SUSTAINABILITY DRIVES INNOVATION AND EFFICIENCY AT CHILEAN MINE

The Polish-Australian owned Sierra Gorda mine announced last year that it is now operating with 100% renewable energy.

DIRECTED BY:

GARY SMITHARTICLE

WRITTEN BY:

LAURA WATLINGThe mine, located in Chile, operates on copper-molybdenum deposits, comprising both sulphide copper ore as well as oxide copper ore. On a daily basis 115,000 tons of ore is processed, producing 108,000 tons of copper annually. Starting production in 2014, the mine has planned life of 20 years.

The latest and most effective technological solutions are implemented in production processes, following the current trends in the mining industry.

One of the mine’s main objectives has been to minimise any potential impact on communities and the environment, and the implementation of its renewable production is part of the company’s sustainability objectives, representing the removal of around 1 million tonnes of CO2 emissions per year

Sierra Gorda operates with the use of seawater from the cooling systems of a power plant in the town of Mejillones. Instead of being recycled to the sea, the water is pumped to the mine through a 144 km pipeline.

The next steps for the mine will be to use100% renewable electrical energy in the operation.

Speaking of the mine’s achievements in implementing renewable energy, General Manager, Tomasz Piwowarczyk stated:

“Our company shows that it is possible to do green and efficient mining with a low grade like ours and develop production in a sustainable way. We are happy to share this great news that comes three years after starting our parcelled supply of green energy, and that today already has us with 100% energy from renewable sources. Thanks to this, the copper and molybdenum that we produce is greener, since it contains a smaller carbon footprint.” 1

Taking on the role of General Manager at Sierra Gorda in October 2023, his appointment signals a further step forward in innovative strategies for the mine.

With an average ore grade of less than 0.4% (compared to an industry average of 0.8%), and an unfavorable ballast-ore ratio. Sierra Gorda is continually incorporating new technologies to improve its management and enabling it to adjust to changing environmental conditions.

“We are constantly searching for technologies that lead us towards a safer, more sustainable and efficient operation,” said Tomasz.

Its use of 100% seawater throughout the production process without desalination results in the surface of the tailings deposit becoming naturally covered by a saline crust.

This “represents a great advantage, since when dry, this material hardens and

there are no fine volatile particles. We carried out a study to project its long-term behaviour and stability and were able to establish that no additional coatings will be required to control potential emissions of unconsolidated material at the end of the project, offering greater control of the deposit,” continued Tomasz.

In addition, the oil used in equipment maintenance is used to manufacture explosives for blasting - the mineral adhered to the grinding balls are recovered through a mechanicalmagnetic separation process, which corresponds to 2.7% of the processed material.

Further to this, the mine also incorporated three PitViper-351 drilling rigs that operate autonomously as well as implementing SierraBot, a unique tool in Latin America in mining, which increases efficiency.

SierraBot is a robotic operator in charge of inventory, which performs a ‘cycle

count’ with the exact location of each material. This has allowed the business to reduce the time allocated to the task of accounting for Stock Codes from 12 hours to 12 minutes. At the same time this reduces the risk of material handling, improving safety performance and obtaining greater productivity in its processes.

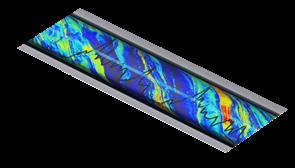

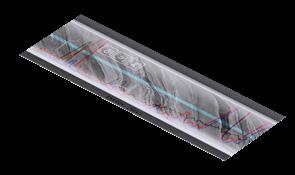

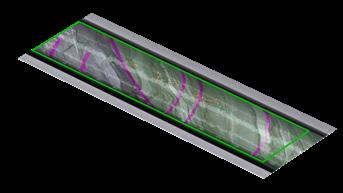

Veracio’s TruScan solution promises to enhance information quality by swiftly delivering a blend of intelligent high-resolution data streams to Sierra Gorda SCM geologists. These streams encompass wet and dry drill core photos, geochemistry via array-calibrated XRF (X-ray fluorescence) obtained through a continuous, automated, high-speed scanning service, with all data processed and analyzed within 24 hours.

Moreover, the solution incorporates AIassisted digital logging utilizing cloud software and processing technologies. Furthermore, it expedites structural

Msteck, a company with a distinguished track record in the supply of materials and services to the mining sector, has established itself as a leader in the provision of essential supplies. Our integrated approach enables us to provide complete solutions in areas such as maintenance, engineering, erection and EPC/EPCM project management. We are not limited to Chile; we have successfully expanded our operations to neighboring mining countries, consolidating our reputation as a reliable and efficient company throughout the region.

As a leader in the production and supply of steel balls, we stand out for our ability to provide quality products that meet the highest industry standards. With an annual production capacity of 200,000 tonnes, we have established our presence as one of the leading suppliers in the industry. Backed by Goldpro New Materials, renowned for its

cutting-edge technology in wear-resistant materials, we ensure the superior quality of our products.

In addition, we have excelled in the supply of fluid transport supplies, such as pipes, valves and fittings of different materials and diameters, ranging from carbon steel to titanium. We also offer 3D scanner survey services, point cloud modeling, drawing generation and engineering development. We also have a workshop where we manufacture metal structures and spools of different materials and diameters. At Msteck, we are committed to maintaining our leadership position through continuous innovation, exceptional quality and first class customer service.

www.msteck.cl

Supplies of Inputs, Components and Spare Parts

Teaching Services

Maintenance, Engineering and construction

Because everything starts in the ore deposit, at Veracio we have set out to unlock the value and utility of scarce resources. Through a powerful fusion of science and technology, we help the mining industry take advantage of its opportunities while mitigating the social and environmental impact of its decisions.

