TECHNOLOGIES 03

Charlotte Bell

Contents

Part A (pages 02-04)

Project Cristalleries Planell.

Architects Harquitectes.

Year 2016

Location Barcelona, Spain.

Part B (page 05)

Lecrure Discorse

Standardised Systems

SIGNIFICANT TO SITE LOCATION

Connectivity Infrastructure

The site is well connected to the main motorways within the Barcelona district. The main road which the site sits is connected the Avinguda Diagonal, one of the key axial routes into central Barcelona. The site is also well connected via rail and metro with the ‘L3’, and ‘L5’ and rail network ‘Media Distancia’ into central Barcelona and the rest of Spain/Europe.

Ecological and Environmental Evaluation

Project Cristalleries Planell. Architects Harquitectes. Year 2016 Location Barcelona, Spain.

Conservation and Listed

Buildings

The site contains 2 remaining façades of a glass factory. The developers brief defined that these façades should be preserved and incorporated into the design. This maintains the architectural style of the area. Using the façades creates constraint of style, geometry and site extent but the opportunity of retrofit and less embodied carbon in design.

Historic District Landmarks

The neighbourhood is largely centred around the catholic church and congregation centre of the church square to the south These are large landmarks of the district as a whole with the opportunity to the building as being in close proximity to the building.

TO SITE CONTEXT

Urban Segmentation

The building is in the district of Sarria- St. Gervasi an outer town district of Barcelona mostly residential. The district is characterised by its close proximity to the Collserola mountain range and its religious heritage.

Grid Network

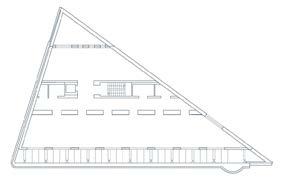

The grid pattern around the site is not extremely strong giving opportunity freedom to the plot sizes and shapes. The key road network create the triangular shape plot of the site constraints to the size and regularity of geometry in design.

Urban Routes of the Neighbourhoods

Urban Morphology/Architectural Style

The existing building incorporated into the design as well as majority of the surrounding buildings are of the ‘Catalan modernist style’building a strong character to the area. The architectural style is recognised by asym metrical shapes and curved lines- often influenced by nature.

SHAPING THE BUILDING WITH THE CLIMATE CONTEXT DESIGN DUE TO THE CLIMATE CONTEXT: summer sun angel 470 winter sun angel 450 large distribution of glazing and a building span atrium used on the south face to enable maximised sunlight into the plan/programmed space solar chimneys faced to the south west as this is the prevailing wind direction south west prevailingdirectionwind north west atrium to naturally light the north of the programme glazing locations solar chimneys How the wind changes the site and how the shape of the site changes the design to not create wind tunnels. Where different aspects are for the sun and the shape is to absorb lots of sun- this is beneficial for the venturi effect. How the wind is used to create pressure vacuum. Sun path to orientation SUN WIND Average Temperature Barcelona (-2020) Wind Rose (prevailing wind) Combined Climatic Analysis 2020 Analysis of Chimney Design (due to climatic considerations)

In creating a sistainable building the architect’s design responds to:

- “2.Priorities Building and Site Reuse”

This is by creating a building which is reusing the site of an derelict glass wear fabric thus enhancing the urban realm and usage of a once derelict land. This is also a signifi

listed facade (of the existing building) the new build intervention SIGNIFICANT TO SITE HISTORICAL CONTEXT

“6. Create mixed use development with density appropriate to local context”.

Despite the building not being mixed use (primarily office/teaching) the building is contextual to its context. Features include building height, architectural style/predictability and it fits within the existing city block.

Sustainable Connectivity and Transport Consideration to the Design’s sustainability in consideration to this RIBA category include:

- “3.Prioritise site selection with good proximity to public transport.” as explored previously the site is well connected to the public transport systems within Barcelona. It connects the district to central Barcelona by the close metro and train stations, but also to the rest of Spain via the same train network. If this is not a accessible feature for some users provision for cars is viable by the extensive road networks, however, car parking is minimal in the close walking distance to the building.

”4.Provide high quality pedestrian links to local amenities.” A shown in the map above the site is extremely well connected to the rest of the building by foot. Pedestrian routes to the local community congregation points and landmarks are direct and easily accessible to most.

- Provisions for increased use of bicycles with a small store in the main entrance (north atrium). This suggests to the users of the building a lower emission form of transport.

The primary structure is comprised many large repeating components building a structural grid. The components are:

-reinforced concrete composite slabs,

-load bearing masonry walls (interior and exterior (Fig. 23)),

-reinforced concrete foundation (strip and pad configuration)

- basement structure (Fig. 04)

- historic masonry facade (south and north west facade are 300-460mm thick with de creative rendering),

- roofing system (Fig. 02).

The Secondary Structure

The secondary structure (indicated in blue) is comprised of support and partitions including:

-I section steel profiles (280mm cross section used (in conjunction with mortar screen and metal ties to support the existing facade on the south facade),

-non load bearing masonry interior walls

- steel cross bracing(used to support the

vertical load load carries down to the primary masonry walls bwlow (to foundations and diserpated into the gfround) vertical load (distributed on via roofing/masonry walls/dynamic loads) horizontal load path to distribute the load the edge of the slabs/ middle primary load bearing structure vertical load path to distribute the load to the below primary masonry walls via the slab reinforcement steels/ concrete load path Grid Pattern Main Roads Subsiduary Roads Pedestrian Routes + Congrigation Areas Main Pedestrian Proximity Route Case Study Site Main LandmarkCommunity(Church) Main Community Congrigation Area (Church Square)

PV flexible panels for solar harvesting welded to the solar chimney structure.

load bearing masonry walls. Pad founda tions are used in parcel to support other primary components. The Section Steel profiles have reinforced concrete pad foundations lie beneath.

