This Issue (Volume

4 / Issue 2)

• CIM MER Society Member’s Corner p. 2-3

- Message from Our New Chairman

- MER Executive Committee Major Responsibilities

• Calendar of CIM MER Upcoming Events p. 4

• CIM MER 2023 Award Winners-Executive Members p. 5

• MER Executive Members Attending AGM p. 6

• MER Executive Members Chairing Technical Sessions p. 7

• Well-deserved dinner! p. 8

• Hoist and Haul 2023 Technical Program & Sessions p. 9–12

• CIM MEMO 2023 Technical Program p. 13

• Wireless Hoisting? p. 14–17

• CIM Journal Paper Submissions p. 18

• CIM Journal Abstracts – Hoisting Related p. 19

• CIM MER Society Awards – Brief Description p. 20

• CIM MER Society List of Scholarships p. 21

• CIM MER Executive 2023–2024 & Newsletter Committee p. 22

• Some CIM MER Society Supporters & Patrons p. 22

MER Today

MER Today is our digital publication covering CIM MER Society news and improvements in Maintenance, Engineering and Reliability in mining.

Please contact the Newsletter Editor to contribute an article or a story.

CIM/ICM StrategicPlan

2021–2023 Quotes:

Vision – Advancing mineral industry knowledge

Purpose – Collaborating towards a sustainable future

1 | MER Today– Summer 2023 MERToday–Summer2023

CIM MER Executive Committee Member’s Corner

Amessage to CIM MER Society members from

Martin Provencher

Global Industry Principal, Mining, Metals & Materials

Martin Provencher

Global Industry Principal, Mining, Metals & Materials

our new Chairman

Dear MERS members,

It is with pleasure and gratitude that I am taking the Chair position for the MERS and I will be honored to follow-up on the excellent work done by my predecessors. I will be happy to work with the Executive committee to ensure a smooth transition as well as meeting with all MERS members during events.

Maintenance has always been a major challenge for our industry. 15 years ago, as a Production Director, I had the opportunity to make a very difficult decision with the cancellation of a major shutdown at the end of a month because of a lack of tonnage. After putting in place safety rules, making sure replacement parts were available on-site and maintenance people were working 24/7 for three weeks in a row, there has been no failure. I then realized that our preventive maintenance plan, based on original equipment manufacturer (OEM) recommendations, was not optimal. Since my background was in technology, I started challenging OEMs and looking at ways to implement predictive maintenance strategies. I also asked OEM vendors to provide “intelligent” assets like bearings, mobile equipment, etc., which would advise of a potential failure on the asset before it occurred This would help improve safety and reliability, remove the need to plan for unnecessary parts replacement and help reduce operating costs. Five years ago, when I joined OSIsoft (now part of AVEVA), I started working with OEM vendors such as Caterpillar, SKF Bearings, and Metso:Outotec to see how they could help their customers move beyond traditional maintenance approaches by helping them leverage the operational data coming out of those assets. Some vendors have started providing a digital representation of their assets that would include known conditions for Condition-Based Maintenance, instead of providing OEM maintenance manuals with preventive maintenance approaches. Some mining companies have also started asking their vendors for a digital representation of their assets with those conditions included when buying a new physical asset. We are moving in the right direction!

Today, most OEM vendors have embarked in that digital journey and are even leveraging advanced analytics to help improve asset reliability. Mining companies are also leveraging more and more of their assets operational data to implement Condition-Based Maintenance strategies, and some are even moving further with Predictive and Prescriptive Maintenance strategies based on that data, using advanced analytics, machine learning, and artificial intelligence.

I look forward to work with our MER Society and will continue moving forward for our industry to leverage more and more digital technologies to help us improve further on our maintenance practices! Even engineering activities are now being combined with our digital assets to enable a true operational Digital Twin that can be used for training, remote troubleshooting, and much more! This is just the beginning of a new era of maintenance practices and I am happy to be part of it with all of you!

