Nibor-D®+ IGR is your ready-to-use secret weapon for eliminating cockroaches, small flies, and other pests in the hard-to-reach places they like to hide.

Nibor-D®+ IGR is your ready-to-use secret weapon for eliminating cockroaches, small flies, and other pests in the hard-to-reach places they like to hide.

by Jim Bunch, BWI President & CEO

As we celebrate BWI’s 67th year in business, we’re filled with excitement and optimism about the future—and we want to take a moment to share that excitement with you, our valued customers and suppliers.

It’s hard to believe that nearly seven decades ago, a young couple—Bob and Betty Bunch—took a bold step and started a small retail seed company in Texarkana, Texas. Bob, a traveling seed salesman for Ferry Morse Seed Company, saw an opportunity when one of his customers wanted to sell his business. With a $1,000 loan at 10% interest, the seeds of BWI were planted.

BWI has always believed that growth isn’t just about doing things the same way; it’s about adapting, taking risks, and evolving with the times. Here are just a few key moments from the past 67 years that helped shape who we are today:

• 1972: We transitioned from a retail seed store to the distribution business.

• 1975: Held our firstever EXPO/Trade Show.

• 1976: We embraced technology with the IBM System 32, stepping into the digital age.

• 1992: Expanded into turf distribution, opening up new markets for our customers.

• 1998: Implemented an automated order entry system for faster, more efficient service.

• 2002: Launched an automated warehouse system to streamline operations.

• 2012: Entered the professional pest control and animal health markets, diversifying our offerings.

• Since 2015: Expanded our distribution network with new locations in San Antonio, Oklahoma City, Atlanta, Austin, Kansas City, and Nashville.

• 2023: Moved to electronic signatures for deliveries, reducing paperwork and improving efficiency.

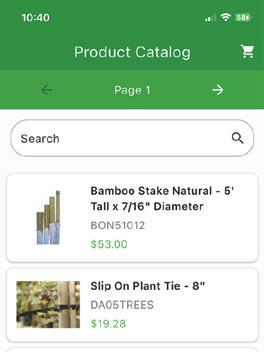

• Ongoing: We’re rolling out a mobile app for you to place orders and access product information more easily.

• 2024: For the first time, we embraced artificial intelligence to enhance our marketing efforts and improve customer service.

This list of milestones is just a glimpse into how we’ve continued to innovate and grow. Through it all, one thing remains constant—our commitment to YOU, our customers and suppliers.

The old saying, “If it ain’t broke, don’t fix it,” has been a popular expression in the business world for years. While this remains true for guiding principles such as core values, company culture, and mission statements, when it comes to customer service, efficiency, and adapting to change, fixing it before it breaks is key to survival and longterm success.

We won’t rest on our laurels. We’ll keep investing in tools, technology, and processes that make your experience with BWI better—faster, easier, and more effective.

At BWI, we believe our success is tied to your success. Our goal is not just to sell you products, but to help your business thrive. When you grow, we grow.

As we look to the future, we’re reminded of the importance of staying ahead of the curve. In business, progress is key—if you’re not evolving, you risk falling behind. We often think of companies that failed to adapt to change, and Kodak stands out as one of the most notable examples.

Founded in 1880 by inventor and entrepreneur George Eastman, Eastman Kodak became a financial empire and one of the most recognizable brand names in the U.S. Eastman, influenced by Henry Gillette’s razor-and-blade sales strategy, sold cameras cheaply and profited from accessories, such as film. This strategy worked for generations, and the phrase "Kodak moment" became universally known.

However, in the 1970s, Kodak invented the digital camera, anticipating that digital technology would eventually replace film cameras. Unfortunately, Kodak didn’t foresee the competition from overseas manufacturers and the rise of cell phone cameras. When digital chips replaced film, Kodak’s revenue from film sales vanished.

In 1976, Kodak held over 96% of the U.S. film market and 85% of the camera market. By 2010, its market share had plummeted to less than 7%. Former employees say Kodak was once the Apple or Google of its time.

In January 2012, Eastman Kodak filed for Chapter 11 bankruptcy protection. Over the next decade, Kodak laid off more than 45,000 employees, closed 13 factories, and shut down 130

processing plants. Kodak was losing $70 million a month and eventually ran out of money.

As someone who grew up with "Kodak moments," it’s truly sad to see such an iconic company file for bankruptcy after 131 years in business. The lesson here is clear: We must adapt and change with the times, always anticipating what’s around the next corner. Too often, we get caught up in the day-to-day fires and forget to plan ahead for the future. We need to carve out time to strategize and position our businesses to ride the next wave.

At BWI, we’re committed to avoiding that fate. We’re always looking ahead, thinking about how we can better serve you and adapt to the changing needs of the market. Whether it’s through new technology, improved customer service, or expanding our product offerings, we’re always working to stay ahead of the curve.

As we move into 2025, we’re focused on one goal—helping you succeed. We want to make sure that your business is equipped to meet the challenges of tomorrow, and we’ll be there every step of the way with the products, services, and solutions you need.

Thank you for being a part of our journey. We’re proud to have served you for 67 years, and we’re excited about what the future holds for all of us.

On behalf of the BWI team and the Bunch family, we THANK YOU for your support, trust, and partnership. Here’s to many more years of shared success!

May your aspirations turn into achievements and your dreams into realities!

Q: What is Ridesco WG insecticide?

It’s a new innovation that holds a unique spot among other BASF dilutables due to its reputation as a rapid-response heavy hitter. Ridesco WG insecticide can be used in situations where speed and impact are critical, including initial services, cleanouts, before a big event or for tough callbacks. It will make a dramatic impression due to being a quick release formulation – the dual active ingredients (AIs) rapidly deploy their full power, swiftly reducing pest populations.

Q: What are the dual active ingredients that cause the swift action?

The AIs are Dinotefuran and Alpha-Cypermethrin, which target two different physiological pathways to quickly overwhelm a broad range of pests. It provides powerful ef cacy against black widow, cellar and brown recluse spiders, American cockroaches, earwigs, and other occasional invaders.

Q: How do you apply Ridesco WG insecticide?

It can be applied using any hand-held, backpack, or truck mounted sprayer equipment. Mist blowers can also be used to treat hard-to-reach areas. Ridesco WG insecticide can also be mixed with a foaming agent to treat voids. Use as a spot, band, crack and crevice, and void type of application. Just check the label if you have any questions about the application methods.

Q: Can using Ridesco WG insecticide save on resources?

