35 minute read

Incident Log

ROAD/RAIL/AIR INCIDENTS

Date Location Vehicle Type Substance Details Source

9/3/22 Muchin, Lagos, Nigeria road tanker gasoline Road tanker with 33,000 litres gasoline caught fire in Idi Oro district, cause unclear; fire service was on site Vanguard quickly, preventing blaze from spreading; no injuries reported; cause under investigation

10/3/22 Houston, road tanker propionic Tank truck overturned, spilled load of acid on 92nd Street; local residents asked to stay indoors as fumes from ABC Texas, US acid spill could be irritant, though no formal shelter-in-place was ordered; no injuries reported

13/3/22 Lugari, Kakamega, Kenya

15/3/22 Hebron, Kentucky, US road tankers gasoline Road tanker exploded after being hit from behind by another tanker, which was engulfed in fire; both drivers Capital suffered burns, one other person died in fire, which also spread to nearby Mukhonje market FM

aircraft jet fuel Estimated 1,700 gal (6,400 litres) jet fuel leaked from aircraft while mechanics were changing fuel pump at WCPO Amazon hub at CVG Airport; spill was flushed into drain to oil/water separator; no off-site impact

17/3/22 Ijora Badiya, road tanker LNG Driver of road tanker with 20,000 tonnes LNG (LPG?) was alerted to leak from tank, attempted to use fire The Lagos, Nigeria extinguisher; tanker exploded; fire crews prevented blaze from spreading to nearby shops; no injuries Eagle

17/3/22 Nashville, road tanker fuel Tennessee, US

21/3/22 nr Kwelera, road tanker fuel E Cape, South Africa Tank truck crashed into concrete barrier on I-24 after swerving to avoid accident, overturned and spilled Tennessean (33.3 m3) unspecified fuel cargo; highway was closed for response; road surface badly damaged

Road tanker and intercity bus crashed on N2 near East London; tanker caught fire; two people killed, 18 more Sowetan injured - not clear if that was due to crash or fire Live

21/3/22 Mount Juliet, freight train propane 12 cars of freight train derailed near elementary school; police advised nearby residents to shelter in place as Tennessean Tennessee, US car was thought to contain propane, though it would appear it was only residual gas

26/3/22 Pune, Maharashtra, India road tanker chemical Driver lost control of tanker on Pune-Mumbai expressway; tanker overturned, manlid opened and spilled Times of unidentified chemical, said to be viscous; subsequent crash of container truck that skidded on spill India

27/3/22 Lagos, Nigeria road tanker gasoline Laden road tanker crashed head-on with another truck; tanker exploded, spreading fire to both vehicles; BBC at least six people reported killed

27/3/22 Rosewood, road tanker gasoline United Petroleum Transport tank truck overturned while attempting turn off Central Texas Expressway; much KDH Texas, US of its 8,700-gal (33 m3) gasoline cargo spilled and proved difficult to contain; remaining cargo transferred News

30/3/22 nr Euless, road tanker jet fuel Tank truck with jet fuel caught fire, exploded at Flint Hills Resources site in east Fort Worth; fire was under FW Star Texas, US control within an hour; no injuries, no evacuations necessary; blast was felt two miles away Telegram

2/4/22 Nayagarh, road tanker LPG Odisha, India Bus carrying 60 passengers collided head-on with LPG tanker in Daspalla; tanker driver killed in crash, 15 Times of people on the bus were injured; no word of fire or explosion India

5/4/22 Buldhana, road tanker fuel Maharashtra, India Road tanker and another truck with trailer collided head-on on Malkapur-Nandura road; both vehicles caught Times of fire, both drivers killed in fire India

MARINE/INLAND WATERWAY INCIDENTS

Date Location Vessel Substance Details Source

24/2/22 Pickensville, barge Alabama, US styrene Barge carrying 17,700 bbl (2,800 m3) styrene ran aground in Tombigbee River; no indication of leak from Incident barge; US Coast Guard requested support with hazard analysis News

8/3/22 Oswego, New York, US pipeline fuel oil Up to 1,500 gal (5,700 litres) No 6 fuel oil spilled from transfer pipe at power station to Oswego harbour; SEC, USCG, Miller Environmental managed to contain spill within harbour; collection underway WRVO

9/3/22 Bangkok, Smooth Sea 2 gasoil, Product tanker (3,000 dwt, 1983), after discharging gasoil, diesel at IRPC pier, suffered explosion, fire on Splash Thailand diesel cargo deck; one crewman injured, one missing; fire under control in an hour; negligence blamed 247

21/3/22 Qingdao, Arzoyi Shandong, China crude oil VLCC (299,150 dwt, 2002), offloading cargo at Haiye Mercuria terminal, broke moorings, drifted aground; FleetMon hose broke, causing small spill; some remaining cargo was lightered to allow tanker to be refloated