-The basement has its own structural grade build up (Fig 04.)

Sustainable Communities and Social Values Social Values and links to the community are key within the design and programme of the building, exemplified in the design:

- “1.Prioritise peacemaking that expresses identity and territory.” The design encapsulates the character of the area sue to architectural style it also retention of the existing listed façades. The design creates a ‘place’ that expresses the area as the programme for linguistics is emerging the new people of the area into the local association and language.

- “3.Create place for social interaction.” This is done by creating mixed use approachable spaces for people to congregate. Due to its close proximity to the other local landmarks (church Paroquai de Sana Matla dol Romoi de les Corts and other cafés and restaurants surrounding the square) this will attract users for leisure- creating a ‘place’.

- The local character of the area is retained and not altered too much by the design being sympathetic and exemplifying the existing listed facade. Similar building height massing and materials are used. The use of glass is an evident reference to the buildings former use as a glass wear factory.

Roof Structure

there is an intermediate concrete slab block support from the load of the solar chimney. The solar chimney steel framework is screwed onto the concrete base with the flat components at the bottom of the linear base.

The modular standardised system at each riser location within the primary load bear ing masonry walls. These walls hold the all vertical servicing of the building. The standardised system fill the bespoke service cavity leading through to the venturi solar chimney at the top creating a whole system for heating cooling and ventilation.

riser modules

service

General Wall Build Up:

operable timber double laminated glass windows

risers and venturi chimney vents within the load bearing masonry walls- are standardised modular in order to distribute ventilation/heating and cooling evenly to the programme

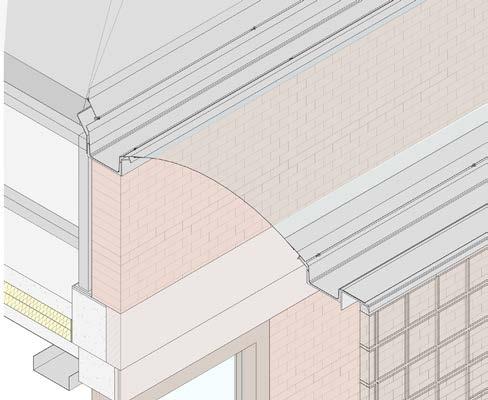

the existing facade wall (load bearing masonry) maintains the character and heritage of the facade. Supported by reinforcement pins and a H280 steel profile

the aluminium profile paves locking mechanism sits upon the parapet of the heritage facade joining to the glass brick. The glass block are then joined to the roofing system via the same mechanism at the top which successes onto the aluminium glazing plate.

A bespoke design was used to explore the heritage value of the retained façades (south and n-west) whilst enabling full structural stability (i.e. structural steel). The new build glass block gives a contemporary design to the facade and has environmental attributes. H280 steel profile

The modulation of the slabs creates a standardised slab with intergrated beams every 50cm. The structure is intergrated using a ‘T-shape’ (slab and projections every 50cm) with screen DPM and Insulation addition (tertiary). The beams are reinforced by the secondary structure of the U shaped cermet casissons (20x40x40cm) for extra support and provide acoustic performance assets to the classrooms. The U-shaped caissons are used to prevent deformation in high load and stress events to the T shaped slab and beam structure.

Load is transferred lateral along the T shape beams and to the vertical (load bearing masonry walls) to e carried to dissipation in the foundations.

to the

old and new build facade work together to create a heat buffer (the atrium

The basement structure is overall primary component as apart of the foundations, however as a competent has secondary and tertiary aspects. The exterior walls (reinforced concrete) are primary with reinforced concrete strip foundations laid under the east-west walls. Inverted buttress filled with screed support the load bearing walls preventing collapse due to the porous earth.

Load is carried via the load bearing concrete walls to dissertation in the reinforced concrete foundations. Axial load is carried via the inverted buttresses when not directly onto the masonry

