Bayer is proud to offer seed varieties that combine the best genetics and most advanced traits in the industry. Every field, crop, and farmer is different; each with their own needs, challenges, and goals. That’s why Bayer is offering farmers tailored solutions – starting with seeds and traits - designed to improve their harvests and make their jobs easier.

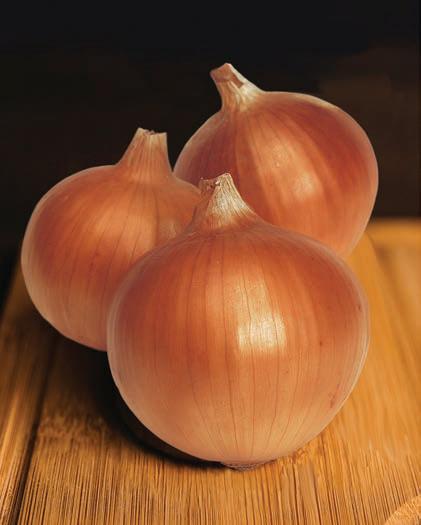

On Tuesday, August 29th, Bayer will be hosting its first ever collaborative event with all its crop science brands. At their Payette, ID Research station, Bayer will invite local growers to explore the family of Bayer brands in a one-stop event for all things agriculture. In the field, plots of Seminis’ portfolio of onions will be joined by Dekalb corn, Westbred wheat and Bayer crop protection products. In addition, Bayer will host ag-tech demos from local industry partners.

Richard Navarrete, local Seminis Technical Sales Representative in the Pacific Northwest, is looking to build upon the success of their 2022 Onion Experience+ event by creating awareness of their other brands. Their goal is to provide local growers with wholistic solutions that best fit their needs for every

planting cycle. Navarrete notes that, “as a farmer, we typically like to stick with what we know works best. With this event, we want to show growers that there could be other products and services out there that can give them an edge to their growing operation.”

Growers will not only learn more about the Seminis onion portfolio and what it has to offer, but they can connect with Bayer’s Crop Protection specialists to learn more about, Velum Prime. This is a nematicide/ fungicide that can be used in combination with Seminis seeds to help with pink root control and thus positively impacting onion yield potential. “We want growers to push the limit and really challenge their day-today growing practices because there could be opportunities left on the table. There are products out there that can help close those gaps.”

For more information on Bayer Experience Field Day event on Tuesday, August 29th, 2023, please contact: Richard Navarrete Technical Sales Representative – PNW 208-317-6451

PO Box 333

Roberts, Idaho 83444

Telephone: (208) 520-6461

Circulation: (503) 724-3581

OnionWorld.net

ONION WORLD CONTACTS

Editor Denise Keller editor@ColumbiaMediaGroup.com

Publisher / Advertising Manager

Dave Alexander dave@ColumbiaMediaGroup.com

Director of Operations

Brian Feist brian@ColumbiaMediaGroup.com

EDITORIAL INFORMATION

Onion World is interested in newsworthy material related to onion production and marketing. Contributions from all segments of the industry are welcome. Submit news releases, new product submissions, stories and photos via email to: editor@ColumbiaMediaGroup.com, or call (509) 697-9436.

ADVERTISING SALES

For information on rates, mechanics, deadlines, list rental, direct mail, inserts or other information, call (208) 520-6461 or email: dave@onionworld.net

SUBSCRIPTIONS

U.S. $24 per year

Canada $40 per year

Foreign $80 per year

Subscribe online at: www.OnionWorld.net/subscribe or call (503) 724-3581.

Email address changes/corrections to brian@ColumbiaMediaGroup.com or mail to: Onion World PO Box 333 Roberts, ID 83444

Onion World magazine (ISSN 0892-578X), is published eight times a year and mailed under a standard rate mailing permit at Idaho Falls, Idaho and at additional mailing offices. Produced by Columbia Media Group PO Box 333, Roberts, ID, 83444. Copyright 2023. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, for any purpose without the express written permission of Columbia Media Group.

For information on reprints call (208) 520-6461.

At Unisorting we are used to taking care of your future with cutting-edge, intelligent and automated solutions able to ensure important and real results over time

With Onions Sort 3 and UNIQ Onions your onions have more value. Nothing is left to chance thanks to an efficient and complete sorting of the qualities: external and internal quality, in addition to weight, optical size and color. Because your business needs certainties. And a bright future.

Enter the world of Unisorting brand of UNITEC. The future of your business will be on the road to success.

Put the future of your onion business on the road to success.

