Architecture Design & Fabrication

Selected Works 2021 - 2024

Architecture Design & Fabrication

Selected Works 2021 - 2024

Born in 1996, Taiwan

Email: chin.lu.23@ucl.ac.uk

Linkedin: chin-lun-lu

2023-24 Bartlett School of Architecture, UCL Design for Manufacture MArch (Distinction)

2020-22 Tunghai University

Architecure Design MArch (Leave of absence)

2015-19 National Cheng Kung University

Environmental Engineering BSc (Major)

Architecture BArch (Minor)

Aesthetics and Arts Credit Program Computer Science

2024 Fifteen Show , Bartlett School of Architecture graduate exhibition

2024 Bartlett in Situ , London Architecture Festival exhibition

2023 Jhonying Elementary School competetion, the 1st prize

2023 YLEPB Office Building competetion, the 3rd prize

2022 Made in Kaohsiung national architecture competetion, the 3rd prize

2019 Best Student Award of the Dept.ENV, NCKU

2019 Graduate Student Representative of the Dept.ENV, NCKU

2018 3-Dimentional Senses , personal animation exhibition

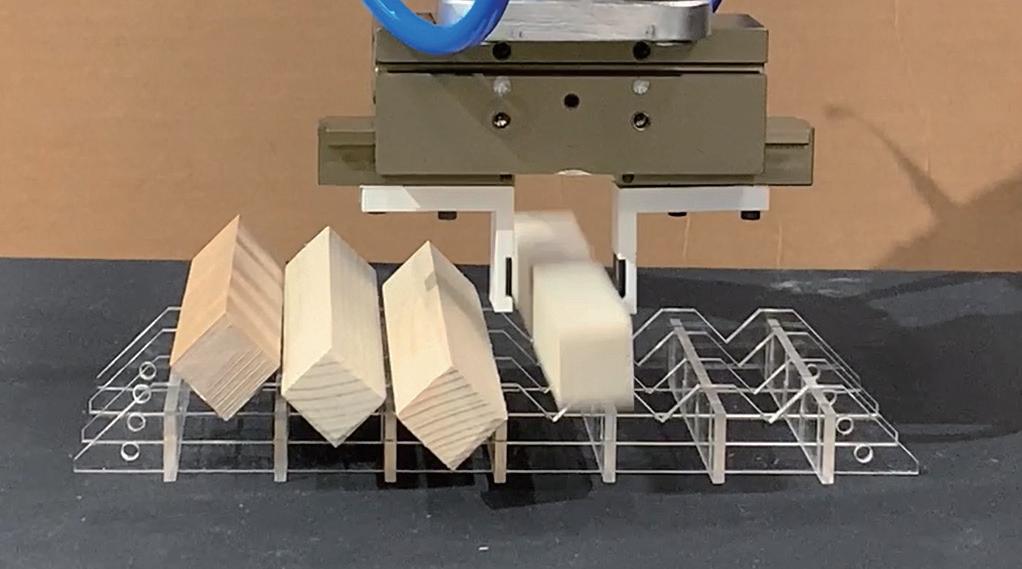

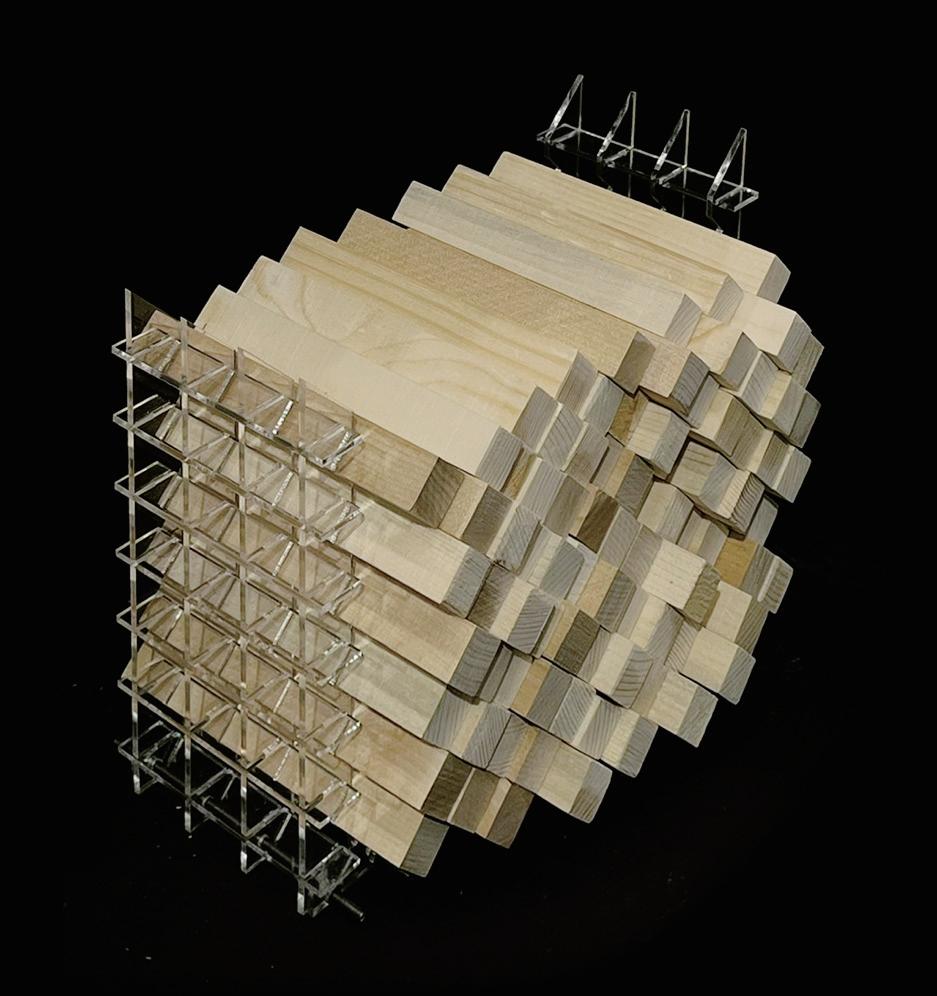

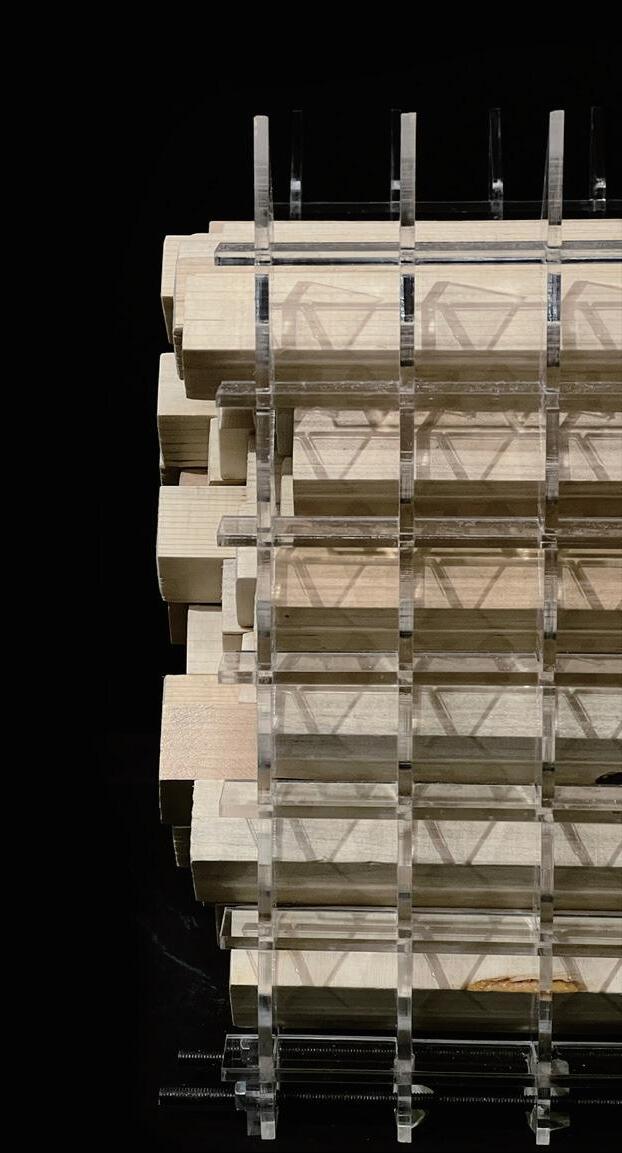

Design for Manufacture, UCL graduate project, 2024 Collabarator: Zhenghao Zhu

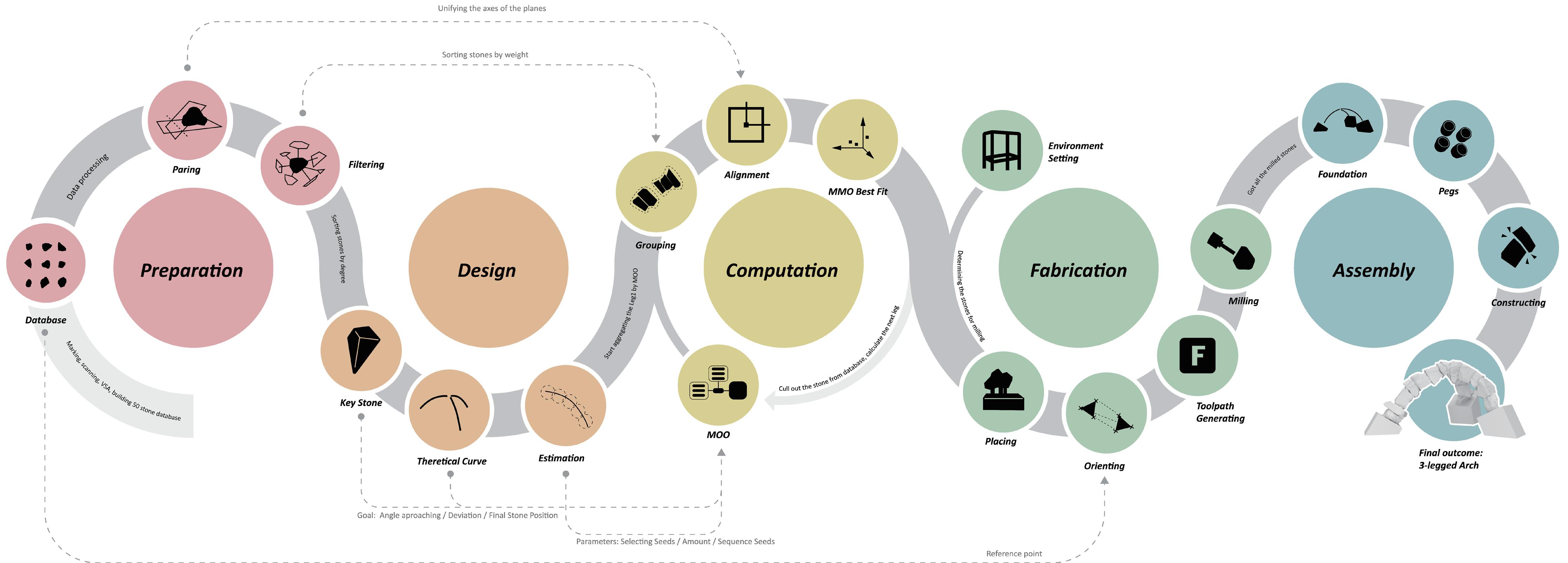

The MArch graduate research presents a novel methodology for sustainable stone construction, emphasizing minimal material modification and reduced carbon emissions inherent in contemporary stone processing techniques. This study introduces an integrated workflow to optimize the geometry of unmodified stone blocks through precise and targeted modifications, enabling construction with locally sourced material and minimal processing. The proposed methodology combines three core technologies: highresolution 3D scanning, algorithmic rationalization, and robotic milling

Computational Workflow for Robotic Subtractive Manufacturing in Dry Stone Assembly

