Uncompromising

quality, forged in stainless steel

Consider us a Super Boutique Store for Stainless Steel Long Products

Stainless Steel Bright Bars (Round Bars, Hexagonals, Squares)

Stainless Steel Wires

Stainless Steel Pipes & Tubes (Seamless & Welded)

Stainless Steel Wire Rods

Stainless Steel Billets / Blooms / RCS

An ISO 9001 : 2008, 14001 : 2004, BS OSHAS 18001 : 2007, PED/97/23/EC & AD 2000 Merkblatt W0

Certified Organisation

02

Hindustan Inox Ltd. is one of the largest manufacturers of Stainless Steel Long Products and has achieved the quality standards to match the needs of customers across the globe in more than 60 countries. With its modern facilities, experienced management and employees, Hindustan Inox has established itself as a business partner to its customers and not just being another manufacturer from India.

Hindustan Group has an experience of 35 years in Stainless Steel Long Products & the group is selling approx. 60,000 MT of Stainless Steel Bars & Wires across the globe.

Quality That Shines Forever

As a result of continuous improvement, with strong emphasis on quality and customer satisfaction,

Stainless Steel Pioneers

today the company is an ISO 9001: 2015, 14001 : 2004, BS OSHAS 18001 : 2007, PED/97 /23/EC & AD 2000 Merkblatt WO Certified organisation and has become one of the most reliable source of quality products.

Forging Global Partnerships

As a global player, Hindustan Inox Ltd. remains committed to maintaining world-class quality, reliable delivery schedules, competitive prices and excellent relationships. Our Company places the customer at the very center of its operations.

We strongly believe that by consistently serving the needs of our customers, we will emerge from being reliable suppliers to partners in progress.

03

at Khopoli, near Mumbai Manufacturing Facility at Khopoli, near Mumbai

Manufacturing Technology

Expertise in every process

Our Facilities Include:

Heat Treatment Division

� Solution Annealing and Annealing Furnaces

� Quenching and Tempering Furnace

� Double Tempering / Double Ageing

� Oil and Water Quenching Tanks

Bright Bar Division

� Schumag Combined Drawing Machines

� Bar Peeling Machines

� Centreless Grinding Machines

� Belt Polishing Machines for Round, Square and Hexagon Bars

Wire Division

� Multi Block Drawing Machines

� Strand Annealing Furnace

� Spooling Machines

Pipe Division

� Tube Mills

� Draw benches / Pilger Machines

� Solution Annealing Furnace

� U bend Tube Manufacturing Facility

Material Testing Laboratories

Fully equipped Chemical & Physical Inspection Laboratories

04

The ultra - modern production and testing facilities used at Hindustan Inox Ltd. ensure highest quality standard demanded by the customers.

Testing Facilities available at Quality Assurance Laboratories:

� 100% Ultrasonic Testing of Internal Defects

� Hydrogen/Oxygen/Nitrogen Testing through LECO Analyzer

� Optical Emission Spectrometers

� Carbon Apparatus

� Radiation Servo Meter

� Material Identification Testing through Mobile Handheld Spectrometer

� Eddy Current Testing

� Surface Testing

Mechanical Tests

� Tensile Strength

� Hardness (HRC, HV, HB)

� Elongation Reduction

� Proof Strength

� Notched Bar Impact Testing

� Torsion Test

Metallographic Tests

� Microstructure

� Macrostructure

� Defect Depth

� Internal Structure

� IGC Testing

� Delta Ferrite Measurement

� Non Metallic Inclusion

Rating (as per ASTM E45 & DIN 50602 - K4 Method)

05

Quality Control

Perfectly calibrated towards quality

Quality can never be achieved by accident. It is always a result of hard work, intelligent planning and careful execution. Hindustan Inox is committed to Quality and the Procedures for Quality Control are properly identified and implemented.

Raw Material Inspection

Raw material is inspected for Chemical and Mechanical Properties and surface defects (if any) before production.

In-Process Inspection

Our team of trained supervisors and quality control inspectors ensure the quality of products manufactured, as per customer requirement. Tolerance, Lobing, Length, Straightness, Surface Finish is checked at different production stages during the production cycle.

Our production team is at the core of the Quality Assurance System.

Finished Goods Inspection

Our Finished goods are inspected from customer's perspective. In this stage surface finish, packing, colour coding, marking, mechanical tests, mercury contamination, macro and micro properties, inter-granular and corrosion properties are looked after. Test certifications comply with the specification and requirements of the customers.

For Guaranteeing quality at every step, we ensure that:

Perfectly documented work-procedures endorsed by 3rd party accreditations, certifications and approvals ensure utmost correctness in Hindustan Inox's everyday operations.

The ultra-modern facilities used at Hindustan Inox ensure highest quality steel demanded by our customers. These facilities are supported by precise input data and work schedules along with ongoing quality checks of all features relevant to the particular order, tailored to meet individual customer's specification.

