°11,3°-1 3042010-26318909-65,80------2 3042011o26318-S559-65,80------2 3042012-2842410012-87,70------2 3042013o28424-S7512-87,70------2 3042014-21053010015-109,70------2 3042015o210530-S7515-109,70------2 3042016-21263611018-1211,70------2 3042017o212636-S8018-1211,70------2

CUTTING DATA

Long tool life

Exhibits superior endurance in high-hardness steel milling.

Tool

AE-BD-H R5X30

Work Material SKD11 (60HRC)

Milling method Pocket milling

Cutting Speed 150m/min (4.800 min-1)

Feed Rate

870mm/min (0,09 mm/t)

Depth of Cut ap = 0,2mm Pf = 0,5mm

Coolant Air Blow

Tool

R5X30

Work Material SKH51 (65HRC)

Milling

Pocket milling

(0,09 mm/t)

Depth of Cut ap = 0,2mm Pf = 0,5mm

Coolant Air Blow

Machine Horizontal Machining Center (HSK63)

High speed milling

Enables stable machining even in high-speed milling of STAVAX (53 HRC)

Machine Horizontal Machining Center (HSK63) Tool

R5X30

Work Material STAVAX (53HRC)

Milling method Pocket milling

Cutting Speed 300m/min (9.550 min-1)

Feed Rate 2.670mm/min (0,14 mm/t)

Depth of Cut ap = 0,2mm Pf = 0,5mm

Coolant Air Blow

Machine Horizontal Machining Center (HSK63)

CUTTING CONDITIONS

AE-BD-H

The machining path is on condition of contouring line operation

AE-BD-H Finishing

High speed Finishing

The machining path is on condition of contouring line operation

0,02D0,05D

1. Use a rigid and precise machine and holder.

2. We suggest using air blow or MQL (mist).

3. These milling conditions are for an end mill where the tool extension length is 4 times the diameter of the end mill. When length of the tool extension from the machine is long, reduce the speed and feed and milling depth.

4. The above condition shows an approximate standard for contouring operation (side milling) with a low machining load. If abno rmal cutting sounds, vibration or chattering occur depending on the machining shape, cutting amount, rigidity of the machine or work holding condition, etc., please adjust the speed, feed and the depth of cut.

5. When the radius of curvature is less than 1.5 times the tool diameter, please reduce the speed to 50-80%, the feed rate to 50-80%, and the pick feed to 20-60% of the above shown cutting conditions.

6. When the machining incline angle (β) is more than 15° , please reduce the speed to 40-60%, the feed 30-50%, and the axial cutting depth to 30-60% of the above shown cutting conditions.

7. If the cutting depth is small, it is possible to further increase the speed and feed.

KEY FEATURES & BENEFITS

AE-CPR4-H

4-flute high-efficiency finishing long neck carbide radius end mill for high-hardness steel

New spiral-shaped gash specification

The new gash specification with a spiral shape from the center to the corner R improves chip evacuation and prevents chips from getting caught

*Applicable to sizes with an outer diameter of θ1 or more and a corner R exceeding R0.1

Superior R precision

Achieves high efficiency milling with 4-flute specification

4-flute configuration for all sizes

Unequal spacing teeth suppresses chattering

Achieves highly efficient machining by the suppression of chattering even in deep milling of L/D = 14

Tool

Work Material SKD61 (50HRC)

Milling method Contour Milling

Cutting Speed 58m/min (9.300 min-1)

Feed 1.300mm/min (0,035 mm/t)

Depth of Cut ap = 0,05mm Pf = 0,36mm

Overhang Length 28mm (L/D=14)

Coolant Air Blow

Machine Vertical Machining Center (HSK-A63)

Smooth Surface Treatment

Improves surface accuracy by smoothening the coating surface

Abundant Variations

206 items (Ø0.2 to Ø4) are available to accommodate a wide range of applications

CUTTING DATA

Stable Performance

Highly efficient and excellent durability in high hardness steel

Tool

AE-CPR4-H

Ø2 x R0,3 x 8

Work Material SKD11 (60HRC)

Milling method Frontal milling

Cutting Speed

Feed Rate

Conventional 2 flutes

72m/min (11.500 min-1)

2.000mm/min (0,043 mm/t)

1.000mm/min (0,043 mm/t)

Depth of Cut ap = 0,036mm ae = 0,48mm

Coolant Air Blow

Machine Vertical Machining Center (BT40)

Wear comparison of the cutting edge after milling 61.2 m

Long Tool Life

Stable wear transition in pre-hardened steel NAK80 (40 HRC)

Tool

AE-CPR4-H

Ø3 x R0,5 x 20

Work Material NAK80 (40HRC)

Milling method Frontal milling

Cutting Speed

120m/min (12.730 min-1)

Feed Rate 1.782mm/min (0,035 mm/t)

Depth of Cut ap = 0,04mm ae = 0,734mm

Coolant Air Blow

Machine Vertical Machining Center (BT40)

Wear comparison of the cutting edge after milling 1.512 m

CUTTING DATA

Stable Performance

Achieves excellent durability and machined surface accuracy in profiling of high-hardness steel

Tool

AE-CPR4-H Ø3 x R0,5 x 8

Work Material SKD11 (60HRC)

Milling method Pocket milling

Cutting Speed

79m/min (8.400 min-1)

Feed Rate 540mm/min (0,016 mm/t)

Depth of Cut ap = 0,04mm ae = 14mm

Coolant Air Blow

Machine Vertical Machining Center (BT40)

Wear comparison of the cutting edge after milling 80,2 m

Bottom surface roughness after milling 80,2m

Good machined surface roughness even when milling long distance

CUTTING DATA

Highly efficient deep milling at L/D = 14 with narrow groove width

Work Material: SKD61(50HRC)

Coolant: Air

Machine:

Main Spindle:

Maximum

Holder: Shrink Fit

AE-CPR4-H NEW SIZES

Milling | Solid carbide

First choice in quality and performance

Carbide end mill with DUROREY coating

For hardened material up to 70HRC

4 flutes, unequal spacing. New spiral-shaped gash specification

312 sizes

85574700,20,020,50,1540,18457,713,880,530,570,610,650,7341 85574710,20,0210,1540,18458,213,071,061,131,21,261,3841 85574720,20,021,50,1540,18458,712,341,61,691,771,85241 85574730,20,0220,1540,18459,211,692,122,242,332,432,6241 85574740,20,050,50,1540,18457,713,930,530,560,60,640,7241 85574750,20,0510,1540,18458,213,111,061,131,191,251,3741 85574760,20,051,50,1540,18458,712,371,591,681,771,841,9941 85574770,20,0520,1540,18459,211,722,122,232,332,422,6141 85574780,30,0210,2540,2845813,021,061,131,21,261,3841 85574790,30,021,50,2540,28458,512,281,61,691,771,85241 85574800,30,0220,2540,2845911,622,122,242,332,432,6241 85574810,30,022,50,2540,28459,511,022,652,782,8933,2441 85574820,30,0230,2540,28451010,483,183,323,453,583,8741 85574830,30,0510,2540,2845813,061,061,131,191,251,3741 85574840,30,051,50,2540,28458,512,321,591,681,771,841,9941 85574850,30,0520,2540,2845911,652,122,232,332,422,6141 85574860,30,052,50,2540,28459,511,052,652,782,8933,2441 85574870,30,0530,2540,28451010,513,183,323,443,573,8641 85574880,40,0210,340,37458,212,411,081,171,281,381,6241 85574890,40,021,50,340,37458,711,711,621,761,892,032,3241 85574900,40,0220,340,37459,211,092,162,332,52,67341 85574910,40,022,50,340,37459,710,532,72,93,13,293,6641 85574920,40,0230,340,374510,210,033,243,473,693,94,3141 85574930,40,0240,340,374511,29,154,314,594,855,15,5741 85574940,40,0510,340,37458,212,451,081,171,271,371,641 85574950,40,051,50,340,37458,711,751,621,751,892,032,3141 85574960,40,0520,340,37459,211,122,162,332,492,662,9941 85574970,40,052,50,340,37459,710,562,72,93,093,283,6541 85574980,40,0530,340,374510,210,053,243,463,683,894,341 85574990,40,0540,340,374511,29,174,314,594,855,15,5641 85575000,40,110,340,37458,212,511,071,161,261,361,5841 85575010,40,120,340,37459,211,182,162,322,482,652,9841 85575020,40,130,340,374510,210,13,233,463,673,884,2941 85575030,40,140,340,374511,29,214,34,584,845,095,5541 85575040,50,0210,440,4645812,391,081,171,261,371,5941 85575050,50,0220,440,4645911,042,162,322,482,642,9741 85575060,50,0230,440,4645109,963,233,453,673,874,2741 85575070,50,0240,440,4645119,074,34,574,835,075,5341 85575080,50,0250,440,4645128,325,365,685,986,256,7741 85575090,50,0260,440,4645137,696,426,797,117,418,0241 85575100,50,0510,440,4645812,431,081,161,261,361,5841 85575110,50,0520,440,4645911,082,152,312,472,642,9641 85575120,50,0530,440,4645109,993,233,453,663,874,2741 85575130,50,0540,440,4645119,094,34,574,825,075,5241 85575140,50,0550,440,4645128,345,365,685,976,256,7741 85575150,50,0560,440,4645137,716,426,797,117,418,0141

AE-CPR4-H NEW SIZES

Milling | Solid carbide

First choice in quality and performance

Carbide end mill with DUROREY coating

For hardened material up to 70HRC

4 flutes, unequal spacing. New spiral-shaped gash specification

312 sizes

85575160,50,110,440,4645812,51,071,151,241,341,5541 85575170,50,120,440,4645911,132,152,312,462,622,9541 85575180,50,130,440,46451010,033,223,443,653,864,2541 85575190,50,140,440,4645119,134,294,564,825,065,5141 85575200,50,150,440,4645128,375,365,685,976,246,7641 85575210,50,160,440,4645137,736,426,787,17,4841 85448210,60,110,4840,55457,812,481,071,151,231,331,5341 85448240,60,0510,4840,55457,812,411,071,161,251,341,5541 85448250,60,0520,4840,55458,811,022,152,32,462,622,9341 85448260,60,0540,4840,554510,89,014,284,554,85,045,4941 85448270,60,0560,4840,554512,87,616,416,767,087,387,9841 85575220,60,120,4840,55458,811,082,142,292,452,62,9241 85575230,60,140,4840,554510,89,054,284,554,795,035,4841 85575240,60,160,4840,554512,87,646,416,767,087,377,9741 85448280,70,021,50,5540,65458,111,561,611,741,861,992,2741 85448290,70,051,50,5540,65458,111,61,611,731,861,992,2641 85575250,70,0220,5540,65458,610,92,152,312,462,622,9441 85575260,70,0240,5540,654510,68,884,294,554,815,055,541 85575270,70,0260,5540,654512,67,486,416,777,097,387,9841 85575280,70,0520,5540,65458,610,942,152,32,462,622,9341 85575290,70,0540,5540,654510,68,94,284,554,85,045,4941 85575300,70,0560,5540,654512,67,56,416,767,087,387,9841 85575310,70,120,5540,65458,610,992,142,292,452,62,9241 85575320,70,140,5540,654510,68,944,284,554,795,035,4841 85575330,70,160,5540,654512,67,536,416,767,087,377,9741 85448220,80,120,6540,75458,410,92,142,292,452,62,9241 85448230,80,220,6540,75458,411,022,142,282,432,582,8841 85448300,80,0520,6540,75458,410,842,152,32,462,622,9341 85448320,80,0540,6540,754510,48,794,284,554,85,045,4941 85448330,80,0560,6540,754512,47,386,416,767,087,387,9841 85575340,80,140,6540,754510,48,834,284,554,795,035,4841 85575350,80,160,6540,754512,47,416,416,767,087,377,9741 85575360,80,240,6540,754510,48,94,284,534,785,015,4641 85575370,80,260,6540,754512,47,476,46,757,067,367,9441 85575380,80,280,6540,754514,46,438,528,949,319,6610,4341 85575390,90,140,740,854510,28,714,284,554,795,035,4841 85575400,90,180,740,854514,26,278,528,959,329,6710,4541 854483110,0520,840,9445810,682,142,292,442,62,9141 854483410,120,840,9445810,742,142,282,432,582,8941 854483510,0220,840,9445810,642,142,32,452,62,9241 854483610,0230,840,944599,483,213,423,633,834,2141 854483710,220,840,9445810,862,132,272,412,562,8641 854483810,0240,840,9445108,554,284,544,795,025,4741 854483910,0260,840,9445127,146,46,757,067,367,9541 854484010,320,840,9445810,982,122,262,392,542,8341 854484110,0280,840,9445146,138,518,939,319,6610,4441

AE-CPR4-H NEW SIZES

Milling | Solid carbide

First choice in quality and performance

Carbide end mill with DUROREY coating

For hardened material up to 70HRC

4 flutes, unequal spacing. New spiral-shaped gash specification

312 sizes

854484210,02100,840,9445165,3710,6211,111,5311,9612,9341 854484310,0530,840,944599,513,213,423,623,824,2141 854484410,130,840,944599,563,213,413,613,814,1941 854484510,1160,840,9455223,9216,8917,5418,1718,8420,3741 854484610,1200,840,9455263,3221,0621,8222,623,4425,3441 854484710,230,840,944599,663,23,43,63,794,1741 854484810,330,840,944599,753,193,393,583,774,1441 854484910,3160,840,9455223,9616,8817,5218,1518,8220,3241 854485010,3200,840,9455263,3421,0521,822,5823,4125,2941 855754110,0540,840,9445108,574,284,544,785,025,4641 855754210,0560,840,9445127,166,46,757,067,357,9541 855754310,0580,840,9445146,148,518,939,39,6510,4341 855754410,05100,840,9445165,3810,6111,111,5211,9512,9241 855754510,05120,840,9445184,7812,7113,2613,7414,2515,4141 855754610,140,840,9445108,614,274,534,775,015,4541 855754710,160,840,9445127,186,396,747,057,347,9341 855754810,180,840,9445146,168,518,939,39,6510,4241 855754910,1100,840,9445165,3910,6111,111,5211,9512,9141 855755010,1120,840,9445184,7912,7113,2513,7314,2515,3941 855755110,240,840,9445108,694,274,524,764,995,4241 855755210,260,840,9445127,246,396,737,047,337,9141 855755310,280,840,9445146,28,58,929,299,6310,441 855755410,2100,840,9445165,4210,6111,0911,5111,9312,8841 855755510,2120,840,9445184,8212,713,2413,7214,2315,3741 855755610,2160,840,9455223,9416,8917,5318,1618,8320,3441 855755710,2200,840,9455263,3321,0521,8122,5923,4325,3241 855755810,340,840,9445108,774,264,514,744,975,441 855755910,360,840,9445127,36,386,727,037,317,8941 855756010,380,840,9445146,248,58,919,279,6210,3741 855756110,3100,840,9445165,4610,611,0811,511,9212,8641 855756210,3120,840,9445184,8412,713,2413,7114,2215,3541 85575631,20,26141,144511,66,986,396,737,047,337,9141 85575641,20,28141,144513,65,958,58,929,299,6310,441 85575651,20,210141,144515,65,1910,6111,0911,5111,9312,8841 85575661,20,36141,144511,67,046,386,727,037,317,8941 85575671,20,38141,144513,65,998,58,919,279,6210,3741 85575681,20,310141,144515,65,2210,611,0811,511,9212,8641 85448511,50,0531,241,434588,883,23,413,63,84,1841 85448521,50,0541,241,434597,914,274,524,764,995,4341 85448531,50,0561,241,4345116,496,396,737,047,337,9241 85448541,50,0581,241,4345135,58,58,919,289,6310,441 85448551,50,05101,241,4345154,7710,611,0811,511,9312,8941 85448561,50,05121,241,4345174,2112,713,2313,7114,2315,3841 85448571,50,05161,241,4350213,4116,8717,5218,1518,8320,3541 85448581,50,141,241,434597,954,264,524,754,985,4241 85448591,50,161,241,4345116,526,386,727,037,327,9141