Using Ridesco WG insecticide can lead to operational ef ciencies. With the advantage of being one rate, the water-soluble formulation is easy to mix, and the builtin measuring cap helps reduce human error, further simplifying the work. After the job is done, Ridesco WG insecticide can be easily stored without concerns about formulation separation or agitation, undesirable odor buildup or molding.

Q: Is the product label exible?

Ridesco WG insecticide can be used indoors and outdoors for residential and commercial accounts, including food handling areas. Outdoor treatments below mulch and rocks are now easier than ever; PMPs can double the volume of water to reach below any soil cover while maintaining the full label rate of 0.15% thus having a direct impact on pests that like to hide during the day.

Always read and follow label instructions.

Ridesco is a registered trademark of BASF. © 2025 BASF Corporation. All rights reserved.

Take out infestations with a powerful upfront strike.

When dealing with infestations, customers want decisive action – now. Enter Ridesco® WG insecticide. This quick release formulation with two trusted active ingredients delivers powerful results that swiftly reduce pest populations. For initial services, cleanouts, tough callbacks or as a pre-treatment for important events, Ridesco WG insecticide delivers rapid results that your customers will appreciate.

Visit pestcontrol.basf.us or contact your BASF rep for more information.

When Steve Hotsenpiller signed a two-year noncompete with the pest control company he’d just quit, the 24-year-old wasn’t worried about it. As far as he knew, his time in the pest control industry was over. He’d taken the job because it sounded interesting and had learned a lot, but he didn’t see a future there.

“During the two years I wasn’t working there, I married the girl I was dating and had a child,” Steve said. “That was motivation to make something happen.”

Steve and his wife Anita started Steve’s Pest Control in Holts Summit, Missouri, in June 1988 while Steve was still working full-time in a shoe factory. The couple turned one of their two apartment bedrooms into an office, outfitting it with a homemade desk and a typewriter where Anita handled the paperwork.

“I would come home at 3:30 p.m., change clothes, and go out and solicit accounts,” he said. “I had a young wife and a baby at home; we needed benefits and regular pay while we were starting out, so I did both jobs until I could support myself with the pest control business.”

After about three months, Steve was able to quit his day job.

“It was still pretty risky, stepping away from health insurance with a six-month-old child,” he said. “I had no advertising or name recognition. There were no cell phones or internet at the time. The only major advertising was the phone book, and I wasn’t in that for a year. Everything was word of mouth and constant cold calling.”

By Traci Pitman

That’s how it started—one customer at a time. As the business grew, they upgraded their equipment and facilities, evolving from a makeshift office in their apartment to a dedicated building, a company truck, and their first employee.

Though he was working long hours and the business was growing, Steve noticed that his profits weren’t keeping up with revenue. When a business consultant called him unexpectedly, offering an internal assessment for just $250, something inside Steve told him to say yes.

“That really turned everything around,” he said.

The assessment exposed inefficiencies and inventory theft, prompting Steve to commit to a six-week overhaul that restructured his business for long-term success. The program helped him establish company policies, a handbook, and an employee survey that provided valuable insights into the business.

Then, Steve attended a branding seminar that changed his approach to marketing. He hired a consulting firm to develop a distinct brand identity and a catchy jingle and started running radio ads on one station, gradually expanding as business grew.

“It took about six months to start seeing a return on radio,” he said. “But if you stay with it and have a good, consistent message—and a good jingle—and you repeat it over and over again, they’re going to think of you first when they have a pest issue.”

Soon, people were commenting on the commercials, and business picked up even more.

“We’ve been on the radio for 24 years now. It’s generational,” he said. “I’ve had people say they grew up listening to the jingle while riding the school bus, and now they’re adults with kids and houses.”

The company Steve started in his apartment’s second bedroom now serves 245 cities and 35 counties in a 120mile radius of their home base in Central Missouri, with a

team of more than 100 employees. The growth isn’t slowing down anytime soon, either. Eight of those employees are field sales representatives

nice people, have a positive attitude, and work their tail end off. If they’re willing to do that, they’re going to be really successful.”

continuously scouting for new clientele, and Steve is prepared to add more branches wherever demand exists.

“We just did the right thing, taking care of one customer at a time, treating them right, and building strong relationships,” Steve said.

Hiring the right people also helps, Steve said.

“We’re very particular about who we hire, and we tell them that upfront,” he said. “You have to have the desire, the burn, the reason why. You have to love to serve people. You have to look professional. The rest we can teach you.”

Steve’s management style isn’t common in the pest control world.

“We try to set them up like they’re in their own business,” he said. “We just do all the parts of the business that aren’t fun, like HR, payroll, supplies, and paperwork. We expect them to serve customers, solve problems, be

Their customers, employees, and vendors all agree—they lead by example. John Long, a BWI outside sales rep, said the company is a toptier organization.

“Everything they do is first class, from the way they take care of their employees to the way they handle their vendors,” John said.

“They couldn’t be nicer people. Their service is outstanding. If Steve himself has to go out and talk to a customer or solve a problem, he will absolutely do it. His work ethic and dedication to quality is second to none.”

Steve and John have been working together for nearly 30 years. For Steve, business has always been about trust—whether with customers, employees, or vendors. So when John moved to BWI, sticking with him was an easy choice.

“I can buy products anywhere, but it’s the relationship and service that matter,” he said. “I’ve respected John for years. He’s gone above and beyond when it comes to service. We order 90 percent of our materials from BWI. I get a personal relationship and great service, and I feel like they’ve got my back and they’re looking out for me. I think that’s what all customers are looking for.”

For Steve, Steve’s Pest Control has never just been about business—it’s been about family. What started as a twoperson operation in a spare bedroom has grown into a thriving company, now run alongside his son and daughter, both part-owners.

“To be honest with you, and this probably sounds sad, but the business is a big part of my life,” Steve said. “Building the business with my kids, watching them take ownership and grow it, that’s been one of the most rewarding things.”

With five grandkids running around, family time is as important as ever. Steve and his wife spend as much time as they can with their kids and grandkids—whether it’s working together, enjoying the outdoors, or simply maintaining their property.

“We’ve never lived outside our means,” he said. “We have nice things, but I don’t have a house at the lake or anything like that. I just like being outside, fishing, and keeping up with the land. That’s what makes me happy.”

At 63, Steve still puts in 50-hour weeks—not because he has to, but because he wants to.

“I don’t work weekends anymore, but I want to be here,” he said. “It’s not just a business—it’s something I built with my family. And I still love being part of it.”

Congratulations to Windmill Nursery of Franklinton, LA for being our grand prize winner of a 2024 Can-Am

LoneStar and trailer.