� EN 10204 3.1B

(Test certificate issued along with all supply)

� EN 10204 3.1 AC (Test certificate issued by an external inspection agency like RMTUV, LLOYDS, Bureau Veritas, DNV, SGS, ITS, etc.)

06

07

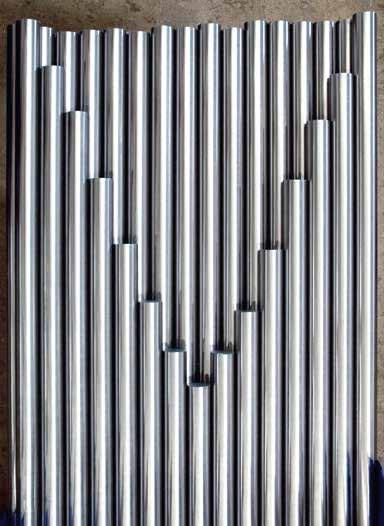

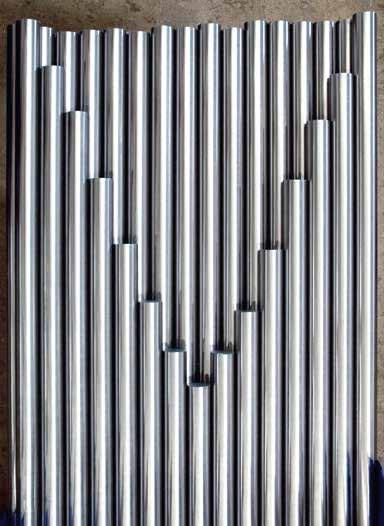

Bright Bars

Superior Quality Bars

Hindustan Inox is one of the largest producers of bright bars. Each bar is very carefully controlled during the heat treatment process in order to achieve a superior quality product.

Round Bars

Size Range : 1.8 mm to 500 mm (1/16" to 20")

Diameter : h8, h9, h10, h11, k10, k12, k13

Tolerances ASTM A484, DIN1013

End Finish : Hot Rolled, Cold Drawn, Peeled & Polished, Forged and Rough Turned Bars

Square & Hexagon Bars

Size Range : 5 mm to 50 mm (1/4" to 2")

Length : 3 meter to 6 meter (10 feet to 20 feet)

Diameter : h11, k11, k12, k13, ASTM A484

Tolerances

Specifications : As per EN, DIN, JIS ASTM, AFNOR, B.S

08

Supply Conditions

Length

3 to 7 metre, 10 to 24 feet and as per customer requirement of specific length

Specifications

As per EN, DIN, JIS, ASTM, AFNOR, B.S, ASME, NACE, AISI, MILS, AMS

Chamfering

Chamfered Ends (30,45,60 Degrees)

End of the Bars above 25 mm are Hard Stamped / Punched with Heat Number and Grade of the material

Heat Treated

Annealed / Solution Annealed, Quenched & Tempered (QT), Quenched & Double Tempered / Double Aged

Special Delivery Conditions

(Available on request )

� Special tolerances - e7, g7, h7, f7, h8, f8, e8, g8

� Special cut to length - tolerance of 10 mm (0.4")

� Surface finish up to Ra value 0.2 (12 RMS)

� 240 -320 Grit Polished

� Straightness up to 0.5 mm per meter TIR

� Special plastic / tube packing for individual bars

� Rings on individual bars to avoid scratch marks

� Wooden slating, Box packaging

� Straps / Slings on the bundles for easy unloading

09

Wide size range in Square, Hexagon & Round shapes

Himax Bars

Himax Brand Himax (IMQ) Bars

HIMAX Bars are Improved Machining Quality (IMQ) Bars produced by Hindustan Inox.

The machinability characteristics are primarily influenced by

� Work hardening rate of chips generated in machining operation

� Nature of sulphide inclusion and their morphology

The three main advantages of IMQ Bars

� Increases Productivity

� Better Tool Life

� Helps achieve excellence in Chip Control (Machinability)

HIMAX Stainless Grades

HIMAX 303, HIMAX 304, HIMAX 304L, HIMAX 316, HIMAX 316L, HIMAX 430F, HIMAX 416

Equivalent DIN - EN Grades

10

1.4305, 1.4301, 1.4307, 1.4401, 1.4404, 1.4104, 1.4005

Precision Ground Bars

Precision Ground Bars

Precision Ground Bars is one of Hindustan Inox's premium product lines. These super finished precision bars are processed using the ultra-modern combined lines and the most up-to-date equipments. The bars are then finished using the specially designed finishing machines which ensure that the size, tolerances and surface roughness are achieved as desired. These bars are packed using a variety of protective materials and distance rings and then placed in strong plywood boxes.