24/3/22 Volga-Caspian Geroy Rossii products Product tanker (6,400 dwt, 2013), in load with unspecified cargo from Astrakhan to Anzali, Iran, grounded FleetMon Sea Channel, Russia Pyatnitskikh in canal, blocking fairway; no breach of hull or leak reported

26/3/22 off Pichilingue, Sam Guillermo vehicle Fire broke out on cargo deck of ferry from Topolobampo on approach to Pichilingue; fire started in trailer of FleetMon Baja Cal, Mexico spreading to others on deck; 24 passengers, all truck drivers, were rescued without injury

27/3/22 Bangkok, Ampar 8 crude oil Product tanker (3,500 dwt, 2007), with 3,000 t crude (presumably lightered), suffered explosion while mooring Splash Thailand at Bangchak depot on Chao Praya river; one killed, three injured; tanker drifted until anchor was dropped 247

MISCELLANEOUS INCIDENTS

Date Location Plant type Substance Details Source

22/2/22 Lawrenceville, pipeline diesel Kinder Morgan pipeline leaked at least 10 bbl diesel to storm drain; leak was only found because residents WABE Georgia, US reported smell; five homes evacuated to allow excavation of line, which is thought to have been damaged

11/3/22 Edwardsville, pipeline crude oil Up to 4,000 bbl crude oil believed to have leaked from Marathon pipeline to Cahokia Creek, a tributary of the ABC Illinois, US Mississippi; line shut in; US EPA issued orders for remediation and a corrective action plan

14/3/22 Baotou, chemical unknown Fire broke out in chemical plant (unidentified in reports) in Hondlon district; fire crews brought blaze under ANI I Mongolia, China plant control within an hour; seven people missing were found dead; investigation underway

16/3/22 Giza, Egypt

20/3/22 Sialkot, Punjab, Pakistan chemical paints Massive fire broke out in chemical and paint plant in Kerdasa district; responders prevented fire from plant spreading to nearby properties; investigation underway to determine whether fire was caused by arson Daily News

garrison ammunition Short-circuit sparked fire, massive explosion in ammunition shed near army base; fire was dealt with quickly Hindustan with no injuries or other property damage; witnesses reported hearing several explosions Times

21/3/22 nr Grevena, dynamite dynamite Three workers were killed by massive explosion at dynamite plant 30 km outside Grevena in north-west Greece factory Greece; explosion could be heard several km away; cause under investigation AP

22/3/22 Williamson, chemical unknown Fire broke out in building at Thatcher Company site; fire crews had blaze under control quickly, said that no Spectrum New York, US plant chemicals were in the area that burned; nearby road closed during response; DEC checking runoff News 1

23/3/22 Dallas, Texas, US pipeline natural gas Car crashed into natural gas pipeline in Mansfield district; driver critically injured in crash, which sparked AP huge fire and evacuation of neighbourhood; fire out in a few hours

25/3/22 Kocaeli, Turkey oil refinery oil At least four workers were badly injured by explosion, possibly in storage tank, at Tupras refinery; blast led to Ilhas fire, which was quickly extinguished; investigation underway

27/3/22 Billings, Montana, US oil refinery unknown Fire broke out at ExxonMobil refinery, said to be structural; not clear if any fuels were involved in blaze, which was put out in four hours; no adverse air quality readings, no injuries reported CNN

ASSAULT ON BATTERIES

LITHIUM BATTERIES • RECENT SHIPBOARD FIRES HAVE RAISED CONCERN OVER THE SAFETY OF LITHIUM BATTERIES IN SEA TRANSPORT AND CARRIERS NEED TO BE AWARE OF THE RISKS, TT CLUB SAYS

RECHARGEABLE EQUIPMENT IS a major feature of the 21st century. The ongoing technological development of rechargeable lithium batteries has enabled ever-growing use of portable computers, smartphones, power tools and electric vehicles. But that growth in the use of this technology has brought with it greater safety hazards, as illustrated by some recent high-profile incidents at sea generally suspected as having been caused – or at least made much worse – by fires in lithium batteries.

“Understanding the risks is crucial,” comments Peregrine Storrs-Fox, risk management director at TT Club. “As with many successful technologies, market demand has outpaced the development of safety regulations. Since the mid-1980s lithium batteries have been classified under dangerous goods regulations for transport based on the weight of lithium contained in the cells or batteries and the potential hazard presented by a given battery is also related to the amount of lithium it contains. However, as technology has advanced, the amount of energy derived from the active material has increased by up to 50 per cent, leading to regulatory mismatch where provisions are essentially framed around mass and energy output.”

Lithium batteries must be certified to an international standard involving a rigorous series of tests performed by an approved independent testing laboratory, to ensure they can both withstand everyday use through their expected lifetime and the rigours of transport. Responsibility for testing and achieving certification rests with the shipper and/or manufacturer. The sharp rise in demand has been accompanied by supply of cheaper, poorer quality and untested batteries, including refurbished and even homemade power banks. E-commerce platforms have facilitated a global trade in potentially lethal products, often circumventing global standards and regulations.

