SUCCESFUL SUCCESSION

FAMILY FOCUS IS ON THE FUTURE

FAMILY FOCUS IS ON THE FUTURE

Utrisha® N can convert atmospheric nitrogen to a plant-available form inside the leaf.

This ground-breaking foliar-applied technology supplies supplemental nitrogen to the crop throughout the growing season, giving growers more flexibility with their nitrogen management strategies.

Utrisha® N is a biological solution that works with a variety of crops for improved plant health and increased yield potential.

Embrace a balanced future

PLANTSTARTER21 delivers faster plant uptake and safer application options to protect your planting investment.

PlantStarter21 also includes bio-stimulants from two di erent seaweed extracts to help increase root mass and support ultimate nutrient take up.

Independent r esearch undertaken by the University of Southern Queensland shows PlantStarter21 to reduce nitrogen leaching by 24%, support up to 98% faster strike rate and 52% greater shoot length when compared to granular fertiliser.

Like all LiquaForce liquid fertiliser products, PlantStarter21 delivers the added advantage of allowing you to plant much more area per day with less labour and machinery required to get the job done, saving you time and money.

Get your plant cane away faster and stronger with PlantStarter21 and capture the full potential of your crop this season!

ROOT EMERGENCE JUST 72 HOURS POST PLANT WITH LIQUAFORCE PLANTSTARTER 21

Editor: Robyn Devine

Design & classifieds: Eleanor Fraser

Articles appearing in Australian Canegrower do not necessarily represent the policies or views of CANEGROWERS.

Published monthly by: CANEGROWERS, GPO Box 1032, Brisbane, Queensland 4001 Australia. ABN 94 089 992 969

Telephone: 07 3864 6444

Email: editor@canegrowers.com.au Website: www.canegrowers.com.au

Subscriptions

Yearly subscriptions for 12 issues (postage included)

Within Australia: $190 inc GST Overseas (AUD): $290

COVER

Peter and Chelley Howe with children Thomas, Jess and David are ensuring their entity remains in the family.

Photo credit: Rock Ridge Farming

Read more on page 24

Together with representatives from 20 other sugar producing countries, CANEGROWERS Chair and CEO attended the World Association of Beet and Cane Growers (WABCG) annual conference held in Fargo, USA.

The WABCG is just one of a number of international bodies where CANEGROWERS represents the interests of all Australian sugarcane growers.

These global relationships are incredibly important, enabling growers to gather and share knowledge, while also building relationships that can assist in positioning the Australian industry.

It is through this kind of work that CANEGROWERS was able to partner with Brazil and Guatemala to bring forward the successful case against India at the World Trade Organization.

Crushing has commenced at Wilmar’s Burdekin mills following an uneasy truce between the company and unions representing mill workers.

For months, the parties have been locked in an increasingly bitter pay dispute, which stalled crushing at Inkerman Mill in June and delayed the start up of the Invicta, Pioneer, and Kalamia mills.

Following increasing calls for a resolution from CANEGROWERS and other industry stakeholders, unions announced a temporary halt to strike action on 13 June, allowing crushing to get underway.

However, with no permanent resolution in sight at Wilmar mills, and industrial action also underway at Tully Sugar,

CANEGROWERS Chairman Owen Menkens cautioned that ongoing pay disputes could still impact season length.

“Obviously we’re extremely glad to see crushing get underway at Wilmar mills, but it’s worth noting that this is only a postponement of strike action. If the parties fail to reach an agreement, we may well see crushing grind to a halt again,” Mr Menkens said.

"Tully Sugar is also in the midst of a pay dispute which needs to be urgently resolved to ensure the harvest is not further disrupted.

CANEGROWERS is calling on all parties to consider the devastating consequences protracted strike action could have on the wider regional community."

In big news, CANEGROWERS will be undergoing a digital revamp over the coming weeks.

The first step has been the launch of a new member portal. The new portal makes it easier for members to set up their own easy-toremember login details.

Once inside they have access tools specifically designed for growers, such as a Cost of Production tool and Sugar Price Ready Reckoners, legal advice articles, marketing information and updates, transport guides, and exclusive membership offers.

Invites to set up a CANEGROWERS member portal login have been rolled out via email over the past few weeks. Invitations were sent to the email address registered with your membership so if you haven't seen it yet, check your inbox and spam folders.

The race is on to get Mossman’s cane crush underway, following confirmation the State Government would chip in up to $6 million towards the cost of transporting the cane 100kms south to MSF’s Mulgrave Mill.

Following months of intensive negotiations between CANEGROWERS Mossman, the local Douglas Shire Council, Douglas Chamber of Commerce, MSF Sugar and the Queensland Government, Premier Steven Miles announced the government would cover nearly half of the transport costs.

“This is a good economic outcome for the industry, with growers looking to recoup some of the $15 million they have put into getting this crop ready,” CANEGROWERS CEO Dan Galligan said.

“I’d like to thank the Premier, as well as Minister for State Development Grace Grace and Minister for Agriculture Mark Furner, for listening to grower concerns and taking action to ensure Mossman’s 2024 sugarcane crop can be cut and crushed.”

While many Mossman growers were looking to enter into a commercial cane supply agreement with MSF, the reality is that without the government, milling company, and growers sharing in the transport costs, the project would be economically unviable.

“Growers will still need to pay up to $12 per tonne for transport costs, so for some the finances of this arrangement are tight, but they are determined that this crop should be turned into an economic outcome.

"This arrangement gives growers certainty around this year’s crop and also provides some breathing room so growers can take a little time to consider their next move.”

CANEGROWERS Mossman Chairman Matt Watson said the government’s commitment was a huge relief for local growers.

“For months we’ve been in limbo, not knowing if someone would swoop in and save the mill or if our crops would be left to rot in the paddocks.

“MSF making a commercial decision to receive and crush the cane was the critical first piece of the puzzle, and I’d like to acknowledge the team at MSF for their diligence and persistence in making that happen.

"Finding a funding arrangement to cover the cost of transport has been the stumbling block to making this venture a reality. It’s been an anxious time for growers, but we can all take a deep breath now and start preparing for the crush.”

Mr Watson said there was still plenty of work to do before harvesting could get underway.

“We have plenty of planning to get harvesters ready to fire up, and the mill is also making preparations. But now that we know the harvest is going ahead, it’s all hands on deck to make this happen.”

CANEGROWERS provides free crop insurance* to members. The premium is paid by CANEGROWERS on behalf of members and will cover growers against accidental

This

There have been some movements across the range of tariffs available to growers. Now is a good time to review your options!

Use our CANEGROWERS Tariff Tool to review your usage and cost across the options.

It has been a mixed bag of increases and decreases amongst the various tariffs, as well as between variable and fixed cost rates, so depending on your pattern of use, things may have changed in terms of which tariff would be most cost effective. The tables, on this page, provide a snapshot of tariff movements for the most popular options for small businesses.

Tariffs 20 and 34 have had similar movements so would probably not warrant any change between the two if you undertook an assessment last year (note that tariffs have been rounded to one decimal place). Variable rates are c/kWh and fixed costs are c/day.

The popular Tariff 22C has however seen some significant adjustments between the time-of-use windows. Unfortunately, this reduces the opportunity to adapt schedules to make the most out of off-peak and shoulder periods which had offered low tariffs to promote usage during these typically low-demand periods.

A key driver of cost changes this year has been the network cost component. In general, the energy cost component has decreased, but at the same time there has been a notable increase in network costs (determined by the Australian Energy Regulator (AER)).

According to the AER, the main drivers were updates to inflation, the regulated rate of return and increased transmission costs. Other factors include adjustments for incentive scheme rewards or penalties and any previous under or over-recovered allowed revenues for each distributor.

Growers are reminded that they can visit the Queensland Ag Energy

Hub, which provides a centralised location with information for farmers navigating the energy needs and requirements of their operations (visit www.qldagenergyhub.com.au).

