ISSUE 57 | SUMMER 2023 Delivering operational excellence in a datadriven world Overcoming legacy systems Ten steps to a net zero future The future of downhole fishing is digital Critical infrastructure cybersecurity 101

DIGITALISATION SIMPLIFIED TECHNOLOGY HUMANISED Meet ut us at Future Oil & Gas 2023 OPERATE YOUR ASSETS SMARTER, SAFER AND GREENER KONGSBERGDIGITAL.COM

CEO

Mark Venables – Editor in Chief mark.venables@cavendishgroup.co.uk

Managing Director

Adam Soroka

Advertising Director

Mike Smith

Managing Director

Adam Soroka

Advertising Director

Mike Smith

mike.smith@cavendishgroup.co.uk

Digital technology can benefit the oil and gas sector by increasing hydrocarbon recovery, ensuring safety throughout the corporate ecosystem, and improving operational reliability. As the world strives for a sustainable future, no industry is more in the crosshairs than oil and gas. Every new project is scrutinized and more difficult to get underway than the next, so it’s critical that O&G companies maximize value from existing operations. One clear opportunity to manage this feat is to do more with the mountains of data that oil and gas companies have at their disposal by applying emerging analytics and AI capabilities to unlock new sources of value and cost savings.

Harnessing data to improve efficiencies and unlock value requires transformative change and close coordination between the business side and IT—two groups that do not always work together well. Focusing on data and digital innovation as well as on

cross-functional collaboration could also help attract young, tech-savvy talent looking for an innovative and inspiring work environment.

According to Gartner oil and gas companies are adopting cloud and edge computing solutions that span physical locations, functional boundaries, and organizational borders. CIOs can use this analysis to move toward a unified computing environment that delivers low latency, easy integration, and data accessibility.

One of the prime benefits of introducing edge computing is converting the data into actionable insights. The data can be analysed to optimise a system, gain efficiencies in the workflow through gathering and processing the data from the sensors and conducting real-time diagnosis and predictive analysis on the spot.

Oil and gas companies encounter many challenges related to production, revenue, monitoring, and profitability. As a result, prices have been impacted and the urgency to tackle these issues has increased dramatically. One way to address these challenges is to accelerate the implementation of digitisation strategies to help improve resilience and encourage innovation.

Adopting edge computing in the supply chain with transparent operating guidelines can be one such measure which organisations can implement. With digital transformation strategies and solutions, organisations can seamlessly leverage agility and efficiency to enable their enterprises to become adaptable for further growth.

Mark Venables Editor Oil & Gas Technology

01

Oil & Gas Technology Cavendish Group Second Floor Front 116-118 Chancery Lane London WC1A 1PP Tel: +44 (0)203 675 9530

SUMMER 2023 Delivering operational excellence in a datadriven world Overcoming legacy systems Ten steps to a net zero future The future of downhole fishing is digital Critical infrastructure cybersecurity 101

Assets with ServiceMax for Oil & Gas

Asset owners and operators need technology that evolves with them:

Enhance return on investment from field assets through proactive management of the asset’s maintenance lifecycle

Control operation & maintenance costs through better visibility to Cost-to-Serve data of field assets

Minimize equipment downtime and failures through optimization of maintenance intervals and asset history traceability

Reduce safety and compliance incidents through monitoring of safety and regulatory compliance

Accelerate Return on Investment by leveraging pre-configured industry best-practice templates to deliver safe and compliant business processes

“

To optimize field efficiency, GE Oil & Gas needed more real-time visibility into its field service operation. We needed better data on the work activities of our field service engineers. And for that, we needed a field service platform.

Leigh Martin Executive Service Director, GE Oil & Gas

Scan the QR code or visit us online at servicemax.com

To create a legacy of change,

companies need to overcome their legacy systems

20 Dominic Bridgman, Chief Commercial Officer at Amdaris explains why in the modern world, the cherished asset for any effective business monitoring, planning and growth is data. But an abundance of legacy systems can exacerbate data collection struggles, leading to timeconsuming, inefficient, and costly processes.

24

Ten steps to a net zero future

Gary Thomson, Vice President of Sales, Endava explains how digital acceleration can bring you closer to net zero in ten steps

03

Updates 6 The latest news from around the globe Interview: Delivering operational excellence in a data-driven world 16

and Gas Technology

meet the

of challenges

face in today’s volatile business landscape.

NEWS AND COMMENTARY FEATURES

Oil

spoke to Brendan Sullivan, Technology Business Leader at Viasat, about how the company is helping oil and gas operators

myriad

they

How to secure, access and utilise data in a distributed environment and changing world

The energy industry has always been subject to fluctuations, but more so now than ever before. With supply chain disruption and geopolitical instability causing rising costs, the industry is in a state of constant flux.

40

Critical infrastructure cybersecurity 101: harnessing knowledge and ensuring visibility

Industrial organisations are increasingly targeted by threat actors, due to their unpreparedness to tolerate even minor levels of unplanned downtime. Threat actors perceive them as more likely to pay ransomware demands to restore data and systems availability, and operational capacity.

A major logistical challenge 42

Yasmeen Alamango, Head of Marketing, Condantis explores the potential of Distributed Ledger Technology (DLT) and Verifiable Credentials (VC) to address common Identity and Access Management (IAM) challenges.

44

Mammoet has broken several world records in moving a huge 20,300t FPSO into AF Offshore Decom’s decommissioning and recycling facility where it can be dismantled in a controlled, environmentally responsible manner.

Using cloud technology to help change the oil and gas industry

Fishing operations can be complex, and the basic nature of traditional fishing tools means that up until now such tasks have been performed somewhat ‘blind’ by oil & gas operators and service companies, an approach which runs the risk of turning any fishing job into a time-consuming saga.

Energy companies transitioning from SAP ECC: why

now

Richard Evans, Head of Solutions and Innovation at Delaware UK explains why as we move towards 2027 and SAP’s planned reduction in support levels for SAP ECC, it is becoming increasingly important that integrated energy companies start putting their response plans in place.

46

Although the oil and gas industry is often criticised for its impact on global emissions and climate change, it remains a crucial component of energy security. Cloud solutions can help oil and gas companies optimise their operations, reduce downtime, and make datadriven decisions that improve their carbon footprint.

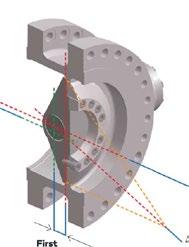

Looking beyond rising stem ball valves

Dehydrating LNG is crucial to the liquefaction process, and valves are central to both molecular sieve system efficiency and ensuring wet gas flows through tanks via continuous thermal cycling.

48

Final word: The pathway to a net zero future for the oil and gas industry

Dehydrating LNG is crucial to the liquefaction process, and valves are central to both molecular sieve system efficiency and ensuring wet gas flows through tanks via continuous thermal cycling.

04 Enhancing operational efficiency with verifiable credentials 32

The future of downhole fishing is digital

36

the time is

38

28

Maximize your AVEVA™ PI System™ investment

Are you realizing the full value of your deployment?

Complex oil and gas environments require a holistic view of advanced engineering and operations to include full life cycle digital twins, predictive analytics, real-time event monitoring, and asset performance management.

By analyzing and optimizing your ET, OT, IT, and IIoT data, you can reduce:

Attend our session

“AVEVA Intelligent Oil & Gas

A holistic approach for advanced Engineering and Operations”

Asset OPEX by 15% 1020%

Project CAPEX by up to

OT/IT spend by 20% or more

Are you ready to reach your digital goals?

See why the oil and gas industry has relied on AVEVA solutions to support critical operations for more than 30 years.

