THE OFFICIAL MAGAZINE OF AUSTRALIA'S SUGARCANE INDUSTRY Price $16.00 Learning the ropes TAKING CONTROL INNOVATION PROVIDES SWEET SOLUTIONS Mossman's devastating news Spotlight on varieties April 2024

®

POUNCE ON OUR MOST POWERFUL PUMA + AFS CONNECT.

+18% FOOTPRINT

66 dBA QUIETEST PUMA

+11% MORE POWER

+8% ENLARGED CAB

A USTRA L IAN MADE

Editor:

Robyn Devine

Design & classifieds:

Eleanor Fraser

Articles appearing in Australian Canegrower do not necessarily represent the policies or views of CANEGROWERS.

Published monthly by: CANEGROWERS, GPO Box 1032, Brisbane, Queensland 4001 Australia.

ABN 94 089 992 969

Telephone: 07 3864 6444

Email: editor@canegrowers.com.au

Website: www.canegrowers.com.au

Subscriptions

Yearly subscriptions for 12 issues (postage included)

Within Australia: $190 inc GST Overseas (AUD): $290

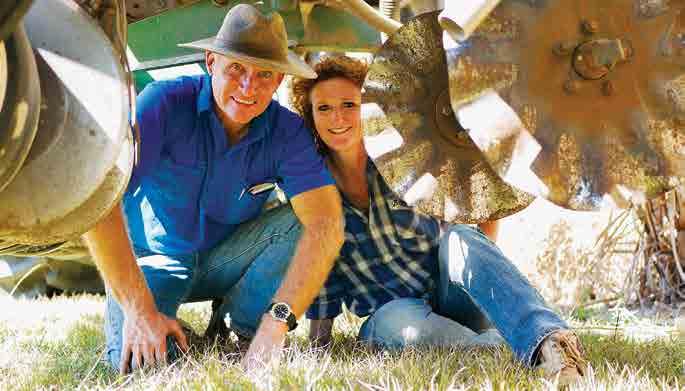

COVER IMAGE

Innisfail grower Joe Zappala found alternative solutions when cane varieties were scarce.

Photo credit: Renee Cluff

Read more on page 24

04 News briefs Thai-Australia Dialogue provides industry opportunities 05 What next for Mossman growers? CANEGROWERS continue discussions for 2024 season 06 Strategic leadership Policy Council continues to ask the hard questions 09 Getting to grips with load restraint NHVR are now responsible for enforcement in Queensland 10 It is a dynamic industry! Dominated by expectations of growth and diversification

Greenhouse gas emissions are the hot topic What does this GHG mean for growers and the industry

Soybeans are a sweet complement Growers crop diversification is helping soil health 22 NFF seek a common sense approach Biosecurity Protection Levy is simply not fair for farmers 24 Innisfail grower takes control One grower's success with tissue culture plantings 34 Regional round-up 40 Policy updates 44 Legal updates 47 Classifieds 44 Rainfall report

14

16

NEWS BRIEFS

QSL CEO ANNOUNCES RETIREMENT

Queensland Sugar Limited (QSL) Managing Director and Chief Executive Officer (CEO) Greg Beashel has announced his retirement and will step down from 30 June 2024.

Mr Beashel’s impending departure will conclude more than 24 years’ service at QSL, including 12 years as CEO and Managing Director, where he played an integral role in the introduction of Marketing Choice for Queensland cane growers.

QSL Board has advised that Mark Hampson has been appointed as QSL’s new CEO and Managing Director from 1 July 2024. Mr Hampson has been with QSL since 2017 and is currently QSL’s General Manager Marketing, where he is responsible for QSL’s Marketing, Risk Management, Treasury, Grower Services and Supply Systems teams.

NEED A NEW PODCAST?

Did you know that Australian growers are the only sugar producers in the world fully exposed to a world sugar market which is distorted by interventions such as price supports and subsidies in other producing nations.

But CANEGROWERS is fighting to make sure Australian sugar gets the recognition it deserves in all trade agreements. Check out the latest episode of the Around the Paddocks podcast on the CANEGROWERS website or from your podcast listening program.

THAI-AUSTRALIAN DIALOGUE

In February, CANEGROWERS Chair Owen Menkens, Vice-Chair Joe Marano and Chief Executive Officer Dan Galligan travelled to Thailand where the 11th Thai-Australia Sugar industry Dialogue was held.

This annual gathering is an opportunity for the Thai and Australian sugarcane industries to consult and cooperate on issues of importance to both countries.

Mr Menkens co-chaired the dialogue with discussions including sessions on market developments, trade technical matters on the diversification opportunities in the bioeconomy, sustainability and emissions reporting, and research and development on the agenda.

The Thai industry is significantly larger than Australia’s industry and is more advanced in some areas in particular the milling sector.

The Australian sugarcane industry does have an edge in areas like mechanised harvesting and sustainable sugar. In fact, the Thai industry has just introduced a best practice program for farms which they freely admit is a carbon-copy of our Smartcane BMP project.

CANEGROWERS was joined in making presentations with Queensland Sugar Limited (QSL), Sugar Research Australia (SRA) and the Australian Sugar Milling Council (ASMC).

Mark Hampson (QSL), Owen Menkens ( CANEGROWERS Chair) and Greg Beashel (QSL) at Port of Townsville July 2023

the official magazine of australia's sugarcane industry 4

MOSSMAN GROWERS URGED TO CONSIDER OPTIONS IN WAKE OF MILL COLLAPSE

Mossman growers have been urged not to make any major decisions about the management of their 2024 cane crop until any options for successfully harvesting the crop have been fully exhausted.

CANEGROWERS is continuing discussions with the Administrator, the State Government and other potential stakeholders to look for the best possible outcome given the circumstances.

“Local CANEGROWERS representatives are still working with a number of parties behind the scenes to see if there is any way we can get this year’s crop off,” CANEGROWERS CEO Dan Galligan said.

“I know growers are frustrated and feeling very pessimistic about the future, but I would urge them not to make any decisions until the dust settles and all options have been exhausted.”

The small north Queensland community was dealt a devastating blow late last month, with a mystery investor pulling the plug on plans to purchase the local sugar mill, sending the region’s single largest employer into liquidation.

The mill’s parent company, the Daintree Bio Precinct Group, had been facing liquidation since going into voluntary administration last November.

The company received a lifeline on 29 February, when creditors supported a proposal put forward by an unnamed investor who stepped in at the last minute with plans to save the mill. But those plans collapsed on 21 March, with the investor backing out of the deal just before the end of a 15-business day statutory deadline.

“It’s heartbreaking, not just for growers and the local sugar industry, but for the whole Mossman community,” CANEGROWERS Mossman Chairman Matt Watson said.

“Local growers have been backing this business for years through investment in our crops and in the mill itself, and we had high hopes when this investor approached the company administrator with a plan to save the mill.

“They laid out their plans for bringing the mill back to profitability over the next four years, before transitioning into a green energy hub.

“To have those hopes crushed at the last minute and for the investor to simply walk away from the community is just devastating.”

CANEGROWERS immediately called on the State Government to honour its commitment to provide the $12 million in funding, announced by Premier Steven Miles at a Community Cabinet meeting in Cairns on 28 February. However, growers have been left in limbo, with the government announcing that money would go to a ‘Transition Program’.

The initial response would be focused on helping “workers find new jobs, access upskilling or training, as well as counselling services” a government statement said.

CANEGROWERS CEO Dan Galligan said many local businesses would suffer if this year’s crop was not crushed.

“Growers have already invested more than $14 million into this year’s crop and the harvest is rapidly approaching. We need the government to come through on its funding commitment so that growers can recoup as much of that money as possible, otherwise a lot of families and businesses in the town will go to the wall,” Mr Galligan said.

“This is not just about growers getting paid, it’s also about mill workers, suppliers, tradies, businesses of all shapes and sizes, right across the region. Growers have put millions into this crop, but if they can’t get it harvested, more than $40 million will be lost to the community.

“Now is the time for government to step up and support the entire community by ensuring we can get this crop off,” he said.

At the time of printing the State Government had agreed to meet directly with cane growers in the region to discuss the transition package and options for the management of their crop.

5 APRIL 2024 – VOLUME46/NUMBER 4

STRONG STRATEGIC DIRECTION

The Policy Council gathered in Brisbane during March to discuss the opportunities and challenges facing growers and the industry.

