Project

Project

by:

Malvern Kandemwa Wordsby:

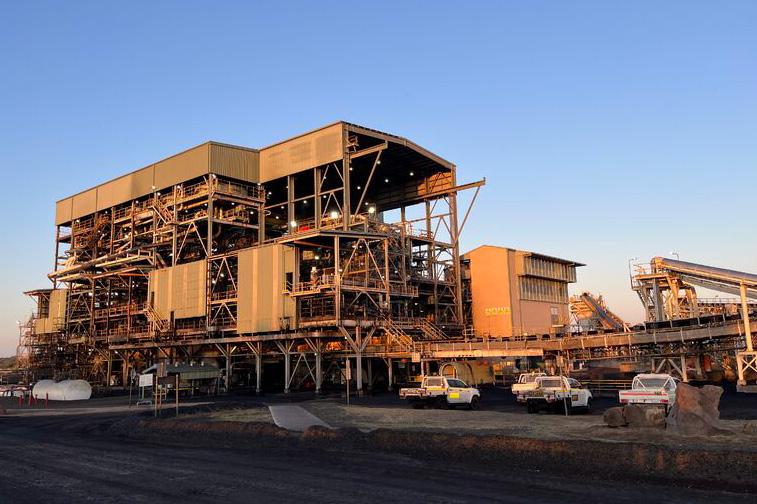

Michelle DuncanThe mining sector is witnessing a significant shift in technological advancements, sustainability practices, and leadership strategies. Kestrel Coal Resources, under the guidance of its CEO Shane Hansen, has emerged as a pioneering force in transforming

the industry. By leveraging innovative technologies, optimising the value and supply chain, and prioritising sustainability, Kestrel Coal Resources has solidified its position as a trailblazer within the mining sector.

Under the leadership of Shane Hasen, Kestrel Coal has fostered a culture of innovation and collaboration. His visionary approach has created an environment that encourages employees to chal-

lenge conventional practices and embrace change. By fostering cross-functional teams and promoting diversity, the mining company has been able to attract top talent and infuse fresh perspectives into their operations. The CEO’s emphasis on transparency and effective communication has played a crucial role in aligning the entire workforce towards the common goal of transformation.

Shane Hasen, CEO, Kestrel Coal

Shane Hasen, CEO, Kestrel Coal

Kestrel Coal Resources has embraced innovative technologies for geological mapping, surveying, and exploration. Utilising advanced geophysical tools such as 3D seismic imaging and remote sensing technologies, the mining company has been able to identify and characterise coal reserves with unprecedented accuracy and efficiency. The introduction

of advanced automation systems, robotics, and real-time monitoring has increased operational efficiency, reduced costs and risks. By leveraging artificial intelligence (AI) and machine learning algorithms, Kestrel Coal Resources has empowered its workforce to optimise resource utilisation, improve planning, and ensure smooth operations. Furthermore, the implementation of innovative data analytics tools has enhanced decision-making processes, en-

abling Kestrel Coal to identify opportunities for continuous improvement.

In the realm of coal extraction, technology has further played a transformative role in enhancing efficiency, productivity, and safety. Kestrel Coal Resources has implemented state-of-the-art mining equipment and automation systems, including autonomous haulage trucks, remote-controlled drilling rigs, and advanced monitoring sensors. These technologies have streamlined the extraction process, increased production rates, and reduced operational costs while minimising the exposure of workers to hazardous environments.

Kestrel Coal Resources has also leveraged data analytics and predictive maintenance algorithms to optimise the performance of its equipment and machinery. By continuously monitoring key operational parameters and equipment health metrics in real-time, they can proactively identify potential issues, schedule maintenance activities, and prevent costly downtime. This initiative-taking approach to maintenance has significantly improved equipment reliability, extended asset lifespan, and maximised operational uptime. Technology has played a crucial role in optimising the coordination and supply chain management processes at Kestrel Coal Resources. Advanced software solutions for inventory management, route optimization, and transportation scheduling have enabled the company to streamline its planning operations, minimise transportation

Australian company ABM Contractors (ABM) is strengthening domestic mining operations with its comprehensive range of services, an offering that puts stronger partnerships at the forefront.

Based in Queensland, the company has become well-known for its high-quality project management, supplementary labour, shotcrete services and longwall support, as well as its work in ground consolidation and coal development.

Through the veteran company, clients can access first rate drill and blast services, secondary support, VCD installations, fault driveage, equipment hire and repair as well as major conveyor installations and recovery services.

ABM Director, Jamie Abraham describes his highly experienced team as specialists in fall recovery, drifts, and ground stabilisation, which positions the company as an ideal partner to many operators within the mineral resources sector.

