57 minute read

WELDING

from Buyer's Guide 2021

FIRED-UP FOR THE FUTURE

THE NEXT GENERATION OF WELDERS ARRIVES

It is a safe bet that, however your business conducted welds in the first decade of the 2000s, it changed the approach in the 2010s.

It is also a safe bet that the 2020s will bring even more significant changes to your business’s approach.

The substances used to build modern automobiles are changing at an unprecedented rate. New steels, some patented by OEMs, are finding their way into blueprints, just as quickly as aluminum alloy alternatives.

This isn’t going to change any time soon. If Acumen Research and Consulting is to be believed, the producers of automotive aluminum alloys can expect to see their market grow by more than ten percent per year until 2027.

The introduction of new materials such as ultra-high-strength steels, aluminum and carbon fibre into modern vehicle designs means that welding has become far more complicated than it used to be. It also means that the consequences of welding badly are far more serious. This is particularly a problem for repairers working with high-strength steels, some of which lose structural integrity at the molecular level if subject to excessive heating.

There are OEM-approved approaches to performing repairs on vehicles with these complicated materials. These methods include squeeze type resistance spot welders (STRSW), MIG/MAG pulse welders, rivet bonding and panel bonding.

In some instances, all four methods can be used when repairing. The use of resistance spot welders has been adapted by OEMs due to the introduction of ultra high strength steels.

So how does a collision facility invest in building the welding infrastructure needed to operate on the vehicles of the 2020s?

Well, by remembering the basics and investing in the tools needed to make it easier for your teams to get the welding process right as quickly and reliably as possible.

In this edition, the Collision Repair team has been somewhat brazen in its willingness to highlight welding hardware that isn’t just capable of conducting a certain type of weld, but capable of reducing the risk of misuse as possible. Read through and prepare to have your heart melted.

Q5.1 Autotransforming Welder

SPANESI

www.spanesi-americas.com Smart Spot Welder 60-3664P

ARSLAN AUTOMOTIVE

arslanauto.com

The Q5.1 is the latest addition to Spanesi’s line of welding machines. After selecting the appropriate program, the Q5.1 welder does the rest of the work for you by automatically determining the best parameters based in the material type, wire diameter and shielding gas being used. With its compact footprint, this single-torch multi-process welding machine is capable of producing welds in MIG/MAG and MMA. Spanesi says the Q5.1 performs excellently for autobody repair work as well as welding aluminum, silicon bronze and steel materials.

i4s Smart Spot Welder

PRO SPOT

prospot.com The SMART Spot Welder by TECNA boasts a digital touch-screen display enabling technicians to easily check welding parameters according to type of tool plus the type and thickness of the sheet(s) being welded. Once the welding gun contacts the metal it will recognize the type and thickness of metals, from there it sets the appropriate force, weld time and power to assure a consistent weld. The 3664P only needs a 60 Amp breaker and is fully water-cooled by means of a closed-circuit cooling system.

Plastic Fusion Pro Station

BETAG INNOVATION

betagnorthamerica.com

The i4s Smart Spot Welder has many useful features, from the auto-weld mode that adjusts to the weld as it’s occurring, to the built-in WiFi allowing users to quickly connect for access to training videos, materials and OEM procedures. Along with instant communication and easy customization for maintaining records and monitoring workflow, the i4s has recently received a Tesla approval, along with a handful of other Pro Spot systems. Approved and recommended by numerous European and Asian OEMs, BETAG’s Plastic Fusion system is a complete plastic repair workstation that enables technicians to produce consistently high-quality plastic outer panel repairs, including: bumper covers; wheel arch liners; headlights, door mirror casings; and other plastic parts.The Plastic Fusion System uses high temperature and low air volume and BETAG’s specially formulated universal welding strips. The Pro Station comes complete with an integrated hot stapler, variable speed grinder and external air and nitrogen connectors, giving technicians the choice to use nitrogen and/or compressed air in the process according to preference.

60-31878 Nitrogen Gas Plastic Welder

ARSLAN AUTOMOTIVE

arslanauto.com 8002 & 8003 Nitro-Fuzer Nitrogen Plastic Welder

POLYVANCE

Polyvance.com

This trolley-mounted 60-31878 Nitro 110v plastic welding tool from Arslan Automotive is designed to be an all-in-one plastic repair tool. With an included hot stapler, smoothing tip and a plastic parts cleaning cutter, the device also comes equipped with a metal roller engineered to make precise plastic surface leveling swift and simple. Pre-cut inside corner staples and two sizes of wave staples are available for the hot staple. Arslan Automotive is headquartered in Pointe Clare, Quebec. The company holds training clinics frequently and the sales team are well trained to train and demonstrate all related equipment.

HSM250 Double-Pulse MIG Welding System

H&S AUTOSHOT

hsautoshot.com The 8002 and 8003 Nitro-Fuzer Nitrogen Plastic Welders incorporate a straightforward analog nitrogen welder with a traditional airless plastic welder allowing technicians to make nitrogen welds economically to almost any automotive plastic. The main difference between the two machines being that the 8003 is a single gas system (air or nitrogen) and includes a nitrogen generator whereas the 8002 model doesn’t include the generator but is dual gas (air and nitrogen). Benefits include speed, versatility, ease of use and cost savings.

PipeFab Ready-Pak K3734-1

LINCOLN ELECTRIC

Lincolnelectric.com

The HSM250 Double-Pulse MIG System is compact, offers three MIG wire feed and torch drives with 28 synergic, synergic single-pulse or synergic double-pulse programs for steel, aluminum and silicone bronze welding. The system also features twin cylinder racks and dual gas inputs for mixed and 100 per cent gases, along with 250 amps of power, making it capable of welding all steel and aluminum alloys from #20GA to ½”. Th e PipeFab Ready-Pak K3734-1 features breakthrough arc performance from the root, to cap to fi nal fi t. Th e company’s new welder also uses digital navigation technology for unmatched simplicity, and its customer-driven design is hugely helpful when it comes to pipe and vessel fabrication. Backed by Lincoln Electric’s customer support, the PipeFab Ready-Pak uses one-button process changes and straightforward, easy navigation for all your fabrication needs.

60-3680 TECNA Automatic Smart Inverter Resistance Spot Welder

ARSLAN AUTOMOTIVE

arslanauto.com PR-205MV Synergic MIG Welder

PROSPOT

prospot.com

The TECNA Automatic Smart Inverter Resistance Spot Welder from Arslan Automotive can recognize types and thicknesses of metals and set all parameters automatically. The tool features a water-cooled transformer gun to help optimize your productivity and increase duty cycle. Plus, a support arm with balancer helps for safe and comfortable operation. A new touch screen with intuitive graphic design lets you choose between Automatic Smart+,Quick and Full modes, while an ergonomic, compact and stable cart allows for easy transportation throughout the facility. Also, Wi-Fi, enabled for factory updates and diagnostics. Suitable for MIG/MAG, MMA + TIG welding processes this new compact, lightweight microprocessor-controlled welding inverter from ProSpot gives the operator complete control in manual mode or automatically adjusts in synergic mode. With a light and versatile design, inverter technology and the ability to be used with a power generator the PR-205MV is the right fit for veteran and novice users alike.