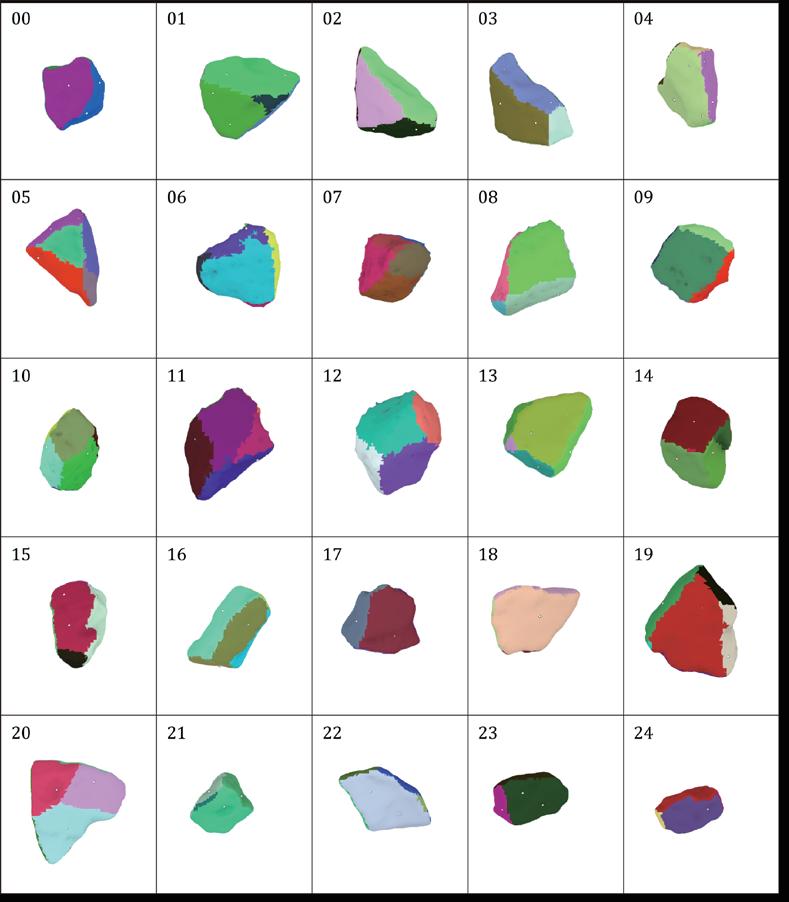

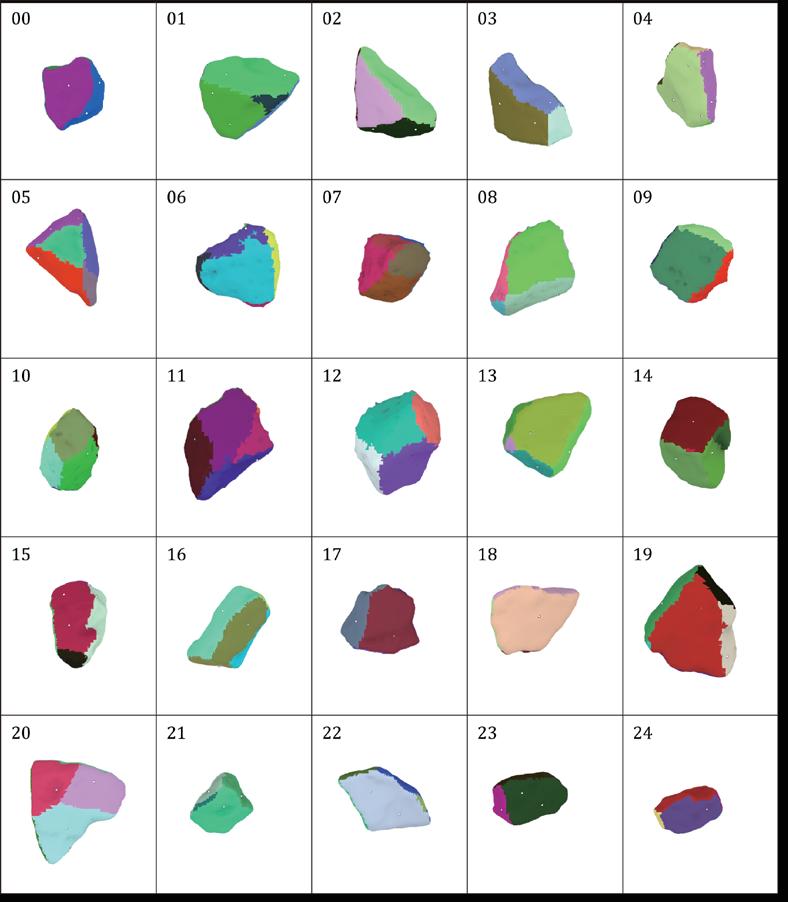

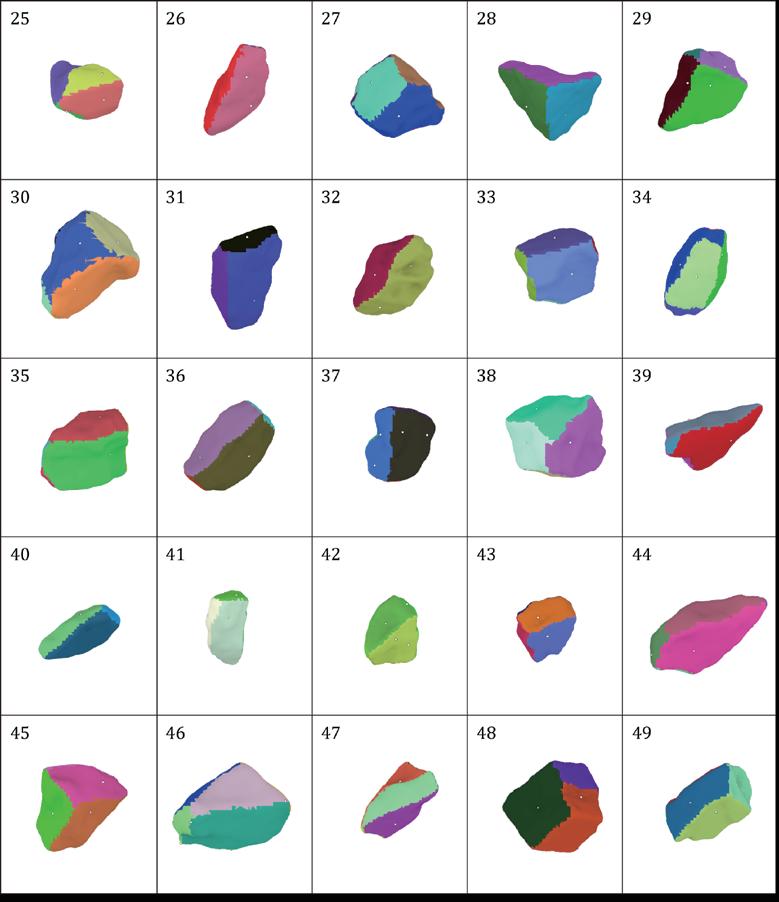

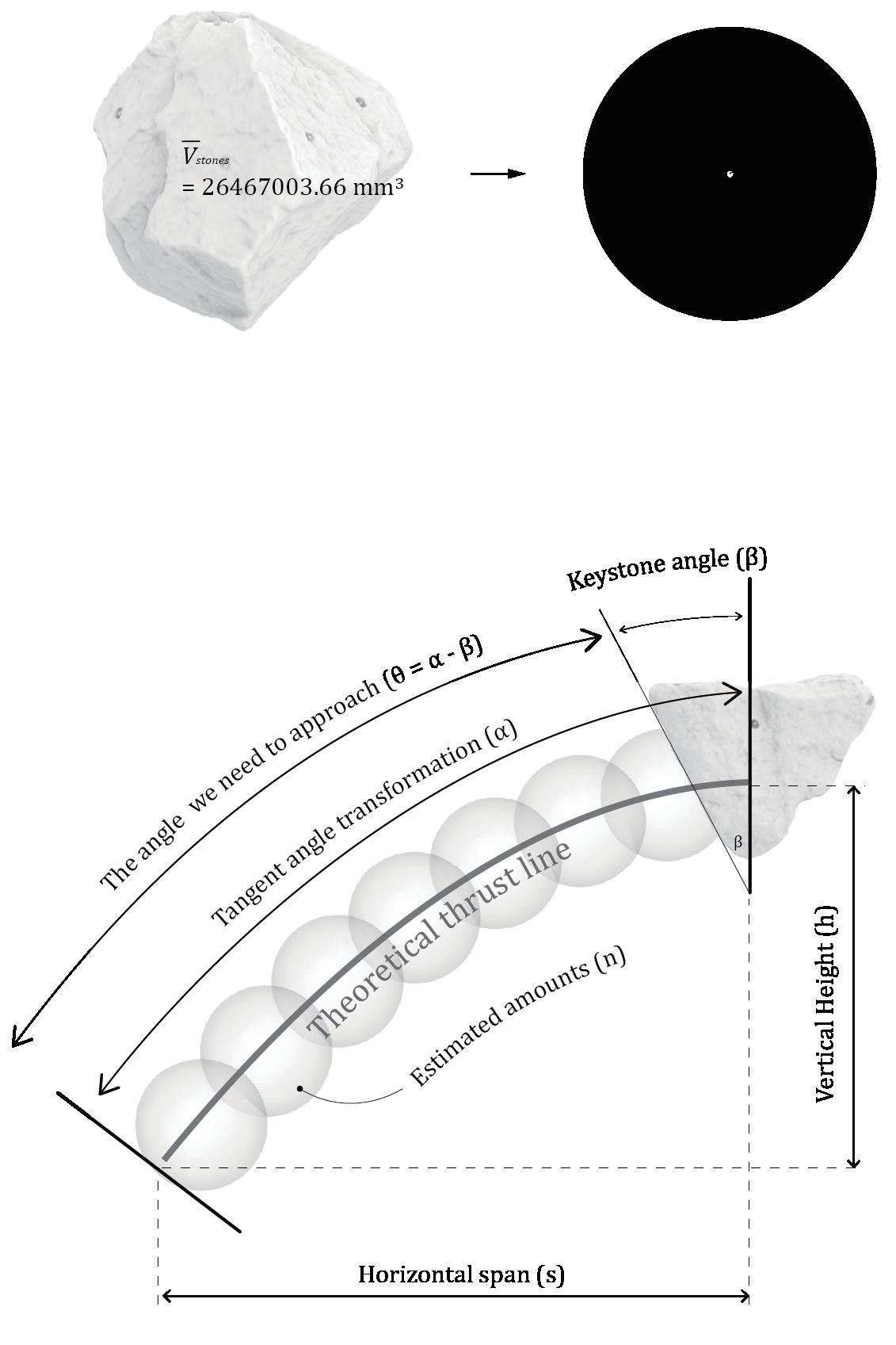

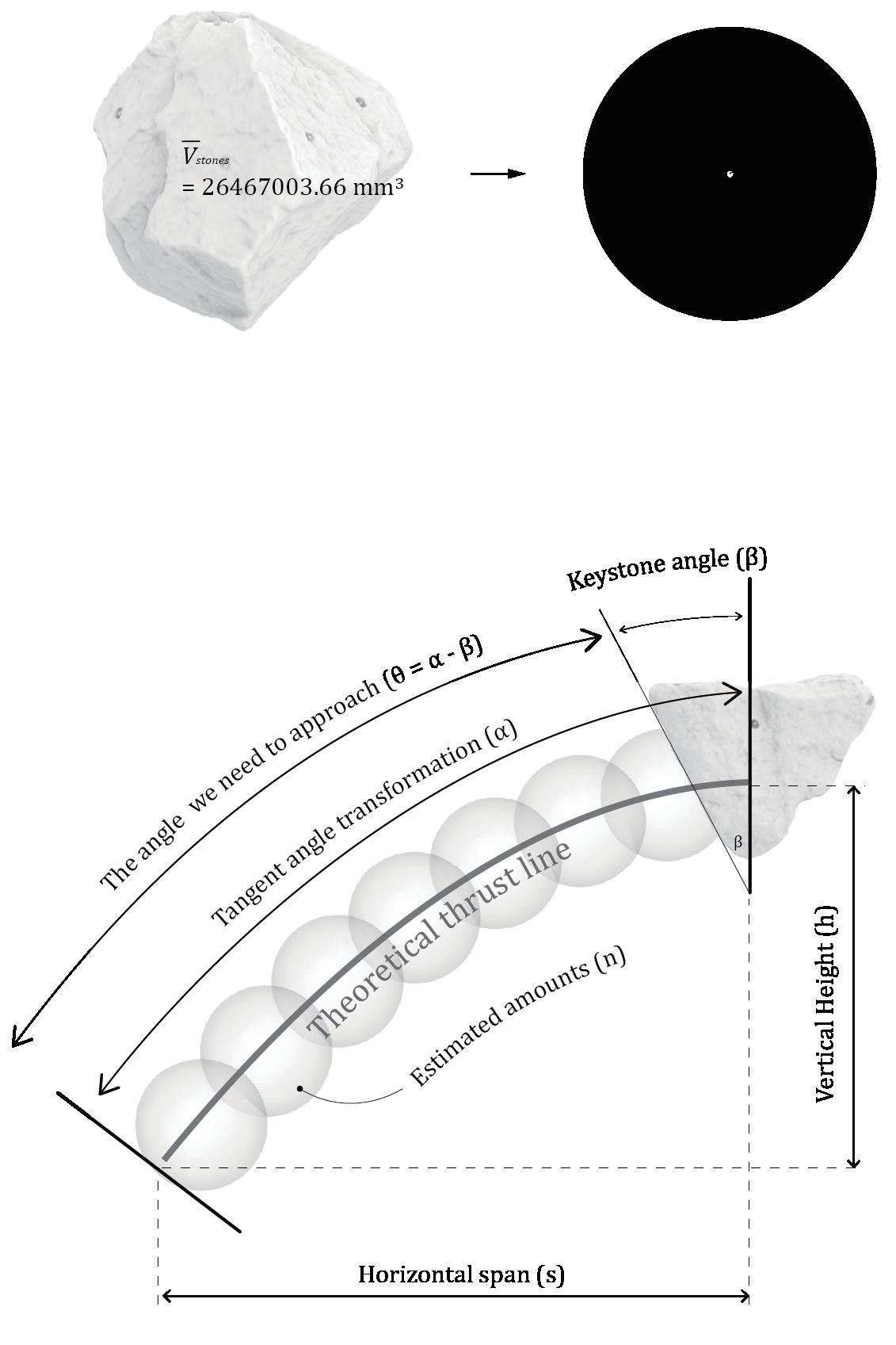

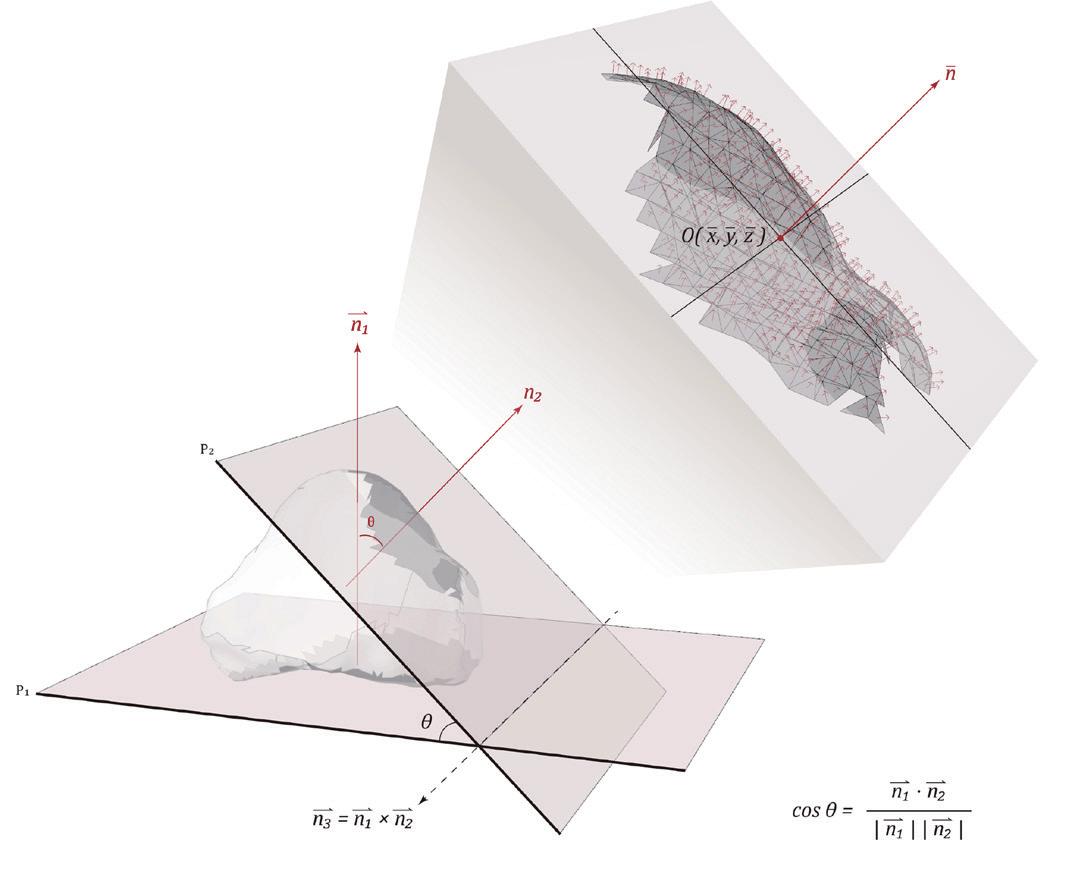

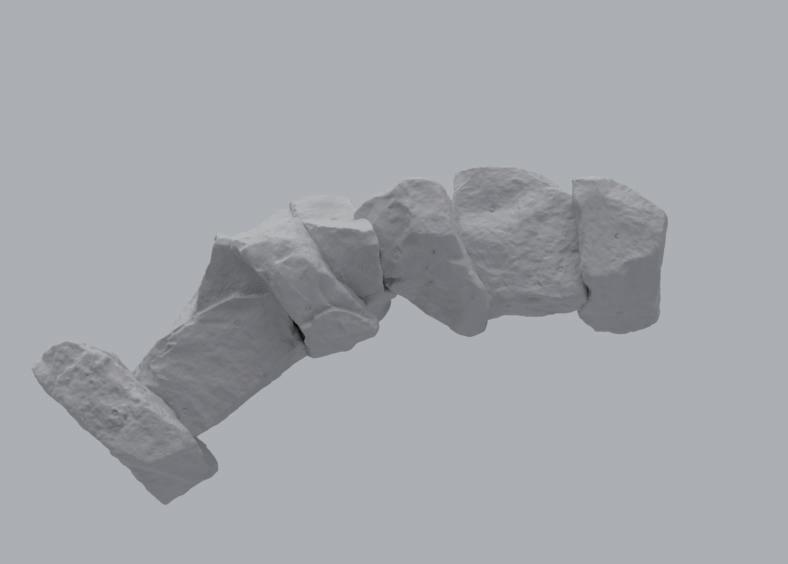

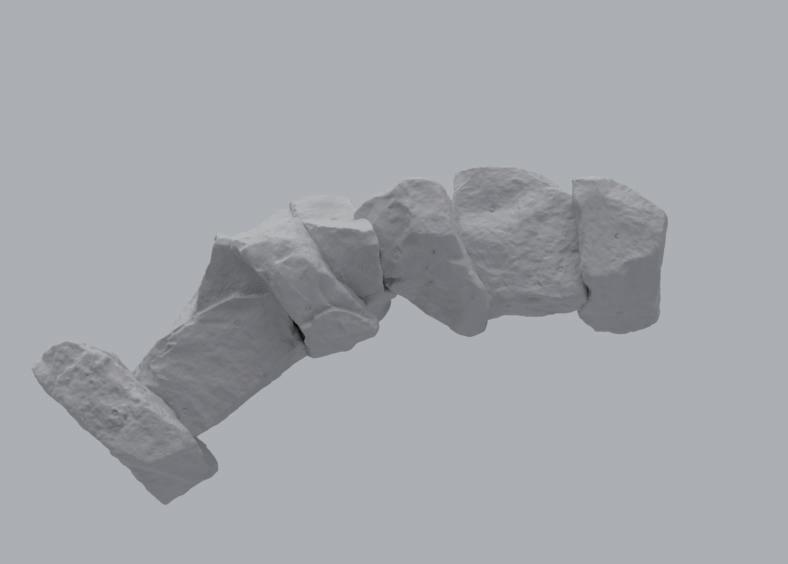

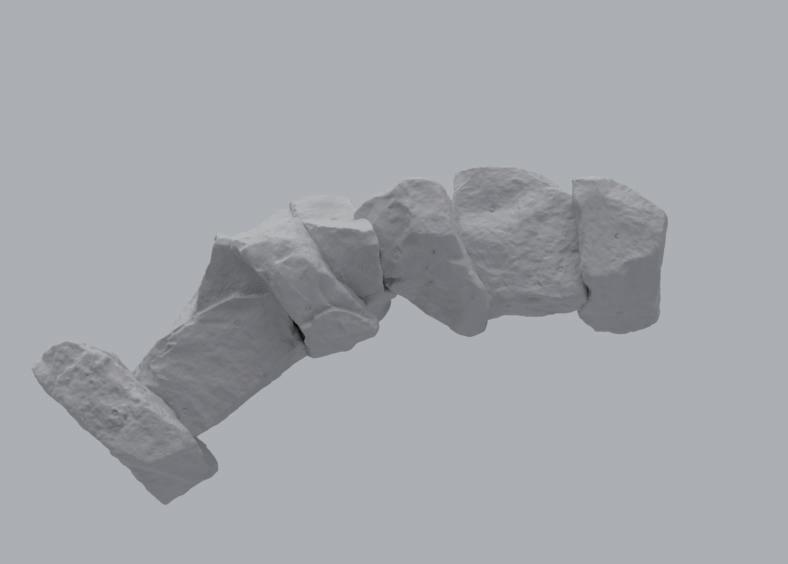

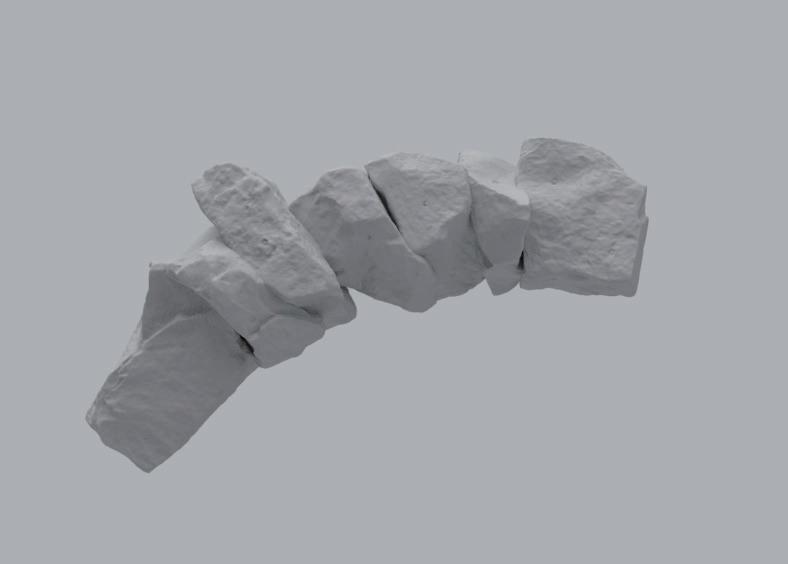