Other prize winners include:

Knox Horticulture - Winter Garden, FL

Davidson Farmers Co-op - Nashville, TN

$3,500 Vacation Voucher

Moore's Feed Store - Pontotoc, MS

Aventon Aventure.2 Step-Through Ebike

Flowerwood Nursery - Loxley, AL

Country Farm & Home - Pittsboro, NC

Casa Verde Farms - Schertz, TX

Southside Nursery - Forest Hill, LA

The Alotian Club - Roland, AR

Turtlebox Waterproof Speaker

Pictured from left to right:

Johnny Nugent, CFO Windmill Nursery

Wayne Hearn, BWI-Meridian Territory Manager

Ronnie Britt, BWI-Meridian Division Manager

Matthew Courtney, BWI-Meridian Sales Manager

Tackling weeds in lawns and landscape beds just got easier. Crew® specialty herbicide offers a powerful solution to over 120 broadleaf and grassy weeds, and is safe to use on a wide range of turf and over 410 ornamentals.

Learn more at corteva.us/turf

The fight to protect plants from root disease, insects, or other stress factors is a constant ongoing battle that growers in the horticulture industry face. Chances are that you, the reader, have already heard that some microorganisms, such as beneficial fungi or bacteria, can help aid in this battle. However, with a lot of misinformation out there, it can be difficult to discern what is true regarding claims that have been made about them. In this article, I will review what these microorganisms are, why you should consider using a growing medium that contains them, and discuss how they can be a cost-effective option for a growing operation.

Active ingredients are natural, non-GMO, living biological microorganisms used for their ability to enhance plant growth, suppress pathogens that can cause root disease, and/or reduce insect populations that can damage plants. Two highly efficient biologicals available to the horticulture industry are Rhizophagus irregularis (formerly known as Glomus intraradices), which is an endomycorrhizal fungi, and Bacillus pumilus, which is a beneficial bacterium. Let’s explore what each of these microorganisms are and learn how they can benefit your plants while saving you money.

Mycorrhizae: Rhizophagus irregularis

Rhizophagus irregularis is an endomycorrhizal fungus that forms a positive symbiotic relationship with approximately 85% of all plants. The way this fungus works is once its spores germinate, they send out filaments into the growing media called hyphae to “search” for plant roots. Then, if these hyphae receive a chemical signal back from a nearby root system, they will grow in that direction

seeking to establish contact with the plant, at which point they will make contact, penetrate the root’s cell, and will provide the fungus with essential carbohydrates and sugars that it needs to survive, while the fungus will act as a “secondary root system” to the plants, pulling in additional water and nutrients, such as phosphorus, zinc, manganese, and copper that the plant may have a difficult time finding in the growing media. As a result, plants will grow faster and more uniform due to increased access to water and nutrients, are more resilient to environmental stresses, such as nutrient deficiencies or transplant shock, and yield more flowers and fruits.

Similarly, Bacillus pumilus is a natural, grampositive bacterium that also forms a mutualistic symbiotic relationship with all plants species. This microorganism works in a couple of unique ways. First, once this bacteria’s spores germinate, they rapidly begin to colonize plant roots and establish a barrier of protection around them. This process

occurs quickly, taking place in as little as 48 hours, and helps stop harmful plant pathogens from coming into contact with plant roots. Additionally, Bacillus pumilus excretes lipopeptides, such as surfactin, and biostimulant molecules, such as auxins, which act as antibiotics to suppress root diseases like Fusarium, Pythium, and Rhizoctonia as well as stimulate root growth and root hair proliferation. Therefore, plants will grow faster and healthier due to an enhanced uptake of water and nutrients from healthier root systems, require fewer fungicide drenches, and the total crop shrinkage (loss of plants) will be reduced during the growing season.

When purchasing growing media with active ingredients,

Source: Premier Tech.

Suppose a grower is growing 10,000 ten-inch hanging baskets that wholesale for $14 per basket. Would active ingredients be a favorable investment for this growing operation?

it is important for a grower to consider all aspects of a growing operation that these two microorganisms can improve. For example, if the primary goal is to increase the profitability of their growing operation, then a grower must either (1) boost their production output or (2) reduce their costs of production. Production output can be augmented by increasing the number of plants grown per square meter, the number of crop cycles grown per year, or the yield from each plant. Conversely, costs of production can be reduced by decreasing plant loss (crop shrinkage) or input of resources. Let's see how microorganisms such as Rhizophagus irregularis and Bacillus pumilus have the potential to achieve both goals and improve various aspects of a growing operation.

In this scenario, if the grower were to sell all 10,000 of their hanging baskets, this would equate to a total revenue of $140,000. However, this is not realistic outcome as we know some plants will be discarded along the way due to plant diseases, uneven growth, watering issues, lack of sales, etc. In the horticulture industry this is what we refer to as crop shrinkage. Annually, shrinkage typically falls somewhere between 4-7% for most growers and 5-15% for retail garden centers. Now if we apply crop shrinkage to this scenario using a rate somewhere in the middle, say around 5%, we would expect a loss of roughly 500 hanging baskets during the growing season for an estimated loss of $7,000.

Conversely, suppose a grower switched to a product that contained Rhizophagus irregularis and Bacillus pumilus that could recapture 2% of their crop shrinkage. What would the loss and yield look like then? Well, depending on the growing medium needed, this would cost the grower an

additional upfront investment of $0.11 per pot (or $1,100 total for the crop). However, this grower would save an additional 200 plants that would have otherwise been lost to crop shrinkage, netting them an increased profit of $1,700 in total revenue. Additionally, this 2% reduction in plant shrinkage did not factor in overhead cost savings that can also be expected from switching to a product incorporating active ingredients, such as a reduction in the number of fungicide drenches a grower typically applies, a reduction in labor costs needed to apply those drenches, and/or a reduction in their crop cycle in the greenhouse. Therefore, a grower’s true savings will likely be much higher.

Conclusion

In conclusion, while incorporating active ingredients into growing media might involve a

higher initial cost, utilizing these microorganisms can save you valuable time, money, and energy at various phases of your growing cycle. These microorganisms enhance crop quality, promote uniform growth, are cost-effective, and provide ongoing protection to your crops throughout the growing season and your customers who purchase them. For these reasons, Active ingredients more than justify their cost.

Premier Tech

Nathan Wallace-Springer WALN Horticulture Specialist

Southeastern US WALN@premiertech.com

Striving for thriving crops? With PRO-MIX® premium growing media and AGTIV® biological active ingredients, it’s in the bag.

Save time. Conserve your budget. Get long-lasting control.

By Traci Pitman

K“I’m

evin Koehler stood at the back door of his home as the wind began to intensify.

not sure,” he called to his wife. “This might be blowing over.”