Gyspot PTI Evolution

GYS WELDING

gys-welding.com Multimatic 235 Multiprocess Welder - 240V

MILLER WELDS

www.millerwelds.com MultiMig 621

CHIEF AUTOMOTIVE

chieftechnology.com

Featuring a clamping force of 550daN with 8bars air pressure, not to mention a welding current that can reach 14,500Amps the Gyspot PTI Evolution is the ideal answer to welding high-strength steels. This machine brings a solution to limited power supply issues as it’s able to operate with 32 Amps to 40 Amps fuses only, while also integrating a high-tech transformer from its C clamp and an automatic welding parameter setting makes operation a breeze. The Multimatic 235 Multiprocess Welder was built for efficiency no matter your skill level, whether you’re using MIG, flux-cored, stick or DC TIG welding methods. With quick and easy setup and Auto-Set Elite, this new welder provides ease of use allowing welders for a faster uptime and the ability to weld confidently. The consumer-friendly interface and total weight of 63 lbs make this machine easy to use anywhere. Chief’s fi rst three-phase, high-amperage model MultiMig 621 features a double pulse element that allows the weld to cool slightly during the low-frequency operation, great when welding vertically or overhead. Loaded with a large number of synergic programs that allow for welding parameters to be preset and various programmable options such as crater fi ll and hot start the MultiMig 621 can be used to weld and braze aluminum, galvanized sheet metal, stainless steel and high-strength steel.

6225 Tab Magic Molding Putty

POLYVANCE

Polyvance.com CTR-7

CAR-O-LINER

Car-O-Liner.com

The new Tab Magic Molding Putty from Polyvance is a two-part moldable, flexible silicone rubber that is non-toxic and temperature resistant. Mix equal parts until a uniform green color is achieved, then quickly press onto the headlight tab where it needs to be welded. The rubber will cure in about 15 minutes and tightly support the fine details on the top of the headlight tab while you weld the backside with your Polyvance nitrogen plastic welder. When finished, peel off the flexible Tab Magic putty to reveal a nearly finished tab that should just need minor work to finish. Although Tab Magic Molding Putty is not remoldable, it is reusable on the same type of headlight tab. e Car-O-Liner® CTR®7 resistance spot welder provides quality spot welds with new high-strength steels using cutting-edge inverter technology. In addition to a wide range of accessories and sophisticated so ware with semi-automatic control features, Car-O-Liner says the CTR®7 meets current OEM requirements and also comes with pre-installed OEM-specifi c Honda welding presets. A lightweight and adjustable design allows for ample vertical fl exibility, and a sharp, 18-centimetre (7-inch) colour screen presents clear navigation for quickly setting weld parameters.

Is your plastic welder gathering dust?

The experts at Polyvance® can help. TRAINING • SUPPLIES • TOOLS • FILLERS • PRIMERS • EVERYTHING FOR PLASTIC

Call us at 800-633-3047 or visit polyvance.com

ENLIGHTENING LIGHTS

HIGHWAY THRU HELL’S AL QUIRING AND J.W. SPEAKER TEAM-UP ON ROADSIDE SAFETY

BY GIDEON SCANLON

If there’s one thing Al Quiring really wants to see his fellow towing professionals do, it is to take their personal safety more seriously.

In fact, when asked what advice he would share with ambitious young people in the towing sector looking to build-up their businesses would be, he says: “Pay attention to what is coming down the road, and make sure it pays attention to you.”

It is good advice. Being struck by a fast-moving vehicle during a roadside operation will end a career far more quickly than any particular business decision.

The Highway Thru Hell star, whose profile on the show has increased significantly in its more recent episodes, has teamed up with U.S. manufacturer J.W. Speaker in order to promote his message—and to promote the company’s own lighting solutions.

It is difficult to imagine a more charming pitchman. Even when promoting J.W. Speaker’s products, Quiring seems absolutely sincere.

“The SmartHeat, is the cat’s meow for keeping the lens clear. I use the Model 8800 SmartHeat Headlights.” explains Quiring. “What is most important to me is that the SmartHeat lets drivers working in adverse road conditions spend less time outside of their cabs, where it is dangerous.”

That’s not to say he doesn’t know his stuff. Even when taken by surprise by a question about the advantages of the SmartHeat lenses over halogens, Quiring doesn’t miss a beat.

“A halogen light generates a lot of heat— most of which is directed inside, not onto the lens. That makes them a big power draw. With my lights, the SmartHeat technology is incorporated into the LED light itself. There’s also a grid pattern on the front, which means nothing is going to stop them from beaming clear down the highway.”

The veteran road warrior, however, can only be held back for so long.

“Look, whether it is a kid chasing a ball, or a herd of wood bison, I don’t want my truck hitting it,” Quiring says. “I could pay $15 for bulbs, but the investment is worth it.”

It is clear J.W. Speaker has no interest in reducing Quiring’s famously frank style into a bunch of agency-approved soundbites. In fact, long before he was a celebrity, J.W. Speaker had sought out Quiring’s input on product performance.

“I wasn’t featured on the show too much until one episode, when I did something all of the crew thought I wouldn’t pull-off. I did.”

“In fact, when I caught the director’s eye, it was the first time I’d ever used LED seeing lights, which J.W. Speaker had asked me to try out. By the time I got home, I had a set for my partner, Gord. I couldn’t let him go another mile without them.”

Quiring isn’t the only towing professional who has worked with the manufacturer to ensure the quality of its products. The J.W. Speaker team says it relies on the input of towing professionals and members of the other industries it creates products for, in order to make sure it is meeting the market’s needs.

“For towing and a lot of our other markets, we get out in the field. We identify what problems towing professionals, agricultural workers, mining engineers – are having, and then we apply our technologies to finding solutions. The SmartHeat itself was originally designed for forklifts,” says Gary Durian, engineering director at J.W. Speaker.

Durian also says that the company’s relationship with industry members means it sometimes receives its best ideas from tow operators without even asking.

“We are very proud of how many ideas come to us directly from industry professionals. They reach out to our customer care folks on a daily basis,” says Durian. “Recently, we were asked if it would be possible to come up with a light that shifts between white and amber, depending on a driver’s needs. It was simple to do, but it hadn’t been done before!”

That idea led to the design of the Model 234 Flash LED Tail Lights with SmartHeat. The taillights are also available in five different colour options: amber, blue, green, red and clear with programmable strobe patterns.

The technology is exciting to Quiring, who had not heard of the colour-changing system, and the pair immediately begin bouncing application ideas off each other, and discussing emergency lighting conventions in different parts of the world.

While the pair may have moved past their speaking notes, the exchange makes it clear why Quiring is the perfect person to pitch J.W. Speaker’s products. He shares the company’s passion for industrial lighting. He wants everyone to be as passionate about it as well.

As he puts it, “We operate in avalanche zones, flood zones and–generally—in bad driver zones. You have to think about your lighting. You’ve got to check it, and adapt it if you want to get home.”

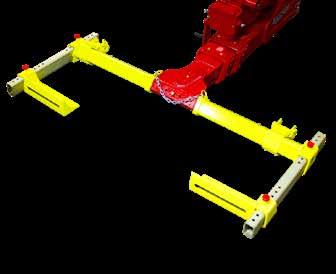

HTL 4000 Sneeker Wheel Lift

SNEEKER LIFT

sneekerlift.com Stealth Unit

DYNAMIC TOW

dynamictow.com

Named for its subtle look, the Sneaker Wheel Lift is capable of lifting 1,550 kg (3,500 lbs) when fully extended, and has a 3,400 kg (7,800 lbs) tow rating. It has an engine-mounted, belt-driven clutch pump kit, a 12-volt electric hydraulic pump, and an air suspension kit. The Sneeker’s fully extendable stage stinger allows for retraction to go from one bumper to another. The three functions of the hydraulic system allow operators to perform labour-free wheel hook-ups. It is operated by a wireless radio signal remote.