CANEGROWERS Policy Council is made up of 19 growers nominated by the district companies and provides strategic guidance for the CANEGROWERS group and industry policy as it relates to the grower community. The Council meet formally three times a year with frequent and ongoing communication on key issues at other times.

At this meeting grower representatives asked the hard questions about election policies, rating practices and load restraints and much more when Opposition Leader David Crisafulli MP, Shadow Ag Minister Tony Perrett, Valuer General Laura Dietrich, and the National Heavy Vehicle Regulator’s Jennifer Rotili addressed the CANEGROWERS Policy Council meeting.

Sugar Research Australia (SRA) also provided updates on their research and development projects implementation.

the official magazine of australia's sugarcane industry 6

NEW FACE FOR CANEGROWERS BOARD

Tully grower, Bryce Macdonald, is the first in his generation to grow cane and the first to admit that agriculture, in particular the sugarcane industry, has supported him throughout his life.

Bryce began growing cane in the tropical north when he purchased his first farm in 2009, he has always been a strong community advocate for the Tully region. He was elected to the Tully CANEGROWERS Board in 2019 and in 2020 he joined the Queensland CANEGROWERS Policy Council as the district’s grower representative.

At the March Policy Council meeting held in Brisbane, Bryce was appointed to a seat on the Queensland Cane Growers Organisation’s ( CANEGROWERS ) Board of Directors. He was elected to the vacant position left when Stephen Calcagno, from CANEGROWERS Cairns Region, stepped down earlier this year.

Bryce is very proud of the industry and his local community and wants to be part of the leadership team to ensure a healthy future.

“Why become a board member? Because everything I do is, and has been, supported by and related to the sugarcane industry. I want to ensure there’s a sustainable future for the industry and the community,” Bryce said.

“Agriculture in general, but the cane industry specifically, is susceptible and vulnerable to many diverse challenges, whether that be environment, regulations, input costs, the fluctuations of global sugar pricing or weather events.

“There’s always an issue or two impacting the industry and its important to be part of the voice and to provide strategic direction.

“I have never grown better cane than since I joined CANEGROWERS ,” Bryce said.

“I have gained so much knowledge and understanding from organisations like Tully Cane Productivity Services, Sugar Research Australia, Tully Sugar and CANEGROWERS .”

Bryce believes that CANEGROWERS is an important resource, an active unified peak body talking to government and community to represent growers and the industry.

“The Policy Council and the Board are a collective that have been put there by membership to give direction to our industry and to secure the future. I am dedicated to this new role.”

7 APRIL 2024 – VOLUME46/NUMBER 4

NHVR Load Restraint Summary

When cane is transported in a heavy vehicle—a vehicle with a GVM over 4.5t—then drivers and parties in the Chain of Responsibility must comply with the Heavy Vehicle National Law requirements about load restraint, among other obligations.

Load restraint is the subject of a specific provision in the HVNL. It is also a component of the primary duty, the broad safety duty that applies to parties in the Chain of Responsibility (CoR).

Section 111, HVNL—Loading Requirements

This provision creates an offence for failure to comply with the “loading requirements” which are set out in Schedule 7 of the Heavy Vehicle (Mass, Dimension & Loading) National Regulation and include the following:

Load must not be placed on a heavy vehicle in a way that makes it unstable or unsafe

Load must be secured so it is unlikely to fall or be dislodged from vehicle

An appropriate method must be used to restrain the load

For more detail about appropriate methods, refer to pp 88-90 of the www.nhvr.gov.au/road-access/massdimension-and-loading/loading#guide. For loose loads and agricultural products, it recommends containment, or covering the load.

Another way of demonstrating that an appropriate method has been used, is to prove that the load will not move to the extent that it makes the vehicle unsafe or unstable, nor fall from the vehicle when subjected to the forces described in the “Loading Performance Standards” ie:

0.8g deceleration in a forward direction

0.5g deceleration in a rearward or lateral direction

0.2g deceleration in a vertical direction relative to the load (for uncontained loads)

Evidence that a load does not meet the loading performance standards would be evidence of a breach of section 111. There is also an evidentiary provision in the HVNL—s115—which states that evidence that a load or part of a load has fallen from a vehicle is evidence of a breach.

Penalties for breaches of section 111

Note: This offence can apply to a driver and to a person who permitted the driver to use the heavy vehicle when its load was not compliant.

There are three categories of breach for this offence, each with a different maximum penalty.

Minor or substantial infringements can be issued by an authorised officer at the roadside. They typically impose a fine that is 10% of the maximum. Severe infringements can only be dealt with by a court. An authorised officer will issue a court attendance notice or similar.

Penalty amounts are indexed annually. NHVR publishes up to date information on its website.

https://www.nhvr.gov.au/document/262

Chain of Responsibility

Businesses and individuals who consign, receive, pack, load, or unload goods on a heavy vehicle, or who contract, employ, or schedule heavy vehicle drivers, or who manage premises where five or more heavy vehicles are loaded or unloaded each day, are parties in the Chain of Responsibility. This means they have a primary duty to ensure, so far as is reasonably practicable, the safety of their transport activities. This is a duty that is shared by all parties. Executives of businesses that are CoR parties have a separate executive duty, to ensure that their business or organisation complies with its primary duty.

The loss of sugarcane billets and trash on public roads could pose a risk to road users.

CoR parties are not automatically liable for other parties’ failures, but each of them must be doing what is reasonably practicable to eliminate the risk that sugarcane billets and trash will fall from vehicles or to minimise that risk so far as is reasonably practicable.

NHVR has published guidance about load restraint for parties in the Chain of Responsibility: www.nhvr.gov.au/ safety-accreditation-compliance/chain-of-responsibility/ regulatory-advice/loading-and-load-restraint

For more information visit nhvr.gov.au or contact the NHVR via phone at 13 NHVR (136487) or email at info@nhvr.gov.au.

max fine: Minor risk infringement $3,771 Substantial risk infringement $6,310 Severe risk infringement $12,600

GETTING TO GRIPS WITH LOAD RESTRAINT

In 2014 the Heavy Vehicle National Law (HVNL) came into effect, providing rules and oversight over the loading and transportation regulation of heavy vehicles, although the enforcement of the law did not change and remained with the Queensland Department of Transport and Main Roads (TMR).

On 20 April, this year the NHVR will take over responsibility for the enforcement of the law in Queensland.

CANEGROWERS has been advised that the 2013 Guide for Loading of Sugar Industry Cane Haulage Units is unlikely to be in full compliance with the NHVL and load restraint regulation. With the withdrawal of the guideline, some changes to load restraint methods will be required, although the current practice of using freeboard may be sufficient in certain low speed environments.

The National Heavy Vehicle Regulator (NHVR) have provided a summary of the relevant load restraint NHVL and regulations on the opposite page.

CANEGROWERS has met with representatives from the NHVR and TMR to understand the NHVR position and develop an industry response.

This is clearly a whole of industry issue and CANEGROWERS has led the formation of a coordinated industry task group to work on the issue. To start this process, we have met with milling company cane supply managers to ensure everyone understands the issue.

This is clearly a whole of industry issue

The goal is to work together as an industry to communicate to NHVR the complexity of the current systems to move 30 million tonnes of cane and identify suitable and cost-effective methods of compliance with the NHVL.

To this end CANEGROWERS has submitted a project application to the Heavy Vehicle Safety Initiative to assist with the development of technical solutions and advice and a communication plan for the industry.

CANEGROWERS is organising a meeting with the CEO of the NHVR to ensure that there is a smooth transition with a reasonable process to meet compliance.

Further CANEGROWERS will also meet with State and Federal Ministers and their opposition counterparts to inform them of the matter and the potential risks to the industry.

There is a lot to do, and we will keep our members updated as further information comes to hand.

9 APRIL 2024 – VOLUME46/NUMBER 4

SUNSET NO MORE

BY DAN GALLIGAN, CEO, CANEGROWERS

“It’s a dynamic industry. There is always something happening, and adapting to change and looking ahead is key to navigating the challenges and opportunities.”

That is the response I give to friends, family and colleagues when they ask me what I love about working at CANEGROWERS and being part of the sugarcane industry.