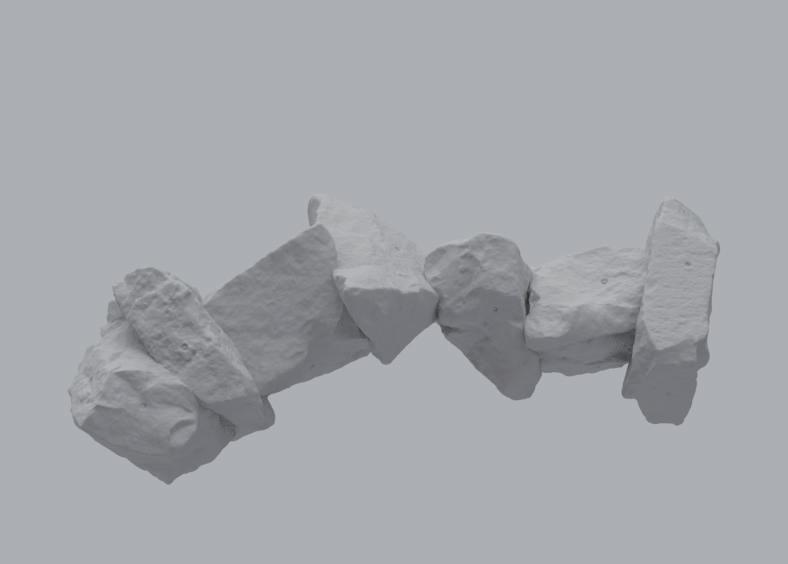

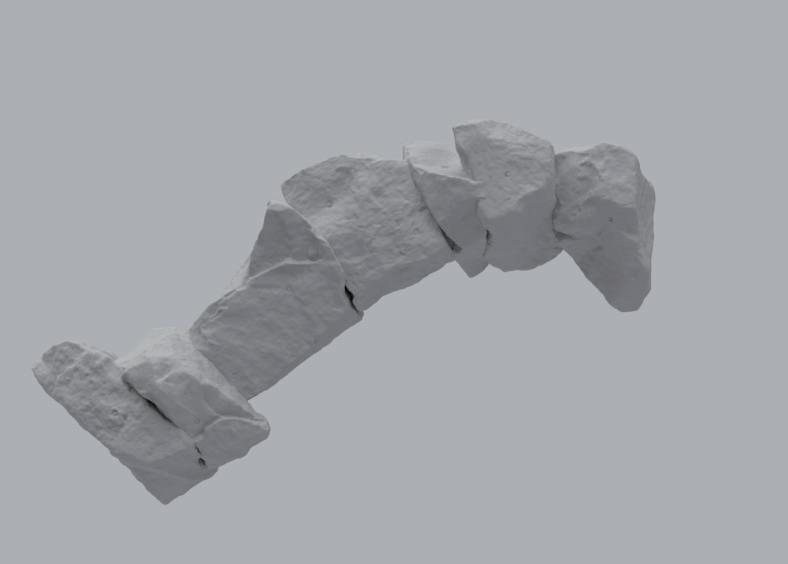

3D scanning accurately captures the geometries and surface features of unmodified stone blocks, generating digital models that serve as the basis for computational design. In this project, we built a database containing 50 stone meshes. The meshes were simplified and divided into several distinct surfaces using the Variational Approximation Algorithm.