Size Range

4mm to 100mm (1/4"- 4")

Diameter Tolerance

h8, h9, f7, f8, e7, e8

Ovality

Half of the Tolerance of the Diameter

Surface Finish

Up to Ra value 0.2 (12 RMS max)

Straightness

0.5 mm per meter

TIR (0.0015” per feet)

Length Up to 6.7 meter (20 feet 2”– 22 feet)

Heat Treatments

Annealing, Solution Annealing, Oil Quenching, Tempering - as per requirement

Grades AISI 303, 304L, 316L, 410, 416, 420, 430F, 431, 174PH

Werkstoff No.

1.4305, 1.4307, 1.4404, 1.4005, 1.4006, 1.4021, 1.4104, 1.4028, 1.4057, 1.4542, 1.4462

11

Wires

Close chemistries in Welding grades

Stainless steel Wires

Hindustan Inox manufacture the finest range of fine, coarse and welding wires in a variety of grades with a multitude of packaging options.

Size Range

0.10 mm to 12.70 mm (0.004"- 0.50")

Grades

Stainless Steel, Nickel Alloy & Duplex Steel

Finish

Soft annealed – 1/4 hard, ½ hard, ¾ hard, full hard. (Matte or Bright Finish)

Products

12

Wire

Wire

Wire

� Fine Wire � Cold Heading

� Spring

� Welding

Stainless Steel for General Purpose

Applications

EPQ Wire Mesh

Hinges

Staples

Fasteners

0.80 mm To 12.00 mm (0.032" - 0.50")

Soft Annealed, 1/4 Hard, 1/2 Hard, 3/4 Hard, & Full Hard (Matte & Bright Finish)

As per customer requirement

Hindustan Inox Ltd. produces high quality wires for various Industries like Well Screen, Kitchen Appliances, Wire Mesh, Fastener ect.

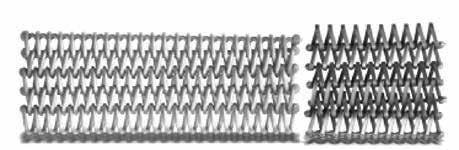

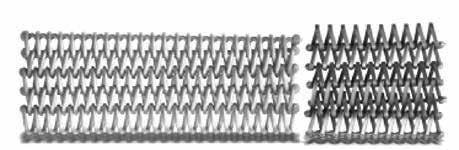

Stainless Steel Wire for Conveyor Belt, Weaving

To Produce Conveyor Belt 0.80 mm to 8.00 mm (0.032" - 0.3125")

Special Characteristics

Bright & Matt

As per customer requirement

� Weaving Wires have beautiful lustrous surfaces and have high resistance to corrosion which combine to account for their profit and yielding market values.

� Hindustan Inox Ltd. Weaving Wires are suitable for various applications in chemicals, petrochemicals, synthetic, fiber, paper and pulp industries, conveyor belts operating in high temperature environment etc.

AISI 200, 300, 400 Series or other International Equivalent Grades

304L, 316L, 314, 310/S, 321, 316Ti, 330cb (35-19 cb)

13

Size Finish Tensile Suitable Grade

Size Finish Tensile Suitable Grade

Applications

Stainless Steel Cold Heading Wires

At Hindustan Inox, we manufacture cold heading wires with very high consistency from 1 mm - 10 mm (0.040" - 0.375") in Annealed and Drawn finish. Our wires are suitable for production of nuts, bolts, rivets, nails ect. We also offer 303cu for special Escomatic applicatoins.

Grades:

302 Chq /XM-7/304 HC/303 Cu/316 cu/305/410/430L

Coating: We offer VICAFIL (Soap) Coating. Our Consistent coating on the wires enables the customer to run our wires at high speeds.

Standards:

ASTM A493 &JIS G4315 standard and other equivalent international standards.

DFARS Approved Cold Heading Wire

DFARS approved Shaved Wires - We also offer DFARS Approved wires with SHAVED Wire-rods for Defence and Aerospace applications.

305, 304L, 316L, 410,430, 316Cu

Stainless Steel Fine Wires

At Hindustan Inox, we manufacture one of the finest quality of fine wires suitable for Knitting, Weaving, Braiding and Spring application. These wires are used in variety of industries like Mesh Automotive, Filtration plants and Braided Hose manufacturing.

Grades: 202/430/304L/316L/316Ti/310/314/321/309/904L

Size : 0.10 mm - 0.80 mm (0.004" - 0.030")

Standards:

ASTM A493 &JIS G4315 standard and other equivalent international standards.

The Characteristics of our Wires are

� Bright and Shiny Finish with high Ra Values

� Consistent Mechanical properties

Wood Screw, Bolts, Rivets, Nuts, Automotive Industries House Hold Appliances, Aeronautics, Building & Construction, etc.