The day before, Hurricane Helene had made landfall near Perry, Florida, as a Category 4 hurricane, slamming the coast with winds as high as 140 mph. The storm barreled inland toward Douglas, Georgia, where Kevin, the general manager of Sunbelt Greenhouses, lives and works. They knew a storm was heading their way, but at 240 miles inland, they hoped it would lose steam before reaching their community on Sept. 27, 2024.

Unfortunately, that wasn’t the case. As the wind howled, the couple sought shelter in their walk-in closet while more than 20 tornadoes swept through the region.

“We’re far from the Gulf Coast, but the storm’s eye came directly over Douglas,” Kevin said. “Douglas used to be full of massive, centuries-old pine trees. The storm uprooted them, and they fell everywhere—on roofs, cars, roads, and power lines. It devastated the town.”

Hurricane Helene caused widespread destruction, flattening millions of acres of Georgia forestland and resulting in an estimated $6.46 billion in agricultural damages, according to the UGA College of Agricultural and Environmental Sciences. It went on to decimate communities and infrastructure in North Carolina with unprecedented flooding and landslides.

But in Douglas, as the sun rose, Kevin’s concern turned to the greenhouses.

“The city was in complete chaos,” he said. “No traffic lights, no businesses open, roads blocked by downed trees. It was overwhelming. I had to find alternate routes to reach Sunbelt the next morning, dodging fallen trees along the way. Mike McCook, our maintenance manager, made it to the facility before me, taking his side-byside through the impassable roads from his house.”

When they arrived, they found the facility still standing but severely damaged.

Hurricane Helene had caused more than $1 million in destruction. Six thousand square feet of greenhouse space was lost, along with more than three acres of acrylic roofs, shade cloth systems, sidewall curtains,

poly roofs and cool cells. The storm also caused more than $100,000 in crop losses, including pansies and poinsettias.

Despite the devastation, the Sunbelt team sprang into action.

“We were shipping orders just four days later,” Kevin said. “We also had to ensure our employees were

supported—housing, fuel, generators, food, and other essential supplies. Everyone was without power or water for weeks. Fortunately, we had backup power for the greenhouses with multiple generators, and we even set up washer and dryer units at the facility so our employees could have clean clothes during the recovery.”

Sunbelt Greenhouses’ success is built on that kind of dedication. The company was founded in 1983 by Lorence Wenke from Kalamazoo, Michigan, and today operates on 20 acres of climate-controlled greenhouses and an additional 8 acres of outdoor production space. The owners, Lisa Ambrosio and Jeff Wenke, also own Wenke Greenhouses, with four locations in the Kalamazoo area and more than 60 acres in production.

The company’s main crops include ornamental plants, vegetables, and houseplants. Their young plant department produces plugs and liners for internal use as well as for sale to other growers. Sunbelt serves a diverse customer base, including individual garden centers, Costco, and landscapers throughout the Southeastern United States. As a leading force in the industry, Sunbelt is recognized for producing high-quality plants.

This spring, they incorporated a Cravo retractable roof greenhouse, which allows them to adjust the roof and sidewalls as needed to improve growing conditions.

“They’re always looking for newer innovations,” said Jay Hatcher, outside sales at BWI. “They’re constantly adapting. They’re not the type to just sit back and do things the same old way. They’re always working toward something newer, better, or more efficient.”

This forward-thinking mindset has helped Sunbelt stand out in the greenhouse industry. Ranked 19th on Greenhouse Grower’s 2024 Top 100 Growers list and 16th among the largest young plant growers in the U.S., Sunbelt serves major clients like Pike Nurseries, SiteOne, Callaway Gardens, and even Disney pre-COVID.

“Sunbelt is an unusual entity in our industry because we’re so far from our ownership,” Kevin said. “The Wenke family has put a lot of trust in me and the other employees in this company, and that’s why we have such strong loyalty.”

Kevin joined Sunbelt in 1985. Originally from Green Bay, Wisconsin, he earned a horticulture marketing degree and worked for several greenhouses

before coming to Sunbelt at age 24. Like Kevin, many of Sunbelt’s 87 fulltime employees have been with the company for decades.

“A number of our employees started here when they were in high school,” he said. “We really don’t have a lot of turnover, but we’re starting to see some now that we’re getting older and aging out. Why do we stick around so long? Maybe because we’re crazy! It’s in our blood.”

That spirit of teamwork is what helped Sunbelt recover quickly after Hurricane Helene, along with support from partners like BWI. Jay worked closely with Sunbelt to ensure they had the necessary supplies, strengthening a business relationship that has spanned over 20 years.

“BWI played a huge role in helping us repair the greenhouses,” Kevin said. “Their customer service is excellent, and their support during the recovery was crucial. Jay is more than a salesperson—he’s a good friend.”

With Hurricane Helene behind them, Sunbelt continues to focus on technology, strengthening partnerships, and

expanding its team. The challenges of recent years have only reaffirmed the company’s commitment to resilience.

“We’ve been through a lot,” Kevin said. “The town is slowly recovering, and we still have a long way to go. But we have a great team, solid partners, and a drive to keep Sunbelt at the forefront of the industry. That’s what keeps us going.”

BWI’s Five Star Product line is formulated for the professional applicator with raw materials of the highest quality and blended in the United States. These products are developed with environmental safety and efficiency of nutrient uptake to ensure plant health and maximum crop production. Our core NPK products start with controlled release, stabilized nitrogen that gives a consistent feed with a low salt index.

Our micronutrient and secondary nutritional products are manufactured with superior performance in mind to ensure you receive the highest quality. All products are tested twice during formulation and then tested again before shipment by our QC department.

BWI’s Five Star product line is committed to quality, consistency and reliability in every application. We look forward to showing you how Five Star Products can help you and your agronomic programs. See our full list of products below:

Five Star 28-0-0 (70% Slow-Release Nitrogen)

Five Star 18-0-6 (50% SRN with Minors)

Five Star 22-0-0 (40% SRN)

Five Star Arbor Pro 15-8-4 (40% SRN with Minors)

Five Star Autumn Pro 6-12-12 (40% SRN with Minors)

Five Star 0-29-26

Five Star 4-0-0 Micro

Five Star LQ Iron 12-0-0 (6% Iron and 2% Manganese)

Five Star 0-0-25 Potassium (KTS)

Five Star Soil Pro Plus

Five Star Granular Tank Cleaner

Five Star Defoamer

Ask your BWI Territory Manager for more details and information.

Get the latest solutions to stop adaptive pests.

Envu is here to provide a portfolio that keeps up as pests become more elusive and challenging to control. And with our newest solutions, we’re helping professionals lock down the perimeter and protect the spaces we all share.