Building of the New

6.02m Structural Floor Height classroom classroom 6.5m 7.0m Dimensions and Programming of the Case Study (in section) 2F (6.2m) 3F (9.30m) classroom Finished Floor Height EF 6.02m 9.12m Structural Floor Height 12.3m Structural Floor Height Atrium South Height (13.8m) 5.85m Finished Ceiling Height 8.95m Finished Ceiling Height 12.05m classroom classroom classroom north entrance atrium Circulation corridor Circulation corridor south atrium 18.8m 10.16m2.0m9.21m Indications of: grid spacing (spans) max: 7.0m min: 5.6.0m Atrium North West Height (xm) Sky Light Central Height (xm) Structural Floor Height Atrium South Height (xm) Structural Floor Height C Sky Light Central Height (xm) Atrium South Atrium North West Height Sky Light Central Height (xm) Structural Floor Height Atrium South Height (xm) Structural Floor Height spans structural grid (speculative) structural circulation core steel structural support Brief Understanding of the Natural Lighting & Ventilation Strategy Sun Winter- 45 Sun Summer 47 Desired Sun Penetrations to Atrium/Internal Rooms The sky light in the centre gives additional light to the internal classrooms- creating natural light source from both orientations The chimneys use the venturi effect, meaning that wind for pressure vacuum and creating large surface area fr heat (via the sun) is needed -1B (xm) Street Level (xm) GF (xm) 1F (xm) 2F (xm) 3F (xm) Atrium North West Height (xm) Finished Floor Height Finished Floor Height Finished Floor Height Finished Floor Height Structural Floor Height Top Building Height (chimney) (xm) A C EF xm Structural Floor Height xm Structural Floor Height xm Structural Floor Height Sky Light Central Height (xm) Structural Floor Height Height (xm) Structural Floor Height xm Finished Ceiling Height Glass Block Wall Atriums Venturi Chimneys Sun Penetration Points Wind Penetration (SW) The Compositions of the Case Study Look at the brief for the things need to detail indications of: - Finished floor + ceiling levels -key datum/levels -grid spacing (spans) The building transforms the heritage listed facade built in 1913 (south and northwest) into a educational office mixed use space. The buildings programme houses “an adult educational centre, a language standardisation consortium” (AV Monografais, 2018, p.68). The atrium are distributed so that the largest facade (with the additional glazing block wall) is on the south facade to optimise lighting. Dimensions of the Case Study (in plan) ii) general arrangement: Atrium North West Height (xm) Structural Floor Height D Sky Light Central Height (xm) Atrium South Height (xm) (structural self imposed)structural load (building envelope/ floor+roof slab/ beams/partitions) offices: 2.5-4.0 kN/m2 partitions: 1-2 kN/m2 plant room- 7.5kN/m2 Ultimate Load FactorsDead Loads- 1.4 kN/m2 Live Load (imposed)- 1.6 kN/m2 Working load- x1.5 kN/m2 Total- 4.5 kN/m2 Live Loadhumans unfixed furniture staircases (in use) Live Load Hydrostatic Pressure Live Load- Wind Live Load- Tectonics Dead Load- Self Structural Weight Dead Load- Human Occupation + Furnishing Top Building Height (chimney) (xm) B D EF Roof Slab/ Envelope Atrium North West Height (xm) add what each space used Structural Floor Height Structural Floor Height Top Building Height (chimney) (xm) A C D EF Structural Floor Height Sky Light Central Height (xm) Structural Floor Height Atrium South Height (xm) Structural Floor Height Finished Ceiling Height Structure Identification of the Composite SlabThe grid is in load bearing positions of the load bearing masonry walls from east to west, with less of a defined pattern from north to south. The pattern is determined by the concrete components at intermittent floors and the reinforced concrete slabs and the T’shape. spacing 50cm. The three exterior walls increase stability as give triangulation to the latices structural grid. *i-iii speculation due to indefinite inflation of the north to south structural grid spacings. 7.0m BESPOKE DESIGN Fig. 01 Fig. 02 Fig. 03 Fig. 04 Fig. 08 Fig. 07 Fig. 05 Fig. 06

the new build additions to south facade: -glass block glazing -H280 steel profile -glazed atrium cover existing listed facade load bearing masonry

screed mortar and stainless steel pins join the retaining wall and steel profile to support the heritage facade

The atrium are glazed sky lights which are crane installed joined with stainless steel screws to the coping on top of the new build masonry Venturi Solar Chimneys(x4) are installed (in positions showed above) over each programmed space. A steel frame truss system is added then ETFE membrane to water proof- this is stretched over the atri um glazing to ensure waterproofing.

Ecological and Environmental Evaluation

Identification of Key Characteristics, Constraints and Opportunities to create an appropriate interior environment:

01 An opportunity if the site is the proximity to the motorway. A constraint due to the in the negative externalities of sound from abundance of passing cars. This could have influenced the arrangement of the design to ensure less glazing on the north side.

02 The building layout defined strongly by the road layout/hierarchy. This is both an opportunity and constraint due to lack of flexibility but ability to have clear determined spaces. The plot size does not change determining the triangular shape. The building programme determined by the road layouts as entrances and sound/ proximity to a main road

03 Opportunity in a sheltered area with the building heights around and the protections from SW wind as are taller (can create a building height whatever wanted)

04 The opportunity to use the climatic conditions to create a well ventilated/ heated/cooling internal environment with use of the solar venturi chimney to opportunity to create a comfortable internal environment with use of understanding of sun for the venturi chimneys. The programme alters to create the optimum use of habitable space.

Massing for a Comfortable and Healthy Environmental Space:

Lighting, Cooling, Ventilation Impact on Massing Stratergies: The habitable spaces which are mostly populated line up with the solar chimneys which determined the heating/cooling /ventilation. This is programmed to make a conformable interior space as vents/services are easily distributed.

ENERGY AND ENVIRONMENT

01 sun path indicates the location of the two atrium for an interior environment lit with natural sunlight. 02 two atrium- north and south 03 the large mass requires 4 solar chimneys which help to regulate the internal environment’s heating. (one over each habitable area). 04 the original site boundary and the west and south retaining facade, constraints to the proposals massing potential

Due to the conditions of the developer requirements to maintain the west and south facade as are listed and a heritage characteristic the massing has to follow the triangular shape of the plot. This was a constraint to the environmental strategy of the site as the strategy had to fit with this irregular shape.

An opportunity of the mass is the largest elevation south facing enabling a glazed wall. This creates a conformable internal environment due to properties of indirect sunlight and heat buffer.

Programming for a Comfortable and Healthy Environmental Space:

The atrium at either side to light the rooms directly next to them (main programme rooms).

The plant room is in the area at the centre with other ancillary as this is the least habitable areas at the GF plan.

Sky light at the centre of roofing to give more habitable well light interior in the centre of the mass where the atrium would not light with natural daylight.

The chimneys are lining up with the main programmed rooms to optimise the internal environment (humidity and heat) of these areas.

The classrooms are on the atrium fro maximised natural sunlight and less use of mechanical systems.

Large breaks in the internal walls to create a larger open plan naturally light and ventilated area.

The only evidence of a drainage system is within the solar chimneys at roof levels. It can be speculated that this drainage system is to capture condensed water from the chimney system. This would occur due to the high pressure air in the roofing area which would have a high water content. The water would exit to the atrium floor/gardens below in a ploy of water recycling.

