HANDS-ON, HANDS-OFF AT THE NANO SCALE

THE DECIDING FACTOR DEEPLY ROOTED

Carnegie Mellon University | Winter 2023

16

Faculty Awards and Honors

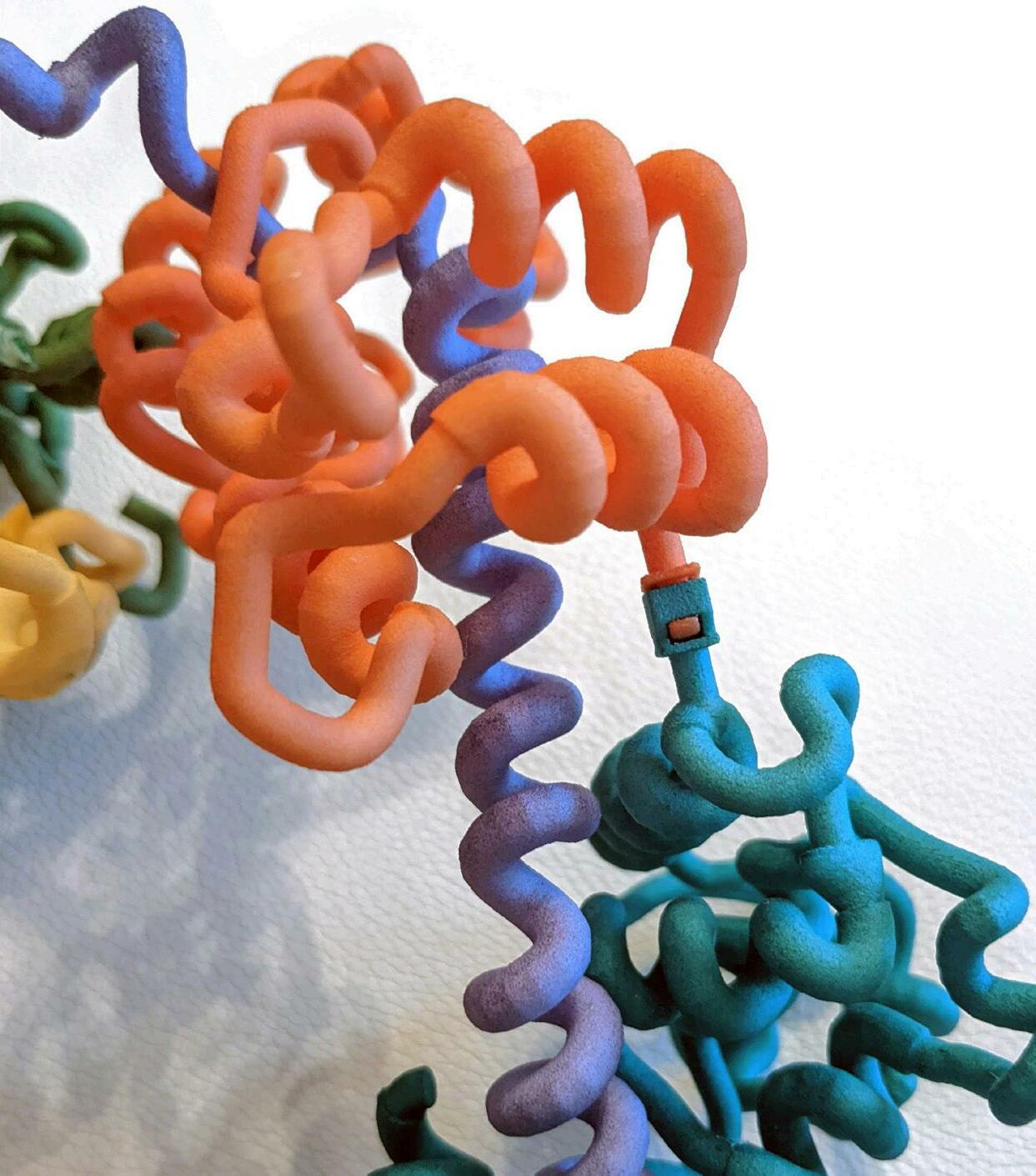

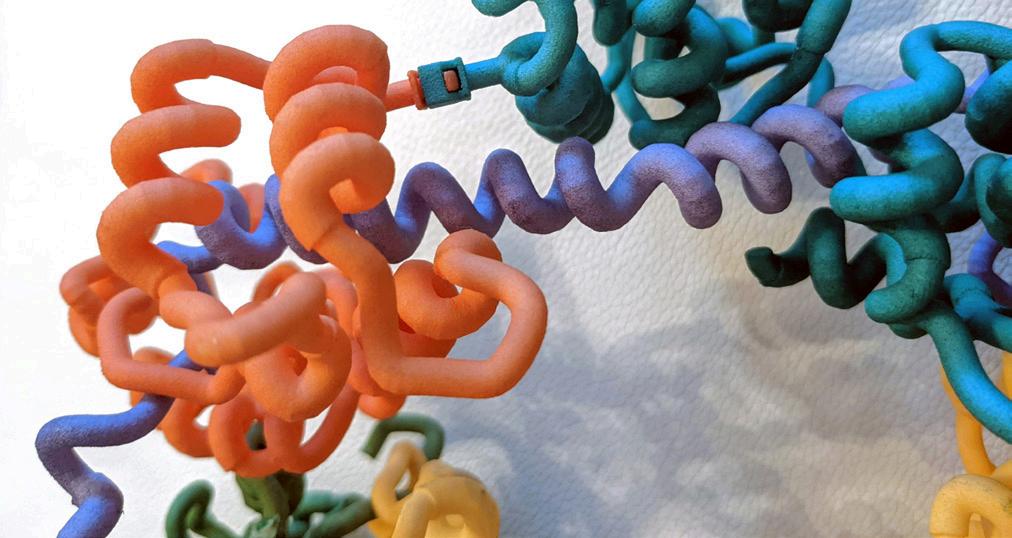

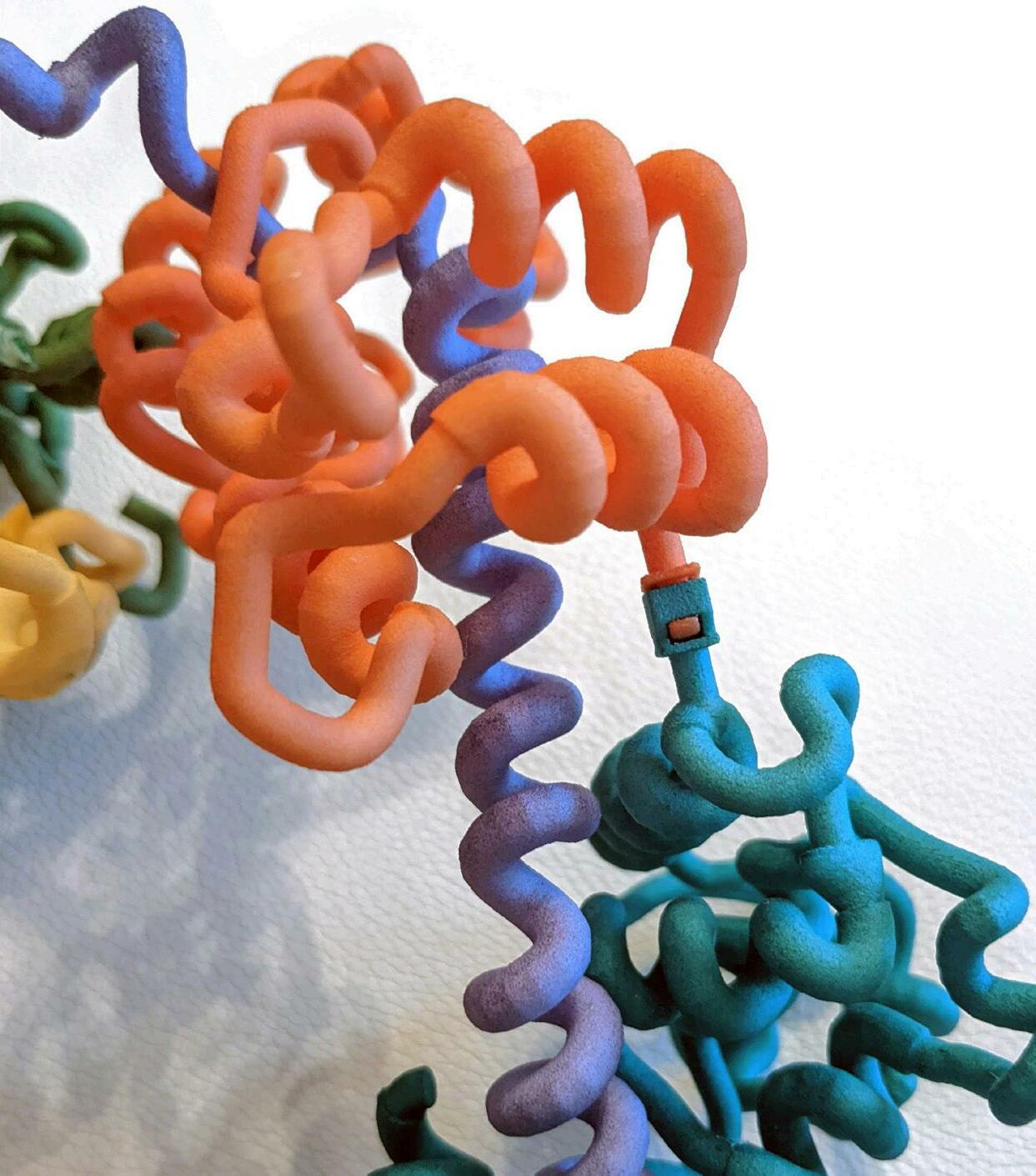

Student Caleigh Goodwin-Schoen is designing more affordable ways to print colorful 3D models of biological nanostructures like proteins and DNA to allow schools and labs to make 3D models specific to their coursework and research.

Department of Mechanical Engineering

Kaitlyn Landram

Communications Manager

Madison Brewer, Amanda Hartle, Lisa Kulick, Kaitlyn Landram, Heidi Opdyke, Kayla Valentine, Giordana Verrengia

Melissa Stoebe Design

Please note: Some of the photos in this issue were taken when facial masks were required due to COVID-19, and other photos were taken when masks became optional (yet strongly recommended). Know that Carnegie Mellon University continues to adhere to safety protocols in this matter.

Carnegie Mellon University does not discriminate in admission, employment, or administration of its programs or activities on the basis of race, color, national origin, sex, handicap or disability, age, sexual orientation, gender identity, religion, creed, ancestry, belief, veteran status, or genetic information. Furthermore, Carnegie Mellon University does not discriminate and is required not to discriminate in violation of federal, state, or local laws or executive orders.

Inquiries concerning the application of and compliance with this statement should be directed to the university ombudsman, Carnegie Mellon University, 5000 Forbes Avenue, Pittsburgh, PA 15213, telephone 412-268-1018.

Obtain general information about Carnegie Mellon University by calling 412-268-2000.

Inside 2 12

ON THE COVER PUBLISHER EDITOR WRITERS DESIGN The Deciding Factor 10 Fulbright Puts Tartan on Global Path Hands-On, Hands-Off Alumni Stories 18

Dear Alumni, Students, Parents, and Friends,

I am writing to you as the new department head of Mechanical Engineering, a position that I am honored to accept after serving as the interim department head for nearly a year. MechE is a community of students, alumni, faculty, and staff that I deeply respect and appreciate — together, we will continue to build an innovative and impactful department!