Events over recent weeks have made me really think about just how much change has occurred and how much is still ahead of us.

Not more than four or five years ago, certainly just before COVID, it would not be uncommon for me to meet with government officials or other agricultural industry reps who would be entirely focused on the demise of the industry.

The general focus was on issues that characterised sugarcane as an industry on the way out, a sunset industry.

Issues such as environmental performance, sugar consumption and sugar tax, or the perennial issues of profitability and succession planning.

Fast-forward a few years and, while those issues have certainly not disappeared, they are being well managed, and I can report that meetings are no longer about sugarcane being a sunset industry. Instead, they are dominated by expectations of growth, diversification and expansion.

Most of this expectation is driven by a rapidly growing interest in developing the bioeconomy, and sustainable aviation fuel (SAF) in particular.

My recent engagements with Bioenergy Australia at the Australian Renewable Fuels week proved just how large the market is and how prominently discussions are focused on the future use of sugarcane as a feedstock.

Always referenced with the comment that it would have to be certified sustainably produced and reliably sourced “feedstock”.

CANEGROWERS has been active in these discussions since they began. Not least, when in 2021-2022, we developed and released the Sugar Plus industry road map, along with industry colleagues from Australian Sugar Milling Council, Sugar Research Australia and Australian Cane Farmers Association.

We have since completed a number of reports around the market demand and technical opportunities from biofuels and bioplastics.

These reports built on the exceptional efforts of growers to have over 42% of the crop certified as sustainably grown via Smartcane BMP.

It will see the sugarcane sector well placed and ready for action when speculation turns into production from the many developers and refiners of biofuels.

Our work at CANEGROWERS will continue, as we talk to industry players about their future needs with respect to feedstock.

But our focus will remain on how we support growers to ensure they achieve a better business outcome from this opportunity.

The numbers associated with the demand for SAF production are huge. This will be global transition, and demand for feedstock for fuel will equally be a global challenge.

No matter which way you look at it, regardless of whether we are growing sugarcane for food or fuel, we have hundreds of thousands of hectares of stored energy in sugarcane that growers across this state sustainably grow every year single year.

If managed well, it should be a new dawn for everyone in the industry.

the official magazine of australia's sugarcane industry 10

Women

Powering Agriculture

Women

Women

Powering Agriculture

P owering Agriculture

RSVP & Pay

Last chance to register

HERBERT

GAINING INSIGHT

Seeing first-hand behind the scenes what is happening in the industry, increasing networks, and gaining insight are key outcomes for a group of enthusiastic young growers from Herbert River.

CANEGROWERS Herbert River Young Growers Development Group ventured south this month visiting the CANEGROWERS Brisbane office, Sugar Research Australia (SRA) Woodford’s Research Station and the CANEGROWERS Rocky Point district.

The group had an intensive itinerary to get through over a three-day period but the passion for their industry, from the growers, the organisations and the people they visited helped to ensure the trip was a great success.

Brenden Accornero, from Ingham, said the opportunity to see first-hand diseased cane and understand the robust testing and trials that SRA do

was very instructive, to gain a greater knowledge of biosecurity and its challenges and will help him when he goes back home.

“We have been looking at the different diseased cane, and learning about the susceptibility of the different varieties, they showed us what the symptoms actually looked like, a lot of the times we don’t get to see that, and we don’t know what to actually look for,” Brenden said.

Rebekah Pace from Pace Farming at Crystal Creek and Bambaroo and has been growing sugarcane since 2018 after she left high school, she said the trip had been both enjoyable and informative.

“It’s a good bunch of people, everyone is asking questions and they’re getting their questions answered,” Rebekah said.

“It’s important to learn new things, you can never stop learning.”

Rebekah highly recommends other young growers to step up when these opportunities are available to gain more knowledge.

“There’s always things to learn and ways to innovate, I’d 100% encourage other growers to be more involved.”

12

the

official magazine of australia's sugarcane industry

While in the Rocky Point district the group visited the Rocky Point mulching facilities, where owner Josh Keith showcased their facilities. The Group were also given a tour through the Rocky Point Mill operations. There was also a great grower-to-grower time when they met up with other young growers from CANEGROWERS Rocky Point.

Todd Erkkila from Abergowrie was suitable impressed with not only the operations of the mulching facility but the possibilities that are available within the industry.

“It was a good eye-opener to understand that there is more to sugarcane than just sugar,” Todd said. This young growers’ group is just one of several districts that are actively visiting other CANEGROWERS districts this year, taking the opportunity to extend networks and gain a better understanding of the industry, as a whole.

Over page: The young growers received a tour of the Rocky Point Mill complex

This project has been funded by the Integrated Engagement and Capacity Building project through the Queensland Government's Queensland Reef Water Quality Program

Top left: Dr. Shamsul Bhuiyan provided insight into the disease trial at SRA's Research station in Woodford while top right the group were fascinated by the operations and opportunities at the Keith Family mulching facilities at Rocky Point

At least double most other hard We solve your welding and wear problems Phone today: 0413 700 175 | E: mick@ccwelds.com | www.ccwelds.com Tracks 607 TIC Extractor Fan Blades 160-OA Extractor Walls 160-OA Side Walls 64-0A/151-OA Points FE40+ Shoes 160 -OA Divider Rollers 64-0A Chopper & Feed Rollers 64-0A/151-OA Base Cutter Discs & Blades FE40+/ 160 -OA CORODUR WIRE • FE40+ Tungsten Carbide - initial point of contact • 160-0A Extreme Abrasion • 64-0A High abrasion/will run out of position • 607TIC High load bearing + impact/moderate abrasion • 151-OA Smooth Running Chrome Carbide Wire

13 APRIL 2024 – VOLUME46/NUMBER 4

FROM THE CHAIR

BY OWEN MENKENS, Chairman, CANEGROWERS

It is hard to go anywhere these days without hearing about greenhouse gas emissions.

All levels of government, both here and around the world, are looking at ways to legislate a reduction in greenhouse gas emissions.

They are doing this by forcing large companies to report their emissions regularly. This includes not only their own emissions, but also the emissions of linked entities in their supply chain (scope 3).

Unfortunately, this means agriculture will get dragged into this emissions reporting process, even though we are still exempt. At CANEGROWERS , we decided that there is no point discussing emission reduction targets unless you know where growers have come from in our farming practices.

CANEGROWERS commissioned a report into the greenhouse gas emissions on farms in the Wet Tropics, Burdekin, and the Mackay regions, inputting all activities that relate to emissions.

When compared to a similar analysis done in the early 2000s, the report found a huge 30% reduction in on-farm emissions during that period due to practice change.

How is this possible you might ask?

As modern growers, we use practices that are not only more efficient they also reduce emissions.

A lot of the efficiency gains we have made on-farm were triggered by economic factors, like a low world sugar price.

It also means that we are one of the lowest emitters of CO2 per tonne of cane in the world. We have a good story to tell, and we should be proud of our current achievements.

The issue is, now that we have an assessment of emissions, how do we continue to reduce them in the future?

Fertiliser and fuel are the main area of emissions on farms and farmers know that if we put on less fertiliser than the SIX EASY STEPS methodology, we may all go broke.

It will come down to technology that probably hasn’t been developed yet. But there is still time for these changes to occur so no one should panic just yet.

Fertiliser manufacturers will have pressure on them to come up with lower emission blends as well.

The area which is concerning is the soil carbon space. There are a lot of tyre kickers out there trying to sell dreams that are not properly researched.

I would ask growers to think very carefully before signing up to programs that are not backed by good science and don’t focus on a profitable and productive farming businesses.

Beyond the individual decision of each farmer, as an industry, we don’t want to sign up to unrealistic emissions reductions targets. This is something some other industries have ended up doing.

We need a science-based approach because eventually all these processes must be tested against the needs of the industry.

I think we should be proud of what we have achieved as growers and not be reluctant to tell our story. We can play a sensible part in the need to reduce emissions, but we must be in the driver’s seat on how.

CANEGROWERS will continue to lobby for sensible rules in this space while also pushing the positive messages about our industry’s achievements.