*All speculative as there is no evidence of another water reclamation system. There is a 2 water tanks in the basement plant room which supply water to the WCs as well as fire safety systems. The water pump extends in pipes to the riser (in cavity void) to the WC units (2x floor). This vertical movement is the only necessary. The same distribution is the grey water/waste disposal into the septic tank (plant room) then to the mains connection.

Ventilation and Heating + Cooling:

cross ventilation between the atrium and daylight into all dimensions of the plan needed (except the circulation core) thus minimising the artificial lighting needed.

How the Solar Chimneys (Venturi Effect) Create an Interior Environmental Quality:

01 the sunlight onto the metallic solar chimney catalyses the venturi effect (adding energy to the system) thus creating the power vacuum.

02 mechanical system (ground source heat pump) pumps cold air into the atrium and classrooms (via vents in the floor) which can mechanically cool the internal environment.

Circulation core which is at the centre as is the least appropriate habitable interior environment as is in the centre of the mass away from the atrium

*the distribution on risers on the north risers is the same as indicated on the individual indicated.

The heating cooling and ventilation is all controlled by the solar chimneys and the chambers associated. There are service voids in the load bearing masonry walls which hold the modular service units which connect to the solar chimney. Using the venturi effect air is heated cooled and ventilated vent to shaft to chimney.

The heating and cooling is also determined by the atrium ‘buffer zone’ reducing the heat loss in winter whilst being used as natural ventilation all generated by the solar chimneys on the roof (and actively by the ground source heat pump). Underfloor cooling and heating is introduced into the under floor systems. The distribution is only that of the programmed classrooms and offices to highlight the passive systems and only use the energy intensive active systems where most needed.

Lighting and Electrical Distribution: electricity is needed for the powering of classroom activities (in cluded in this description the distribution of fibre). The fire sys tems, socket and lighting systems all need the electrical power and therefore the provision for electrical distribution via the riser (x2 in load bearing masonry walls) and 3 horizontal is distributed east to west. Subsidiary distributes are north to south for extra connections. The servicing follows the riser to the service hori zontal distributor trays in the ceiling and then feeder wire binders to the lights, windows,sockets etc.

HEATING + COOLING

The impacts of the atrium on the internal environment create a soft sunlight indirect at most periods of the day. Indirect sun light prevents glare, solar gain and over lighting. By use of the natural daylight in a conferable way, the provision for artificial daylight is diminished (until night) with only one light source per room.

The south elevation is largely glazed at the top floors to allow increased sunlight into the south atrium thus the interior to maximise the buildings orientation. By using top-light atrium, this maximises the assets of the buildings orientation as allows fro maximised lighting.

To prevent excessive solar gain the atrium is useful in creating a heat buffer.

Passive Mechanism (mostly effective in Summer):

The venturi system (using he solar chimneys on the roof of the building work in a passive system on the premise of a pressure/heat vacuum. A shown in the diagram to the left the air is circulated when the pressure decreases due to its heat. It exits thought the chimney top and the cycle repeats to ensure the internal temperature and air quality is maintained. Stale and hot air is prevented. The components needed for this are the chimney shaft, vent and chimney structure. As explored previously the shape and colour of the chimney further enhance this

Underfloor Heating and Cooling System (Active)- via ground source heat pump

The active system of underfloor heating and cooling is mostly only used in winter to heat the building. A lot of the cooling is passive via the solar chimneys. The system works by the ground source heat pump retrieving the heat stored 100s of metres below ground level and then heating water which is pumped through the fleets. The water heats the air around it heating the interior space. In summer the cooled water (from the ground source heat pump) automatically adapts to the interior temperature- balancing the interior humidity levels and avoiding condensation.

OVER VIEW OF SEASONAL HEATING+COOLING AND LIGHTING STRATERGIES

In the hotter summer months, the buildings systems are prevailing the overheating of the building as well as air quality control in ventilation and humidity.

In the cooler summer months, the buildings systems are pr4eventing heat loss and poor air quality.

03 there is a pressure gradient from the GF to the top of the chimney with high pressure to low pressure. The hot (low pressure air) moves to the top along the pressure gradient. Visualising the Internal Environment Created:

04 there are vents in each room (main programmed class rooms) which bring the hot air up into the chimney to be dispersed.

05 the air exits the top of the chimney due to the pressure vacuum being maintained by the SW prevailing wind.

06 the internal temperature and conditionals are conformable due to the circular systems of the venturi systems.

Water Cycle In creating a sustainable building the architect’s design responds to: - “1. Provide Low Flow Fitting and Appliances” In order to reduce the amount of flow thus water use in the building the toilets are reduced in number to 2 per floor. This is within regulatory guide lines. The toilets and sinks used a low flow.

- “3.Provide Leak Detection” By use of the ETFE waterproof membrane the likelihood of leaks is minimal due to its durability and longevity.

- “6. Create Sustainable Urban Drainage that supports natural aquatic habitats and human amenity” Placement of a small terrace garden under in the south atrium creates a habitat. The urban drainage system is directly above therefore it can be speculated this is the water source for the garden.

- No provision for any other points are provided in rainwater, grey water collection or recycling. It can be

Good Health and WellBeing Consideration to the Design’s sustainability in consideration to this RIBA category include:

- “5. Design spaces with good indoor daylighting,lighting and glare control” with use of both natural daylighting designed by the atrium and artificial lighting the indoor space is designed well for lighting. The design allows for operable window closings to manage glare- the atrium space is also indirectly lighting the indoor area therefore the light is not too intense thus comfortable.

- “6. Design spaces to adaptive thermal confront standard” due to the environmental strategy including both passive and active system the thermal comfort mechanisms are adaptable. Underfloor heating and cooling can be used to directly change to comfort levels and the venturi solar chimneys enable a ‘normal’ thermal comfort level.