+ Botanical-based formula that’s safe for everything – except mosquitoes

+ 100% mortality rate in 24 hours* for Aedes

+ Doesn’t harm bees, butterflies, people or the environment

Get a safer way to stop mosquitoes

+ Control a range of hard-to-kill pests

+ Quick knockdown with results in 30 seconds

+ Power of two products in one with fast knockdown and long-lasting residual control for up to 18 months**

Discover the power of two-in-one

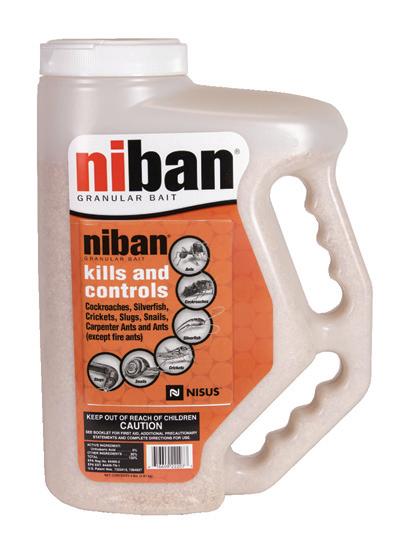

Fire ants pose a significant threat to any size operation, affecting productivity, safety, and infrastructure. Left uncontrolled, they can cause costly damage and create hazardous conditions for humans, animals, wildlife and equipment. They can also deliver a financial blow by damaging turf and ornamentals.

Understanding how to identify fire ants, along with when and how to treat effectively is key to minimizing their impact on your bottom line.

Fire ants infest over 309 million acres in 14 states. They spread through mating flights, mass colony movements or by floating in flood waters. They are also dispersed via shipments of soil, sod and nursery stock. The USDA regulates the import of agricultural products, plants, and related materials in an effort to protect US agriculture and natural resources from invasive pests like fire ants. It’s critical to keep these quarantine requirements in mind when considering treatment methods, and make sure to select products and ingredients that meet USDA fire ant quarantine requirements.

When dealing with fire ants, it’s also critical to identify the differences between worker fire ants and queens – controlling the queen is the key to controlling a fire ant infestation:

• A mature fire ant queen can produce up to 1,500 eggs per day. Without eliminating the queen, the population will quickly rebound after workers are killed.

• Some fire ant colonies have multiple queens. These colonies can grow faster, making it even more critical to control all queens.

2. Colony Survival

• Worker ants exist primarily to support and protect the queen. Even if most workers are eliminated, survivors will focus on protecting the queen, helping her rebuild the colony.

3. Longevity

• Fire ant queens can live for several years, continuously producing offspring. In contrast, worker ants have short lifespans (4-6 weeks on average). Removing workers alone is a temporary solution.

4. New Colony Formation

• During certain seasons, winged reproductive ants (alates) leave the colony to start new nests. If the queen survives, infestation can spread.

The economic burden of fire ants is estimated to exceed $6 billion annually in the United States. Their tall, hardened mounds can damage equipment and interfere with irrigation and electrical systems. Nesting inside electrical boxes and machinery, fire ants can cause short circuits

and malfunctions, leading to expensive repairs and operational downtime. When the harneded mounds aren’t visible in tall grasses, mowers, cutters, and other farm equipment can be severely damaged on impact.

In the south, fire ant infestations in hunting, grazing, or other large land areas can cause serious economical damage by swarming and killing quail, calves, young deer, and more. Fire ants also pose a safety risk to humans. Their painful stings can cause allergic reactions, leading to medical expenses, lost workdays for employees, and reduced productivity. These disruptions can quickly add up, making proactive fire ant management essential.

Baits: Baits containing insect growth regulators (IGRs) or slow-acting toxins are ideal because they are carried back to the nest, eventually reaching and eliminating the queen.

Hydramethylnon, an adulticide, and (S)-methoprene, an IGR, are effective, USDA-approved active ingredients. The Hydramethylnon kills worker ants, while the (S)-methoprene sterilizes the queen, allowing colony elimination to be seen within two weeks.

Blending fire ant bait with dry fertilizer or other dry inputs is a cost-effective practice that saves time and resources, helping to control fire ants and the damage they cause with regularity.

Mound treatments, while effective in killing workers, can often leave the queen unharmed, able to rebuild the colony. According to

Texas A&M Extension’s fire ant control research, applying individual mound treatments can also be more labor intensive and can result in the use of more insecticide.

When using bait treatments, keep in mind that baits are most effective when ants are actively foraging. This allows ants to carry bait back to the colony, ensuring the entire mound is affected.

Foraging typically occurs when soil temperatures are above 60°F, making early spring and early fall ideal treatment windows. Treating at these times maximizes impact and helps prevent future infestations.

A simple test can confirm if fire ants are actively foraging:

1. Place a crumbled potato chip near a fire ant mound.

2. Wait a few minutes to see if ants begin feeding.

3. Once you confirm foraging activity, proceed with treatment for best results.

To optimize fire ant control, follow these guidelines:

1. Apply bait when conditions are dry and no rain is expected for at least six hours.

2. Avoid treating areas wet from dew or irrigation, as moisture reduces bait effectiveness.

3. Reapply 2–3 times annually or whenever new activity is spotted.

4. Allow 24 hours after treatment before watering the area.

The combination of direct costs (property damage, medical bills, etc.) and indirect costs (losses in agriculture, environmental harm) makes fire ants a major economic threat that should not be overlooked. Contact your local BWI representative for recommendations that fit your business.

NovaGraz™ herbicide. NovaGraz™ herbicide is a ground breaking weed control solution that enables producers to preserve white clover and annual lespedeza while providing enhanced broadleaf weed control. That means reaping the benefits of white clover in pastures with improved forage quality and animal performance benefits. Learn what NovaGraz can add to your operation at NovaGraz.us/ByTheNumbers

if

As a professional who works in crawl spaces and basements, your reputation hinges on reliability, customer trust, and quality assurance. That’s why we’re proud to introduce the new Santa Fe Total Peace of Mind 6-Year Warranty, the most comprehensive and reliable warranty on the market.

+ Industry-Leading 6-Year Warranty:

Experience unmatched confidence with our comprehensive 5-year replacement and additional 1-year parts warranty. We stand behind our quality, so you can too.

+ Unparalleled Reliability:

Equip your business with a dehumidifier designed for longevity. Santa Fe Dehumidifiers deliver sustained performance, reducing callbacks and enhancing customer satisfaction.

+ Cost Effective Solution:

Minimize operational disruptions and save on long-term costs with a product that’s built to last. Our warranty ensures you’re covered, letting you focus on growing your business without unexpected expenses.