Take your spraying program to the next level of accuracy and performance with RightSpot™ precision technology from Ag Leader. Suitable for retrofitting to most self-propelled or trailed sprayers, RightSpot utilises blended pulse technology to maintain consistent droplet size and coverage at all operating speeds. With independent control of up to 144 nozzles, automatic turn compensation and automatic reticulation, priming and flushing, RightSpot significantly reduces input costs and the potential for spray drift. Contact your local Ag Leader dealer and find out how RightSpot can optimise the efficacy of your spraying program.

Ag Leader® and Ag Leader Technology® are registered trademarks of Ag Leader Technology Incorporated. RightSpot™ is a trademark of Ag Leader Technology Incorporated. ©2024 Ag Leader Technology Incorporated. AGL24200. MAKING FARMING EASIER YOUR NOZZLE-BY-NOZZLE ADVANTAGE

CONSISTENT DROPLET SIZE INDIVIDUAL NOZZLE CONTROL WIDE SPEED RANGE AUTOMATIC TURN COMPENSATION HIGH VISIBILITY TOUCHSCREEN Halpin Precision Ag

DMD Ag Solutions (Mackay) Farmacist (Burdekin)

(Bundaberg)

NEW PUSH TO SWEETEN SOYBEAN PLANTINGS

BY REBECCA THYER Supplied by GRDC GroundCover™

From a project instigated by a mayor in Queensland’s tropics to a new industry development officer further south, there is a push to reinvigorate the soybean industry in the northern region.

When he was elected mayor of the Hinchinbrook Shire Council in 2016, Ramon Jayo’s platform was to diversify the region’s economy and reduce its reliance on sugar.

In this part of tropical north Queensland, sugarcane has been the number-one crop since it was first planted in the 1860s.

Mr Jayo says sugarcane is “bomb proof”, which suits the area’s volatile weather. “We can have no rain for six months and then 16 inches (400 millimetres) overnight. Sugarcane can handle that.”

However, as a sugarcane grower himself, he knew that practice changes, including controlled-traffic farming, would help improve the chances of alternative crops also having success. He instigated a ‘Grain in the Rain’ project with the Queensland Department of Agriculture and Fisheries (DAF).

“I wanted to show that we could grow something in conjunction with and complementary to the sugarcane cycle, diversifying our economics. We needed an alternative cash crop that would give us a cash boost while providing a break crop and enhancing soil quality.”

The project is one example of a recent push to reinvigorate the soybean industry across the state, with DAF agronomists and industry development officers playing a key role.

Mr Jayo is working closely with DAF’s Brock Dembowski, while further south DAF’s Carla Atkinson and Neil Halpin are working to boost soybean growth around the Burdekin, Mackay and Bundaberg. Soy Australia has also appointed its first-ever industry development officer—well-respected soybean agronomist and grower Judy Plath.

GRDC grower relations manager— north—Vicki Green says soybeans are a great fit in high-rainfall coastal and hinterland areas. To support growers as they explore increasing soybean production and the crop’s fit in the coastal farming system, GRDC has

Right: Ramon Jayo

Right: Ramon Jayo

the official magazine of australia's sugarcane industry 16

Far right: Soybeans are pushing north into Queensland’s Ingham region. (credit Brock Dembowski, DAF)

invested in two projects. One is with DAF in Queensland and the second with DPI in New South Wales, both focused on growing agronomic knowledge. Soybean’s fit with cane Together, DAF and GRDC have worked closely over the past 20 years with the region’s sugarcane growers and industry to increase soybean production as a means of diversifying operations, improving soil health and reducing nitrogen fertiliser use in the Great Barrier Reef catchment area. Today, the growing alternative protein market gives this added momentum, with Australian-grown soybeans being used in non-meat alternatives.

For Townsville-based Brock Dembowski, an industry development officer with DAF, the aim is twofold: to diversify sugarcane growers’ portfolios and de-risk the option of planting soybeans. “And we’re pushing further north of the Burdekin into Ingham, a traditional cattle and cane area,” he says.

Mr Dembowski has been working with Mr Jayo and other growers in the Hinchinbrook region and as far north as Mossman, and credits newer varieties Kuranda HB1A, Mossman HB1A and HaymanA, developed by CSIRO’s Dr Andrew James, in allowing this to occur.

“For many of these sugarcane growers, new soybean varieties have given those in the north the opportunity to grow beans. They have been a game changer.”

He says Kuranda HB1A tends to yield an extra half a tonne compared with other varieties. “But HaymanA is preferred by soybean processors as a food grade bean. Its gelling capabilities for tofu are meant to be better.”

That said, Mr Dembowski tells new growers not to worry too much about this. “Soybeans have great benefits to the following sugarcane crop. So, I tell new growers to work back from when they want to harvest and plant the variety that suits that timeframe; aim for crushing and not food grade.

What are the agronomic benefits?

Queensland Department of Agriculture and Fisheries (DAF) principal farming systems agronomist Neil Halpin says research findings show soybeans are a great fit for those wanting a legume rotation crop.

“Our department has been involved in a range of soybean research projects over the last 20 years or so and we’ve come to understand just how valuable this legume is in the sugarcane farming system,” he says.

Cane growers can expect a 10 per cent yield increase in the cane crop following a well-grown soybean

crop, compared with a ploughout replant.

DAF research has also shown that a well-grown crop of soybeans can return 300 kilograms of plantavailable nitrogen to the soil if green manured.

“Growers who are growing soybeans for harvest can gain extra income from the soybeans and still expect 60kg or more of ‘free’ nitrogen for their next crop,” he says.

The soybean expansion project, jointly supported by GRDC and DAF, is planning to run a bus tour to southern Queensland and northern NSW in early 2024.

CONTINUED NEXT PAGE ‣

17 APRIL 2024 – VOLUME46/NUMBER 4

“If it gets to food grade, that’s great. But often weather impacts during the wet season influence seed quality and market pricing.”

Mr Jayo says the ‘Grain in the Rain’ project has been well received and opened local cane growers’ eyes to other opportunities to better use fallow periods. About 20 young growers are keen to keep growing alternative break crops in the fallow.

“The first-year trials of soybeans, mungbeans and industrial hemp were smashed by drought and then heavy rain. But, since then, a few growers are harvesting food grade soybean and mungbeans.”

Pests and prices

Challenges remain for the northern Queensland region though. “The general feeling is that soybeans are more labour-intensive and riskier than mungbeans,” Mr Jayo says.

“Soybeans have a propensity to attract insect pests. And if they do, we want to spray them quickly. But if it’s been wet, we may not be able to get on paddocks. We’d prefer to use ground rigs but have been trialling some drones too, to get around this issue.”

DAF senior development extension officer Carla Atkinson says this region and south to the Burdekin has also faced the perfect storm for disease pressure in recent years. “Humidity adds to the disease pressure, but we can decrease the likelihood of disease via agronomic choices. We are looking more into that, ensuring growers know about varieties that will tolerate disease,” she says.

Other challenges include traditional cane farm size, Mr Jayo says, and with that header access. “There are limited areas where we can get headers on, so trials have been done on more broadacre areas. A lot of other areas in my region are crisscrossed by rivers and creeks.”

High sugar prices—at $900 a tonne—in late 2023 tend to “make growers forget

about other options”, he says. And with many buyers located in Queensland’s south, logistics can be challenging. But he is positive that pulses have a place in traditional sugar areas. “If we keep at it, the markets will follow.”

The tyranny of distance

Ms Atkinson agrees that freight costs can be daunting. “Freight costs doubled from $100/t to $200/t at one point in 2022,” she says. It means that growers look to alternatives including the feed market and export.

DAF has tried to address this at grower days by inviting local transport companies. “They have had a chat about options. We’ve also had some more local processors come to our meetings, which could help some growers bypass the expensive freight.”

Transport itself is often a new idea for sugar growers. “Sugar growers tend to take it to the nearest mill and there is an extensive rail network for that. They just take it a kilometre or so, always to a train pad area. Soybean marketing is very different; it’s a different mental mindset.”

Two decades of benefits

Jeff and Judy Plath integrated soybeans into their farming system 20 years ago.

Jeff says he saw immediate benefits. “Not only do soybeans supplement our income, but they also improve our soil structure, return nitrogen to the soil, and allow us to reduce cultivation in our farming system.”

The Plaths use a zero-tillage planting system that allows them to plant the soybeans directly through the trash from the previous cane crop.