- “10.Provide indoor and outdoor planted spaced” the planted terrace creates an indoor niche.

of

There are atrium at either side of the programme (long slender south atrium and triangular north west atrium). This interior feature of design creates an interior light with indirect sunlight. By having an atrium at either side of the mass this allows the large interior to be fully naturally light The daylight is indirect thus appropriate in a classroom environment.

It can be shown that due to the atrium at the north (Fig.09) and south (Fig.10) the interior sunlight is of a low exposure, preventing glare, however ample enough fro a conformable and effective workspace.

Net Zero Operational Carbon Social Values and links to the community are key within the design and programme of the building, exemplified in the design:

- “1. Prioritise deep retrofit of exquisite g buildings” there cannot be claims of deep retrofit as the building only maintained two façades. This is retrofitting of some building elements whoever critical to deep retrofitting.

- “3. Fine tune internal environment with efficient mechanical systems.” The internal environment is design to be predominantly run on passive mechanical systems, therefore reducing the operational carbon for energy running. The components of this system are the venturi solar chimney, operable windows and the north and south atrium- working together creating an effective environmental strategy running with low operational carbon needs. The system is not ‘zero’ operational as lighting using electrical power and heating/cooling using the GSHP.

The chimneys allow for the air hot,humidity stale air to be removed (using the venturi effect, acting like a vacuum). The ground source heat pump ventilates the space using a chamber into the south atrium. With operable windows the air is replaced in the internal space.

Cross ventilation is limited for the air from north to south due to the programmitic liner spaces. To enable full cooling underfloor cooling in run.

The two top light atriums (north and south) let lighting into the internal mass and into the programmed spaces indirectly via the operable windows The step sun angel allows direct sun path.

It is evident that the solar natural daylighting is not effective at the early morning. However it is shown the natural daylighting experience is better in the summer 09:00 than winter.

The primary method of heating is regaining the heat load built up in the thermal mass of the masonry and concrete and the inertia of the wall structure with air drawn in from the atrium. The active underfloor heating systems is used to counter the potential low temperatures (which the thermal mass/inertia/solar chimneys could not compassionate for). To prevent the loss of heat due to irradiation, the atrium acts as a buffer zone (Fig. 07)

To prevent statement air the operable windows can be opened to allow the ground source heat pump to recycle the air (using the solar chimneys as the exit). Due to the extensive glazing of the south facade and top light f both atrium, the natural daylighting is not effected by the lower sun angle in winter.

ad exposure even in winter, throughout the day.

The quality of light decreases to a dusk, where intervention of artificial lighting is needed- especially pat 16:00.

Summer (July)

The quality of light in the morning only using natural daylight s not effective increasing a comfortable interior environment. Artificial lighting would hae to supplement in the early morning.

Due to the sun angel the lighting is optimal for exposure, glare and quality through most of the day (10:0-17:00) in the summer months.

The daylighting ampel in creating a comfortable internal environment in the summer due to the longer daylight hours. After 17:00 the daylight might have to be supplemented with artificial lighting.

Class Rooms off the North

Atrium (location B) Summer (July)

At the north atrium classrooms the daylight is less direct and of lower intensity. The risk of glare and over exposure in mid summer is reduced, however, the need for artificial lighting is added due to the need to add exposure later in the day (or in winter).

12:00 (above)

16:00 (below)

DETAILED ENVELOPE STUDY

Significant features and characteristics of the detailed design concept to explain its ENVIRONMENTAL CONFIDENTIAL and ECOLOGICAL CREDENTIALS

LEED Gold NC+MR 2009 certification

The certification gave 67 pointed awarded by USGBC because the deign opted for a building that had the highest environmental performance. This is due to the design of: venturi solar chimney design (passive air movement), retention of the facade treatment, material selection, energy conception, passive lighting in envelope system and water reclamation systems. Evidenced below in other pointers.

Passive/Low Energy Heating/Cooling/Ventilation Systems

The bespoke intergrated solar chimneys allow the passive heating cooling using pressure gradients and sunlight. There are no artificial means of air movement (air-conditioning)- the solar chimneys allow a heat vacuum in order to naturally regulate the heat in the summer. Shown in Fig 14. By including the underfloor heating system by aid of the ground source heat pump, the active system enables a efficient and effective heating of the proposal when required in the winter. Shown in Fig 15. This is a low energy requirement system as the ground source heat pump is using the heat of ground.

Modular Systems- reduction in carbon intensity

The use of a modular system and prefabricated components allows lower omitting and disrupting construction method. Negative externalities are negated by construction off site due to potential and smell. The process is also more time effective and creates higher quality produce.

Illustrated in Fig 06.

Solar Capabilities

Double facade- Natural Sunlight- the double facade creates an enclosed atrium space, enabling indirect sunlight to reduce the amount of active artificial lighting. Shown in Fig 21.

Solar Harvesting- ntergrated within the venturi solar chimneys, the photovoltaic panels an generate electricity reducing the need to use active electricity systems form the mains. The design optimises the absorbency of solar rays thus power by placing 12 meters of panels (3KWp) on the south elevation of the chimney and other large flatter surfaces for winter low sun. Shown in Fig 01.

Continuity of Thermal, Vapour and Airtight Membrane

The ground floor creates a thermally and vapour proof scheme by using a VPM and WPF as well as double panel of insulation. Continuity of these layers between the two façades means the envelope is uninterrupted between the two façades indicates this. By using the ETFE foil (for the WPM) it can be better ecological solution to glass as is less energy intensive in production and in manufacturing, fabrication and installation of structural materials. There is better end of life systems for ETFE due to its easy recyclability and durability to time and climate.

High embodied Carbon Materials

By using the existing facade the retrofit reduces the embodied carbon of the case study. The material use, fabrication and instillation minimises the carbon omissions of the overall embodied carbon. Shown in Fig.22.