Come visit us: Booth #9

27th June

Russell

Herbert

Industry Principal – Oil and Gas

05

ADNOC’s new EPC logistics business unit secures first major contract

ADNOC Logistics and Services has announced that it has been awarded a $975-million artificial island construction contract by ADNOC Offshore. As part of ADNOC’s In-Country Value program, at least 75% of the total contract value for dredging, land reclamation and marine construction of an artificial island “G” for the Lower Zakum offshore field, will flow back into the UAE economy.

This award is a significant milestone in ADNOC Logistics & Services’ (ADNOC L&S) strategy to pursue new growth opportunities. ADNOC L&S’ Integrated Logistics business unit is an end-to-end, fully integrated energy logistics services provider. The provision of Engineering, Procurement and Construction (EPC) services in the integrated logistics business is a new offering by ADNOC L&S in line with its announced strategy to achieve

significant ongoing growth, including expansion into new verticals. The EPC market is expected to experience substantial growth in the region in the coming years. The company aims to offer a broader range of services to its customers while facilitating the growth of ADNOC’s upstream and downstream operations.

This is the first major award for ADNOC L&S after it listed on the Abu Dhabi Securities Exchange (ADX) on 1 June 2023 following the highest demand globally for an IPO this year.

Captain Abdulkareem Al Masabi, Chief Executive Officer of ADNOC L&S, said: “Capitalizing on our project management expertise, end-to-end logistics solutions, and strategic partnerships, ADNOC L&S is primed to execute major offshore EPC contracts that support our customers’ ambitious growth plans and deliver value to our shareholders. This contract award for the construction of artificial island ‘G’ exemplifies our strategy to tap into new growth areas, showcasing the expanding range of services we offer to our customers and the trust that ADNOC Offshore has placed in us as their partner of choice.”

The Award is part of Lower Zakum’s Long-Term Development Plan, aiming to safely and sustainably unlock greater value while helping to meet the increasing global energy demand. ADNOC Offshore has extensive experience in deploying the artificial island concept for project delivery, resulting in significant cost savings and environmental benefits compared to conventional approaches that require more offshore installations and infrastructure.

With a diverse fleet of 245 vessels and approximately 540 vessels operated and chartered annually, combined with its 1.5 million square meter logistics base in Abu Dhabi and integrated logistics capabilities, ADNOC L&S is the region’s largest shipping and integrated logistics companies.

ADNOC L&S is targeting an average annual EBITDA growth in the low teens over the medium term. This growth will be driven by new contract awards, further expansion of its Integrated Logistics Services Platform (ILSP), and optimized redeployment of jack-up barges.

06

First accredited low-carbon ammonia shipment for power generation dispatched from Saudi Arabia

A first shipment of independently certified low-carbon ammonia has arrived in Japan for use as fuel in power generation. It represents another milestone in the development of this lower-carbon energy solution. The shipment is the result of a successful multiparty collaboration across the low-carbon ammonia value chain. The ammonia was produced by SABIC Agri-Nutrients (“SABIC AN”) with feedstock from Aramco, and sold by Aramco Trading Company to the Fuji Oil Company (“FOC”).

Mitsui O.S.K. Lines (“MOL”) was tasked with shipping the liquid to Japan, then the lowcarbon ammonia was transported to the

Sodegaura Refinery for use in co-fired power generation, with technical support provided by Japan Oil Engineering Co (“JOE”).

The ammonia is categorized as low carbon because CO2 from the associated manufacturing process was captured and utilized in downstream applications.

Olivier Thorel, Aramco Senior Vice President of Chemicals, said: “This is another milestone that highlights the possibilities for low-carbon hydrogen and ammonia made from Aramco feedstock, with the potential to play a role in a lower-carbon future. Not only is low-carbon ammonia a means to transport lower-carbon hydrogen, it is an important energy source in its own right that can help decarbonize key sectors – including power generation for both utilities and industries. By dispatching this accredited low-carbon ammonia to Japan, we are helping chart a course for the development of this vital commodity.”

In 2020, Aramco collaborated with SABIC to dispatch the world’s first shipment of low-carbon ammonia to Japan in a demonstration project. Then, in 2022, Aramco and SABIC AN received the world’s first independent accreditation for low-carbon hydrogen and ammonia products. By the end of that year, the two companies had delivered the world’s first accredited low-carbon ammonia shipment to South Korea. The latest shipment to Japan brings this lower-carbon energy solution one step closer to the mainstream.

At the convergence of Reality Capture & Digital Twins

Cintoo Cloud enables oil and gas companies to leverage their laser scan data in a digital cloud; improving stakeholder collaboration, workflows and ultimately maximising the ROI of laser scanning technology.

Navigate your laser scans with mesh-based scan data coupled with advanced tagging features for quick and easy management of your existing assets and equipment in their existing conditions. Plus, easily upload all of your 3D CAD or Digital Twin models for comparison work. cintoo.com

how Cintoo Cloud can enhance your Digital Twin workflows Watch our demo

See

UK Energy Security Investment Mechanism is step in right direction but many more need to be taken

Offshore Energies UK has responded to the announcement of the Energy Security Investment Mechanism for the Energy Profits Levy (windfall tax) that will see the current total 75 per cent rate be removed if prices fall in the future.

The UK Government has this morning announced that the levy will remain in place until March 2028, introducing a mechanism which means if oil and gas prices fall the tax rate for oil and gas companies will return to 40%. This would be triggered when oil reaches $71.40 per barrel and gas reaches £0.54 per therm for two consecutive quarters.

The industry still faces considerable

challenges to safeguard the jobs of its 200,000 strong skilled workforce, ensure the UK’s homegrown energy security and power the transition to net zero and beyond with homegrown oil and gas rather than imports.

“We’ve always been clear that when the windfall conditions go, the windfall tax should go,” OEUK Chief Executive David Whitehouse said. “This is a step in the right direction, but many more will need to be taken to restore confidence to our sector. We will now work closely with government and lenders to understand the detail of the measure and its effectiveness at unlocking investment.

“Enabling continued UK energy production now and in future depends on a predictable and fair fiscal environment. The UK must be competitive if we are to be successful in the global race for energy investment.

“We are proud to make a huge contribution. In 2022/23 alone we will add over £20bn to the UK economy overall. We provide over 200,000 good, skilled jobs across the length and breadth of the UK. As we build the future there is no simple choice between oil and gas or renewables. The reality is we need both. In the mid-2030s, oil and gas will still provide 50% of our energy needs.

“By investing in homegrown production, we avoid costlier, less secure, and higher carbon imports while supporting an industry we need to make cleaner, more affordable energy in the UK, for the UK. Our sector is expanding into renewable energy, supported by a world class supply chain. We will continue to work closely with government and all parties on the journey to restore sector confidence.”

Collaboration plans to optimize asset performance of FPSOs

Rockwell Automation Inc. (NYSE: ROK), Sensia LLC and Cognite today announced a collaboration that will accelerate the evolution of the offshore industry’s floating production storage and offloading (FPSO) facilities. Digital capabilities developed by the four-company coalition will improve the reliability, availability, safety and efficiency of these critical assets—all while lowering the carbon footprint of their offshore operations.

“Global energy demand continues to increase, and every part of the value chain is evolving to improve production and reduce emissions,” said Steve Gassen, president, Production Systems, SLB. “As digital performance integrators, the power of this coalition comes from our collective knowledge, expertise, and belief that open collaboration will accelerate innovation and decarbonization. SLB will bring advanced digital solutions, subsurface domain expertise, and complex integration and project management capabilities to scale up efficiencies and lower the carbon footprint of operations across every stage of the FPSO life cycle.”

The coalition integrates the entire data life cycle with

targeted automation, analytics, simulation and visualization capabilities to enhance efficiencies in FPSO performance. This results in optimized equipment utilization and energy consumption, improved safety, reduced risks of equipment failure and unplanned downtime, plus better-informed strategic decision making.