AE-CPR4-H NEW SIZES

Milling | Solid carbide

First choice in quality and performance

Carbide end mill with DUROREY coating

For hardened material up to 70HRC

4 flutes, unequal spacing. New spiral-shaped gash specification

312 sizes

85448601,50,181,241,4345135,528,498,919,279,6210,3941 85448611,50,1101,241,4345154,7810,611,0711,4911,9212,8841 85448621,50,1121,241,4345174,2212,6913,2313,7114,2215,3641 85448631,50,1161,241,4350213,4216,8717,5118,1418,8220,3441 85448641,50,131,241,434588,933,23,43,63,794,1641 85448651,50,241,241,434598,034,264,54,744,975,441 85448661,50,231,241,434589,043,193,393,583,774,1441 85448671,50,341,241,434598,124,254,494,724,955,3741 85448681,50,331,241,434589,143,193,383,563,754,1141 85448691,50,531,241,434589,363,173,353,533,714,0641 85448701,50,541,241,434598,294,244,474,694,915,3241 85448711,50,561,241,4345116,746,366,686,987,267,8141 85448721,50,581,241,4345135,688,478,879,239,5610,341 85448731,50,5101,241,4345154,9110,5811,0411,4511,8612,7841 85448741,50,5121,241,4345174,3212,6713,213,6714,1615,2741 85448751,50,5161,241,4350213,4816,8517,4818,118,7620,2441 85575691,50,261,241,4345116,576,386,717,027,37,8841 85575701,50,281,241,4345135,568,498,99,269,610,3741 85575711,50,2101,241,4345154,8110,5911,0711,4811,912,8541 85575721,50,2121,241,4345174,2512,6913,2213,714,215,3441 85575731,50,2161,241,4350213,4416,8717,5118,1318,820,3141 85575741,50,361,241,4345116,636,376,77,017,297,8641 85575751,50,381,241,4345135,68,488,899,259,5910,3441 85575761,50,3101,241,4345154,8510,5911,0611,4711,8912,8341 85575771,50,3121,241,4345174,2712,6813,2113,6914,1915,3241 85575781,50,3161,241,4350213,4516,8617,518,1218,7920,2941 854487620,0541,641,92508,17,094,264,514,744,975,441 854487720,0561,641,925010,15,696,386,717,027,37,8941 854487820,0581,641,925012,14,758,488,899,259,610,3841 854487920,05101,641,925014,14,0810,5811,0611,4711,912,8641 854488020,05121,641,925016,13,5712,6813,2113,6914,215,3541 854488120,05161,641,925020,12,8616,8617,4918,1218,8-41 854488220,05201,641,926024,12,3921,0221,7722,5623,4-41 854488320,161,641,925010,15,726,376,717,017,297,8841 854488420,261,641,925010,15,776,376,777,287,8641 854488520,361,641,925010,15,836,366,696,987,267,8341 854488620,561,641,925010,15,946,356,676,967,237,7841 854488920,141,641,92508,17,134,264,54,744,965,3941 854489120,241,641,92508,17,214,254,494,724,945,3741 854489320,341,641,92508,17,34,244,484,714,935,3541 854489520,541,641,92508,17,484,234,464,684,895,341 855757920,181,641,925012,14,778,488,899,259,5910,3741 855758020,1101,641,925014,14,0910,5811,0511,4711,8912,8541 855758120,1121,641,925016,13,5812,6813,2113,6814,1915,3441 855758220,1161,641,925020,12,8716,8517,4918,1218,79-41 855758320,1201,641,926024,12,3921,0221,7722,5523,39-41

AE-CPR4-H NEW SIZES

Milling | Solid carbide

First choice in quality and performance

Carbide end mill with DUROREY coating

For hardened material up to 70HRC

4 flutes, unequal spacing. New spiral-shaped gash specification

312 sizes

855758420,1251,641,926029,11,9826,227,1228,09--41 855758520,281,641,925012,14,818,488,889,249,5810,3441 855758620,2101,641,925014,14,1210,5811,0511,4611,8812,8341 855758720,2121,641,925016,13,612,6713,213,6714,1815,3141 855758820,2161,641,925020,12,8816,8517,4818,1118,78-41 855758920,2201,641,926024,12,421,0121,7622,5423,38-41 855759020,2251,641,926029,11,9926,227,1128,08--41 855759120,381,641,925012,14,858,478,879,239,5610,3241 855759220,3101,641,925014,14,1510,5711,0411,4511,8612,841 855759320,3121,641,925016,13,6312,6713,1913,6614,1615,2941 855759420,3161,641,925020,12,916,8517,4818,118,76-41 855759520,3201,641,926024,12,4121,0121,7522,5323,36-41 855759620,581,641,925012,14,938,468,859,29,5410,2741 855759720,5101,641,925014,14,2110,5611,0211,4211,8312,7641 855759820,5121,641,925016,13,6712,6613,1813,6414,1315,2441 855759920,5161,641,925020,12,9216,8417,4618,0718,73-41 855760020,5201,641,926024,12,432121,7422,5123,33-41 855760120,5251,641,926029,12,0126,1927,0928,0529,08-41 85448872,50,110242,45513,13,310,5611,0211,4211,8512,841 85448882,50,120242,45523,11,8720,9821,7322,51--41 85448902,50,130242,47033,11,3131,3332,42---41 85448922,50,230242,47033,11,3131,3332,42---41 85448942,50,310242,45513,13,3510,551111,411,8212,7541 85448962,50,320242,45523,11,8920,9721,7122,48--41 85448972,50,330242,47033,11,3131,3332,41---41 85448982,50,530242,47033,11,3231,3232,39---41 85576022,50,210242,45513,13,3310,5511,0111,4111,8312,7841 85576032,50,220242,45523,11,8820,9821,7222,5--41 85576042,50,510242,45513,13,410,5410,9811,3811,7912,7141 85576052,50,520242,45523,11,920,9721,722,46--41 854489930,142,562,85559,88,764,224,434,644,845,2441 854490030,162,562,855511,87,286,326,616,897,157,7341 854490130,182,562,855513,86,238,418,789,129,4510,2141 854490230,1102,562,855515,85,4510,510,9411,3311,7512,741 854490330,1122,562,855517,84,8412,5913,0813,5514,0515,1941 854490430,1162,562,855521,83,9516,7517,3617,9818,6520,1641 854490530,1202,562,855525,83,3420,9121,6422,4223,2525,1341 854490630,1252,562,857030,82,826,0826,9927,9629-41 854490730,242,562,85559,88,844,214,424,624,825,2241 854490830,2102,562,855515,85,4810,510,9311,3211,7412,6841 854490930,342,562,85559,88,924,24,414,614,815,1941 854491030,382,562,855513,86,328,48,779,099,4210,1741 854491130,3102,562,855515,85,5110,510,9211,3111,7212,6541 854491230,542,562,85559,89,094,194,394,584,775,1541 854491330,582,562,855513,86,418,398,759,079,410,1241 854491430,5102,562,855515,85,5810,4910,9111,2911,6912,6141