• Combines the knockdown of an adulticide (Hydramethylnon) and the long-lasting control of an insect growth regulator (IGR) (S)-methoprene

• Stops young colonies from developing into problem colonies

• Destroys visible and hidden colonies

• Approved for use on residential turf and landscapes, commercial nurseries, pasture land and around saplings and non-fruit bearing trees

top shelf grower & retail products with full POS/POP support

limited product offering limited support programs

BACCTO GROWER PRODUCTS feature

BALES - LOOSE FILL BAGS - BULK BAGS

BACCTO RETAIL PRODUCTS feature

CO-OP ADVERTISING - PALLET STANDS

STORE BANNERS & PRODUCT POSTERS

EMPLOYEE SALES TRAINING

Introducing the “pink bag that is going to make a difference”

for every bag of RAISED GARDEN BED SOIL purchased, Michigan Peat will make a donation to the AMERICAN ASSOCIATION for CANCER RESEARCH

Order product anytime and anywhere, right from the palm of your hand!

Features:

• View purchase history, pricing, and current open orders.

• Website and mobile app order interchangeability makes things even easier.

• With the same login information, you can start, finish, or edit orders via the mobile app, website, or a combination of the two.

•

• E icacy. Controls weeds faster with two di erent modes-of-action.

Congratulations to the BWI Dallas team on becoming the 2023-24 Division of the Year. Pictured left to right: Jim Bunch, BWI President and CEO; Rick Newell, BWI Dallas Division Manager (retired); Tom Benton, BWI Dallas Sales Manager; Robert Bunch, BWI Co-President and CAO.

BWI Employee of the Year

1. Jason "Jo Jo" Jungers - Warehouse/Seed Coordinator (Texarkana, TX)

BWI Department Managers of the Year

2. Barbara Coursey - Office Manager (Springfield, MO)

3. Jeremy Stoever - Transportation Manager (Schulenburg, TX)

BWI Corporate Employees of the Year

4. Henry Munson - Lead Programmer (Nash, TX)

5. John Brown - Warehouse/Safety Manager (Nash, TX)

Stratos Premium Pet Food is always within your reach. Formulated with fresh ingredients and balanced nutrition to provide your pet exceptional nutrition at a great price.

• 5 formulas and counting

• 30 lbs or 40 lbs bags

• Dog and Cat formulas

• Produced in Texas

By Eric Reasor, Ph.D., Southeast Research Scientist

Summer is the busiest time of the year, filled with mowing, irrigation, cultivation, fertilization, and pesticide applications. This causes valuable time to be spent on herbicide applications. Expanding your post-emergent herbicide applications by combining two or more herbicide products, active ingredients, and modes of action can save time and yield better results. However, choosing the appropriate herbicide for the specific situation can be difficult.

Why?

1. Save time by reducing the number of applications. Using multiple herbicide products or active ingredients can control a broader weed spectrum. Combine broadleaf herbicide with grass and sedge herbicides to widen the range of a single herbicide application.

2. Better control on tough weeds. Summer is filled with difficult-tocontrol weeds, and additional herbicides can provide greater control on weeds such as chamberbitter, doveweed, goosegrass, ground ivy, spurge, Virginia buttonweed, wild violet, Kyllinga spp., and nutsedges.

3. Herbicide resistance management. This issue is rapidly increasing in turfgrass and applying multiple herbicide modes of action is one of the best methods to manage against herbicide resistance.

1. Pre-mixed products. Selecting products already formulated with multiple herbicide active ingredients and modes of action is the easiest way to expand your herbicide application. However, not all herbicides are or can be pre-mixed into a single formulation.

2. Tank-mixing multiple products. Selecting different products to mix together yourself can work when certain herbicide active ingredients are not premixed into a single formulation. It is important to follow recommended tank-mixing steps when mixing products of different formulations (e.g., WDGs mixed with liquid formulations). It is also important to read the product safety data sheet (SDS) for any incompatibility issues.

It is important to look outside the synthetic auxin herbicides (Group 4) 2,4-D, dicamba, MCPP, and MCPA when selecting herbicides. These active ingredients are highly effective on a wide range of broadleaf weeds, but they do not adequately control grassy weeds

and sedges. Moreover, there are reported herbicide resistant weeds to these active ingredients.

Quinclorac is a synthetic auxin herbicide that controls more than just broadleaf weeds. It can be very effective for crabgrass control if applied at the appropriate timing and with the addition of an adjuvant. Many pre-mixed products include quinclorac for its control spectrum.

Q4® Plus Turf Herbicide for Grassy & Broadleaf Weeds combines quinclorac with 2,4-D, dicamba, and sulfentrazone in one product to control many weeds.

ALS-inhibiting herbicides (Group 2) are great partners for synthetic auxin and other herbicides. They can provide broadleaf, grass, and sedge control depending on the specific active ingredient. For example, metsulfuron has mainly broadleaf activity, whereas flazasulfuron and trifloxysulfuron can control grasses and sedges in addition to broadleaf weeds. Katana® Turf Herbicide (flazasulfuron) mixed with herbicides such as SpeedZone® EW Broadleaf Herbicide for Turf has proven to provide longer-term

weed control than either herbicide applied alone.

PPO inhibitors (Group 14) are a great herbicide application addition to increase the speed of herbicide activity. For example, active ingredients carfentrazone and sulfentrazone are safe on cooland warm-season turfgrasses, and have activity on a broad spectrum of broadleaf weeds. Sulfentrazone can also be used for Kyllinga spp. and sedge control. Carfentrazone and sulfentrazone can be tankmixed with many other herbicides; however, Avenue® South Broadleaf Herbicide for Turfgrass, Q4 Plus, PowerZone® Broadleaf Herbicide for Turf, Surge® Broadleaf Herbicide for Turf, SpeedZone EW, SpeedZone Southern EW Broadleaf Herbicide for Turf, and TZone® SE Broadleaf Herbicide for Tough Weeds already include either carfentrazone or sulfentrazone for end-user ease.

HPPD inhibitors (Group 27) or “bleachers” are great for most coolseason turfgrasses to control a variety of weeds. Both mesotrione and topramezone herbicides have activity on crabgrass, nimblewill,

and many broadleaf weeds, but control of those weeds increases when combined with other herbicides (e.g., 2,4-D and triclopyr). Topramezone is highly effective on goosegrass, but the threat of herbicide resistance is looming. Tank-mixing SpeedZone EW with topramezone is a great resistance management strategy while also increasing goosegrass control. And the bleaching symptomology on weeds is often negated when mixed with certain herbicides.