By Heather MacKay and Lindsey du Toit, Washington State University

Christy Hoepting, Cornell Cooperative Extension

By Heather MacKay and Lindsey du Toit, Washington State University

Christy Hoepting, Cornell Cooperative Extension

After completing three years of regional surveys in 12 states for onion bacterial diseases and three years of field trials on management of bacterial diseases in onion crops, the “Stop the Rot” research team is moving into the final phase of documenting the knowledge gained and sharing the information with the onion industry. In addition, the team is planning clear pathways for the knowledge gaps addressed by the project and identifying the most important unknown aspects of onion bacterial diseases on which to follow up after the end of the current USDA Specialty Crops Research Initiative project.

Regional bacterial disease survey work, pathogenicity of the numerous bacterial isolates obtained from onion crops, and management strategies being tested can now be viewed on research posters. Although the project has detected over 100 different genera associated with onion bulb rot, only four or five of those are dominant genera, which vary among different onion growing regions of the U.S. and have varied across growing seasons. Many of the bacterial strains isolated from onions are not pathogenic (i.e., do not cause diseases). See the poster presented at the International Conference on Plant Pathogenic Bacteria, in Assisi, Italy, in July 2022 at www. alliumnet.com/stop-the-rot-publications-and-resources.

Symptoms of bacterial bulb rot are seen in an onion.

A bulb is infected with Pseudomonas aeruginosa.

Photo by Claudia Nischwitz, Utah State University

Symptoms of bacterial bulb rot are seen in an onion.

A bulb is infected with Pseudomonas aeruginosa.

Photo by Claudia Nischwitz, Utah State University

Results on various aspects of managing bacterial diseases of onion, including irrigation, nitrogen fertility, bactericides, cultural practices and postharvest applications of disinfectants, have been published from field trials in multiple states over three seasons in “Plant Disease Management Reports,” and there are more reports to come. Check out the reports at www. alliumnet.com/stop-the-rot-publications-and-resources.

A presentation by Lindsey du Toit, project director for Stop the Rot, during the 2023 Southeast Regional Fruit and Vegetable Conference, provides a snapshot of onion bacterial disease research findings from the project to date. Check it out at www.alliumnet.com/stop-the-rot-publications-andresources.

About 50 percent of the pathogenic strains of Pantoea agglomerans that have been sequenced so far carry genes that confer resistance to copper bactericides, similar to those found in other bacterial plant pathogens. In contrast, these genes have not been found in the Pantoea ananatis strains isolated in the surveys of onion crops and sequenced to date. This might explain some of the differences in effectiveness of copper bactericide treatments evaluated in field trials in participating states across the U.S. For example, copper bactericides generally have proven effective in Georgia, where P. ananatis is prevalent, while bactericides have generally failed in regions where other bacterial pathogens are common. We plan to investigate copper resistance further in Pantoea and other genera of bacteria pathogenic to onion.

In an effort to make the Alliumnet website, home of the Stop the Rot project, readily searchable for growers to find answers to their bacterial rot questions, we are organizing the homepage with questions that might be commonly asked. Answers to these questions are now at www.alliumnet.com/ frequently-asked-questions.

• What causes onion rot?

• Do bactericides work?

• Does neck length at harvest affect bacterial bulb rot?

Answers to these questions will be added:

• How is bacterial bulb rot different from other bulb rots?

• How do onions get infected with bacterial diseases?

• What are the best strategies to control onion bulb rot?

• Does nitrogen application increase bulb rot?

• How relevant is irrigation to causing bulb rot?

• Are any onion varieties resistant to bacterial rot?

• Does mechanical pulling and harvesting affect onion bacterial bulb rot?

• What is the effect of timing of undercutting on bacterial bulb rot?

• What is the effect of rolling the tops prior to harvest on bacterial bulb rot?

• Does treatment of onion bulbs with ozone control bacterial bulb rot?

• Does heated, forced-air curing after harvest control bacterial bulb rot?

Additionally, researchers will be giving updates on the Stop the Rot project over the next year at various onion educational meetings across the U.S.

Please reach out if you have suggestions for extension resources you need, would like more information on the Stop the Rot project or have recommendations for this project.

Proven for use in: Whites, Reds, Golds, Browns, Spanish, Pearl Onions & More

Onion Sizing Video Now Available: www.kerian.com

GENTLE: Separates without damaging onions

ACCURATE: Precisely grades onions of all shapes and varieties

FAST: Thirteen standard models custom-designed to meet your needs sort from 1000 lb/hr to 80,000 lb/hr

SIMPLE: Effective but simple design provides a rugged, low cost, low maintenance machine at a high value to our customers. It can even be used in the field!