AE-CPR4-H NEW SIZES

Milling | Solid carbide

First choice in quality and performance

Carbide end mill with DUROREY coating

For hardened material up to 70HRC

4 flutes, unequal spacing. New spiral-shaped gash specification

312 sizes

854492130,262,562,855511,87,346,316,66,887,147,741 854492430,362,562,855511,866,316,66,877,127,6841 854492830,562,562,855511,866,36,586,847,17,6341 855760630,282,562,855513,86,288,418,779,119,4410,1941 855760730,2122,562,855517,84,8612,5913,0713,5414,0415,1641 855760830,2162,562,855521,83,9716,7517,3517,9718,6420,1441 855760930,2202,562,855525,83,3520,921,6322,423,2425,1141 855761030,2252,562,857030,82,8126,0826,9827,9528,99-41 855761130,2302,562,857035,82,4131,2532,3333,4934,74-41 855761230,2352,562,857040,82,1236,4137,6839,0340,49-41 855761330,3122,562,855517,84,8912,5813,0713,5314,0215,1441 855761430,3162,562,855521,83,9916,7517,3417,9618,6220,1141 855761530,3202,562,855525,83,3720,921,6222,3923,2225,0841 855761630,3252,562,857030,82,8226,0726,9727,9428,97-41 855761730,3302,562,857035,82,4231,2432,3233,4834,72-41 855761830,3352,562,857040,82,1236,4137,6739,0240,47-41 855761930,5122,562,855517,84,9412,5713,0513,5113,9915,0941 855762030,5162,562,855521,84,0216,7417,3317,9418,5920,0641 855762130,5202,562,855525,83,3920,8921,6122,3723,1925,0441 855762230,5252,562,857030,82,8326,0726,9627,9128,94-41 855762330,5302,562,857035,82,4331,2432,3133,4634,69-41 855762430,5352,562,857040,82,1336,437,663940,44-41 854491540,183,263,8460124,828,418,779,19,4410,241 854491640,1123,263,8460163,6112,5813,0713,5314,0415,1741 854491740,1163,263,8460202,8916,7417,3417,9718,64-41 854491840,1203,263,8460242,4120,8921,6222,423,24-41 854491940,1253,263,8460291,9926,0726,9727,94--41 854492040,1303,263,8475341,731,2332,3233,48--41 854494340,283,263,84601288,48,769,099,4210,1741 854494440,2123,263,8460161212,5813,0613,5214,0215,1541 854494540,383,263,84601288,48,759,089,4110,1541 854494640,3123,263,8460161212,5713,0513,5114,0115,1241 854494740,583,263,84601288,398,749,069,3810,141 854494840,5123,263,8460161212,5613,0413,4913,9815,0741 85449494183,263,84601288,368,799,319,9841 854495041123,263,8460161212,541313,4413,914,9641 855762540,2163,263,8460202,916,7417,3417,9618,62-41 855762640,2203,263,8460242,4120,8921,6222,3923,22-41 855762740,2253,263,846029226,0626,9627,93--41 855762840,2303,263,8475341,731,2332,3133,47--41 855762940,2403,263,8475441,3141,5743,01--41 855763040,3163,263,8460202,9216,7417,3317,9518,61-41 855763140,3203,263,8460242,4220,8921,6122,3823,21-41 855763240,3253,263,846029226,0626,9627,92--41 855763340,3303,263,8475341,7131,2332,3133,46--41 855763440,3403,263,8475441,3241,5643---41

* Ifthereisnovalueintheactualeffectivelength(Lecolumn)fortheworkgradientangleα,itindicatesnointerference.

AE-CPR4-H NEW SIZES

Milling | Solid carbide

First choice in quality and performance

Carbide end mill with DUROREY coating

For hardened material up to 70HRC

4 flutes, unequal spacing. New spiral-shaped gash specification

312 sizes

855763540,5163,263,8460202,9516,7317,3217,9218,58-41 855763640,5203,263,8460242,4420,8821,5922,3623,18-41 855763740,5253,263,8460292,0226,0526,9427,928,9341 855763840,5303,263,8475341,7231,2232,2933,44--41 855763940,5403,263,8475441,3241,5642,99---41 855764040,5503,263,8490541,0851,8953,69---41 855764141163,263,8460203,0216,7117,2817,8718,519,9341 855764241203,263,8460242,520,8621,5622,323,1-41 855764341253,263,8460292,0526,0426,9127,8528,85-41 855764441303,263,8475341,7431,232,2633,39--41 855764541403,263,8475441,3441,5442,95---41 854492260,1124,865,8570-------42 854492360,1184,865,8590-------42 854492560,1244,865,8590-------42 854492660,1304,865,8590-------42 854492760,1484,865,85120-------42 854492960,2124,865,8570-------42 854493060,2184,865,8590-------42 854493160,2244,865,8590-------42 854493260,2304,865,8590-------42 854493360,2484,865,85120-------42 854493460,3124,865,8570-------42 854493560,3184,865,8590-------42 854493660,3244,865,8590-------42 854493760,3304,865,8590-------42 854493860,3484,865,85120-------42 854493960,5124,865,8570-------42 854494060,5184,865,8590-------42 854494160,5244,865,8590-------42 854494260,5304,865,8590-------42 854495160,5484,865,85120-------42 854495261124,865,8570-------42

CUTTING CONDITIONS

AE-CPR4-H

Regular Milling

CUTTING CONDITIONS

AE-CPR4-H

Regular Milling

CUTTING CONDITIONS

AE-CPR4-H

Regular Milling

30,2

CUTTING CONDITIONS

Regular Milling

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

3

4

4

4

4

4

4

6

6

6

6

6

6

6

6

6

6

CUTTING CONDITIONS

AE-CPR4-H

Regular Milling

1. Use a rigid and precise machine and holder.

2. When machining carbon steels or hardened steels, using MQL(Minimum Quantity Lubrication / mist coolant) is recommended.

3. The above condition shows an approximate standard for contouring operation(side milling) with a low machining load.

If abnormal cutting sounds, vibration or chattering occur depending on the machining shape, cutting amount, rigidity of the machine or work holding condition, etc., please adjust the speed, feed and the depth of cut.