We developed an integrated workflow that combines physical and digital operations, overcoming the challenges of computing and fabricating materials with irregular shapes— especially through robotic fabrication, which is rarely researched in the digital fabrication field.

Global Aggregation Design and Multi-objective Optimization

Algorithmic rationalization is employed to optimize assembly strategies, ensuring structural integrity and maximizing the use of each stone’s natural form. By analysing the angles of simplified mesh surfaces, optimal face pairs were identified to minimize the volume of material requiring modification during the machining process. Aggregations were subsequently generated by aligning these planes with a digitally designed global geometry.

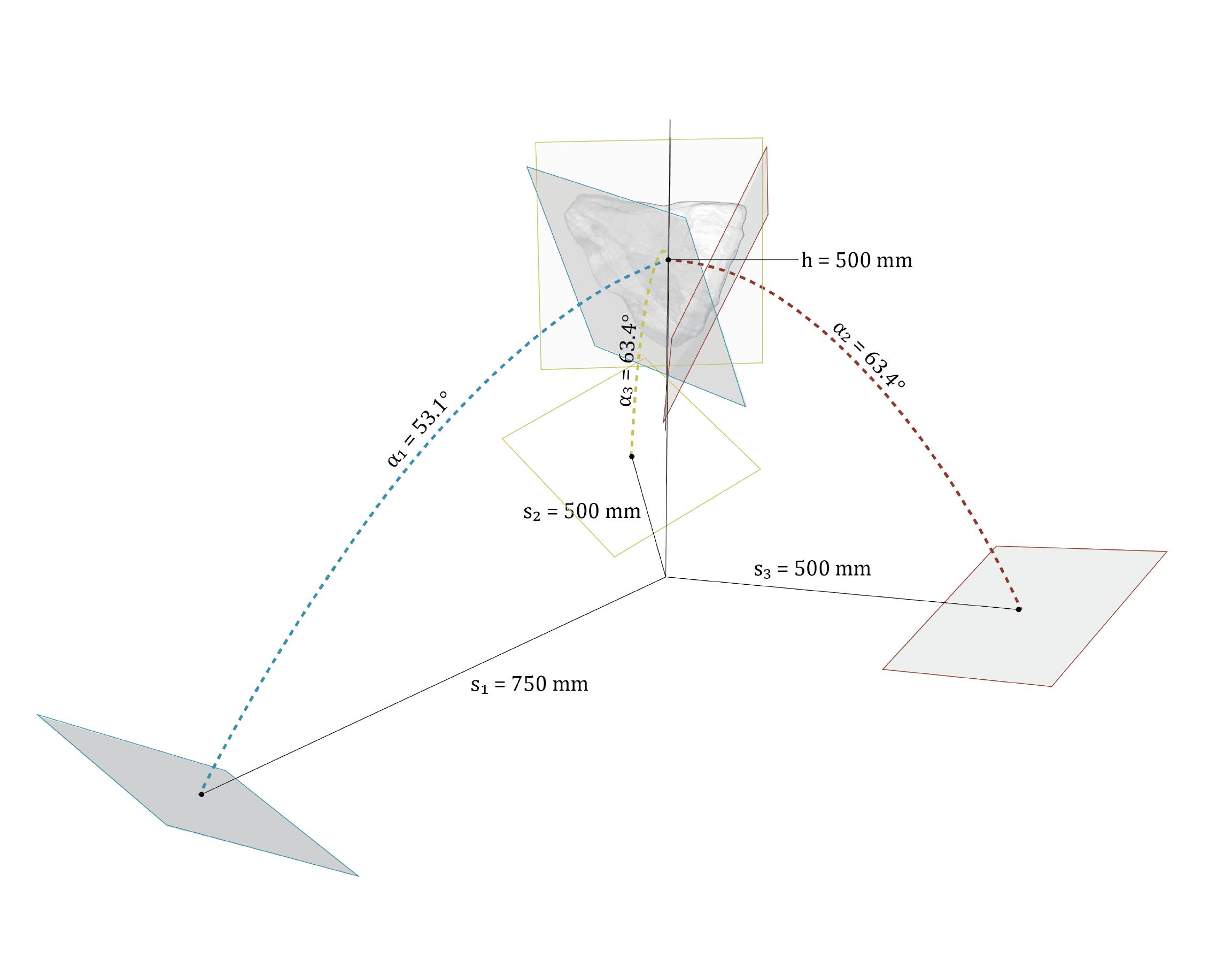

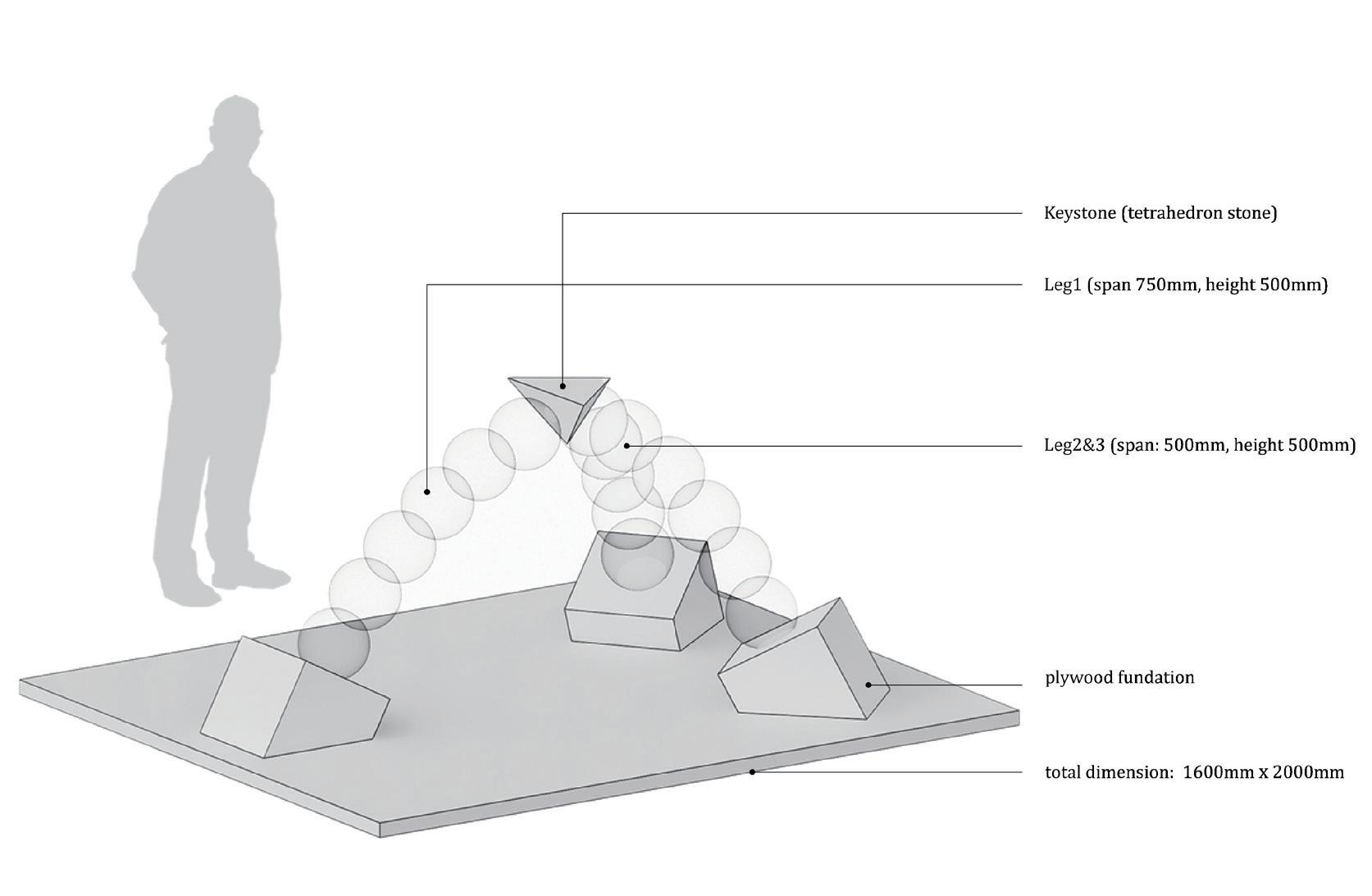

Multi-Objective Optimization was employed to refine parameters such as the quantity, indexing, and sequencing of stones, achieving configurations that met target span, height, and structural stability criteria. Robotic milling was utilized to execute the targeted modifications, significantly reducing material waste and energy consumption compared to conventional machining methods.

An adaptive milling strategy was developed to accommodate the high geometric variability of natural stones. This workflow was validated through the fabrication of 18 stones, which were assembled into a three-legged arch, demonstrating the feasibility and structural performance of the proposed approach.

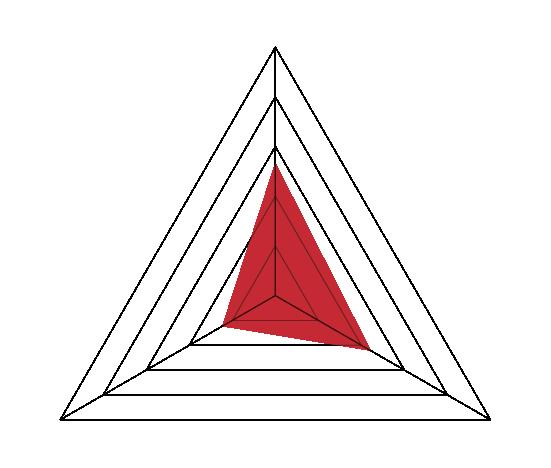

Parameter 1: Stone Amount

Parameter 1: Stone Amount

The amount of stones in one leg.

The amount of stones in one leg.

Parameter 1: Stone Amount

The amount of stones in one leg.

Stone Amount: 7

Stone Amount: 7

Selecting Seed: 1266

Selecting Seed: 1266

Selecting Seed: 1249

Selecting Seed: 1249

Stone Amount: 7

Selecting Seed: 1266

Selecting Seed: 1249

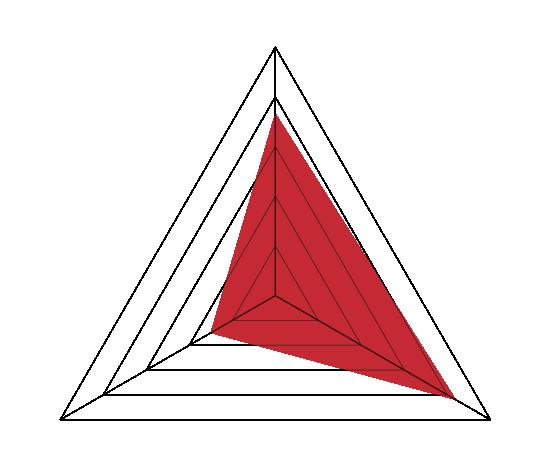

Parameter 2: Selecting Seed

Parameter 2: Selecting Seed

Stone Amount: 4

Stone Amount: 4

Selecting Seed: 1266

Selecting Seed: 1266

Selecting Seed: 1249

Selecting Seed: 1249

Stone Amount: 4

Selecting Seed: 1266

Parameter 1: Quantity

Selecting Seed: 1249

Randomly select stones from the top 70% smallest angle database.

Randomly select stones from the top 70% smallest angle database.

Parameter 2: Selecting Seed

Randomly select stones from the top 70% smallest angle database.

Stone Amount: 7

Selecting Seed: 1266

Stone Amount: 7 Selecting Seed: 1266

Selecting Seed: 1249

Selecting Seed: 1249

Stone Amount: 7 Selecting Seed: 1266

Selecting Seed: 1249

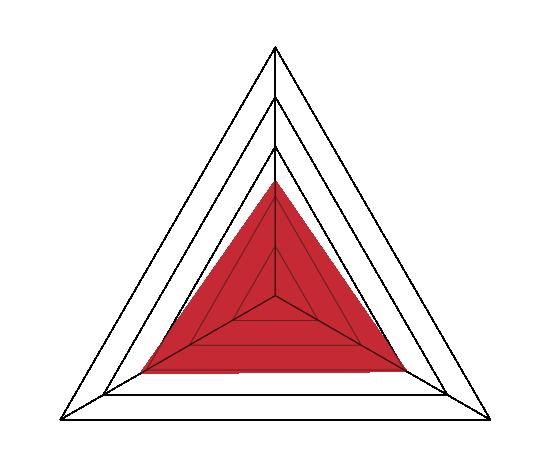

Parameter 3: Sequencing Seed

Parameter 3: Sequencing Seed

Stone Amount: 7

Stone Amount: 7

Selecting Seed: 226

Selecting Seed: 226

Selecting Seed: 1249

Selecting Seed: 1249

Stone Amount: 7

Selecting Seed: 226

Selecting Seed: 1249

Parameter 2: Indexing

Randomly arrange the sequence of selected stones.