“As the leading OEM module automation supplier, Rockwell brings to the coalition its expertise in control and safety systems for FPSOs, as well as extensive experience in power systems,” said Frank Kulaszewicz, senior vice president, Lifecycle Services, Rockwell Automation. “We’ll be complementing the advanced digital solution portfolio of the coalition, as well as bringing network and cybersecurity capabilities to the team.”

SLB has been awarded a contract to develop and implement a control system and dynamic process simulation solution for Petrobras. This strategic multipurpose dynamic simulation (MPDS) solution is being developed in partnership with Inprocess Technology and Consulting Group, a worldwide leader in MPDS, and Sensia, the leading control system and automation specialist in oil and gas.

The MPDS solution will leverage SLB’s expertise as an original equipment manufacturer (OEM) and in offshore construction and operations to provide an immersive digital twin environment to dynamically simulate operational processes and their control and automation systems, train personnel, and strengthen safety elements at five new FPSO units to be installed in Búzios Field in the Santos Basin.

08 Update

Baker Hughes announces major LNG order from QatarEnergy

Baker Hughes has announced an order to be booked in the first quarter of 2023 with longtime partner QatarEnergy to supply two main refrigerant compressors (MRCs) for the North Field South (NFS) project, which will be executed by Qatargas. The MRCs are part of two LNG “mega trains” representing 16 million tons per annum (MTPA) of additional capacity that is estimated to further boost Qatar’s LNG production capacity to 126 MTPA, helping to propel Qatar as a leader in global LNG production by 2027. The order reflects more than two decades of trust and successful collaboration between Baker Hughes, QatarEnergy and its various operating companies across the energy value chain. Most notably, Baker Hughes has supported Qatargas since the early 1990s with core LNG liquefaction technology. This most recent contract, which builds upon a previously announced award for North Field East (NFE) expansion in 2020, will bring the overall number of LNG “mega trains” driven by Baker Hughes’ leading energy solutions to 12.

“We are pleased to be a long-time partner to Qatar, helping to position the country as a leading supplier of LNG and helping to unlock more global capacity,” said Lorenzo Simonelli, chairman

and CEO of Baker Hughes. “LNG will enable the energy transition by acting as a more reliable, affordable and flexible energy source alongside other new energy sources, including renewables and hydrogen. As an LNG technology leader, Baker Hughes is committed to supporting the sector to capture, transfer and transform gas in a way that meets rising energy demand and reduces emissions.”

Like the trains supplied for the NFE project, Baker Hughes’ LNG technology will contribute to improving the energy efficiency of the project through enhanced machine performance. Each MRC train will consist of three Frame 9E DLN Ultra Low NOx gas turbines and six centrifugal compressors across two LNG “mega trains” for a total scope of supply of six gas turbines to drive 12 centrifugal compressors. Packaging, manufacturing and testing of the gas turbine/compressor trains, a unique Baker Hughes offering, will take place at Baker Hughes’ Gas Technology facilities in Italy and leverage its service site in Ras Laffan, Qatar, for maintenance and technical assistance services.

The North Field is the world’s single largest non-associated natural gas field. The NFS project, owned by QatarEnergy in partnership with a number of international oil companies, and operated by Qatargas, is the second phase of the North Field Expansion Project, which was announced in 2017. When fully completed, it will increase Qatar’s LNG production capacity from 110 MTPA, which will be achieved by the end of the first phase North Field East expansion in 2025, to 126 MTPA by 2027.

10 Update

www.bwoffshore.com

We help our clients power communities – by designing, delivering, and operating energy infrastructure for today and tomorrow.

We drive smarter, cleaner, and more sustainable solutions for a lower-carbon future. Together we can do more – faster.

We breathe new life into old assets

We’re developing new ways to extend field life while minimising carbon intensity

We simplify the complex We make decommissioning predictable and cost-efficient

We make big ideas happen

We’re applying our project management and construction expertise to the new energy sector

Talk to our team today

Find out how we can support your needs and contact us by visiting petrofac.com/services

When we work together our energy is limitless

We engineer offshore production solutions to progress the future of energy.

BP starts oil production at Argos platform in the Gulf of Mexico

bp has successfully started oil production at its Argos offshore platform, delivering more energy at a critical time and strengthening bp’s position as a leading producer in the deepwater US Gulf of Mexico.

With a gross production capacity of up to 140,000 barrels of oil per day, Argos is bp’s fifth platform in the Gulf of Mexico and the first new bp-operated production facility in the region since 2008. The semi-submersible platform ultimately will increase bp’s gross operated production capacity in the Gulf of Mexico by an estimated 20%. bp expects to safely and systematically ramp up production from Argos through 2023.

bp chief executive Bernard Looney said: “The start-up of Argos is a fantastic achievement that helps deliver our integrated energy strategy – investing in today’s energy system and, at the same time, investing in the energy transition. As bp’s most digital facility worldwide, applying our latest technologies, Argos will strengthen our key position in the Gulf of Mexico for years to come.”

Argos is the centerpiece of bp’s Mad Dog Phase 2 project, which extends the life of the super-giant oil field discovered in 1998. It is one of nine high-margin major projects that bp plans start up by the end of 2025 globally.

Starlee Sykes, bp senior vice president, Gulf of Mexico and Canada, said: “Safely starting up the Argos platform is an

incredible milestone for bp and a proud moment for our team who delivered the project with an impeccable safety record. Producing some of bp’s highest value, lowest operational emissions barrels, our Gulf of Mexico business has an important role to play in delivering the energy the world needs. I am grateful to everyone who worked on Argos over the years – from discovery to start-up.”

David Lawler, chairman and president bp America: “Argos demonstrates bp’s continued commitment to investing in the US. We’re one of the largest energy producers in the country and are adding more resilient hydrocarbons at a critical moment.”

Operating in 4,500 feet of water about 190 miles south of New Orleans, Argos will support 250 permanent jobs. Standing 27 stories tall, the platform has a deck the length and width of an American football field and weighs more than 60,000 tons. Ewan Drummond, senior vice president, projects, production and operations, said: “Projects like Argos don’t just happen. They take years of careful planning, execution excellence, and brilliant teamwork. Argos is key to our strategy of increasing our Gulf of Mexico production to around 400,000 barrels of oil equivalent per day by the middle of this decade.”

Argos is bp’s most digitally advanced platform operating in the Gulf of Mexico, featuring bp’s proprietary LoSal® Enhanced Oil Recovery (EOR) and Dynamic Digital Twin technologies. Argos has a waterflood injection capacity of more than 140,000 barrels of low-salinity water per day to help increase oil recovery from the Mad Dog field. The platform also has a Dynamic Digital Twin, a bp patent-pending software that links complex data from Argos to 3D digital models of those systems, allowing remote operators wearing Virtual Reality headsets to access data in real time to improve decision-making, efficiency and safety.

12 Update

TotalEnergies renews its OML130 deep offshore license in Nigeria

TotalEnergies, operator of OML130 in Nigeria, has announced the renewal of the production license on this block for 20 years. Located 150 kilometers off the Nigerian coast, the OML130 block contains the prolific Akpo and Egina fields which came into production in 2009 and 2018 respectively. In 2022, production amounted to 282,000 boe/d: nearly 30% was gas sent to the Nigeria LNG plant, notably contributing to Europe’s energy security. The production start-up from Akpo West, a short-cycle project, is expected by the end of 2023. In addition, OML130 contains the Preowei discovery, to be developed by tie-back to the Egina FPSO.