Throughout their intermodal journey the primary risks exist when batteries are poorly manufactured, untested or defective; these have a higher propensity to malfunction. However, supply chain risk – at any point of handling, storage or transport – is compounded by used, fully or partially charged batteries. As such the reverse logistics of batteries must be carefully managed; damaged and faulty products being returned or shipped as waste for disposal or recycling present increased risk.

UNFORGIVING FIRES The consequences of lithium-fuelled fires can be more extensive than others. They are very difficult to extinguish, prone to thermal runaway and present an explosion risk. Due to the heat generated, re-ignition once a fire has been extinguished is an additional risk. In the unforgiving maritime environment, where the crew’s capability to fight fire is strained, the hard lessons learned by land-based fire responders, particularly relating to electric vehicles, need to be assimilated.

“The majority of shippers will take all practicable steps to ensure that their lithium batteries achieve certification and are classified, packaged, packed, labelled and declared correctly. A small – frankly criminal – minority are motivated to avoid compliance, entering cargo into the supply chain that presents great risk to all,” Storrs-Fox observes.

“Once lithium batteries are placed into the intermodal supply chain, there is little opportunity for the cargo to be checked, visually or otherwise, to verify compliance. For all who are contracted to transport, handle or store lithium batteries, developing a thorough understanding of this particular cargo is a prudent step. Moreover, due diligence into the origin of manufacture and integrity of the shipper instigating the move of these potentially lethal power sources is critical.” www.ttclub.com

COMING DOWN THE PIPE

NORTH AMERICA • COSTHA’S 2022 ANNUAL FORUM PROVIDED THE IDEAL PLATFORM FOR DUTYHOLDERS TO LEARN ABOUT THE CHANGES TO THE REGULATIONS COMING FROM THE US AND CANADA

FOR THE PAST 50 years, the Council on Safe Transportation of Hazardous Articles (COSTHA) has provided a haven for the much put-upon members of the hazmat fraternity, primarily though not only in North America. Its annual forum and expo offers an ideal place to meet and hear from the most senior regulators from agencies in the US, Canada, Europe and elsewhere.

Like other event organisers, though, COSTHA has had to take its Annual Forum online for the past two years; it is unfortunate that regular delegates (including HCB) miss the opportunity to talk dangerous goods late into the night around the bar (or pool or fire pit, as has been the case at some venues over the years), to discuss issues of common interest and to hang out with the regulators. It is to be fervently hoped that we will all be able to get back to that next year but, in the meantime, at least COSTHA has been able to keep its audience informed about recent and upcoming regulatory changes and to arm them with the knowledge and tools they need to do their jobs to the best of their ability.

One upside of the need to move to a virtual platform is that the training sessions that accompany each year’s Annual Forum do not have to be packed into the weekend before the event officially opens. As was the case this year, those sessions ran over the course of three weeks following the conference sessions, giving plenty of time for attendees to digest the information provided.

The Forum itself, under the title ‘Navigating the Future of Compliance’, opened on 4 April with a meeting of the International Vessel Operators Dangerous Goods Association (IVODGA) which, like COSTHA itself, is administered by Currie Associates. That session heard from a broad range of speakers on topics such as the new requirement to provide a safety data sheet (SDS) for highhazard chemicals when in the Shanghai area, new provisions for data loggers, enforcement by the Container Inspection Training and Inspection Team (CITAT), work of the US Environmental Protection Agency (EPA) on hazardous waste under the Resource Conservation and Recovery Act (RCRA) and relevant activities of the Federal Railroad Administration (FRA).

That packed session was followed by concurrent meetings of the North American Automotive Hazmat Action Committee (NAAHAC), a voluntary group of hazardous materials professionals working in the automotive sector, and the Air Carrier Roundtable, which featured presentations from the Pipeline and Hazardous Materials Safety Administration (PHMSA) and the Federal Aviation Administration (FAA).

RULES IN PROGRESS Sam Moyers, associate vice-president and director of transportation safety at Arcadis and COSTHA president, opened proceedings on 5 April with an early morning (in North America, at least) annual membership meeting, before moving on to introduce the first conference session, a round-up of important developments in China, Australia and India.

Concentrating on North America, however, the second session offered the much anticipated annual review of regulatory rulemakings by PHMSA and its counterparts in Canada. This year, the US element of the session was given by Glenn Foster, chief of the

Regulatory Review and Reinvention Branch of PHMSA’s Office of Hazardous Materials Safety, Standards and Rulemaking Division.

At the top of the list of priority items for the current year at PHMSA is to get the HM-224I rulemaking to final rule stage; this will introduce new regulations for the carriage of lithium batteries by air, bringing US domestic regulations into closer alignment with the international provisions. Glenn mentioned also that PHMSA is involved in a pro-active multi-agency group to look at the management of battery hazards as technology progresses.