Randomly arrange the sequence of selected stones.

Parameter 3: Sequencing Seed

Randomly arrange the sequence of selected stones.

Selecting Seed: 1249

Selecting Seed: 1249

Stone Amount: 7

Selecting Seed: 1266

Selecting Seed: 1249

Sequencing Seed: 177

Sequencing Seed: 177

Stone Amount: 7

Selecting Seed: 1266

Sequencing Seed: 177

Parameter 3: Sequencing

Stone Amount: 5

Stone Amount: 5

Selecting Seed: 1266

Selecting Seed: 1266

Selecting Seed: 1249

Selecting Seed: 1249

Stone Amount: 5

Selecting Seed: 1266

Selecting Seed: 1249

Stone Amount: 7

Stone Amount: 7

Selecting Seed: 260

Selecting Seed: 260

Selecting Seed: 1249

Selecting Seed: 1249

Stone Amount: 7

Selecting Seed: 260

Selecting Seed: 1249

Selecting Seed: 475

Selecting Seed: 475

Stone Amount: 7 Selecting Seed: 1266 Selecting Seed: 475

Stone Amount: 6

Stone Amount: 6

Selecting Seed: 1266

Selecting Seed: 1266

Selecting Seed: 1249

Selecting Seed: 1249

Stone Amount: 6

Selecting Seed: 1266

Selecting Seed: 1249

Selecting Seed: 1249

Selecting Seed: 1249

Stone Amount: 8

Selecting Seed: 1266

Selecting Seed: 1249

Selecting Seed: 1249

Selecting Seed: 1249

Stone Amount: 9

Selecting Seed: 1266

Objective 1: Centroid Deviation

Selecting Seed: 1249

Stone Amount: 7 Selecting Seed: 447

Stone Amount: 7 Selecting Seed: 447

Selecting Seed: 1249

Selecting Seed: 1249

Stone Amount: 7 Selecting Seed: 447

Selecting Seed: 1249

Stone Amount: 7

Stone Amount: 7

Selecting Seed: 1266

Selecting Seed: 1266

Selecting Seed: 694

Selecting Seed: 694

Stone Amount: 7 Selecting Seed: 1266 Selecting Seed: 694

Selecting Seed: 1249

Selecting Seed: 1249

Stone Amount: 7

Selecting Seed: 1411

Selecting Seed: 1249

Selecting Seed: 1711

Selecting Seed: 1711

Selecting Seed: 1249

Selecting Seed: 1249

Stone Amount: 7 Selecting Seed: 1711

Selecting Seed: 1249

Objective 2: Endpoint Deviation

Selecting Seed: 1266

Selecting Seed: 1508

Selecting Seed: 1733

Selecting Seed: 1733

Selecting Seed: 1266

Selecting Seed: 1733

Objective 3: Angle Deviation

Parameters

Stone Quantity: 7

Indexing Seed: 996

Sequencing Seed: 623

Result

Endpoint Deviation(mm): 221

Centroid Deviation(mm): 328

Angle Deviation(°) 21

Parameters

Stone Quantity: 6

Indexing Seed: 379

Sequencing Seed: 918

Result

Endpoint Deviation(mm): 328

Centroid Deviation(mm): 652

Angle Deviation( ) 27

Parameters

Stone Quantity: 7

Indexing Seed: 185

Sequencing Seed: 1611

Result

Endpoint Deviation(mm): 185

Centroid Deviation(mm): 472

Angle Deviation(°) 22

Parameters

Stone Quantity: 6

Indexing Seed: 1472

Sequencing Seed: 1249

Result Endpoint Deviation(mm): 169

Centroid Deviation(mm): 334

Angle Deviation(°) 63

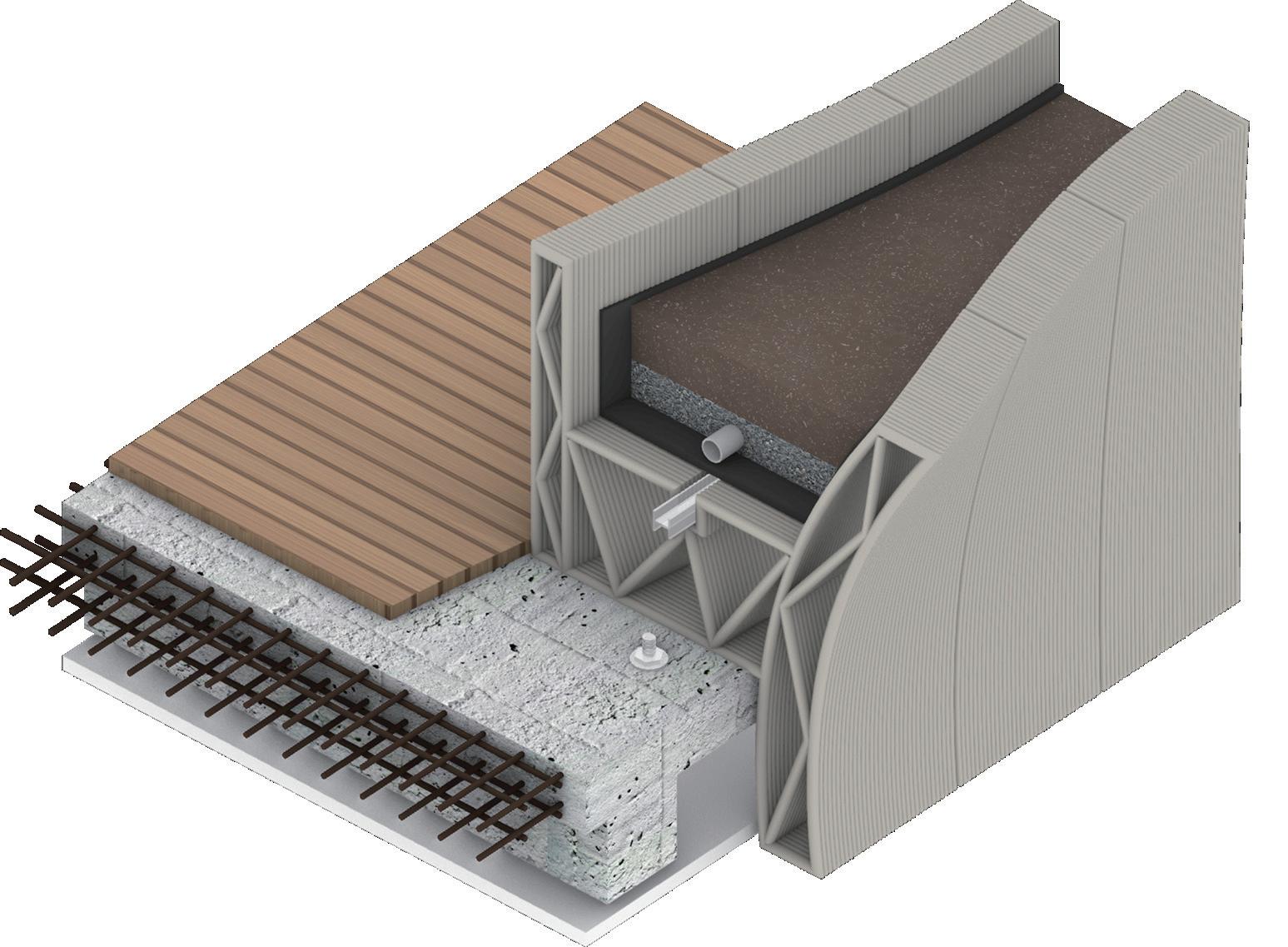

Minimal Modification Stone Bridge: New Materialism in the Post-digital Era

The assembly of the arch shows the potenial of linear stone structure. Since stone is good at handling compression, a stone arch bridge could be a strong application for our algorithm. In the AEC scenario, the milled stones can be connected by post-tensioned tendon. steel plate is placed between the interfaces, providing resistance against shear forces. The stone structure carries the bridge with cables that pull the stones downward, theoretically tightening the structure and distributing weight through the arch.

The stone bridge is a material-driven design that presents the butalness of the natural material, evoking the vitality of stones. By the computational aggregation, we can manufacture with minimal modification and assemble the modified stone with tensioned stone system, achieving the principle of DfMA, emphasizing sustainability and efficiency in material usage.