“Through the OML130 license renewal, TotalEnergies is pleased to continue its contribution to the development of Nigeria’s oil and gas sector. This 20year extension will enable us to move forward with the FEED studies on the Preowei tie-back project which aims to valorize a discovery using existing facilities in line with Company’s strategy focusing on low-cost and low-emission assets”, said Henri-Max Ndong-Nzue, Senior Vice President Africa, Exploration and Production at TotalEnergies.

TotalEnergies Upstream Nigeria Limited operates OML 130 with a 24% interest, in partnership with CNOOC (45%), Sapetro (15%), Prime 130 (16%) and the Nigerian National Petroleum Company Ltd as the concessionaire of the PSC.

Unlock Operational AI with INTELIE We’ve made it easier than ever to achieve your business’s full potential Get the most out of artificial intelligence Visit us at www.viasat.com/intelie Copyright © 2023 Viasat, Inc. All rights reserved. Viasat, the Viasat logo and the Viasat signal are registered trademarks of Viasat, Inc. 1911566-060923-002 Update

ExxonMobil Guyana advances fifth offshore Guyana development

ExxonMobil made a final investment decision for the Uaru development offshore Guyana after receiving required government and regulatory approvals. The company expects Uaru, the fifth project on Guyana’s offshore Stabroek block, to add approximately 250,000 barrels of daily capacity after a targeted startup in 2026.

“Our fifth, multi-billion-dollar investment in Guyana exemplifies ExxonMobil’s long-term commitment to the country’s sustained economic growth,” said Liam Mallon, president of the ExxonMobil Upstream Company. “Our Guyana investments and unrivalled development success continue to contribute to secure, reliable global energy supplies at this critical time.”

The $12.7 billion Uaru project plans to include up to 10 drill centers and 44 production and injection wells aimed at developing an estimated resource of more than 800 million barrels of oil.

MODEC is constructing the Floating Production Storage and Offloading (FPSO) vessel for the Uaru project, which will be called the Errea Wittu. ExxonMobil is utilizing its diversified supplier base to help reduce costs and safely accelerate development in its Guyana operations. The company’s diverse supplier base includes nearly 1,000 unique local Guyanese suppliers, exemplifying Guyana’s growing in-country supply chain capabilities. Two FPSOs, the Liza Destiny and Liza Unity, are currently operating offshore Guyana and safely produced an average of 375,000 barrels of oil per day in the first quarter. A third FPSO, the Prosperity, is expected to be operational later this year, adding 220,000 barrels of daily capacity from the Payara development. ExxonMobil made a final investment decision on the fourth offshore project, Yellowtail, last year. The company is targeting to have six FPSOs online by the end of 2027, bringing Guyana’s production capacity to more than 1.2 million barrels per day.

ExxonMobil’s Guyana developments are generating around 30% lower greenhouse gas intensity than the average of ExxonMobil’s upstream portfolio. According to the independent research firm Rystad Energy, they are also among the best performing in world with respect to emissions intensity, outpacing 75% of global oil and gas producing assets.

ExxonMobil affiliate Esso Exploration and Production Guyana Limited is operator and holds 45% interest in the Stabroek Block. Hess Guyana Exploration Ltd. holds 30% interest and CNOOC Petroleum Guyana Limited holds 25% interest.

14 Update

Learn more: http://yt-twixbeam-gb-en.layher.com

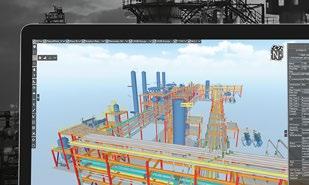

UniversalPlantViewer 6 was designed to enhance collaboration and optimise your entire plant lifecycle. A complete digital model with 3D model, P&ID, LaserScan, drawings documents, data – all linked together and simple accessible for every stakeholder, everywhere on all devices. UniversalPlantViewer has unique functions to keep your digital model up-to-date and support your workflows.

2 The TwixBeam is the high-strength and multifunctional aluminium beam for every requirement.

2 Low weight, easy dismantling and high strength.

2 It fixes, stabilises, bridges and connects.

2 The TwixBeam has surprising variability and flexibility.

The Aluminium TwixBeam THE SMART BEAM IN SCAFFOLDING

www.caxperts.com

UniversalPlantViewer See your Industry in new dimensions Interested? Ask us for individual solutions!

Delivering operational excellence in a datadriven world

Oil and Gas Technology spoke to Brendan Sullivan, Technology Business Leader at Viasat, about how the company is helping oil and gas operators meet the myriad of challenges they face in today’s volatile business landscape.

16 ARTIFICIAL INTELLIGENCE

As the world’s leading network and technology provider for connecting and securing complex, distributed sites and operational assets, Viasat provides optimised solutions that deliver competitive advantages for oil and gas operators. With over 12000 onshore and offshore sites deployed around the globe, Viasat is the world’s leading provider of secure communications networking solutions for remote exploration and drilling. Viasat provides system integration services that can be customised to deploy communications systems for global connectivity. The monitoring tools and support and designed to protect the remote network and site data.

One of its essential offerings to the industry is Intelie by Viasat. This machine learning platform uses automated realtime processes to manage operational risks that threaten safety, compliance, integrity and performance. Viasat delivers powerful AI solutions that help organisations transform data into results.

What knowledge will you impart to the delegates at the upcoming Future Oil and Gas events?

I use this event to focus on operational AI for oil and gas operators to increase profitability. It all comes back to data, an industry awash with data, especially at the operational level.

Intelie by ViaSat is what we call operational AI, and the whole point is to eliminate or reduce what they call NPTnon-productive time - or hidden loss time. We are using data and machine learning on top of data to achieve these results, but where the rubber meets the road is on a decent size fleet for big operators. If you can get a one per cent improvement in efficiency, that is around a billion dollars of actual savings.

Data is not new to the oil and gas industry; it is very mature in digital

data, so how can you help them get business value from that data?

They are good at data because of all the seismic data they collect. There is just a new way to take advantage of that data and let them change their operating procedures while the process is running, rather than waiting on the analysis of a one-year campaign to say we could have been more efficient. We are increasing the cycle time of operational improvements using machine learning and AI on top of the data in real time.

Can you give me an example of what that means for operators?

Almost all operators and contractors now have collectors on rigs, mostly deepwater rigs. They are collecting 10,000 to 50,000 data points a second of downhole and topside data for a drilling campaign. That is a tonne of data, and a lot of that data goes dark, but it is sampling almost every single second.

Intelie focuses on real-time operating centres where we take this data in real-time. We have experts sitting on shore rather than being on each rig, and can we have them look over the shoulder, suggest improvements in the operational process, and make decisions faster? Suppose you can remove a couple of people off the rig. In that case, that is millions and millions of dollars of savings because you can have a 25-year expert helping five or seven rigs at a time instead of sending them out individually to each rig.

Suppose you can do that real-time advisory system on top of these drilling campaigns. In that case, you can save hundreds of millions of dollars in cost because you speed up decision-making, and at the same time, you significantly improve safety, which oil and gas care more about than just making a profit. The drill room itself is the most dangerous place on the rig, so getting some of these people out of the red zone and even just putting them somewhere else on the rig also significantly improves safety.

Is this data there already, or do you need to add extra sensors to gain complete results?

You have the sensors on the rig and the connection in between; even deepwater rigs are all connected by satellite. Then you have all the work happening in the cloud to conduct data analytics in real-time. We do nothing with sensors; we let the experts handle that.

Is this drilling as well as its completion and flow control? What benefits do you deliver?

We concentrate on drilling and completions. We do offer some production solutions, but we focus much more on

17 ARTIFICIAL INTELLIGENCE

upstream and support both the drilling contractor and the operator. If it is a drilling contractor, they get most of the value out of predictive maintenance; they just want the assets to be up more often, and some deepwater drill rigs are up to a million dollars daily. If they have unplanned downtime of several days, they lose millions of dollars in deferred or lost revenue. Anything you can do to increase uptime benefits the drilling contractor.