“A more gentle way to size your onions quickly and accurately.”

Carlos Bonilla is the new director of the Oregon State University (OSU) Hermiston Agricultural Research and Extension Center (HAREC). As director, Bonilla serves as a leader at the station, provides support to conduct research

and extension, facilitates communication with stakeholders and collaborates with the main OSU campus.

Bonilla hails from Chile, where he gained almost 20 years of faculty experience and worked with many crops

similar to those grown on the West Coast of the U.S. He will use his background in agronomy, hydraulic and environmental engineering, and soil science to work on soil- and water-related issues, mainly focusing on irrigation and soil and water quality.

Bonilla saw the position at the HAREC as an interesting opportunity to use his leadership skills to contribute to research that addresses environmental challenges while helping farmers increase yield.

Looking ahead, Bonilla has four goals for the station. He and his team will work to continue cutting-edge research and science to enhance farmers’ competitiveness, maintain a local and regional focus in research to meet grower needs, effectively communicate the relevance and impact of research and discoveries, and develop dynamically adaptable recommendations.

Onion World caught up with Bonilla to learn more about the new man at the helm of the HAREC.

Tell us something about yourself that people might find surprising.

I like driving a lot, which is required for this position at this station. I know some people hate driving on the highway or freeway. But I like to drive a lot. If you put good music in your car and you have a decent car, I like to drive and see the landscape.

As a child, what did you want to be when you grew up?

I wanted to be an airplane pilot, and another job was some kind of builder. I have a lot of the skills and enjoy working as a carpenter. I love tools and I have a lot of tools. Since I was a kid, I was working right next to my dad all the time. He’s an engineer, but he was very good at building things.

If Hollywood made a movie about your life, who would you like to see cast as you?

I would like to have the brilliance and the attitude that Harrison Ford has in his movies. He’s a good example of a good actor. He played Indiana Jones and was in Star Wars, and they’re very different movies, and he became a different person in a very easy way. That’s interesting because I like when an actor adapts and puts his skills to a new

movie, and that’s something I try to do every day in the way that I talk to people. One of the challenges in this position is one minute you are talking to a farmer, the next minute you can be talking to a politician, the next time you can be talking to a student, and then you are talking to a technician. So you have to adapt in some way to the person you are talking to. It’s not acting, but you need to have the right words to introduce a topic in a very specific way to each of them.

If you had to eat one meal, every day for the rest of your life, what would it be?

A roast beef sandwich, that’s one of my favorites. I will order my standard recipe: a roast beef sandwich with pepper jack, lettuce, tomatoes, green peppers and olives.

What advice do you have for growers competing in today’s market?

Agriculture is something that has been in my family for a while, and I’m very familiar with that and see how hard it is. I couldn’t be arrogant to say I have advice for you guys because farmers know a lot. However, one thing I can say is our purpose is to help in that process, provide them with new technologies, the best practices and the best recommendations for their activities. And they will always find a group of people here ready to help them.

How can something smaller than a grain of rice cause so much damage?

If you’re wondering what I’m referring to, here’s a hint: it’s a pest that is ubiquitous in many crops but causes consistent damage to onions. It’s small, yellowgreen, winged, can reproduce by itself, carries and transmits pathogens, and reduces crop size and quality. Still not sure? It’s thrips!

Thrips impact onion growers around the world and can pose a threat to crop yields. Because thrips are so small, prolific and mobile, control is extremely difficult but extremely important.

Thrips are such a prolific pest due to several physiological traits. First, they have a very short generation time; this is the timeframe from birth to reproduction, and it’s only seven to 14 days (hot weather increases thrips’ time to reproduction). This means that the time between egg hatching and egg laying is about a week. When you consider this timing throughout a season, there can be as many as 20 generations of thrips created in hot and dry growing areas. While numbers more typically range from eight to 10, that’s still a lot of thrips.

Each generation is growing in numbers

and potential resistance to insecticides. And when it comes time for thrips to lay eggs, they either lay them on the surface of the leaf or, at times, can create galls and embed their eggs in the tissue of the plant. Thrips also don’t mind being on their own because they can reproduce with a partner or by themselves, reducing the barriers to increasing populations in the field.