4. Adjust the speed, feed rate, and depth of cut if chattering, vibration or abnormal grinding sounds occur.

5. Helical or ramp milling is recommended during the approach of a Z cut.

6. When using a tool with a diameter of θ 0.5 or less, or L/D (aspect ratio) is greater than 10, high loads can cause tool breakage. Therefore, adjust the cutting conditions based on the machining situation.

7. When RPM are insufficient, please reduce the RPM and feed rates at same ratio as listed above.

CUTTING CONDITIONS

AE-CPR4-H

Side Milling (Contour Line Finish Milling)

CUTTING CONDITIONS

AE-CPR4-H

Side Milling (Contour Line Finish Milling)

CUTTING CONDITIONS

AE-CPR4-H

Side Milling (Contour Line Finish Milling)

2

CUTTING CONDITIONS

AE-CPR4-H

Side Milling (Contour Line Finish Milling)

CUTTING CONDITIONS

AE-CPR4-H

Side Milling (Contour Line Finish Milling)

1. Use a rigid and precise machine and holder.

2. When machining carbon steels or hardened steels, using MQL(Minimum Quantity Lubrication / mist coolant) is recommended.

3. The above condition shows an approximate standard for contouring operation(side milling) with a low machining load. If abnormal cutting sounds, vibration or chattering occur depending on the machining shape, cutting amount, rigidity of the machine or work holding condition, etc., please adjust the speed, feed and the depth of cut.

4. Adjust the speed, feed rate, and depth of cut if chattering, vibration or abnormal grinding sounds occur.

5. Helical or ramp milling is recommended during the approach of a Z cut.

6. When using a tool with a diameter of θ 0.5 or less, or L/D (aspect ratio) is greater than 10, high loads can cause tool breakage. Therefore, adjust the cutting conditions based on the machining situation.

7. Adjust the speed, feed rate, and the depth of the cut according to the shape of the work, rigidity of the machine, and how the work is held.

8. When RPM are insufficient, please reduce the RPM and feed rates at same ratio as listed above.

KEY FEATURES & BENEFITS

AE-CPR2-H

2-flute high-precision finishing long neck carbide radius end mill for high-hardness steel

2-flute specification

Low resistance suppresses tool deflection and enables high-quality machined surface

Three-dimensional negative geometry

Achieves both sharpness and cutting edge rigidity

Flat cutting edge specification

Achieves higher precision machined surface quality

Flat cutting edge

*Excluding some sizes

Abundant variations

201 items (0,2 x R0,02 × 0,5 ~ Ø3 x R0,5 × 35) are available to accommodate a wide range of applications

KEY FEATURES & BENEFITS

High-quality finishing

Achieves excellent durability and machined surface accuracy in profiling of high-hardness steel

Tool

AE-CPR2-H Ø1 x R0,1 x 6

Work Material STAVAX (53HRC)

Milling method Contour milling

Cutting Speed

57m/min (18.000 min-1)

Feed Rate 840mm/min (0,02 mm/t)

Depth of Cut ap = 0,01mm ae = 0,21mm

Coolant MQL

Machine Vertical Machining Center (HSK-E32)

Surface roughness of flat surface

Processed shape

Wear condition of the cutting edge after finishing

Smooth Surface Treatment

Improves surface accuracy by smoothening the coating surface

Superior corner radius precision and shank accuracy

- Corner radius precision -Shank accuracy

Supports h4 tolerance (0/-0,004)

CUTTING DATA

Long tool life

Stable wear progression in NAK80 pocket milling

Tool

AE-CPR2-H Ø0,8 x R0,2 x 4

Work Material NAK80 (40HRC)

Milling method Pocket milling

Cutting Speed

Feed Rate

50m/min (20.000 min-1)

565mm/min (0,014 mm/t)

Depth of Cut ap = 0,01mm ae = 0,2mm

Coolant Air-blow

Machine Vertical Machining Center (HSK-E32)

High Precision Milling

Achieves excellent surface roughness with 2-flute specification

Tool

AE-CPR2-H Ø0,8 x R0,2 x 4

Work Material NAK80 (40HRC)

Milling method Pocket milling

Cutting Speed 50m/min (20.000 min-1)

Feed Rate 565mm/min (0,014 mm/t)

Depth of Cut ap = 0,01mm ae = 0,2mm

Coolant Air-blow

Milling Length 1st pocket: 19,1m 11th pocket: 210,1m

Machine Vertical Machining Center (HSK-E32)

Bottom surface roughness after milling 1 pocket

Milling | Solid carbide

First choice in quality and performance

Carbide end mill with DUROREY coating

For hardened material up to 70 HRC

2 flutes, long neck, corner radius

201 sizes

85452450,20,020,50,1540,18457,713,880,530,570,610,650,732 85452460,20,0210,1540,18458,213,071,061,131,21,261,382 85452470,20,021,50,1540,18458,712,341,61,691,771,8522 85452480,20,0220,1540,18459,211,692,122,242,332,432,622 85452490,20,050,50,1540,18457,713,930,530,560,60,640,722 85452500,20,0510,1540,18458,213,111,061,131,191,251,372 85452510,20,051,50,1540,18458,712,371,591,681,771,841,992 85452520,20,0520,1540,18459,211,722,122,232,332,422,612 85452530,30,0210,2540,2845813,021,061,131,21,261,382 85452540,30,021,50,2540,28458,512,281,61,691,771,8522 85452550,30,0220,2540,2845911,622,122,242,332,432,622 85452560,30,022,50,2540,28459,511,022,652,782,8933,242 85452570,30,0230,2540,28451010,483,183,323,453,583,872 85452580,30,0510,2540,2845813,061,061,131,191,251,372 85452590,30,051,50,2540,28458,512,321,591,681,771,841,992 85452600,30,0520,2540,2845911,652,122,232,332,422,612 85452610,30,052,50,2540,28459,511,052,652,782,8933,242 85452620,30,0530,2540,28451010,513,183,323,443,573,862 85452630,40,0210,340,37458,212,411,081,171,281,381,622 85452640,40,021,50,340,37458,711,711,621,761,892,032,322 85452650,40,0220,340,37459,211,092,162,332,52,6732 85452660,40,022,50,340,37459,710,532,72,93,13,293,662 85452670,40,0230,340,374510,210,033,243,473,693,94,312 85452680,40,0240,340,374511,29,154,314,594,855,15,572 85452690,40,0510,340,37458,212,451,081,171,271,371,62 85452700,40,051,50,340,37458,711,751,621,751,892,032,312 85452710,40,0520,340,37459,211,122,162,332,492,662,992 85452720,40,0530,340,374510,210,053,243,463,683,894,32 85452730,40,0540,340,374511,29,174,314,594,855,15,562 85452740,40,110,340,37458,212,511,071,161,261,361,582 85452750,40,120,340,37459,211,182,162,322,482,652,982 85452760,40,130,340,374510,210,13,233,463,673,884,292 85452770,40,140,340,374511,29,214,34,584,845,095,552 85452780,50,0210,440,4645812,391,081,171,261,371,592 85452790,50,0220,440,4645911,042,162,322,482,642,972 85452800,50,0230,440,4645109,963,233,453,673,874,272 85452810,50,0240,440,4645119,074,34,574,835,075,532 85452820,50,0250,440,4645128,325,365,685,986,256,772 85452830,50,0260,440,4645137,696,426,797,117,418,022 85452840,50,0510,440,4645812,431,081,161,261,361,582 85452850,50,0520,440,4645911,082,152,312,472,642,962 85452860,50,0530,440,4645109,993,233,453,663,874,272 85452870,50,0540,440,4645119,094,34,574,825,075,522 85452880,50,0550,440,4645128,345,365,685,976,256,772 85452890,50,0560,440,4645137,716,426,797,117,418,012 85452900,50,110,440,4645812,51,071,151,241,341,552