If we are dealing with the operator, they care much more about staying to plan, getting to first oil faster, and shortening the drilling campaign from six to five months. The quicker they finish with the upstream, the faster they reach profitability. We try to work on the penetration rate, feet per hour or days drilled. Then, avoid things that make you redrill, such as washouts.

How much of a problem is it getting access to real-time data from all the operators and OEMs involved in the programme?

It is their data, and for the last ten years, operators have been writing into their contracts with the drilling contractors that they have to have access to this data. What it is really about is that there are better ways to use the data than ten years ago. There have been significant advancements in machine learning, which keeps improving each year. Maths has been around since the 50s, but we did not have the

computational power to do as many maths models in real time as we do today, with edge computing and the power of the cloud.

How difficult is it to develop accurate algorithms?

Many people can do real-time visibility, and many people are competing in lab-built machine learning models. The big problem with that dream of taking data and putting it in a lab scenario is that it takes six months to develop a new predictive algorithm. Ninety per cent of those never make it out of the lab and into production. Most of those projects have high aspirations, but they fail, and it is because they are very tricky when there is that much data and even in the same oilfield, there can be a lot of nuances. There is a lot of noise in that data, either the quality of the data or missing data, that when you are building a lot of algorithms and using a lot of sampling, you have to tune them in production. This takes a while, people lose patience, and the operations guys lose trust. Where we are different is we try to do three things at once, we try to build this absolute real-time state model to give you visibility into exactly where you are on the ground and precisely what is going

18

ARTIFICIAL INTELLIGENCE

right or wrong. We have over 100 different dashboards running over 200 models simultaneously in the cloud. We have a real-time state model that we create, and then we conduct physics models, so nothing predictive, but there are complicated maths models on calculated events. We have a state model and a series of physics models, and then we will apply predictive models on top of that. It predicts where you should be against what the other models say, which is where it gets interesting. If we change some assumptions about speeding up, slowing down and taking a bit more risk, can we get back to plan?

Are these the ‘what if’ simulations you run to create the best scenarios?

Yes, you hear these terms thrown out, which I think is just jargon for jargon sakes from data scientists. It is all about heuristic models or stochastic models. Suppose you are running an extensive simulation with a stochastic model. In that case, you are taking every variable and changing the conditions, and you might run 20 million simulations to see which is better. Assuming the following parameters is the best possible plan with the best probability of the outcome you want.

When you run a heuristic model, it is like solving Sudoku. You have to guess and see and then work backwards to see if it worked. The same happens in very complicated scenarios, and with maths, there are too many unknown variables. So you must lock a few in, make an educated guess, and then simulate it. Doing heuristic models in real time is tricky, but that is where we are going; we are trying to present all those things together.

How do you deliver it, and how can someone monitor the 100s of dashboards you provide?

We go into year one of the new engagement, and we will throw out 100 or 200 dashboards, and then it will get rationalised down to around ten that are

used. We try to use Intelie to remove all the subsystems from OEMs and be the integration platform so that you can go from different dashboards to one set.

The end customers for Intelie are not data scientists; our platform is designed for senior engineers, like the 20-year-old veteran who knows the oil and gas process backwards and forwards. It is for them to look through the data and make a decision faster. We have to throw a lot of different looks out there because, depending on your speciality, they are used to seeing information in a particular format, and they still want to see that.

Are your real-time insights advisory only and not control?

No, that is not true. We started as read-only, and then we went to advisory, which is much more of a legal thing than a technology thing because people would not hand over decision-making to the machines. You did not want the operator doing advanced maths. In my keynote, I will talk about our joint venture of ViaSat and Transocean, the biggest drilling contractor in the world, and a robotics company out in Norway called Intellilift, and we created a JV for autonomous well construction. We are remotely piloting and running the drill room from transition and shore using AI.

It seems like Intelie is at the cutting edge of AI in the oil and gas sector.

Intelie is not a new solution; it has been around since 2009 and has worked in oil and gas since 2012. There have been many startups in the last couple of years and a lot of unproven technology; a lot of snake oil is being sold. We have patents in history, meaning we have been through all this pain before and learned many lessons.

Secondly is what we already talked about: we try to use multiple forms of visibility and context through physical models and then apply them on top of it. We go from basic to enhanced to advanced.

Thirdly we try to create an innovative human-machine interface and try to dumb information down for super advanced users and allow them to modify our code directly if they have the skills to do that. We will enable them to reorganise all their views to get it the way they need to see the data, and with that human-machine interface, we took a step further by putting robotic control into it. It is not just an advisory system, it is now a fully round trip system, and by doing that, you take it to a whole new level. This is one of the most advanced AI platforms in the world.

19 SMARTER

ARTIFICIAL INTELLIGENCE

To create a legacy of change, companies need to overcome their legacy systems

These legacy systems typically operate in silos and often rely on on-premise servers rather than the cloud. Both scenarios are incredibly inhibiting to digitalisation changes needed to provide a holistic overview of resources and assets.

For oil and gas companies, there’s an apparent delay between initiating digital projects and seeing them through, with McKinsey research showing that 70 percent of such endeavours have not gone beyond the pilot phase. Much of the recent data on the sector comes from 2020, with 63 per cent of oil and gas executives then describing ‘the ability to change quickly enough’ as a major challenge. The pandemic has certainly prolonged this issue.

As companies look to tackle these issues, what exactly is blocking the pathway to change?

The blockers to progression

The very fact that many digital projects are

20 LEGACY SYSTEMS

Dominic Bridgman, Chief Commercial Officer at Amdaris explains why in the modern world, the cherished asset for any effective business monitoring, planning and growth is data. But an abundance of legacy systems can exacerbate data collection struggles, leading to timeconsuming, inefficient, and costly processes.

not progressing beyond the pilot phase could signal either problems with the integration of technology or with organisational culture and operations. Rather than any technological issues, McKinsey pinpoints the three primary organisational blockers to project progression as: demonstrating clear value, employee uptake and skills, and siloed digital projects.

For the oil and gas sector these blockers can often be apparent. Legacy systems can be ingrained into many operations and the nature of measuring value can shift in line with meeting current production needs alongside evolving business goals. Instead, companies need to initiate projects that can deliver and quantify this value.

This involves migrating systems to a central cloud-based server to provide a unified overview of applications, leveraging external expertise (if needed) and upskilling employees in the process. With this implemented, these companies can then calculate current operational efficiency, highlight bottlenecks and set out tangible metrics for

measuring project results and KPIs.

Inefficient and unused systems can also be counterproductive, with up to a quarter of data centre power consumed by equipment that no longer performs ‘useful work’. Likewise, integrating new digital systems in silos inhibits overall efficiency needed for sustainable power consumption. The more systems you have working independently, the less overview you have of your assets to make overall operations more efficient.

An effective digital transition is paramount to confronting these issues, and Industry 4.0 is ushering company operations into the world of the Internet of Things, cloud computing, AI and analytics.

Overcoming the legacy issue with external expertise

There are businesses that have acquired a host of bespoke developments and commercial off-the-shelf (COTS) software over the years. This accumulated range in systems can create an imbalance in the standards, functionality, efficiency and security of some of these products. It’s a recurring issue that Amdaris has observed over its 15 years developing software and systems in businesses — both within the oil and gas industry and elsewhere. Consequently, organisations are enlisting external software development teams to conduct the task of pivoting their legacy systems to a cloud-based, integrated structure.

