9 minute read

Letter from the editor

GREEN SEAS

AMMONIA • HYDROGEN MUST PLAY A MAJOR ROLE IN THE ENERGY TRANSITION BUT IMPORTING IT INTO EUROPE MAY BE EASIER IN THE FORM OF AMMONIA. PLANS ARE MOVING AHEAD IN ROTTERDAM

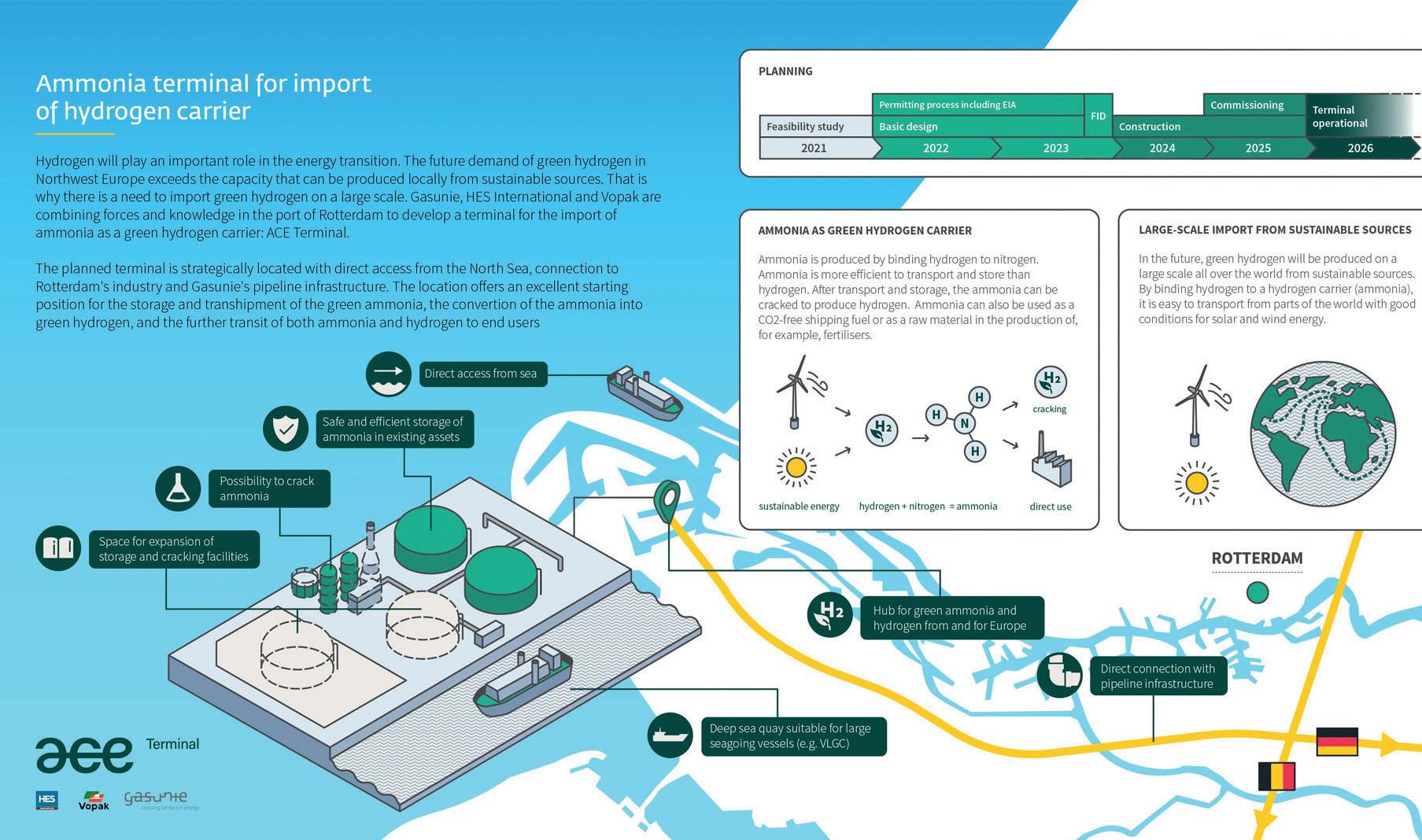

GASUNIE HAS TEAMED up with terminal operators Vopak and HES International in a partnership to investigate the viability of establishing a green ammonia import terminal, named ACE Terminal, on the Maasvlakte in Rotterdam. The project aims to respond to growing global demand for green energy and the clear need in northern Europe to be able to import sustainably produced energy carriers at scale.

Work on the basic design will start before the middle of the year, with the aim of getting the terminal up and running in 2026.