14

Grade Diameter in mm Surface Finish 302HQ, XM7 304HC,

1.00 -10 mm (0.040"

Annealed or

Application

to 0.375")

Soap - Coated

Diameter Tolerance (mm) Tensile (N/mm2) 0.100 - 0.40 mm (0.004" - 0.015") +/- 0.005 850 max 0.401 - 0.80 mm (0.015" - 0.030") +/- 0.007 800 max Packing and Spool type DIN 125/160/200/US200 DIN 160 / DIN200 / DIN250 / US200 DIN 355

Stainless Steel Spring Wires

At Hindustan Inox, we manufacture high quality

Stainless Steel Spring Wires from size: 0.10 mm to 4.00 mm (0.004" - 0.160") in various grades & finish.

The wires can also be supplied with Eddy current testing.

Key Characteristics of

Hindustan lnox Limited Spring Wire:

� Very high consistency in Tensile & Coating resulting in higher productivity for customers.

� With Eddy current testing.

� In Coated or Bright Finish.

� In Normal (NTS) or High Tensile (HTS).

� In various customized packaging option.

Our

Stainless Steel Spring Wires can be supplied with packaging options as under:

Type:

Weight:

15

Diameter

Product

Surface Finish Standards Grade AISI JIS DIN Temper 0.10 - 4.00 mm (0.004" - 0.160") Stearate Coated or Bright ASTM A313 EN 10270-3 JIS G4314/BS 2056 DIN 17224 302 304 / 304H 316 904L 17 - 7 ph SUS302 SUS304 SUS316 1.4310 1.4301 1.4401 Half Hard ¾ Hard Full Hard Size in mm Plastic Spool Coils on carriers or Pallets Wooden Reel

Range as under:

DIN

160, 200, 250

2 - 30 kgs. 5Ibs - 60 lbs

As per

20 - 250 kgs 50 lbs - 500 lbs

550 / 760 K

200 - 500 kgs 500Ibs - 100 lbs

Type:

Request Weight:

Type:

Weight:

Finish Plastic Spool Wooden Spool Metal Spool 0.10 - 0.80 0.80 - 4.00 Bright Stearate Coated X X X Coil Form

Stainless Steel Core Wire

At Hindustan Inox, we manufactures high quality stainless steel wire for welding electrodes

Grades:

ER 308L, ER 309L, ER 310, ER 312, ER 316L, ER 317L, ER 318L, ER 321, ER 347, ER 2209, ER 410 ER 430L, ER 410 NIMO, 330 cb

Application size:

To make welding electrodes

1.60 mm to 5.00 mm (0.062" - 0.187")

Finish: Bright and Matte

Tensile:

700 N/MM2 - 1600 N/MM2

Packing: In coil form or in cut length, packed in wooden boxes

Packing:

In cut length

250 mm to 1000 mm

In bundles

25-300 kgs (25-700 lbs)

In coils

100-1000 kgs (200-2000 lbs) on tubular carriers

Stainless Steel SAW Wire

Grades:

ER 308L, ER 308Lsi, ER 309L, ER 309Lsi, ER 310, ER 312, ER 316L, ER 316Lsi, ER321, ER 347, ER2209, ER403L

Application size:

1.60 mm - 5.00 mm (0.062" - 0.187")

Finish:

Bright or Matt

Packing: In spool 25 kgs/ 50 lbs & packed in wooden box

Weight: 25 kgs / 50 lbs

Weight: 25 kgs / 50 lbs

16

In Coils and in cut length

MM 1.60 2.00 Inch 0.062 0.080 2.40 0.093 3.20 0.125 4.00 0.156 5.00 0.192

Coil with cardboard core

K 415 / Wire Basket

Stainless Steel MIG Wires

Grades: ER 307si, ER 308Lsi, ER 309Lsi, ER 310, ER 312, ER 316Lsi, ER317L, ER318si, ER321, ER347si, ER2209, ER409cb, ER410, ER430LNb, ER 385,330 cb, ER410 NIMO

Size Range : 0.60 mm to 1.60 mm (0.025" to 0.062")

Finish: Bright or Matt

Packing: Spools packed in corrugated boxes and then in wooden boxes of 1000 kgs. We also offer customized packaging options as per customer requirement.

Stainless Steel TIG Wires

Grades: ER 308L, ER 309L, ER 316L, ER 310, ER 312, ER 317L, ER 321, ER347, ER 385, ER2209, ER410 NIMO, ER420.

Size Range : 11.0 mm - 5.00 mm (0.040" - 0.192")

Finish: Bright Finish

Packing: IPacked in Plastic tube/ corrugated boxes of 5kg / lOlbs & then packed in wooden boxes. We also offer customised packaging options.

17

Size (mm) Size (inch) Wire Basket K300 Plastic Spool SD300 Plastic Spool SD200 Plastic Spool SDl00 0.60 0.80 0.90 1.00 1.20 1.60 0.025" 0.030" 0.035" 0.040" 0.045" 0.062" 12.5 kgs / 15 kgs 25 lbs/ 30 lbs 12.5 kgs / 15 kgs 25 lbs/ 30 lbs 5 kgs 10 lbs 1 kgs 2 lbs

Pipes & Tubes

Pipes & Tubes

Hindustan Inox has one of the most experienced production and Q.C team for SS Pipes/Tubes that enables them to produce high quality products, consistently.