This process, for instance, could involve carrying out a three-stage plan of stabilisation, optimisation and enhancement. The external team could provide immediate value with both current operations and any skills gaps by shadowing teams and conducting a research and discovery process to understand legacy applications. This approach means companies can take advantage of a smaller and cost-efficient group of experts who can spend time with end users, integrate COTS applications, and help to train employees and encourage uptake of any new systems.

Moreover, through mapping out an entire architecture of a company’s application suite onto the cloud, the team can eliminate any

apps from the system not being regularly used to provide instant cost savings alongside enhancing automation with tools such as data input and report generation. The creation of this central database means that individual system maintenance is no longer required and focus can shift to enhancing applications to boost efficiency, reduce running costs through cloud optimisation, and, ultimately, drive innovation.

The pod approach

Some companies will already have applications in place or have recently completed a digital transformation process. What they need is someone to run their day-to-day operations and implement any upgrades as and when necessary. Yet a major operational risk — and perhaps a factor for projects falling at one of the first hurdles — is an over-reliance on an employee for software expertise. This is a short-term approach that places your dependency for these knowledge and skills on a tightrope: if that employee departs, it leaves a major skills gap and heightens operational risk.

A managed services provider alleviates this concern by providing a whole team of support. However, some of these providers can comprise thousands of support staff working across hundreds of clients — each with their own range of application suites — obstructing any means to develop expertise in a single system or identify any issues as they emerge. This can lead to a quick-fix mentality as opposed to implementing longerterm solutions.

Some solution providers, such as at Amdaris, approach managed services with a methodology that mitigates a reliance on an overstretched service. This is the ‘pod’ approach. Teams of dedicated support workers are built in ‘pods’, with each pod large enough to circumvent individual points of failure but also small enough to offer continual support. Any enhancements to applications and systems can be identified as the pods progress and familiarise themselves with a company’s applications.

Of course, each product — and each company — has its own set of requirements. The essence of

21 LEGACY SYSTEMS

outsourcing and the pod approach means that the pods are incredibly adaptable and able to respond to fluctuating business requirements; and as a company expands, so too can the size of the pod, helping to meet growing service needs and demand.

Gaining a real-time overview with APM

Through developing such a system architecture and support ecosystem, companies can then carry out improvements that add value: upgrades can be made with little operational interference and unscheduled outages can trigger automated alerts, even before the team is aware of issues. This ability to capture data and spot and predict issues is an example of asset performance management (APM) and it can be instrumental in transforming a company’s software strategy.

The process involves bringing technologies together to gather data across operations and store it in a database that is accessible across the organisation. Real-time tracking, for example, can empower companies to monitor energy consumption of appliances and ways to optimise

power networks, while advancements in AI and predictive analytics can foresee infrastructure problems, including the potential for damaging leaks and spillages, by understanding patterns in data. Through this real-time understanding of infrastructure, companies can then optimise resources accordingly.

From managing supply chains to enhancing transport networks, having a central hub of data that gives decision makers an understanding of their physical assets is fundamental for optimising efficiency, productivity and sustainability. It empowers leaders to spot trends that would not have been possible to see otherwise and, as a result, to take the most appropriate and effective action. Oil and gas has to keep up and even forge ahead of these sectors. That process starts with overcoming its current legacy systems predicament.

Creating a legacy of change

With software skills and expertise increasingly hard to come by, and with resources and budgets also stretched by factors such as tech job losses and cost-of-living constraints, organisations are

seeking other means of managing and developing their software applications. This is leading companies to engage with outsourcing options to build exceptional teams on limited resources and adopt agile processes.

But this is not simply a case of ‘working together’. At Amdaris we have found that through adopting a progressive delivery ethos, organisations can leverage extended software development teams that seamlessly integrate into their business, culture and operations. Through the pod approach, each team is bespoke and able to adapt to a company’s unique needs, collaborating as their ‘strategic partner’. And, finally, through investing in APM, companies can have the oversight to spot and predict issues before they happen, saving valuable time and reducing costs.

If the industry is to progress forward, maximising efficiency while enhancing access to data and system upgrades, then making the move from legacy systems to cloud-based technology will be fundamental to creating its own positive legacy of change.

About Amdaris

Established in 2009, Amdaris is your trusted partner for building high-velocity extended delivery teams. Working from our Bristol headquarters and Eastern European delivery centres, Amdaris acts as a flexible, strategic partner that supports, guides, and challenges our clients to lead from the front and stand out from their competition. With a Progressive Delivery Approach and a team of exceptional professionals, Amdaris works to make impossible challenges a reality by integrating with our clients’ business and culture to deliver game-changing solutions and take them to the next level. From consultancy to delivering expert software development teams, a partnership with Amdaris is about more than just ‘working together.’ We dream together, tackle obstacles together and, ultimately, we win together.

22 LEGACY SYSTEMS

Ten digital steps to a net zero future

Gary Thomson, Vice President of Sales, Endava explains how digital acceleration can bring you closer to net zero in ten steps

As even a cursory look at the agenda for Future Oil and Gas 2023 will demonstrate, Net Zero is both a priority and a problem for this industry. There is no simple route to a decarbonised business model for an extractive sector. But an industry-wide programme of digital acceleration can build a critical mass of sustainable practices that will drive emissions down.

When we talk about digital acceleration, we’re describing an iterative, continuous process of taking on new technologies that further your strategic aims.

Digital technologies are force multipliers for all sorts of efforts to mitigate the industry’s environmental impacts. At the upstream stage, tech frameworks like data analytics and cloud computing can make exploration and production greener.

The industry’s willingness to modernise its systems will be a defining aspect of its transition towards Net Zero. Let’s go through ten key steps for how you can make your own digital acceleration journey a success.

24 SUSTAINABILITY

1 Define challenges

Nothing worth doing is easy, but the climb ahead for the oil and gas industry is particularly steep. To reach Net Zero, the sector must be replace many timetested processes with more sustainable substitutes that might not instantly bed in.

Oil and gas companies will also have to add new technological layers on top of these workstreams, like carbon capture and renewable generation. There’s no way around this; customers, governments, and the planet all demand it.

2 Draft the strategy

Taken on its own, digital acceleration is a challenging journey that requires a cleareyed strategy. But using that journey as a means to a larger end introduces a new dimension of complexity.

Each organisation will build its own long-term strategy, consisting of its goals for reducing emissions and how the technology it adopts will support that mission. Targets and timescales must be set, roadmaps drawn up and visions communicated to chary stakeholders.

3 Define what success looks like

What percentage reduction in total Scope One emissions, over five years, would constitute a meaningful reduction for a supermajor? What average flaring intensity should a state-owned producer aim for by 2035? These are the kind of key performance indicators (KPIs) that oil and gas companies will already be charting in their sustainability journeys.

But let’s peel back a layer and think about the metrics for tracking the success of the digitalisation strategies designed to unlock these sustainability wins.

Good strategies aren’t interchangeable; what is crucial information for one

organisation might seem beside the point for another. But speaking broadly, every company will want to track metrics around process efficiency, data quality, analytics maturity, automation and cybersecurity.

4 Assess your technology infrastructure

Digital acceleration is impossible without a robust technology infrastructure to build on. Your network, compute resources, data platform and edge capabilities must be capable of scaling to incorporate new products and platforms.

For most energy players, this will look like a hybrid cloud setup that incorporates on-premise data centres, commercial cloud and edge devices.

The only way to really know which technologies you can feasibly integrate is to carry out an assessment of your integral infrastructure. Establishing the health of your systems, their level of modernity, their security and their scalability will reveal how ready you are to proceed with your digital acceleration project.

5 Drill for data

Armed with a strategy and (hopefully) an IT infrastructure that’s up to scratch, the task of digitalising the upstream process can begin in earnest.

Making exploration and production processes greener depends largely on two things: how much data you can collect and how you analyse it.