This includes reducing expenditure and case studies from farms that have successfully implemented savings initiatives, as well as fact sheets on pumping, irrigation, energy efficient farm buildings and more.

Access the CANEGROWERS

Tariff Tool

Update from the load restraint task group led by CANEGROWERS and including Australian Sugar Milling Council (ASMC) and the National Heavy Vehicle Regulator (NHVR).

This task group was formed to address any potential issues arising with regard to the sugarcane industry’s compliance with the Heavy Vehicle National Law loading and load restraint requirements and to ensure safety during the transport of sugarcane on roads.

This was partly initiated to understand what may change with NHVR taking over the compliance role from Queensland Transport and Main Roads in April this year.

In general, NHVR has advised that they will increase heavy vehicle compliance activity across the state, and this will mean more heavy vehicles will be pulled over for inspection.

When heavy vehicles are pulled over, even if fully compliant, NHVR Safety and Compliance Officers (SCOs) may

ask a standard series of questions to gather information and inform their monitoring activities. This is not targeted at the sugarcane industry but will include heavy vehicles hauling cane.

However, if a vehicle is not compliant with the load restraint requirements i.e. spilling cane and is pulled over either in a general inspection at a fixed site or a random patrol, then the SCOs will record additional information like the cause of the loss of load, the type of sugarcane load loss, location of loss of load, is the bin covered, posted speed and ask other questions about the loading and point of origin of the vehicle.

This does not mean that there will be no infringement action. This is up to the discretion of the SCO on site.

Purchase

However, the NHVR enforcement policy is generally to educate, warn and then issue infringement notices when necessary (informing, educating, monitoring and enforcing the Heavy Vehicle National Law).

The main aim is to gather information and collect evidence to identify the areas which pose the greatest safety risks so that as an industry we can adopt measures to address them. Finally, as the season gets underway it is important to remember the following:

A load must be secured so that it is unlikely to fall or be dislodged from a vehicle and not be loaded in a way that makes it unstable or unsafe

A vehicle does not have to have a cover if the load is contained and not spilling cane

BY DAN GALLIGAN, CEO, CANEGROWERS

The recent State Budget was absolutely pitched at meeting the cost-of-living pressures.

The sweeteners on offer included generous rebates on electricity bills, very cheap public transport fares for six months, and free kindy.

In what was a seen as a huge political risk, prior to budget night the LNP opposition made it clear they would fully support all budget provisions.

In reality, it was mostly political theatre.

Oppositions in Queensland rarely reject government budgets, and with a unicameral parliamentary system it wouldn’t matter if they did, as the government can pass their budget at will.

What it did do was de-politicise the budget.

But that will only delay the real political manoeuvring.

As we hit the second half of this year, the real political campaigning will begin.

This year’s state election is shaping up to be one of the most fascinating for many years.

The Miles Government is lagging in the polls and looks on the verge of defeat. Other than two spells in opposition from 1996-98 and 2012-15, Labor has been in power since 1989.

But Queensland feels like a very different place today, compared even to our last election in 2020.

The electorate is still getting used to fixed four-year terms, while the economy is still clawing its way out of the impacts of COVID 19.

Yet there is a huge policy and economic shift underway, bought on by the dual drivers of the Queensland emissions reduction target of 75% (reduction on 2005 levels) by 2035, and its associated policy of a shift to renewable energy sources, with a renewable energy target of 80% by 2035.

These two “hand in glove” government targets, which are the driving force behind many economic policies and investments in this state, were not a consideration just two elections ago.

So, how does agriculture policy fit in within this dynamic.

At CANEGROWERS , we are well advanced in working with the Queensland Farmers’ Federation to finalise our election platform.

Between emissions reduction, cost-of-living pressures, and renewable energy, one thing is for sure, agriculture policy is front and centre in this election.

We must see this as an opportunity.

We are being, and must be, proactive in policy development to ensure the politicians see the intersection between food, fuel, profitability, and sustainability.

The risks of perverse outcomes from politicians who set bold, yet popular targets, without understanding the tradeoffs or the context, are obvious.

You can be assured that while the harvest will no doubt have its challenges, and while growers are working hard to get the crop off, at CANEGROWERS , we are working over the next crop of Queensland parliamentarians.

75 g/kg isoxaflutole +

g/kg terbuthylazine

200 g/L fipronil 900 g/kg diuron

720 g/L 2,4-D DMA + IPA

75 g/L picloram + 300 g/L 2,4-D

g/L fluensulfone 750 g/kg isoxaflutole

132 g/kg hexazinone + 468 g/kg diuron

240 g/L picloram

330 g/L paraquat 240 g/L imazapic

g/L fluroxypyr

625 g/L 2,4-D amine

750 g/kg metribuzin

750 g/L MCPA amine 240 g/L bifenthrin 900 g/kg atrazine

750 g/kg hexazinone + 150 g/kg imazapic 400 g/L asulam 625 g/L propiconazole

g/L MSMA

SUPPLIED BY SUGAR RESEARCH AUSTRALIA

In the week commencing 20th May, SRA established that the variety SRA34A was in fact, genetically identical to KQ228A and therefore the same variety.

This creates challenges for some productivity services organisations (PSOs) who now have more KQ228A in their Approved seed pipelines than planned, and results in some growers having on-farm propagations of KQ228A instead of what was supposed to be a new variety.

SRA immediately contacted the directly impacted PSOs and the four growers who ordered SRA34A tissue culture from SRA. We then began working with those directly impacted to understand the implications and to identify appropriate remedial actions.

The DNA fingerprinting procedure was reviewed, and the root cause of this unusual issue was identified. Two changes to the procedure have since been implemented to remove the risk of a similar issue happening again and to prevent a misidentification being perpetuated over time.

Status of SRA34A

SRA34A was approved for release by the NSW Regional Variety Committee (RVC) in 2021 and by the Southern and Burdekin RVCs in 2022. Performance information was included in the Variety Guides showing agronomic performance and productivity were competitive with KQ228A and the disease resistance profile was generally equivalent. The visual similarity of the two varieties has been a subject of significant discussion and is noted in the guides.

Approved seed of SRA34A has been supplied to growers by PSOs in the Condong, Rocky Point, Maryborough

and Bundaberg mill areas. 20,416 tissue culture plants have been delivered or were in the process of delivery to PSOs and individual growers including in the Burdekin. SRA34A has been propagated in Approved seed plots for commercial supply to growers for 2024 planting in Burdekin, Southern region and NSW. The variety is in Final Assessment Trials in the Central and Northern regions and is at an earlier stage of testing in the Herbert.

Cutting the wrong sample from field plots is a recognised risk in plant breeding and Approved seed production, and mix ups also happen on farm. A range of procedures are in place to minimise the risk and to identify when mistakes occur. Highest on the hierarchy of controls is DNA fingerprinting, which has successfully identified mistakes in the breeding pipeline and in Approved seed plots before impacting growers.

In 2023, there were 1,846 samples processed for DNA based variety identification. Some samples are from routine quality control, and many are triggered by concerns about identity, so the results are not an estimate of error rates across the industry. Last year, 10 percent of samples from growers and PSOs were not the expected variety, and 5 percent of samples from SRA identified a mistake in trial plots or propagations. DNA fingerprinting has been used for over 20 years and has proven to be a very useful tool.

Directly impacted PSOs and growers who ordered SRA34A tissue culture from SRA were immediately contacted and advised of the situation. All SRA34A in trials, propagations,

distribution plots and commercial production will have its name changed to KQ228A. This material is valid for ongoing use and SRA is working with those that now have a problematic oversupply of KQ228A

The SRA34A selection history, DNA test history, and the variety identification procedure were reviewed. SRA34A had been tested with DNA fingerprinting on 32 occasions and was never identified as a match to KQ228A. Root cause analysis demonstrated the misidentification came from a unique mistake made in the analysis of the first reference sample by the Australian Genome Research Facility in 2018. The result returned to SRA was that clone QS09 -7888 (subsequently released as SRA34A) had a unique genetic fingerprint when compared to all other varieties and experimental clones in the database.

