CAN YOUR CAR BE SUSTAINABLE WITHOUT BEING EV?

CHARLES TRENT

CHARLES TRENT PROJECT

DIRECTED BY:

JORDAN BOSWELL ARTICLEWRITTEN BY: LAURA

WATLINGOn 21st September 2023, Prime Minister of the UK Rishi Sunak announced a U-turn on climate commitments, including those around the sale of new petrol and diesel vehicles.

In his address, Sunak stated the government will delay its phase out of the sale of new petrol and diesel vehicles by five years to 2035.

So, what does that mean for those hoping to see more sustainability on Britain’s roads now?

As fate would have it, Business Enquirer had the opportunity to speak with the CEO of one of the UK’s leading experts in vehicle recycling the day after Sunak’s announcement. Fourth generation owner of the family business, Marc Trent, told Business Enquirer that all is not lost.

Established in 1926, originally focussed on scrap metal, Charles Trent are one of UK’s largest and longest established car breakers. Most often, cars are broken down once they reach end-of-life, either due to age or when written off by an insurer.

The business, which currently employs 250 people across two sites, typically collects, stores, processes, and re-sells near to 50,000 vehicles per year. In turn, this allows the business to produce nearly 200,000 parts annually & stock over 80,000 used car parts, ready to give roadworthy vehicles a new lease of life.

CEO of Charles Trent shares how you can drive green without the charging point

Inaugurated in a time where vehicles were far and few between (and initially focussed on scrap metal), Charles Trent has continued to innovate.

“We have broken the mould in how cars are recycled,” explained Marc, “we have developed a reverse production line, which is an efficient process and keeps the integrity of the parts”.

With this method, Charles Trent can break down around 500 cars a week, in comparison to the traditional car recycler which can break just 10% of that.

Now, the business has its sights set on a big target, of 10 X that figure to 5000 cars a week.

Supporting this vision, Charles Trent opened its first-of-a-kind in the UK reverse production facility. The 100,000 square foot facility, which opened in Poole in 2022, enables the business to recover fully tested car parts faster than ever seen before.

Meanwhile, certain parts not suitable for resale can be recovered for remanufacture, including higher-grade scrap commodities such as aluminium & copper wiring harnesses. All of this goes towards the EU’s recycling target of 95% set in 2002, with Charles Trent achieving 96.3% at the last audit.

“The facility was built to be operational 24 hours a day. We are now in the third

Marc Trent, managing director, is the great-grandson of the founder Charles Trent.

Marc Trent, managing director, is the great-grandson of the founder Charles Trent.