Stainless Steel Seamless & Welded Pipes

Outer Diameter

1/8" NB to 8" NB (10.30 mm to 219.08 mm)

Wall Thickness

SCHS to SCHXXS

Specifications

ASTM, ASME, DIN EN (GERMAN)

NF (AFNOR), JIS (JAPAN)

Stainless Steel Seamless/ Welded Tubes & U-Bend Tubes

Outer Diameter

6.00 mm to 101.60 mm (1/4" to 4")

Wall Thickness

0.5 mm to 6.00 mm

Specifications

ASTM, ASME, DIN EN (GERMAN)

NF (AFNOR), JIS (JAPAN)

18

Stainless Steel Welded Pipe Product Range

Outside Diameter: 1/8" NPS to 8" NPS

Wall Thickness:

SCH 5S to SCH 80S

Grades:

TP 304/L/H, TP 316L/H/Ti, TP3 321/H, TP 409, TP 310/S

Applications:

� Onshore and offshore Oil and Gas Production

� Chemical & Petrochemical

� Food and Beverage Processing

� Mechanical and Plant Engineering

� Pharmaceuticals, Paper & Pulp

� Sugar & Railways

Welded Tubes & U Tubes

Outside Diameter: 6.0 mm to 101.60 mm

0.50 mm to 6.00 mm

TP 304/L/H, TP 316/L/H/Ti, TP 317/L, TP 321/H, TP 347 /H, TP 405, TP 409, TP 410, TP 430, UNS S 31500, 31803, 32205, 32750, 32760.

ASTM, ASME, DIN EN (GERMAN) NF (AFNOR), JIS (JAPAN)

� Heat Exchangers, Condensers & Pressure Vessels

� Chemical & Petrochemical

� Power Generation

� Pressure Vessels

� Marine Equipments

� Food & Beverage Processing

19

Stainless Steel Seamless Pipes

Product Range

Outside Diameter: 1/8" NPS to 8" NPS

Wall Thickness:

SCH 5S to SCH XXS

Grades:

TTP 304/L/H (304L: 8% Ni and 10% Ni),

TP 316/L/H/Ti (316L; 10% Ni and 11% Ni),

TP 317/L, TP 321/H, TP 347/H,

TP 410 UNS S 31500, 31803, 32205, 32750, 32760.

Specifications:

ASTM, ASME, DIN EN (GERMAN)

NF (AFNOR), JIS (JAPAN)

Applications:

� Onshore and offshore Oil and Gas Production

� Chemical & Petrochemical

� Energy and Power Generation

� Mechanical and Plant Engineering

� Liquefaction Projects

Stainless Steel Seamless Tubes & U Tubes

Product Range

Outside Diameter: 6.00 mm to 101.60 mm

Wall Thickness: 0.50 mm to 6.00 mm

Grades:

TP 304/L/H, TP 316/L/H/Ti, TP 310/H/L/S, TP 317/L, TP 321/H, TP 347/H, TP 405, TP 409, TP 410, TP 430, UNS S 31500, 31803, 32205, 32750, 32760.

Specifications:

ASTM, ASME, DIN EN (GERMAN)

NF (AFNOR), JIS (JAPAN)

Applications:

� Heat Exchangers

� Chemical & Petrochemical

� Gas Industry

� Nuclear Power Generation

� Pressure Vessels

� Marine Equipments

� Food Processing

� Automotive

20

Tests & INSPECTIONS

We have a 100% in-house testing facility to conduct the below test which insure defect free material

Air Under Water Test

This test is conducted at 150 PSI as specified in ASTM specification. It is conducted over and above the Hydro test to eliminate any error that can occur due to human visual observation.

Weld Decay Test

As specified is ASTM A249 or ASME SA249, Clause S7, the test gives information of the weld and its rate to dissolution. The amount of AsCst structure of the weld broken down by Bead Hammering and / or Rolling is evaluated.

Eddy Current Test

It is conducted as per ASTM specification and ASTM E 426 on entire length of tube.

This test detects as well as controls surface and subsurface defects in thin walls.

Ultrasonic Test

It is conducted as per ASTM specifications on the entire length of the tube to detect cracks

Corrosion Test

It is conducted as per ASTM A262, Practice A, B, C and E. The test ensures that the tube / pipe has adequate corrosion resistance.

Chemical Analysis

We have an in-house chemical testing laboratory to perform analysis on the product.

Hydro Test Packing

Hydro Test is conducted as per ASTM A450, A530 or as customer's specification on 100% pipes and tubes. It ensures that fluid flowing in the pipe and tube is not contaminated with externally flowing fluid.