The experimental clone had been mistakenly replaced prior to 2013 by KQ228A and this test should have identified the mix up. In future, any sample that shows close similarity to an existing variety will trigger manual investigation and a meeting to discuss the results.

A second limitation was identified that allowed the misidentification of SRA34A to continue over time. The first step in the query structure is to determine if the sample matches to the reference for that variety. If there is a match, then the sample is identified, and the query goes no further. In the case of SRA34A the reference was mistakenly a sample of KQ228A. The query structure has been changed to now test the genetic fingerprint of the unknown sample against the entire database. If this had been in place previously, SRA34A would have been identified as KQ228A the second time it was tested rather than masquerading as a new variety for several years.

Two online meetings were held with members of the six Regional Variety Committees in the week of 27th May and a face-to-face meeting of the Southern Regional Variety Committee

was held 12th June. This consultation has supported a collective understanding of the issue, impacts and actions to be taken.

Direct communication with SRA members and publication in the CaneMatters magazine are aimed at providing information to the broader industry. Information is also being prepared to support SRA and PSO staff in explaining the revised DNA fingerprinting process for shed meetings and grower events.

For further queries or more information, please don’t hesitate to contact your local Variety Officer:

SRA Northern Variety Officer, Andrew Rigby at arigby@sugarresearch.com.au

SRA Herbert Variety Officer, Juan Briceno at jbriceno@sugarresearch.com.au

SRA Burdekin Variety Officer, Catherine Kettle at ckettle@sugarresearch.com.au

SRA Central Variety Officer, Christopher Tom at ctom@sugarresearch.com.au

SRA Variety Development Manager Southern, Roy Parfitt at rparfitt@sugarresearch.com.au

SRA New South Wales Variety Officer, Anthony Cattle at acattle@sugarresearch.com.au

sugarresearch.com.au

BY OWEN MENKENS, Chairman, CANEGROWERS

It has been a challenging start to the crushing this year.

We have seen industrial action at the Wilmar and Tully mills following a breakdown in negotiations for a new Enterprise Bargaining Agreement (EBA). This has pushed back the season finish dates for a lot of districts which is a big concern for many growers.

EBA negotiations are not something that CANEGROWERS is normally involved with, but when these discussions break down it is the growers that have to bear the brunt of the costs involved in the longer season.

Therefore, the chairmen of the districts involved and I have been meeting regularly to help work through solutions. We have also been in contact with senior management of the mills and the unions providing them with specific data around the costs to growers that come about when the season is extended or not completed. At this stage there has been no final agreement, and the parties remain in negotiations however the mills are running which is some positive news.

The other major issue heading into the start of the crush has been the position for Mossman mill and more importantly the growers who supply it. After an enormous number of negotiations, the cane from Mossman will be crushed at Mulgrave mill after a three-way deal was struck between the growers, MSF and the Queensland Government. This was achieved by the incredible effort and actions undertaken by CANEGROWERS Mossman board members, CANEGROWERS Mossman district manager

Evelyn Matthews and CANEGROWERS CEO Dan Galligan. They should be congratulated for their effort.

It is still unclear what will happen to the mill going forward but with the leadership of CANEGROWERS Mossman I feel confident about the future. When we choose to represent growers, it is never easy but putting the interests of the growers and industry first is at the forefront of our decisionmaking process.

At the time of writing, I am in transit from the World Association of Cane and Beet Growers (WABCG) conference in Fargo, North Dakota. This conference brings together sugarcane and beet farmers from all over the world to discuss issues affecting our industry. All of the representatives are also farmers and all look to put the interests of their industry forward for the benefit of their growers.

We are facing similar challenges whether that be government or market based. The annual WBACG Conference is a great opportunity to learn about how others around the world deal with these issues, so I can do my job here better. The good news is that it does not look like production is increasing anywhere in the world and given consumption is increasing it does bode well for the price going forward.

I wish all of you the best for the start of the crush.

Take your spraying program to the next level of accuracy and performance with RightSpot™ precision technology from Ag Leader. Suitable for retrofitting to most self-propelled or trailed sprayers, RightSpot utilises blended pulse technology to maintain consistent droplet size and coverage at all operating speeds. With independent control of up to 144 nozzles, automatic turn compensation and automatic reticulation, priming and flushing, RightSpot significantly reduces input costs and the potential for spray drift. Contact your local Ag Leader dealer and find out how RightSpot can optimise the efficacy of your spraying program.

Halpin Precision Ag (Bundaberg)

BY PETER ALBERTSON QAWN OFFICER FOR CENTRAL QUEENSLAND

Since COVID, there’s been a major shortage of haulout drivers for harvesting contractors in all the sugarcane growing regions of Queensland.

CANEGROWERS Mackay has been successfully operating a Haulout Training Course for the past 20 years in Central Queensland, and in mid-April the course was replicated for the first time in Tully, as part of a Queensland Agriculture Workforce Network (QAWN) initiative to address this issue and expand the Central Region’s Haulout course.

The training course involves one full day of theory and three days of practical,

hands-on experience operating haulout vehicles under field conditions and the opportunity to receive four units of competency towards a Certificate II in Rural Operations. The course is funded through the Department of Education, Small Business and Training’s (DESBT) Skilling Queenslanders for Work (SQW) Program.

One of the key factors to ensure the success of a haulout course is having highly skilled trainers, a skilled

assessor and industry supporters who are willing to provide the heavy machinery required, in this case three haulouts and one cane harvester. As occurs in Mackay, the trainers are also the individuals willing to supply the heavy machinery.

For the Tully course, Dale Bray, a local harvesting contractor, not only provided all the heavy machinery but was also one of the Junior Trainers.

“I have experienced firsthand the shortage of haulout drivers recently,” Dale said. “It only seems to be getting worse each year.”

He had previously heard of the CANEGROWERS Mackay Haulout Course and was eager for it to be trialed in Tully.

“It may be a way to attract new people into the industry,” he said. “From my experiences when trying to recruit new haulout drivers, they don’t seem to be either truly interested in the role or they’re completely unaware of the high demands and commitment level required.”

Consequently, finding a suitable applicant for the haulout role has been extremely difficult for Dale, and this is a common experience for most harvesting contractors throughout Queensland’s sugarcane growing districts.

One point that Dale raised was that although this labour shortage issue is a significant one for the sugarcane industry, the full impact is only fully felt and understood by the harvesting contractors.

This was also previously identified by QAWN in Central Queensland through phone surveys and discussions with contractors. They detailed the significant family sacrifices made to ensure that their businesses’ harvesting teams were fully staffed.

Many described having to call on family members to return to the farm to fill the labour shortages. This included senior family members who had retired or young adults who had started tertiary education or work elsewhere. In these instances, it can cause significant stress within a small, family-run, harvest contracting business which can have a longlasting, negative impact.

“I have experienced firsthand the shortage of haulout drivers recently”

To address this difficulty experienced when attempting to source haulout drivers, the CANEGROWERS Mackay Haulout Course has three key approaches, an extensive promotion and marketing campaign to maximise the number of Expression of Interests (EOIs) in the course, a strong assessment and selection process to choose the best 10 candidates for the

training and employment placement organisations are not involved in the course or, more importantly, the selection process.

Although everyone is invited to submit an EOI in the course, the selection of trainees is based on individual merit, capability and willingness to fulfil the obligations of a haulout driver.

Within 10 days of promoting the course in late February, CANEGROWERS Tully staff were inundated with 64 EOIs. This high level of interest exceeded expectations and forced an earlier closure to further applications.

Phone interviews of all EOI applicants were conducted by CANEGROWERS Tully as the first stage of the selection process. A review of the collected phone interviews led to the second stage of the selection process where 20 applicants were offered face-to-face interviews.

During the face-to-face interviews, the QAWN Central Officer provided a ‘warts and all’ understanding of what the haulout operator role involves and what is expected of them. This was followed up with a series of set questions for each trainee to respond to and an opportunity for the interviewee to have their own questions answered.