As the community has begun to open up from the pandemic, I’ve had the opportunity to connect with many of you. Last spring, we gathered with MechE alumni for an outdoor breakfast during Spring Carnival. It was great to see such a turnout despite the rain.

We also celebrated our first in-person diploma ceremony in three years. We filled the Carnegie Music Hall with pomp and circumstance to honor the graduates of 2022, 2021, and 2020 while family, friends, faculty, and staff cheered them on. The experience reminded us that life moves forward despite its challenges.

I’m eager to share with you the latest issue of MechE Magazine. You’ll learn about students working to solve nanoscale problems, from teaching the modeling of DNA to automating chemical experiments. You’ll read about alumni leveraging their MechE education to solve problems in community health and process engineering.

As always, we have more news to share than what we can fit on these pages, so I urge you to visit meche.engineering.cmu.edu to stay engaged with our work.

In other news, we continue to wait with anticipation as we watch the new Scaife Hall construction. We’re on schedule to start moving into MechE’s new home in spring 2023. It’s going to be a fantastic building and focal point for the department and college.

MechE is the family it is because of you and your continued engagement and support of the department. I sincerely thank you. I invite you to visit campus and the new Scaife Hall when the building opens, and partake in our celebration as we advance Mechanical Engineering in the 21st century.

I wish you all a healthy, vibrant 2023!

Sincerely,

Jon Cagan

David and Susan Coulter Head of Mechanical Engineering and George Tallman and Florence Barrett Ladd Professor in Mechanical Engineering

MECHANICAL ENGINEERING 1

MECHANICAL ENGINEERING 2

HANDS-ON, HANDS-OFF AT THE NANOSCALE

It might be too small an object to investigate with the naked eye. Or, it might require monotonous grunt work in the lab. Either way, mechanical engineering students have an inventive approach to advancing nanoscale science.

3D PRINTING GIANT NANOTECH MODELS

STUDENTS’