Heavy Duty Wheel-Lift

ZACK LIFT

zacklift.com The hauler Body Stealth is ideal for light-duty towing with underbody mounting, in-cab controls, and removable jaws. The unit has a hydraulic underbody wheel lift, making it ideal for dual rear wheel pickups. It lays flat on the ground for a low clearance hookup. The unit features in-cab controls, two toolboxes, three storage boxes, ratchets, straps, safety chains, tire spacer blocks and a tow light plug. Options include a remote camera, a clutch pump kit and frame support upgrades.

Forklift Wrecker by Minute Man Wheel Lifts

MINUTE MAN WHEEL LIFTS

minuteman1.com

Want to build a lift based on your specific needs? Zack Lift provides ruggedly constructed lifts designed to be as customizable as possible. Options include wireless remotes with rechargeable batteries and six or eight function winches. If a non-PTO/pump use is required, a 12V self-contained power system can be subbed. Sometimes, the simplest design is the best. Designed with ease-of-use in mind, the Forklift Wrecker allows operators to quickly lift vehicles with a forklift. With no additional hydraulics required, the Forklift Wrecker immediately transforms a forklift into a vehicle lifter that secures itself around immobile vehicles in minutes.

THE ARSLAN AUTOMOTIVE WAY

YOUR SOURCE FOR OEM APPROVED EQUIPMENT

In 2019, Arslan Automotive had its most successful year yet—and COVID-19 has certainly not stopped the company from fulfilling their vision of success for this year.

Arslan Automotive has become a staple name in collision repair due to the professional quality and reliability of its welding and 3D measuring equipment brands, which have become well-recognized in Canada among collision repair professionals.

The company is best known for its welding equipment, including popular models FIMER Inverter MIG-MAG Pulse welders and the TECNA Smart/Smart Plus Inverter Spot Welders, both of which have captured a respective slice of the Canadian market.

Arslan Automotive also offers Accuvision-3D, a 3-D measuring system developed by Arslan Automotive Canada and assembled in Montreal—which has turned into a great success for the Canadian auto market. The company states that the 10-AV700 3D measuring system is the “quickest, simplest and most accurate” 3D measuring system in the world.

Since the 3D measuring system was first introduced in 2017, it has received a tremendous positive reaction from body shops across Canada. Its ease of use, simplicity, accuracy and moderate price has attracted many users even among some shop owners that had already purchased other systems from competitors.

In 2019 two new additional features were added to the Accuvision3D; the first, a wheel alignment diagnostic feature to its software, allowing all past users access to download the additional feature from the Accuvision-3D.com website at no additional charge. The second added feature is the new infrared camera and pointer systems using IR LEDs. This new system allows users to operate the system camera under direct sunlight without affecting the camera’s reception of the LEDIR signals from the handheld pointer. As the Accuvision-3D needs no calibrations nor a flat level surface for the vehicle to be measured on, this feature even allows for vehicles to be measured outdoors.

As for Arslan’s OEM certifications, company founder Arman Guararslan says its welders are certified by all major OEMs—a huge plus for modern shops seeking automaker approvals.

Guararslan says how this year has been different due to the pandemic, yet his sales continued at a steady rate. He believes this is because more people are looking to drive their own car instead of taking public transit, causing an influx of new consumers.

The company is happy to confirm that it has been able to appoint and train sales agents and distributors covering 75 percent of the U.S. market, and says it is also interested in expanding more into the European market.

Arman’s greatest lesson for the industry is to listen to feedback and keep on improving what it is you do and how you do it.

“Thank you to all our valued partners in making our brands a success.”

ARSLAN AUTOMOTIVE 84 Avenue Leacock Pointe-Clare, Quebec H9R 1H1 (800) 465-8575

SOLERA’S QAPTER SOFTWARE GETS UPDATE, COLLAB WITH GOOGLE CLOUD

Qapter™, the new end-to-end automotive claims workflow from Solera Holdings, Inc., streamlines the claims process by offering the most robust enhancements catalog for body shops that need more than just collision estimating. Qapter™ is optimized for mobility in the shop and enables multi-browser support in a real-time, modern interface, providing the right data for faster, seamless repairs the first time, every time.

As they continue to look into the future of claims management through digital transformation, Solera recently embarked on a collaboration with Google’s Cloud team for improved infrastructure. Using Google Cloud, Solera created a Qapter™ software update that allows the program to scale globally, driving speed and savings in automotive claims management. The app is expected to launch on the world stage in the upcoming months.

Solera is able to tap into more than 40 years of historical vehicle and claims data thanks to our proven Repair Science™ algorithm which is more robust and complex than our competition’s and capable of more precise and accurate estimates provided quickly, consistently, and at scale.

Evan Davies, Solera’s CTO, spoke to the company’s use of proprietary AI technology in developing Qapter™.

“We have a significant number of proprietary AI algorithms we are continuously enhancing to increase value to our customers,” he said. “Google Cloud’s ecosystem has saved substantial time for our developers, allowing us to develop numerous integrations and continued investments in new tools and capabilities that support Solera’s iterative and ongoing enhancements.”

To stay up to date with future enhancements, please follow us on our digital channels or visit audatex.ca.

SOLERA | AUDATEX audatex.ca/qapterupgrade/

THE ADDED BENEFITS OF INTEGRATED CAR PART PRO

As technology continues to evolve, we as an industry need to evolve together and embrace the opportunities that are upon us. Car-Part.com integrated software solutions are designed to help users be ready for what lies ahead.

In last year’s Buyer Guide, some of Car-Part Pro’s newest features were highlighted such as more recycled part options and better integration with the collision industry as a result of a new Car-Part Interchange version. This year, Car-Part.com’s CEO Jeff Schroder has more exciting news to share including an automated assembly enhancement and new analytics features.

The Car Part Pro Marketplace provides over 750 Canadian tiered alternative part provider locations and their customers with a common platform. More than a recycling database, Car Part Pro is an online auto parts marketplace for insurers, repairers and independent appraisers that provides access to 200 million parts across North America. Car-Part’s integrated Car Part Pro (iPro) is a one-of-a-kind open parts marketplace designed to meet the collision repair industry’s increasing needs for alternative parts and supply chain solutions with real time delivery information. iPro integrates with all major estimating systems to allow a one-click launch of the Car Part Pro marketplace from an estimate. iPro has an optimized assembly workflow, identifying component parts on an estimate and mapping them to recycled replacement part assemblies to bridge the gap between components and recycled assembly parts.

How it works: iPro automatically associates the correct components with an assembly when an assembly, such as a front bumper and front door assembly, is chosen in iPro. Components are only auto associated when they are included on the assembly and correct for the estimated vehicle based on the interchange number of the assembly.