After soybeans are harvested, the soybean trash is left intact

for as long as possible to protect the soil from erosion, conserve soil moisture, improve soil organic matter levels and allow for the strategic release of the nitrogen stored in the soybean plant material.

Before planting sugarcane, Jeff cultivates the soybean paddock with two passes. “Occasionally the seasonal conditions mean I need to cultivate earlier, or more often, but in general over the last 10 years or more I have been able to plant most of my soybean blocks back to sugarcane with minimal cultivation,” he says.

18

the official magazine of australia's sugarcane industry

Mr Dembowski agrees. “Growers are also often bottlenecked by freight. To increase production in the north, I think we need to continue to focus on local feed markets and look at export opportunities through the Port of Townsville. Supplying local markets reduces freight costs. There’s a chook farm here using an extruder, and many growers will sell to them. On-farm storage buffers this supply, so some growers are putting in silos.”

Retelling the soybean story

To encourage more soybean plantings, the story of soybeans may need to be retold—something that Judy Plath, a grower and soybean agronomist from Bundaberg, is keen to do.

In late 2023 she was appointed as a soybean industry development officer with industry body Soy Australia. The newly created role aims to help boost plantings in coming seasons to meet targets to double annual production over the next decade.

Ms Plath has been involved in the coastal Wide Bay soybean industry for 20 years. “I began promoting soybeans as an ideal legume break crop for sugarcane in the Wide Bay area in 2003. In time I married into a local cane farming family and have seen first-hand the benefits that soybeans offer to our farming system and our bottom line.” She says there was a lot of momentum 20 years ago. “Since then, there has been a lot of change in the sugar industry. We don’t want knowledge lost.”

Those changes include a move to more macadamia plantings. “We’ve lost a lot of growers. A lot of hectares in this area have converted from sugarcane to macadamias. Once a farm is planted to trees, there’s no opportunity to plant something else, such as soybeans.”

Crop competition is another issue, with some cane farmers opting to lease land to horticultural growers,

while some have chosen peanuts over soybeans. “Peanuts are a higher-risk crop, but there’s a higher potential income. However, with the recent jump in soybean prices, soy is definitely worth revisiting.”

Ms Plath says the other challenge has been growers’ age, with many transitioning to retirement. “Fitting in another crop may not be their highest priority. Many will be a one-man band and they focus on their core business, which is cane.”

She says the initial excitement about soybeans needs to be revitalised. “When we first really got excited about soybeans 21 years ago there was a real excitement about them. It was being talked about a lot. There were trials and we were all learning about it.

“All those things created a buzz and kept them front of mind for people. And then, as we became more confident with them, some of those learning opportunities dropped off and they became more of a matter of course.

“Some people kept at it and soybeans became a core part of the farming system every year.”

Ms Plath sees an opportunity to educate the next generation about soybeans and their soil fertility benefits. “There’s plenty of good data available

on the sort of nitrogen returns to expect from a well-grown crop of soybeans, whether it is green manured or harvested.

“Growers can feel really confident in that data and in knowing that if soybeans are grown, they are going to get a fair chunk of free nitrogen which they can allow for in their fertiliser programs.”

Soy Australia chair Paul Fleming, who is a grower from the northern New South Wales region, says the organisation is keen to help build broader awareness of agronomic best practice as well as the economic benefits of soybeans in key growing regions such as the coastal regions of North Queensland, the Wide BayBurnett, the Northern Rivers and Northern Tablelands of NSW and the Riverina region.

“While the Australian soybean industry is small by global standards, it plays an important role in many farming systems across Australia and is increasingly providing a highervalue crop option for growers,” Mr Fleming says.

“Soy Australia believes the demand for non-genetically modified, Australiangrown, good-quality soybeans is strong, but we need to increase production if we hope to develop long-term relationships with our end users.”

19 APRIL 2024 – VOLUME46/NUMBER 4

On-farm storage helps to support local supply chains, while reducing freight costs. (Credit: Brock Dembowski, DAF)

TAKE CONTROL OF YOUR POWER SUPPLY AND COSTS WITH FREEDOM WON AUSTRALIA

Electricity on commercial farms is a critical element for stable and reliable operations.

It is also one of the major cost items in the production of the end product. Having reliable power and control over the cost of it, is instrumental in a successful farming operation.

A growing number of farmers in Southern Africa, who deal with similar weather conditions as those in Australia, and a consistently unreliable and expensive power supplier, have turned to Freedom Won technology to transform their agricultural operations which has reinstated the needed power reliability and saved them money.

“If you had asked me 10 years ago if there would be power the next day, I would have said the odds are very high. If you ask me that today, I’d say there’s a certain chance there won’t be power tomorrow.” So says Lourens du Plessis, owner of Louma farm between Thabazimbi and Koedoeskop in South Africa. Louma Farm engaged Freedom Won and Thaba Solar, a local solar installer, who joined forces to provide Louma Farming with the stability and peace of mind that they urgently needed: to be completely independent from the country’s power provider,

Eskom, and instead rely on their own renewable energy network to power the daily operations of the farm.

Louma Commercial Farming now runs 30,500ha of commercial farming under 70 pivots, which operate on 9MW of solar panels and 8MWh of batteries, with 23km of overhead lines. With this solution, Du Plessis’ high power bills are history and he is saving $240,000 per month. Along with the guarantee of a reliable power supply and energy cost savings, Louma Farms can also be confident that Freedom Won batteries will endure long beyond the warranty period. The batteries will only lose 20-30% of their storage capacity after 18-20 years, as long as they are not discharged more than 50-60% on a regular basis.

Du Plessis has now grown his first wheat crops under solar energy from start to finish and he is very pleased. “I got my tonnes and on top of that, I could rest assured that the pivots would never stop. It was also much easier for my managers in these consistent circumstances.”

Freedom Won offers custom power room solutions in collaboration with local renewable and electrical engineers, tailored to meet your specific operational needs and budget. We provide end-to-end solutions with market-differentiating products for integrated wind and solar energy. Ongoing support is guaranteed for the lifespan of the solution.

Take back control of your own power generation and supply and transform your business. Contact us for a free, no obligation, consultation. We would love to show you what is possible for your business.

Contact us on:

+61 422 251 938 or sales@freedomwonaustralia.com

ADVERTORIAL

the official magazine of australia's sugarcane industry 20

QSL GROWER PRICING UPDATE

Market Update

The raw sugar futures market traded in a relatively narrow range in late February into March as market participants awaited the beginning of the upcoming Centre South Brazil (CS Brazil) harvest. The March 2024 futures contract expired at 22.58 USc/lb with 1.3 million tonnes of exclusively Brazilian sugar delivered to the tape, representing the second largest March contract expiry.

BRAZIL

There has been much debate around the size of the upcoming CS Brazil crop which has experienced below-average rainfall for the last 3 and a half months. The key cane growing region of Sao Paulo has received approximately 700mm of rain in that period, significantly less than the historical average of 1000mm. Whilst the rainfall deficit is expected to hinder the size of the cane crop, the hot and dry weather will likely boost sugar yields in early-season cane and partially offset the reduced

Grower Pricing Update

The highest grower-managed pricing levels achieved across all growing regions using QSL products to date (all gross price actual/tonne) are:

crop size. In conjunction, CS Brazil mills have seen investment in their sugar crystallisation capacity in the off-season due to the 8 USc/lb premium that sugar has been paying over ethanol. The asset upgrades could see the maximum sugar mix increase by 1-2% and produce an additional 1-2 million tonnes of sugar for their industry. With Brazil expected to be responsible for 70% of all sugar exports in the 2024/25 Season, the risks around weather disruptions and logistical issues are heightened. Any interruptions during the upcoming harvesting season will likely result in volatile market action.

THAILAND

Strong sugar yields and additional cane supply has resulted in higher-than-expected production figures for the Thai harvest which has kept some downward pressure on the raw sugar market. In early February many analysts had revised current season forecasts down to 7-7.5 million tonnes of sugar, however in the final stages of the harvest season production has surpassed 8.55 million tonnes.

• 2023 Target Price = $950 / IFC $960 (Mar24)

• 2024 Target Price = $840 / IFC $870 (Jul24)

• 2025 Target Price = $735 / IFC $735 (Oct25)

• 2026 Target Price = $685 / IFC $690 (Jul26)

• 2027 Target Price = $650

Current as at 18 March 2024.