INGENUITY AUTOMATES SCIENTIFIC RESEARCH

MECHANICAL ENGINEERING 3

MECH E featuring: HANDS-ON, HANDS-OFF AT THE NANOSCALE

3D PRINTING GIANT NANOTECH MODELS

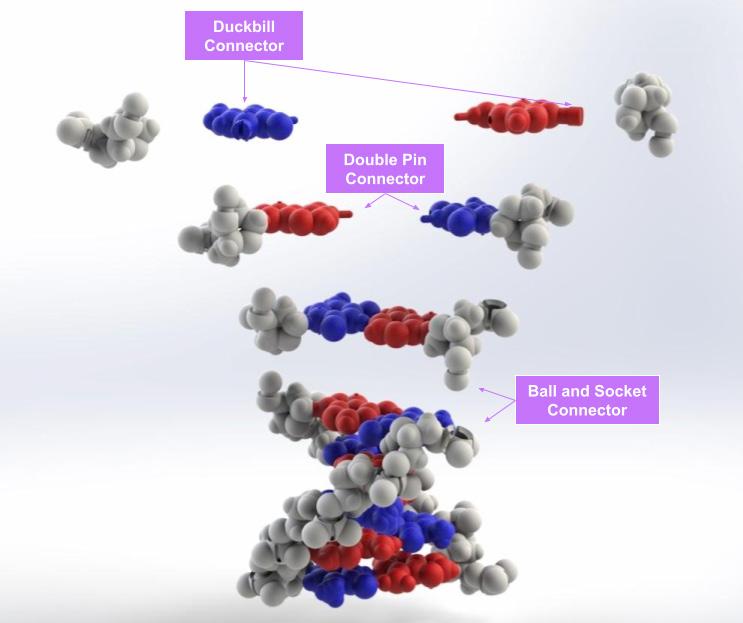

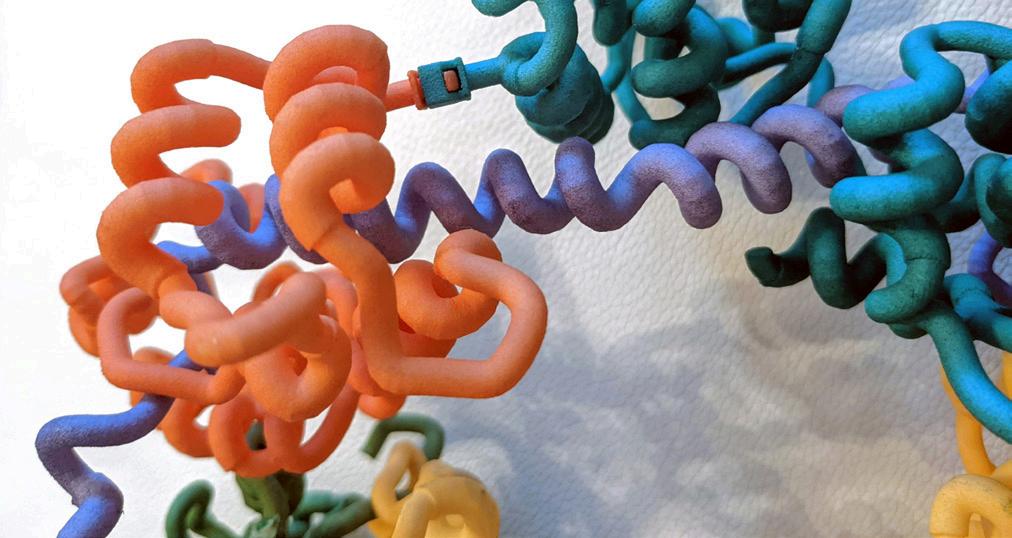

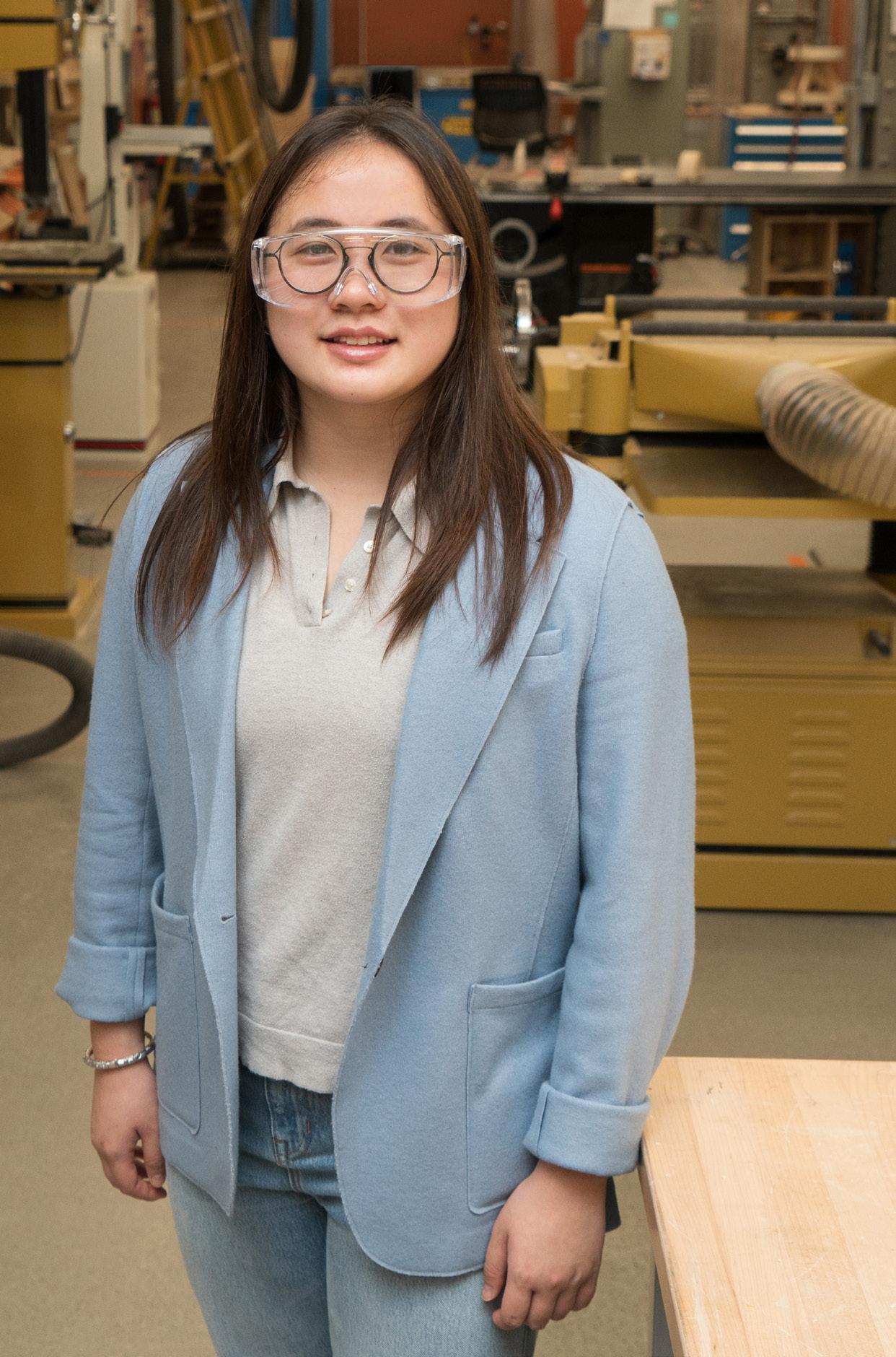

One challenge of researching nanotechnology is that you can’t manipulate the pieces with your hands. You can look at computer models, but it isn’t the same as tactile interaction. Models can be 3D printed, but this can be unrealistic for small high schools, universities, or labs that lack the funding required to pay for it. To tackle these issues, Rebecca Taylor, associate professor of mechanical engineering, and her student Caleigh Goodwin-Schoen are 3D printing models of proteins and DNA and optimizing the designs for affordability. The DNA project was adapted from mkuiper’s product on Thingiverse.

�The point of the physical models is that you can hold them in your hand and play around with them,� GoodwinSchoen said. �That allows you to analyze the model more easily and get a better feel of how you would work with it in research.�

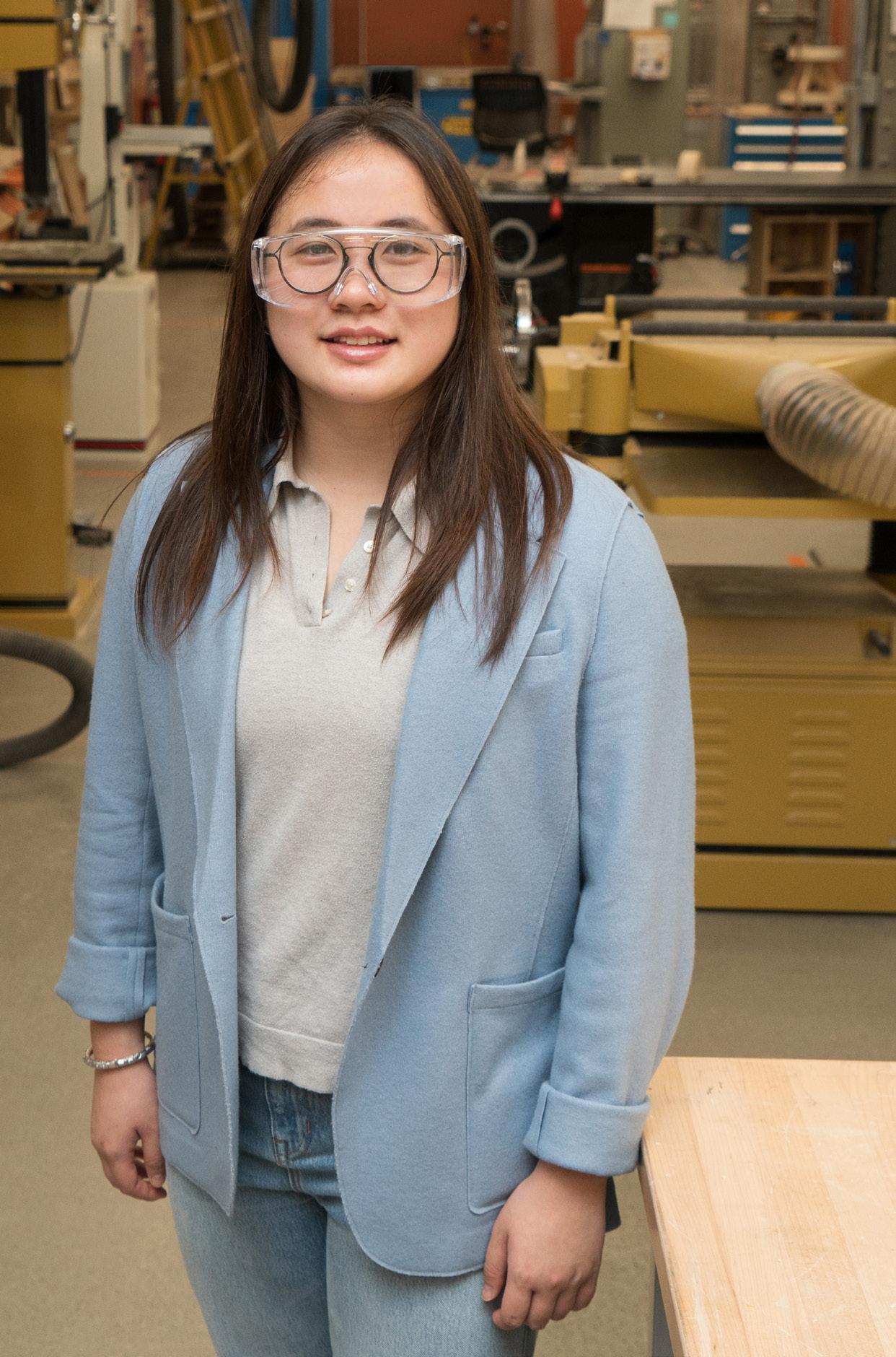

Goodwin-Schoen, a fourth-year student in the mechanical engineering integrated master’s/bachelor’s program, has been working on this project since her sophomore year. The project combines additive manufacturing, nanotechnology, and education.