During the years of the Trump administration, PHMSA – as well as other Department of Transportation (DOT) bodies – fell behind with its work to maintain overall harmonisation with international rules. However, Glenn said, work to bring the HM-215P rulemaking to final rule stage is progressing well; indeed, the final text is currently under review and it should be published in good time to enter into force on 1 January 2023. HM-215P is the latest in the regular biennial updates and will align the US Hazardous Materials Regulations (HMR) with the 22nd revised edition of the UN Model Regulations and the other international regulations that derive therefrom. PHMSA always reserves the right to vary from the Model Regulations and there will be some variations included this time round; HCB will look more closely at HM-215P when the final rule is published. Meanwhile, Glenn said, work has already started on the next biennial update, HM-215Q.

Also on the priority list is HM-264A, which will suspend (temporarily, at least) the provisions that authorise the transport of LNG in rail tank cars, in response to an Executive Order. The notice of proposed rulemaking (NPRM) under HM-264A was published on 8 November 2021 and by the time the comment period closed on 23 December PHMSA had received around 7,000 comments. Those comments, along with the chance PHMSA took to consult with its colleagues at FRA and external technical experts on recent research, have provided valuable information that will help support any future rulemaking on the topic.

Also currently in progress are two smaller rulemakings, both heading towards the final rule stage: HM-241, which will incorporate the provisions of ASME Code Section XII; and HM-260B, which contains editorial corrections to HMR.

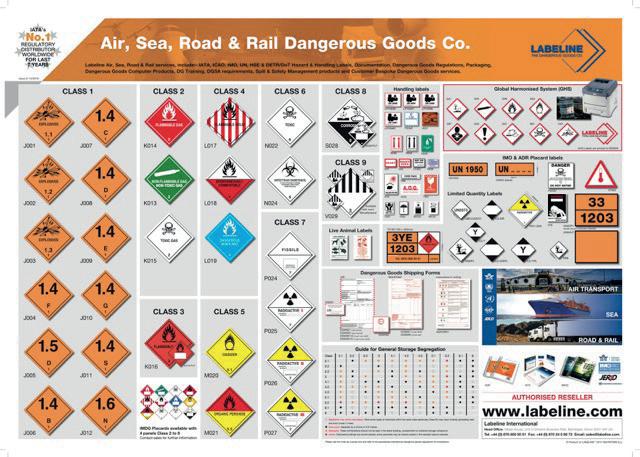

ALL THOSE INVOLVED IN THE TRANSPORTATION OF

HAZARDOUS MATERIALS ARE SUBJECT TO THE

REGULATIONS, WHETHER AS SHIPPERS, CARRIERS OR

SERVICE PROVIDERS Who do you contact for the latest DG compliant labels?

Free DG Label ID poster with every order

Tel: +44 (0)870 850 50 51 Email: sales@labeline.com

www.labeline.com

Glenn highlighted another rulemaking that will be of interest and relevance to a lot of stakeholders – HM-265, which will aim to enhance modal safety. This is another initiative that cuts across various agencies and it will be very interesting to see what its NPRM contains.

AROUND THE MODES There are several other rulemakings working their way towards NPRM stage. HM-250A on radioactive materials, which aims to align HMR with the International Atomic Energy Agency (IAEA) Transport Safety Standards, is already drafted and will be published soon. HM-263 will address real-time train consist information and HM-264B will look more broadly at the safety of LNG in transport. Some others aim to streamline and improve PHMSA’s regulatory work: HM-253G is another rulemaking to convert long-standing Special Provisions into HMR; HM-219D will respond to petitions for rulemaking; and HM-257A will streamline the approvals process for energetic substances. PHMSA is also working on HM-265A, which will look at regulatory reform initiatives and will appear first as an advance notice of proposed rulemaking. “We’re getting there, little by little,” Glenn added.

Glenn was followed by Don Burger, chief of PHMSA’s Special Permits and Approvals branch, who appealed for applicants to provide all the necessary (and correct) information and to use the online submissions portal. He noted that the branch has lost around one-third of its staff over the last two years, while the volume of applications is as big as ever.

Later in the day, COSTHA delegates enjoyed a suite of presentations from modal authorities, beginning with FAA’s Michael Cameron, division manager for Policy, Standards and Stakeholder Engagement, and Victoria Lehman, branch manager. They described FAA’s three-pronged strategy to improve safety in the transport of dangerous goods by air, covering packing, cargo awareness and operational safety.

But, as might be expected, FAA’s focus over the past two years has been on the transport of Covid-19 vaccines. The agency established a dedicated team in October 2020, which works in coordination with DOT, other federal agencies, the airline industry, pharmaceutical manufacturers and other stakeholders; the aim is to ensure that vaccines are not only transported safely but also in an efficient and timely manner. FAA actively engages with external stakeholders through the Vaccine Distribution Engagement Meeting (VDEM) to share ideas and learn about successes and challenges. More information on this work can be found at www.faa.gv/coronavirus/vaccine_ transport/.