Recently introduced, Car-Part Interchange Plus (CPI+) is another enhancement embedded in the Pro search which increases the availability of recycled part types for hard-to-find parts. CPI+ enhances interchange for 100-part types not available with standard interchange including engine parts, interior parts, and body parts, and includes additional interchange for later model Mitsubishi and Mazda vehicles. “WE ARE EXCITED TO ANNOUNCE THE NEW AUTOMATED ASSEMBLY FEATURE AND EXPANDED PART COUNT ANALYTICS. THESE NEW ENHANCEMENTS WILL ENABLE USERS TO NOT ONLY INCREASE EFFICIENCY WITH MORE INTEGRATION AND PART OPPORTUNITY BUT ALSO SEE THE RESULTS ON ESTIMATES, EMPOWERING THEM TO DO MORE.” — JEFF SCHRODER, CEO OF CAR-PART.COM

IPRO ANALYTICS ENHANCEMENT

iPro analytics, powered by Tableau®, provides detailed reporting for MSOs and Banner Organizations including: • Percentage of part types on the estimate • Reporting and management hierarchy • Filtering by claim number, part type, shop, and estimator

At the request of insurers, part count per claim (by part type) now accompanies the part dollar analytics to help with industry trends analysis.

CAR-PART.COM 859-344-1925 http://Products.Car-Part.com

CANADA’S NEW CAR DEALER COLLISION REPAIR NETWORK

BRINGING THE BODY SHOP TO THE SHOWROOM

Craig Kirby – CCS Sandy Liguori – CCS and Woodchester Collision Chris Chinn – CCS Mike Beier – CCS Curtis Bennett – CCS Tom Langton – CCS and Consolidated Dealers

“Sometimes you have to look in the rear-view mirror just to realize how far you have come,” says Sandy Liguori, President of Consolidated Collision Services and Woodchester Collision Centre in Mississauga. Liguori has the unique vantage point of being both a new car dealer and someone who first began his career in the collision repair industry. Consequently, Liguori witnessed firsthand the numerous struggles and challenges among fellow dealership collision centres in the market.

“For years the challenge for dealer collision centres has been how to improve customer retention and profitability in an increasingly competitive marketplace, while delivering an OE Dealership level of customer experience,” says Liguori.

Who would better understand what dealers want and need? Thus, the CCS network was born in 2013 to develop and deliver collision repair solutions and support services exclusively for car dealers who want to grow their collision centres and compete on a national level for insurance partnerships.

With a distinct focus on enhancing customer retention, increasing shop performance, and cars to the door from insurance partners, CCS has been helping dealerships grow their collision business from the ground up. “The key to success is having your collision centre be top of mind with your customers before they are involved in a collision,” says Mike Beier, CCS General Manager, “bringing the collision centre to the show room, and being the one-stop automotive destination for all of your customers”.

Our members tell our story best, Chris Laking, owner and president of Laking Toyota, Northern Nissan and Imperil Collision in Sudbury, Ontario noted that “CCS has been a vital partner in the growth of our business. From providing management tools, to hosting meetings with like-minded repair shops, CCS is a key partner in the growth and evolution of our successful collision repair business. The ability to share ideas on how to run our business and not be directed, makes CCS a unique partnership”.

Steve Billings, Director of Body Shop Operations for the Kaizen Group of Dealers in the Alberta market cited “As an original Alberta member joining CCS in 2015 the three Kaizen collision centres have experienced a steady increase in our insurance referrals. The CCS team with their industry knowledge are a great resource for my collision centre managers and front office staff, they share best practices that help my teams to be more productive.”

Corrado Olindo, Collision Centre manager at Highland Chevrolet Cadillac in Aurora, Ontario says “In the past, we felt that as a dealer we had to chase business for our body shop. Today, by implementing key CCS initiatives, Highland has elevated their game to compete not only at the dealership level but with the largest players in the industry while achieving record levels of customer retention, personnel development, and profitable growth. “ CCS has now grown to over 75 collision centres representing over 180 new car dealers throughout Ontario, Alberta, Nova Scotia and Manitoba with a combined annual collision revenue of more than $200 million. The networks members include some of the largest and most successful dealer collision centre operations in Canada.

MY CAR…MY DEALER…MY CHOICE.

CONSOLIDATED COLLISION SERVICES 441 Hanlan Rd. Woodbridge, ON L4L 3T1 289-795-9955

AIDER À ÉLIMINER LE STRESS DE LA RÉPARATION DES COLLISIONS HELPING TO TAKE THE STRESS OUT OF COLLISION REPAIR

La source de nouvelles, d’analyses et d’informations sur la carrosserie la plus populaire au Québec

The source of news, analysis and information about Quebec’s most popular bodywork

Suivez Collision Québec. Visitez ou abonnez-vous à collisionquebec.com dès aujourd’hui!

PAINT, BODY SUPPLY AND BEYOND NAPA/CMAX—YOUR SOURCE FOR ALL THINGS AUTOMOTIVE

With its nearly 95-year history in the Canadian automotive landscape, UAP, doing business as NAPA and NAPA/CMAX, has quite the reputation as the only distributor providing paint and body supply products from coast to coast.

NAPA/CMAX has more technical reps than ever before—meaning wherever you are in Canada, a representative is ready to assist you in finding exactly what you need. From scanners and car benches to welders, paint and so much more; NAPA/CMAX is prepared to connect you with your product solution, whatever your needs may be.

This year, NAPA/CMAX say one of its hottest products has been the electronic inventory control systems, which allows bodyshops to control and track their material consumption.

When it comes to tracking paint, the electronic inventory control system from Axalta can track by the gram, ensuring that you never take more paint than necessary for any job. Furthermore, the system integrates the paint mix directly into the repair order, allowing you to add the exact amount of paint used to the bill, and—If you’re using the Mitchell interface, that information will automatically go into the Mitchell system. “HERE AT NAPA/CMAX, WE PARTNER WITH COLLISION CENTRES—WE ARE MORE THAN A SUPPLIER.”

“We’ve been able to accurately gauge inventory values in collision centres using this tool and, in some markets, we’ve even been able to accelerate delivery of products to once a day to centres within a short distance,” said Keith Tuttosi, national director for paint and bodyshop major accounts for NAPA/CMAX.

NAPA/CMAX handles much more than just paint and body—the company offers nearly every tool an automotive repairer needs in their arsenal.

“We can get you enough products for you to build a car, aside from the tires, windshield, glass, and frame—we can pretty much source everything else,” said Tuttosi.

“Here at NAPA/CMAX, we are very happy to partner with collision centres; we want to be a partner, not just a supplier.”

For more information on NAPA/CMAX, visit NAPACanada.com.

NAPA | CMAX napacanada.com

IT’S THE JOURNEY, NOT THE DESTINATION

GARD-X AUTOMOTIVE REFINISH’S LONG-TERM COMMITMENT TO IMPROVEMENT

After more than 25 years in the PBE paint distribution business, one of the key lessons learned is that it is the journey as the destination keeps changing. Regardless of wins and successes or losses and disappointments—so long as the journey remains a blast, you rock on. For Eric Chan, the owner of Gard-X Automotive Refinish Inc., the key to enjoying the journey is having a fantastic crew and staff and a close human relationship with clients and vendor suppliers. It is an understatement to say there has been dramatic change in the collision repair industry in the last 10 or so years. Despite many challenges and consolidation of both collision repair facilities and distributor/suppliers, Gard-X Automotive has remained independently owned and operated and continues to enjoy steady growth.

With two locations, one in Scarborough and the other in Mississauga, Gard-X Automotive services the key southern Ontario corridor from Hamilton to the GTA and east to Port Hope. Being authorized distributors of the PPG and Akzo Nobel refinish paint brands, Gard-X Automotive has premium products to service and supply automotive collision repair, fleet and commercial and industrial finishing. Carrying both PPG and Akzo Nobel has allowed Gard-X Automotive to not only offer two of the most premium high quality refinish paint lines but also the best services support programs that include both product technical training and business development programs.

