3 minute read

FLOORS, WALLS & CEILINGS

The building envelope makes a significant contribution to overall energy usage – therefore, tighter U-values in walls, floors and roofs is absolutely key. It’s why getting the design right from the outset is far less costly than retrofitting later. Here, Ben Cheetham, Specification Manager at Keystone Lintels, looks at the benefits of a one-piece thermally-efficient lintel including low thermal conductivity performance, buildability, improved SAP calculations and why they are up to five times more thermally efficient than standard lintels.

Advertisement

KEYSTONE LINTELS

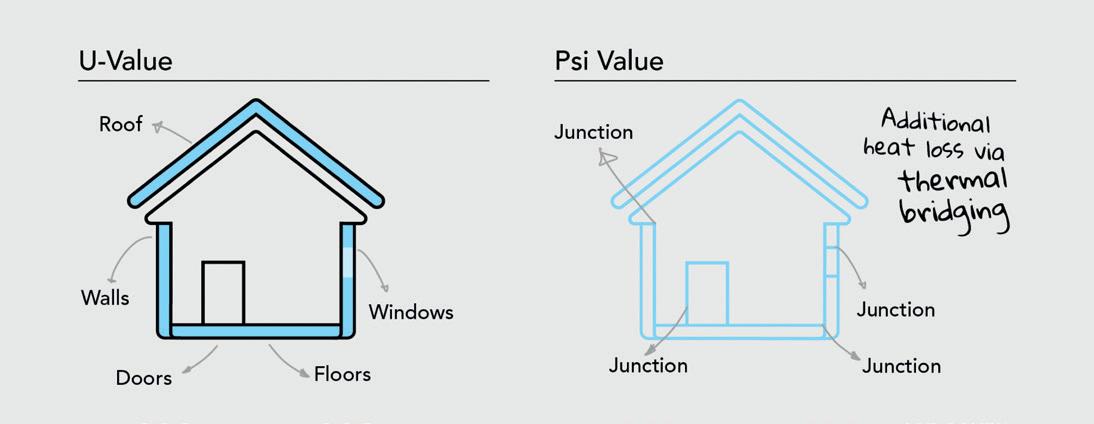

Ensuring our homes are climateready has never been more important and is why limiting heat loss in buildings through improved fabric measures is, without doubt, one of the most effective and sustainable ways to reduce energy consumption. This fabric-first approach concentrates efforts on improving fabric U-values, reducing thermal bridging and improving airtightness. When compared to other options such as installing more costly renewable technologies, which have a limited lifespan and risk a significant increase in CO2 emissions from a development once they reach end of life, fabric-first is the secret to improving thermally-efficient building envelopes.

Thermal efficiency

Today, almost all lintels in domesticscale dwellings are made from steel for a number of reasons, such as providing more design flexibility and easier onsite handling than other alternatives. However, steel has a high conductivity value, and with lintels typically spanning across long lengths when you add them all up in a building, it’s no surprise they are considered one of the most significant contributors to heat loss via thermal bridging. Therefore, considering the thermal performance of lintels at the design and specification stage is more important than ever. A lintel design which incorporates a thermal break will outperform and be much more thermally efficient than a standard lintel. In fact, it can generate up to 34% reduction in nonrepeating thermal bridging.

Improved SAP calculations

The Standard Assessment Procedure (SAP) is adopted by Government as the UK’s methodology for calculating the energy performance of buildings and, ultimately, demonstrates compliance with Part L Building Regulations. By improving the lintel Psi value alone, this can, in turn, significantly improve the fabric efficiency rate within SAP and possibly negate the need for other more expensive technologies or materials to be included in order to comply.

Low thermal conductivity

A one-piece, thermally-efficient lintel has an impressively low thermal conductivity, with a typical Psi value of 0.03 to 0.06 W/m.K, making it the ideal low-cost and sustainable solution for specifiers aiming to achieve Building Regulations with the fabricfirst approach. Appendix R of SAP 2012 details the specification for a notional dwelling of identical proportions and dimension which provides the target for the CO2 and the Fabric Energy Efficiency Standard (FEES). If a dwelling is built conforming to Appendix R values, it will achieve the CO2 and Fabric Energy Efficiency targets to comply with Part L. Appendix R requires a lintel Psi value of 0.05 W/m.K, which a one-piece lintel such as the Keystone Hi-therm+ lintel is able to achieve. In short, it is five times more efficient than a traditional standard steel lintel.

Buildability

Unlike a two-part solution, which can add costs and double installation time, the simplicity of a one-piece, structurally-superior top hat design assists stability between the internal and external leaves and throughout the building process. Separate lintels will also require propping during installation, which is an additional cost and process. Installing a one-piece lintel will, therefore, save time on installation and reduce the overall cost of the build.

Cost-effective

Offering significant savings compared to other popular alternatives, a one-piece, thermally-efficient lintel is a costeffective solution to lowering carbon emissions with SAP. For example, in a comparative case study for a house type, using a one-piece lintel would incur less than 20% of the cost of increasing the cavity width by 50mm for the same saving in CO2. These CO2 savings are important within SAP because they give flexibility for compliance in situations where other built details are not meeting the standards in Appendix R.

Achieving a reduction in CO2 emissions is not the only consideration when designing thermally-efficient housing. Improvements in thermal comfort can have a positive impact on the wellbeing of occupants, greatly increasing their health and productivity.

The benefits are increasingly widely realised, and ongoing research continues to reinforce the significant positive impact this approach can have – economically, environmentally and socially.

www.keystonelintels.com