Goodwin-Schoen’s original goal involved making connectors for protein models. These connectors would hold each part of the protein in their 3D configuration. Each piece of the protein model comes apart, so it can be rearranged like LEGO® structures.

The 3D printing method most people are familiar with works by depositing liquid plastic one layer at a time. Goodwin-Schoen’s project uses a different kind, called selective laser sintering (SLS). In these printers, a thin layer of nylon powder is hit with a laser, binding it into a solid mass. Then, another thin layer is added, and the process repeats. The benefit of using SLS is that the final product is equally strong in all directions. One challenge Goodwin-Schoen had to face was the lack of documentation on making connectors using SLS. She’s had to conduct many tests to figure out the best techniques.

MECHANICAL ENGINEERING 4

MECH

featuring: HANDS-ON, HANDS-OFF AT THE NANOSCALE

E

CALEIGH GOODWIN-SCHOEN

Originally, each piece of the model was printed separately. But the cost of printing could be decreased if everything could be printed together. In fact, Goodwin-Schoen says the price would fall from hundreds of dollars to less than $100. She came up with a way to weakly connect the pieces so they could be easily separated after printing.

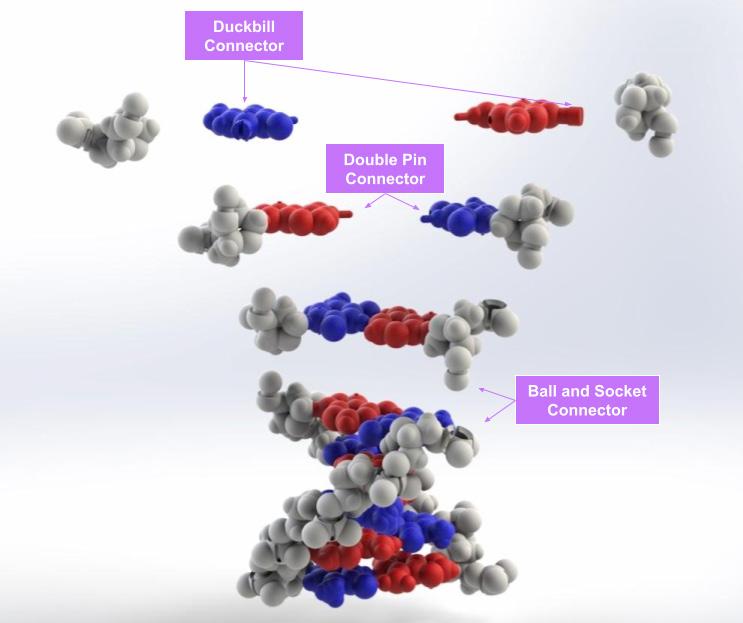

One important aspect of making useful models is finding ways to show how different pieces connect with each other.

The connection between the two nucleobases can be represented as having just one degree of freedom, so she chose a simple snap connector that doesn’t allow much movement. The connection between the base and the backbone, however, has three degrees of freedom. She picked a ball-and-socket connector to represent this physical property.

�You can’t tell from a diagram, so it’ s pretty cool and pretty useful to just see how all the pieces move relative to one another,� Goodwin-Schoen said. �They sort of zip up and form a DNA structure, and you can stack up structures with them.”

Goodwin-Schoen has also created a post-processing technique to color the models. Adding colors makes it easier to distinguish between adjacent pieces. 3D printing in color gets expensive fast, but she realized fabric dye could be used to make the models more vibrant at a much lower cost.

Next, Goodwin-Schoen will work on creating PNA models. PNA, or peptide nucleic acid, is a synthetic polymer that has a similar structure to DNA. She also plans to create a program that will convert files describing the geometry of a protein into a file that can be 3D printed. This would allow schools and labs without mechanical engineers to make 3D models specific to their classes and research.

�It would be really exciting to see my work be used throughout many classrooms and labs,� GoodwinSchoen said. �It seems so applicable to research and education, the grounds where all innovation starts.”

MECHANICAL ENGINEERING 5

“The point of the physical models is that you can hold them in your hand and play around with them. That allows you to analyze the model more easily and get a better feel of how you would work with it in research.”

STUDENTS’ INGENUITY AUTOMATES SCIENTIFIC RESEARCH

If you were to walk around a factory producing medical equipment, like the linear accelerators used in radiation therapy, you would see a slew of automated tools driving production. However, in a lab researching gold nanoparticles’ ability to enhance radiation therapy, you would likely see manual effort alone.

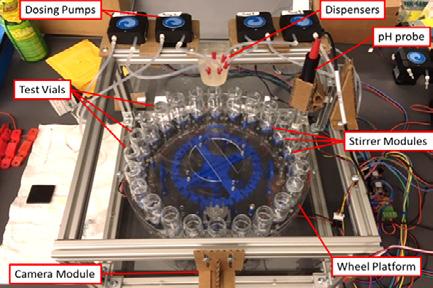

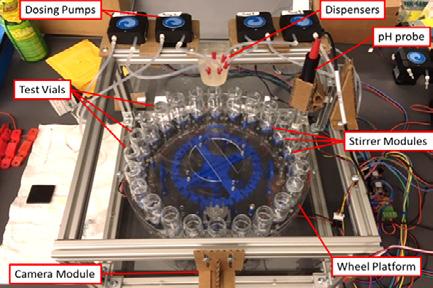

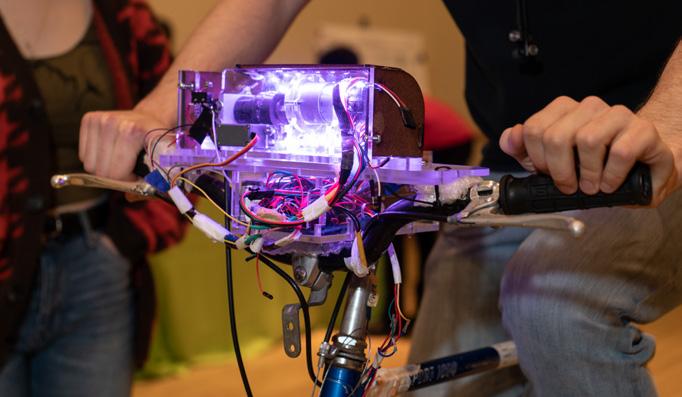

Morgan Chen and Ari Fiorino are working to transform this by using robots to automate and modernize scientific research. Chen, a mechanical engineering Ph.D. student, has made a robot that is able to conduct basic chemistry experiments from start to finish without human aid.

The robots’ modular design comes from one created by Daniel Salley from the Cronin Group at the University of Glasgow and allows researchers to easily manipulate the hardware to set it up for various experiments.

Chen is working with Reeja Jayan, associate professor of mechanical engineering, in collaboration with the Air Force Research Laboratory (AFRL) through the DataDriven Discovery of Optimized Multifunctional Material System (D3OM2S) Center of Excellence.

While automating chemistry with machine learning is not a new interest, the COVID-19 pandemic expedited the need as researchers were required to work from their labs remotely. So, in the fall of 2020, without access to advanced material synthesis equipment available in a lab, Chen began to build.

By using commercial parts available online, and even making use of the cardboard boxes the parts came in, he was able to get the robot up and running. Fiorino, a machine learning master’s student, played a major role in constructing the algorithms implemented in the robot.

Up until now, cost and specificity were the primary obstacles in laboratory automation. But with Chen’s resourcefulness and penchant for modular design, robots like this could be available in laboratories around the world. �If I can build this during a pandemic,” said Chen, “then it’s definitely affordable and doable by the average scientist.”

Autonomy will revolutionize research. The Air Force’s Autonomous Research System (ARES) has been able to complete upwards of 100 times the number of experiments per day that a human researcher can conduct.

Not only will automation save laboratories time and money, but it will allow researchers to spend less time on tedious experiments and more time applying their findings to real-world problems.

MECHANICAL ENGINEERING 6 MECH E featuring: HANDS-ON, HANDS-OFF AT THE NANOSCALE

“Robots with the ability to handle monotonous benchmark research that is inherent in material science will be a tool to complement the human researcher and free up their time to focus on more high-level, creative tasks.”