SPECULATORS

Speculators have been largely inactive in the ICE 11 raw sugar futures market over the past month, holding a position of just 88 lots net long as of 5 March. The speculative community appear to be content with non-participation following the mass close out of their large net long position in December which caused the market to collapse 8.5 USc/lb.

CURRENCY

Foreign exchange markets remain largely focused on the commencement of interest rate-cutting programs by global central banks. With inflation in the US services sector remaining sticky, projections for the first rate cut from the Federal Reserve has been delayed from March to June. This change in outlook saw the US Dollar strengthen and push the Australian Dollar below the 65-cent mark in early February. Many economists from large banks are expecting the Australian Dollar to appreciate towards 70 US cents in the second half of 2024 should the US begin cutting interest rates before Australia.

Key Dates:

• 20 April: Last day to achieve pricing allocated to the May 2024 ICE 11 contract through the Individual Futures Contract and Self-Managed Harvest contract. Any unpriced tonnage after this date will be priced by QSL at the next market opportunity.

• 20 April: Last day to price 2023-Season Target Price Contract tonnage. Any unpriced tonnage after this date will be priced by QSL at the next market opportunity.

• 30 April: Last day to nominate tonnage to QSL’s 2024-Season Actively Managed Pool, Individual Futures Contract and Target Price Contract.

Your Trusted Partner Disclaimer: This report contains information of a general or summary nature and is based on information available to QSL from many sources. While all care is taken in the preparation of this report, the reliability, accuracy or completeness of the information provided in the document is not guaranteed. The update on marketing and pricing activity does not constitute financial or investment advice. You should seek your own financial advice and read the QSL Pricing Pool Terms, which are contained on QSL’s website. Nothing contained in this report should be relied upon as a representation as to future matters or that a particular outcome will be achieved. Information about past performance is not an indication of future performance. The information in the report is current as at the time of publication and is subject to change, as the information is based on many assumptions and is subject to uncertainties inherent in any market. QSL does not accept any responsibility to any person for the decisions and actions taken by that person with respect to any of the information contained in this report. This chart captures all pricing achieved as of 18.03.24 by growers from across all sugarcane growing regions using QSL’s Target Price Contract, Individual Futures Contract and Self-Managed Harvest products. Prices quoted at AUD/tonnes actual gross. 2023 Season 2024 Season 2025 Season QSL GROWER-MANAGED PRICING FILLS – 2023, 2024 & 2025 SEASONS 0 20,000 40,000 60,000 80,000 100,000 120,000 140,000 160,000 180,000 Tonnes 200,000 < $499 $500 $520 $540 $560 $580 $600 $620 $640 $660 $680 $700 $720 $740 $760 $780 $800 >

PARLIAMENT TO SIDE

The National Farmers’ Federation (NFF) implored politicians to use common sense and do the right thing by Australian farmers, as the controversial Biosecurity Protection Levy was debated in the House of Representatives on Tuesday 19 March.

NFF President David Jochinke said despite the mounting evidence the levy was poor policy and should be scrapped, the government had the numbers to wave it through the lower house.

“We call on Senators to see commonsense and hit pause on this legislation so they can listen carefully to the criticism this flawed policy has drawn,” Mr Jochinke said.

“It’s not just Australia’s 85,000 farmers who have raised alarm bells, it’s also the Productivity Commission, the Australian National University, the Office of Impact Analysis and even importers.

“While we never wanted this legislation to get this far, the best-case scenario is

for it to be sent to Senate Committee for appropriate scrutiny and this will provide the time and analysis to properly consider farmers’ concerns.

“We remind Senators, Australian farmers already spend millions of dollars each year in existing levies that incorporate biosecurity spending as well as through managing the pests and diseases on-farm brought to our shores by importers and travellers.

“By paying another tax towards biosecurity services, they are effectively subsidising foreign competitors who import food products into Australia.

“Along with it being at odds with standard policy design and tax practice, this levy simply isn’t fair.”

GIVE YOUR CROP A HEAD START, AND SAVE TIME AND MONEY, WITH PLANTSTARTER21 PLANTSTARTER 21 GET A HEAD START ON 2024 WITH LIQUAFORCE.COM.AU MACKAY REGION: Callan Bradford, 0488 297 528 Ross Bradford, 0498 562 778 BURDEKIN REGION: Robert Woods, 0429 658 318 INGHAM REGION: Giano Celotto, 0428, 187, 633 Cameron Liddles, 0427 765 711 TULLY & FNQ REGION: Maurice Shephard, 0457 924 762 NFF URGES

FARMERS

WITH

official magazine of australia's sugarcane industry 22

the

Updating our grower shareholders

STL recognises the need to keep Shareholders and the broader industry regularly updated. Outlined below are just some of the items already underway or completed in the current FY. As always, we welcome your feedback!

First Half Financial Performance

STL’s H1 results were recently released and included the announcement of a $15.9M profit. This enables STL to have the funding to invest in the Terminals for their long term future, provides a modest dividend to our shareholders and also holds costs down for terminal users.

2023 Crushing Season

The 2023 crushing season saw most mills crush out in early December which hopefully provided the opportunity for a well earned break for Growers across most regions. In total, we received 3.5M tonnes of raw sugar and experienced a strong shipping program in H1. Currently the terminals are sitting at roughly 35% of capacity which enables detailed inspections of shed floors and walls that are typically covered with stored sugar. STL is well prepared to start receiving when the crush commences in late May / early June 2024.

Investing in the Industry’s Assets

Whilst STL is the custodian of these vital industry assets, the importance of maintaining them to the highest possible standard requires significant ongoing investment. Works undertaken in H1 of FY24 include:

• replacement of the 12km Lucinda Conveyor Belt in late 2023 (circa $9M)

• progressing HV substations at Lucinda and Townsville (circa $4.8M)

• fire system improvements at all Terminals

• installation of Shiploader Anti Collision Systems

Income Diversification

STL reached a milestone in H1 with the successful completion of the Bundaberg Common User Infrastructure (CUI). The CUI will allow STL to handle a wide range of bulk agricultural and mineral products without impacting our priority to handle raw sugar. This project is a joint venture with Gladstone Ports Corporation and was delivered on budget by STL despite significant construction cost inflation. Loading of a commissioning shipment of silica sand is shortly due to occur. A few other examples of diversification currently being explored include:

• bulk minerals through Mourilyan woodchips through Lucinda

• sugar cane biofuel pellets through Townsville

A key aim of income diversification is to reduce terminal operating costs borne by the Sugar Industry.

Inactive Growers

STL has constantly reminded shareholders of the need to dispose of their shares once they become an ‘inactive’ or dry shareholder. To further progress this issue STL has established a subcommittee chaired by Independent Director Leanne Muller and supported by G Class Directors Tony Bartolo and Steve Kirby and M Class Director Rohan Whitmee. The focus will initially be on identifying inactive growers and then consideration of the options to transact such shares into the hands of active Growers. We will keep you updated on progress and will work with the various Industry Associations to seek their input.

Simplified Operating Model

STL continues to progress towards an insourced operating model by 30 June 2026 (or earlier by mutual agreement). We are actively planning for this transition with significant work already underway in relation to key functions like IT, Finance and Payroll. This change will remove unnecessary duplication, reduce cost and drive greater efficiencies.

Regional Visits by STL Directors

STL Directors have recently embarked on a series of ‘face to face’ information sessions in the regions. Meetings were recently held in the far north and further visits are scheduled in the Herbert, Burdekin, Mackay and Bundaberg regions amongst others. These sessions will give you the opportunity to engage with Directors on items of interest. Dates will be communicated well in advance.

Thank you for your ongoing interest in STL and I wish you a safe and productive crush.

David Quinn Chief Executive Officer

David Quinn Chief Executive Officer

STL Grower Update | april 2024 | info@sugarterminals.com.au www.sugarterminals.com.au

TAKING CONTROL

BY RENEE CLUFF

An Innisfail cane grower has made tissue culture the foundation of his planting program.

Joe Zappala farms in Innisfail’s Mena Creek area on picturesque, unique red soil. The 100 hectares, predominantly under sugarcane but also papaya, contain the basalt-derived Eubenangee soil series, a Red Ferrosol of the Krasnozem soil group. Eubenagee soils make up just two-per-cent of the sugarcane area in the Johnstone catchment and are considered a rarity nationally and globally due to their physical and chemical properties.