Bigger vision. Smarter data. Smaller footprint.

At Veracio we have made leaps and bounds to unlock hard-to-find minerals that are essential for a sustainable future. As well as liberating precious time thanks to the automation of workflows, spanning from exploration to geoscience production.

And not only that, we have additionally strengthened our workforce to make a difference in the market with cloudconnected systems that keep the world’s brightest minds at its fingertips. And it is through this fusion of science and technology that Veracio is helping miners leverage advanced orebody knowledge to optimize opportunities.

Without a doubt, its rise in the industry is already turning heads, and the numbers echo these remarkable results. With more than 15 years operating, today Veracio already has 8 offices around the world in critical mining hubspots, in addition to more than 4 million scanned cores, more than 250 patents, and more than 140 geoscientists, data-scientists and global operators that create and run a valuable range of products and solutions.

Digital accessibility, by the way, is the hallmark of our technological innovation. Whether it is employing next generation scanning technology, surveying with robust data governance or leveraging AI to accelerate real-time, on-site decision making and significantly improve efficiency, profitability and sustainability worldwide throughout the value chain of mining exploration.

And with a comprehensive ecosystem of products and solutions based on data platforms for better orebody knowledge in deposits, Veracio’s business is uniquely connected to both the lifecycle stage of a miner and the volume of drilling that is carried out. The greater the volume of drilling, the greater the value we can unlock.

By embracing change and progress, as a supplier company we seek to revolutionize geological data collection to promote the efficiency and competitiveness of mining. The bet is ambitious: we believe that the mining sector will no longer be the same because the future is right here... and we are already there. Holding knowledge as the key element for success and empowering each player in the industry with this advantage.

The call is then for those that wish to come with Veracio along this new path that clears the way to opportunities and challenges for prosperity.

WWW.VERACIO.COM

Utilises automated core scanning (TruScan® and Minalyzer™) to collect a vast array of comprehensive, consistent, accurate, and highly granular geological data in a single pass. This is done in an automated, controlled and repeatable manner under the supervision of a single field technician at the drill rig whilst the rig is on the site and passing the full data set onto the geologist in near real time.

This represents a massive step change in efficiency (and cost saving) whilst also providing much more effective result where the comprehensive nature of the attributes can contribute to cross checking and verification resulting in less errors, thus validated data sets. The streamlined process not only speeds the process from hole to data but presents the data already verified with multiple attributes collected on the same basis so that it can be immediately used orebody modelling or in multivariate statistical processing such as machine learning and AI application that are now becoming common practice.

Hofmann Engineering is an Australian company with more than 50 years of experience developing and manufacturing critical components and providing engineering services for various industries, with an important focus on Mining.

Hofmann’s highly dedicated team members constantly seek to improve in order to achieve their goal: to be recognized as world leaders in engineering and innovation by customers. Our skills and combined experience are the basis of our commitments to our clients, being a strategic partner for them, taking their problems as our own and solving them in the best possible way.

transmission repair workshop that has provided excellent service for the Chilean market. Today HECL has a 10-year expansion project that will allow it to offer, in Chile and South America, machined components and critical repairs produced locally.

We are a supplier with focus on HPGR equipment, Crushers, Kiln Ovens, Agglomerators, Mills, Gearboxes and Mobile Mining Equipment.

Work processes and methodologies are part of our business, constantly developing new technologies, products and services. Our workshop in Antofagasta is designed to reinforce Hofmann’s footprint in this region

recording and rock quality designation (RQD), furnishing geologists and engineers with standardized, precise, and timely access to structural data while diminishing manual handling. This advancement ensures greater accessibility and quality of geoscientific data, pivotal for the mine’s long-term value, and the centralization of information for geoscientific personnel.

Veracio expresses confidence in the significant benefits Sierra Gorda SCM will derive, including an overall reduction in environmental impact aligned with broader ESG initiatives. This encompasses an immediate decrease in the carbon footprint associated with transportation and processing of core samples, along with substantial potential for reduced consumption of water and energy through alternative design options, production optimization, and improved ore and waste management.

Furthermore, Veracio reports that their clients have witnessed notable improvements, such as up to 8 hours per day in logging productivity savings, millions in drilling cost reductions, and

over $1 billion in capital cost reduction across projects.

Sierra Gorda recently received environmental approval for its Updating the Tailings Deposit and Annexed Facilities project which modifies the plan of the deposit. The project will see an investment of around $400 million.

The aim of the project is to optimise tailings management by reducing the height of the walls that surround the enclosure to improve its stability, reduce the movement of material, increase the evaporation rate, and minimise filtrations.

Now, Sierra Gorda is preparing a feasibility study to install a fourth grinding line to boost throughput by 18% to 58Mt/y, with completion projected for June 2024.

55% owned by KGHM, and 45% by South32, the latter shareholder aims to increase its investment into Sierra Gorda from US$14 million to US$210 million. It has also indicated that by the end of this year the mine will reach a processing capacity of 130,000t/d.

www.sgscm.cl/es

www.sgscm.cl/es

info@busenq.com

www.busenq.com

The editor and publishers do not guarantee the accuracy of statements made by contributers or advertisers, or accept responsibilty for any statement they express in this publication. The opinion of the contributors may not necessarily be the opinion of the editor or publishers. All content including the presentation therof in this magazine is the property of BE Media and protected by internation al copyright laws. You may not copy, reproduce, distribute, transmit, modify, create derivitave works, or in any other way exploit any part of copyrighted material without prior written permission from BE Media ©BE Media