` 100

www.autocomponentsindia.com Vol 8 Issue 06

August 2021

#TRENDING

COMPONENTS

INDIA

Digitisation In Manufacturing

VOICE OF THE AUTOMOTIVE SUPPLIERS

THE ESLA OPPORTUNITY FOR MORE INDIAN SUPPLIERS BEV GO-PARTS AND WEAR-PARTS International

Mobilised

Dual-Sided-Cooled Silicon Carbide Inverter @autocomponentsindiaofficial

@ACImagazine

Autonomous Mobility Theme Day 2021

@autocomponentsindia

Lanxess EV Charging Inlets

www.autocomponentsindia.com

ACI Mag

t.me/acimagazine

/acimagazine

Leading Manufacturer of Plastic Auxiliary Equipment

�����������������������... �������������������������.

! "# Serving Wide Range of Industries for: Injection Moulding | Extrusion | Blow Moulding | Compounding | Thermoforming

Nu-Vu Conair Pvt. Ltd. Plot No. 147, 148 & 154, Devraj Industrial Park, Piplaj-Pirana Road, Piplaj, Ahmedabad - 382 405, Gujarat, INDIA. E: marketingindia@conairgroup.com | W: www.conairgroup.com/india

+91 79 2970 8147 +91 97129 28201 +91 90990 76206

buildbrand 9426051465

C

22

ontents

August 2021

Cover Story The Tesla Opportunity For More Indian Suppliers

Considered to be the flagbearer of EVs, Tesla, Inc has a strong supplier base supporting operations in each of its markets. Ashish Bhatia looks at this ecosystem and the underlying opportunities for more suppliers in India.

06 Newscast l

l

l

l

l

l

l

l

l

l

l

l

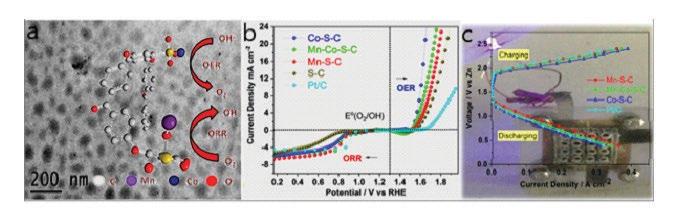

Catalysts for cost-effective and efficient metal-air batteries NATRAX High Speed Track Ministry of Power incentivises power trade TKM best practices for the future ZF India four-point strategy Ceat Tyres home fit services MTech in defence technology Mobile calibration lab services New leadership in key ministries ION Energy Pre-Series A funding Tata Power rapid charger Steep decline in operating profits

14 Mobilised

l Silicon Carbide Inverter

l Valeo Electric Powertrains l Cutting Edge Solutions

26 Special Reads

l Simulation Applications Streamline

Development Of Electric Vehicle Motors

30 #Trending

l Digitisation in Manufacturing

32 International

l Autonomous Mobility Theme Day 2021 l Lanxess EV Charging Inlets

40 #Trendsmap

To Subscribe turn to page 4

AUTO COMPONENTS INDIA n AUGUST 2021

42 WWW.AUTOCOMPONENTSINDIA.COM

H

otspot

A Cue From Cannes!