Based on their responses, 10 applicants were offered a traineeship and a further three were placed on a standby list.

“It was provided by the Training and Assessment Team who are also reallife farmers with extensive practical industry expertise”

Leading up to the training course several trainees declined their traineeship and were promptly replaced by those on the standby list. This is a common occurrence when conducting the course in Central Queensland so for the Tully course, a significant number of standby positions were implemented to ensure that the course had a full complement of 10 trainees at its commencement.

The first day of the course was theory work which was conducted in the Tully Mill’s Recreation Hall. Dale was also in attendance and, although the true test of how well an applicant can perform is during the practical training, his overall first impression of the trainee group was cautiously positive and optimistic.

As a Junior Trainer, Dale also provided parts of the practical training component and experienced the skills of all trainees firsthand. Unfortunately, due to his business commitments, he couldn’t provide Junior Trainer duties for the full course, but had one of his senior staff, Ross Hansen, take his place for Days 2 and 3, while on the fourth and final day, both Ross and Dale were in attendance.

As part of completing the four competencies towards a Certificate II in Rural Operations, the trainees’ bookwork had to be marked by Axiom College’s, the course’s Registered Training Organisation (RTO) assessor, Chloe Ottone. Ms Ottone also has over five years’ experience in haulout driving.

Whether a trainee is awarded a pass was determined by all four of the

trainers as well as the assessor. These individual decisions are not taken lightly as it is the trainer’s ‘industry reputation’ that is at stake.

For the Tully Haulout Course all 10 trainees passed and all received the four competencies towards a Certificate II in Rural Operations.

Within two weeks, all trainees had been offered haulout positions with harvesting contractors and 90% have accepted. As eight of the ten trainees had been unemployed prior to the course and all have now secured employment, this is a fantastic outcome not only for those individuals but also for Tully and the local cane industry.

One of those trainees was Nicholas Porter, a 41- year-old, who had moved to Tully from Brisbane in early 2020. He had previously worked in the sheet metal industry as well as paid and voluntary work for the Queensland Fire and Emergency Service. The reasons for Nicholas’s decision to leave Brisbane were numerous, but mainly to be closer to his son and also offered adventure and better fishing.

When Nicholas saw the haulout driver course advertisement in social media, he was extremely interested.

“Seasonal work would allow me to have some freedom in the offseason to do some travelling, fishing and being able to spend the whole summer school holidays with my son,” Nicholas said.

Nicholas Porter (LHS) with his Certificate of Attendance awarded by Bryce Macdonald, Chair of CANEGROWERS Tully Board during the Award Ceremony on the final day of the course

“I liked the course as it was thorough and that it was provided by the Training and Assessment Team who are also real-life farmers with extensive practical industry expertise.”

Within a few days of completing the course, Nicholas had been contacted by a local harvesting contractor in Tully who offered him a haulout role for the 2024 season, which he gratefully accepted. He is now looking forward to his new job as a haulout driver and the work/life balance that the seasonal work will provide.

Another glowing endorsement of the Tully Haulout Course has been the recruitment of three of the ten trainees for the 2024 season by Dale Bray.

As a ‘pilot’, there is always room for improvement, particularly in making slight modifications to better suite the different requirements and processes in Tully compared to Mackay, however these modifications are slight and will be made prior to the 2025 season.

From Dale’s perspective, he foresees a strong industry need to continue the course in Tully into the future. The concept is for CANEGROWERS Tully to submit a project proposal to the SQW Program in late 2024 for them to manage the course in 2025, and hopefully this year’s ‘pilot’ project has provided significant evidence and justification for DESBT to approve it.

The course’s success is strongly correlated to the involvement of key

industry stakeholders who supported the Tully ‘pilot’ haulout course from concept through to fruition. This consisted of the Haulout Training and Assessment Team, Ron Gurnett (Senior Trainer), Dale Bray (Junior Trainer), Peter Zamira (Junior Trainer), Ross Hansen (Junior Trainer) and Chloe Ottone (Assessor for Axiom College) and the QAWN Officers from Central, Peter Albertson, and Far North Queensland, Leanne Kruss. This team was greatly assisted by the Mackay and Tully CANEGROWERS district office staff and the Tully Mill (COFCO).

For further information please feel free to contact Peter Albertson, QAWN Central Officer, peter_albertson@ CANEGROWERS .com.au or 0457 201 927

This Skilling Queenslanders for Work project is proudly funded by the Queensland Government. Skilling Queenslanders for Work funds not-for-profit communitybased organisations to deliver projects that respond to the needs of local job seekers and employment opportunities in their area. The Queensland Agriculture Workforce Network (QAWN) is funded by the department of Agriculture and Fisheries and supports Queensland agribusiness to attract, train and retain workers. QAWN is a free service available to Queensland agribusinesses regardless of commodity or organisational membership. The QAWN Central Officer’s role is hosted by CANEGROWERS Mackay.

The 2024 Tully Haulout course was funded through the Department of Employment Small Business, Employment and Training (DESBT) following a successful project submission by Queensland Agricultural Workforce Networks (QAWN) Central and Far North Qld Officers to the Skilling Queenslanders for Work (SQW) Program.

The course enabled 10 trainees the opportunity to receive four units of competency towards a Certificate II in Rural Operations.

The four competencies are:

AHCWHS201 Participate in Work Health and Safety Processes;

AHCMOM214 Operate a Cane Haulage Vehicle;

AHCMOM202 Operate Tractors and

AHCMOM204 Uptake Operational Maintenance of Machinery.

Your Trusted Partner

Current as at 18 June 2024.

By Elliott Apel, Marketing & Risk Officer

Brazil

India

Thailand

Speculators

By the end of May, 140 million tonnes of cane had been harvested in Centre South Brazil resulting in the production of 7.8 million tonnes of sugar, marking an approximate 11% increase year on year. The surprising factor, however, was the unexpectedly low sugar mix of 48.28% recorded in the second half of May, falling short of market analysts’ expectations of 50%. With the weather remaining extremely dry, standover cane that has been harvested is of poor quality and young cane is being cut before it has fully matured. This situation is raising concerns as weather forecasts show no sign of rain and if the rapid pace of the harvest continues, it will be difficult for cane development to match the speed of operations.

The monsoon arrived in India as expected on 1 June, bringing slightly above-average rainfall to the key cane-growing states of Maharashtra and Karnataka. However, rainfall has not yet made its way to the northern states, which have experienced extremely hot temperatures. At the time of writing, no news had been received regarding export policies for the 2024/25 season, as both the industry and the government are likely waiting to assess the progression of the monsoon.

It has been a varied wet season in Thailand, with some northern regions receiving abundant rainfall, while central areas have missed most of the rain and are experiencing hot and dry conditions. Due to the inconsistent rainfall across the country, crop forecasts remain uncertain, with expectations ranging between 95-110 million tonnes of cane to be harvested in the upcoming season

After building to an 81,750-lot net short position by early June, speculators trimmed their position to 71,650 lots net short as of 11 June. The news of Brazilian weather risks and a lower sugar mix were likely the drivers behind some of the speculative community beginning to buy back their positions.

The AUD finally managed to gather the strength to break free of its 65-66 US cent range in June, trading to highs of 67.01 US cents. The US Federal Open Market Committee (FOMC) remained convinced the cash rate was at its terminal level and that it was only a matter of time before it can begin its rate-cutting cycle which could deliver up to two rate cuts in late 2024. The Reserve Bank of Australia (RBA), on the other hand, is less convinced of the possibility of delivering rate cuts this year, given that the Australian monthly CPI indicator showed inflation increasing from 3.4% to 3.6% between February and April 2024.

The outlook ratings above are in relation to AUD/tonne sugar prices. A bullish outlook is considered positive. A bearish outlook is considered negative.