Renewably sourced hydrogen is regarded as an essential element in the future renewable energy mix, with demand growing in the power generation, transport and petrochemical sectors. While there will be some production of green hydrogen from wind and solar power in the Netherlands, that will not be able to achieve the volume needed to meet the UN and EU targets for decarbonisation by 2030 and 2050.

The partners in ACE Terminal see an import site for green ammonia as making a vital contribution to the supply of green hydrogen in this decarbonisation scenario. Green ammonia as a carrier of hydrogen offers a relatively straightforward way of moving energy in bulk over long distances and is something that the Port of Rotterdam is already investigating – it is, for instance, involved in a joint venture in Brazil looking to export green ammonia or hydrogen from the Stolthaven Santos terminal. Compared to hydrogen, ammonia offers the advantage that the supply chain is well developed and ammonia has been moved in bulk on gas tankers for many decades. It can be readily converted into hydrogen, with nitrogen the only by-product, and will also be used directly as a marine fuel, with marine engine suppliers already producing propulsion systems capable of running on ammonia.

LOCATION ADVANTAGE The intended location for ACE Terminal on the Maasvlakte will provide access to oceangoing ships carrying ammonia from all parts of the world; initially, the partners say, that may also include ‘blue’ ammonia produced with the use of methane, which is a relatively low-carbon source but not entirely decarbonised.

ACE Terminal will make use of existing infrastructure and logistics facilities within Rotterdam and will have space for the construction of an ammonia-to-hydrogen conversion plant, which ultimately will be connected to a national hydrogen network that Gasunie is developing to serve the future hydrogen needs of the Netherlands and further afield.

HES International already has a terminal on the Maasvlakte, with quayside capacity; Vopak handles ammonia at six of its terminals around the world and has extensive experience in the safe storage of the product; and Gasunie has storage tanks and pipelines in the Port of Rotterdam. “By joining forces,” the three partners say, “an attractive starting point will be established from which – within just a few years – the partners will be able to realise the import location for green ammonia in Rotterdam.”

A final investment decision has yet to be taken and will depend on an analysis of the likely level of demand for throughput capacity as well as the necessary permitting process. The partners are basing their plans on an independent and open-access infrastructure. A market consultation procedure is soon to be launched, in which potential users can express their interest in the supply, storage and transhipment of green ammonia and hydrogen. Initial discussions are already underway with international market parties, the partners say. www.aceterminal.nl

THE PLANNED ACE TERMINAL WILL HAVE TO BE PART OF

TAKE IT TO THE STREETS

MIDDLE EAST • HOYER IS TAKING ITS EXPERTISE INTO NEW TERRITORY, WITH THE FORMATION OF A SAUDI JOINT VENTURE AND NEW FILLING AND BLENDING PLANT

HOYER MIDDLE EAST is currently building a new filling plant in Al-Jubail, Saudi Arabia on an area of around 10,000 m2. On completion later this year, the facility will offer four storage tanks, two blending tanks, two filling lines and a warehouse for palletised goods. The filling plant’s capacity will amount to some 30,000 to 50,000 tonnes per year.

This new investment is the first fruits of a new joint venture established by Hoyer in Saudi Arabia to help expand activities in the Supply Chain Solutions (SCS) division of its Chemilog business unit. Hoyer has acquired a 51 per cent stake in a Saudi-based business, with local partners Petrochem Middle East FZE and Al Fahdah Al Arabia Trading Company holding 24.5 per cent each, which has been named Hoyer Middle East Ltd.

“The joint venture pools the regional and international strengths of the two partners with the core competences of Hoyer as an international logistics company specialising in handling dangerous goods,” Hoyer states.

“Hoyer Middle East will offer extensive blending, filling, bulk storage, quality testing and dispatch processing services, together with warehouse storage of palletised and non-palletised goods,” Ulrich Grätz, global SCS director at Hoyer, elaborates. “We are specialised in handling in dangerous goods and satisfy the highest international environmental, quality and safety standards.”

Menno Douwes Dekker, managing director Middle East & India for Hoyer, adds, “It’s the first professionally operated off-site blending and filling plant in Saudi Arabia, and therefore very attractive for chemicals producers with international operations. Furthermore, we can also offer international intermodal transport beyond the plant, because we collaborate closely with the Hoyer Business Unit Deep Sea.” BRAND EXTENSION Establishment of the regional joint venture marks continued growth and geographic expansion in Hoyer’s SCS division. SCS now operates at 16 locations in five countries, and has recorded a doubling of its order volume since 2008, making it one of the strongest growing business activities within the Hoyer group.