The high embodied carbon of materials is due to the use of load bearing masonry as the primary structure. This is ‘50% more embodied carbon than an equivalent timber frame’. The embodies carbon factor is also raised due to use of reinforced concert slab, foundation and primary support system. Concrete is a high emitter in the curing and fabrication process. Shown in Fig 08.

Alternate opinion: the reinforced concrete components are durable and therefore will have longer life spans than parts of the building system. The recast members are modular and therefore have potential for disassembly and reuse. The masonry is also extremely durable and the embodied carbon and upkeep is minimal allowing for an longer lifespan than other material options. The reuse of reclaimed masonry is also an option.

Double Layer Roofing Insulation

Double layer of insulation (wood wool insulation 2x 250cm panels) are used to ensure the heat needed to activate the venturi effect and pressure gradient in the solar chimneys is maintained. This heat should not be lost to the areas below (classrooms) as this would disrupt the system of the solar chimney but also would create a warmed unconformable internal environment. To prevent thermal loss further: to the south (into the atrium) masonry is used and to below the insulation is concrete. These are both thermal masses therefore intake the thermal energy- and this can be input-ted back into the system when there is less solar thermal input (e.g. night).

Evidencing the Electrical System: Electrical Power,Telecoms, Fibre: the electrical system flows vertically the same service voids (Fig. 19) as many of the services. To horizontal-ly distribute three service trays carry the electrical wiring for all services to the building. These are played east to west therefore smaller trays are used to further distribute north to south.

Lighting: Provision for lighting is minimal therefore use of the horizontal distributor trays is used for lighting (Fig. 12). The trays have an intergrated LED lighting panel which can be mechanised by the switch on the wall. The vertical service voids will distribute wiring to the switch.

A Double Facade

A key driver and characteristic of the design is the double facade (creating an atrium on both north and south façades). This creates a thermal buffer, allows natural conformable daylighting to all the interior programmed spaces and enables retention of the heritage facade without disrupting its aesthetic. The thermal buffer and passive lighting designs a low energy and emittance environmental strategy.

Cause of Failure: moisture, lifespan, no maintenance

Reuse: repair or replacement to modular systems.

Longevity:

It is clear that in material choice the intended lifespan of the material is considered. This is due to masonry, concrete and steel all have long lifespans which also require little maintenance and will be infrequently in need for replacement. The facade with most wind exposure (west) is the only facade fully masonry- however not integral due to the climate context of Barcelona.

The longevity of services and accessibility is designed in order to aid easy replacement/maintain therefore small scale upkeep is easier. The modular nature of the service system allows for stratified and clear replacement methods at the end of life.

Adoption of Programme and Future Use:

The potential flux in use of the building is possible due to the large spaces and intergrated/exposed servicing. The intermediate walls within the programme are not load bearing therefore, easy adoption of the space is possible. The intergrated and concealed service are minimal allowing easy adoption of the service for programme or due to technological advances.

End of Lifetime Material Plan:

The plan for material reuse/abandonment is not clear however it can be speculated that due to the modular nature of a lot the components, a lot the building could be disassembled and reused into other construction projects. Some materials e.g. glass and ETFE membrane can be recycled therefore extending much of the building materials lifespan.

Life Cycle Cost Consideration to the Design’s sustainability in consideration to this RIBA category include:

- “3. Measure energy cost” due to the LEED gold MC and MR achievement a energy costing would have to take place. In order to achieve this standard it would have to constitute a low coating speculatively attributed to the low emissions/energy consuming heating, cooling and ventilation system of the venturi solar chimney.

- “7. Measure added value of sustainable outcome of the building” even though the architects may not have completed this it can be attributed to the building that an extensive effort in creating a sustainable building all socially, environmentally and economically. Efforts of making the building sustainable environmentally were most focuses join the operational and embodied energy through environmental plans as well as the building materials.

- There is no other evidence that any of the outcomes have been met in this sustainable outcome section, however due to its other sustainable decision making and design it can be speculated that many of them would be met.

Net Zero Embodied Carbon Emissions To enable a lower or ‘zero’ embodied emissions the design:

- “1. Prioritising Building Reuse” the building is retrofitted using the two existing façades of the existing glass wear factory. This reduces the embodied carbon due to less omission in building demolition and construction (new build). This is not 100% applicable as not all the building was retrofitted as it was not all still remaining.

- “8. Consider Modular Off-Site Construction systems.” The serving systems used are modular created in a factory and distributed and installed on site. This creates a lower embodied carbon design as the emission of a standardised design are lower. This is the only standardised modular design therefore Net Zero Embodied Carbon would not be achieved.

- “9. Detailing to be Long Life and Robust” it can be inferred that the design is intended to be long lasting and recyclable to many different functions. This is due to material choice suggesting long lifespans and programme being flexible with easily adaptable building components. This would make a lower embodied carbon building because the lifetime embodied carbon of reuse of the building is reduced.

ii Envelope Assembly (Sequential Thumbnails)-

Construction Sequence

Stage01- Listed Facade Restoration

-Structural and aesthetic repairs to the heritage wall to improve its structural integrity. -The existing windows are either glazed or brickwork is added to block them up.

Stage02- Facade Reinforcement

Structural steel profiles are added with concrete strip foundations and metal pins to attach the profile to the listed facade.

Stage03- Building of the Load Bearing Masonry Wall The exterior masonry walls are built upon a strip foundation. These are on the north facade and the internal load bearing walls. Lintels are constructed for window openings.

The

Stage04- Internal Glazing Insulation Operable timber framed double laminated windows are installed in the locations left for by lintels. Connections to the operable mechanical system is made.