MORGAN CHEN

Chen explains, �Robots with the ability to handle monotonous benchmark research that is inherent in material science will be a tool to complement the human researcher and free up their time to focus on more high-level, creative tasks.“

Jayan’s group is using the robot to further familiarize themselves with and contribute to the movement toward autonomous experimentation as part of the AFRL center. It will also be used to test the ARFL’s ARES operating system.

Currently, the robot has successfully completed tasking ranging from pH optimization to synthesizing gold nanoparticles, but Chen hopes to see it autonomously conceive and run �intelligent� experiments more relevant to his group’s research goals such as understanding how exposure to electromagnetic radiation affects materials on an atomic scale.

The overall goal is to discover away-fromequilibrium materials with properties unattainable under normal processing conditions. Morgan was recognized as a 2021 National Science Foundation (NSF) Graduate Research Fellow for his work on this project.

MECHANICAL ENGINEERING 7

ARI FIORINO

STUDENTS’ MODULAR ROBOT

The overall goal is to discover away-fromequilibrium materials with properties unattainable under normal processing conditions.

STUDENT ACCOLADES

Three Minute Thesis (3MT®) is an internationally recognized competition that challenges Ph.D. students to present a compelling oration on their thesis and its significance in just three minutes, in language that anyone can understand. In March 2022, MechE’s Emma Benjaminson earned third place at CMU’s competition with her thesis, �Predicting Assembly of Nanorobots Built with DNA.” Sathvik Divi was a finalist with “Role of latches in latch-mediated spring actuation systems for high-acceleration movements in small-scale robots.�

Carnegie Mellon Racing earned three awards at Dartmouth University’s Formula Hybrid & Electric Competition at the New Hampshire Motor Speedway: IEEE Excellence in Project Management Electric Class, IEEE Engineering the Future Award, and first place overall in the electric vehicle category.

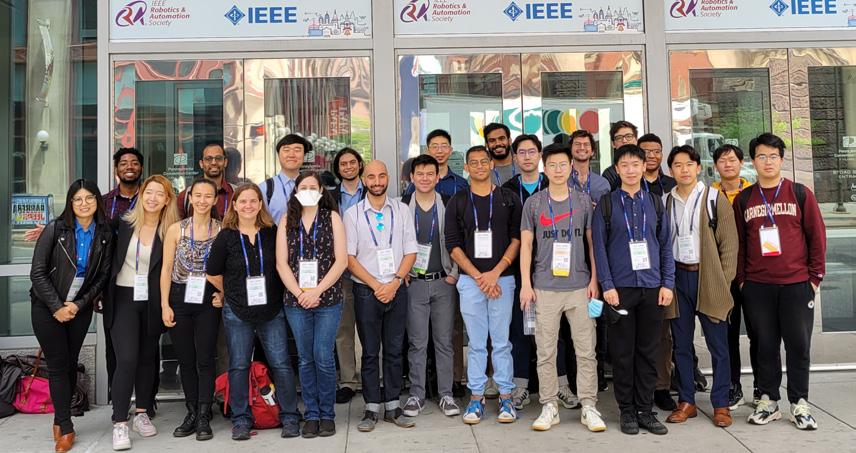

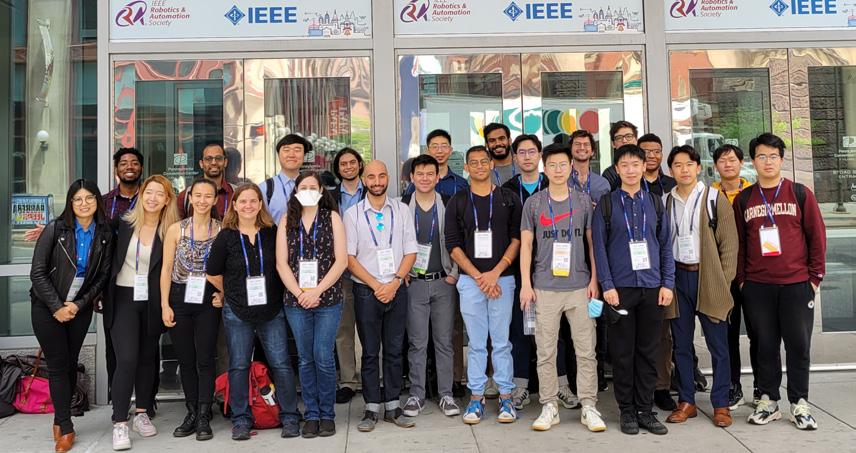

MechE was well represented at the 2022 IEEE International Conference on Robotics and Automation (ICRA) held in Philadelphia in May.

MECHANICAL ENGINEERING 8 MECH E STUDENT ACCOLADES

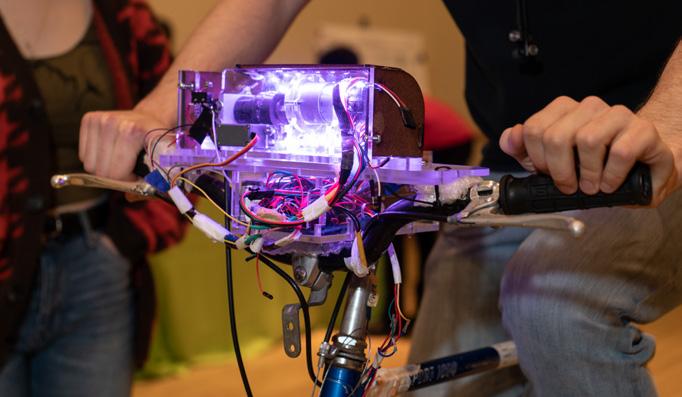

For delivering a captivating presentation and engaging attendees in discussion of their project �Auto Bike Transmission,” a team of MechE students won the �Most Engaging” award during the 2022 Tech Spark Design Expo. The event invited seniors from departments across the College of Engineering to showcase their design projects.

We were excited to celebrate the MechE graduates of the classes of 2022, 2021, and 2020 at an in-person diploma ceremony in the Carnegie Music Hall in May.

Current doctoral candidates presented their research to faculty and visiting, newly admitted students during MechE’s Ph.D. Research Symposium at Phipps Conservatory last spring.

MECHANICAL ENGINEERING 9

Professor Alan McGaughey ran into grad students

Dan Emerson and Mikayla Schneider at the 36.7 mile Rachel Carson Trail Challenge, a sunrise to sunset endurance hike held each June.

MECHANICAL ENGINEERING 10

“What I found really interesting about this program is that they combined engineering practices and design. At its core, it is trying to show how these two disciplines come together to lead to innovation.”

Victoria Nguyen

FULBRIGHT PUTS TARTAN ON GLOBAL PATH

Victoria Nguyen, a sophomore in mechanical engineering with an additional major in biomedical engineering, was selected by the U.S.-U.K. Fulbright Commission to attend the Fulbright Scotland Summer Institute on Technology, Innovation, and Creativity hosted by the Glasgow School of Art and the University of Strathclyde.

The three-week academic and cultural program is aimed at U.S. undergraduate students who have little or no travel experience outside of North America, and participants can explore the culture, heritage, and history of the U.K.

�What I found really interesting about this program is that they combined engineering practices and design. At its core, it is trying to show how these two disciplines come together to lead to innovation,” Nguyen said.

�These are the two main disciplines I want to explore at my time at CMU. I’m an engineering student, but I want to dabble in user design to lead to innovation in engineering biomedical devices.”

Among her career goals are making medical devices more accessible, in part from watching a family member live with an autoimmune disease.

�There isn’t a cure, but there are treatments that can prolong and increase a person’s quality of life. These types of treatments are a luxury that a lot of people don’t have access to,� said Nguyen, who is a first-generation student and a Tartan Scholar at CMU.

�Throughout my college career, I want to see what health care looks like in other countries and also create more accessible options in underserved areas.”

A member of the Global Medical Brigades at CMU, she virtually shadowed doctors in Honduras to understand some of that nation’s medical challenges.

�During this year’s telebrigade, I had the opportunity to consider how available resources, geography, culture, amongst many other factors affect access to health care,” she said. �While abroad, I look forward to seeing what factors promote innovation and creativity to one day find solutions to these disparities in health care.”

MECHANICAL ENGINEERING 11 MECH E STUDENT STORIES

“During this year’s telebrigade, I had the opportunity to consider how available resources, geography, culture, amongst many other factors affect access to health care.”

