4 minute read

OSB*w

Rank Company

(including number of OSB plants)

Louisiana-Paci{ic Corp., Nashvile, Tn.

14 plants: Hanceville, Al.; Dawson Creek, B.C.; Woodland, Me.; Athens, Ga.; Houlton, Me.; Sagola, Mi.;Two Harbors, Mn; Hayard, Wi.; Swan Valley, Manitoba; Roxboro, N.C.; Jasper, Carthage, Tx.; Maniwaki, St.-Michel, Chambord, Quebec

J- Weyerhaeuser Co., Federat way, wa.

9 plants: Arcadia, La.;Grayling, Mi; Elkin, S.C.; Sutton, W.V.; Drayton Valley, Edson, Alberta; Wawa, Ontario; Miramichi, Hudson Bay, Saskatchewan

I Norbord Industries, toronto, ontario r I plants: Hughley, Al.;Cordele, Ga.; Bemidii, Mn.; Gunlown, Ms.;Joanna, S.C.; Jetferson, Nacogdoches, Tx.; La Sane, Quebec

EII

Georgia-Pacific Corp., ntranta, ca.

6 plants: Fordyce, Ar.; Grenada, Ms.; Dudley, N.C.; Brookneal, Skippers, Va.; Mt. Hope, W.V.

IiI

Grant Forest Products, Engteharr, ontario

3 plants: Englehart, Timmins, High Level (50% JV with Ainswonh) l5I Tolko Industries, Hish Prairie, Atberta r 3 olants: High Prairie; Slave Lake, Alberta; Meadow Lake, Saskatchewan

Huber Engineered Woods, ctrartone, N.c.

4 plants: Commerce, Ga.; Spring City, Tn.; Easton, Me.; Crystal Hill, Va.; (sth plant opens in 2004 in Broken Bow, Ok.)

Iil r 3 olants: 100 Mile House; Grand Prairie, Alberta; High Level, Alberta (50% JV with cranr)

Ainsworth Lumber, 100 Mite House, B.c.

Potlatch Corp., spotane, wa.

3 plants: Cook, Bemidji, Grand Rapids, Mn.

Slocan Forest Products, Richmond, B.c.

'I plant: Fort Nelson (Bought in 2004 by Canfo0 l-P[4t Banrick (Bought in 2004 by Ainsworth)

Boise, goisie, td.

Martco Partnership, Le Moyne, La.

'1 olant: Le Moyne

Tembec, ll|c,, Temiscaming, Quebec

1 plant: St.-Georges-de-Champlain, Quebec

Langboard, Inc,, euirman, Ga.

1 olant: Quitman

2003 2003 2002 2002-03

with better durability, thickness tolerances and longer warranties against material imperfections such as delamination and edge swell.

These high performance subfloor sheathing or single floor OSB panels are now in direct competition with similar plywood panels, and are becoming more readily accepted by most builders and designers.

Treated OSB

Several products are now on the market for areas that are prone to insect infestations such as termites. Panels are treated with borates or coDper-based preservatives that are highiy efficient as insecticides, while at the same time imparting a higher moisture tolerance than untreated commodity OSB panels. Improved mold- and fire-resistance are added benefits.

Thermally

Reflective Overlaid OSB

A number of companies have developed a decking product in which foil is overlaid on OSB boards. The result is a radiant barrier sheathing that significantly reduces heat transfer through the roof, reduces attic temperatures, prolongs the life of heating and air conditioning systems, helps retain heat during the winter, and cuts energy costs.

Overlaid OSB

1282

Companies, such as Kronopol, have also pioneered innovative flooring systems for basements. There are other various brands but the concept is the same: OSB or waferboard subflooring tiles glued to polyethylene cleats, high density polystyrene or corrugated plastic are placed on the cement basement floor, typically without nails or glue. Airflow is created between the cleats and the floor, deterring mold and allowing for moisture to be channeled away to a central drain. Various types of flooring (laminate, vinyl and engineered hardwood) can be placed over this subfloor system. The result is a warmer. drier. less dusty and more comfortable basement.