Third Party Inspection

We accept 3rd party inspection like Ell, PDIL, Bureau Veritas, H&G, UHDE INDIA, SGS, TOYO ENGG, TUV, LLOYD Register, LINDE Process and many others.

Marking

Apart from requirements specified by the customer, we mention the following on the final product : Material Condition, Manufacturing, Grade, Size, Specification & Heat No.

Material is packed in Hessain Cloth, Jute Cloth, Plastic Wrapping or Wooden Boxes. Packing can also be done as per customer requirement.

Microstructure

We certify Microstructure Grain Size (as per ASTM E112). This test ensures that the carbides are dissolved and the corrosion resistance is at its maximum value. The grain size confirms uniformity of property.

Eddy Current Machine

21

Micro Structure Testing

Billets/ Blooms/RCS

Billets/Blooms/RCS

Application

Round Bars and Wire Rods by Rolling, Forged Bars, Forged Flanges by Forging

Grades

201, 202, 303, 304, 304L, 310, 316, 316L, 321, 410, 416, 420, 430F, 431, etc.

Sizes

100 × 100, 120 × 120, 140 × 140, 160 × 160, 200 × 200, 250 × 250

Condition

Concast Blooms & Billets

Surface As Cast Size 40 mm to 160 mm

Condition Round Corner Squares (RCS)

Surface As Rolled

22

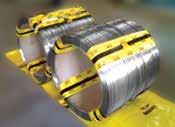

Wire Rods

Wire Rods

Grades

201, 202, 204Cu, 302, 303, 303Cu, 304, 304Cu, 304L, 308, 308L, 308LER, 309Lsi, 310S, 314, 316, 316L, 316Cu, 316Ti, 317, 403, 409Ti, 410, 416, 420, 430F, 430L, 431

Size

5.50 mm to 32.00 mm (0.217" to 1.220")

Tolerance + / - 0.03 mm (+ / - 0.011")

Surface Defect

1% of Diameter mm &

O.D 1200 / 1250 mm

Coil Weight 500-1000 kg (I.D 750/800 mm and O.D 1200/1250 mm)

Packing

HDPE wrapped coils 500 to 1000 kg

Heat Treatment

Solution Annealing for Austenitic Grades, Normal Annealing for Martenistic Grades

Surface Treatment

Hot Rolled for Hot Rolled Annealed and Pickled (with or without coating)

Applications

Bright Bars, Wires, Fasteners, Chains, Threaded Rods, Cutlery, Welding Products

23

Chemical Composition

AUSTENITIC GRADES

24

GRADE W. No. ASTM C Max % Si Max % MN Max % P Max % S Max Max Max Max Max % Cr % Ni % Cu % Mo % Max Nb % Max N2 (ppm) % Ti % Co % 201Cu AISI 201 (3.5% Ni) AISI 202 Ni 4% AISI 204 Cu AISI 302 AISI 303 AISI 303Cu AISI 304L AISI 304HC 304Cu/XM-7 AISI 302 CHQ AISI 305 AISI 310/310S AISI 314 AISI 316L AISI 316Ti AISI 321 AISI 309 AISI 347 1.4372 1.4597 1.4310 1.4305 1.4570 1.4307 1.4567 1.4845 1.4841 1.4404 1.4571 1.4541 1.4828 1.4550 0.15 0.15 0.15 0.10 0.120 0.10 0.08 0.03 0.03 0.03 0.03 0.12 0.08 0.25 0.03 0.08 0.08 0.20 0.08 1.00 1.00 1.00 2.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.50 1.50-3.00 1.00 1.00 1.00 1.5-2.5 1.00 7.00-9.50 5.50-7.50 7.50-10.00 6.50-9.00 2.00 2.00 2.50 2.00 2.00 2.00 2.00 2.00 2.00 2.00 2.00 2.00 2.00 2.00 2.00 0.100 0.060 0.060 0.040 0.045 0.045 0.045 0.045 0.045 0.045 0.045 0.045 0.045 0.045 0.045 0.045 0.045 0.045 0.045 0.030 0.30 0.030 0.030 0.030 0.15-0.35 0.15-0.35 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.015 0.030 14.00-16.00 16.00-18.00 17.00-19.00 15.00-18.00 17.00-19.00 17.00-19.00 17.00-19.00 18.00-19.50 18.00-20.00 17.00-19.00 17.00-19.00 17.00-19.00 24.00-26.00 23.00-26.00 16.50-18.00 16.05-18.00 17.00-19.00 19.00-21.00 17.00-19.00 1.00-1.50 3.50-5.50 4.00-6.00 1.50-3.00 8.00-10.00 8.00-10.00 8.00-10.00 8.00-10.50 8.00-10.00 8.00-10.00 9.00-11.00 11.00-13.00 19.00-22.00 19.00-22.00 10.00-13.00 10.50-13.50 9.00-12.00 11.00-13.00 9.00-13.00 1.50-2.50 2.0-3.5 <=1.00 1.4-3.0 2.0-3.0 3.0-4.0 3.0-4.0 0.30 1.00 0.10 2.00-2.50 2.00-2.50 2500 max 2500 max 2500 max 1000-3000 1000 max 1100 max 1100 max 1100 max 1100 max 1000 max 1199 max 5X (C+N)0.70 5X(C+N)0.70 Nb>+ 10 x%C

