6 minute read

COMES TRUE A PREDICTION

Neil Sandhu, SICK UK product manager for imaging, measurement and ranging explores the brave new world of ‘SensorApps’

Nearly three years ago, SICK began signposting a future in which it will be commonplace to download a ready-made “App” to program and configure a programmable vision sensor, perfect for a specific application. It was a concept that some found difficult to envisage at first, especially coming from a traditional sensor hardware manufacturer.

Advertisement

Now that prediction is coming true and it’s all down to SICK’s ground-breaking AppSpace software ‘ecosystem’. While, it can, and will, be a model that could be applied to all kinds of smart sensors, SICK AppSpace offers the tantalising prospect of being a game-changer to demystify machine vision, and especially 3D vision, for the many and no longer just the few.

It might seem curious for a sensor company to be taking the lead in the field of software. Yet, according to SICK, once sensors become smart and programmable, investing in software development, and even marketing application ‘kits’ including all the necessary hardware, makes perfect sense.

Machine-builders and systems integrators are already beginning to reap the rewards of cheaper, quicker and easier integration using AppSpace. End-users, too, are benefiting from the plug and play benefits of a growing basket of ‘SensorApps’ rolled out by SICK’s own R&D teams. With SICK AppSpace, developers have the freedom to design, develop and deploy their own customised solutions, to perfect simple web-based graphical user interfaces for operators and to distribute their applications across multiple hardware platforms and locations.

Developers use the SICK AppStudio to create customerspecific applications, then the SICK AppManager to import Apps into the sensor and adapt it to the task in hand. The SICK AppPool cloud service makes it easy to install, manage and download sensor Apps to programmable SICK devices anywhere in the world.

Developers have access to industry-standard image processing libraries including HALCON. They can work with their preferred programming technologies including graphical flow Editor, Lua scripting tools as well as C++ or Java. There are many integrated support functions such as auto completion, so that programmable sensor app developments will insert themselves easily into existing development processes.

Helpful utilities such as emulators, debuggers, resource monitors, and an extensive range of documentation and demo apps also make the development process easy. All software components are combined by the PackageBuilder into a single package that safely defines access rights.

Previously developed ‘Apps’ can be adapted without having to start from scratch, then set-up and configure as required.

Meanwhile end-users can dispense with costly and time-consuming programming by downloading and adapting a ready-made SensorApp that already has most of the hard work done for them. As a result, set up time is dramatically reduced, rapid product changeovers are easily accommodated, and localised edge-based sensor solutions can be easily configured using Sensor Integration Machines.

ROBOT GUIDANCE

This is all being made possible by greater accessibility to ‘all-in-one’ intelligent vision sensors, such as SICK’s fully programmable TrispectorP1000 3D vision camera. One of the first Apps to be developed was the SICK Trispector P Beltpick, a complete vision-guided belt-picking solution for industrial and collaborative robots. It offers the improved z-axis control available through 3D vision, so products with complex profiles can be picked from variable heights without risk of damage.

More recently, SICK launched an innovative 3D SensorApp that has enabled rapid, damage-free guidance of automated and driver-assisted high-bay forklifts into pallet pockets, as well as the precise and efficient pick-up of dollies by automated guided vehicles (AGVs).

The SICK Pallet Pocket and SICK Dolly Positioning SensorApps run on SICK’s Visionary T-AP 3D time-offlight snapshot camera. The new SensorApps work by positioning the camera in front of the pocket or dolly chassis. Using a single shot of light, the SICK Visionary T-AP 3D camera captures a 3D image, then pre-processes and evaluates the co-ordinates of the pallet pocket or space under the dolly, before outputting to the vehicle controller. The information can also be sent to a driver display to aid manual forklift operation, particularly useful in high-bay warehouses.