Thrips have rasping mouthparts, and when they feed, they essentially “punch” through the cell walls of the leaf and extract sap from the plant. They then siphon plant contents including chlorophyll. This results in a reduction of photosynthesis, which, in turn, will reduce bulb weight and cause plant stunting. These feedings also result in a broken cell-wall structure, which allows for loss of water and a predisposition to fungal and bacterial pathogens as well as Iris yellow spot virus. Studies have shown as much as a 50 percent reduction in yield due to severe thrips infections in onions, so control is a must to protect a crop.

Insecticides are needed to control these pests and are normally sprayed

anywhere from twice a month to weekly. Unfortunately, these insects have developed resistance to several classes of insecticides due to their high reproduction rate and short generation time. But control is still possible and should be prioritized.

There are new insecticides and control methods that are making thrips control easier. One of these is Averland FC from Vive Crop Protection. This product is a translaminar insecticide/miticide/ nematicide that is great for in-season thrips control. Built with Vive’s patented Allosperse Delivery Technology, Averland FC can be seamlessly mixed with liquid fertilizers, foliar feeds, micronutrients and other crop inputs without causing any tank mix issues for an easy and efficient in-season application. This flexibility allows a grower to easily apply liquid fertilizer, knock down weeds and spray for thrips all at the same time.

In any successful thrips control program, using multiple modes of action is essential. Adding Averland FC to the rotation will allow for better thrips control while also increasing the efficiency of the application.

Agri-Stor Companies helps growers take control of their onion storage with Gellert’s Agri-Star Control Panel. Since 1964, Agri-Stor has designed and sold thousands of Agri-Star panels for a wide range of post-harvest products. Through these years of application experience and university-based research, AgriStor Companies has developed its most user-friendly, advanced control panel yet. Features include a full-color, interactive touchscreen, easy-to-understand programming and internet capabilities with an intuitive app.

Fully adaptable to growers’ onion storages, the Agri-Star panel can handle everything including curing mode, burners, humidity, refrigeration, airflow, temperature, carbon dioxide levels, heat and lights. When growers match the AgriStar panel with Gellert’s climate control equipment, their onions are wrapped in the perfect climate, extending their life and quality.

The newest onion bagger from edp, model EB-2218-DF, is the most accurate and highest capacity bagger built by edp Australia. This machine will accommodate most any open-mouth bag on the standard 9-inch bag holder. Most customers in the U.S. use this machine for a range of bags from 20 pounds to 50 pounds.

Also available is the ability to fill cartons or crates with the optional cartonfilling attachments. Speed control of both feed belts, pneumatic bag clamps, batch counters and monitoring of weight averages are among the standard features on the EB-2218-DF.

The Kerian Speed Sizer sorts onions by size quickly, accurately and gently. The constantly rotating rollers help the turning flaps align the onions with the rollers so that they are consistently sorted by size. The Kerian Speed Sizer is proven in use for whites, reds, golds, browns, Spanish, pearl and many other varieties of onions.

Lee Shuknecht & Sons, Inc.’s SP-132 is a self-propelled twobed harvester that eliminates windrowing while simultaneously direct loading two beds, for a total production width of 132 inches using 47-inch chains. This low-maintenance mechanical harvester provides the highest percentage topping of green and/or dry onions of all Shuknecht’s onion harvesters while it harvests two to three tons per minute. Powered by a standard 190-hp Cummins engine, the solo operator seated in an air conditioned cab has complete control over blower speed, primary and rear elevator speeds, cutter bar speed and height and ground speed. The twobed harvester features a 4-foot high-capacity boom and easily controlled front pickup elevators with spring-assist floats.

Available options include a moveable 4- or 5-foot dipper, rotating cab, stainless blower housing liners and a 240-hp engine. Digital readouts for the blower, primary chain and ground speed can be included, as well as hydraulic adjustment front elevator gauge wheels. Ground sync primary chain control, a posi-traction fourwheel-drive system and hydraulic trash chain drive can all be built into the SP-132.

The company also custom manufactures pull-behind models with the same quality and topping system to accommodate smaller onion growers.

CROSSOVERS/WINDROWERS

2018 Allan 6 row

2015 Double L 6560 6 row 2009 Double L 951 4row

SIZER ONLY

1998 Spudnik Model 910 72” acorn rolls 230 volt 3phase, spring adjustable

MISC.