First choice in quality and performance

Carbide end mill with DUROREY coating

For hardened material up to 70 HRC

2 flutes, long neck, corner radius

201 sizes

85452910,50,120,440,4645911,132,152,312,462,622,952 85452920,50,130,440,46451010,033,223,443,653,864,252 85452930,50,140,440,4645119,134,294,564,825,065,512 85452940,50,150,440,4645128,375,365,685,976,246,762 85452950,50,160,440,4645137,736,426,787,17,482 85452960,60,0520,4840,55458,811,022,152,32,462,622,932 85452970,60,0540,4840,554510,89,014,284,554,85,045,492 85452980,60,0560,4840,554512,87,616,416,767,087,387,982 85452990,60,110,4840,55457,812,481,071,151,231,331,532 85453000,60,120,4840,55458,811,082,142,292,452,62,922 85453010,60,140,4840,554510,89,054,284,554,795,035,482 85453020,60,160,4840,554512,87,646,416,767,087,377,972 85453030,80,0520,6540,75458,410,842,152,32,462,622,932 85453040,80,0540,6540,754510,48,794,284,554,85,045,492 85453050,80,0560,6540,754512,47,386,416,767,087,387,982 85453060,80,120,6540,75458,410,92,142,292,452,62,922 85453070,80,140,6540,754510,48,834,284,554,795,035,482 85453080,80,160,6540,754512,47,416,416,767,087,377,972 85453090,80,220,6540,75458,411,022,142,282,432,582,882 85453100,80,240,6540,754510,48,94,284,534,785,015,462 85453110,80,260,6540,754512,47,476,46,757,067,367,942 85453120,80,280,6540,754514,46,438,528,949,319,6610,432 854531310,0520,840,9445810,682,142,292,442,62,912 854531410,0530,840,944599,513,213,423,623,824,212 854531510,0540,840,9445108,574,284,544,785,025,462 854531610,0560,840,9445127,166,46,757,067,357,952 854531710,0580,840,9445146,148,518,939,39,6510,432 854531810,05100,840,9445165,3810,6111,111,5211,9512,922 854531910,05120,840,9445184,7812,7113,2613,7414,2515,412 854532010,120,840,9445810,742,142,282,432,582,892 854532110,130,840,944599,563,213,413,613,814,192 854532210,140,840,9445108,614,274,534,775,015,452 854532310,160,840,9445127,186,396,747,057,347,932 854532410,180,840,9445146,168,518,939,39,6510,422 854532510,1100,840,9445165,3910,6111,111,5211,9512,912 854532610,1120,840,9445184,7912,7113,2513,7314,2515,392 854532710,220,840,9445810,862,132,272,412,562,862 854532810,230,840,944599,663,23,43,63,794,172 854532910,240,840,9445108,694,274,524,764,995,422 854533010,260,840,9445127,246,396,737,047,337,912 854533110,280,840,9445146,28,58,929,299,6310,42 854533210,2100,840,9445165,4210,6111,0911,5111,9312,882 854533310,2120,840,9445184,8212,713,2413,7214,2315,372 854533410,2160,840,9455223,9416,8917,5318,1618,8320,342 854533510,2200,840,9455263,3321,0521,8122,5923,4325,322 854533610,320,840,9445810,982,122,262,392,542,832

First choice in quality and performance

Carbide end mill with DUROREY coating

For hardened material up to 70 HRC

2 flutes, long neck, corner radius

201 sizes

854533710,330,840,944599,753,193,393,583,774,142 854533810,340,840,9445108,774,264,514,744,975,42 854533910,360,840,9445127,36,386,727,037,317,892 854534010,380,840,9445146,248,58,919,279,6210,372 854534110,3100,840,9445165,4610,611,0811,511,9212,862 854534210,3120,840,9445184,8412,713,2413,7114,2215,352 85453431,20,26141,144511,66,986,396,737,047,337,912 85453441,20,28141,144513,65,958,58,929,299,6310,42 85453451,20,210141,144515,65,1910,6111,0911,5111,9312,882 85453461,20,36141,144511,67,046,386,727,037,317,892 85453471,20,38141,144513,65,998,58,919,279,6210,372 85453481,20,310141,144515,65,2210,611,0811,511,9212,862 85453491,50,0531,241,434588,883,23,413,63,84,182 85453501,50,0541,241,434597,914,274,524,764,995,432 85453511,50,0561,241,4345116,496,396,737,047,337,922 85453521,50,0581,241,4345135,58,58,919,289,6310,42 85453531,50,05101,241,4345154,7710,611,0811,511,9312,892 85453541,50,05121,241,4345174,2112,713,2313,7114,2315,382 85453551,50,131,241,434588,933,23,43,63,794,162 85453561,50,141,241,434597,954,264,524,754,985,422 85453571,50,161,241,4345116,526,386,727,037,327,912 85453581,50,181,241,4345135,528,498,919,279,6210,392 85453591,50,1101,241,4345154,7810,611,0711,4911,9212,882 85453601,50,1121,241,4345174,2212,6913,2313,7114,2215,362 85453611,50,231,241,434589,043,193,393,583,774,142 85453621,50,241,241,434598,034,264,54,744,975,42 85453631,50,261,241,4345116,576,386,717,027,37,882 85453641,50,281,241,4345135,568,498,99,269,610,372 85453651,50,2101,241,4345154,8110,5911,0711,4811,912,852 85453661,50,2121,241,4345174,2512,6913,2213,714,215,342 85453671,50,2161,241,4350213,4416,8717,5118,1318,820,312 85453681,50,331,241,434589,143,193,383,563,754,112 85453691,50,341,241,434598,124,254,494,724,955,372 85453701,50,361,241,4345116,636,376,77,017,297,862 85453711,50,381,241,4345135,68,488,899,259,5910,342 85453721,50,3101,241,4345154,8510,5911,0611,4711,8912,832 85453731,50,3121,241,4345174,2712,6813,2113,6914,1915,322 85453741,50,3161,241,4350213,4516,8617,518,1218,7920,292 85453751,50,531,241,434589,363,173,353,533,714,062 85453761,50,541,241,434598,294,244,474,694,915,322 85453771,50,561,241,4345116,746,366,686,987,267,812 85453781,50,581,241,4345135,688,478,879,239,5610,32 85453791,50,5101,241,4345154,9110,5811,0411,4511,8612,782 85453801,50,5121,241,4345174,3212,6713,213,6714,1615,272 85453811,50,5161,241,4350213,4816,8517,4818,118,7620,242 854538220,0541,641,92508,17,094,264,514,744,975,42