2 | MER Today– Summer 2023

MER Executive Committee

Major Responsibilities

Organize the MEMO (Maintenance/ Engineering – Mine Operators) Conferences in conjunction with other societies, the hosting CIM Branch, and CIM National

Promote, chair, and solicit papers for Technical Sessions at the CIM Conference & Exhibition

Administer awards and scholarship programs

Provide peer review of technical papers for publication

3 | MER Today– Summer 2023

CalendarofCIMMERUpcomingEvents

International Conference on Hoisting and Haulage

Hoist and Haul

August 13–16, 2023, Montreal, QC

CIM MEMO 2023

Sep 17

20,2023,Saskatoon,SK

4 | MER Today– Summer 2023

–

Congratulations to the following CIM / MER Executive Members:

McParlandMemorialAward For Excellence in Maintenance, Engineering and Reliability in the minerals industry

CIMDistinguishedLecturer For accomplishments in scientific, technical, management, or educational activities related to the minerals industry

5 | MER Today– Summer 2023

MartinProvencher

Martin Provencher receiving McParland Memorial Award on May 1, 2023 at CIM Convention in Montreal

MustafaKumral

Mustafa Kumral receiving CIM Distinguished Lecturer Award on May 1, 2023 at CIM Convention in Montreal

MER Executive Members

attendingAGM Meeting at the CIM 2023 Montreal

Convention onApril 30, 2023

6 | MER Today– Summer 2023

From right to left in front row: RichardMcIvor,JeanVavrek,DominiquePrivé,MartinProvencher,AgusSasmito,Guests&Members

MER Executive Members

Chairing Technical Sessions at CIM AGM 2023 Montreal Convention

Technical Session: Hoist and Haul (Mine Operations)

Tue, May 2, 2023, 3:30 – 4:45 PM

Session Chair: Richard McIvor, President, McIvor Engineering

Presentations:

3:30 – 3:55 PM

Strategies to Reduce Energy Costs in Mine Hoisting Through Application of Drive Technologies

Andy Stewart, Principal Electrical Engineer - Mining, Hepburn Engineering Inc.

3:55 – 4:20 PM

Review of Industry Best Practices for Shaft Rope Maintenance on Conventional Drum Hoists and Multi-Rope Friction Winders

Patrick Smith and Andrew Axiuk, Haggie North America Inc.

4:20 – 4:45 PM

Optimizing Loading and Hauling Cycle Times

Satish Penmetsa, CEO, GroundHog

Other Sessions Chaired by MER Executive Members

Session Chair: Richard McIvor, President, McIvor Engineering

Automation and Control in Mining (Mining in the 21st Century)

Session Chair:Agus Sasmito, Professor, McGill University

Future of Materials Handling (Mining in the 21st Century)

Session Chair: Mustafa Kumral,Associate Professor, McGill University

Smart Maintenance (Mining in the 21st Century)

7 | MER Today– Summer 2023

Well-deserved dinner of MER Executive members & spouses at Bonaparte Restaurant in Montreal following AGM Meeting and Convention Opening Ceremony on April 30, 2023

Well-deserved dinner of MER Executive members & Spouses at Bonaparte Restaurant in Montreal following Convention on April 30, 2023

8 | MER Today– Summer 2023

International Conference on Hoisting and Haulage

August 13–16, 2023, Montreal, QC

DoubleTree by Hilton Montreal

1255 Jeanne-Mance St, Montreal, Quebec H5B 1E5

CONFERENCE CHAIRPERSONS

Richard McIvor, Conference Chair

Jean Vavrek, Sponsorship Chair

CIM Contact

Chantal Murphy, Convention Planner

Hoist and Haul is the ninth in a series of International Conferences on Mine Hoisting and Haulage and is generally held every five years. This edition will host technical sessions focusing on the latest state-of-the-art developments and technologies in the shaft hoisting and transportation component of personnel and material. Throughout the conference, you will have the opportunity learn about recent developments in technology and methods related to mine hoisting equipment and to network with international mining experts and colleagues in this dynamic field. (Source: CIM Website)

Technical Program

Monday Aug 14, 2023

Maximizing Mine Performance with Innovative Hoist Systems

Redefining Haulage – Alternatives to Conventional Hoisting

New Developments in Hoist System Risk Management

Tuesday Aug 15, 2023

Improving Safety and Efficiency – Creative Conveyance Concepts

Wire Ropes – The Weakest Link?