Ace Roll over Hyd. Reset Plow 5 bottom

1998 Milestone 36”x 48’

1987 Spudnik 550 30” x 48’

SCOOPERS

1990 Spudnik 100 24” 3ph

1982 Spudnik 100 24” 3ph

TRUCKS

1995 Ford LTL9000 CAT- 3176, 13 spd, Chalmers susp., 318,000 miles, 1995 Spudnik 2100 22’ bed Combo, New Paint

1982 IH 2500 Cummins NTC300, Auto Trans., Hendrickson Susp., 325,000 miles 1991 Spudnik 2100 22’ bed Combo, New Paint

2004 Kenworth W900 M11 Cum 350hp 15 speed Tran. Spudnik 26’ bed

1997 Peterbilt 377 Cummins diesel, 18spd 20’ bed frame

BULK BEDS/BOXES/SELF

UNLOADING

1991 Logan 20’ 90-Series Electric

1985 Logan 20B Electric 20’

2000 Spudnik 2100 20’ Electric New Paint

1999 Spudnik 2100 20’ Electric

1997 Spudnik 2100 20’ Electric

1992 Spudnik 2100 20’ Electric

1990 Spudnik 2100 20’ Electric

1990 Spudnik 2100 26’ Electric

1986 Spudik 2000 20’ electric

Double L 851 4 row 2012 Lockwood 554 4 row

Lockwood 5000 4 row RH Ext

Lockwood 5000 4 row RH Ext

Logan 2 row RH BC

Spudnik 6160 6 row R&L discharge

Spudnik 6140 4 row

Spudnik 5140 4 row

Spudnik 5140 4 row

HARVESTERS

2017 Allan 3 row Electric with VFD controls

2018 Double L 7340 4 row

2004 Double L 859 2 row 69”

2003 Grimme SE 75-30

2012 Lockwood 474H 4 row

2004 Lockwood 484 4 row

2012 Spudnik 6640 4 row

2009 Spudnik 6400 4 row

2008 Spudnik 6200 2 row multi sep

2001 Spudnik 5625 2 row

CROP CARTS

2020 Allan AEC 35T, Scott Table

STINGERS

2015 Double L 832 36” BC with fingers

2007 Double L 833 30” Belt Chain only

3- 2014 Logan Trac Pro 30” x 10’ belt only

1994 Spudnik 2230 36” belt only

CONVEYORS TELESCOPIC

Spudnik 1255 30”/36”x 85’ TC 220 Volt 1ph

1997 STI 30” x 70’ 3ph Tel. Conv.

CONVEYORS STRAIGHT

Double L 809’s 30” x 40’ 3ph x 6

Spudnik 1200 30” x 40’ 3ph x 4

Spudnik 1200 30” x 30’ 3ph

Spudnik 1205 30” x 30’ 3ph

DIRT ELIMINATOR W/ SIZER

1997 Double 807 Dirt Elim. 62” BC 3ph

Stingers 72” Sizer

2013 Milestone Model MSDS 96 BC Elev Sizer clod drum split picking table

2010 Milestone 60” sizing table only w/acorns quick adjust arms

1994 Milestone 72” Dirt Elim. Sizer, 2 – 24” x 12’ stingers

2011 Spudnik 96” 990 BC Elev. Reverse roll table, sizing table, split picking, cross out conv.

2004 Spudnik 995 DES 72” Q A dirt & Size roll tables, split picking 230 volt 3ph

2002 Spudnik 72” DE belt elev

DIRT ELIMINATOR ONLY

2017 Milestone 96” 480 3phase

1998 Double L Model 806 BC, fingers, belt table, 2- pups 230 volt 3ph

2006 Spudnik 995 72”Finger rollers, ellis table, Belt Chain table 230 Volt 3phase

1990 Spudnik 950 72” 230 volt 3phase

ROCK/CLOD/AIR ELIMINATORS

2013 Harriston 4240 Clod Hopper 3ph

2013 Harriston 3240 Clod Hopper 3ph

2011 Harriston 3240 Clod Hopper 3ph

1999 Harriston 240 Clod Hopper 3ph

2003 Harriston 200 Clod Hopper 3ph 480 volt Ellis table

EVEN FLOWS/ SURGE HOPPER

New Logan Surge Pro Hoppers 60” 72”

DIRT TARE PILER

New Logan Dirt Tare Pro 30” 36”