W

AUTO COMPONENTS INDIA

608, Trade World, 6th floor, C wing, Kamala Mills Compound, Senapati Bapat Marg, Lower Parel (W), Mumbai - 400013, India. Tel +91 9321546598, Email us at a.bhatia@nextgenpublishing.net Executive Editor Ashish Bhatia Editorial Advisory Board H. S. Billimoria, Aspi Bhathena Head - Design & Production Ravi Parmar Correspondent: Deepti Thore Asst Art Director Ajit Manjrekar Production Supervisor Dinesh Bhajnik Publisher Marzban Jasoomani Associate Publisher & General Manager (North & East) Ellora Dasgupta General Manager – South Girish Shet Deputy General Manager – North & East Chanchal Arora (Delhi) Regional Marketing Manager Salma Jabbar (Chennai) Marketing Manager Minocher Parakh (Mumbai) Manager Circulation - North and East Kapil Kaushik (Delhi) Subscription Supervisor Sachin Kelkar Tel +91 9321546598 Apple Newsstand & Magzter Queries: help@magzter.com Territory Sales Incharge (Circulation) Srinivas Gangula (Hyderabad) Cell +91 09000555756 Territory Sales Incharge (Circulation) Vidyasagar Gupta (Kolkata) Mob: 09804085683 REGIONAL MARKETING OFFICES Next Gen Publishing Pvt. Ltd. 608, Trade World, 6th floor, C wing, Kamala Mills Compound, Senapati Bapat Marg, Lower Parel (W), Mumbai - 400013, India, Mumbai -400013. Tel +91 22 9321546598 26 B, First Floor, Okhla Industrial Estate, Okhla Phase III, New Delhi - 110020, India Tel +91 11 42346600/78, Fax +91 11 42346679 Unit No:509, 5th Floor, ‘B’ wing, Mittal Towers, MG Road, Bengaluru - 560001, India Tel +91 080 66110116/17, Fax +91 80 41472574 Cenetoph Elite, No.5, Cenetoph 1st street, Teynampet, Chennai - 600018, India Tel +91 044 421-08-421/044 421-75-421 Devendra Mehta - Mob No.- 09714913234 Ahmedabad S.No.261/G.L.R.No.5, East Street,Camp Pune - 411001. Tel + 91 20 26830465

WWW.AUTOCOMPONENTSINDIA.COM WWW.AUTOCOMPONENTSINDIA.COM

Just like one industry shouldn’t be blamed for climate change, the onus of a clean up shouldn’t rest on just one either. Watch out for Rajashthan’s EV policy next.

hat can you tell a person who notices climate change and an automotive connection at perhaps the most celebrated international film festivals? Hosted by the resort town Cannes on the French Riveria, it had everybody close to me going gaga over the list of screenings and of course, the celebrity sashay papped on the red carpet. I dare say I did not notice the business as usual! However, I also noticed the unprecedented! Besides adhering to Covid19 protocols like social distancing, the festival abolished the use of plastic in yet another testimony to stakeholders transcending industry boundaries to tackle climate change, cohesively. Transport was undertaken through electric cars. The red carpet which was half the size this year was made using recycled material indicating a conscientious approach, in sync, the world over even as climate change wreaks havoc globally. The weeks after weeks of the various state governments of India doling out incentives to electric manufacturers and buyers, to boost both supplies and demand come as no surprise then. Especially tangible in the two-wheeler segment that witnessed a much sought after price deduction from the OEMs on eligible products. The latest EV policy announcement that came from Maharashtra has the state commit to electrifying 10 per cent of the state’s new vehicle registrations in 2025. It assumes significance given the contribution of the state to the overall automotive pie in the country. The state has offered D+ incentives to all EV components and battery manufacturing facilities. It has also gone on to partner with the Climate Group’s EV100 initiative. The partnership is aimed at building a robust demand for EVs and supporting the faster uptake of the policy in the words of Maharashtra’s Environment Minister Aditya Thackeray. Just like one industry shouldn’t be blamed for climate change, the onus of a clean up shouldn’t rest on just one either. Watch out for Rajashthan’s EV policy next. Ashish Bhatia Executive Editor | a.bhatia@nextgenpublishing.net /autocomponentsindiaofficial /autocomponentsindia ACI Mag