The highest grower-managed pricing levels achieved across all growing regions using QSL products to date (all gross price actual/tonne) are:

• 2024 Target Price = $840 / IFC $870 (Jul24)

• 2025 Target Price = $735 / IFC $735 (Oct25)

• 2026 Target Price = $685 / IFC $690 (Jul26)

• 2027 Target Price = $650

• 2028 Target Price = $550

Key Dates:

• 20 September | Any 2024-Season Target Price Contract tonnage not priced by this date will automatically have its pricing window extended and roll costs may apply.

• 20 September | Any unpriced tonnage allocated to the October 2024 contract through the Individual Futures Contract and Self-Managed Harvest Contract that is not rolled by this date will be priced by QSL at the next market opportunity.

The Gough family have been allied with the sugarcane industry for over 100 years.

Originally growers and Innovators from Ingham the family-run Gough Plastics was initially established from an innovative solution to an industry challenge.

As canoeing and outdoor enthusiasts, the Gough family had been making canoes out of their farm shed in Lannercost from corrugated iron, then out of fibreglass, to tackle the mighty Herbert River rapids. Then they experienced moulding canoes in plastic and the rest they say is history. They had an Industry they knew suited their creative souls, but they couldn’t make canoes because their friends were, so what to make?

Knowing from friends in the Cane Harvesting industry, especially the Kirks and the Crisafullis that the steel harvester extractor hoods were heavy and costly to repair each year, they moved their innovative minds to this challenge and they designed and moulded their first plastic extractor hood, and it took off. They actually made their first oven themselves, but if anyone knows Peter Gough and his sons, Andrew, Simon and Ian, they wouldn’t be surprised.

Gough Plastics is now based in Townsville and is a Research, Design and Manufacturing company that specialises in new products from conception through to point of sale. Their expertise as Rotational Moulders has seen them supplying products around the world.

“We have a huge range of products that we sell all around the world, but yes, our very first product was a cane harvester extractor hood,” Ian Gough Director of Gough Plastics said.

“We have always been sugarcane focused, starting our business in 1989, moving from the backyard shed, to rented sheds, then our own shed in 1995 and were now in the process of building a brand new factory beside the Port Access Rd in Townsville that’s part of the new Queensland Government State Development site, we are doing this with assistance from a Federal Government NADP Grant, which is greatly appreciated”.

“We’re the only Australian manufacturer of sugarcane harvester hoods, everything’s designed in-house, and we’ve got an Australian industrial designer that was educated here in Queensland.

“The materials we use, have been sourced from our research, where we literally searched the planet to find the best plastic to use. It’s our unique blend of materials that we put together, and it’s long-lasting, and most times they get the harvesting contractors through the season – we talk with other moulders in Australasia, and they can’t believe the punishment the Hoods & Liners get.

“We now make almost everything that’s needed on farm, whether it’s a Water Tank, Chemical tank, Molasses Tank and now on farm Diesel Tanks, Stationary in 12 and 240V and Cartage tanks as well.”

“We can also custom make things too, so if a farmer needs something made that is specific to their needs, their business or farm, all they need to do is give us a call as we can hand-fabricate one-off items. So just pick up the phone, or text, or get a hold of us via Linkedin or our socials –I know we will be able help.”

BY RENEE CLUFF

Tully has commemorated 100 years since the Far North Queensland town was built on the sugar industry.

Thousands of people turned out to multiple events in Tully last month, to celebrate 100 years of the sugar town’s history.

The Tully Sugar Works Area began being built in 1924. A school and township homes were among the first buildings to be erected, after a parcel of land was set aside for what was then known as the Tully River Sugar Mill.

“When the mill started to be built, the town was built around it,”

CANEGROWERS Tully Chairman Bryce Macdonald reflected. “Back then, the Tully area was known as Banyan after Banyan Creek. The main town was originally surveyed at Rockingham, just to the south. Those plans were abandoned when the mill was built in the current location.”

Tully was officially gazetted as a town in 1925. Like the mill, it received its title from the Tully River, which had been named after Surveyor General William Alcock Tully. 1925 also heralded the town’s first sugar crush.

Special events to mark Tully’s beginnings and the 100 years since have included cemetery tours, a canecutters smoko, art and photograph exhibitions, an oral history project and a fashion parade showcasing a century of style trends. Also among the highlights were a soldout dinner dance and a street parade, which included a CANEGROWERS Tully and Mitre 10 (co-op) float.

“There was a fear factor that there would be more people in the parade than cheering them on in the streets but in true Tully form, the streets were lined from the Golden Gumboot to the school,” Bryce quipped.

“It was a town reunion”

“All the ticketed events were sold out well ahead of time. The celebrations were really well supported and everyone who was involved in organising the events and volunteering their time did a wonderful job.”

The celebrations will continue next year, when Tully Sugar Limited and industry partners, including CANEGROWERS Tully, officially mark the centenary of the first sugar crush. ‘Sugar Week’ will be held next May.

BY RENEE CLUFF

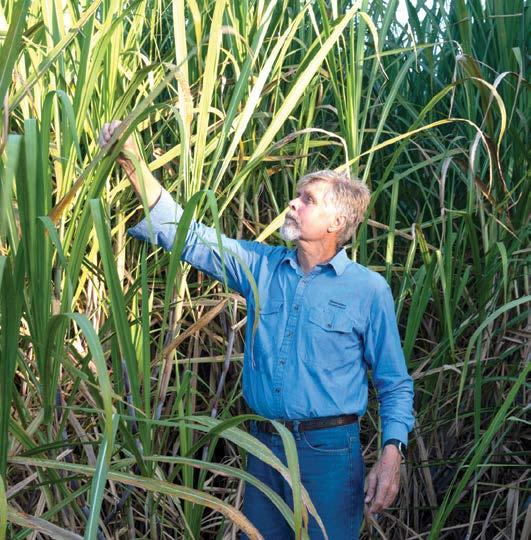

A Tablelands farm succession plan is ensuring the operation remains in steady hands for the next generation.

Thomas, Jess and David Howe are passionate about agriculture. “Farming is in our blood,” eldest brother Tom explained. “It’s a good lifestyle and we enjoy the work, which is challenging and varied.”

The siblings’ futures as fourth generation farmers are secure thanks to a complex but clear succession plan created by their parents.

Peter and Chelley Howe operate Rock Ridge Farming in the Tableland district, where they grow sugarcane alongside bananas and avocados.

Their children, who are all aged in their 20s, are Operations Managers in the business.

They each returned to the farm after completing tertiary education. Tom gained certification as an autoelectrician, Jess obtained a business degree and David completed an apprenticeship as a diesel fitter.

Father Peter said his children are an integral part of the operation, particularly as it continues to grow and evolve. “Going forward, Thomas, Jess and David will be vital in the operation of Rock Ridge Farming,” he said.

“The coming years will present challenges that this generation of farmers will be best equipped to take advantage of.”

Developing a fair and equitable succession plan is an intricate and ongoing endeavour, which Peter said is aided by the business structure he and Chelley established.

“We’ve got multiple farms and they’re all owned under different company names, so it’s possible for each child to get his or her own company,” he explained.

“We did that on purpose. When we buy a new property, the name of the company that property is purchased by directly relates to the child that’s probably going to end up with that property. In our wills, the children will get equal parcels of property.

“There are some properties that they will have to share, such as our packing shed, so they will still need to work together and sort out any differences.

“There are also the monetary values and the water allocations we can use to even up the three parcels. We’re trying to keep everything fair.

“We talk to the kids, and they know what properties they’re probably going to be getting.

“But it’s always changing.”

“It has to be flexible because the business is growing"

It’s a transparent approach which his children recognise as being beneficially straightforward and unequivocal. “Us kids really appreciate that Mum and Dad have made everything so clearcut,” David said.

“Ultimately, the stress of splitting up the farms is the last thing we want to be worrying about if the worst happens,” added Jess.

Peter said his own experience as a third-generation farmer was very different. His story goes back a century, when his grandfather migrated to Far North Queensland from Italy and began cutting sugarcane at Pine Creek, south-east of Cairns, before buying his own farm.