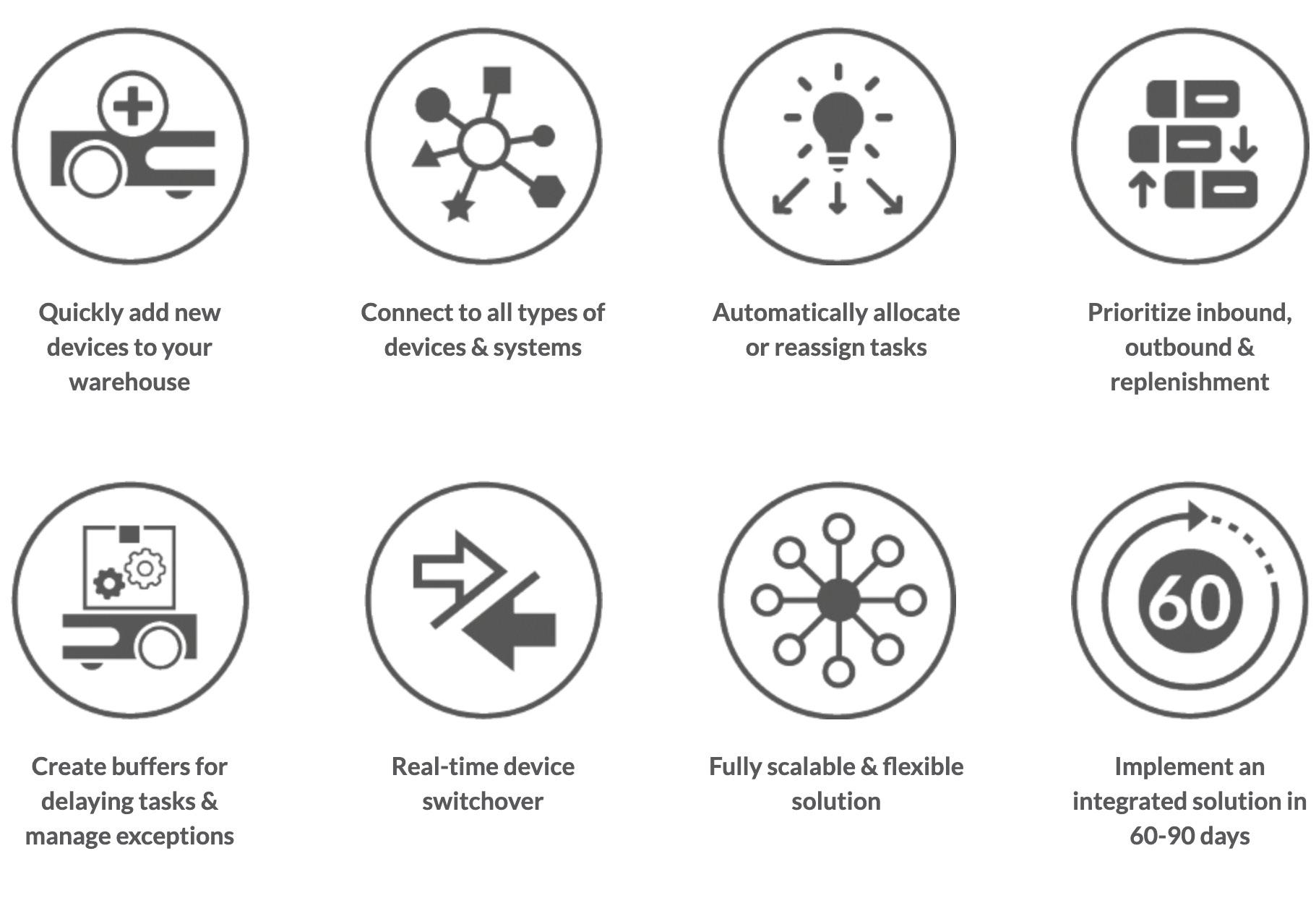

It delivers cutting edge technology at a fraction of the cost of traditional installations and, unlike other warehouse management systems, is quick and easy to implement, giving you a rapid return on investment.

Once up and running SnapFulfil is highly configurable and can adapt to meet evolving fulfilment demands.

As businesses adopt new technologies and automation to mitigate labor challenges and make warehouses more efficient, the ability to rapidly integrate and operate these investments is critical.

SnapControl extends the functionality of the robust and flexible rules engine in the Tier 1 WMS solution SnapFulfil. It is a device agnostic multiagent orchestration platform that provides you with seamless and efficient control of all warehouse devices and robots, with a low total cost of ownership and rapid time to value.

One of the UK’s top three car automotive recycling companies is powering forwards with its ambitious five-year growth plan thanks to timely investment in a digital warehouse management system (WMS).

Since installing SnapFulfil WMS, Charles Trent Ltd, based in Poole, Dorset has doubled its stock holding with over 3,000 ‘green’ parts being processed every week without increasing head count. And with operations much more streamlined, efficient, productive, and profitable, the company is on track to achieve its predicted turnover of £250 million by 2026.

The family-owned business, which was founded in 1926, has continued to thrive thanks to its forward-thinking attitude to technology. Influenced by Amazon, the firm’s high-tech operation is the only one of its kind in the UK where you can source a particular part online and then have it delivered next day.

Having invested £4 million in a 30,000 sq. ft. distribution centre (DC) in nearby Holton Heath at the start of 2021, Charles Trent realised that an architecturally robust, highly flexible, and easily configurable WMS needed to be part of their new digital infrastructure. The award-winning SnapFulfil cloud suite was selected because of its reputation for delivering strong value through rapid ROI, industry-leading deployment speed and low total cost of ownership (TCO).

Charles Trent’s Distribution & Operations Manager, Matt Groves, said: “Our labourintensive paper picking process wasn’t geared up for quick expansion and was open to human error, with returns on wrong products and parts going missing a particular problem, with no validation of picking. Drives highly accurate storage “Almost

immediately, SnapFulfil was able to drive highly accurate storage, putaway, picking and packing via the RF scanners and massively improve visibility for all parties across some unique and diverse product ranges.”