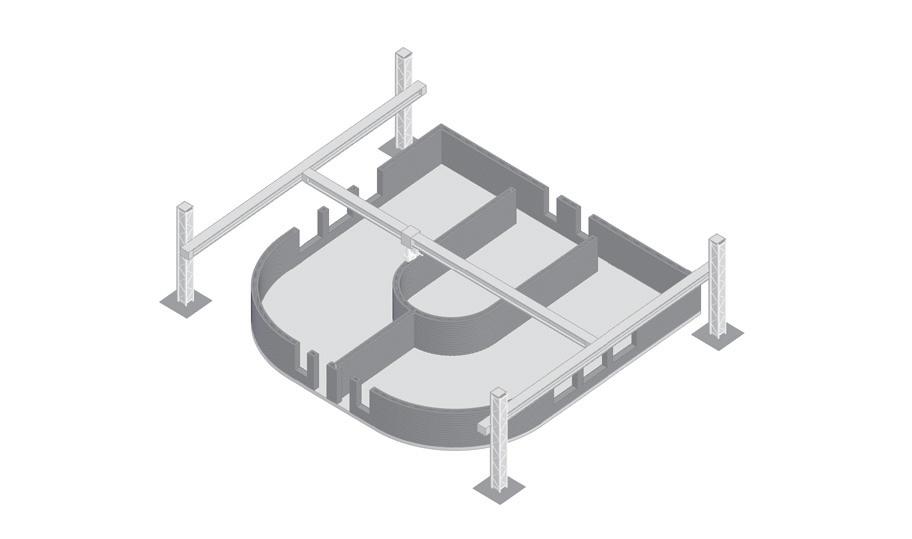

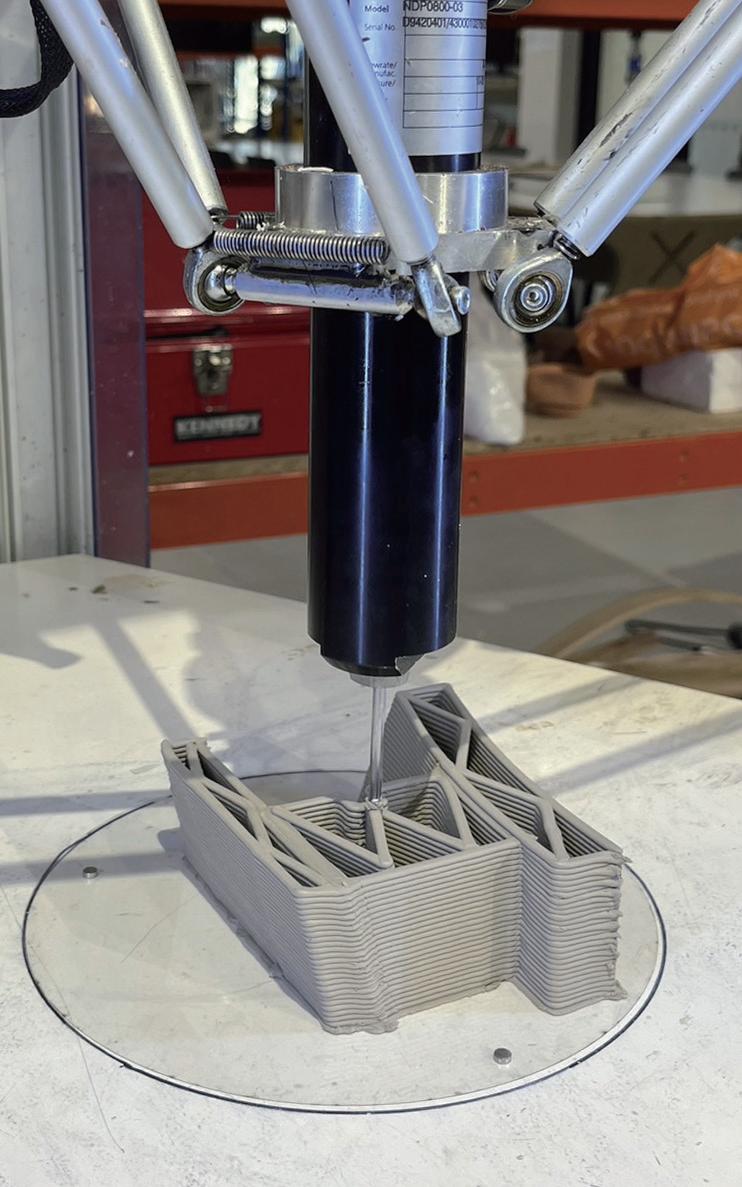

Design for Manufacture, UCL module project, 2024

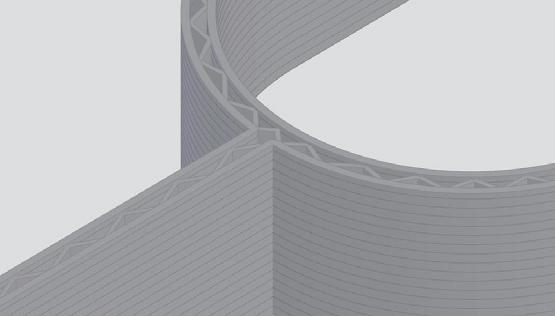

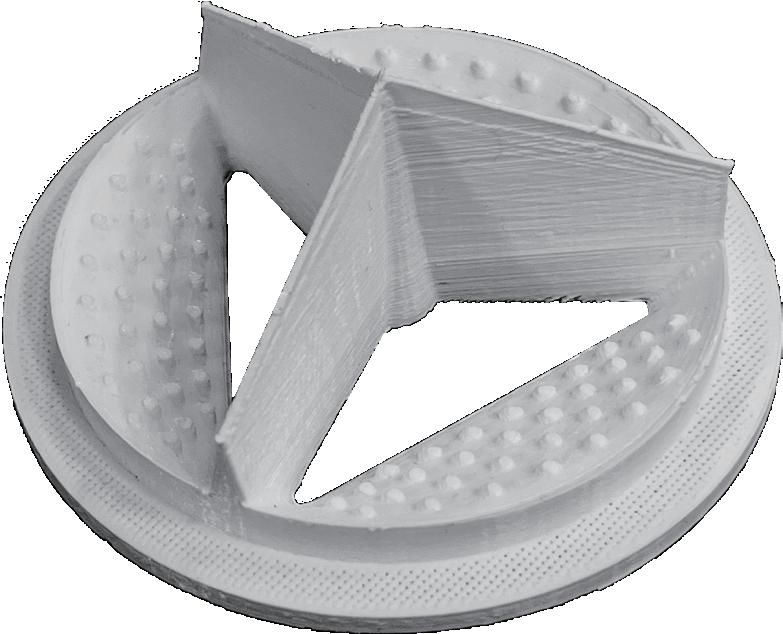

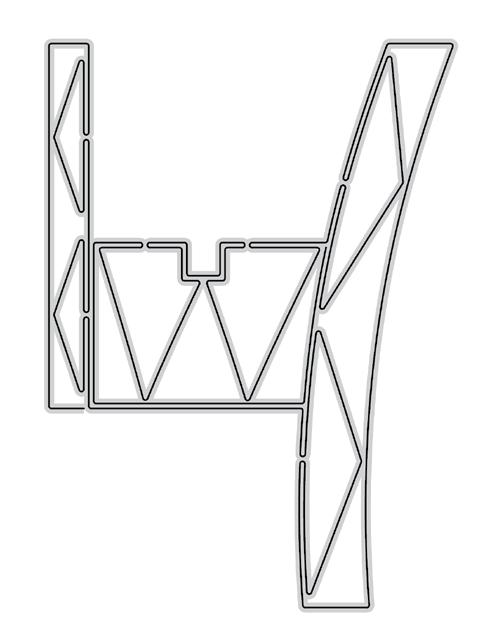

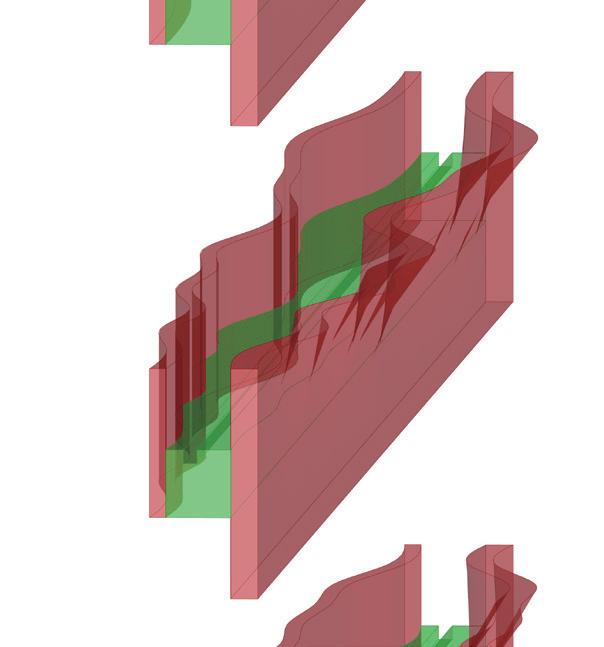

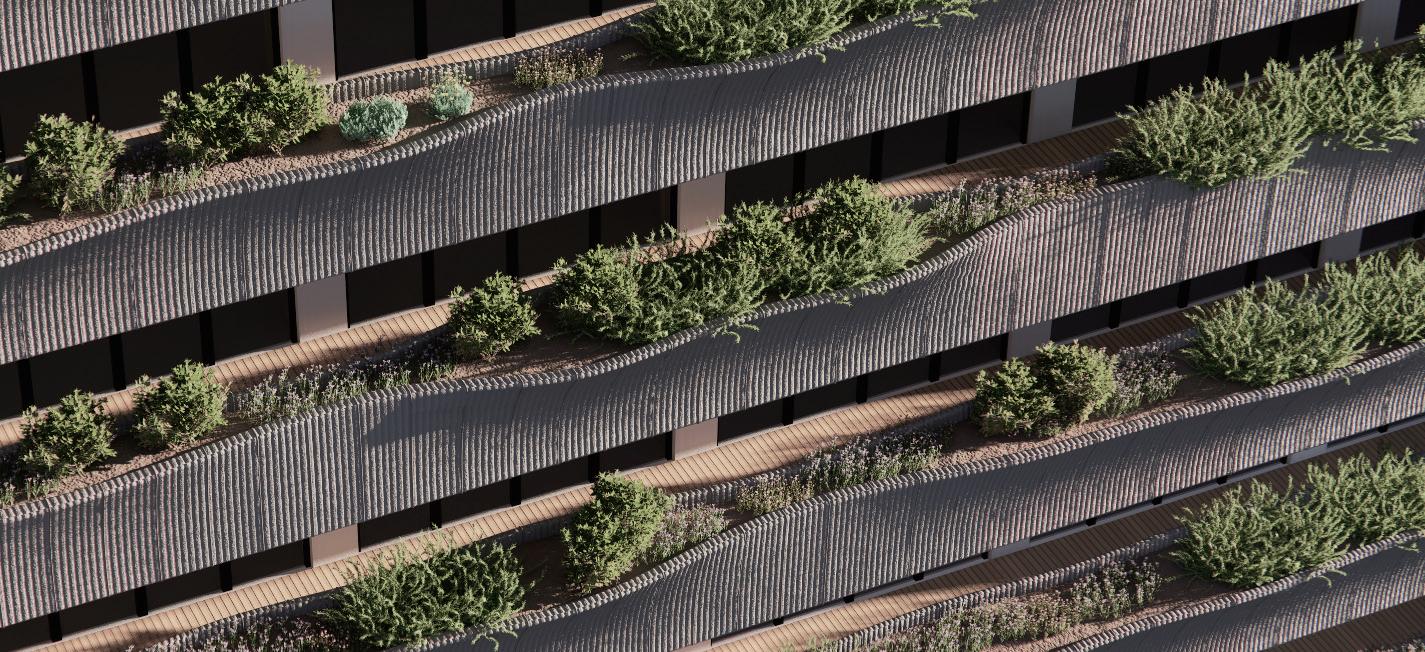

One of the MArch module focuses on training in clay printing operations using a 3-axis machine. The design showcases my understanding of 3D printing technology applications in AEC scenarios, including the principles of printing toolpath design, assembly, and fabrication constraints.

The balcony design proposal utilizes 3D concrete printing and integrates planter functionality, allowing plants to grow within the structure. The wavy form highlights the advantages of this advanced construction technology, demonstrating how complex geometries can be built in an efficient and sustainable way.