“SCS scores points through the expertise of the Hoyer group in the logistics and handling of dangerous goods, and brings this know-how into its comprehensive, customer-oriented portfolio of services: on-site and off-site logistics, filling, blending, handling of liquid dangerous goods, dry-bulk logistics, the operation of intermodal and dangerous goods terminals, and planning support for change management projects in plants,” the Hamburgbased company explains. “The utilisation of synergies, efficiency and transparency are important values in this respect.”

So far, SCS’s operations have been largely confined to Europe, so the new Saudi business marks an extension into a new theatre of activity. SCS has more than 450 staff in Europe at a number of logistics facilities, many of them on third-party premises. The division leverages Hoyer’s infrastructure assets to provide them on a needs-oriented basis to its clients.

The Hoyer group as a whole, which was founded in 1946, employs some 6,100 people in more than 115 countries around the world; its assets include some 2,400 trucks, 2,900 road tankers, 37,300 tank containers, 41,200 intermediate bulk containers (IBCs) and numerous logistics facilities, including tank depots, workshops and cleaning stations. www.hoyer-group.com Expanding horizons Driving change to meet the energy transition At Exolum we see the energy transition as an opportunity to expand our horizons. A chance to diversify our business and meet the challenges of climate change and our customers’ businesses. We have adopted Sustainable Development Goals (SDGs) to touch every aspect of our business and made a commitment to minimising our impact on the environment by striving to use energy resources and raw materials e ciently.

HOYER IS PARTNERING WITH LOCAL INTERESTS TO LEVERAGE DIFFERENT EXPERTISE IN CHEMICAL LOGISTICS Europe’s leading bulk liquid logistics provider

A NEW START

STRATEGY • OILTANKING MARKS ITS 50TH ANNIVERSARY THIS YEAR WITH IMPORTANT PLANS TO TAKE ITS BUSINESS MODEL INTO THE NEW ERA UNDERPINNED BY THE LOOMING ENERGY TRANSITION

OILTANKING WAS ESTABLISHED by Hamburg-based trading house Marquard & Bahls in 1972 through the merger of formerly independent tank farms in Germany, originally focusing on oil products. Through five decades of international development, it now has a large presence in the chemicals sector and, more recently, in gases and new energies, with a global network of 41 terminals in 18 countries and a total storage capacity of more than 16m m3 .

This month, Oiltanking is making a significant change to that business model, with the spin-off of a large slice of that terminal capacity into a new company, which

SINGAPORE IS DUE TO GET ASIA’S FIRST GREEN will focus on growth in chemicals, gases and new energies, and have a strong commitment to embed sustainability in all aspects of its business. Building on Oiltanking’s tradition of close partnership and consistent delivery, the new company will support the sustainability agenda and energy transition journey of its customers and partners.

Oiltanking’s current operations in Belgium, China, Finland, the Middle East, Singapore and the US will all transfer to the new company, which will be headquartered in Rotterdam with Bas Verkooijen as CEO, supported by Douglas van der Wiel, Claas Pinkenburg, Yvan Tavernier and Liz Mayhew as the leadership team, together with 1,200 employees worldwide.

“We are excited about the next chapter in Oiltanking’s journey,” says Matti Lievonen, Oiltanking’s CEO. “Oiltanking is widely recognised for its leading global role in the energy storage and logistics infrastructure. The new company is our pledge to enable and expedite the energy transformation in our industry by applying a clearly defined strategy that embraces the energy transition in true partnership with our customers and partners.”

PLANS FOR GREEN FUEL One example of that transformation was also announced last month, with the formation of a partnership to establish Asia’s first green e-methanol plant in Singapore. Oiltanking is working alongside PTT Exploration & Production, Air Liquide, YTL PowerSeraya, Kenoil Marine Serices and AP Moller-Maersk on a ‘Green Methanol Value Chain Collaboration’, which will explore the feasibility of establishing a green e-methanol pilot plant, with a minimum capacity of 50,000 tpa, and will be the first of its kind in south-east Asia.

The pilot plant envisaged for Singapore will use captured biogenic carbon dioxide and renewable electricity to produce green hydrogen and green e-methanol, making the fuel commercially accessible for the maritime industry.

Green e-methanol is being considered as one of the candidates for alternative fuels to meet the 2030/2050 goals for emissions reduction set out by the International Maritime Organisation (IMO). This project will potentially yield a substantial carbon reduction impact, Oiltking says. As one of the world’s premier maritime bunkering hubs, and with the support of the Maritime and Port Authority (MPA), Singapore will serve as an ideal location to take this important step towards exploring alternative future fuel solutions to advance the multi-fuel transition of the global shipping industry.

The partners will now embark on feasibility studies of the technical and economic aspects of the project; these studies are expected to be completed by the end of this year. www.oiltanking.com