Subsequently, the storage and distribution transition from the old Poole HQ warehouse (18,000 sq. ft. over three levels) and processes to the digitally-driven Holten Heath DC - which is 14 levels high and has a top picking height of 13 metres and state-of-the-art rackingwas seamless. There’s also perfect platform alignment with the company’s in house Pinnacle system (specifically for car parts and salvage).

Furthermore, the implementation was largely managed remotely, driving down costs and time to go live. SnapFulfil excels in creative, digital onboarding, while producing the same positive results in adoption and use as traditional on-site engagement, but with associated economies of scale.

The more recent Poole distribution centre, which opened in August 2022, followed this successful model – but with more warehousing space of 45,000 sq. ft. – and with fulfilment, production and quality control all under one roof, it’s an even more impressive facility totalling 100,000 sq. ft.

Plans are now in place for Holton Heath and Poole to increase operations from 18 hours daily across two shifts to 24/5, which will massively increase the company’s order processing capacity, demonstrating the flexibility and efficiency gains of SnapFulfil.

Groves added: “We used to have about 2-3 orders per day going astray within the old system, but we achieve very close to 100 per cent accuracy with SnapFulfil. Full traceability like this is a huge advantage in a variable business such as ours.

“It’s about tempo and efficiency, because in receiving goods staff can scan, process, and have them on the shelf in next-to-no-time – and handle 30 at a time without being label reliant. SnapFulfil is easy to pick up and use for new operatives, with new staff at both DCs quickly up-tospeed and taking advantage of task grouping for optimum picking and sequencing.

“I also like how SnapFulfil - even from a long list of locations - identifies the part by the prefix of the vehicle class, as this means it can be used by our staff in both DCs, simultaneously, and at any point in our operations.

“It’s a smooth and reliable system overall, plus I like the visual aspect and colour coding of the HTML5 ‘tile’ dashboard, which is dynamic, intuitive, engaging and easy to follow, plus really improves the planning and metrics side of the job.”

Charles Trent now acknowledges it has the very latest in WMS technology to help realise plans and is confident its two distribution centres are unique in the UK.

The business is looking to open another four new recycling and distribution centre sites by 2026, in major population centres across the UK – and SnapFulfil’s kitting functionality especially can support rapid scaling of fulfilment processes, as well as quick succession of multiple site facility rollouts, as they have already benefitted from with the bigger Poole DC onboarding.

The SnapFulfil WMS by Synergy Logistics is renowned for being high tech in terms of functionality, but what further sets them apart is a new software solution that orchestrates all automation devices and robotic systems within the warehouse from one convenient platform.

As a multiagent, rather than just a point solution, SnapControl brings a more uniform approach to automation and is also completely device and technology agnostic.

It orchestrates the prioritisation of warehouse inbound, outbound and replenishment workflows, automatically allocates tasks, evaluates which robotic devices and technologies best match specific operations, and enables data capture to assess the value each device yields.

Importantly, the solution allows for buffer creation to delay tasks, exception management, and real-time switchover if devices are damaged or unavailable. All these capabilities help to avoid subsystems for AMR deployments, which otherwise increase cost, complexity, and time constraints.

Most interestingly, it uniquely promotes bi-directional messaging between the WMS and remote warehouse devices, so human decision makers can have a ‘conversation’ with the technology, enabling the most crucial and efficient DC decisions to be made automatically.

In today’s especially challenging times the ability to rapidly augment and orchestrate your technology investments, without unnecessary service fees, has never been more important. It’s now mission critical to harness control with 24/7 visibility from one centralised system.

For further WMS or SnapControl information, visit www.snapfulfil.com, email info@snapfulfil.com, or call 0333 241 2082.

week of trialling a 24/5 operation and it’s showing positive results,” shared Marc, “its supporting demand and allowing us to supply parts around the clock”.

Now, the car breaker plans to expand this blueprint across the country to achieve its ambitious but achievable target.

“Over the next five years we’re planning to add another five of these facilities across the UK in strategic locations. Each will employ around 300 staff, increasing our headcount by over 600%, which will offer a great employment opportunity across the country,” added Marc.

For those looking to replace a part in their car, it's important to be aware of either unregulated or illegal car breakers. Ensuring a safe and satisfied experience, Charles Trent are fully licensed and regulated, and are members of the Vehicle Recycling Association and e2e Total Loss Vehicle Management.