Computational Design Process

1. Global form-finding (random curve)

2. Detailed form-finding (balcony shape)

3. Stereotomy

4. Toopath generation

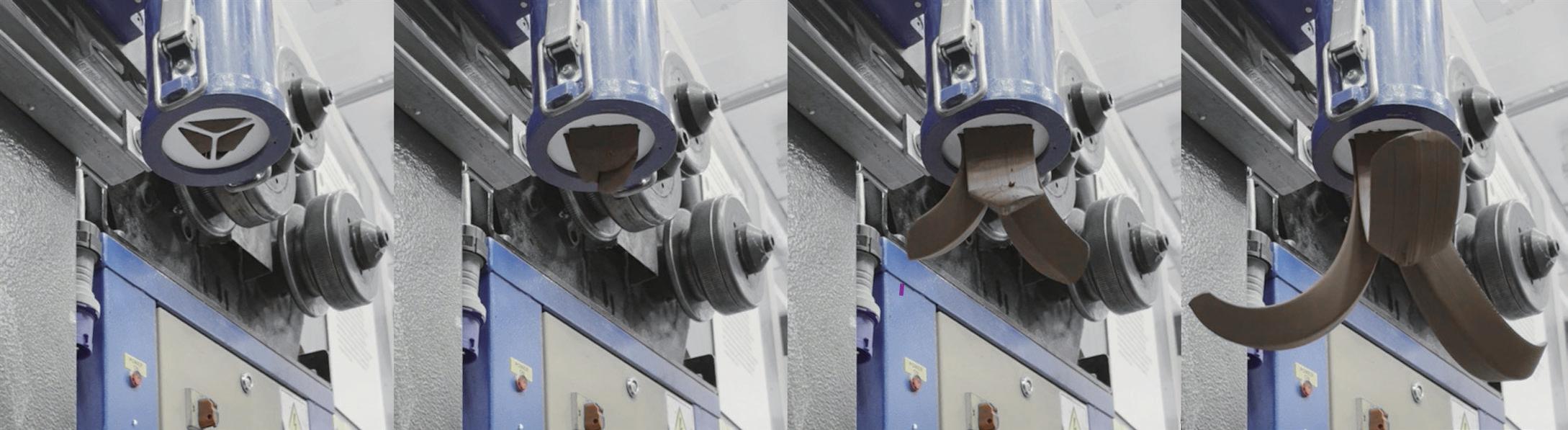

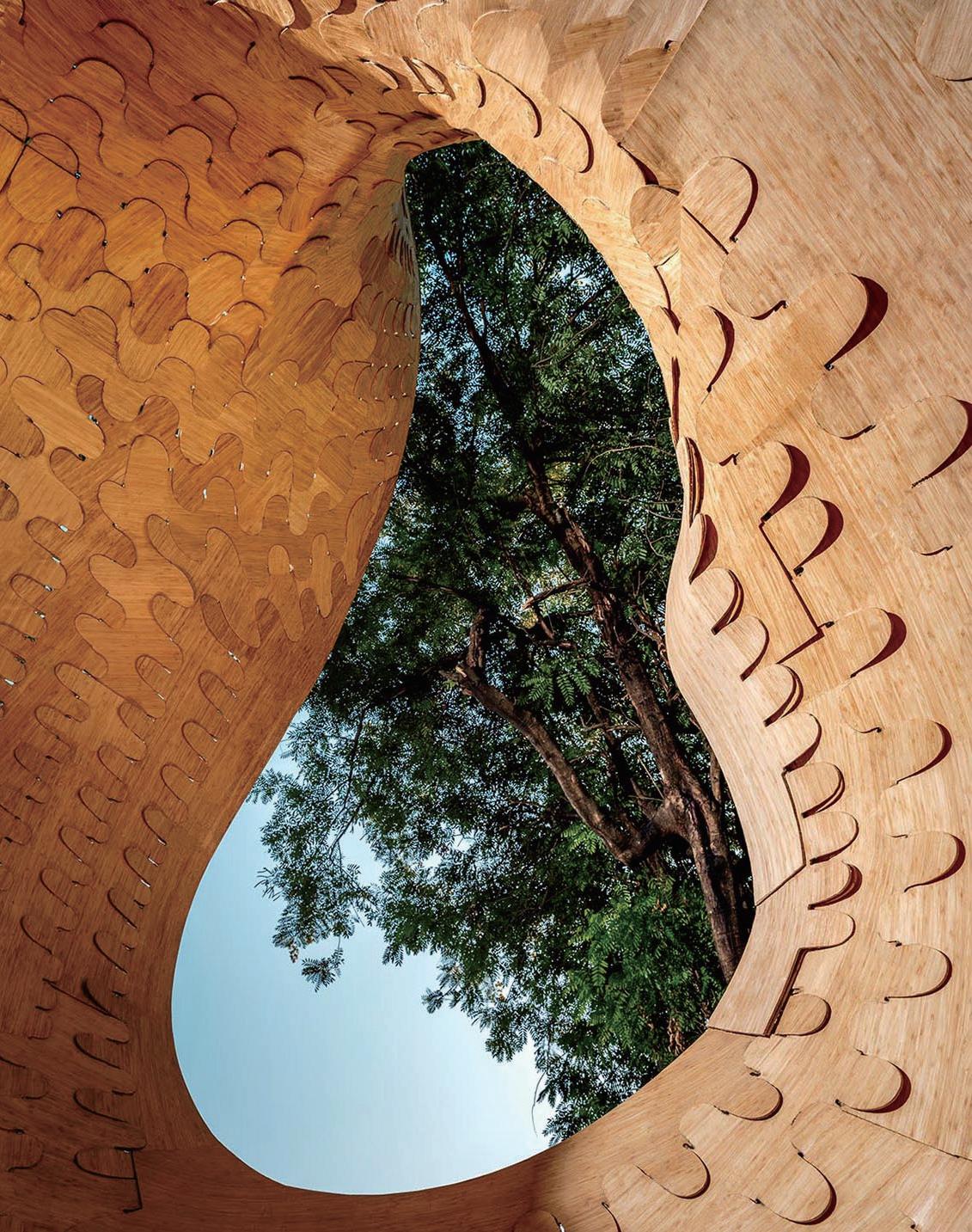

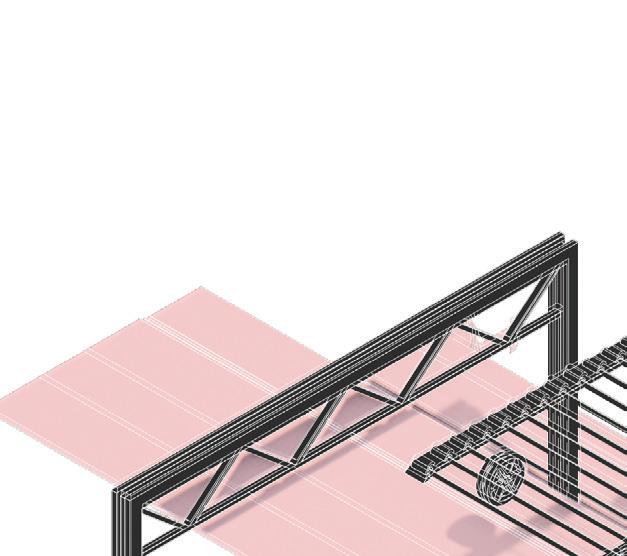

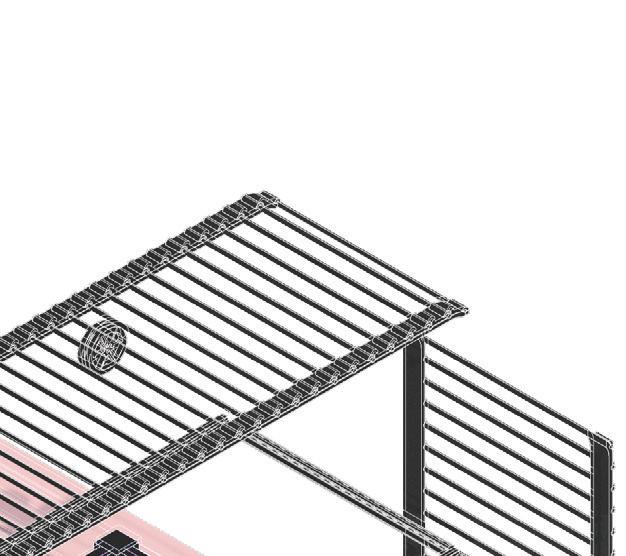

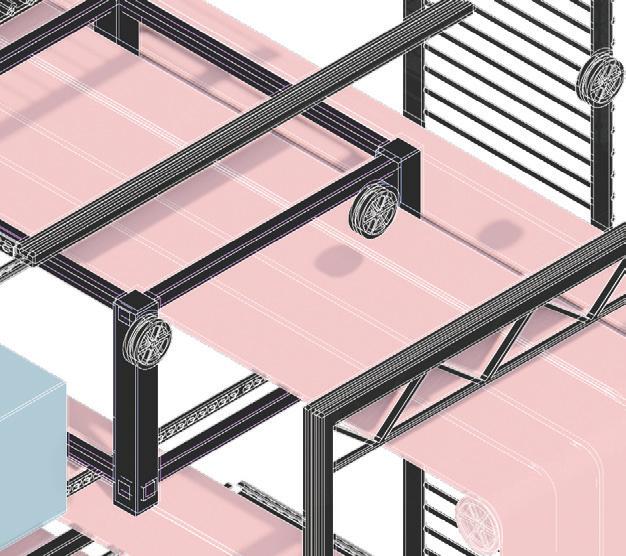

Professional working in ROSOcoop, 2022

This design work shows a bamboo composite plate, which can be used in the construction and fabrication process of complex freeform surfaces. This material makes use of the properties of the mixed composite material composed of bamboo and glass dimensions to explore the structure system and modeling of curved surface thinning. At the same time, the computational design and digital fabrication tools are used to show that the bamboo design is different from the traditional appearance. This style is different from the truss structure of the traditional bamboo structure, which uses the raw material as the structural element. In the part of material research, through the investigation of relevant literature, this design work carried out the research on the bamboo composite materials of glued bamboo and glass materials, in order to improve the properties, ductility and bonding strength of the materials.

In the ROSOcoop project, my primary role was fabricating and assembling the bamboo composite plates. The main challenge was optimizing this novel material's performance by gluing multiple layers of different materials to achieve both high structural strength and flexibility. The process required patience and precision to complete the large plates.

During construction, I was responsible for planning the assembly sequence and assembling CNC-cut components using finger joints. The pavilion was built in approximately two weeks by a team of four to six people.