Rim Board

Several producers offer these specialty OSB products as part of a package, installed as perimeter beats in IJoist floor systems. They consist of thick OSB, usually 1-l18" or l-114" thick, with higher compressive properties to resist vertical sravitv loads from the walls above.

Stairs

Some OSB manufacturers, such as Ainsworth Lumber and Weyerhaeuser, market engineered stair systems combining OSB treads, risers and stringers, which are marketed as single branded packages that eliminate squeaks and provide solid dimensional stability.

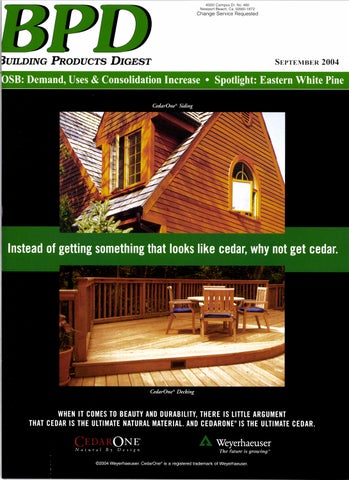

Siding

Another OSB manufacturer's panel siding combines OSB with a paint-based overlay that creates a cedar grain texture. It doesn't look like OSB but a natural wood product. Keys to its weather-, insect- and moisture-resistance are its resin-saturated composition, borate-based treatment, and edge and groove coating. This product signals OSB gaining a larger share of the siding market in which sales last year were dominated by stucco and related non-brick masonry materials, vinyl and wood.

Aside from applications for new residential construction, there is significant potential for OSB products to tap the remodeling and industrial markets, respectively the largest markets for OSB following residential construction. OSB already is being used for packaging and crating, chair seats and backs, decks and platforms, furniture frames, trailer walls, and shelving and display racks. The aim for manufacturers is to develop OSB products with greater value benefiting business users and consumers. This has begun in some key categories that many previously found difficult for OSB to succeed in.

Concrete Forms

The largest obstacle to OSB penetrating this market was finding a reliable and cost-efficient means to combining OSB with an overlay to avoid imprinting OSB's strand surface on concrete and to developing a board that was resistant to damage over multiple pours. Louisiana-Pacific Corp. has tapped this market with an OSB concrete form that has a higher concentration of resin, creating strength and durability. The board also has a smooth medium density overlay-properties that put it on a par performance level with competing fir concrete forms. This also marks OSB's deeper entry into the concrete form market.

Oriented Strand Lumber

At least one firm, Grant Forest Products, is marketing oriented strand lumber for use in molded upholstered furniture frames. OSB used in furniture applications is generally developed under the same principles as ordinary structural OSB except that longer strands all oriented in one direction are utilized with more resin to create thicker wood members. OSL replaces solid wood for furniture parts including stress rails, arms and backs.

The Future

More breakthroughs are expected in molded OSB for furniture and OSL for lumber framing. "These products are likely to enter the market within the next five years," says Angelini. "The impact will be considerable."

According to Angelini, OSB won't just match or better non-engineered products in these categories as far as price or product performance. He said, "It will also have an environmental advantage over traditional wood products because OSB uses all parts of the tree and is harvested from fast-growth species or plantation thinnings-factors that help promote environment management and efficiency."

OSB Capacity Changes

ARIENTED strand board has \-fmatured from a questionable alternative to plywood in the early 1980s to the most widely used structural sheathing panel in North America. Demand for OSB continues to rise, thanks to a healthy housing market-in which new construction and remodeling jobs consume about 75Vo of the industry's annual production of 4l billion sq. ft. of OSB.

The OSB industry also enjoys environmental benefits because modern panel manufacturing uses more of each tree harvested and relies on fastgrowing, non-traditional timber species instead of those from oldgrowth forests. Unlike other types of building materials, the OSB manufacturing process uses nearly 1007o of a log for the finished product.

Broader Applications

One of the primary reasons that OSB now dominates the structural panel market, from a mere 47o share in 1980 to 57Vo share in 2003, is the broadening range of applications for the material. Another reason is the cost effectiveness of manufacturins