Pushing the Limits – Deep Hoisting

Beyond Conventional Hoisting – Special Topics

Wednesday Aug 16, 2023

It’s Just a Hole in the Ground – Or is it?

Taking Control – 21st Century Solutions

Taking Care of Business – Hoist System Maintenance

9 | MER Today– Summer 2023

Hoist and Haul 2023 Monday Technical Sessions

Hoist and Haul 2023 Technical Program / Sessions – Monday, August 14

08:30-10:00

10:00-10:30

10:30-12:00

10:30

11:00

11:30

Opening Remarks and Keynote: Roy Slack, Cementation Americas

The San Jose Mine Rescue of 2010 – Reflections & Lessons Learned

Coffee Break

Maximizing Mine Performance with Innovative Hoist Systems

Platreef Mine Shaft and Ore-Handling System

Olympic Dam Clark Shaft Technology Upgrade - Case Study

Improvement in the Design of Mechanical Drive System and Challenges Faced in Its Installation in Coal Mine Friction Hoist

12:00-13:30 Lunch

13:30-15:00

13:30

14:00

14:30

15:00-15:30

15:30-17:00

15:30

16:00

16:30

17:00-18:00

Redefining Haulage – Alternatives to Conventional Hoisting

Vertical Conveyors in Deep Shaft Mining

Techno-Economic Factors in the Selection of an Underground Mine Ore Haulage System – An Australian Perspective

Future Proofing Conveyor Haulage Systems

Coffee Break

New Developments in Hoist System Risk Management

Practical Implementation of Risk Management Programs for Shafts and Hoist Plants

Next Level of SIL (Safety Integrity Level) by a New Integral Approach for a Complete Hosting System

An Improved Method for Mine Hoist Risk Assessments Using a Quantitative Approach

Cocktail Reception

10 | MER Today– Summer 2023

Hoist and Haul 2023 Tuesday Technical Sessions

Hoist and Haul 2023 Technical Program / Sessions – Tuesday, August 15

8:30-10:00

08:30

Improving Safety and Efficiency – Creative Conveyance Concepts

Cage Guardian, Safety Brake for Steel Guides

09:00 Optimisation of Winder Skip Wear Liners Using the Discrete Element Method

09:30

10:00-10:30

10:30-12:00

10:30

DEM Modeling of Skip Loading & Unloading Performance Provides the Confidence to Increase Hoisting Capacity in Existing Mine Shafts

Coffee Break

Wire Ropes – The Weakest Link?

Findings from the Goldex Shaft #1 Field Trial of Fully Synthetic Rope for Mine Hoisting

11:00 Koepe friction hoist rope replacement method without a friction winch

11:30 New Rope Handling Equipment, Stand-Alone Operation and System Integration at Nutrien Allan

12:00-13:30 Lunch

13:30-15:00 Pushing the Limits – Deep Hoisting

13:30 The Impact of Using Hybrid Ropes on a Koepe Hoist

14:00

14:30

15:00-15:30

Developing Performance Requirements for BMR Hoist Compensating Sheaves

Shaft Hoisting Systems for a New Mine in Russia, Including the World’s Deepest Koepe Hoist, SKS1 Shaft Norlisk/Siberia

Coffee Break

15:30-17:00 Beyond Conventional Hoisting – Special Topics

15:30

16:00

16:30

18:30

Heavy Lift Block Hoists

Emergency Egress Hoist Plant Selection

Development of AS4730 Series of Standards: Mining – Winding Equipment

Reception & Banquet

11 | MER Today– Summer 2023

Hoist and Haul 2023 Wednesday Technical Sessions

Hoist and Haul 2023 Technical Program / Sessions – Wednesday, August 16

8:30-10:00 It's Just a Hole in the Ground – Or is it?