Strong vendor/supplier relationships have always been a key strategy for Gard-X Automotive. In 2019 Gard-X can still offer the promise “Satisfaction Guaranteed or a Credit Note will be issued”. Being loyal and having a good relationship with our vendors means having our clients backs as we know our vendors have ours.

With technology and “smart” being the buzz word these days, Gard-X Automotive has been at the forefront of the info revolution. Gard-X Automotive offers multiple technology pathways to streamline the collision shop materials inventory requirements. It has very successful implementations of both the Lean-Tec and Saint Gobain TIM inventory management systems. Both are cloud based software utilizing bar code scanning of material with automatic reordering based on minimum inventory levels while also being fully customizable.

Vehicles have become increasingly sophisticated in every regard from multi-layer colour special effects to multi material construction for weight-saving occupation crash protection and that is not to mention a sensor for just about anything you can think of. Modern vehicles pose a particular challenge to today’s collision repair shops as they need to modernize with new equipment and tooling in order to perform a proper repair and meet certification requirements whether from their banner franchise or OEM dealership. Being regular attendee at international trade shows, Gard-X Automotive has a core staff well versed in the latest collision repair equipment and industry trends and has built up solid relationships with international vendors to get preferential service for its clients.

Gard-X Automotive has been a Uni Select member for over 30 years, an Across Canada member for over 15 years and works closely with CSN, Fix Auto and CARSTAR collision shops. The core client base of Gard-X Automotive however, has always been the independent owner operator many of whom Gard-X Automotive has had the pleasure of servicing for more than 25 years. The journey has truly been a memorable adventure with all of them. As long as you can still enjoy the relationships, the journey continues.

GARD-X 9 Golden Gate Ct. Scarborough, ON M1P 3A4, 7050 Bramalea Rd. Unit 20 Mississauga, ON L5S 1T1 416-656-0663

NEW DIGITAL FEATURES FROM IMPACT AUTO AUCTIONS CANADA

Impact Auto Auctions Canada provides the advantage in salvage auto auctions, with its digital auction model giving buyers more access across North America’s broadest salvage auction facility footprint, broad product selection and exceptional customer service.

The global IAA (Insurance Auto Auctions) name boasts more than 170 corporate-owned facilities across the United States, Canada and the UK. A subsidiary of the global brand, Impact Auto Auctions Canada provides vehicle suppliers and buyers with powerful solutions to process and sell insurance total loss, recovered theft, fleet lease, donation and rental vehicles.

online bidding and buying decisions. Merchandising tools and features provide buyers with an unmatched research process, improved purchasing guidance and greater trust.

With its global reach, Impact attracts buyers across the globe. To learn

more about the company, visit impactauto.ca.

Earlier this year the company launched Impact 360 View, which allows buyers to virtually inspect vehicle parts, components and damage through images and video. Most recently, Impact enhanced the 360 view program to include the Feature Tour tool, which allows buyers to identify value-added features and options present on each listed vehicle.

Impact Auto Auctions Canada provides the advantage in salvage auto auctions with its digital auction model across North America’s broadest salvage auction facility footprint, broad product selection and exceptional customer service.

IMPACT AUTO AUCTIONS www.impactauto.ca

GET STUCK IN THE MAGIC OF GLUE PULL REPAIR (GPR)

They aren’t magic—but if you saw the types of repairs Keco Body Repair Products are capable of, you wouldn’t be surprised if they were.

Drawing on over 50 years of manufacturing experience and 10+ years manufacturing tools for paintless dent repair business (PDR), Keco Body Repair Products of Oklahoma City has been leading the aftermarket as a developer of high-quality tabs, tools and accessories. [Keco Body Repair Products] are all centred around glue pull repair. The least invasive, highest quality way to repair a dent today; doesn’t damage the front side of the panel or the backside of the panel. “Our line handles big damage and small damage. From big, aggressive dent damage, down to very fine, precision detail-type PDR damage removal,” said Chris White, president of Keco Body Repair Products.

White and his team at Keco take an almost holistic approach to the practice of glue pull repair, co-opting the Hippocratic Oath taken by doctors.

“Doctors, before they begin practising, they have to take what is called the Hippocratic Oath. The Hippocratic Oath says, first: do no harm. So that’s basically the truth of glue pull repair—we’re doing no harm as we begin to make the repair,” said White.

Keco Body Repair Products uses high-quality materials in their products to ensure absolute safety and precision for both the operator and the repair itself.

“With our tools, both the GPR tools and the tools to address the high spots; all of our various shapes and sizes of hammers and knockdowns are all either highly polished metal that won’t damage paint, or they are plastic-coated. Everything that we address, either a dent or a high-spot, doesn’t do harm,” said White.

Mastering the art of GPR is not done overnight, however, White and his team continue to develop new and less-invasive repair solutions for customers.

“There is no question that we have the most expansive line of gluepull repair products and you’d look at us and think, ‘gosh they’ve done everything.’ The truth is, we’re still learning every day how to make GPR more successful,” said White.

“We have, in the last couple of years, developed a line of patentpending tabs that we call Dead Center. Dead Center technology is basic: by varying the ratio between the diameter of the tab neck to the tab face, it creates a much better centre pull, it’ll bottom the dent out better and it’s much easier to knock down. Those Dead Center tabs— we started out with round ones and then we developed a creased version. Now we have a Dead Center SuperTab that we’re getting ready to release. SuperTabs are one of our oldest, big-damage-addressing tabs. We’ve added the Dead Center technology to that line.”

The Keco K-Beam is the ideal pulling tool to use for controlled, double-action glue pulls on large damage.

“DOCTORS, BEFORE THEY BEGIN PRACTICING, THEY HAVE TO TAKE WHAT IS CALLED THE HIPPOCRATIC OATH. THE HIPPOCRATIC OATH SAYS, FIRST: DO NO HARM. SO THAT’S BASICALLY THE TRUTH OF GLUE PULL REPAIR—WE’RE DOING NO HARM AS WE BEGIN TO MAKE THE REPAIR.” – CHRIS WHITE, PRESIDENT OF KECOTABS

The Keco Robo Lifter is the foundation of the entire system and provides precision and finesse for small to medium size damage.

KECO BODY REPAIR PRODUCTS www.kecotabs.ca

PRO SPOT ON POINT COMMITMENT TO INNOVATION FUELS PRO SPOT’S SUCCESS

In 2018, Pro Spot opened its new Education and Training Center in Carlsbad with classroom and full demonstration areas.

From its early work with Ford on the all-aluminum Ford F-150 to the futuristic i4s Spot welder with a myriad of features not seen before, Pro Spot leads the industry in providing new and timely products and services to the collision industry.

Based in Carlsbad, CA, Pro Spot celebrated its 30-year anniversary in 2018. Starting as a small, 139 sq. m. (1,500 sq. ft.) manufacturing facility in neighbouring Escondido, Pro Spot has continually expanded and now boasts a 6,500 sq. m. (70,000 sq. ft.) location housing manufacturing, R & D, engineering, education center, materials testing lab and head office sales, marketing and customer service.