2020 Logan Barrel Washer for little potatoes belly dump unloader attachment for Scooper

Evenflows: 1200 cwt, 900 cwt, 400 cwt

Greentronics Scale

Kerian 72” sizer

Mayo 60” flat washer belt chain elevator

Tri Steel 60” felt dryer

Flumes, pumps, rolling tables

PLANTERS

2020 Checchi Magli 4 row used but like new

2005 Lockwood 6 row pick planter 6 row 36”

2003 Kverneland 3300 cup 6 row 34” pull hitch

2013 Spudnik 8069 bed planter 9 units in 6 row pull Type

2008 Spudnik 8080 Pull type cup, 8 row, 36”

2008 Spudnik 8060 Cup 6 row 36” Semi Mount

2004 Spudnik 8060 Cup 6 row 36” Semi Mount

SEED CUTTERS

Better Built model 448 single phase 220 volt 48”

TREATERS

2016 Excel 10” liquid and dry treater 230 V 3ph

2002 Better Built 12” Cannon Duster

1991 Better Built CDT10- 8” Cannon Duster

WATER DAMMERS

2014 Logan 8 row Yield Pro 36”

folding wings Water Dammer

Turbo Top’s TT-268 is a self-propelled two-bed onion harvester. Green onions are one of Turbo Top’s specialties, allowing users to start harvest earlier and control curing. Day or night harvest? Turbo Top is capable of both. Adverse conditions? Turbo Top can work through the toughest of conditions. The TT-268 has dual 68-inch-wide pickup elevators for a total harvest pickup width of 190 inches, allowing onions to be picked up how they are grown without windrowing to reduce damage.

TT-268 is powered by a 410-HP John Deere Tier IV Final Package engine. It has infinite cab control of fan speed, primary chain speed, ground speed, load boom speed/movement, cutter bar height, and front elevator depth. An exclusive large topping area eliminates weeds and debris and allows even the greenest tops to be sorted before topping.

Turbo Top comes in different models and has many options to fit growers’ needs.

New short day yellow granex introduction: Strong upright tops with great plant habit. High yielding deeper granex shape, strong root system, and firm bulbs. Pink root and bolting resistance.

Earliness: Early main

Sowing period: 09-15 - 09-25

Taste: Sweet Pyruvates: 3.6

Lacrymatory Factor: 2.8

Shape: Granex

IR: Foc; Pt

Early maturing grano red. Strong healthy tops. Pink root resistance. Excellent bulb firmness and color. Uniform round bulbs. Good internal color. Widely adapted across short day growing regions. High percentage single centers.

Earliness: Early

Sowing period: 09-25 - 10-05

Taste: Very sweet

Shape: Grano

IR: Foc; Pt

Late season short day yellow granex with upright tops. Deeper high yielding granex shape. Bolting resistance and very uniform. Strong outer skin layers. Produces well sized bulbs that result in good yields. Great option to fill later season slot in Vidalia.

Earliness: Late

Sowing period: 09-25 - 10-05

Taste: Very sweet

Pyruvates: 3.5

Lacrymatory Factor: 2.4

Shape: Granex IR: Foc; Pt

Main Season short day yellow granex. Attractive lighter colored skin. Uniform and extra firm bulbs with high yielding deeper granex shape. High percentage of jumbos. Great post harvest appearance. A widely adapted variety across many short day regions.

Earliness: Main

Sowing period: 09-18 - 09-28

Taste: Sweet

Pyruvates: 3.4

Lacrymatory Factor: 2.6

Shape: Granex

IR: Foc; Pt

Bejo Seeds Inc. (main office) 1972 Silver Spur Pl. Oceano, CA | T: 805- 473-2199 | E: info@bejoseeds.com

bejoseeds.com

As the U.S. distributor for Upmann packaging machines, Rietveld Equipment is able to bring the planning, design, construction and final assembly of one of the leading manufacturers of weighing and packaging technology in Europe to the U.S.

Upmann offers fully automatic filling and sealing machines for net bags, trays, boxes and poly bags. Upmann’s product line offers everything from clippers and baggers to carton-fillers and robotic arms. Using one company to supply the entire packaging line, as well as the design of the line, assures that all aspects of the packing line work together seamlessly.

Symach has a long history of palletizing onions and innovating to provide customized modular designs guaranteeing a high stacking rate with maximum flexibility. From 50-pound bulk and baled bags to complex Octabins, Symach has solutions to handle all customers’ palletizing needs.

Symach also offers options to stabilize the pallet at the end of the line, including wrapping and double stacking, and palletizing within the margins of the pallet to ensure ease of loading during the shipping process.

The 2023 XTR is Top Air’s newest onion topper loader. Available in twoor four-bed models, the XTR combines the industry’s highest capacity with superior handling. Featuring a high-performance rotary cutting system, this harvester outperforms in the most challenging harvest conditions on both short- and long-day onions.