Stage05- ‘Atrium’ Glazed Block Wall Insulation Institutional of the glazed block to the external south facade to build the atrium up. The glazed block is attached with adhesive mortar reinforced with reinforced stainless steel

Stage06- Facade Joining with Covering and Bracing (Creating the ‘atrium’) The glazed roofing system joins the two façades using a crane ensuring waterproofing. An ETFE membrane is welded to the roofing to ensure waterproofing. Cross bracing ties (steel tube 60x90mm cut and welded) into support bracing are add ed between the two façades to ensure structural integrity as a joint facade system. *Atrium glazing technically not part of the facade however allow joining between the two main components.

Exemplified by a key- continuity in waterproofing, vapour proofing and thermal layers is ensured with different materials at different layers. Insulation is limited due to the climate and passive systems of a heat buffer from the atrium. This means continuity is ensured by the south and north atrium and the insulation found in the flooring a sheet 250mm. The roofing has a double layer insulation (2x250mm). Waterproofing is determined by a waterproofing membrane at the ground level extending from the perimeter at the north and through all atrium and ground work. It wraps the foundations also. Waterproofing of the exterior roof structure is of a welded ETFE sheet which wraps all surfaces- as it is clear this does not disrupt the aesthetics. To prevent vapour damage (e.g. condensation mould) vapour proof membranes are used on the warm side of the insulation.

and Heating Cooling Internal Systems: dences where the service void for the modular service systems to the

chimney are. The systems leads to the venturi chimney shown.

Critical Reflection

The Zenith Building

Design Methodology + Technological Strategy

This case study linked closely to the my person year3 studio work as uses the practice of deep retrofit By keeping the shell of the existing building and rehousing a similar or contrasting function. This is further exemplifies the atelier’s position as attributes retrofit to the reduced implications of design due to the decreased embodied carbon as a form of adaptive re use.

Within this case study, the architects increased the provision off equali ty through implementing non-gendered toilets on each floor, improving the rights gender no conforming users allowing for improved accessibility and comfort t. The toilet provision was also made more accessible, making usable toilets for all genders on each floor- rather than gendered on alternating floors. can identify this approach as aligning with exemplary practice because it makes a more equitable building for all regardless of how the user may want to identify.

The case study also used retrofit to reduce the impacts onto the environment whilst being empathetic design to the building/ context design and past. The retrofit reused key parts of the form identified from the historical analysis of the building to maintain the similar form which is outstanding. The architects also maintained the structural frame to reduce demolition associated omissions as well as material production and installation of a new structure/building. believe this is a exemplary practice of contemporary design as is acknowledging the overall lifetime carbon omissions associating with each component/practice, whilst creating a comprehensive and convincing case of understanding the building on its surrounding context.

Responsibilities

Professional responsibilities as an architect was to create a Grade A standard office space. This would be the professional responsibility as this is the clients brief, influenced the design as specific guidelines have t0 be met, e.g. car loading has to be at an 80% capacity.

Legal responsibility lies within statutory requirements (e.g. removal of asbestos), also duty of care due to the risks associated with this material. The contractual obligations can also be deemed as legal responsibilities.

The statutory requirement of the architects means that the scheme has to gain planning and conservation area (upper King Street Conservation Areas) consent for external alterations. The character of the heritage area was acknowledged by the use of the limestone finishes to the podium- for consistency of material use in the conservation area/city.

Compliance

One key regulatory consideration was the fire standards which had to be updated from the original deign. The architects developed a comprehensive new fire escape and smoke system was designed. This shaped the proposal as a new extension had to be added- altering the exterior massing of the design by adding a new element to the front facade. This was estentials to adhere to the modern standards of health and safety in terms of escape form fire in law ‘Fire safety: Approved Document B’. It enabled effective removal of smoke from the building with addition of the extension as a smoke shaft as well as a smoke chamber to some existing stairs.

Lecture

Speaker

buildings environmental strategy aims to passively mechanise a lot of the buildings strategies. This links to the ateliers positions as is creatively using material and design to enable as low emissions in construction and usage.

One design feature which aligns with what deem to be good contemporary design is the adaptable office space which can cater to different needs, timings and preferences. This allows for an adaptable and continuously used space which is likely to have longevity in use as is conscious of the users desires for a space. Another design featured identified from the Edge’s design is the app in which is used to book, identify preference and schedules employees spaces/schedules. This contrasts with what align as good contemporary design because there is risk of data sharing of this specific personal detail- even through the usability of the building can be enhanced.

Responsibilities

In the Netherlands it is a statute under the law to comply with the BREEAM regulations, therefore the legal and statutory responsibilities lie within following these regulation. BREEAM is a platform which provided whole LiveCycle assessment for the built environment. One factor which was influenced in the design was the provision for solar harvesting. The Edge surpass the requirements allowing for the building to be sufficient on sunlight alone (floor plan analysed above).

The professional responsibility fall in creating the most desired space possible- by using materials with known health/wellbeing benefits, whilst answering the clients brief. This influenced the design by using timber for the internal finsih as is a ‘growing’ and ‘breathable’ material which has known ‘physiological benefits’.

Compliance

The regulations which shaped the design fall within the BREEAM regulations determining how much natural daylight is required in the ‘habitable’ areas of the building. This is influential in the design as this allows for a ‘hand’ shaped building to allow more projections with external walls to capture the sunlight. The building is further designed so that the zones of circulation areas (e.g. lift cores) are in the centre (where darkest) as this by law is deemed uninhabitable thus can not be used for ‘office activities.’ This is analysed above showing in purple where the regulatory standards would not deem the area habitable (e.g.)

iers position refers to an increased life cycle importance in material choice as it can have more longevity in material ‘traditional techniques and natural materials’ allowing ‘minimal processing and therefore low-embodied energy’ creating a ‘continuous life cycle’.