Led by founder, Ron Olsson, Pro Spot services the collision industry worldwide with additional offices, warehouse and education facilities in Nashville, Italy, Germany and Sweden. With its extensive distribution network, Pro Spot has the ability to provide on-site training and maintenance service to all of its customers with factory-trained representatives to serve shops needs. “We believe that our purpose as a manufacturer is to provide the right products to the collision repair industry at the right time to help our customers repair vehicles with products that work with the latest OEM materials and processes,” says Olsson. Training and Education Center In 2018, Pro Spot opened its new education and training center in Carlsbad with classroom and full demonstration areas. Pro Spot Director of Training Ryan Swanson provides hands-on technical and sales training to distributors, customers and I-CAR training to industry technicians. Many OEMs have used the facility to test out products for their collision repair programs. Applications Engineering Laboratory In 2019, Pro Spot opened a brand new Materials Testing Lab at its Carlsbad location. This state-of-the-art lab features some of the latest and most advanced testing equipment. Pro Spot now has the ability to work with all of the latest materials being brought out by OEMs to ensure that Pro Spot equipment stays current with the latest materials developments.

Pro Spot Goes Green In 2017, Pro Spot decided to use the massive amounts of sunshine in southern California to good use. The entire roof of the Carlsbad headquarters became one giant solar panel. At more than 1,670 sq. m. (18,000 sq. ft.) it now provides clean renewable solar power directly to the manufacturing operations saving the manufacturing

centre countless dollars.

Factory Technicians put the new i4S Spot Welder through its testing paces before shipment.

PRO SPOT 5932 Sea Otter Place, Carlsbad, CA 92010 1-760-407-1414

Your Cabin Care Professionals 1-833-266-8425

Comprehensive Services Include

Airflow Testing Preventative Maintenance Contracts OEM Replacement Parts Booth / Floor Coatings Lighting Upgrades (LEDs) Compliance Evaluations Burner Services Paint Booth Cleaning Breathing Air Testing Compressed Airline Installations Breathing Air Testing Relocations and Installations Grate Cleaning And Much More

1833 boothclean is the authority on spraybooth maintenance, filters and cleaning. Founded in 2017 this group of cabin care professionals are backed by over 25 years of field experience and are ready to service your painting and HVAC equipment. Industrial, commercial, and automotive preventative maintenance contract available.

RESOURCEFUL, SKILLED AND FOCUSED

RS FINISHING—PARTNER WITH A SUPPLIER YOU TRUST

RS Finishing Systems, Inc is a leading Canadian supplier of custom Spraybooth Solutions and Associated equipment to commercial and industrial clients.

For the past 25 years, RS Finishing has provided equipment, consultation, engineering, installation, project management, turnkey solutions, preventative maintenance, technical troubleshooting and ongoing support to leading firms within Canada.

RS Finishing’s success stems from its “Yes We Can” attitude, providing unique solutions rather than the catalogue style sales approach. With more than 100 years of collective industry experience and a family-run history, the RS Finishing team is there to help you grow.

“We make a point to find what the customer’s end goal is—whether it be adding new technologies to entice new technicians or increasing their workflow—and help them get there,” said Edward Bannister, president of RS Finishing.

The newest addition to the firm has been the introduction of full inhouse 3D design and fabrication equipment for your next project. This allows RS Finishing to bring your project from conception to realization, from the smallest replacement panel or part to a fully custom paint finishing system.

RS Finishing’s fully stocked 743 sq. m. (8,000 sq. ft.) warehouse, located in Aurora, Ontario houses the company’s vast inventory of filters, spare parts, stock and fabricating machinery.

When you partner with RS Finishing, you’re choosing to partner with more than an equipment supplier. The company goes above and beyond to ensure that its clients not only receive top-notch product, but also to provide much-needed support.

RS Finishing distributes equipment for many of your collision repair needs, including: Unoliner frame and tooling, Reglo pneumatic safety axcess platforms, SATA, Devilbiss, Like 90, Pig industries, Airpipe, Freudenberg, Camfil, Rammstein air, and SAS.

Visit rsfinishing.com for more information. “OVER THE YEARS WE HAVE BECOME THE DISTRIBUTORS FOR SOME OF THE MOST RESPECTED NAMES IN COLLISION REPAIR EQUIPMENT, FROM PAINT BOOTHS TO FRAME MACHINES. WE ARE ALWAYS LOOKING FOR THAT PRODUCT THAT WILL IMPROVE PRODUCTION FOR OUR CUSTOMERS.” – RS FINISHING

The newest addition to the firm has been the introduction of full inhouse 3D design and fabrication equipment, allowing you to bring your project from conception to realization, from the smallest replacement panel or part to a fully custom paint finishing system.

RS FINISHING SYSTEMS 145 Industrial Pkwy. Unit #2 Aurora, Ontario L4G 3V5 info@RSFinishing.com 905-881-9768

SATA®Loyalty Program coins & more

SATA®Loyalty Program

1. Download App & register

coins & more 2. Scan QR Code & collect coins 3. Convert into rewards

The App is available in the App Store or Google Play Store

www.sata.com/ca/loyalty-ios

COINS

www.sata.com/ca/loyalty-android

Scan the QR Codes in all our RPS boxes with the SATA Loyalty App, collect coins and convert them into attractive rewards for your bodyshop. Each RPS cup corresponds to one coin!

Further information: www.sata.com/en/loyalty

SATA Canada Inc. 125 Buttermill Avenue Vaughan, ON, L4K 3X5 Office: +1-905-660-1101 Toll-free: +1-844-554-SATA (7282) Fax: +1-905-760-1250 E-mail: contact@sata.ca www.sata.ca

THE SATA STRATEGY EQUIPMENT, TRAINING AND EVERYTHING IN BETWEEN

SATA Canada is headquartered in Vaughan, Ontario.

The facility occupies a total of 1,395 sq. m., including offices, warehouse and training centre. The headquarters also features a service facility with the goal of turning any product around within a 24-hour period.

In January 2020, SATA Canada received approval from the Ontario Ministry of Labour, training and Skills Development to offer an automotive painter apprenticeship program at its in-house training centre.

SATA spray equipment has been available in Canada since the 1980s. When glossy surfaces are of utmost importance, painters swear by SATA. SATA products are designed and manufactured in Germany allowing demanding customers worldwide to obtain the perfect tools, to create perfect finishes.

SATA sets the standard for paint spray guns, cup systems, breathing protection, filter technology and accessories. The company’s close cooperation with painters from various trades and industries as well as its research and development departments with application technicians from the leading paint manufacturers allow us to produce superior products of the highest quality.

“SATA Quality” is a firm conviction for any painter: reliability, durability and ergonomics of their SATA products are not something to be questioned.

The home of the SATA brand is Kornwestheim, a town in the district of Ludwigsburg, Baden-Württemberg, about 10 kilometers north of Stuttgart. SATA is a leading spray gun manufacturer with 276 employees, active in over 100 markets worldwide with 2,436 customers.

SATA has a long history of producing superior products of the highest quality dating back to 1907. The company’s original focus was on medical instruments but began production of spray guns in 1925.

Throughout its history SATA has focused on meeting the demands of new technologies and perfecting its equipment to attain consistency for the industry.

In 2005, SATA pioneered a multi-purpose cup system, SATA RPS (Rapid Preparation System) for the efficient mixing, painting, refilling and storing of paint. Participate in the SATA Loyalty Program and collect coins with every cup. Scan the QR code located on every box of SATA RPS cups, collect points and convert them into attractive rewards for your shop.

SATA continues a tradition of quality and technological leadership with the introduction of the SATA air vision 5000 system for health protection and the SATAjet X 5500 spray gun.

SATA is the first spray gun manufacturer to offer a nozzle system based on two distinct spray fan shapes for each nozzle size. Parallel and oval-shaped. The SATAjet X 5500 provides an incredible wealth of perfect solutions. For all kinds of painters. Using only one spray gun.