Peter’s grandmother and his mother, who was born in Italy, joined his grandfather in Australia in 1929.

As an adult, his mother travelled to Sydney, where she met Peter’s father and married.

“Mum and Dad heard all the stories about the money you could make farming up here (in Far North Queensland), so they planned to come up only for a few years to make their fortune and move back down to Sydney, but Mum was still here 80 years later,” he joked.

Peter’s parents had eight children and together they grew a mixture of crops, including tobacco, watermelon and pumpkins. When his father died in his late 60s, the children and their mother kept the operation going.

“We did it tough for years,” Peter recalls. “It was only due to Mum’s stubbornness that the banks didn’t sell us up. She was a force to be reckoned with, that’s for sure.

“Mum also worked hard in the field, while cooking for all the men. It didn’t do her much harm; she only died a couple of years ago aged almost 99. She was fit. I think all the girls worked harder than us out in the field and then also had to work when they came back to the house.”

The property Peter’s parents purchased at Walkamin remains in the family today, operated by Howe Farming, which is owned by some of Peter’s siblings.

“With such a large family, that’s where you learnt the importance of succession planning,” Peter explained.

In 2011, he and his wife Chelley went out on their own and started Rock Ridge Farming, which today employs around 200 people and includes a state-of-the-art packing shed at Tolga.

Their farms encompass about 800 hectares and are spread across all corners of the Tablelands at Dimbulah, Mareeba, Tolga, Kairi and Yungaburra.

“We’ve put in some hard yards and hopefully it pays off,” Peter said.

It’s a legacy his children are sure to build upon as the years progress.

Peter has a love for vintage machinery. This one is among many housed in his packing shed Thomas Howe

L-R Chelley, David, Peter, Thomas and Jess Howe

Omnia’s devotion to improving fertilizer efficiency through increasing root development is commendable. Illustrating their impressive results on several different crops, including sugar cane.

Sugar cane root analysis was performed through the SARDi Root DNA analysis at three different sites all at different growth stages. The results returned with a 51% increase in root DNA in the treated plots verses non treated. The culprits of this increased root development are Bacstim 100 and Rhizovator OB.

Bacstim® 100, containing 5 strains of beneficial bacteria, enhances nutrient absorption by colonizing the soil immediately surrounding the root tip and rendering nutrients within the vicinity more available to the plant. Rhizovator™ OB complements this by stimulating root growth whilst retaining nutrients within the rootzone for longer periods of time.

Combined, these products significantly boost root development and ultimately crop productivity. This improved productivity is highlighted by the two-year trial conducted in Innisfail, Queensland, where treated plots recorded a 27% increase in sugar production over the control. Providing a significant increase in monetary returns.

To maximise fertilizer efficiency without any loss in productivity is the ultimate goal of any farming enterprise. And this holds especially true for the Australian Sugar Cane Farmer. At a time where inputs are high and increased environmental pressures are governing the use of fertilizer, there is no better time to start looking at alternative methods to remain not only productive but also profitable.

“To maximise fertilizer efficiency without any loss in productivity is the ultimate goal of any farming enterprise”.

Harnessing the power of biostimulants continues to produce outstanding trial results in Sugarcane.

• 3 different sites analysed in Oct 2022

• 3 different growth stages: - 3 months post planting

- 7 months post planting - 8 months post planting

• Average increase in root DNA over control was 51% to find your nearest Omnia Agronomist

Venturing into the field offered a unique chance to dismantle misconceptions surrounding the growth of sugarcane in Queensland for a cohort of students from the University of Texas at Austin.

Last month 24 students visited third-generation grower Steve Pilla at his farm in Giru in the Burdekin and gained immensely from seeing first-hand how innovation, technology and the industry’s best management practice program, Smartcane BMP, are all integral components of his farm management systems.

Many of the students were impressed by how effective self-regulation has allowed farmers to orchestrate their sustainability and by the use of technology to automate irrigation

The automatic pumps and sensors were notable to the students, and they were amazed to realise that on Steve’s farm, almost every segment of irrigation is fully online which assists him to streamline his approach to water use, saving time and money.

Rhonda Evans, Associate Professor of Instruction in the Department of Government and Director of the Edward A. Clark Centre for Australian and New Zealand Studies, designed the course on the Politics of Protecting the Great Barrier Reef, which just finished its third year. The class study the different ways in which human activities impact the Reef.

“Most students,” Dr. Evans observed, “have spent little or no time on a working farm, so they come in with a lot of misconceptions about farming and farmers. Learning about sugarcane farming on-site and talking with Steve about his work transforms student mindsets and allows them to think about regulation from more practical perspectives.”

“And, honestly, my visits to farms over the past two years have affected my own thinking in similar ways. The opportunity to see cane farming firsthand has become an integral part of the curriculum and a real highlight for the students. I’m very grateful to CANEGROWERS for facilitating these visits.”

The students’ interaction with CANEGROWERS continued in

Brisbane with discussions from CANEGROWERS policy team members, Burn Ashburner, Chris Gillitt and Matt Kealley on advocacy, farming practices and sustainability.

CANEGROWERS Senior Manager

Membership and Engagement

Matt Kealley said these types of invaluable engagements with international students can help in breaking down any stereotyping of the Queensland sugarcane industry.

“The chance to get students out in the field and talk with growers and industry representatives ensures a greater knowledge of the industry,” Mr Kealley said.

“It also helps the students to better understand the growers’ strong stewardship of the land on which they farm.”

BY KATE REARDON

A key reason for some growers to be hesitant in Smartcane BMP is the several myths around keeping records. Keeping records for your farming business isn’t just for Smartcane BMP accreditation—for example, it’s a regulatory requirement under Chemical Usage (Agricultural and Veterinary) Control Regulation, Workplace Health and Safety, and Industrial Relations legislation.

Good records form the foundation of understanding your business outputs, helping you monitor trends and changes over time. While the task may seem burdensome, a distraction from the ‘real’ work, maintaining records doesn’t have to be complicated. And it can be done in a way that suits you – on paper, a map, in a spreadsheet, or on your phone.

Whichever method you choose, ultimately it needs to work for you. Elements to consider are fit for purpose, ease of use and availability. There is no value in implementing an option if it only meets a small range of your needs. Start by determining what data you need and what you want to achieve with your records. Consider its complexity, if it’s too complex or requires frequent retraining, it’s less likely to be used consistently. Finally, is it readily accessible, whether in the field or the office and either online or offline.

Options range from simple methods like using record keeping books, to advanced farm management programs with Geographic Information System (GIS) capabilities, each with a variety of strengths and weaknesses. Traditional paper records are accessible and straightforward to use, however they can be easily lost or

damaged. Digital spreadsheets offer versatility and can be adapted to suit your needs with built-in functions to automate calculations and generate visual charts for better insight.

However, accessibility in the field and offline can present a different set of challenges. There are numerous agriculture-specific apps designed for field record-keeping. These apps often offer features like GPS mapping and real-time data entry. However, they’re not always user friendly and can take time to learn.

Comprehensive farm management software provides an all-in-one solution for data recording and analysis. However, they can be expensive and lacking in customer support services when issues arise.

By choosing a method that best suits your preferences and farm conditions, you can ensure that your field records are accurate, practical and easy to use.

During a Smartcane BMP audit, a grower is required to provide a sample of their field records as evidence of meeting requirements for Smartcane BMP, such as using the SIX EASY STEPS program. A random selection of field records for irrigation, chemical

application and nutrient management are reviewed by the auditor. Field records can be in any format, so long as they contain all the details needed and the auditor can establish they are compliant with best practice.

Any records reviewed during an audit remain with the grower with no hard copies kept by the audit or stored within the Smartcane BMP database.

Setting up your record-keeping system might be the hardest part, but once established, it will support you in making solid business decisions and a successful Smartcane BMP accreditation audit. So, be smart about your record keeping, make it a seamless part of your cane farming operation and get in touch today with your Smartcane BMP Facilitator about working towards your accreditation.