“One of the major properties is they have a very tight bonding of phosphorous so the application of phosphorous is critical and it can get locked up in our soils very quickly,” Joe explained. “Our Phosphorous Buffer Index (PBI) on our best soil is probably about 450 and on our most difficult soil it can be up to 700 to 800 PBI.

“That’s unheard of in most places around Australia”

The volcanic Eubenangee soils are fertile because of their topsoil structure and ability to hold nutrients. They’re also naturally acidic and despite having a high clay content, are considered a sandy clay and drain quickly. Because of these divergent properties, sugarcane variety selection is vital, and Joe describes access to a choice of varieties as crucial for productivity.

“Soil nutrition is one thing, but our biggest challenge at the moment in our area is varieties,” he said. “In the red soils it’s a bit more difficult because there are more challenges in regards to drier soils when the rain stops, and you need a good cover and good trash blanket for weed and erosion control.”

Access to new varieties has posed a problem for Joe in recent years, which he says dates back to the smut incursion of the late 1990s. “There are a couple of promising varieties now, but that is something we have lacked for a very long time,” he said.

“After smut came into the industry, SRA had to change the breeding program because of susceptibility to smut and they more or less had to target smutresistant varieties.

CONTINUED PAGE 26 ‣

Bottom: Joe uses a seedling planter to plant both his sugarcane tissue culture and papaya plants

the official magazine of australia's sugarcane industry 24

Right: Tissue culture growing in the red soils of the Innisfail district

That had to happen, but we have sacrificed a lot in our productivity. Our yields and CCS aren’t indicative of the potential of our soil types.”

About eight years ago, a lack of access to newer varieties was in part why Joe began planting tissue culture trials. However, this initiative transitioned to become a permanent part of his planting program, as he sought to prevent disease. “Initially, I dabbled with tissue culture a little bit, but I predominantly used to get whole stick cane from the local productivity services,” he said. “In 2018-19, SRA26 was released in this area. I planted in clean ground only to find it was infected with RSD.

“That really put my planting of SRA26 back two years. That’s cost me a fair bit of money because subsequently, we have learned that SRA26 is a good producer and returns good dollars per hectare for the growers.

Fortunately, Joe was well set up to plant tissue culture because he also has a horticulture crop. The seedling planters he uses to plant papaya are also suitable for the sugarcane

“I needed to take back control”

seedlings. This method is now being replicated across the Johnstone catchment through the Cassowary Coast Reef Smart Farming program, which is also planting tissue culture to accelerate adoption of the newer, higher-performing varieties.

Joe said the irrigation system he has for the papayas can water the sugarcane seedlings, too. “I only plant about 200 metres of tissue culture,” he said. “It’s quick and easy and then I run drip tape off one of my main lines to irrigate it, so I water it every time I water my papaya.

“Weed control can be an issue so what I use is something like S-Metolachlor over the top of the tissue culture, it doesn’t seem to affect it too much. I do not use Paraquat. If there are some broad-leaf weeds, I might put a bit of 2,4-D with it or a bit of MCPA depending on the weed pressure or the weed type.

Joe continues to plant tissue culture for his own seed plots simply because it’s easier and more efficient.

“If I can plant 200-metres, I can get equivalent to two whole stick cane trailers the following year,” Joe said. “That’s enough multiplication of clean seed material to keep me moving. I can rapidly escalate my volumes.

Joe grows sugarcane on the unique, red Eubenangee soil series in the Innisfail district

26

the official magazine of australia's sugarcane industry

“It’s not cut and dried, you’ve got to adapt as you go”

With whole stick, there’s a bit more involved, especially when it comes to transporting that material from the productivity board plot to my farm, which isn’t easy and involves crossing the Bruce Highway. I find I can get enough in trays of seedlings.”

The papaya and cane also work in tandem through Joe’s fallow cropping system. Papayas are planted as a break crop to regenerate blocks over a two-year period. The other big bonus is that the papayas also earn an income for Joe’s enterprise.

“There’s no point having ground sitting there and not earning you an income or costing you money because you’ve got to keep it clean or plant a legume crop,” he said. “I plant papaya and it’s probably the best situation for the soil because it’s a totally different crop, you’re following totally different management practices, and it reduces a lot of pathogens in the soil.

“Nutrition also has to be more spot on with papaya so you’ve got to get your pH right and they use a little bit of fertiliser so you build your nutrition up in your soil. When I plant a sugarcane crop after papaya, I don’t have to top dress with potassium or urea, I just use DAP fertiliser at planting and that’s it and I usually get a very good crop. The nutritional capacity of the soil is a lot better.”

Top: Tissue culture plants are grown in an agar gelling agent

Middle: Tissue culture seedlings growing in the nursery at Sugar Research Australia’s Tully station

27 APRIL 2024 – VOLUME46/NUMBER 4

Bottom: The Cassowary Coast Reef Smart Farming program has adopted Joe’s method of using seedling planters to plant tissue culture plots

SHINING THE LIGHT ON SUPERIOR SUGARCANE

SUPPLIED BY SUGAR RESEARCH AUSTRALIA

The Annual Variety Selection Meeting focuses on the best performance.

Every year a pivotal event shines a spotlight on superior sugarcane performance to date and that is the two-day meeting of the Sugar Research Australia (SRA) Variety Development teams from across the industry.

This year the Annual Variety Selection meeting was held in Bundaberg in March. District teams joined the meeting from as far away as Cairns and northern New South Wales.

To the outsider, the meeting may look dull - just a group of people in a room presenting tables of figures and graphs on a screen to each other. But this is where the rubber hits the road in plant breeding terms and the discussions can become intense.

The most advanced sugarcane clones which have been developed and trialed for the past eight to ten years are being put through their paces.

District performance data is closely scrutinised for the best clones to put forward to the industry.

“New cane varieties form the foundation of SRA’s work to improve the productivity, sustainability and competitiveness of Australia’s

sugarcane industry,” General Manager Variety Development Dr Jason Eglinton said.

“The SRA breeding program must identify and select parents for crossing with traits that will enhance their progeny’s performance to meet each district’s challenges. These parents come from the vast SRA germplasm collection of experimental clones, old and current varieties, and wild and foreign varieties. It is a huge library from which we can draw on lessons of past superior performance and incorporate the latest techniques to ensure a pipeline of strongly performing varieties for the future,” Jason said.

“SRA plants around 100,000 new seedlings annually as potential varieties for the future. It then takes between 10 and 12 years to evaluate the target traits and their performance in trials across crop classes and environments. Only a small number of candidates will have the commercial potential that survives the selection process.”

Every year new clones are assessed for their suitability for local release by six Regional Variety Committees

the official magazine of australia's sugarcane industry 28

(RVCs). Each committee is presented with detailed data from new candidates compared to the relevant commercial varieties of the region. The commercial merits of candidate clones are considered against the local production constraints and challenges of each region and the strengths and weaknesses of the current mix.

The committee, comprising voting members from local grower representative organisations and milling companies, must vote unanimously on what should be released.

Productivity is the priority, so the weighting of tonnes of cane per hectare (TCH) and commercial cane sugar (CCS) is paramount. However, other characteristics that affect the agronomic fit of varieties are also considered including lodging, arrowing, suckering, side shooting, germination behaviour, and early vigour.

A range of milling and sugar quality parameters are also considered in release decisions.

Experimental clones advancing through the selection program are screened for disease resistance to smut, Fiji leaf gall, leaf scald, mosaic and red rot at SRA’s Woodford station; yellow spot, brown rust and orange rust at SRA’s Meringa Station; and Pachymetra root rot at SRA’s Tully

station. This means disease ratings are available before commercialisation decisions are made.

The RVCs have a formal responsibility for biosecurity. Once a variety is released it is added to the Approved variety list for the region which is required to meet every grower’s General Biosecurity Obligation under the Queensland Biosecurity Act (2014). Cane supply agreements also commonly reference delivery of only Approved varieties.

Maximising profitability and minimising risk by adopting a balanced mix of varieties across a farm with different productivity constraints, disease

pressures, and harvest timing can be a complex task. Good decision-making in variety adoption and management relies on good information about variety characteristics and performance.