SATA Canada has responded to the demands of the worldwide pandemic to create an all in one solution to disinfect automobiles, public transportation and facilities.

The SATA Sanitization Kart combines; spray gun, breathing & filtration equipment, hoses, RPS cups and most importantly, a compressor. An all in one easily transportable solution. The entire package is mounted on a highly maneuverable tri-wheeled dolly that allows the SATA Sanitization Kart to be easily transported up and down stairs.

At SATA, success is an obligation. SATA employees and distribution network will always do their best to be there for you.

The SATA Sanitization Kart, ideal for office, school and automotive environment.

Perfect ergonomic design of SATA 4400 B, flexibility and ease of transport of SATA Sanitization Kart.

SATA CANADA INC. 125 Buttermill Ave.Vaughan, ON, L4K 3X5 Office: +1 905 660 1101 Toll free: +1 844 554 SATA (7282) www.sata.ca

SPANESI, A TIMELESS COLLISION REPAIR TRADITION

MORE THAN 50 YEARS OF PASSION AND INNOVATION

The week before Orazio Spanesi’s 14th birthday, he was approached by a friend with exciting news—there was a job available.

Orazio was enthusiastic because his family lived in the country and they were very poor. So, he rushed over to meet with the business owner. During their conversation, the owner offered Orazio a job in a collision repair business and gave him a bicycle to use to get to work.

The bicycle was too tall. But that didn’t stop Orazio. He learned how to ride the bicycle by putting one of his legs under the crossbar and rode that bicycle to and from work for more than 2 years.

ORAZIO OPENS HIS OWN FACILITY

In the summertime of 1969, Orazio Spanesi opened his own collision repair facility in the village of Padova, Italy. Orazio used tools he created to repair his customer’s vehicles.

“I knew immediately that I had the ability to create equipment,” explained Orazio. “I never did it just for me, but I made it with the idea of selling it.”

While Orazio designed and tested his tools in his own business, he was also curious about what the rest of the world had to offer. He began travelling and visiting the national and international tradeshows, looking for just the right answer to his efficiency needs. Along the way, Orazio came to the realization that those tools didn’t exist, and the market was too slow to adapt to his business’s needs.

SPANESI BEGINS MANUFACTURING EQUIPMENT

Orazio took his passion, intuition and experience to the collision equipment manufacturing industry in 1989 and when he founded his namesake business, Spanesi®, S.p.A. The very first frame straightening bench was manufactured in 1989, along with the Spanesi Universal Jig System. To this date, the original Universal Jig System is still sold and has only had to be updated to accommodate aluminum vehicles.

In 1992, Orazio recognized there had to be a better way of measuring vehicles. So, he set out to show the world how to measure, repair and document damaged vehicles. Designed from the ground up, Spanesi produced their first Touch electronic measuring system.

A young Orazio Spanesi. Orazio took his passion, intuition and experience to the collision equipment manufacturing industry in 1989.

A glimpse inside Spanesi America’s U.S. Training Centre.

ONE BRAND, COMPLETE FOCUS

Spanesi’s vast and deep array of equipment offerings are accepted by most OEM repair programs today.

Spanesi is the only company to offer a complete Spanesi 360o Concept for the collision repair industry. From structural repair benches, threedimensional electronic measuring systems, vacuum systems, prep stations, spray booths, MIG / MAG welders (aluminum, steel and silicon-bronze), squeeze-type resistant spot welders, office furnishings, paintless dent repair systems and facility design services.

Even today, all Spanesi’s products are used in Orazio’s collision repair facility, which is now surrounded by his manufacturing plant in that little village of Padova.

SPANESI AMERICAS, INC. 123 Ambassador Dr. STE 107 Naperville, IL 60140 USA 224 SPANESI | (224) 772-6374

Productivity Building Productivity Building 2K Solutions 2K Solutions

From substrate to final finish, SprayMax 2K products From substrate to final finish, SprayMax 2K products can enhance shop productivity while delivering can enhance shop productivity while delivering premium quality results with an adjustable broad jet premium quality results with an adjustable broad jet nozzle for superior control and transfer efficiency. nozzle for superior control and transfer efficiency. • Easy to use• Easy to use • No cleanup time • No cleanup time • Meets OE specifications • Meets OE specifications • A product for every repair need • A product for every repair need

2K SprayMax Primers and Fillers 2K SprayMax Primers and Fillers set the foundation for durable set the foundation for durable small damage repairs. small damage repairs. Featuring excellent adhesion, Featuring excellent adhesion, smooth flow, and outstanding smooth flow, and outstanding sealing properties.sealing properties. 2K FillClean and 1K FillClean solvent-based 2K FillClean and 1K FillClean solvent-based and water-borne aerosol containers are and water-borne aerosol containers are compatible with all popular manufacturer compatible with all popular manufacturer paint brands – perfect for cut-ins, parts paint brands – perfect for cut-ins, parts and small panel refinishing. The FillClean and small panel refinishing. The FillClean system allows for advanced colour system allows for advanced colour preparation so painting and blending preparation so painting and blending is ready when you are.is ready when you are. 2K Clears and 1K Spot Blender are 2K Clears and 1K Spot Blender are the perfect complement to any the perfect complement to any basecoat application. A full range of basecoat application. A full range of options can match OE clear finishes options can match OE clear finishes while achieving excellent flow and while achieving excellent flow and durability without colour deviation. durability without colour deviation.

Go with the Pros. Go SprayMax. Go with the Pros. Go SprayMax.

www.spraymax.com www.spraymax.com

THE RIGHT CHOICE FOR AEROSOL SOLUTIONS

WHERE SPEED AND PROFITABILITY MEET

Peter Kwasny GmbH based in Gundelsheim, Germany has long been recognized as an industry leader by achieving breakthrough solutions in small damage repair with the SprayMax system. Professional automotive repairers appreciate the process flexibility with both 1K and 2K technology options and how SprayMax can reduce cycle time and add throughput to their operations. In addition to saving time and material costs, they still maintain spray gun-like quality results with this premium aerosol system.

A key advantage of SprayMax is the patented variator nozzle for improved atomization and adjustable control of the spray pattern. To deliver true two-component technology, SprayMax designed a unique can which houses hardener in a separate internal chamber until its needed to activate the primer, paint or clear.

Kwasny works globally with countless OEM paint manufacturers to develop and test new products to solve common repair challenges while ensuring compatibility across technologies. The company takes great pride in being certified by many OEM automobile manufacturers in both the products SprayMax markets and the application techniques it designs.

Over the years the line has grown and now encompasses a wide range of surface preparation, primers, primer fillers, base coats, topcoats, clears and spot blender enabling professional results from substrate to final finish. This flexibility allows for impressive results whether in-booth or on the shop floor with standard air filtration equipment.

To ensure customers get the most out of the SprayMax system, the company has a team of product specialist, technical agents, and distributors who can introduce the line or individual products to get you started. There are also helpful demonstration videos which cover everything from plastic to metal/plastic to in-process repair procedures on both 1K and 2K technologies. Adopting the SprayMax system can transform shop productivity with easy to follow costefficient repair solutions.

You can learn more about SprayMax products by visiting spraymax.com and downloading the product comparison brochure along with product guides for the latest information.

Need a personal follow-up? Just call SprayMax’s Customer Support Line at 1.844.426.6330.

Peter Kwasny GmbH Gundelsheim, Germany Head Quarters and Production Facilities.

A technician repairs a metal fender with SprayMax products.