In the first instance, adding IoT sensors and drones at various points in the upstream process will give you so much more to work with. You’ll now be able to start monitoring your equipment’s performance and energy efficiency in real-time.

25 SUSTAINABILITY

SUSTAINABILITY

6 Process your data

Much like oil, data is useless until its refined. That’s where today’s advanced data analytics and machine learning algorithms come in.

These tools can sift through vast amounts of geological and seismic data. The insights they produce can improve reservoir characterization and optimise drilling operations.

The current boom in AI tools may well prove to be a pivotal moment in the energy sector’s sustainability mission. You’ve probably heard a lot of chatter in recent months about the potentials of ChatGPT to upend fields like media and software development. But this field of technology has similarly transformative ramifications for the energy sector.

AI models can analyse wave action and stress on oil rig assets, seismic data, production history, and reservoir characteristics. This near-immeasurable mass of data points is then moulded into simulations of future output. By inferring the hidden patterns in dense data that humans can’t spot, AI could blaze a trail for sustainable energy.

7 Change the extraction energy mix

No software application will ever turn oil and gas into renewable resources. But digital acceleration programmes can mitigate the environmental stress of their extraction.

Most upstream projects are themselves fuelled by the kind of hydrocarbons they are set up to extract. But advances in battery technology mean that wind, solar and wave power sources are now capable of powering rigs.

Carbon capture, utilisation and storage (CCUS) gets a sceptical hearing from some quarters. Yet few commentators have quite appreciated the efficiency boost that contemporary data analytics frameworks can bring to this crucial prong of decarbonisation. When fed to automation systems, the performance insights generated by machine learning algorithms allow CCUS systems to become self-optimising. As these capabilities are rolled out further, we may see carbon capture rates rise with them.

8 Work on your people’s skills

All this can only happen with the right know-how. Drilling engineers may, quite understandably, not be well-versed in data management best practice. But to pull off a successful digital acceleration programme, the whole organisation should have some familiarity with what’s going on. That requires an institutional mindset of continuous learning.

You can upskill employees in core digital acceleration technologies and principles by collaborating with educational institutions and industry partners. Rather than mandatory tick-box exercises that employees mindlessly click through to get back to what they’re doing, courses should inspire employees to engage with the rationale behind the project.

9 Use digital to stay compliant

More and more national governments are moving towards enshrining Net Zero targets in law This makes complying with a constantly variegating mass of regulation increasingly onerous. One happy byproduct of adopting digital technologies is that they can take much of the hard work out of this obligation.

The data acquisition and analytics capabilities you’ve cultivated along your digital acceleration journey will make environmental monitoring and reporting significantly easier. The environmental standards built into most of the new technologies you’re likely to adopt should also bring down the average environmental impact of your operation as a whole.

10 Find your place in the energy ecosystem

To paraphrase John Donne, no company is an island (even if its rigs are). Every organisation in this space exists alongside and leans on other entities, large and small. These include service providers, technology companies, governments, and, of course, other energy producers.

There’s a lot of knowledge to go around, and your path to Net Zero will only become smoother by tapping into it. Form partnerships and build bridges wherever you can; when it comes to technology adoption, expertise is everything.

Let’s go for green

Digital acceleration is hard, exacting work. But the chance it offers the oil and gas industry to transform its environmental impact is reason enough to start immediately.

This project will require precise technical know-how that not every organisation will have at hand. That’s where Endava can help.

Our teams of engineers, analysts and consultants have joined forces with some of the world’s top energy producers, wholesalers, and retailers. We’ve worked with them to integrate technologies and principles like AI, machine learning, UX, predictive analytics and cloud compute. As a result, they’re not just leaner; they’re greener too.

We’re ready to help you define and execute a technology strategy that will secure your contribution to a more just and sustainable future. Let’s connect.

26

How to secure, access and utilise data in a distributed environment and changing world

Climate change and the push towards renewable energy sources only add to the complexity. In addition, energy companies are increasingly vulnerable to cyberattacks - recent research indicated that the energy sector is the most likely to pay cybercriminals’ ransom demands - significantly increasing the need for effective IT solutions.

IT teams in the energy sector are being challenged to navigate this landscape while also managing costs, ensuring network resilience, and keeping up with the latest technological advancements. Some of their concerns include:

Feeling the strain of significant data growth: Unstructured data on company file systems is growing inexorably, with employees struggling

to find the information they need and data management becoming more complicated with the rising use of larger file formats like 4D Grappling with growing demands and lower budgets: IT teams needing to match data management strategies to changed budget priorities

Adopting modern technologies successfully: Companies are pushing to use smart technologies such as Artificial Intelligence (AI) or Machine Learning (ML) to gain quicker and greater insights into available energy reserves or anticipate market trends, but such solutions can increase IT infrastructure data loads, creating new accessibility issues Protecting against the ever-growing threat

of ransomware: The continuously increasing threat of cyber attacks demands new approaches to ensure data security. For the energy industry, this brings acute challenges because its legacy IT infrastructures are hard to defend and modernise.

Priorities for data managementfive key tips

Modern cloud storage infrastructures and file data services can help address these priorities while delivering a series of game-changing operational benefits for challenging data management conditions. Here are five fundamental priorities that energy organisations’ IT managers should consider:

# 1 - Modernise infrastructure with cloud storage Explore supporting your organisation’s

28 DATA MANAGEMENT

The energy industry has always been subject to fluctuations, but more so now than ever before. With supply chain disruption and geopolitical instability causing rising costs, the industry is in a state of constant flux.

changing business growth initiatives with cloud-native infrastructures that deliver effective file access. These will help eliminate on-premise storage infrastructures and piecemeal connections for regional offices or hybrid working models that require constant maintenance. It’s reckoned that cloud storage delivers 60% savings over legacy infrastructures’ capital costs.

#2 - Replace static infrastructure with flexibility

Plan the shortest path from all locations, however extreme or remote. Cloud storage unites the data from multiple locations and does away with the need for manual back-ups to disk at local offices. The caching of active files for fast access means that all remote or offshore teams can be brought more effectively into collaborations and project work.

• #3 - Embrace a cloud-first approach

Shift to a cloud-first file data services strategy to manage business-critical scale in a flexible, cost-effective way – new offices and capacity can be

added without the need for long planning cycles or budgeting for additional infrastructure management costs.

#4 - Favour modern approaches over traditional file backup

Create a golden master of all data using immutable objects – cloud platforms maintain immutable copies of every file and provide a local access point.

#5 - Take a holistic approach to tackling ransomware

Protect, detect, recover – deploy a fast and robust protection and recovery strategy at all levels of the stack - cloud storage systems and file data services deliver game-changing disaster recovery capabilities in the event of outages or malicious attacks because they can roll back to the exact point immediately before an incident to identify damaged files locally and complete file restoration often in minutes without the users even noticing – unlike legacy systems where damage assessment alone can take days.

Rapid recovery is a breakthrough for energy companies. The research by Sophos found that energy and utility companies typically recover less than two-thirds (62%) of information lost, even after paying cybercriminals’ ransoms.

Reaping the benefits of a modern approach to data management

Real-world examples show the impact of these five priorities in the field:

Global oil and gas services provider Penspen has undertaken more than 10,000 projects since its formation, and now has major offices in London, Mexico, Houston, Abu Dhabi, and Bangkok, with operations in over 100 different countries. The company modernised its infrastructure with the Nasuni File Data Platform, benefiting from unlimited capacity, enhanced data protection, and one global namespace. Nasuni, backed by Azure Blob storage, enabled a transition from traditional file server hardware and backup systems to a single file data services platform, giving the company a more agile, flexible infrastructure. The Nasuni cloud-native approach to file data enabled an

29 DATA MANAGEMENT

DATA MANAGEMENT

accelerated shift to virtual desktop infrastructure (VDI) at the start of the coronavirus pandemic, to support the now remote workforce without having to worry about disrupting project delivery, global collaboration or productivity.