Architecture competition, 3rd Prize, 2022

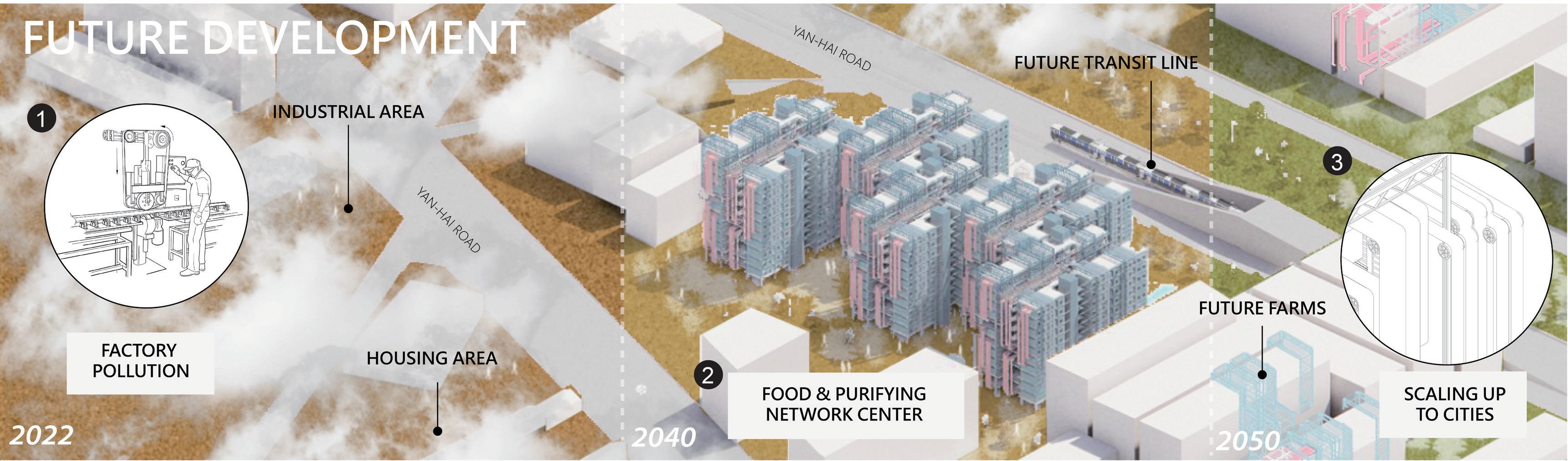

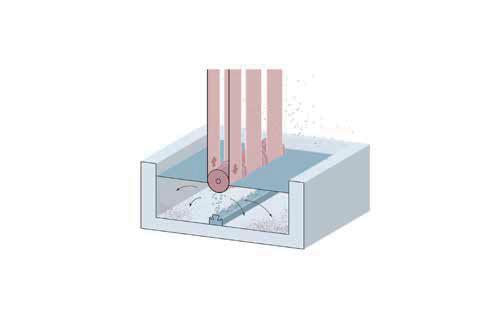

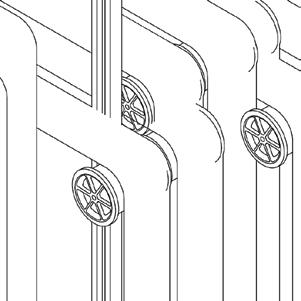

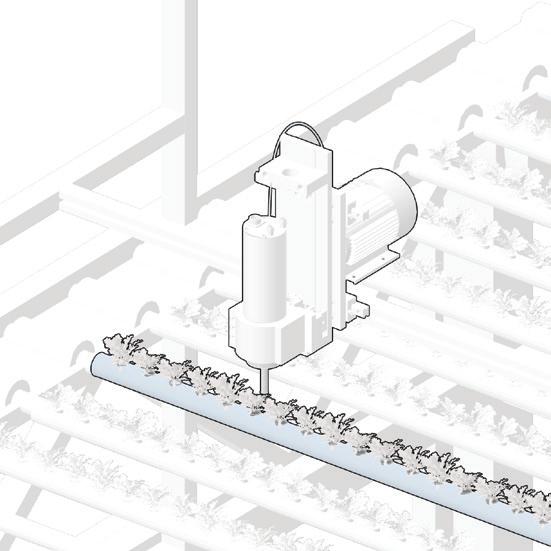

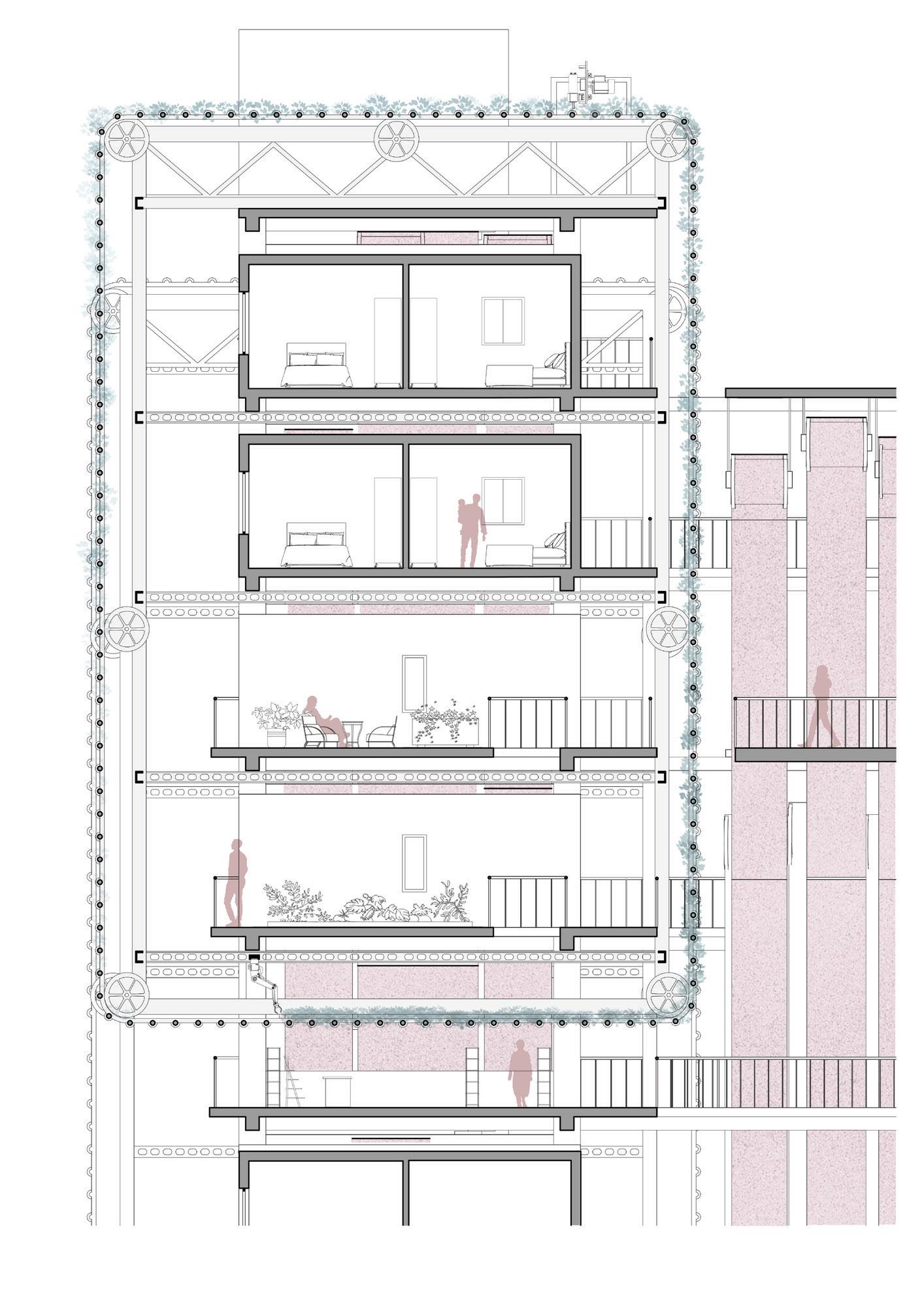

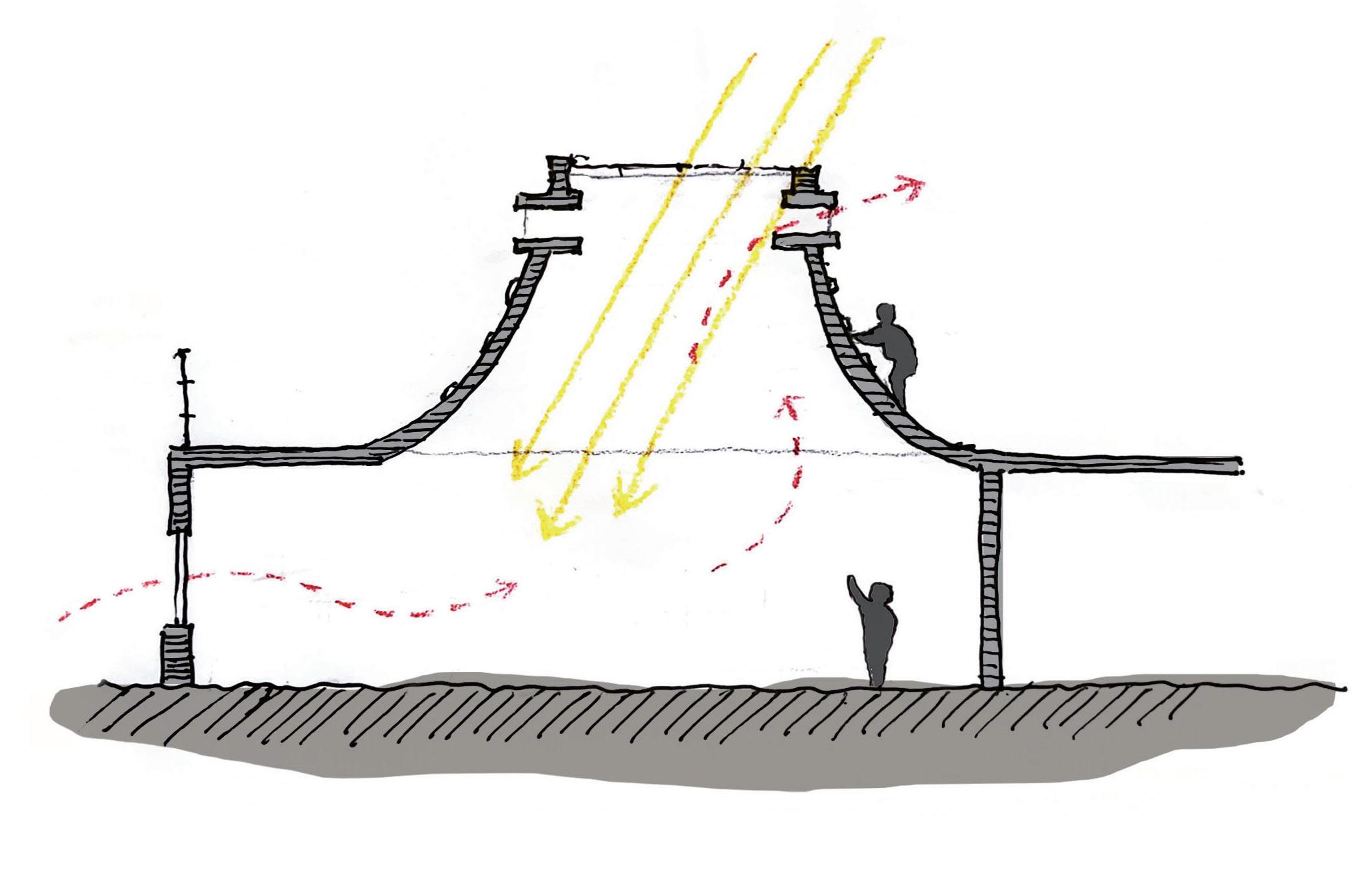

In Lin-Yuan District, Kaohsiung City, lying on the boundaries between the industrial factories and the gradually-replaced farm plots that will turn into housing complexes in the near ten-year development. For years, the Lin-Yuan residents have lived under the smog and pollutions caused by the neighboring industries as well as lack of urban green space, coupled with the loss of farm plots and future population bursts that come after the new transit line development, we see an urgency to create an intervention that will provide a healthier living condition for the people as well as to prevent future resource-scarcity crises. Our inspiration combines traditional keel waterwheels with rollers and conveyor belts. We aim to create simple, low-tech, fabric-clad machinery that wraps around the structure, functioning as both an urban air purifier and a vertical, rotational farming system. This system provides fresh produce for residents while enhancing environmental conditions.

As boundaries between industry and living, urban and nature, and growth and harvest blur, these layers create protective yet nourishing cycles. Our goal is to integrate natural systems that rejuvenate the ecosystem with minimal intervention, fostering healthier cities and happier communities for the future.

In creating our personal and public spaces, we reuse fabric and factory elements as part of the rejuvenation (physical, mental, social, wellbeing). By using local, available materials, we also wish to reduce the carbon footprint produced in the process.

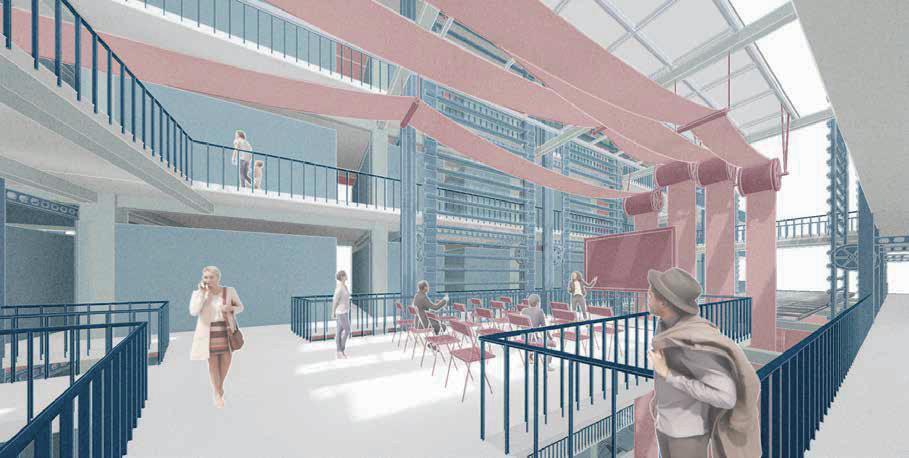

Through soft boundaries, we blur the division between community spaces, where we work, live and socialize. As more and more Lin-Yuan residents take up remote work, through our spaces we provide places to work and study under colorful fabrics that also provide comfortable thermal microclimate conditions.

The fabric can filter the air by absorbing toxic molecules, cleaning the particles and generating clean air. Through soft boundaries and rotational cycles, we blur the division between community spaces, where we work, live and socialize. As more and more LinYuan residents take up remote work, through our spaces we provide places to work and study under colorful fabrics that also provide

comfortable thermal microclimate conditions. Because of the versatile structures, it can be used in our bustling, greyish cities where the majority of the worlds population reside, at different scales (from balconies to doubleheight terraces) through our light additions, creating a network of purifiers and food sources.

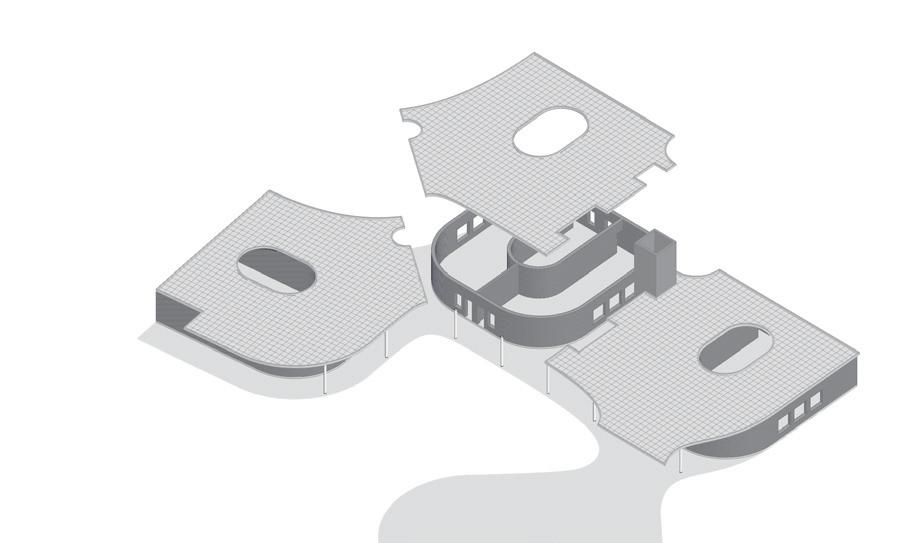

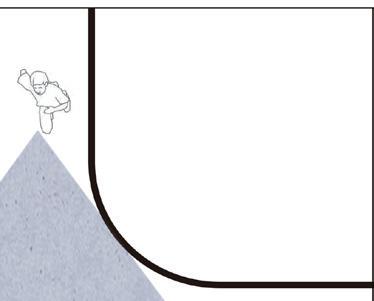

The kindergarten design aims at creating a space that makes kids feel novel, joyful, and comfortable. The free-form plan presents unique space experiences, like an amusement park for kids to run and play. With a corridor linking the volumes, some outdoor corners become intermediate spaces, helping kids transform their emotions. These corners (the garden or the sandpit) allow kids to penetrate and have fun in outdoor spaces.

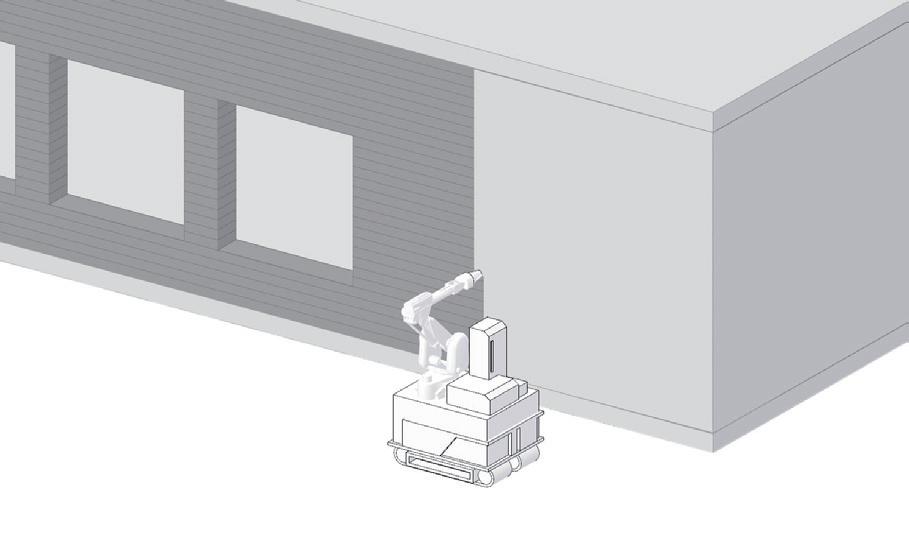

The design also discusses about the value of advanced construction automation technologies, such as 3D printing and automatic finishing , proposing the possible architectural construction processes of the next generation.

Concept: Intergrating the Form and the Function of the Roof as a Playground

To consider that kids require sufficient space for activities, and curved wall is less dangerous than perpendicular walls due to broader visibility. Hence, develop the prototype with curved walls, deriving the units of classroom and office by combining two prototypes. On the roof of the classrooms, the 3D printing concrete walls transforms into the hills called 'Volcanoes', offering kids playing function, in addition, the hills themselves are ventilation towers as well, and let the skylight go down into the toilet. It's a special experience for kids while they are using the toilet.