AE-CPR2-H NEW

Milling | Solid carbide

First choice in quality and performance

Carbide end mill with DUROREY coating

For hardened material up to 70 HRC

2 flutes, long neck, corner radius

201 sizes

854538320,0561,641,925010,15,696,386,717,027,37,892 854538420,0581,641,925012,14,758,488,899,259,610,382 854538520,05101,641,925014,14,0810,5811,0611,4711,912,862 854538620,05121,641,925016,13,5712,6813,2113,6914,215,352 854538720,05161,641,925020,12,8616,8617,4918,1218,8-2 854538820,05201,641,926024,12,3921,0221,7722,5623,4-2 854538920,141,641,92508,17,134,264,54,744,965,392 854539020,161,641,925010,15,726,376,717,017,297,882 854539120,181,641,925012,14,778,488,899,259,5910,372 854539220,1101,641,925014,14,0910,5811,0511,4711,8912,852 854539320,1121,641,925016,13,5812,6813,2113,6814,1915,342 854539420,1161,641,925020,12,8716,8517,4918,1218,79-2 854539520,1201,641,926024,12,3921,0221,7722,5523,39-2 854539620,1251,641,926029,11,9826,227,1228,09--2 854539720,241,641,92508,17,214,254,494,724,945,372 854539820,261,641,925010,15,776,376,777,287,862 854539920,281,641,925012,14,818,488,889,249,5810,342 854540020,2101,641,925014,14,1210,5811,0511,4611,8812,832 854540120,2121,641,925016,13,612,6713,213,6714,1815,312 854540220,2161,641,925020,12,8816,8517,4818,1118,78-2 854540320,2201,641,926024,12,421,0121,7622,5423,38-2 854540420,2251,641,926029,11,9926,227,1128,08--2 854540520,341,641,92508,17,34,244,484,714,935,352 854540620,361,641,925010,15,836,366,696,987,267,832 854540720,381,641,925012,14,858,478,879,239,5610,322 854540820,3101,641,925014,14,1510,5711,0411,4511,8612,82 854540920,3121,641,925016,13,6312,6713,1913,6614,1615,292 854541020,3161,641,925020,12,916,8517,4818,118,76-2 854541120,3201,641,926024,12,4121,0121,7522,5323,36-2 854541220,3251,641,926029,11,9926,227,128,07--2 854541320,541,641,92508,17,484,234,464,684,895,32 854541420,561,641,925010,15,946,356,676,967,237,782 854541520,581,641,925012,14,938,468,859,29,5410,272 854541620,5101,641,925014,14,2110,5611,0211,4211,8312,762 854541720,5121,641,925016,13,6712,6613,1813,6414,1315,242 854541820,5161,641,925020,12,9216,8417,4618,0718,73-2 854541920,5201,641,926024,12,432121,7422,5123,33-2 854542020,5251,641,926029,12,0126,1927,0928,0529,08-2 85454212,50,210242,45513,13,3310,5511,0111,4111,8312,782 85454222,50,220242,45523,11,8820,9821,7222,5--2 85454232,50,230242,47033,11,3131,3332,42--2 85454242,50,510242,45513,13,410,5410,9811,3811,7912,712 85454252,50,520242,45523,11,920,9721,722,46--2 85454262,50,530242,47033,11,3231,3232,39---2 854542730,282,562,855513,86,288,418,779,119,4410,192 854542830,2122,562,855517,84,8612,5913,0713,5414,0415,162

Milling | Solid carbide

First choice in quality and performance

Carbide end mill with DUROREY coating

For hardened material up to 70 HRC

2 flutes, long neck, corner radius

201 sizes

854542930,2162,562,855521,83,9716,7517,3517,9718,6420,142 854543030,2202,562,855525,83,3520,921,6322,423,2425,112 854543130,2252,562,857030,82,8126,0826,9827,9528,99-2 854543230,2302,562,857035,82,4131,2532,3333,4934,74-2 854543330,2352,562,857040,82,1236,4137,6839,0340,49-2 854543430,3122,562,855517,84,8912,5813,0713,5314,0215,142 854543530,3162,562,855521,83,9916,7517,3417,9618,6220,112 854543630,3202,562,855525,83,3720,921,6222,3923,2225,082 854543730,3252,562,857030,82,8226,0726,9727,9428,97-2 854543830,3302,562,857035,82,4231,2432,3233,4834,72-2 854543930,3352,562,857040,82,1236,4137,6739,0240,47-2 854544030,5122,562,855517,84,9412,5713,0513,5113,9915,092 854544130,5162,562,855521,84,0216,7417,3317,9418,5920,062 854544230,5202,562,855525,83,3920,8921,6122,3723,1925,042 854544330,5252,562,857030,82,8326,0726,9627,9128,94-2 854544430,5302,562,857035,82,4331,2432,3133,4634,69-2 854544530,5352,562,857040,82,1336,437,663940,44-2

CUTTING CONDITIONS

AE-CPR2-H

Regular Milling

CUTTING CONDITIONS

AE-CPR2-H

Regular Milling

CUTTING CONDITIONS

AE-CPR2-H

Regular Milling

1. Use a rigid and precise machine and holder.

2. When machining carbon steels or hardened steels, using MQL(Minimum Quantity Lubrication / mist coolant) is recommended.

3. The above condition shows an approximate standard for contouring operation(side milling) with a low machining load.

If abnormal cutting sounds, vibration or chattering occur depending on the machining shape, cutting amount, rigidity of the machine or work holding condition, etc., please adjust the speed, feed and the depth of cut.

4. Adjust the speed, feed rate, and depth of cut if chattering, vibration or abnormal grinding sounds occur.

5. Helical or ramp milling is recommended during the approach of a Z cut.

6. When using a tool with a diameter of θ 0.5 or less, or L/D (aspect ratio) is greater than 10, high loads can cause tool breakage. Therefore, adjust the cutting conditions based on the machining situation.

7. When RPM are insufficient, please reduce the RPM and feed rates at same ratio as listed above.

CUTTING CONDITIONS

AE-CPR2-H

Side Milling (Contour Line Finish Milling)

CUTTING CONDITIONS

AE-CPR2-H

Side Milling (Contour Line Finish Milling)

CUTTING CONDITIONS

AE-CPR2-H

Side Milling (Contour Line Finish Milling)

1. Use a rigid and precise machine and holder.

2. When machining carbon steels or hardened steels, using MQL(Minimum Quantity Lubrication / mist coolant) is recommended.

3. The above condition shows an approximate standard for contouring operation(side milling) with a low machining load. If abnormal cutting sounds, vibration or chattering occur depending on the machining shape, cutting amount, rigidity of the machine or work holding condition, etc., please adjust the speed, feed and the depth of cut.

4. Adjust the speed, feed rate, and depth of cut if chattering, vibration or abnormal grinding sounds occur.

5. Helical or ramp milling is recommended during the approach of a Z cut.

6. When using a tool with a diameter of θ 0.5 or less, or L/D (aspect ratio) is greater than 10, high loads can cause tool breakage. Therefore, adjust the cutting conditions based on the machining situation.

7. Adjust the speed, feed rate, and the depth of the cut according to the shape of the work, rigidity of the machine, and how the work is held.

8. When RPM are insufficient, please reduce the RPM and feed rates at same ratio as listed above.

KEY FEATURES & BENEFITS

AE-LNBD-H

2 flutes high-precision finishing long neck Carbide ball end mill for high-hardness steel

Thickness at the center

Thickening of the center core to prevent deformation of the ball tip and improve control of chipping. Improves surface accuracy by smoothening the coating surface (R0,3 or above).

Smooth Surface Treatment

Superior ball R precision

Secures stable R accuracy across 180°

Teardrop-shaped outer periphery

Strong back taper geometry enables milling by point, which prevents chattering and chipping, resulting in improvement of surface accuracy.

Superior shank accuracy

Supports h4 tolerance (0/-0.004).

Abundant variations

261 items (R0.05 to R3) are available to accommodate a wide range of applications.