08:30

Headframe Design Selection: Steel vs. Concrete Headframe, Version 2.0

09:00 Shaft Guide Design: Fixed Guides vs. Rope Guides

09:30

Machine Learning A Dynamic Model for Strain-Energy Absorption Systems

10:00-10:30 Coffee Break

10:30-12:30 Taking Control – 21st Century Solutions

10:30

11:00

11:30

12:00

Embedded Control System Simulation for Mine Hoists

CERBERUS SIL Shaft Radio System – Shaft Communication Compliant to Australian NSW Mining Regulation and SIL Rated

Use of Digital Tools for Mine Hoist System Monitoring

Single Drum Winders: Design Considerations for Improved Brake Control

12:30-13:30 Lunch

13:30-15:30

13:30

14:00

14:30

Taking Care of Business – Hoist System Maintenance

Hoisting System Maintenance - A Risk Based Approach for Establishing Safe & Efficient Strategies

Annual Inspections of Mine Hoists

Hoist Maintenance Safeguard System Implementation at Vale’s Sudbury Operations

15:00 Hoist Life, Fatigue Life and Insurability

15:30-16:00 Coffee Break

16:00-16:30 Closing Session

16:00 Next H&H Presentations + Voting

16:30 Closing Reception

12 | MER Today– Summer 2023

CIM MEMO 2023

Sep 17

CONFERENCE CHAIRPERSONS

Paul Labbé, Co-Chair

Brian Fagan, Co-Chair

CIM Contacts

Marie Tota, Conference Planner

1-514-939-2710 ext. 1330

Nadia Bakka, Sales Manager, Exhibition & Sponsorship

1-514-939-2710 ext. 1360

ConferenceTopics

The theme of MEMO 2023, “The Next Level,” was set to reflect the significant changes to the industry in the past few years. We are excited to explore the growth of mining since experiencing a disruptive pandemic and the move to a minerals-driven industry based on electrification and decarbonization. MEMO 2023 will be a forum to bring together maintenance engineers and mine operators and their allies to learn from practical experience. Over 300 delegates attended MEMO 2017 in Saskatoon for the opportunities in networking, knowledge sharing, and personal development. We look forward to you joining us.

(Quote from CIM MEMO 2023 website)

Mining

Maintenance and Reliability

Environment

Rock Mechanics

Innovation

Ventilation

Health and Safety

Geoscience Communities

Processing HR Recruitment

13 | MER Today– Summer 2023

–20,2023,Saskatoon,SK

Wirelesshoisting?

CanmetMINING weighs the advantages of synthetic hoist ropes

By Carolyn Gruske | January 09, 2020

Ryan Bergen, Editor-in-chief CIM Magazine

By Carolyn Gruske | January 09, 2020

Ryan Bergen, Editor-in-chief CIM Magazine

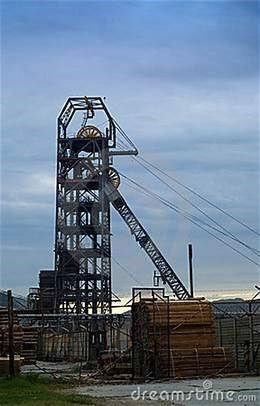

Synthetic rope is being tested in the Goldex Shaft #1 by CanmetMINING. Courtesy of CanmetMINING

Martin Côté sees a future where ropes made of synthetic fibres will be used to lower miners down shafts or lift payloads full of ore up from deep in the ground.

“The technology is ready to go,” said Côté.

Côté is manager, mining extraction technologies at Canmet-MINING Natural Resources Canada, and one of the projects he has been supervising is the testing of Teijin Aramid B.V.-based Twaron paraaramid fibre rope.

Compared to traditional steel rope, Côté says, synthetic rope is one-fifth the weight, requires less maintenance (there is no need to grease synthetic rope) and is easier to handle, remove and install.

Because of its lightweight nature, Côté said it allows mining companies options they never had, particularly as mines go deeper.

“When a steel rope or a shaft reaches a certain depth, the weight of the rope is so much that you wouldn’t be able to muck or to put ore in the conveyance. With the fibre rope you can either go deeper or increase the payload so you would be able to increase your production rate ”

Although synthetic rope is not new, it is new to the mining industry. According to Côté, manufacturers have been producing similar products for marine and petroleum applications, using the rope to moor drilling platforms. After hearing about ropes made of Kevlar and Kevlar-like materials at a conference, CanmetMINING put out a request for a product that would work in mines, and in return, promised the manufacturers that CanmetMINING would assist in the testing and monitoring processes. Atlantabased Teijin Aramid, the company that makes the fibres used in the rope’s construction and Whitehill Manufacturing Corp., the company that turns the fibres into finished rope, responded and are participating in the testing process.