Victoria Nguyen

THE DECIDING FACTOR

Carnegie Mellon undergraduate students almost always say that CMU’s high rank in academic programs was a main draw when applying to college. For senior engineering student Gabe Blanco, it was also the most welcoming option, thanks to the Tartan Scholars Program.

When Gabe Blanco was applying to colleges, he knew he wanted to pursue some kind of engineering based on his positive experiences in math and science courses. By the end of his application process, Blanco had a final list of around seven schools to choose from. All of them ranked highly in engineering programs, so he looked to other factors to make his choice.

One factor in the back of his mind was his rekindled passion for juggling, a skill he had learned in grade school and picked back up in high school on a whim. Blanco explained that, �when you’re juggling, the whole goal is not to think,” which can be a welcome break from academic rigor.

During his search for the perfect college, he noticed that Carnegie Mellon University has a juggling community called Masters of Flying Objects. Now a junior studying mechanical engineering and engineering and public policy, he has been an active member since he was a first-year, continuing to practice his juggling with other students, staff, faculty, and Pittsburgh visitors.

But the biggest factor when deciding where to attend college for Blanco was cost — not just the final amount loaned out and paid, but also the value offered by the institution. Blanco is one of three triplets, all of whom were applying to attend college at the same time, which could put a huge financial weight on the family’s shoulders. So when he was invited to join a program aimed at high-achieving students who come from limited resources, he knew his decision was made.

The Tartan Scholars Program finds students like Blanco by consulting with staff in admissions and financial aid. They identify applicants from limited-resource backgrounds, which can have various definitions: the family is in a low socio-economic bracket, the high school does not offer AP or advanced courses, they

MECHANICAL ENGINEERING 12 MECH E STUDENT STORIES

live in a rural or urban area where resources are scarce or spread too thin, they are the first individual in their family to attend college, or other factors. Once identified, the student gets an invitation to join Tartan Scholars in their first year.

�Tartan Scholars is a retention program at the heart of it,” explains Branden Ballard, the program manager for the Tartan Scholars Program. An assessment of student performance keyed in on Pell-eligible students at CMU and discovered that students from limited-resource backgrounds typically earned a full letter grade lower than peers from more affluent backgrounds and were graduating at rates 10-15% lower after six years.

Those who initiated the Tartan Scholars Program, including Ballard, asked �What is causing this to happen? Because, clearly, all these students got here based off their own merit. What is it about our ecosystem that is causing this discrepancy that we’re seeing? What supports should we be providing to students that we currently aren’t?”

The program began in August 2019 (during Blanco’s first semester) as a response to this data. In the program, students are encouraged to see themselves as belonging at CMU, to develop a growth mindset to help them overcome obstacles, and to use their own voices and experiences to affect their campus environment via self-authorship and leadership.

In Blanco’s own words, the Tartan Scholars Program is �a program focused toward people in a lower socioeconomic class, to connect us to resources and opportunities that we wouldn’t have had otherwise.”

Although the program does not offer scholarships in a traditional way, students can receive help to secure resources such as laptops, calculators, medications, and travel assistance. During the COVID-19 pandemic, the program even helped students to get vaccinated as soon as they could in their various locations around the world.

�The program also connected us to each other, which was kind of the most important thing — having this community to be a part of,” says Blanco.

Taking foundational classes as a group, receiving mentorship from faculty and staff, eating meals together, and socializing, all give the Tartan Scholars a network of peers that they can turn to if they have problems with stress, imposter syndrome, and other struggles that first-years often face.

The program will complete its third academic year this May. One student has already graduated early and many others, such as Blanco, are truly thriving at CMU.

�There are people who clearly see that it’s working,” says Ballard. �Back in November of last year when the Posner Family Foundation gave their significant gift to the university, $10 million came to my program, which placed Tartan Scholars into perpetuity. And so, clearly people believe that the program’s working, and I believe it is as well.”

MECHANICAL ENGINEERING 13

“The program also connected us to each other, which was kind of the most important thing — having this community to be a part of.”

Gabe Blanco

BRINGING ROBOTICS INTO EVERYDAY LIFE.

An engineering revolution is underway in soft machines and robots to assist people in new ways through nextgeneration systems.

In Softbotics, our vision is to create a step change in moving robotics from large industrial scale to smaller human scale and thereby entering households, workplaces, hospitals, and aspects of the environment to provide new solutions.

One day people around the globe will be touched by the enhanced performance these technologies will offer.

Learn more about partnering with us: softbotics.org.

GROWING A DIVERSE, EQUITABLE, AND INCLUSIVE CULTURE

The MechE Diversity, Equity, and Inclusion (DEI) Task Force serves and empowers students, staff, and faculty to work together to create a welcoming and supportive community where all persons prosper, benefit, and reach their full potential.

Through activities and events developed through subcommittees, the DEI Task Force has explored a range of important topics from addressing microaggressions to encouraging STEM outreach in Pittsburgh. In the spring of 2022, it hosted a Community Conversations forum that invited participants to discuss the intersection of race and disability. A mentorship program and professional development series are also offered.

A new initiative launched for the fall 2022 semester was the Mechanical Engineering Inclusive Teaching Fellow Program. Three current master’s students were hired for three graduate core courses: Engineering Optimization, Engineering Computation, and Machine Learning and Artificial Intelligence for Engineers.

For each course, the fellow examines the learning material such as syllabi, homework assignments, and in-class exercises to find opportunities to incorporate DEI principles. The fellow collaborates with the course’s professor to bring about new understanding of how the classroom can become a more inclusive space.

The fellows participated in the College of Engineering’s Justice, Equity, Diversity, and Inclusion (JEDI) programming and worked regularly with Carnegie Mellon University’s Eberly Center for Teaching Excellence and Educational Innovation.

A future goal of the Inclusive Teaching Fellow Program is to disseminate the insights and the lessons learned from the experience to other faculty members and teaching assistants within the department.

MECHANICAL ENGINEERING 15

FACULTY AWARDS & HONORS

Teaching Professor Mark Bedillion (’98, ‘01, ’05) received the 2022 Outstanding Teaching Award from the American Society for Engineering Educators (ASEE), North Central Section. He also received the 2022 Benjamin Richard Teare Teaching Award from the College of Engineering.

Professor and Department Head Jon Cagan delivered a keynote presentation on AI-human hybrid teaming at the DESIGN 2022 conference. The talk examined engineering teaming and ways that artificial intelligence is evolving to change the performance and dynamics of teams.

Associate Professor Reeja Jayan authored the chapter �Nonlinear Pathways into Mechanical Engineering” in the book �Women in Mechanical Engineering: Energy and the Environment.” The work is part of the Springer Women in Engineering and Science series to raise awareness of the pivotal work women are undertaking in areas of keen importance to the global community.

Assistant Professor Eni Halilaj received a 2022 National Science Foundation CAREER Award to study musculoskeletal modeling with cameras and wearable sensors. Her work seeks to make gait analysis more accessible for rehabilitation research and therapy monitoring.

Associate Professor Aaron Johnson (ECE ’08) has earned the 2022 College of Engineering Dean’s Early Career Fellowship for his groundbreaking work in the field of robotics.

Associate Professor Rahul Panat was named the Associate Director of Research for CMU’s Manufacturing Futures Institute (MFI) which conducts research, educates manufacturing leaders, accelerates research translation into industry relevant applications, and partners with its communities.

Professor Ryan Sullivan organized the workshop “Everyday-Everywhere Chemicals and the Human Exposome: What drives our exposure to toxic chemicals in our daily lives and how can we reduce this?” The workshop was part of his senior fellowship at the Collegium Helveticum, a joint institute bringing together scholars to promote interdisciplinary exchange.

Associate Professor Rebecca Taylor led collaborative research with CMU’s Department of Chemistry that was selected for inclusion in the Women in Polymer Science Virtual Issue of the Journal of Polymer Science. The paper was titled “Rapid self-assembly of yPNA nanofibers at constant temperature.�

Professor Conrad Tucker serves on the U.S. Chamber of Commerce’s Commission on Artificial Intelligence Competition, Inclusion, and Innovation to advance U.S. leadership in the use and regulation of AI technology. He co-chaired the “Artificial Intelligence and Justified Confidence: A Workshop� by the National Academies of Sciences, Engineering, and Medicine. He was also an organizer for the West Africa Conference on Digital Public Goods and Cybersecurity.