Use of modular design aligns with what I deem to be good contemporary design. At the Capital Docks in Dublin it can be seen that modular prefabricated design creates higher quality and lower carbon omitting design, with low embodied carbon as is manufactured in large qualities in a Use of test modelling at a 1:1 scale can also be deemed as good contemporary design as allows for maximum test for both health and safer (e.g. fire) but also quality and finish. This gives the client a representation and understanding of the final outcome. This was used in the MECD University of Manchester building for a facade panel which underwent rigorous weather testing to ensure durability and structural integrity.

Responsibilities

Professional responsibility controls the design by the cost of materials and labour. The speaker analysed the cost of a tower crane on the instillation of components such as prefabricated rooms and balconies. The Professional responsibility of understanding the cost increase for an increase ‘hook time’ on institutional of these components and therefore overall costing for project viability. This would therefore alter design choices as the architect be deterred from using components that need these types of cost intensive mechanisms.

Statutory responsibility means that material and typical bay testing is needed to ensure high performance and safety. Performance would test the weather proofing, vapour/waterproof-ness and in performance testing on a typical bay Crescent City Baku- Azerbaijan. The country uses Russian code which means that integration of factors such as wind load is rigorously tested to ensure factors such a sway and shattering are removed. 8knpN2 wind load is tested.

Compliance

Regulations regarding environmental sustainability by BREEAM to materials used, regulating the U-values of these materials in their thermal capacity, as well as factors such as longevity/lifespan of materials. Madison with Make Architects LBS Properties ensured the thermal capacity of to surpass the BREEAM U-value grades. The values are taken from an average instead of unitemised- averaging at a 0.74% with the industry recommended by regulation at 1%. This was archived by developing designing double thermal breaks in extrusions.

Speaker

Speaker

Year 2021

Location Manchester, United Kingdom

First Choice Homes + The Hive Design Methodology + Technological Strategy

The main two case studies explored in this lecture are the First Choice Homes building association HQ, Oldham and The Hive, Manchester. These two case studies explore how to uncomfortable internal office in terior spaces using predominantly passive environmental mechanisms.

The theory of both case studies link to my atelier’s position as the environ mental stratergies attempt to minimise the impacts on the environment via low embodied and operational carbon commissions. This highlights how the passive systems can alter a design to create a more carbon/envi ronmentally consistence building.

The Hive indicates examples of deep retrofit. This is one of the RIBA sustainable outcomes under ‘Net Zero Embodied Carbon’. The buildings’ this reduces the embodied carbon as omissions were decreased in minor demolition of site and less construction/transportation omissions. I deem this good contemporary deigns as this creates an environment which is climate conscience for the users. To reduce the operational carbon (another RIBA sustainable outcome- ‘Net Zero Operational Carbon) passive systems such as solar shading; thermal mass with night cooling and cross ventilation mechanisms are put in place. This also aligns with the ideals of contemporary design as it is design which is focused around commissions in unsafe and not only construction.

Responsibilities

The Professional responsibilities of the design are the desire and requirement of the architect to create conformable and habitable office spaces. This is design in principles of using long spans for flexible structure and space and creating a comfortably light space. This is exemplified in the First Choice HQ as the floor plates are left an open floor promoting collaboration but also adaptability into the future. A large central atrium is used to light the deep plan for indirect light- preventing glare and over exposure.

Legal responsibility in these case studies is the funding of th projects with legally binding contacts of requirements in design. The funders of design often insist in contract certain design feature- for example insulation standards. This is legally binding as the contracts specify figures for these design quotes. The intensive the funders would have are to create a ‘marketable environmentally friendly building’ for potential tenants.

Compliance

BCO guide is followed in both case studies which specifies the the building, energy and sustainability and people needs in a building (2014). This determines how the buildings function. One way how the compliance to this regulatory document shaped the design is the use of cross ventilation. This shaped the design of the Hive as allowed for full floor to floor heights to be exposed as ceiling equipment was limited. This therefore also improved the office space created. This also informs the BREEAM regulations as ensures the environmental assets at different times of the construction/design process- for example in material sourcing. This links back to the legal requirement of contract of client or funding requirement as they may specify the BREEAM rating.

with the Continuity in Architecture’s ethos as the design is purposefully climate resilient. This means the structure have longevity and will withstand climate and ware thus preventing the need for a intermittent replacement.

Passive design through designing high provisions for insulation; use of thermal masses to heat the interior and solar shading, which aligns with what consider good contemporary design because by use of passive mechanisms, the operational carbon of a building is reduced. This makes a more ‘climate change conscience’ building and design. The deisng also took climate statistics such as flood risk and temperature values from predictions instead of the current days. This is to prevent need fr futher mechanisms to be added in the future but to also future proof the building. This aligns with my ethos of good contemporary practice as is not in climate change denial.

Responsibilities

Specific professional responsibility that the architects had in the design is the impact the building had post life. The IDEA house uses low impact material which at end of life can be modular reuse or recycles. This is engineering zero waste. For example, in mass the trellis system can be reused on the facade of an alternate scheme.

Responsibility of Stature falling consideration for Passive House. Housing requirements mean that the home’s thermal barrier must reach the passive house U- Value system. This means that the thermal capacity of the material are effective enough. This shapes the design as may include further insulation or material with higher thermal capacities.

Compliance

The deigns is shaped by the compliance of the IES thermal analysis. The IDEA House architects compared their deigns to that of the baseline house to ensure that the hearing and cooling was effective and surpassing that of what is the statuary baseline. The baseline is 20 degrees for every 1 finite the building is habituated. This shaped the deigns of the building as required rigorous material modelling and testing to ensure high enough standard to surpass the design. The outcome is a thermal mass floor slab, which prevents current heat gain but allows the material to be a thermal mass- a interesting characteristic of the material.