AE-LNBD-H

Milling | Solid carbide

First choice in quality and performance

For high hardness materials

2 flutes, long neck type for high precision finishing

305610020,10,050,2450,087,540,09514,69°0,210,220,220,230,241 305610120,10,050,3450,087,640,09514,52°0,30,310,320,330,361 305610220,10,050,5450,087,840,09514,16°0,510,530,540,560,61 305610320,20,10,3450,167,440,1914,55°0,320,330,340,350,371 305610420,20,10,5450,167,640,1914,18°0,530,540,560,580,621 305610520,20,10,75450,167,940,1913,74°0,790,810,840,860,931 305610620,20,11450,168,140,1913,33°1,041,081,111,151,241 305610720,20,11450,1611,860,1913,86°1,041,081,111,151,241 305610820,20,11,25450,168,440,1912,94°1,31,351,391,441,551 305610920,20,11,5450,168,640,1912,58°1,561,611,671,731,861 305611020,20,11,75450,168,940,1912,23°1,821,881,942,012,171 305611120,20,12450,169,140,1911,9°2,082,152,222,32,481 305611220,20,12,5450,169,640,1911,29°2,62,682,782,883,11 305611320,20,13450,1610,140,1910,74°3,113,223,333,453,721 305611420,30,150,5450,247,440,2914,24°0,530,540,550,570,61 305611520,30,150,6450,247,540,2914,06°0,630,650,660,680,731 305611620,30,150,75450,247,740,2913,79°0,780,810,830,860,921 305611720,30,151450,247,940,2913,36°1,041,071,111,141,231 305611820,30,151,25450,248,240,2912,96°1,31,341,391,431,541 305611920,30,151,5450,248,440,2912,59°1,561,611,661,721,851 305612020,30,151,5450,2412,260,2913,34°1,561,611,661,721,851 305612120,30,151,75450,248,740,2912,23°1,821,881,942,012,161 305612220,30,152450,248,940,2911,89°2,082,142,222,292,471 305612320,30,152,25450,249,240,2911,57°2,342,412,492,582,781 305612420,30,152,5450,249,440,2911,27°2,592,682,772,873,091 305612520,30,153450,249,940,2910,71°3,113,213,323,443,711 305612620,30,153,5450,2410,440,2910,2°3,633,753,884,024,331 305612720,30,154450,2410,940,299,74°4,144,284,434,594,961 305612820,30,154,5450,2411,440,299,31°4,664,824,995,175,581 305612920,30,155450,2411,940,298,93°5,185,355,545,746,21 305613020,40,20,5450,307,340,3814,27°0,540,560,570,580,621 305613120,40,20,75450,307,540,3813,8°0,80,820,850,870,931 305613220,40,20,8450,307,640,3813,71°0,850,880,90,930,991 305613320,40,21450,307,840,3813,37°1,061,091,121,161,241 305613420,40,21450,3011,560,3813,91°1,061,091,121,161,241 305613520,40,21,5450,308,340,3812,57°1,581,631,681,731,861 305613620,40,22450,308,840,3811,86°2,092,162,232,312,481 305613720,40,22450,3012,560,3812,82°2,092,162,232,312,481 305613820,40,22,5450,309,340,3811,22°2,612,72,792,883,11 305613920,40,23450,309,840,3810,65°3,133,233,343,463,721 305614020,40,23,5450,3010,340,3810,14°3,643,763,894,034,351 305614120,40,24450,3010,840,389,67°4,164,34,454,614,971 305614220,40,24,5450,3011,340,389,24°4,684,8355,185,591 305614320,40,25450,3011,840,388,85°5,25,375,565,766,211

* If there is no value in the actual effective length (Le column) for the work gradient angle α, it indicates no interference.

AE-LNBD-H

Milling | Solid carbide

First choice in quality and performance

For high hardness materials

2 flutes, long neck type for high precision finishing

305614420,40,25,5450,3012,340,388,49°5,715,96,116,336,831 305614520,40,26450,3012,840,388,15°6,236,446,666,917,451 305614620,50,250,75450,407,340,4813,85°0,80,820,840,860,911 305614720,50,251450,407,640,4813,4°1,061,091,121,151,231 305614820,50,251,5450,408,140,4812,58°1,581,621,671,731,851 305614920,50,252450,408,640,4811,85°2,092,162,232,32,471 305615020,50,252,5450,409,140,4811,2°2,612,692,782,883,091 305615120,50,253450,409,640,4810,62°3,133,233,333,453,711 305615220,50,253,5450,4010,140,4810,09°3,643,763,894,034,331 305615320,50,254450,4010,640,489,61°4,164,34,444,64,951 305615420,50,254,5450,4011,140,489,18°4,684,8355,185,581 305615520,50,255450,4011,640,488,78°5,195,375,555,756,21 305615620,50,255,5450,4012,140,488,41°5,715,96,116,336,821 305615720,50,256450,4012,640,488,08°6,236,446,666,97,441 305615820,50,257450,4013,640,487,48°7,267,517,778,058,681 305615920,50,258450,4014,640,486,97°8,298,588,889,29,931 305616020,50,259450,4015,640,486,52°9,339,649,9810,3511,171 305616120,50,2510450,4016,640,486,12°10,3610,7111,0911,512,411 305616220,60,30,75450,507,240,5513,8°0,860,880,90,920,971 305616320,60,31450,507,440,5513,34°1,121,141,171,211,281 305616420,60,31,2450,507,640,5512,99°1,321,361,41,441,531 305616520,60,31,5450,507,940,5512,5°1,631,681,731,781,91 305616620,60,32450,508,440,5511,76°2,152,212,282,362,531 305616720,60,32450,5012,260,5512,78°2,152,212,282,362,531 305616820,60,32,5450,508,940,5511,1°2,672,752,842,933,151 305616920,60,33450,509,440,5510,51°3,183,283,393,513,771 305617020,60,33450,5013,260,5511,83°3,183,283,393,513,771 305617120,60,33,5450,509,940,559,98°3,73,823,954,084,391 305617220,60,34450,5010,440,559,5°4,224,354,54,665,011 305617320,60,34450,5014,260,5511°4,224,354,54,665,011 305617420,60,34,5450,5010,940,559,06°4,734,895,055,235,631 305617520,60,35450,5011,440,558,67°5,255,425,615,816,261 305617620,60,35,5450,5011,940,558,3°5,775,966,166,386,881 305617720,60,36450,5012,440,557,96°6,286,496,726,967,51 305617820,60,36,5450,5012,940,557,65°6,87,037,277,538,121 305617920,60,37450,5013,440,557,37°7,327,567,828,118,741 305618020,60,37,5450,5013,940,557,1°7,838,18,388,689,361 305618120,60,38450,5014,440,556,85°8,358,638,939,269,991 305618220,60,38,5450,5014,940,556,62°8,879,179,499,8310,611 305618320,60,39450,5015,440,556,41°9,389,710,0410,4111,231 305618420,60,39,5450,5015,940,556,2°9,910,2410,610,9811,851 305618520,60,310450,5016,440,556,01°10,4210,7711,1511,5612,471 305618620,60,311500,5017,440,555,67°11,4511,8412,2612,7113,711 305618720,60,312500,5018,440,555,36°12,4912,9113,3713,8614,961

AE-LNBD-H

Milling | Solid carbide

First choice in quality and performance

For high hardness materials

2 flutes, long neck type for high precision finishing