Work on that subject is ongoing – as is the Covid-19 pandemic. The Office of Management and Budget (OMB) granted FAA emergency approval to allow the voluntary collection of information from parties that have experience in the transport of Covid-19 vaccines, in order to support continued operational safety and efficiency. In early February this year, FAA published a notice regarding the information collection programme, which ran from 15 March to 29 April.

FAMILIAR FACES Also on the programme was long-time COSTHA presenter James O Simmons, transportation specialist at the Federal Motor Carrier Safety Administration (FMCSA), who described how the agency goes about its business of maintaining oversight of the nation’s trucking industry. FMCSA has also responded to the Covid-19 crisis, issuing several waivers to provide relief for operators unable to meet the normal requirements for licensing, reporting and testing, and to enable the transport of emergency relief materials. Some of those waivers expire at the end of May 2022.

FMCSA is also attempting to ameliorate the current driver shortage, introducing a new Entry-Level Driver Training programme this past 7 February. This establishes new minimum training standards for new entrants to the profession as well as to those upgrading or seeking an endorsement (hazardous materials, passengers and school buses) for the first time. Those obtaining a Commercial Learner’s Permit (CLP) after that date must complete the relevant training from a registered training provider, before taking a Commercial Driver’s License (CDL) skills or knowledge test.

There is also a system of information management, which involves training providers registered on the Training Provider Registry (TPR) and self-certifying that they meet all FMCSA and State requirements. The

TPR system is free of charge to users. Once a driver successfully completes the required training, the training provider must then electronically submit the driver’s certification to TPR.

James highlighted another issue of urgent concern to the trucking industry, resulting from the closure of 3G networks by telecommunications providers, as from February 2022; this is affecting those electronic logging devices (ELDs) that rely on 3G communication, which will no longer function properly. Motor carriers need to verify that their ELDs continue to meet FMCSA technical standards since, unless an extension is granted, they have only eight days to get a malfunction resolved. James explained the required details for obtaining an extension – which only relate to a malfunction caused by the ‘3G sunset’ – but noted that those issued thus far were to expire by the end of April at the latest.

Moving to the water, Lt Joseph Kolb, staff engineer within the US Coast Guard’s (USCG) Hazardous Materials Division, explained the

PHMSA AND OTHER MODAL BODIES WORK IN CONCERT

WITH THEIR COUNTERPARTS IN CANADA TO HELP ENSURE

SEAMLESS CROSS-BORDER TRANSPORT OF HAZARDOUS

MATERIALS agency’s organisation and its activities in the Who do you contact for hazmat arena. He began by noting that there the latest DG compliant are changes at the top at USCG planned for labels? this summer, with Admiral Karl Shultz taking over as Commandant. The Hazardous Materials Division’s current priorities, Joe explained, are to improve education and compliance in relation to undeclared and mis-declared hazardous materials, to review compliance with HMR in ferry operations, to improve its outreach and education efforts, and to ensure US interests are well represented at the International Maritime Organisation (IMO).

As part of that remit, USCG works with its modal partners and with PHMSA in the development of rulemakings; it was involved in HM-215P and the HM-260B final rule, which made some editorial corrections and clarifications to HMR. USCG is also, perhaps surprisingly, involved in the development of the NPRM under HM-263, which derives from the Fixing America’s Surface Transportation (FAST) Act and will require Class 1 railroads transporting hazardous materials to generate accurate electronic train consist information in real time.

Joe brought delegates up to speed with recent activity at the IMO, although as with other regulatory bodies it has moved towards virtual meetings and the USCG team have not

Free DG Label ID poster with every order

Tel: +44 (0)870 850 50 51 Email: sales@labeline.com

IATA’s Leading Distributor

Free Worldwide Shipping on the 63rd Edition

ADR available in spiral format

***NEW***

IATA available in spiral format

A Guide to Exemptions from the International Carriage of Dangerous Goods by Road 5

th Edition

ROGER WRAPSON

Tel: +44 (0)870 850 50 51 Email: sales@labeline.com

www.labeline.com

had the opportunity to visit London lately. The Editorial & Technical Group (E&T) on the International Maritime Solid Bulk Cargoes (IMSBC) Code conducted its 36th session virtually on 7 to 11 March and is due to meet again – perhaps in person this time – for its 37th session in the last week of September. The COSTHA meeting came just as the Sub-committee on Pollution Prevention and Response (PPR) was holding its ninth session, and the Sub-committee on Carriage of Cargoes and Containers (CCC), which has responsibility for the International Maritime Dangerous Goods (IMDG) Code, is scheduled to hold its eighth session from 19 to 23 September, though this may be extended depending on the outcome of the upcoming sessions of the Marine Environment Protection Committee (MEPC) and Maritime Safety Committee (MSC).

NORTH OF THE BORDER Over the past two or three years, Canada has upped the velocity of its rulemaking under its Transportation of Dangerous Goods Regulations (TDGR) and Christopher Blain, executive director at the TDG Directorate’s Regulatory Frameworks and International Engagement division, gave a detailed presentation of the latest developments.