Choosing pre-mixed products or tank-mixing with certain active ingredients and modes of action are great ways to expand postemergent herbicide applications. Herbicide efficacy can be maximized by understanding the strengths and weaknesses of specific herbicide active ingredients. This can save time by controlling more weeds for longer periods of time with fewer herbicide applications, all while managing against herbicide resistance.

Florikan has been the leader in plant nutrition for more than 40 years.

Florikan controlled-release fertilizers deliver high-quality nutrition to plants at an optimal rate. Our slow-release technology ensures a steady supply of nutrients over several months, leading to increased yields, reduced labor, and more consistent plant growth quality.

Our award-winning team brings years of industry knowledge and best-in-class products to market to improve plant nutrition and provide a better growing outcome.

When Lane Jacobs’ grandpa set up shop in Carmine, Texas, in 1931, he wasn’t just starting a business—he was laying the foundation for a family legacy that would span generations.

“He was a hard worker,” Lane said. “He had a feed store, a grocery store, a meat market—kind of a little bit of everything. Then he got into commercial egg production.”

Jacob family has always had a knack for business.

Lane’s dad and uncles followed in their father’s footsteps, and his parents eventually took over Jacob Store from his grandfather.

“I got my start working in the egg processing plant, handling all the eggs and learning the ropes,” he said. “After a while, I told my dad I wanted to work more with feed and customers, and I moved over to the feed store.”

When Lane was engaged to his wife, Robyn, she started helping his grandfather with the business’s finances.

“He had a big ledger book that was like five feet wide, and I’d write in the numbers with black, red, and green pencils,” Robyn said. “That’s how it started—I helped him with bookkeeping, and Lane worked with his dad.”

The couple married in 1982, and before long, they approached Lane’s parents about taking the helm.

“I told him that Robyn and I wanted to buy Jacob Store,

By Traci Pitman

change the name to Carmine Feed, and continue building on what my grandpa started,” Lane said. “Then we just started getting bigger.”

Lane and Robyn wasted no time growing the company. Around 1990, they bought out Kieschnick Feed, a Nutrena store in Giddings, Texas. A few years later, they built a new store when they outgrew their existing building. And when Lane saw an opportunity to build a fertilizer plant, they jumped on it.

“It was a great move,” he said. “We just saw so much opportunity for growth there. Just this year, we added on to the fertilizer plant again. We’ve just kept expanding. There’s a lot of business out there that we could win if we had the volume and materials, so that’s what we’re working toward.”

Expanding into fertilizer took the business to the next level.

“When we built that plant, everything started getting bigger,” Robyn said. “We outgrew the original Kieschnick location in Giddings after a year, then built a bigger, newer store. Once we had that store, we started adding some nursery and landscape products—a tomato, a pepper, a flower, a tree. Eventually, we were taking up so much room in the

feed store that we decided to buy the lot across from us, and we built the garden center.”

John Salem, BWI outside sales, said adding the garden center—which operates under the name Giddings Nursery & Garden Center—created a one-stop shop that sets the enterprise apart.

“It’s a real first-class farm and ranch store,” John said. “You can pick up dog food at the feed store, then go across the street and pick up your bedding plants, fertilizers, and chemicals. They also have novelty items like kids’ toys, jewelry, home accessories, and gifts.”

Beyond the essentials, the business has expanded to meet the needs of a diverse customer base. The feed store stocks everything from livestock feed and custom fertilizer blends to animal health products and farm supplies, while the garden center offers a wide selection of plants, trees, and landscaping materials. Customers can also find specialty fertilizers, highquality pottery, gardening tools, and more, making it a go-to destination for both serious growers and casual shoppers alike.

Expanding the business is one thing, but maintaining its reputation and service standards is another. That all comes down to the team.

“Once we get good people, they stay because we treat them right. We’re familyowned, and we take care of our employees,” Robyn said. “But the hardest part is finding the right people— customer service is everything to us. Lane and I put in long hours and usually don’t get home before 9 p.m. most nights. Not everyone wants to match that work ethic, so it can be tough to find the right fit. But when we do, we pay them well and appreciate them, and they stick with us. They know they’re working for someone who values them.”

Their team has grown to 34 full-time employees, including several who’ve been with them for a decade or longer, and their business partnerships are just as strong. John said he’s been calling on Lane and Robyn for BWI for nearly 30 years.

“I’ve grown with them,” John said. “Their nursery is just booming. I can’t sing enough praises. They’re just good, down-to-earth people— no showboating. And they have some really good, knowledgeable employees. Not only are the Jacobs good customers, but they’re really good friends.”

Lane said BWI has been instrumental in their success.

“BWI is top-notch,” he said. “They’re truly a great distributor to work with.

Nobody else comes close. What sets them apart is their service and the quality of their products. Service is everything to me, and BWI delivers. If I need a single case of something by tomorrow, one phone call and it’s here. I know I’m bragging on them a lot, but they deserve it.”

Like any good vendor, BWI has played a big part in helping them grow.

“Between their products, their competitive pricing, and the way they operate, they’ve been a key part of our success,” Lane said.

Service isn’t just an expectation for the Jacob family—it’s their standard.

“We take a lot of pride in our service, and I challenge anyone to do it better,” Lane said. “Whether it’s putting out fertilizer, getting spreaders where they need to be, delivering feed, or keeping products stocked and ready when customers need them—that’s our priority. My managers understand that, and it’s something we take seriously.”

Their commitment to exceptional service has not only attracted new customers but also kept lifelong ones returning to Carmine Feed & Fertilizer and Giddings Nursery & Garden Center.

“The feed store customer base has stayed about the same, but now we’re seeing the sons and daughters of the people that we served 10-15 years ago, which is very cool,” Robyn said. “The garden center has brought in a whole new crowd, especially folks moving in from Houston and building homes out in the Round Top area.”

Through all the growth and long hours, they’ve never lost sight of what’s most important. Lane and Robyn have three kids and six grandkids who all live close by, and they make time for hunting trips, weekends at the lake, and just being together. Looking back, they’re proud of what they’ve built, but they’re not ones to make a big deal out of it. They’ve still got work to do.

“We’ve never lived outside our means, and we’ve worked hard for what we have,” Lane said. “We’re grateful for it. It’s been good for our family, no doubt, and we’re proud to keep it going. We’ll keep working hard as long as folks need us.”

CONTACT YOUR DISTRIBUTOR SALES REPRESENTATIVE TO PLACE AN ORDER

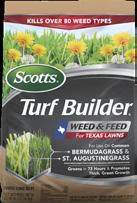

UNMATCHED LAWNS INNOVATION

Guaranteed results for evolving consumer needs

• Scotts® Turf Builder® Triple Action

• Scotts® Turf Builder® Rapid Grass

• Scotts® Turf Builder® Thick'R Lawn

Great products across Soils and Plant Foods for continued gardening success!