CANEGROWERS delivers the Smartcane BMP project (20222026) with funding from the Queensland Government's Reef Water Quality Program and CANEGROWERS

You know your farm and what you want to achieve.

Smartcane BMP recognises how you farm and supports improvements you want to make.

Talk with your district facilitator about how they can help you.

It took until the last few days of May, but the monthly rainfall managed to exceed the monthly average yet again; albeit by only 5mm.

The growing conditions for the crop improved greatly during May and June, with the cooler nights and less humid days setting off wide-spread flowering of the cane across all districts.

Even after the Cyclone and flood event in late 2023, the crop is still upright and looks perfect for harvest. Our biggest concerns will be the unknown debris that could still be sitting in paddocks and may hamper the harvest to some extent.

We finally managed to get confirmation that Julatten cane will be transported to the Tableland Mill and those growers have been offered a three-year rolling contract. Meanwhile coastal growers were preparing to deliver as much of their crop as they could to Mulgrave mill.

Due to delays in securing some assistance, coastal growers were slated to start deliveries to Mulgrave mill about three weeks after Mulgrave growers started their crushing. This would put first deliveries in early July.

On 7 June the second meeting of the Mossman Region Transition Program Stakeholder Advisory Committee was held in Mossman clashing with a Public Meeting held by the Hon Bob Katter MP around securing Mossman Mill and making the factory operational again. Quite a few members of the public and industry were in attendance and a number of views were expressed by those present.

On 10 June grower representatives attended a meeting at Mulgrave with mill staff and representatives and transport representatives to work through a dry run of the supply chain for coastal cane from harvest to transport to receival at the mill, to processing to payment.

There were a number of issues raised from different perspectives which were discussed and worked through. It was a very beneficial session for all involved.

On 12 June a second Delegation went to Brisbane to meet with the Minister for Agriculture and the Minister for State Development and Infrastructure and the Premier.

It was a full day and representatives of growers, the Douglas Shire Council and the Douglas Chamber of Commerce put forward their best case for continued support for the agricultural industry in the Shire due to its importance to the diversity of the Shire and the economy of the region.

The board representatives had attended a brief update

session with the Liquidator for the Daintree Bio Precinct companies on 18 June.

Growers had an update meeting on 19 June where they heard the latest from government, MSF, and the transport contractor representatives and received an update from board members regarding what is happening with FNM assets.

The mill started crushing on 24 May.

Due to the Mossman mill closure, the sugarcane from Julatten will now be crushed at the Tableland Mill. This has raised the total estimate for the district to 895,000 tonnes, adding another week to the season length, estimated finish date 7 December.

The water auction conducted by RuralCo on behalf of Sunwater, running from 29 April to 15

May, has concluded with only 5898 ML out of 11,500 ML of water allocation being sold. 5067 ML of the 10,677 ML Zone “D” water sold for an average price of $3,255/Ml.

The total amount of 831 ML which was available in the East Barron Zone has sold for $4,132/ML. Sunwater has confirmed that it will consider its options, however at this stage there are no plans for further sales or auctions.

Cooler weather and sunny days have finally graced the Cairns Region and growers are in full swing working ground whilst the opportunity is there.

Both the Mulgrave and South Johnstone Cane Supply Contract negotiations are now completed. Thank you to the negotiators who represented CANEGROWERS Cairns Region members throughout this process.

The value of the contracts has been maintained with some key improvements including changes to the planting allowance and moving to a rolling contract from a 3-year contract to allow growers the ongoing option to forward price.

Clauses within the contract have been improved to protect growers’ rights within the rolling contract by addition of a 3-year review and dispute resolution clause.

The final GBRF Mulgrave Russell Water Quality Program Forum was recently held. The Forum included site visits to one of the TropWATER Controlled drainage sites and a soil pit hosted by Farmacist prior to project presentations and lunch.

The Mulgrave Russell Water Quality Program funded under the Great Barrier Reef Foundation has now finished. The TropWATER water quality monitoring and first flush retention part of the project is continuing for another 12 months allowing the project to collect additional data from the project sites.

Both the Mulgrave and South Johnstone Mills were scheduled to start crushing on 18 June.

The recent Business Essentials workshop held in the Mulgrave office was well attended by growers who found the two days very informative and well worth the time.

Over 80 members and invited guests attended the CANEGROWERS Innisfail Annual General Meeting on 30 May, pictured.

The Organisation’s showcase event was a great opportunity for growers to connect over a meal and to hear the latest industry and organisation updates. Guest Speaker, Bernard Shroeder gave an insightful presentation on the role of research in ensuring the Australian Sugar Industry remains competitive on the global stage.

The group also welcomed an update from CANEGROWERS Chair Owen Menkens who spoke broadly about advocacy efforts, partnerships, Smartcane BMP opportunities and workforce and education initiatives. The CANEGROWERS Innisfail Board, Management and Staff would like to thank all those that came along and ensured the evening’s success.

CANEGROWERS Innisfail members are currently signing

the new iteration of the Collective Supply Agreement (CSA). Key advances in this contract include an increase in the planting allowance, a rolling term conducive to forward pricing opportunities and grower choice with regards to productivity service provider investment.

CANEGROWERS negotiating representatives are to be acknowledged for their commitment to this arduous task and congratulated for upholding and increasing the value of the CSA.

The Cassowary Coast Reef Smart Farming team once again held their highly coveted shed meetings. The meetings are considered the “go-to” event for growers across the Innisfail region with the latest in locally relevant productivity and water quality data being shared by skilled practitioners.

The South Johnstone Mill commenced crushing under ideal (cool and dry) weather conditions on the scheduled date of 18 June.

Finally, there has been a lengthy period of days with fine weather.

June has provided more days of no recorded rain than the months from January to May. The continuous rain has been tormenting the north for months.

Reports of bird and rat damage are frequent across the districts. For the growers that also had time to get around to all your farm, now is the time to check cane fields near tree lines and drains. Feral pigs are still a problem, as the cane matures, pigs move into the paddocks and won’t move unless threatened.

Planting contractors will be under pressure this year, as the window of opportunity gets smaller by the day. Generally, the month of June allows for some planting to be done across the district, particularly the southern end of the cane growing area.

From the second week of June, there has been opportunity to plant. As it is with harvesting, there is a general shortage of contract planters across the tropical north, due to the expense of equipment and availability of short-term workers.

After a long spell of rain, the district is finally experiencing some respite.

As a result, preparations for planting are in full swing for the district, and some growers have already started the planting process.

Lime and Dolomite blends are becoming increasingly popular, as the benefits are starting to be more recognisable. The popularity of the products is leading to delays in delivery and spreading, particularly because of the extended wet. Generally, there would have been more lime applied earlier in the year, even though planting doesn’t start until May.

Tully Mill started on 17 June, with a below average crop expected for 2024. Original estimates shifted from 2,440,000 tonnes to 2,340,000 tonnes.

Crop ripening is less popular this year as the crop yield is reduced and masses of flowering indicates that the crop has matured early. Some varieties are indicating early sucker growth. Crop ripening products may be used to control unwanted suckers.

I would like to take this opportunity to remind readers of the importance of cane train awareness on roads and paddocks. Also the “Look up and Live” motto and the importance of safety during the harvest.

We have submitted a letter and a comprehensive statement to both parties, urging them to reach a compromise as soon as possible to prevent any disruptions to the season. Due to industrial action and the mills not being ready, the start date for the crushing season has been postponed twice. At the time of writing, the mills are scheduled to begin crushing on 24 June.

In other news, CANEGROWERS Herbert River recently hosted a meeting with the district's young growers, leading to the establishment of the

With a somewhat troubled start to the season, three mills commenced crushing almost a week ahead of the last mill to start.

Delays due to workforce and contractor availability along with industrial action adding to those problems.

All four mills are now crushing, some performing better with daily loadings increasing. However, problems within the factories are still causing some issues and one mill having reduced loadings from what we understand to be staffing problems, lack of Loco drivers.