The overarching feature of current activity is the ‘TDG Transformation’ programme, which aims to implement a suite of 18 initiatives that will enable the TDG programme “to innovate alongside industry” and improve Transport Canada’s ability to effectively and efficiently oversee the safe and secure transport of dangerous goods. Those initiatives cover regulatory, legislative and organisational changes and are being introduced after extensive consultation with stakeholders.

One important initiative is what Chris called ‘TDG Core’, which is designed to modernise IT systems within the TDG Directorate. As part of that, its inspectors are now using cloud-based systems to write and upload reports. It will all help the TDG Directorate to become a more data-centric and agile department and to produce evidence-based regulations.

One external but fundamental part of the transformation programme is the development of the Client Identification Database (CID), which is designed to create an accurate and reliable inventory of those companies and the sites where dangerous goods are handled, offered for transport, transported or imported into Canada. The policy phase has been completed and a digital solution is under development; Chris said he expected publication of proposals in Canada Gazette Part I (CG I) for comments this spring, with the final rule likely to appear in Part II (CG II) in spring 2023.

Of more immediate import to dutyholders, perhaps, is the planned publication in CG I this spring of Canada’s major international harmonisation rulemaking. This has been an extensive undertaking, with consultation going back as far as 2016 and the final rule unlikely to appear until the third quarter of 2023. The TDG Directorate has had to coordinate with several other national agencies as well as industry and its US counterparts.

The rulemaking will modernise some outdated requirements for the transport of dangerous goods by air as well as taking updates from the IMDG Code, the International Civil Aviation Organisation (ICAO) Technical Instructions and the UN Model Regulations into TDGR. Canada also plans to harmonise certain parts of TDGR more closely with HMR, in order to improve cross-border transport, in areas such as the recognition of PHMSA Special Permits, placarding requirements and toxic inhalation hazard (TIH) substances.

MORE TO COME FROM CANADA Already published in CG I this past December, following the publication of the Canadian General Standards Board (CGSB) Standard 192.3 in November 2020, is an update and expansion of the training requirements in Part 6 of TDGR, which will introduce a competencybased training and assessment approach, similar to that being introduced by ICAO in the air transport sector but here applied to all modes. The consultation period is now closed and comments are being analysed, with the aim of getting the final rule into CG II in spring 2023, at which point CGSB 192.3 will enter into force (though there will be a 12-month transitional period). Transport Canada will prepare and publish guidance documents on its website to help dutyholders assimilate the new provisions.

The TDG Directorate is also working on what it calls a ‘fee modernisation’ plan, which will introduce new fees and service standards for its means of containment (MOC) Facilities Registration Program. This aims to cover some of the costs of administering the programme, rather than leaving it all to the

Canadian taxpayer, and has been subject to Who do you contact for the latest DG compliant extensive consultation with stakeholders. Regulatory development is now complete, labels? Chris reported, with publication in CG I planned for spring this year. The proposals also include development of a digital system by which stakeholders can make applications online, while Transport Canada is also preparing guidance materials and outreach efforts.

A more general update of TDGR is planned, following consultation going back to 2015; more detailed consultation was held at the end of 2021. The TDG Directorate is seeking to update and clarify TDGR to more closely align with new industry practices and to address comments that have been received in recent years. Chris acknowledged that the rulemaking has been a long time in development and that some aspects contained in earlier drafts have been overtaken by later events. He now expects publication in CG I in spring of 2023 and noted that it may include specific provisions for the transport and delivery of dangerous goods by drones, which is currently not allowed under civil aviation rules in Canada.

Finally, Chris came to the ‘regulatory sandbox’ that Transport Canada has been running to assess the feasibility of the use of electronic shipping documents. The project came to an end on 31 March 2022 after the participation of seven carriers in four studies, two live simulations and one table-top simulation exercise. A simulation using drones is planned for the third quarter of this year. Transport Canada is continuing to work with PHMSA on the subject and is aiming to publish its report later this year.

At this point, it appears that there will need to be changes in Part 3 of TDGR and that they will focus on rail transport. This will require outreach to raise awareness among first responders and wider use of the expertise provided by Canutec. Transport Canada has taken onboard the message that a ‘single window’ approach is crucial and is continuing to work with the UN Sub-committee of Experts on TDG and PHMSA to identify a harmonised solution.

HCB will report further on discussions during this year’s COSTHA Annual Forum in a forthcoming issue.

IT WAS CLEAR FROM THE PRESENTATIONS AT THE COSTHA

ANNUAL FORUM THAT THOSE INVOLVED IN HAZMAT

TRANSPORT WILL SOON FACE A LOT OF REGULATORY

CHANGES

Who do you contact for DG Regulations? IATA’s Leading Distributor Free Worldwide Shipping on the 63rd Edition ADR available in spiral format ***NEW*** IATA available in spiral format

Free DG Label ID poster with every order

A Guide to Exemptions from the International Carriage of Dangerous Goods by Road 5

th Edition

ROGER WRAPSON

Tel: +44 (0)870 850 50 51 Email: sales@labeline.com

www.labeline.com Tel: +44 (0)870 850 50 51 Email: sales@labeline.com

www.labeline.com

You need Labeline.com

Labeline is the leading worldwide “One Stop Dangerous Goods Service” for Air, Sea, Road, and Rail

We serve Freight Forwarders, Shippers, Airlines, DCA’s, Port Authorities, Petrochemical industry and the Pharmaceutical industry.