MECHANICAL ENGINEERING 16 MECH E FACULTY

Assistant Professor Victoria Webster-Wood led a team of multidisciplinary researchers to earn top honors at IEEE’s International Conference on Robotics and Automation 2022 in the Outstanding Mechanisms and Design Paper category for their submission, �Design of a Biomimetic Tactile Sensor for Material Classification.�

Associate Professor Kate Whitefoot received the 2022 American Society of Mechanical Engineers’ Design Automation Committee Young Investigator Award for her accomplishments in design automation at the intersection of economics and market systems.

Professor Jessica Zhang delivered a semi-plenary lecture at the 8th European Congress on Computational Methods in Applied Sciences and Engineering 2022. She also delivered a virtual keynote at the International Workshop on Combinatorial Image Analysis. She was elected secretarytreasurer of the U.S. Association for Computational Mechanics Executive Council.

Assistant Professor Ding Zhao received the George Tallman Ladd Research Award as part of the 2022 Engineering Faculty Awards from the College of Engineering.

RUBIN RETIRES

After 53 years on the MechE faculty, Professor Ed Rubin has transitioned to emeritus status. Also a founding member of the Department of Engineering and Public Policy, he played a key role in creating the undergraduate double major program and curricula.

He pioneered the field of energy and the environment through new educational and graduate research initiatives that became nationally prominent and a model for programs elsewhere.

An internationally recognized expert in energy systems, environmental technology innovation, and climate change mitigation, Rubin is the most highly cited authority on carbon capture and storage systems. For his work on the Intergovernmental Panel on Climate Change (IPCC) in 2007, Rubin became the only faculty member in Carnegie Mellon University’s history to share in the Nobel Peace Prize.

Among his many other awards and professional recognition, he received the College of Engineering’s Distinguished Professor of Engineering Award, the college’s highest honor. We offer him MechE’s heartfelt gratitude, appreciation, and best wishes!

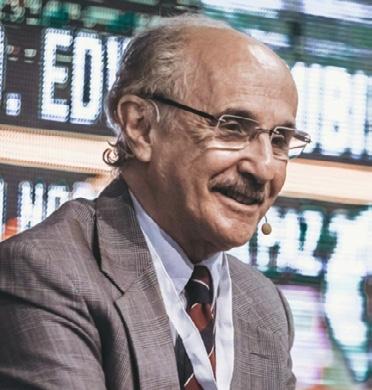

NORMAN CHIGIER

Professor Emeritus Norman Chigier passed away on August 22, 2022. He taught courses in undergraduate fluid mechanics and combustion, and played a central role in the department’s spray and combustion research area, which blossomed in the early 1980s. With his expertise in this field, he served as the editor of the journal Progress in Energy and Combustion for over 40 years.

Colleagues at Carnegie Mellon recall his friendly, engaging personality, his vigor for skiing, and his passion for the arts. He was often seen at cultural events on campus.

We extend our deepest condolences to his family and friends.

MECHANICAL ENGINEERING 17

IN MEMORIAM

“At CMU, they teach you at one level, but then they test you at a much higher level. Somehow you have to figure out how to make that connection, that jump. You have to think, ‘They taught me this, but how do I extrapolate this to make connections beyond the basics I was taught.’”

Tiffani Maycock (’96)

MECHANICAL ENGINEERING 18

DEEPLY ROOTED

Each morning as she slips into her white coat, Dr. Tiffani Maycock (’96) also mentally prepares for the seemingly endless hats she must wear following her rounds to check on patients.

Family medicine and obstetrics physician, associate professor, program director, board member — she does them all, but the Carnegie Mellon University alumna’s favorite role in her multihyphenate life has been community engagement.

�I love being able to get out into the community, make community health connections, and improve health literacy,” says Maycock, who graduated from the College of Engineering in 1996 with a bachelor’s degree in mechanical engineering.

From health fairs that educate attendees on blood sugar to elementary school visits to talk about fruits, veggies, and careers in medicine, Maycock strives to make a difference on a personal level and build healthy futures regardless of zip code.

And now with her new role on the American Board of Family Medicine, her impact can be magnified to a national scale.

�When I heard that I was nominated for the board, I asked how they even found me down here in middle of nowhere Selma, Alabama,” she jokes. �But then I realized that my life and career experiences as a female, African American, and a D.O. in the rural South were very unique. I know I can offer perspectives that can help others and change outcomes for the better.”

A SQUARE ENVELOPE

Growing up in Daytona Beach, Florida, Maycock had never heard of Carnegie Mellon University until a square envelope arrived in her mailbox.

�Back in the day, they’d send these cute little square booklets, and they really stood out in the stack of booklets from other schools,” Maycock says. �I soon learned that I could study engineering and specialize in robotics, too. I knew it was going to be a cool place.”

She visited campus for the first time the summer before she started classes as part of the Carnegie Mellon Action Project.

Renamed the Carnegie Mellon Advising Resource Center in 2006 and now part of the Center for Student Diversity and Inclusion, the program supported CMU students of color in accessing community and resources to help them persist and thrive.

And thrive she did: helping fellow Tartans as an RA, playing French horn in the Kiltie Band, leading Voices United Gospel Choir, building engines in mechanical engineering courses, mastering the best layering techniques to survive a Pittsburgh winter, and learning lessons she still uses in her many roles.

�At CMU, they teach you at one level, but then they test you at a much higher level,” Maycock says. �Somehow you have to figure out how to make that connection, that jump. You have to think, ‘They taught me this, but how do I extrapolate this to make connections beyond the basics I was taught.’”

She decided to pursue medicine after taking a course in musculoskeletal biomechanics and learning her teaching assistant was headed to medical school, an option she hadn’t considered.

�I knew I enjoyed the musculoskeletal system, yet from my research, I knew I didn’t want to do orthopedic surgery, and I saw a poster with those tear-off postcards you’d mail in to get more information,” Maycock says. �It was an osteopathic school, and I knew it was perfect. It’s the musculoskeletal system, manipulation, and conventional medicine. It was the best of both worlds for me.”

Continued on page 25

MECHANICAL ENGINEERING 19

MECH E ALUMNI STORIES

MICROSCOPIC ENGINEERING MACROSCOPIC VALUE

Process engineering, a hidden gem in mechanical engineering, involves designing, implementing, and optimizing the production process. For alumnus Alexander Kwakye (‘18), production on a micro-scale emphasizes the importance of quality over quantity.

�At Intel, I manage our key metrics, such as output, defects, and quality. Quality is a big component of the job because we’re replicating this process 24/7, so we need to maintain the standard.”

Kwakye’s work in process engineering began during his time at Carnegie Mellon University, starting with his exposure to nanofabrication, which he explored in both his undergraduate and graduate studies. The industry fascinated Kwakye, who wanted to try something different from what mechanical engineers typically pursue.

In the Claire & John Bertucci Nanotechnology Laboratory at CMU, he was assigned the task of reducing stress placed on wafer–thin slices of semiconductor used when creating integrated circuits–processes. Kwakye worked with a Physical Vapor Deposition (PVD) machine to deposit small, thin amounts of metallics onto a wafer using plasma at a very low vacuum rate. He performed the measurement process, checking the thickness of the wafers. The goal was to streamline the service for other customers and researchers utilizing the lab.

�My work and apprenticeship with the NanoFab facility elevated my maturity and my exposure in the field, developing the foundation that I would need to succeed in areas such as metallics and working with wet and dry etching.” Kwakye has continued working with wet and dry etching, processes used during the microfabricating of circuit boards, in his career with Intel.

When asked what advice he would give to current and incoming CMU students alike, Kwakye emphasized the importance of collaboration and utilization of resources.

�When I look back at my graduate research project, which involved working with a lot of individuals who were in the biomed field, such as professors at the University of Pittsburgh and CMU, I find that I loved the interweaving effect of what I was doing and expanding what I thought my research could achieve,” he said.

MECHANICAL ENGINEERING 20

MECH E ALUMNI

�Students need to have open expectations and a willingness to work with each other outside of their specific field,� said Kwakye, �I think we take that for granted; when you arrive at school, you’re dead-set on one thing, and you don’t tend to see the fruition of other opportunities that could also assist in your endeavors.”

Kwakye graduated from CMU in 2018 with a master’s of science degree in mechanical engineering. He joined Intel Corporation as a dry etch process engineer that year.

MECHANICAL ENGINEERING 21 ALUMNI STORIES

“My work and apprenticeship with the NanoFab facility elevated my maturity and my exposure in the field, developing the foundation that I would need to succeed in areas such as metallics, and working with wet and dry etching.”