Each year SRA publish Variety Guides for each region summarising productivity data, disease resistance profiles, agronomic characteristics, herbicide toxicity information, and increasingly maturity curves to support selection of varieties to propagate and evaluate on your farm.

Guides for the 2023/24 season will be released in the coming weeks.

Variety Officer Herbert, Juan Briceno, presents performance data on new clones to the team

Variety Officer Herbert, Juan Briceno, presents performance data on new clones to the team

29 APRIL 2024 – VOLUME46/NUMBER 4

THE VALUE OF KEEPING IT CLEAN

BY KATE REARDON Smartcane BMP Program Manager

Cutting corners or doing it on the cheap may save you initially but in the long run, it can end up costing you more.

A key element of Smartcane BMP is ensuring growers are using clean seed for replanting.

Why use approved clean seed?

Planting Clean Seed cane is one of the easiest ways to increase productivity on a cane farm. Diseases alone can have the potential for yield losses of up to 40% or more of the infected cane crop.

Diseases such as ratoon stunting disease (RSD), Fiji leaf gall, smut, leaf scald, chlorotic streak and mosaic can be transmitted in planting material from one block to another, reducing the crop yield significantly.

Because the disease can be transmitted via plant material so easily, best management practice doesn’t support planting approved seed into plough out replant blocks, as it creates a mixed selection of varieties and, possibly, infected planting material from the previous crop.

Ideally, clean seed should be planted into blocks that have had legumes, small crops, or sprayed out fallows with trash retention.

Local productivity service groups have conducted surveys and found that growers who regularly obtain clean seed cane have better yielding crops than those who do not obtain clean cane, particularly in districts where RSD is prevalent. Evidence shows disease pressure is minimised and productivity potential maximises, if growers only plant 1% of their plant area with approved seed cane.

Local productivity services groups produce clean seed under strict quality assurance guidelines in their propagation and distribution blocks. All cane planted into seed plots for multiplication is supplied by SRA and is treated and screened for diseases before release. Tissue culture can also be sourced through local productivity service groups, which is another way of obtaining approved seed.

It is an effective way of obtaining quantities of a new variety for early propagation and bulking up for commercial production.

Clean seed is the building block of a crop and is a relatively low cost investment when given the overall high cost to establish and harvest a crop of cane. It makes good commercial sense to purchase clean seed regularly from clean local plots while taking care to keep it disease free for future plantings. The potential yield of a crop will not be attained if planting seed is of poor quality. So, investing in planting cane free from the risk of disease gives the crop the greatest opportunity to be a profitable one.

CANEGROWERS delivers the Smartcane BMP project (2022-2026) with funding from the Queensland Government’s Reef Water Quality Program and CANEGROWERS

the official magazine of australia's sugarcane industry 30

CANEGROWERS REGIONAL ROUND-UP

SUPPLIED BY CANEGROWERS DISTRICT OFFICES

MOSSMAN

Surprisingly, even though we had a wet February, and it felt like a continuation of a very wet summer, the monthly average rainfall was only 73% of the long-term average for the month.

There was very little change when the month rolled over to March which means efforts to get onto headlands and slash or spray continue to be hampered. The grasses and vines are starting to be a real issue in some places and cane in low areas is stunted due to continual wet feet. However, there are also paddocks of good cane so it continues to be very difficult to estimate what the ultimate crop size and yield might be for 2024.

As reported in the last edition of the magazine, Mossman mill continued to defy the odds as an Investor provided sufficient information for the Administrator to change his recommendation to the Creditors and proceed with securing a Deed of Company Arrangement. The Administrator had 15 business days to secure this which was by end of day 21 March 2024. The Investor visited Mossman mill on 18 March and Bargaining Agents met with the Administrator on 19 March for an update. However, even though all efforts were made to get a DOCA executed by the

deadline, creditors were notified on 22 March that the Investor had withdrawn and the DBP group of companies, including Far Northern Milling, were in liquidation. The priority now is the 2024 crop for growers and how to ensure it is harvested and delivered to a mill so they can recoup their investment in the crop and have the income needed to move forward.

Everyone cast their votes at the local government elections on the 16 March 2024. The shire held two forums which were well attended, and the community had lots of questions as the recent disaster had focused the public eye on water infrastructure and road access issues.

The Manager and one CANEGROWERS Mossman Director attended the QCGO Policy Council meeting over two days in Brisbane during March.

The past month has been very busy for CANEGROWERS Tableland, attending workshops and meetings in preparation for the coming season.

Sugar Research Australia (SRA) organised a field trip to the Burdekin region to highlight the

irrigation trials that are being undertaken. This was a very informative trip for those who attended, with numbers a little disappointing.

The Tableland Mill is starting preparations for the 2024 season with the coordinating of estimates. There is some ambiguity with regards to the

TABLELAND

Community Cabinet Cairns rally—3 Feb 2024

Policy council 3 March 2024

MSF growers’ workshop “Securing the Future through Productivity” held at the Babinda RSL

32

the official magazine of australia's sugarcane industry

crop size, due to the flooding that occurred in December and the ongoing rain. Some of the statements that have been issued is that the early plant and ratooned cane appears to be better than last season, with the late ratoon not performing as well due to the wet conditions.

The crushing season is set to start at the end of May.

MSF has received approval from the parent company to upgrade the cooling tower at the Tableland Mill at a cost

of $4,000,000 to help offset issues that arise when the temperatures increase towards the end of the year.

MSF held a grower workshop, “Securing the Future through Productivity”, for all their mills, i.e. Tableland, Mulgrave and South Johnstone. Krisda Monthienvichienchai, President/ CEO at Mitr Phol Sugar Corp, gave an opening address, where he advised that the aim was to increase productivity to 4,000,000 tonnes for the three mills by 2027.

CAIRNS

Wet weather has continued across the CANEGROWERS Cairns Region throughout the month of March.

The Chair, Manager and Environment and Sustainability officer took the opportunity to meet with Minister for Agriculture Mark Furner whilst in Cairns for the Community Cabinet to discuss growers’ challenges following the Cyclone Jasper and subsequent flooding event.

Issues raised with Minister Furner included the lack of assistance available to severely affected growers who needed to undertake substantial replanting operations in 2024 to recover from the event.

Cane Supply Agreement negotiations have continued in both the Mulgrave and South

Johnstone Mill areas, with negotiations nearing completion.

The GBRF Mulgrave Russell Water Quality Project is now in its final stages with the Project set to wrap up 30 June 2024. To date the Project has been a major success with an overall investment of $6.2 million within the catchments involving two on-ground delivery providers, Farmacist and TropWATER engaging growers as part of the investment under the Reef Trust Partnership.

The Program aims to support precision agriculture, improved farming practices, water quality monitoring and controlled drainage to reduce Dissolved Inorganic Nitrogen runoff and improve catchment water quality, productivity, and sustainability outcomes.

INNISFAIL

CANEGROWERS Innisfail, along with other industry stakeholders in the MSF Mill Areas, met in early March to discuss potential solutions to the region’s declining productivity.

Industry experts, including CANEGROWERS Innisfail Grower Services Manager, Deb Telford gave presentations on topics such as cane breeding, productivity constraints and disease pressures as well as current and potential remedies. The event, spearheaded by Thai mill owners, Mitr Phol, reiterated their commitment to investing in the cane industry in the Far North. Innisfail growers gathered for the Organisation’s annual pre-season meeting in March. As always, the meeting was a valuable opportunity for growers to mingle and catch up as well as hear the latest industry updates. Topics of discussion on the night included Cane Supply Contract negotiations,

Disaster Assistance Recovery Grants, transport legislation, the 2024 season forecast and foreseeable issues and productivity services.

Growers welcomed a presentation from SRA’s Phil Patane and CANEGROWERS

Innisfail’s Deb Telford regarding the South Johnstone Productivity Plan Review. Special thanks to invited guests and members for their participation in what is always a very interactive meeting.

CANEGROWERS Innisfail

Directors welcomed the opportunity to meet with STL representatives on the 18 March. CANEGROWERS

Innisfail Chairman, Joseph Marano, reiterated his concerns regarding STL’s commitment to insource terminal operations. The Company’s focus on diversification was also discussed with reassurance from STL that these activities would not compromise the service provided to the sugar industry.

South Johnstone Productivity Plan Review