Labeline is one of the world’s leading regulatory services and product provider; we hold comprehensive stocks with a fast worldwide delivery service.

We are one of the very few authorised Multi-mode providers worldwide and described by industry as a pro-active organisation, our name is recommended by many leading authorities and a world class service providers.

When it’s time to order your DG products and services, Labeline will be your “One Stop Service”

Compliant with IATA, ICAO, ADR, IMDG, RID, DoT

Dangerous Goods Labels Regulations Documentation Packaging Software Training GHS Chem Regs

Tel: +44 (0)870 850 50 51 Email: sales@labeline.com

www.labeline.com

CALM WATERS

INLAND WATERWAYS • THE ADN SAFETY COMMITTEE’S JANUARY SESSION ADOPTED SEVERAL AMENDMENTS FOR ENTRY INTO FORCE IN 2023, ALONG WITH SOME CORRECTIONS AND REVISIONS

THE JOINT MEETING of Experts on the Regulations annexed to the European Agreement concerning the International Carriage of Dangerous Goods by Inland Waterways – the ADN Safety Committee – held its 39th session this past 24 to 28 January. It was chaired by Henk Langenberg (Netherlands) with Bernd Birklhuber (Austria) as vice-chair. The meeting was attended by representatives of 13 countries, the Central Commission for the Navigation of the Rhine (CCNR), the Danube Commission, the European Commission and Transport Community, and nine non-governmental organisations.

The first part of this two-part report on the Committee’s session in last month’s HCB covered questions on implementation and interpretation of the provisions of ADN along with some proposals for amendments to be included in the 2023 text.

FURTHER PROPOSALS CCNR had been doing a lot of work to ensure harmonisation between the different language versions of ADN and had spotted an issue in the text in 3.2.3.1 on the use of stabilisers. There was a difference between the French and German wording and it seemed to the Commission that the German text was correct. The Safety Committee agreed and also changed the English version of ‘1’ under remark 33 (n) in column (20) to read: “The addition date of the stabilizer and the duration of its effectiveness,”.

CCNR had also noticed that the German, French and English texts of special provision 651 were slightly different, and also that they varied from the same provision in ADR. It asked whether it was appropriate to keep SP 651 in ADN and, if so, whether it should be aligned with ADR. The Safety Committee felt it should stay but adopted a change to the text. The English version will now read:

Special provision V2 (1) of ADR does not apply if the net explosive mass per transport unit does not exceed 4 000 kg, provided that the net explosive mass per vehicle does not exceed 3 000 kg.

An informal document from the European Chemical Industry Council (Cefic), the European Barge Union (EBU) and the European Skippers Organisation (ESO) addressed those dangerous goods that cannot be detected with a toximeter, suggesting the extension of the requirements of ADN to cover those substances if other methodologies of determining toxicity could be applied. The Safety Committee preferred to pass this idea on to the informal working group on substances and it was agreed to resume discussion at the next meeting.

EBU and ESO also put forward formal proposals to amend the provisions for cofferdams in inland tank vessels, following discussion at the previous two sessions. It was felt that the existing provisions do not reflect current vessel designs and, indeed, in some places are based on very old riveted designs. Most delegates supported the proposals in principle, although some clarification was called for. On the basis of revised wording put forward by EBU and ESO, the changes were adopted.

Paragraph 7.2.3.1.1 is amended to read:

The cofferdams shall be empty, as long as the adjacent cargo tanks are not empty. They shall be inspected before each filling and if not filled

they shall be inspected frequently, at least once a week, in order to ascertain that they are dry (except for condensation water). The beginning of 7.2.3.20.1 is amended to read:

Cofferdams fitted out as service spaces, and hold spaces containing insulated cargo tanks shall not be filled with water.

Cofferdams, not fitted out as service spaces, may be filled with water, provided that: (a) the adjacent cargo tanks are empty; (b) this has been taken into account in the intact and damage stability calculations; and (c) filling is not prohibited in column (20) of Table C of Chapter 3.2.

Double-hull spaces, double bottoms and hold spaces which do not contain insulated cargo tanks may be filled with ballast water provided:…

An editorial change to the transitional provision in 1.6.7.2.2.2 has been made to reflect these amendments.