Top Air is now taking reservations for 2024 models.

Unisorting, a brand of Unitec, develops and manufactures lines for onion sorting that combine high efficiency in the process and preservation of product integrity during each stage.

Onions Sort 3 and Uniq Onions are the latest systems, 100 percent developed in house, for external and internal quality selection of all varieties of onions. These solutions allow users to select the valuable or non-valuable characteristics of any type of onion without damaging the integrity of the product.

An accurate selection of external quality and internal quality, in addition to the detection of weight, optical size and shape, offers high performance solutions for every need. The dedicated technologies, semi-automatic or fully automated, are designed to offer the best possible result and give customers a highly reliable product without internal defects.

With 30 years of experience in building one-row onion harvesters, Univerco has introduced its new two-row onion harvesters.

The two-row models are available in both short-day and long-day onion versions. Both units have a similar harvest capacity per day, a steering axle to reduce turning radius on headlands and a system of three cameras so operators can easily monitor the key functions of the machine.

The short-day model has even more options available such as a sorting table, brushes under the topper table to keep the rollers clean at all times, and more angle and speed adjustments of the topper table. These improvements were made in an effort to minimize mechanical damage to onions.

Verbruggen has more than 30 years of experience in stacking onions and other agricultural products. A team of engineers is continually innovating and developing the company’s machines and software, allowing Verbruggen to offer effective palletizing solutions for agricultural products.

Machines can stack bags of onions in the range of 5 pounds to 120 pounds and offer high flexibility for future changes in product sizes and patterns. Systems can palletize single bags, bags in boxes and boxes/crates and can perfectly stable stack to the height of 8 feet. Machinery includes an easy-to-use operator station and is low maintenance for high up time. The company offers regionally based sales and service, as well as remote-monitored support.

The VST30 palletizer is designed to offer high stacking performance with minimal manual labor. It can reach a capacity of 22 bags per minute and will position product with the utmost accuracy. The automatic pallet in-feed ensures an automated process, which reduces labor costs.

Volm Companies offers a complete selection of end-of-line palletizing solutions. Volm engineers, constructs and installs Volmstack palletizing systems and has built an impressive portfolio that includes robotic, conventional, case stacking, bin filling and plate palletizing systems.

Weeksago, the Michigan Onion Committee heard the news that the Michigan Department of Agriculture and Rural Development had given preliminary approval to the Specialty Crop Block Grant submitted earlier this year. This means that the Michigan Onion Committee now awaits final USDA approval. The project is titled “Influence of Tip/Leaf Burn and New Fungicides on Onion Stemphylium Leaf Blight.” This research will be done by Mary Hausbeck’s lab in the Department of Plant, Soil and Microbial Sciences at Michigan State University (MSU).

Two other grants being administered by the Michigan Onion Committee are also in progress. These are “Combining Pest Control Strategies to Increase Quality of Yield of Michigan Onions” and “Leaf Blight Decreases Michigan Onion Yields and May Increase Bulb Rot: New Approaches Are Needed.” Results from each of these projects will be on display at the Great Lakes Fruit, Vegetable and Farm Market Expo (www.glexpo.com) scheduled for Dec. 5-7 in Grand Rapids, Michigan.

Michigan Onion Committee members Bruce Klamer with V&W Farms and James Young with Takii Seed helped make preparations for the industry bus tour that was part of the National Onion Association (NOA) summer convention held June 14-17 in Grand Rapids, Michigan. The tour included stops at Duda Farm Fresh Foods to see its sweet corn tray pack and cello radish packaging and at Schreur Farms to check out the farm’s onions, celery, greenhouses and packaging operation. Washington-based Carbon Robotics joined the tour to demonstrate its LaserWeeder.

For many years, Michigan’s onion industry has been gathering one evening during August for the Twilight Onion Trials. This year’s event is scheduled for Aug. 16 in Byron Center, Michigan. Staff from Syngenta will arrive with their mobile grilling trailer to fire up a steak dinner for attendees.

The onion trials have been happening for decades with MSU’s Darryl Warncke at the helm. 2023 has brought some changes to the trials. Warncke continues to coordinate the trials, but onion seed sales representatives decided where to plant the seeds. The sales representatives are responsible for making sure the onions are tended to and are required to harvest the trial samples to be brought to the twilight event. This year, companies with seeds in the trial include Clifton Seed, Crookham Company, Hazera Seeds, Rispens Seeds, Seedway, Bejo Seeds, Solar Seeds, Stokes Seeds, Seminis, Takii Seed and Enza Zaden.