PETER KWASNY INC. 62-64 Enter Lane, Islandia, NY 11749

PETER KWASNY SPRAYPAINT CANADA INC. 2275 Lake Shore Boulevard, Suite 530, Toronto, ON, M8V 3Y

TITANIUM TOOLS AND EQUIPMENT

SPECIALIZING IN EQUIPMENT FOR OEM CERTIFICATION

Titanium Tools and Equipment Inc was established in 2013, but the history of the owner Matthew Bannister and the connection to the collision repair industry goes back more than 30 years.

In fact, it was the collision industry and his father Richard’s involvement with the Spraybake Spray booth company that brought them from England to Canada in 1986.

Matt has represented Celette, Wielander and Schill and ProSpot for more than 20 years and introduced the famous Miracle System of panel repair to the Canadian market. Titanium also keeps in stock many products from Dent Fix, Induction Innovations, DJS dollies and Flexible paint stands.

The office, warehouse, training center and service center is located just north of Toronto from where the company provides sales and service across Canada.

When you work with Titanium Tools, you can expect quality tools at competitive prices, backed up by good service and support. Buying quality tools is important, but equally important is also the support The Xpress800 rivet gun is Ford, behind them. Mercedes Benz, “At Titanium, years of experience with the same brands means Tesla, GM and JLR certified. we have experience on what goes wrong and keep the spare parts in stock. In many cases we provide loaner machines which gets you going quickly,” said the company. “Our dedicated service person has been WIELANDER AND SCHILL trained in California and Germany and will get you running ASAP.” Wielander works hand in hand at the OEM level to provide specialty repair tools for many of the OEM programs. Its MIG welders, Spot CELETTE welders and Rivet guns are certified for most OEM programs making

Celette is known for its dedicated fixtures and has now released a them a great choice if you are seeking multiple certifications. Further, universal fixture solution called Cameleon, both of which Titanium the Xpress800 rivet gun from Wielander is very well priced and is Tools and Equipment carry. Cameleon is essentially two toolboxes that, Ford, Mercedes Benz, Tesla, GM and JLR certified. with the use of a computer, allow you to build any jig for any vehicle. From the oldest to the newest and future vehicles Cameleon has you covered. New from Celette is the compact and cost-effective Eagle ProSpot is a US manufacturer promeasuring systems. This compact measuring system allows you to ducing a range for quickly document the vehicle before and after repair. Also new from products from spot welders, MIG weldCelette is the Smart Rhone—a drive-on lift-up bench that can be used ers and rivet guns for small repairs with the measuring system right up to heavy damage to dustless sanders and dent pullers. with dedicated jigs or Cameleon universal jig. PROSPOT ProSpot is a US manufacturer producing a range for products from spot welders, MIG welders and rivet guns to dustless sanders and dent pullers. The company still provides spare parts for some of their oldest products, and, thanks to Matt, Titanium says it was one of the first ProSpot distributors in Canada.

Welding programs for: • MIG brazing 0,8-1,0 mm • Aluminium 1,0-1,2 mm • Steel / stainless steel 0,6-1,2 mm • TIG (WIG) • Pulse and double pulse welding 2-cycle & 4-cycle mode including special mode thin metal sheet - ACT for steel welding Cameleon is essentially two toolboxes that, with the use of a computer, allow you to build any jig for any vehicle. This high-quality Miracle panel repair system is made from titanium and aluminum, making it resilient and sure to last more than 20 years, says Titanium Tools and Equipment. MIRACLE SYSTEM

Miracle System is the famous Panel repair system from Japan. This high-quality system is made from titanium and aluminum, making it resilient and sure to last more than 20 years, says Titanium Tools and Equipment. Titanium Tools and Equipment stocks every single nut bolt screw and wheel required to keep this system running forever.

TITANIUM TOOLS & EQUIPMENT 10557 Keele Street, Unit #10 Maple, Ontario, L6a 0j5 Canada 1-647-494-9696

www.titanium22.ca

2021 Buyer’s Guide

ADVERTISER INDEX

COMPANY PAGE

3M Automotive .................................06

Airpro Diagnotics.............................. 85

Arslan Automotive ......................... 100

Audatex | Solera ............................. 102

Autel ...........................................80, 86

BASF ................................................. 04

Cardinal Couriers .............................09

Car-O-Liner .................................... 131

Car-Part.com ................................. 104

CARSTAR Canada ......................... 132

Color Compass .............................. 108

Consolidated Collision Services ... 106

Dent .................................................. 67

Equalizer ........................................... 34

Eurovac ............................................. 41

Finixa ................................................ 57

Flatline .............................................. 23

Fuji Spray ......................................... 12

Gard-X ............................................ 112

Global Finishing Solutions .............. 52

Impact .............................................114

Keco ................................................ 116

Max Flow Maintenance Inc. .......... 126

NAPA/CMAX ................................... 110

Nitroheat .......................................... 48

OPUS................................................. 42

Polyvance .........................................96

PPG Canada .................................... 02

ProSpot .......................................... 118

Rexall ................................................ 37

R.S.F................................................. 16

RS Finishing Systems..................... 120

SATA Canada ................................. 122

Sherwin-Williams .......................50, 59

Spanesi ......................................... 124

Steck .................................................66

Symach ........................................... 54

The Ted Group .................................. 47

Titanium Tools................................. 128

Unoliner ............................................ 24

URG ................................................. 73

Wedge Clamp ................................... 74 ON TO THE NEXT NEW NORMAL? NO PROBLEM

BY ALLISON ROGERS

If you recall, in last year’s Collision Repair Buyer’s Guide, we had cautioned that the 2020s would see the business of collision repair change beyond recognition.

Clearly, we were right.

This year brought far more chaos than anyone could have imagined. Sure, we’d expected the typical fast-paced changes alongside new technologies— but no one could have prepared us for the socially-distanced reality this year had to offer.

Don’t forget that this is only the beginning. There’s still far more to come, and the shift toward electric-powered and autonomous vehicle repairs could sneak up on you the same way 2020 snuck up on the world—should you have your back turned.

Canadian automakers have taken leaps and bounds in recent months to ensure that the nation is part of the new wave of automotive electrification. Quebec recently announced plans to cease the sale of gas-powered vehicles by 2035, while British Columbia plans to only sell zero-emissions vehicles by 2040.

Electrification is coming—fast. Along with it come a myriad of other expectations: new metals, continued OEM standards, consolidation—heck, the Canadian government has even teased wooden automotive parts. The future is upon us, and it’s time to react.

Come 2021, your business will face a choice—will you do whatever it takes to stay alive and thriving, or keel to the pressure of the new normal?

If you’re reading this, you already have your answer. You hold in your hand the very reason to be optimistic about the future of your business. Flip through the information-packed pages of this guide and embark on a path to success and profitability.

With information drawn from the resources of Collision Repair’s 20 years of publication, the 2021 Buyer’s Guide offers the most comprehensive overview of the top-notch products being used in the most forward-thinking collision repair centres. Moreover, the informed conversations with industry leaders, business owners, technicians packed between these pages— along with our daily eZine coverage and digital content—will guide you toward the right choices for you and your business.

Whatever the challenge, the 2021 Buyer’s Guide offers your solutions. This is the key to your business’ future—make sure you flip the ignition.

Allison Rogers is the editor of Collision Repair’s Buyers Guide. She can be reached at allison@mediamatters.ca.

QUICK, EASY & ACCURATE MEASURING FROM TOP TO BOTTOM