CANEGROWERS Herbert River Young Growers Branch. We are pleased to announce that Ray Cervellin was elected Chair and Rebekah Pace was elected Secretary.

During the meeting, the young growers received updates from the CANEGROWERS Herbert River executive and directors and discussed plans for the next young growers’ development group trip. Congratulations to the new branch, and we look forward to seeing the contributions and initiatives from our young growers.

However, the ongoing dispute between Wilmar mills and the unions has been a significant cause of concern. The CANEGROWERS Herbert River members are anxious about the impact this could have on the crushing season.

This is a worrying issue with the threat of industrial action likely to hang over our heads throughout the season.

With contractors exiting the industry last year, some growers were still facing the issue of securing a new harvest group to harvest their crop for this season.

CANEGROWERS Burdekin (CBL) has been helping however we can to resolve this problem, including assisting with siding access issues.

We have noticed over the years that more contractors are leaving the industry due retention of staff issues in the field (due to long waits) or late delivery of allotments and with possible industrial action looming the problem is not going to disappear.

Added to this is the visible presence of the National Heavy Vehicle Regulator (NHVR) in the district, growers and contractors were reminded to be conscious of the loading of bins and any loose material on their haulouts that may draw the attention of the compliance officers. Bin mesh size is still proving to be a contributing factor to this problem.

CBL had a meeting with Regional Development, Manufacturing and Water (RDMW) to gain

a better understanding of meter validation in the Burdekin Ground Water management area.

Land holders with bore water entitlements will need to have their Meter Validation Certificate (MVC) by 30 November by Certified Meter Installer (CMI).

Considering the limited access to CMI in the area it was recommended that entitlement holders register with a CMI as soon as possible to ensure they are on record. Other areas have still not completed their MVC due to backlogs.

The crop estimate remained at 1.7 million tonnes for a targeted 24 June start.

It was encouraging to hear of good cane quality results in neighbouring regions that had already started crushing with interim CCS being set at 14.18 for the Proserpine Collective.

With the recent cold spell and widespread flowering, cane was maturing well which would hopefully improve cane quality for those areas harvesting early.

Industrial action at Proserpine Mill continued through the start of June with some respite coming in withdrawal of notices of action by both Wilmar and the Unions (at the time of writing). With mill preparations already impacted, the planned earlier start had been delayed by two weeks.

As further action remains possible, it is hoped further impacts on mill operations would be limited. The persisting

The NBN has teamed up with the Regional Tech Hub and asked for our assistance in meeting with growers to complete a free independent Connectivity Report.

As growers adopt more technology in the running of their on farm operation, the lack of connectivity has shown to be a limiting factor in the operational efficiency in these investments.

This type of consultation can only, hopefully, lead to less dead zones throughout the area.

Young Farmers hosted several ‘more experienced’ growers and various re-sellers at their Pre-season BBQ on 17 June (pictured).

This formed part of the Integrated Engagement and Capacity Building Project through the Queensland Government’s Reef Water Quality Program. An event where growers could share knowledge through peer-to-peer discussions. It is anticipated this event could be repeated in future with good feedback from those attending.

As the Show Cane 2024 week begins, all growers young and old are encouraged to participate with the best cane they can put up. Supported with over $13,000 in sponsored prizes, it is one of the biggest events on the CANEGROWERS Proserpine calendar.

From introducing a Young Farmer Trophy last year to a new Kids Cane entry this year, the event will hopefully be another success that continues to increase in support and interest from the Proserpine community.

“La Nina Watch” continued to increase the potential for late season rains while ensuing colder and drier conditions across the region improved the support for a late June start.

CANEGROWERS continued to intervene as deemed necessary with grower ‘Impact Statements’ submitted to all parties involved. It cannot be overstated how large an impact that a late start or disruptive milling season can have on growers with potential economic losses communicated.

CANEGROWERS Proserpine Board members attended a mill tour at the start of June. This included a meeting with mill management and team supervisors from Wilmar Sugar. While there was still significant work to be done, it was encouraging to see some of the upgrades made at the mill. To benefit from continued good pricing, it is hoped 2024 can prove a successful season for all.

The region’s growers have grappled with a delayed start well into June at Mackay Sugar’s Marian Mill and Wilmar’s Plane Creek Mill.

It has been a matter of incomplete shutdown season works at the former, and the well documented industrial dispute for the latter.

Our thoughts and concern lay with growers affected and it is to be hoped that the millers will have a good season in terms of mill performance to counteract that delayed start.

Chairman Kevin Borg led a delegation to present to Mackay Regional Council on 12 June, with Deputy Chairman Joseph Borg, District Manager Michelle Martin, and Communications and Membership Development Manager Kirili Lamb also attending.

In the presentation, an industry update was provided, with opportunities and challenges for the canegrowing sector outlined including the importance of maintaining land

under cane given the emerging bio-commodities sector and the regional economic development opportunity it offers.

Mr Borg affirmed the importance of government policy- including local government rating structures in supporting the development of a cane-based renewables and biocommodities sector for Mackay.

On 31 May Plane Creek Productivity Services held its annual Productivity Awards, of which CANEGROWERS Mackay is a sponsor, we congratulate all growers who saw success on the well-attended evening at Koumala Community Hall, and to PCPSL staff for organising an excellent evening. Particular thanks to members of Koumala State School P&C for the beautiful catering and hall decoration.

CANEGROWERS Mackay sponsors the Canegrowing Excellence Award, which acknowledges growers who produce the highest Tonnes of Sugar/Ha (TSH) above their zone average. Congratulations to Fred, Janelle and Ryan Axiak,

who performed at 31% above their zone average at 15.72 TSH.

Jake Galea won the CANEGROWERS Mackay Next Generation Award, which commends outstanding young farmers. Jake, who farms just to the north of Sarina (Plane Creek) will be featured in the July Billet, alongside his family’s farming enterprise in which Jake is succeeding and developing.

Winter in Mackay means show season, with Pioneer Valley

Show leading off on 16 June and Mackay Show following over 18-20 June. Sarina will follow at the start of August. As ever, CANEGROWERS is sponsoring and championing show cane sections.

Any growers requiring assistance with any issues are encouraged to call 4944 2600 to get the ball rolling on a solution. Keep an eye on our Facebook page, The Billet and weekly District Manager Updates for emerging training and industry opportunities.

Bundaberg Sugar began crushing pre-season mill owned cane on Tuesday 21 May with the Core Season starting on Monday 10 June.

A total of 72,903 tonnes was crushed pre-season (including organic) and an average CCS of 11.37 was achieved.

We welcomed QSL representatives to the district on 6 June to discuss upcoming season payment arrangements, STL issues, receive a market update and meet with new QSL CEO, Mr Mark Hampson.

From the 2024 Season, Bundaberg Sugar growers will move to the full QSL Direct model and sugar payments will now come directly from QSL rather than Bundaberg Sugar. QSL are also taking over third-party payments such as leases and liens, you can find remittance advices for these in your QSL Direct account.

There are no changes to the way you do your bookwork and Bundaberg Sugar will continue to supply you with the usual Recipient Created Tax Invoice (RCTI) to use for your BAS and other bookwork. Should

you have further queries, please contact Glenn Harris on 0409 601 349 or QSL Direct on 1800 870 756

Some growers have experienced the first round of Reef regulation compliance checks in the region. To ensure Bundaberg growers are prepared for future compliance checks they should contact Matt Leighton as he has assisted the selected growers with the audit.

Oreco payments to growers have fallen behind schedule and we are working to get these back on-track and contract negotiations for a renewed 2024-2026 Trash Supply

Contract should be complete by time of publication. If you would like to supply cane trash in the 2024 Season please contact the office on 4151 2555

The Queensland Competition Authority (QCA) have released their final determination on 2024-25 regulated retail electricity prices for regional Queensland, electricity price increases will apply from 1 July 2024.

If you require assistance with your electricity accounts or a review of your tariffs to ensure you are on the most cost-effective tariff for your situation, please contact Courtney.