AISI 403 AISI 409 AISI 409Gb AISI 410 AISI 416 AISI 420A AISI 420 B AISI 420 C AISI 431 431 S29 AISI 430 F 1.4006 1.4512 1.4006 1.4005 1.4021 1.4028 1.4034 1.4057 1.4418 1.4104 1.4313 1.4122 0.080-0.15 0.08 0.06 0.080-0.15 0.060-0.15 0.16-0.25 0.26-0.35 0.43-0.50 0.12-0.20 0.12-0.20 0.060 0.10-0.17 0.050 0.33-0.45 1.50 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.70 1.00 1.70 1.00 1.00 1.00 1.00 1.00 1.25 1.00 1.50 1.00 1.00 1.00 1.50 1.50 1.50 1.50 0.040 0.045 0.045 0.040 0.040 0.040 0.040 0.040 0.040 0.040 0.040 0.040 0.040 0.040 0.030 0.030 0.040 0.030 0.15-0.35 0.030 0.030 0.030 0.030 0.030 0.030 0.15-0.35 0.015 0.030 11.50-13.50 10.50-12.50 10.50-17/.75 11.50-13.50 12.00-14.00 12.00-14.00 12.00-14.00 12.50-14.50 15.00-17.00 15.00-18.00 15.00-17.00 16.00-17.50 12.00-14.00 15.50-17.50 0.75 0.50 0.75 1.50-2.50 2.00-3.00 4.00-6.00 3.50-4.50 1.00 6x%C 0.60 0.80-1.50 0.20-0.60 0.030-0.70 0.80-1.30 0.020 min 200 min. MARTENSITIC

Cb10Xc Min . 0.75max

GRADES

Chemical Composition

25

ER304L ER 307Si ER-308L ER-308LSi ER308L(Low¾Si) ER-309L ER-309LSi ER-310 ER-312 ER-316L ER-316LSi ER-317L ER-318Si ER-320 ER-321 330GB ER-347Si ER-385/904L ER-409 ER-410 ER-410NiMo ER-420 ER-430 ER-430LNb ER-2209 1.4307 1.4370 1.4316 1.4316 1.4332 1.4332 1.4842 1.4337 1.443 1.443 1.4438 1.4576 1.4551 1.4519 1.4006 1.4021 1.4016 1.4462 0.03 0.20 0.030 0.030 0.02 0.030 0.030 0.08-0.15 0.15 0.030 0.030 0.03 0.080 0.070 0.080 0.150 0.080 0.025 0.080 0.120 0.050 0.25-0.40 0.10 0.03 0.030 1.00 0.65-1.00 0.30-0.65 0.65-1.00 0.25 0.30-0.65 0.65-1.00 0.30-0.65 0.30-0.65 0.30-0.65 0.65-1.00 0.30-0.65 0.65-1.00 0.60 0.30-0.65 1.00-2.00 0.65-1.00 0.50 0.80 0.50 0.50 0.50 0.50 0.50 0.90 2.00 5.0-8.0 1.0-2.50 1.0-2.50 1.0-2.50 1.0-2.5 1.0-2.5 1.0-2.50 1.0-2.50 1.00-2.5 1.00-2.5 1.00-2.50 1.00-2.5 2.50 1.0-2.50 2.00 1.00-2.50 1.0-2.50 0.80 0.60 0.60 0.60 0.60 0.60 0.50-2.00 0.030 0.03 0.03 0.03 0.020 0.03 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.03 0.030 0.030 0.030 0.020 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.20 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.020 0.030 0.030 0.015 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 8.0-10.50 7.0-10.0 9.0-11.0 9.0-11.0 9.0-11.0 12.0-14.0 12.0-14.0 20.2-22.50 8.00-10.0 11.0-14.0 11.0-14.0 13.0-15.0 11.0-14.0 32.0-36.0 9.0-10.5 34.00-37.00 9.0-11.0 24.0-26.0 0.60 0.50 4.00-5.00 0.60 0.60 0.60 7.50-9.50 18.00-19.50 17.00-20.00 19.50-22.00 19.50-22.00 19.5-22.0 23.0-25.0 23.0-25.0 25.0-28.0 28.0-32.0 18.0-20.0 18.0-20.0 18.5-20.5 18.0-20.0 19.0-21.0 18.5-20.5 20.00-23.00 19.0-21.0 19.50-21.50 10.5-13.50 12.0-13.50 11.0-12.5 12.0-14.0 15.50-17.0 15.5-17.0 21.5-23.5 0.75 0.50 0.75 0.75 0.75 0.75 0.75 0.75 0.75 0.75 0.75 0.75 3.0-4.0 0.75 0.75 0.75 1.20-2.00 0.75 0.75 0.75 0.75 0.75 0.75 0.75 0.50 0.75 0.75 0.75 0.75 0.75 0.75 2.0-3.0 2.0-3.0 3.00-4.00 2.50-3.00 2.0-3.0 0.75 0.75 0.75 4.20-5.20 0.75 0.75 0.40-0.70 0.75 0.75 0.75 2.50-3.50 1100 max 300-800 300-1000 300-1000 1000-1500 1000-1500 NA NA NA NA NA NA NA NA 1100 max NA NA NA NA NA NA NA NA 1000-2000 NA NA NA NA NA NA NA NA NA NA 10XC-1.0 8XC-1.0 NA 1.00-1.50 10XC-1.0 NA NA NA NA NA NA 8XC-1.20 NA NA NA NA NA NA NA NA NA NA NA NA NA 9XC-1.0 NA 10XC-1.50 NA NA NA NA NA NA NA NA NA NA NA NA NA NA NA