14 | MER Today– Summer 2023

Originally, CanmetMINING conducted lab tests on the rope (a six-strand braid that provides all of the rope strength, covered by an outer sleeve) and determined that after about 40,000 cycles, the rope began to show wear on the outer sleeve and the rope strength rating was 87%. In comparison, the same diameter steel rope gained observable breaks after 17,000 wear cycles.

Underground trial

The results of that test gave Côté and his team the confidence to try a field test. In 2016, the rope was installed in the Goldex Shaft #1 in the Val-d’Or area by contractor Procon Val-d’Or under the supervision of project engineer Sébastien Ménard. Procon prepared and cleaned the hoist, worked on the head frame, modified the deck, installed and tensioned the rope on the hoist, and then performed all of the required tests.

The testing process lasted for 10 months and 10,000 cycles of loading, hauling, and unloading full loads. No people were lifted during testing. The most noticeable effect was that the 3,000-ft rope gained a permanent stretch of 4 ft, roughly twice the stretch of steel cable when loaded with 4,000 kg.

“We saw a lot of spring effect in the rope during the testing. When we were at the lower station, for example, and we stopped the hoist, the cage went up and down three to four feet. It is maybe something we can live with or maybe it is something that can get better, by reducing the spring effect in the rope,” said Ménard.

In addition, the weakest part of the rope the crossover section where the rope rubs against the drum as it is being coiled over onto the next layer that had been subjected to the deliberate and severe wear and tear on the drum and that had received no preventive maintenance began to show some damage and weakening, much in the same way steel rope would under similar conditions.

Making the rope less susceptible to wear and abrading can be addressed with design tweaks, said Amy Jenkins, industrialsaleslead forthe Americas at Teijin Aramid.

“There are certain things you would do if you want to get a longer bending life or if you need to deal with the crossover points. You might pick a different grade of fibre that has a little bit better bending life. Or you might put different finishes on the fibre itself. Or you might change the rope design so that it does better in those applications ”

There were a few other issues that Ménard and his team noticed during the testing.

“It is harder to put tension on this rope because when tensioning it on the drum hoist it slipped over our tensioner. Many mines use dead weight to tension the rope, so this will maybe not be an issue for these kinds of mines,” he explained. Additionally, he said that operators will require training to learn how to securely fasten the rope.

15 | MER Today– Summer 2023

He also reported that “after some weeks of testing, we saw some flattening of the rope … but for the operator of the hoist, I believe it is almost the same as steel wire rope.”

Overall, however, Ménard was impressed by the rope.

“We really appreciated the weight of the rope. It is a pleasure to work with this kind of rope because it is clean and without any grease,” he said, adding that he can see a place for the rope in Procon’s future operations.

“We are a contractor, but we are also a mine operator. In our mine, we have a production issue. We can’t load at the full capacity of the hoist because of the weight of the rope. So, I believe the gain we can get with this kind of rope is amazing.”

He did caution, though, that any company that wants to deploy a synthetic rope will have to put in an effort to educate its workforce about the rope’s safety and properties.

“All of the people we worked with are thinking about their safety with this rope. All the miners are afraid to go in the cage suspended by this rope because I believe they don’t really know the material, the Kevlar. They are afraid [about what happens] if a piece of rock strikes the rope.”

Côté echoed Ménard’s thoughts about the difficulty of introducing the rope to miners.

“The biggest challenge will be how we talk to the

industry because there is a very strong feeling that you are exchanging a strong steel rope with a weak synthetic rope but it’s not weak. So, we really have to show results and address how we talk to the industry, how we present the information [about the rope’s properties].”

Explaining the rope’s capacity and what that means for the bottom line will be one of the messages the rope’s supporters will deliver, said Jenkins.

“We’ve done some studies and found that you can almost double yourpayload if youuse a lighterrope if you use this rope rather than steel rope so the impact on production ismassive,” she said, adding that mines using this rope could potentially have the ability to go deeper, without having to add a secondary, lower-level hoist system.