"Charles Trent were one of the first companies in the UK to achieve VRA accreditation. The accreditation is all about the journey of the part from the car to the shelf which includes quality, testing & provenance,” shared Marc.

“With almost 100 years in the industry, we are seen as one of the most trusted vehicle recyclers, and this has been one of the driving factors behind our growth,” he added.

Both the UK and EU fall within the 2002 EU end of life vehicle directive (ELV Directive), which sets clear targets for ELVs and their components. It also sets out minimum standards for operating sites such as impermeable surfaces.

The directive is largely aimed at the operator known as an authorised treatment facility (ATF) and the car manufacturers under producer responsibility. Over 21 years the recycling target for all ATF’s has increased from 75% to 95%. In 2023 the directive has been

“P&D Casemaking Ltd have been fortunate enough to work alongside Charles Trent for close to two decades now, watching and being a part of their growth has been an interesting journey and has led to our projects changing considerably. We began creating cases for high end motor vehicle parts and engines to ship around the globe, moving onto electric vehicle battery storage and transport solutions.This has developed into a super slick warehousing operation with us creating/designing alongside Charles Trent’s large scale warehousing solutions.

We are proud to be a supplier of such a forward thinking and innovative business in the south of England, who are renowned for being a reliable employer and well known entity in our local area.”

Colin Bell, Managing Director, P&D Casemaking Ltd

Colin Bell, Managing Director, P&D Casemaking Ltd

revised significantly & put forward for consultation.

Marc said, if implemented, this will place more responsibility onto the car manufacturers as it clearly mentions the circular economy and the circularity of parts & materials that arise from ELV.

“This can only work viably through the facilities & processes we have developed,” he said.

Other factors are at play in Charles Trent’s growth too, with Marc witnessing a cost increase of new spare parts at around 10% in the last year. Alongside this, consumers are keeping their cars for longer due to a slower supply chain of new vehicles, therefore needing to extend the life of their existing vehicle.

“We’ve been working with Charles Trent for two years and their commitment to best practice when it comes to waste tyre recycling is second to none. Shared knowledge in this field has helped our relationship develop industry leading handling and processing.”

Henry Hodge, Managing Director, Black-Ram Recycling Ltd

Henry Hodge, Managing Director, Black-Ram Recycling Ltd

I am an Independent Tool supplier that has been selling tools to the Local Mechanics, Garages and Businesses for the last 11 years. Having starting out as a Franchisee for a Large Tool Brand, I always sold to Charles Trents. However In 2020 I took the difficult decision to leave the Franchise and set up on my own, and be totally Independent with my own Tool van. I was Grateful for Charles Trents for allowing me to continue to go on site and still sell to them as well as their workforce. In 2021 they then approached me and asked me to quote to supply the tools for their New Recycling Facility, Which I was successful in getting. Huge thanks to Marc, Neil & Jonathan for giving me this opportunity. I feel that even as Big as Charles Trents are, that they do support the Small Local Independent Businesses like myself. And I hope that we long may continue working together.

Luke Johnson Johnson L Ltd“Not only do we provide an easy to access solution with parts available 24/7 online and shipped worldwide, we are more cost effective, and of course sustainable,” Marc explained.

Realising that the business must do more than offer a sustainable product, Charles Trent also runs its facilities entirely from solar power.

“Not only are we more efficient than some of our competitors with our unique lean reverse production line, we are a business offering a green solution from a green operation,” said Marc.

Joining the business in the 1980’s, Marc now owns the business alongside his two brothers Neil and Jonathan.

“We spent our childhood working at the family business, at the weekends and in the school holidays, it was a natural progression for us to follow in our father, grandfather and great-grandfather’s footsteps,” shared Marc, “Not only are we family, but our colleagues are family too - a big family”.

But what about the next generation? With six children beneath the three brothers, two are set to follow in their footsteps and join the family business.

“It’s never been forced upon any of the family to take on roles, but there are some fantastic opportunities at Charles Trent, for any of our staff,” said Marc, highlighting that the newest facility in Poole sees the employment of qualified line operators and mechanics.

Ultimately, as long as there are vehicles being manufactured, there are many more years left for the historic car breakers. And, whilst the bulk of the vehicles it sees down its line are petrol, diesel and hybrid, Charles Trent is fully equipped to recycle EVs, too - even if it is some time until they dominate our roads.

www.trents.co.uk