• Miracle-Gro® Shake 'n Feed® Extended Boost

• Miracle-Gro® Organic Raised Bed & Garden Soil

• Miracle-Gro® Organic All Natural Mulch

• Miracle-Gro® Tropical Houseplant Food

• Miracle-Gro® Tropical Potting Mix

• Scotts® Turf Builder® Weed & Feed for Texas Lawns

RELIABLE CONTROLS FOR PEST & WEEDS

New and expanded solutions to help you enjoy your home and yard to the fullest!

• Roundup® Dual Action Sure Shot Wand

• Roundup® Weed & Grass Killer₄ Concentrate

• Ortho® Fire Ant Mound Blitz

• Tomcat® Repellents Rodent Repellent

• Ortho® Home Defense MAX® Indoor

• Ortho® Bug-Geta® Snail & Slug Killer2

• Ortho® GroundClear® Weed & Grass Killer

March 1–May 31, 2025

It’s time to save on our expanded range of products. The Lawn Kickstart Program through My Envu Rewards offers rebates on the solutions you need. You’ll get the trusted defense to drive callbacks down and put a stop to weeds and crabgrass. Sign up today and save on a portfolio designed to keep your business moving forward.

Scan to see how you can start saving

Looking for a way to expand your profits and the services of your pest control business? Consider adding termite baiting!

Over the past 10 years, Pest Management Professionals (PMPs) have provided an increasing number of subterranean termite baiting services. In 2011, termite baiting comprised about 13% of U.S. termite treatments. By 2021, that percentage had increased to 35%. (Specialty Products Consultants, 2021). It’s obvious by the numbers that baiting for subterranean termites has become a high growth opportunity for PMPs!

There are many benefits to termite baiting, including higher visibility of stations and ongoing protection, higher customer account retention and lower labor inputs required at time of installation (versus conventional liquid treatments). There’s also flexibility for when termite baiting systems go into the ground, since they can be installed pre-construction or postconstruction (please refer to the bait system label). To see an example, review the Trelona® ATBS Annual Bait Station label, which can be accessed at http://www.cdms.net/ldat/ ldE28005.pdf. A major tenant of Trelona Annual termite baiting is that structural protection is afforded by adherence to the label directions and through the elimination of the subterranean termite colonies that locate and feed upon the bait within the stations.

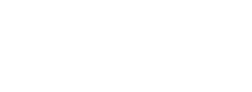

As with all professional pest control services, attention to detail by the PMP is key to providing highly effective services. With the right tools for the job, the quality of a termite baiting service is enhanced. Here are the tools we recommend the when installing Trelona ATBS Annual Bait Stations:

1. Comprehensive Site Diagram (digital or hard copy)

2. Measuring device (tape, wheel, etc.)

3. Smartphone (camera for pictures)

4. Long soil probe or screwdriver (looking for rocks, sprinkler lines, etc.)

5. Soil auguring tool (manual, gas or electric powered drill with augur bit)

6. Hard surface coring drill and drill bit (can be hired out to a 3rd party)

7. Personal Protective Equipment (ear, eye and hand protection for power augers and hard surface coring)

8. Station / cartridge scanning device (if scanning into company software system)

9. Permanent marker or paint pen (numbering stations and/or cartridges)

10. Spider tool (open the Trelona stations)

11. Siesta® Insecticide Fire Ant Bait and/or Advance ® 375A Granular Ant Bait (reduce ant activity)

12. Termidor ® Termiticide (option to treat termite active areas (foam or liquid dilutable))

To make ongoing termite bait station inspections a snap, gather and have the following tools on hand:

1. Tote or bucket caddy (carry tools and supplies)

2. Comprehensive Site Diagram (digital or hard copy)

3. Smartphone (camera for pictures)

4. Knee pads (or kneeling pad)

5. Long soil probe or screwdriver (locating mulch or debris covered stations)

a. RFID Station Locator (another option for covered stations)

6. Spider tool (to open the Trelona stations)

7. Cotter pin/key puller (retrieve cartridges from stations)

8. Clean out auger or melon baller (remove obstructing soil from interior of station)

9. Brush with firm bristles (remove obstructions from station top for lid replacement)

10. Medium size nail claw (cartridge removal)

11. Extra station lids (replacements)

12. Extra Trelona bait cartridges (replacements)

13. Extra Trelona Stations (additions or replacements in vehicle)

14. Soil auguring tool (manual, gas or electric powered drill with augur bit-in vehicle)

15. Station / cartridge scanning device (if scanning into company software system)

16. Permanent marker or paint pen (numbering stations and/or cartridges)

17. Advance ® 375A Granular Ant Bait (eliminate ants from station(s)

18. Termidor ® Termiticide (option to treat termite active areas (foam or liquid dilutable))

items. Trelona ATBS Annual Bait Stations, training materials and collateral can be found at https://pestcontrol.basf.us/ products/trelona--atbs.html.

Good Luck and Let’s Be Careful Out There!

Dr. Bob Davis, Technical Services Representative, BASF Professional & Specialty Solutions.

Contact your BWI sales representative to purchase these

Mavrik Aqua ow® Insecticide/Miticide, Enstar® AQ Insect Growth Regulator, and ClearLeaf® Insecticide/Miticide o er versatile solutions, providing immediate and long-term control of insects impacting owers, foliage, cuttings, ornamental plantings, trees, shrubs, and plantscapes. Visit

about protecting your profits.

FoxFarm

ICL

Innovacyn ........................................................

Jacto

Medina Agriculture

Merck Animal Health

Michigan Peat/BAACTO

Miller Manufacturing

Nisus ..........................................................

Nursery Supplies

PBI-Gordon ..................................................

Premier Tech Horticulture

Queen Horse Bedding

Santa Fe Dehumidifiers

Scotts Miracle-Gro

Tarter Farm & Ranch US

Sludge, gunk, crud.

Whatever you call it, clogged irrigation emitters are a big problem that will cost you big money. Low-end water-soluble fertilizer can gum up your lines, resulting in more down time and wasted labor and water. Peters Professional is a premium product that delivers premium results. Its pure formulation keeps irrigation lines clean while delivering the highest quality nutrition available. Keep your lines and profits flowing—contact ICL today.

Learn more.

• Use on vegetables, roses, flowers, trees, shrubs and ornamentals

• Kills and protects up to 8 weeks

• Labeled for over 300 insects • Controls above and below ground