LABEL INSPECTION

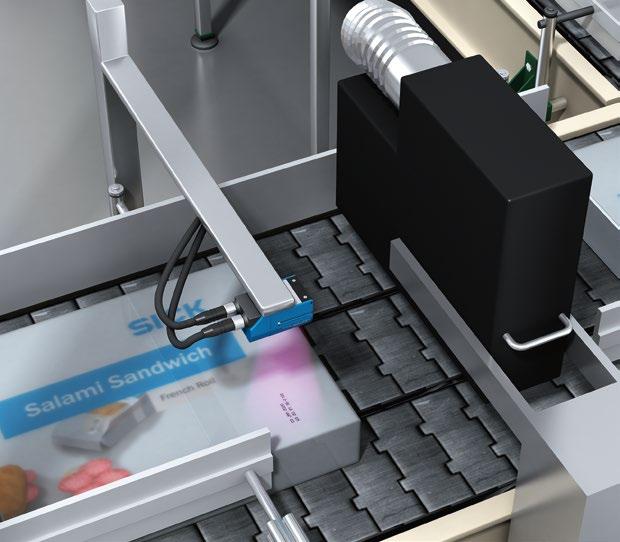

Among the first integrators to successfully exploit the opportunities of SICK AppSpace has been AutoCoding Systems. Their new 4Sight Automatic Print Inspection System is a breakthrough innovation for label inspection and validation that operates on SICK’s Inspector P smart 2D vision camera.

AutoCoding’s 4Sight solution enables a direct, closed-loop communication of the printed message from standard inkjet, laser or thermal transfer printers and the smart camera. All processing is undertaken onboard the SICK camera where the 4Sight software resides, so no line-side PC is needed. With AutoCoding’s unique ability to selfoptimise the inspection, error-proof validation of printed codes such as dates, batch and line numbers is assured.

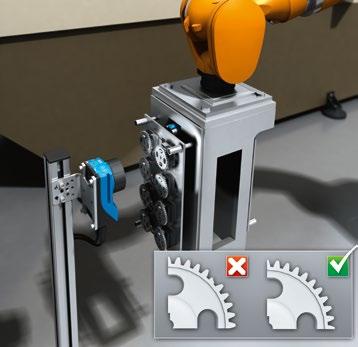

SIMPLE PASS/FAIL

SICK’s Quality Inspection is a freely downloadable, easy to set up, SensorApp for the Inspector P programmable vision camera. It supports simple and economical pass/fail quality inspection tasks. It can be downloaded with a convenient user-guided set up and an accompanying tutorial video and is easily integrated into new or existing machinery to master a wide variety of classic 2D presence inspection tasks. The SICK LabelChecker, also running on the SICK Inspector P, provides an integral label quality control system without the need for an additional

evaluation unit. Compact and stand-alone, it can be set up to recognise and switch between different label types, with custom settings for each type. Its capabilities encompass many standard types of 1D and 2D code, dot matrix printed and indented (peened) text, as well as Optical Character Recognition and Optical Character Verification in multiple regions and lines.

With the MQCS (Modular Quality Control System), SICK is offering a complete package, with pre-written software for its high-performance Ranger3 3D camera, together with a control cabinet and HMI. Originally developed for mould inspection chocolate bar production for leading European brands, SICK has expanded the concept into a universal and scalable 3D high-speed quality control system. Application modules support specific inspection tasks, such as code comparison, counting, label inspection, volume measurement or 3D object inspection.

Most recently launched is SICK’s Colour Inspection and Sorting SensorApp, a low-cost easy set up solution to a very common task in FMCG, food & beverage production. The SensorApp can be supplied as a package with the ultracompact SICK Pico- or midiCam 2D streaming camera, a SICK Sensor Integration Machine, LED illumination and a photoelectric sensor. The system is used to check that goods, assemblies or packs on a conveyor are the right size or colour. It can count objects with different sizes and colours as well as validate the correct colour or colour gradations, e.g. of baked goods. Objects with anomalies can be sorted out or the integrity and completeness of secondary packaging can be detected.

SAVE TIME AND COST

AppSpace promises huge flexibility for vision engineers and programmers because they can save a great deal of time and development costs. SICK has established a Developers Club to provide support, training and encourage knowledge-sharing among the community, with its own annual Developers Conference.

Meanwhile, SICK will continue to roll out its own SensorApps and make them available as “plug and play” solutions on SICK devices for end users, as well as launching ready-made hardware and software packages.

For the future of SensorApps, simply watch this space.

MV