Alexander Kwakye (‘18)

ALUMNA “PAYS IT FORWARD” WITH SCHOLARSHIP

“I remember telling my mom once, ‘I hope one day I’m able to give back as much as I got in scholarships so that somebody else could do the same,’ sort of as a pay-it-forward gesture.’”

Lauren (Milisits) Gonzalez (’13, ‘14)

MECHANICAL ENGINEERING 22 MECH E ALUMNI MECH E

Alumna Lauren (Milisits) Gonzalez (BS MechE ’13, BS CS ’14) still remembers getting the letter in the mail that meant she could attend Carnegie Mellon. It wasn’t her acceptance letter; that had already arrived. It was a scholarship award notice. With it, combined with federal grants, she could afford to accept her CMU admission.

�I remember telling my mom once, ‘I hope one day I’m able to give back as much as I got in scholarships so that somebody else could do the same,’ sort of as a pay-itforward gesture,” Gonzalez said.

She recently set up an endowed scholarship for the Department of Mechanical Engineering to do just that with the help of her employer’s match program. By endowing the scholarship, Gonzalez ensured it will partially support at least one engineering student each year in perpetuity.

�If I’m able to make what I do go further, then I might as well,” she said, noting that many companies match their employees’ charitable donations — doubling their impact — like Shell does for her.

WOMEN IN ENGINEERING

Gonzalez hopes the scholarship will encourage undergraduate students to pursue engineering, particularly women, given their persistent underrepresentation in science, technology, engineering, and math (STEM) fields.

Growing up in Pittsburgh’s Squirrel Hill with parents who encouraged her interest in STEM, Gonzalez said she didn’t realize there was a gender imbalance in STEM until after high school. Over the years, her parents had enrolled her in as many university outreach programs as they could.

�It was through all of those free programs that kept my interest in science and engineering. And I never once doubted that I could do it,” she said. �So then, when I actually was going to school (for engineering), I started to hear the stereotypes of, ‘Oh, you’re a woman. Are you sure you’re going into Engineering?’ or … ‘Oh, you’re in CS? You don’t look like a CS major.’”

Those responses irritated her, driving her to help more women get into STEM.

TACKLING BIG PROBLEMS

After her undergraduate years, Gonzalez moved to Texas where she worked as a test automation engineer at a startup and enrolled at the University of Texas at Austin to earn her master’s in mechanical engineering. She briefly interned for Shell while still a graduate student. The company then offered her a full-time position, leading to an opportunity to work offshore on one of the company’s largest floating platforms, Appomattox, in the Gulf of Mexico. She continued to climb, becoming a project manager and, now, a business advisor to the vice president of information and digital engineering in Houston.

COVID-19 added challenges and barriers, but Gonzalez said she’s proud of her and her team’s resilience throughout the pandemic. They delivered a multi-milliondollar project on time, on budget, and on target �from our pajamas at home,” she joked. And she delivered a baby in the middle of it.

Continued on page 24

MECHANICAL ENGINEERING 23

ALUMNI STORIES

Continued from page 23

Her experience in the Department of Mechanical Engineering helped equip her for such challenges by exposing her to different people, projects, and work ethics, she said. She found that she likes �big problems that challenge the world, that have major impact.”

�We worked our butt off in school,” Gonzalez said. “And knowing how difficult that can be … it helps to build up the mindset that when something’s not easy, (you) don’t just quit right away and give up, because we wouldn’t be tackling big problems and we wouldn’t be changing things if as soon as you hit a roadblock, you quit.”

The College of Engineering also provided some of her favorite memories while at CMU — trips to Peru and China with educational and industry components. Opportunities she never would have had if not for scholarships.

Education changed her life, she said, and motivates her philanthropy. Gonzalez encourages other alumni to consider how they can change someone’s life, even with small donations.

�Because I’m telling you, every thousand dollars, every hundred dollars I got towards the scholarship completely changed my path,” she said.

ALUMNI NEWS

Conrad Zapanta (’91), a teaching professor in CMU’s Department of Biomedical Engineering, has been appointed the new associate dean for Undergraduate Studies in the College of Engineering. He will oversee the first-year program for engineering students.

24 MECHANICAL ENGINEERING MECH E ALUMNI

Continued from page 19

She received her doctor of osteopathic medicine and master’s degree and completed a fellowship in manipulative medicine at Ohio University’s Heritage College of Osteopathic Medicine. After three years of family medicine residency training, she started to think of the future and sought another way to combine her new dreams: delivering babies and mission work.

She found it in a one-year surgical obstetrics fellowship sponsored by the UAB Huntsville Family Medicine Residency Program and the Alabama Rural Health Board.

IN THE COMMUNITY

Maycock’s mother grew up in rural Alabama, and her family still celebrates Thanksgiving together in Midway each year. So her fellowship in Huntsville, which also required her to teach or work in an underserved area after her training, seemed to be a perfect match.

Maycock learned how to perform cesarean sections and manage high-risk obstetrics patients and fostered her love of community medicine and outreach by teaching in the University of Alabama (UAB) Huntsville Family Medicine Residency Program.

�I took over the community medicine rotation, and I grew it,” Maycock says. �It became my niche.”

She wrote and directed the community medicine curriculum and coordinated health fairs, lecture series, and screenings. She teamed up with community partners in Selma at an early literacy program, the YMCA, area schools, and the public library system and expanded a free family medicine clinic called Doc On The Spot.

Soon though, she got married, had two children and moved to Virginia — only to find herself looking to head south. When a friend mentioned an open position for the UAB Selma Family Medicine Residency Program, she knew she’d found another fit.

A HEALTHIER FUTURE

In addition to her director role, she also serves as an associate professor in the Department of Family Medicine at UAB’s School of Medicine and hospitalist director at Vaughn Regional Medical Center and instructs residents and medical students as part of the Rural Training Track Collaborative designed to sustain health professions education in rural places.

Those “hats� vary from day to day: shuffling between a hospital or clinic supervising residents; traveling to nursing homes and personal residences to treat patients; and serving on boards at the national level like her new role on the American Board of Family Medicine where she is the second D.O. in the board’s 40-year history. But no matter which one she is wearing, she is always working to expand health literacy around nutrition, boost access to medical care and fresh foods, and break generational cycles reinforced by the realities of day-to-day life in underserved communities.

�That’s why I really enjoy working with kids,” Maycock says. �If we can get them engaged and help them to see there are healthier and better ways forward, that will be huge.”

“Some of these barriers are difficult, but I’m really excited about the opportunities ahead.”

This story originally appeared on the Engage with CMU website.

Tartans on the Rise celebrates recent CMU alumni who are making an impact in their organizations and in their communities, across the nation and around the world through leadership, innovation, and career achievements.

Doug Bernstein (’12), the co-founder and

chief executive officer of PECA Labs, and Thomas Healy (‘14), the founder and chief executive officer of Hyliion, were recognized.

FLASHBACK

After two alumni got married in 1985, they returned to campus to take photos at the Fence, painted in honor of their wedding. Thanks for sharing, Peter (‘79) and Nancy (‘80) Bond!

want to hear from you! Email your news to me-alumni@andrew.cmu.edu

We

Mechanical Engineering

Carnegie Mellon University

5000 Forbes Avenue

Pittsburgh, PA, 15213-3890

CMU.Mech

CMU_Mech

CMUEngineering

CMUEngineering

meche.engineering.cmu.edu

As a student at Carnegie Mellon University, Andre embraced the collaborative nature and strong community of the College of Engineering. The relationships he built with faculty, staff, and students continue to have a lasting impact in his personal and professional lives.

Andre and his wife, Nicole, are active volunteers and generous donors to Carnegie Mellon. Andre has served as a mentor to Engineering students and is a dedicated member of the Mechanical Engineering Advisory Council. Passionate about supporting students, Andre and Nicole gave a gift to the renovation of Hamerschlag Hall and the construction of ANSYS Hall through the Sutanto Collaborative Space.

GIVE STRATEGICALLY, SUPPORT GENEROUSLY

Learn how you can achieve your philanthropic vision at Carnegie Mellon by visiting engineering.cmu.edu/waystogive.

Non-Profit Org. U.S. Postage PAID Pittsburgh, PA Permit No. 251

ANDRE AND NICOLE SUTANTO WITH THEIR CHILDREN, CONRAD AND EMILY OUTSIDE OF ANSYS HALL

“

I THINK INVESTING IN EDUCATION IS THE BEST INVESTMENT WE CAN MAKE FOR THE FUTURE .” -ANDRE

SUTANTO

( MechE ‘13)