Part of the process of reaching out to the industry and extolling the benefits of the rope will be teaching people new monitoring techniques. Whereas with steel rope, visual inspections are written into the regulations, Côté said that visually inspecting a synthetic rope doesn’t really reveal any useful information, given that damage to the outer sleeve does not necessarily indicate damage to the internal fibres. To that end, Côté said that CanmetMINING tested three non-destructive and continuous monitoring systems to ensure rope integrity

The one that worked the best was a magnetic system that required rope strands be treated with a nickelbased magnetized metal application. Monitoring the magnetic flux allowed the CanmetMINING team to

16 | MER Today– Summer 2023

understand when the rope’s integrity was at issue.

Côté also explained that more data will have to be collected and gathered into a safety database to use as a reference about when the rope needs to be replaced and recycled. Regulations will also have to be rewritten to allow the use of this kind of rope. Côté said that there are plans to meet with the subcommittee on hoist machine security to discuss how to regulate the rope, but that will only happen after CanmetMINING and all of the partners on the rope study are able to “address the effect of the stretch of the rope on infrastructure adaptation,” and that is likely to happen during the next phase of testing, which is currently being planned.

Despite all of the work that needs to be done to ensure that everybody is comfortable with the safety and viability of this kind of rope, Côté is adamant there is a place for it in the industry. Even though he said the synthetic rope is roughly three times the price of steel cable at this point in time, the energy savings gained by using a smaller hoist to haul up the lighter rope, the increased depths that are able to be reached with this rope, the higher payload the rope is able to carry, and the longer service life all mean overall savings for mining companies.

And when it comes to the safety of the rope, Côté has no concerns. During a presentation, he told attendees of the Future of Deep Mining conference that he would trust his life to a synthetic rope.

“Would I travel in a cage attached to a synthetic rope? Yes.”

17 | MER Today– Summer 2023

CIM Journal

CIM Journal is a quarterlydigital publication for peerreviewed technical papers available to all CIM National Members for free and to non-members for free (if open access) or for a fee. Papers cover all facets of the mining and minerals industry, including geology, mining, processing, metallurgy, materials, maintenance, environmental protection and reclamation, social responsibility, mineral economics, project management, health and safety, risk management, redevelopment, operations, and regulatory practices and issues. (Article updated by Janice Burke)

We also publish periodic special-themed issues. Volume 14, Issue 1, 2023 is a Special Issue, Innovations in Underground Ventilation, containing invited papers from the North American Mine Ventilation Symposium (Editors A. P. Sasmito, McGill University and P. Tukkaraja, South Dakota Mines).

As of 2020, CIM Journal is being published by Taylor & Francis. The editorial process remains the same. CIM National Members continue to have free access to the journal, but new papers are now hosted on the CIM Journal site at Taylor & Francis. Papers published prior to 2020 can be found on the CIM Technical Paper Library or on OneMine.

Paper Submissions

CIM Journal welcomes original papers in English or French. Submissions are assigned to a CIM Technical Society for double-blind peer review. Our authors and audience are international in scope. Topics covered in CIM Journal include geology, mining, processing, metallurgy, materials, maintenance, environmental protection and reclamation, social responsibility, mineral economics, project management, health and safety, risk management, research and development, operations, and regulatory practices and issues.

Read the instructions for authors then create an account at Taylor & Francis.

18 | MER Today– Summer 2023

Abstracts from Hoisting related articles peer reviewed by MER & Published by

MER Society of CIM Peer-Review Team

Agus P. Sasmito, PhD, Peer-Review Chair, MER; Editor, CIM Journal (agus.sasmito@mcgill.ca)

Janice M. Burke, MSc, Editorial Coordinator, CIM Journal

MAINTENANCE,ENGINEERING& RELIABILITY

Keynote Session: Mine Hoist Plant Design Fundamentals

Convention - SDC 2019

Year - 2019

Author: Richard McIvor, McIvor Engineering and Maintenance Services Inc.