Bulbs are ready for inspection at the 2021 Twilight Onion Trials.

EFFICIENT UNDERCUTTING AND WINDROWING

• RIGID FRAME + FOLDING MODELS IN A WIDE RANGE OF CONFIGURATIONS

TOP AND CURE ONIONS IN WINDROWS

• HIGH CAPACITY

• GENTLE HANDLING

• STANDARD + XL MODELS

TOPPER LOADERS

INDUSTRY LEADING TOPPING AND CAPACITY FOR OPERATIONS OF ALL SIZES

• SUPERIOR DIRT & DEBRIS ELIMINATION

• BEST IN CLASS RELIABILITY

• MODELS FOR ALL GROWING CONDITIONS

INCORPORATED

Aug. 8

Utah Onion Summer Field Tour

Weber County, Utah

Dan Drost, dan.drost@usu.edu or (435) 770-4484

Aug. 29

Crookham Onion Reveal

Wilder, Idaho

Lyndon Johnson, lyndonj@crookham.com or (208) 369-3390

Aug. 29

The Bayer Experience

Featuring Onions, Specialty Crops and More Payette, Idaho

Richard Navarrete, richard.navarrete@bayer.com or (208) 317-6451

Aug. 30

Malheur Experiment Station Onion Variety Day

595 Onion Ave., Ontario, Ore.

Janet Jones, janet.jones@oregonstate.edu or (541) 889-2174

Aug. 31

WSU Onion Field Day

Warden, Wash.

Tim Waters, twaters@wsu.edu or (509) 545-3511

Nov. 15-16

Pacific Northwest Vegetable Association Conference and Trade Show

Three Rivers Convention Center

Kennewick, Wash.

Sheri Nolan, (509) 585-5460 or www.pnva.org

Nov. 29 - Dec. 2

NOA Annual Convention

National Allium Research Conference

San Antonio Marriott Riverwalk

San Antonio, Texas www.onions-usa.org

www.alliumnet.com/narc

Editor’s note: To have your event listed, please email Denise Keller at editor@columbiamediagroup.com. Please send your information 90 days in advance.

Gowan Company LLC has received federal registration of its Sonalan HFP herbicide for use in onions and has sent labels to each state for approval.

Sonalan HFP is a FRAC Group 3 DNA herbicide containing ethalfluralin in a liquid EC formulation. It is tank-mix compatible with most preemergence herbicides for expanded control of annual grasses and key broadleaf weeds before emergence. Sonalan HFP provides extended weed control, which minimizes onions’ competition for water and nutrients, allowing the crop to yield to its maximum potential, according to the company. In addition, the product is billed as an excellent addition to herbicide resistance management programs. Visit www.gowanco.com.

UNITED STATES

Lancaster & San Joaquin Valley

(661) 9785342

Desert Southwest

(928) 4467737

Colorado & New Mexico

(970) 3969728

Idaho, East Oregon, Utah & Nevada

(208) 9411421

Skagit Valley, Washington (360) 9417503

Rio Grande Valley & West Texas

(956) 6185574

MEXICO

Torreón, Coahuila

(461) 1173878

Colima, Col.

(461) 1040134

San Luis Potosi

(461) 1409452

Chihuahua

(461) 1719401

Tamaulipas

(461) 1342421

Irapuato, Gto.

(461) 5465792

Megan Wheeler has joined Vive Crop Protection as chief of staff. A member of the executive team, she will partner closely with the company’s CEO on key initiatives such as mergers and acquisitions, fundraising and effective scaling. The chief of staff role is new to Vive, but this is Wheeler’s third time in such a role. She has over 17 years of marketing and operational experience in technology across multiple disciplines, including real estate, pharmaceutical, custom software development, finance and digital accessibility.

Redox Bio-Nutrients has hired Sam Straight as its new chief operating officer (COO) and general counsel. Straight comes to the Idaho-based plant nutrition product company after a 24-year career at a Salt Lake City law firm, where he worked with Redox as a client.

His position at Redox includes operational, sustainability, regulatory and legal matters.

TELONE™ II is the world's best defense against destructive plant parasitic nematodes. Applying TELONE™ before planting creates a zone of protection, allowing developing root systems to thrive—leading to healthier plants, higher yields, and improved quality. A custom blend of TELONE™ (to combat nematodes) and chloropicrin (to target soil borne diseases) is an effective one-two punch for all of your onion pre-plant needs.

Remember, there's no coming back from a poor start!

Contact