GRADE W. No. ASTM C Max % Si Max % MN Max % P Max % S Max Max Max Max Max % Cr % Ni % Cu % Mo % Max Nb % Max N2 (ppm) % Ti % Co % AISI 441 AISI 434 Mo AISI 430 AISI 430Nb 1.4509 1.4113 1.4016 1.4511 0.03 0.08 0.08 0.08 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 0.040 0.040 0.040 0.045 0,015 0.030 0.030 0.030 17.50-18.50 16.00-18.00 16.00-18.00 16.00-18.00 0.90-1.40 (3xC+0.30) - 1.00 0.10-0.60 Nb12 x%C FERRITIC GRADES UNS S32205 1.4362 1.4662 0.030 0.030 0.030 1.00 1.00 1.00 2.00 2.00 2.00 0.035 0.035 0.030 0.015 0.015 0.020 22.00-24.00 21.00-23.00 22.00-23.00 3.50-5.50 4.50-6.50 4.50-6.50 0.10-0.60 0.10-0.60 2.50-3.50 3.00-3.50 0.050-0.20 0.10-0.22 0.14-0.20 DUPLEX GRADES AISI 630 AISI 631 1.4542 0.070 0.090 0.70 1.00 1.00 1.00 0.040 0.040 0.030 0.030 15.00-17.00 16.00-18.00 3.0-5.0 6.5-7.80 3.0-5.0 0.60 5XC-0.45 AI 0.751.50 PRECIPITATION HARDENING GRADES 1.4541 X10NiCr SiNb 35-22/ 1.4887

WELDING GRADES

Packaging Process

Hindustan Inox's vision is not restricted to manufacturing good quality products but to safely place these highly finished products on customer shelves. Before the highly finished products are carefully packed, every product is packed as per the requirements for easy identification, storage and handling.

Bars

One end of bar is colour coded as per and ends of the bars above 35 mm are Hardened, Stamped / Punched with the heat number and the grade of the material. Rings are installed on bars to avoid clashing. Bars are also wrapped with High Density Bio-degradable/ Recyclable laminated sheets/wooden boxes.

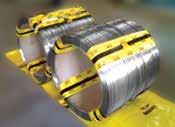

Wires

There are several packaging options for wires. Customers can choose from packing on Euro Coils, coils on carriers, spools, bare coils, HDPE packaging, wooden boxes, drums on pallete or in cheese coil format. We can provide any of the above options with labels for easy identification.

Pipes & Tubes

Each pipe is laser marked with the grade and size for easy identification. Pipes and Tubes can be strapped in uniform quantities and can be wrapped with HDPE, Plastic wrapped or wooden boxes. Packaging can be done as per customer requirement.

26

Rings to prevent collision on every bar

Bars in HDPE packaging

Bars in wooden boxes

Wires in Euro Coil

Wire on crown carrier

Himax Bars with antistatic paper Specs marked on every tube

Pipes strapped in uniform quantity

A Legacy in Stainless Steel

Awarded the Star Performer

in the Category of Stainless Steel from Engineering Export Promotion Council

8 times in a row

Exporting Globally

Our excellent quality and service has won us clients from all over the world

Decades of Experience

For over 35 years we have served the stainless steel industry with our expertise

27

C ELEBR ATI N G

35

11/13, Raghuvanshi Mansion, Raghuvanshi Mill Compound, Senapati Bapat Marg, Lower Parel (West), Mumbai 400 013. Maharashtra, India

+91 22 4340 1414 • Fax: +91 22 4340 1400

sales@hindustaninox.com

Office

Tel:

E-mail:

www.hindustaninox.com