ABSTRACT

It is important to ensure that the basic mine hoist plant design fundamentals are incorporated into any new mine hoist plant project before detailed design engineering is commenced. Some of the basic design fundamentals to be considered are: hoist rope fleet and flight angles for good hoist rope coiling, hoist rope harmonic frequency study to ensure that the hoist rope does not run at full speed at a rope resonance frequency, head frame and shaft clearance diagrams to establish the optimum positions for the loading and dumping of the shaft conveyances, access in the head frame and shaft collar for hoist rope and shaft conveyance installation and removal. Failure to consider the hoist plant fundamentals before detailed engineering commences will result in extra costs for hoist plant redesign or a significant increase in operating and maintenance costs for the mine due to increased hoist plant downtime to perform tasks and a lower mine operating efficiency.

An Improved Method for Mine Hoist Risk Assessments Using a Quantitative Approach

Convention - CIMBC22 Year – 2022

Author: Francis Lacasse; Alonso Morey

ABSTRACT

Mine hoists are used for transporting people, material and ore between the mine underground levels and the surface in various conditions and environments. Over the years, they have evolved from fully manually operated machines to fully automated machines using complex control systems and automation technologies striving for seamless operation and increased safety. As the conditions, requirements and regulations can vary significantly between regions, selecting and designing mine hoist control...

19 | MER Today– Summer 2023

an article

Submit

CIM Journal

Journal Homepage

Latest articles

CIM MER Society AWARDS – Brief Description

McParland Memorial Award

For excellence in Maintenance, Engineering and Reliability

CIM Distinguished Service Medal

For meritorious service to the Institute or the mineral industry

CIM Distinguished Lecturers

For accomplishments in scientific, technical, management, or educational activities related to the minerals industry

CIM Fellowship

For outstanding continuous contributions to CIM and/or the mining, metallurgical, and petroleum industries

CIM MER Graduate Student Research Excellence Award

The aim of the award is to provide a platform for the dissemination of innovative thinking of benefit to the mining industry from the Society’s brightest new minds and to provide a means to allow such contributions to be recognized.

20 | MER Today– Summer 2023

CIM MER Society List of SCHOLARSHIPS

1. CENTENNIAL SCHOLARSHIP

2. KEN HILDEBRANT MEMORIAL SCHOLARSHIP

3. EDWARD MELVILLE (Ed) PATTON MEMORIAL SCHOLARSHIP

4. J. D. "PAT" PATTERSON MEMORIAL SCHOLARSHIP

5. MER MEMORIAL SCHOLARSHIP

For description of all the CIM MER Scholarships click HERE to access CIM MER Website.

J. D. "PAT" PATTERSON MEMORIAL SCHOLARSHIP

The CIM Maintenance, Engineering and Reliability Society J. D. “Pat” Patterson Memorial Scholarship was created in 1991 in memory of Mr. Pat Patterson, a past CIM MER Society chairman who was a well-known individual in the Canadian mining industry.

Type of Scholarship Post-secondary entrance, non-renewable Value of Scholarship $2500 payable in two equal portions in December and the following February of the academic year for which the award is made. In order to receive the second installment, the recipient must provide an official communication from their institution confirming successful completion of the fall semester.

Eligibility: This scholarship is open to any CIM National member (including student members) or the son, daughter, or spouse of a CIM National member, who is currently enrolled full time in a post-secondary educational institution to study the MER disciplines with the intent of pursuing a career in the mining industry. The MER disciplines constitute engineering or technologist level studies in Mechanical, Civil, Electrical, Electronics, Instrumentation, Chemical, Computer Sciences, Material Sciences, Manufacturing, and related disciplines.

Application Form

Note: CIM National Membership is open to students from a very broad range of degree disciplines, including those that extend well beyond science and engineering. Students and prospective students can join the CIM online at: http://store.cim.org/en/cim-national-memberships

21 | MER Today– Summer 2023

CIM MER Executive Committee 2023–2024

Chair, Martin Provencher

Immediate Past Chair, Dominique Privé

1st Vice Chair / Chair Elect, Lee Weitzel

2nd Vice Chair, Vacant Treasurer, RichardMcIvor

(mdjivre@gmail.com)

Copy Editor: Janice M. Burke, MSc (jmburke@cim.org)

Directors:

SOME CIM MER SOCIETY SUPPORTERS & PATRONS

22 | MER Today– Summer 2023

Martin Provencher

Global Industry Principal, Mining, Metals & Materials

Martin Provencher

Global Industry Principal, Mining, Metals & Materials