The secretariat had checked the amendments already adopted and came with a few corrections; Austria also noticed an error in the Dangerous Goods List and the Safety Committee agreed that ‘VE04’ should

THE ADN SAFETY COMMITTEE, IN COMMON WITH OTHER

MODAL REGULATORY BODIES, IS HAVING TO ADDRESS THE

USE OF ALTERNATIVE FUELS BOTH FOR VESSEL

PROPULSION AND FOR CARRIAGE AS CARGO be added in column (10) against UN 1950 Aerosols, toxic, flammable, corrosive.

EBU and ESO reminded the Safety Committee of discussions at the January 2021 session on the installation of low-pressure valves or additional vacuum valves and the need to clarify the relevant provisions in ADN. Germany and the Netherlands agreed to prepare a joint proposal for the next session.

WORKING GROUP REPORTS Much of the detailed work to update the regulations annexed to the ADN Agreement is carried out by informal working groups, generally meeting (in person or by correspondence or online) inter-sessionally. The informal working group on loading on top in barges, for instance, had held its sixth meeting on 13 and 14 October 2021 and the Netherlands introduced a report of that gathering.

The working group had agreed that the informal working group on substances should continue to develop a ‘positive list’ of those dangerous goods that can be loaded in a cargo tank in one or more batches; this will apply only to cargoes with the same UN entry. There will need to be a definition of what is meant by ‘same cargo’ and a method by which new substances can be added to the positive list. Cefic offered to supply a list of such substances to act as a starting point.

The Safety Committee felt that the informal working group on loading on top should refrain from further discussion on the loading of different substances. It confirmed, however, that this does not apply to the addition of inhibitors, colourants or other additives to a cargo. FuelsEurope was invited to develop a proposal to make this explicit in the regulations. In the meantime, it appeared that the informal working group had completed its tasks.

The chair of the Group of Recommended ADN Classification Societies reported on the outcome of the group’s online meeting of 20 October 2021. The Safety Committee was particularly interested in two topics, namely the acceptance of deepwell pumps for use in Zone 0 cargo tanks on gas tankers, and transitional provisions for electrical and non-electrical equipment in Zones 1 and 2, and asked the Group to continue its work. Belgium urged more work on electric propulsion systems and energy storage and offered to prepare a proposal for consideration at the next meeting.

There had been some discussion on the wording of 1.15.3.8 on the recognition of classification societies under ADN. The Safety Committee, after a long exchange of views, felt that classification societies should undergo a recurrent assessment by an accreditation body in order to retain their

THE WORK OF THE ADN SAFETY COMMITTEE IS MADE

COMPLEX BY THE NEED TO CONSIDER PACKAGED GOODS

AS WELL AS THOSE SHIPPED IN BULK IN TANK VESSELS

status under ADN. The Committee recalled that the Group had been asked on more than one occasion to prepare a detailed document with their views on the accreditation process.

The correspondence group on fumigated cargoes had held positive discussions with consignors of such cargoes and with carriers on the possible risks and measurement methods for their carriage. The Netherlands underlined the importance of the issue and pledged continued cooperation.

CCNR offered some terms of reference for an informal working group on certificates and other onboard documents in electronic format, which was accepted by the Safety Committee. The Netherlands volunteered to lead the work, with CCNR offering secretariat services.

The Netherlands submitted draft terms of reference for an informal working group on loading and unloading instructions. The Safety Committee welcomed its offer to lead the group, with the first meeting tentatively scheduled for April 2022.

ADMINISTRATIVE COMMITTEE Following the ending of the ADN Safety Committee’s session, delegates continued under the ADN Administrative Committee, with the same chair and vice-chair. This body gave the Recommended ADN Classification Societies another nudge for evidence of their certification in accordance with EN ISO/IEC 17020:2012.

The Administrative Committee noted the details of the special authorisation granted by the Netherlands for the transport of UN 1288 Shale oil in tank vessels as well as the discussions in the Safety Committee.

Germany reported that it was experiencing difficulties in complying with the new card format for the ADN specialised knowledge certificates and had been unable to meet the 1 January 2022 deadline. The Federal Waterways and Shipping Agency was continuing to issue these documents in the ‘old’ format and asked other Contracting Parties to refrain from objecting to their ongoing use until the end of 2022. The Administrative Committee felt it would require the signing of a multilateral agreement and invited other Contracting Parties to countersign the agreement once it has been circulated.

Romania, France, Germany and the Netherlands supplied examination statistics, which the Administrative Committee found very useful; it invited all countries to submit such data regularly.

The Administrative Committee endorsed and adopted all the amendments and corrections for ADN supplied by the Safety Committee and asked the secretariat to take the necessary steps to communicate the corrections to all Contracting Parties. It also asked for a consolidated list of all the amendments adopted for entry into force on 1 January 2023.

The Safety Committee is due to hold its 40th session on 22 to 26 August 2022; the 28th session of the Administrative Committee will take place on the last day of that session. The Safety Committee will only consider for adoption in the 2023 edition of ADN additional amendments and corrections to texts already adopted, or proposals to ensure harmonisation with the 2023 editions of RID and ADR. All other matters will be held over for consideration during the next biennium.