The company is proud of its work at the Kestrel Coal Mine, one of the world’s largest producing underground coking or metallurgical facilities. During this project, a key ingredient of ABM’s successful relationship with Kestrel Coal Mine was its shared commitment to local community support, and

to improve host communities and embracing environmental sustainability goals, meaning it was critical for the company to partner with service providers that had similar vision.

First established in 2000, ABM has gained a nationwide reputation for tackling tough jobs headfirst both on time and on budget. The family-owned business is also poised to start a new venture providing underground specialised shotcreting services, cutting-edge ground consolidation products, and range of ventilation control devices to operators within the coal industry.

Health and safety: During the execution of its projects, ABM takes particular care to ensure that all risk is evaluated and managed effectively.

Social Responsibility: ABM’s vision is to enhance the quality of life for the host communities in which it operates.

Environmental Stewardship: Conservation and the continued health of our planet is everyone’s responsibility, and ABM will continually strive to facilitate the least possible harm during operations.

Quality: ABM’s commitment to quality flows from the fact that long after project completion, its reputation will continue to be influenced by the work and service provided.

People: A core set of values binds ABM together and provides the ethical framework for conducting day to day business.

Integrity: To be honest and reliable, reflecting the highest ethical standards in all business practices.

Respect: To trust and treat people with respect and dignity.

Leadership: To recognise the unique contribution and intrinsic worth of everyone and provide an inclusive environment focussed on consistently delivering value.

Value Creation: To focus on doing the simple things well. Collaboration – Promote open communication as the key towards influencing and inspiring high-performance outcomes.

For more information, visit www.abmcontractors.com.au

Phone 00 61 (07) 4982 2174

General enquiries email: admin@abmcontractors.com.au

Employment opportunities: careers@abmcontractors.com.au

costs, and ensure timely delivery of coal to customers. Additionally, the implementation of blockchain technology has enhanced transparency, traceability, and security across the supply chain, further strengthening Kestrel Coal Resources’ position as a reliable and trusted partner in the coal market.

Furthermore, Kestrel Coal has revolutionised its value chain by integrating digital technologies, which enable seamless coordination and collaboration between mining operations, coordination, and customers. By optimising the value chain, they can streamline processes, reduce lead times, and enhance customer satisfaction. Kestrel Coal’s supply chain practices prioritise efficiency and

sustainability, ensuring responsible sourcing, reducing waste, and minimising the environmental footprint. By embracing technologies like blockchain, the company ensures transparency and traceability throughout the supply chain, gaining a competitive advantage in the market.

Most importantly, technology has been instrumental in enhancing safety standards and promoting environmental sustainability within Kestrel Coal Resources’ operations. The company has invested in state-of-the-art safety technologies such as real-time monitoring systems, wearable devices, and virtual reality training simulations to mitigate risks and ensure the well-being of its workforce. They implemented

KESTREL COAL HAS REVOLUTIONISED ITS VALUE CHAIN BY INTEGRATING DIGITAL TECHNOLOGIES, WHICH ENABLE SEAMLESS COORDINATION AND COLLABORATION BETWEEN MINING OPERATIONS, COORDINATION AND CUSTOMERS.

a comprehensive sustainability strategy. The Mining company is committed to reducing its environmental impact by investing in renewable energy sources, reducing greenhouse gas emissions, and implementing comprehen-

sive rehabilitation programs. Kestrel Coal actively engages with local communities and stakeholders to ensure the preservation of biodiversity and supports community development initiatives. Furthermore, Kestrel Coal Resources has embraced environmentally friendly practices, including the use of clean energy technologies, water recycling systems, and reclamation initiatives, demonstrating its commitment to responsible mining practices and environmental stewardship.

In its pursuit of continuous improvement, Kestrel Coal has remained at the forefront of innovation. The company has embraced emerging technologies such as Internet of Things (IoT), predictive maintenance, and renewable energy integration. By adopting electrification solutions in its mining operations, Kestrel Coal has significantly reduced its carbon emissions and environmental impact. Furthermore, the company has made strides in leveraging

big data analytics and AI to optimise resource allocation, predict market demand, and develop predictive maintenance models. Kestrel Coal Resources transformation under the leadership of CEO Shane Hansen is a shining example of how the mining sector can embrace technology, redefine operational processes, and prioritise sustainability. By leveraging advanced technologies, optimising the value and supply chain, and spearheading sustainability efforts, Kestrel Coal Resources has set a new benchmark within the industry. As the mining sector adapts to the challenges of the future, Kestrel Coal’s transformation serves as an inspiration for industry players seeking to embrace innovative technologies and sustainable practices.