Nasuni’s data backup and recovery capabilities have also proven invaluable, given the need to manage the growing threat of ransomware. Having had to manage instances of files and folders caught by ransomware, the organisation utilised Nasuni’s Continuous File Versioning to dial back files to the last snapshot before the attack, enabling them to get back up and running within a few hours.

Penspen’s shift to Nasuni delivered real value as the entire global workforce was transitioned to a working from home model, without having to worry about disrupting project delivery, global collaboration or productivity. With Nasuni, Penspen can now spin up Edge Appliances to cache active files wherever fast access is needed – and spin those VMs down just as quickly. Yet that single source of truth is still the gold copies of all files stored in Azure Blob.

Nasuni ensures that all file data scales in low-cost Azure Blob storage, while the Edge Appliances running in Azure use only a small amount of Azure premium disk to deliver high-performance I/O for frequently used files. Thanks to Nasuni’s intelligent caching algorithms, Penspen only provisions premium disk for 1.8% of its total storage footprint. Even that could be overkill, and the infrastructure team might successfully reduce that number.

Major oilfield services provider Ithaca Energy was struggling with slow and cumbersome information sharing across worldwide locations due to its existing file storage set-up. With a diverse portfolio of offshore assets and an onshore office, the company aims to deliver sustainable growth underpinned by operational excellence and financial discipline. The acquisition of Chevron’s Central North Sea assets had expanded Ithaca’s file data by 250% but the infrastructure team had already begun looking for a new way to store, protect, and share its unstructured data, long before that deal.

The company decided to invest in a new cloud-native

storage system that would replace the existing legacy network attached storage (NAS) file system and chose Nasuni. The company put together a cost model which included, amongst other things, hardware file storage, tape backups and other products incurring annual maintenance fees.

Ithaca offshore users can now access data locally without the requirement for additional equipment. Meanwhile, the onshore teams are able to access the same files and folders simultaneously. If Ithaca lost their on-site storage or Aberdeen headquarters, the Nasuni platform would enable them to load an appliance into Microsoft Azure, allowing access to their files through a web browser for seamless business continuity.

When Ithaca analysed the new set-up, it was clear that the Nasuni subscription-based model offered cost savings. In addition, its infrastructure team would not have to go through a refresh every three to five years or purchase large volumes of tapes. These cost efficiencies that played a critical role in its selection of Nasuni. The new infrastructure resulted in file access being reduced to merely minutes, helping the company save a staggering $15 million in resource costs across the business. The upgrade

improved the company’s operations, making its data management far more efficient and agile.

Improved file sharing without compromise

Cloud storage and file data services are proving to be a real game-changer for energy companies struggling with data management challenges, allowing them to share business-critical data with greater ease and security while substantially cutting costs associated with traditional legacy infrastructures.

Despite tough operational constraints, energy companies are now able to benefit from sharing critical data with each other and third parties, without the traditional downsides, thanks to modern cloud storage architecture and file data services. The real-time access to data that is inherent in these modern approaches means companies can respond rapidly to fast-changing conditions and opportunities. Combined with efficient data analysis and processing capabilities, this presents immense operational and business benefits for energy companies to shape the future of their industry.

30

THE BLUEPRINT FOR UNSTRUCTURED DATA

Reliable access to cloud enterprise storage is critical to maintaining connection to oil rigs and construction sites around the world, but their remote locations add a layer of complexity. The oil and gas sector needs the ability to store and share large seismic files on a global scale — while maintaining the sanctity of data.

USER PRODUCTIVITY

Global File Sharing

BUSINESS CONTINUITY

Data Protection and Ransomware Recovery

POWERED BY CLOUD SCALE

GLOBAL INFRASTRUCTURE

Multi-Site Scalability

BUSINESS INSIGHTS

Data Intelligence

CLOUD CHOICE

Multi-Cloud Portability

To combat this challenge, Nasuni has created the oil & gas industry’s first Blueprint for Unstructured Data. This guidance helps IT leaders meet their responsibility of putting data first.

POINT 01

POINT 02

POINT 03

Be ready to support business growth initiatives

Implement the shortest possible path to final storage from all locations

Adopt a cloud-first data storage strategy

POINT 04 POINT 05

Create a golden master of all data from day one, using immutable objects

Protect, detect, recover

Nasuni is a leading file data services company that helps organizations create a secure, file data cloud for digital transformation, global growth, and information insight. WWW.NASUNI.COM Scan this QR Code to download the eBook!

Enhancing operational efficiency with verifiable credentials

As digital innovation continues to disrupt the traditional oil and gas sector, it has become increasingly important for companies to adopt new technological solutions that improve operational efficiency while maintaining strong security measures. Digital identity emerged as a critical area as companies need help managing the access identities of employees, contractors, and partners across a complex network of systems.

By leveraging the emerging technology of Distributed Ledger Technology (DLT) and Verifiable Credentials (VC) or adopting a hybrid approach, companies can improve security, streamline operations and empower their remote workers across the value chain. Further on, we will examine a Proof of Value (PoV) project in the nuclear sector, highlighting the benefits of VC for remotely managing employee identities, and tracking training credentials and security clearances.

While every organisation has unique cybersecurity and identity requirements, there are common needs across industries where IT infrastructure is large, complex and distributed. How can organisations leverage emerging technologies to enhance operational efficiency?

With complex supply chains and multiple stakeholders involved in the production and distribution of oil and gas resources, robust

identity verification and authorisation mechanisms are essential to ensure only authorised personnel have access to critical systems and data. The common challenges we see across the sector centre around the following three themes:

1. Identity and Access Management (IAM) –Managing access identities of employees, contractors and partners; Ensuring robust identity verification and authorisation mechanisms

2. Operational Efficiency – Streamlining operations to reduce costs and improve productivity; Empowering remote workers to access critical systems and data

3. Cybersecurity – Protecting critical systems and data from cyber threats

IAM plays a vital role within an organisation’s overarching digital transformation programme. As companies increasingly rely on digital technologies to drive growth and operational efficiency, they need strong IAM systems to protect their digital front door and safeguard network and data security and integrity. Once mere concepts, new technologies, like Verifiable Credentials, have been rolled out across healthcare, nuclear, and education sectors in response to the growing demands of the pandemic to move highly skilled workers between distributed sites swiftly and securely.

Verifiable Credentials use distributed ledger technology and are a digital representation of

attributes such as certifications, special training or qualification. A specific party, such as an employer, training centre, or regulatory body, issue them. They allow individuals to securely hold these credentials in a digital wallet to share personal attributes with an organisation for verification or authorisation. The credentials are tamper-proof and can be cryptographically secured, making them a safer alternative to traditional identification methods. These credentials could help companies to reduce the risk of fraud, streamline their supply chains, and improve operational efficiencies, unlocking the full potential of digital transformation.

Distributed identity and Verifiable Credentials provide a secure, transparent way of managing and sharing personal information that puts the individual at the heart of the solution and allows individuals to have greater control over their data, which they can share with specific entities without compromising their privacy.

As centralised systems are often the targets of cyber-attacks, distributed identity reduces the reliance on centralised systems by moving critical data to decentralised networks. Furthermore, distributed identity systems can facilitate cross-border identity verification and authentication, eliminating the need for cumbersome and expensive identity verification processes.

32 DIGITAL IDENTITY

Yasmeen Alamango, Head of Marketing, Condatis explores the potential of Distributed Ledger Technology (DLT) and Verifiable Credentials (VC) to address common Identity and Access Management (IAM) challenges.