1 minute read

focused on safety

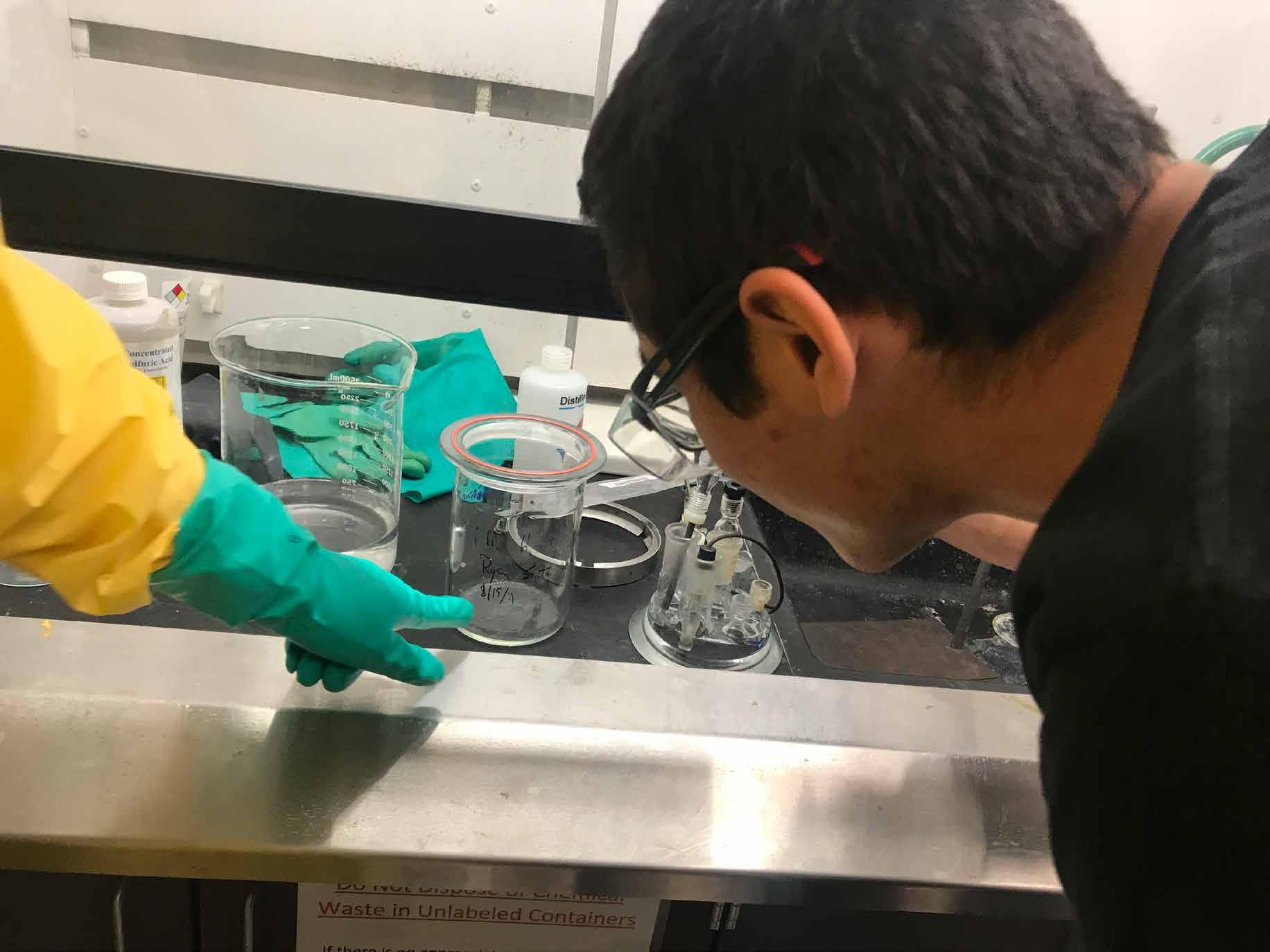

Student technician helps keep Materials Engineering Department running smoothly

by Emily Slater

Advertisement

Materials engineering major Jacob Reed plays a critical role as the department’s student safety technician, managing chemicals and making sure standard operating procedures are followed.

Students in the Materials Engineering Department learn about the various materials that make up everything from rockets and computer chips to electric vehicles and biomedical devices. They also design and test new materials, which involves significant lab time and much more chemistry than other engineering majors.

As a result, MATE students regularly handle a variety of chemicals.

“Chemicals are a means to an end,” said Reed, a third-year student who was hired as a safety technician in 2021. “As materials engineers, we can use them as a tool to get the effect that we need.”

One of the effects, he said, is etching metal — the department’s most common use of chemicals — to look at the microstructure of the material.

He added that the general goal is to get MATE students into the lab as soon as possible, because so much of their learning will happen in that space.

As safety technician, Reed spends even more time in MATE labs.

“I am more comfortable with all the lab equipment than most people I know,” he said with a grin.

Outside the lab, he coordinates with students, faculty and Environmental Health and Safety to make sure regulations are met and safety plans are followed.

“I make sure that everyone is on the same page,” he said.

Much of Reed’s energy is spent following protocol to safely dispose of chemicals.

“A big chunk of my time is spent taking care of hazardous waste for the department,” he explained.

Reed also organizes chemicals for disposal and storage, labeling containers and positioning them so that oxidizers are not near flammables, for example.

He aids students who must fill out safety documents for projects, including one that involved taking samples to the Cal Poly Pier to see how the materials corroded in seawater.

Because he is a student, Reed said his peers feel comfortable texting or calling him with their questions. He welcomes those queries because they may prevent someone from taking an unsafe action.

The more responsibility Reed has taken on, the more faculty have come to rely on him, which he also appreciates.

“I’ve had the chance to build relationships with faculty and, also, build my own confidence coordinating people,” he added.

Reed is on track to graduate in 2024 to pursue a career in corrosion, but not before he passes down his hard-earned knowledge to a new safety technician as is the practice in the MATE Department. n