t.me/acimagazine

Views and opinions expressed in the magazine are not necessarily those of Next Gen Publishing Pvt. Ltd. Next Gen Publishing Pvt. Ltd. does not take responsibility for returning unsolicited manuscripts, photographs or other material. All material published in Auto Components India is copyright and no part of the magazine may be reproduced in part or full without the express prior written permission of the publisher Printed by Marzban Jasoomani Next Gen Publishing Pvt. Ltd., 608, Trade World, 6th floor, C wing, Kamala Mills Compound, Senapati Bapat Marg, Lower Parel (W), Mumbai - 400013, India.. Published by Marzban Jasoomani on behalf of Next Gen Publishing Pvt. Ltd., 608, Trade World, 6th floor, C wing, Kamala Mills Compound, Senapati Bapat Marg, Lower Parel (W), Mumbai - 400013, India. Printed at Spring Graphics, 215 & 238, Shah & Nahar Industrial Estate, Sun Mill Compund, Lower Parel (West), Mumbai 400013, India. Published at Next Gen Publishing Pvt. Ltd., 608, Trade World, 6th floor, C wing, Kamala Mills Compound, Senapati Bapat Marg, Lower Parel (W), Mumbai - 400013, India.

@ACImagazine

www.autocomponentsindia.com /acimagazine

All readers are recommended to make their own independent enquiries before sending money, incurring expenses or entering into commitments in relation to any advertisement appearing in the publication. Auto Components India does not vouch for any claims made by advertisers for their products and services. The editor, publisher, printer and employees of the publication shall not be held liable for any consequence in the events of such claims not being honoured by the advertisers. All disputes are subject to the exclusive jurisdiction of competent courts and forums in Mumbai only. Editor Ashish Bhatia

AUTO AUGUST COMPONENTS 2021 n AUTOINDIA COMPONENTS n AUGUST INDIA 2021

5

N

ewscast

Catalysts for cost-effective and NATRAX High Speed Track efficient metal-air batteries

The discovery of a new nonprecious, metal-based, bi-functional electrocatalyst is believed to have the potential to decrease cost and increase the efficiency of metalair batteries. The International Advanced Research Centre for Powder Metallurgy and New Materials (ARCI), an autonomous R&D Centre of the Department of Science and Technology (DST), of the government of India, has found a solution to this by developing a costeffective electrocatalyst. The research has been published in ACS Applied Energy Materials. It is well known how the rise in demand for different energy sources has led to efforts being made globally to develop different kinds of energy devices. These include lithium-ion batteries,

lead-acid batteries, redox flow batteries, lithium-air batteries, zincair batteries, sodium-ion batteries, fuel cells, and super-capacitors. The Zinc-air batteries among these have particularly drawn attention due to their claimed low cost and high energy density. Known as compact power sources for electric vehicles and energy storage devices, they are said to introduce efficiencies in the management of energy flow among renewable energy generators like wind turbines, photo voltaic panels, and electric grids. Catalyst development has been identified to be a major challenge here. The conventional catalysts available consist of noble metals in their composition, and are said to make batteries costly.

The National Automotive Test Tracks (NATRAX) inaugurated a High Speed Test (HST) track in Indore. Touted as the largest test track in the world, the four-lane track is 11.3 kilometres long and is also Asia’s longest track. The track will be used for the development and homologation of multiple vehicle segments, from passenger cars to heavy commercial vehicles. Each track will enable original equipment manufacturers to conduct coast down tests, brake tests, constant speed fuel consumption tests, speedometer calibration, noise, vibration tests and mileage accumulation among other tests.

Ministry of Power incentivises power trade from renewable energy sources

The Ministry of Power recently issued an order extending the waiver of Inter-State Transmission System (ISTS) charges on the transmission of electricity generated from renewable energy sources like solar and wind for projects to be commissioned up to June 30, 2025, effective June 30, 2023, previously. The move is expected to promote the hydro Pumped Storage Plant (PSP) and Battery Energy Storage System (BESS) projects for meeting the balancing

6

AUTO COMPONENTS INDIA n AUGUST 2021

requirement of the grid as a result of large scale integration of renewables. An estimated 450 GW by 2030. The waiver of transmission charges is also extended to the trading of electricity generated and or supplied from solar, wind, PSP and BESS in Green Term Ahead Market (GTAM) and Green Day Ahead Market (GDAM) for two years, till June 30, 2023. Notably, RE developers will be allowed to sell power in the power exchanges and

stand to get paid on delivery of power itself without a lag. In addition, the buyers will also have an opportunity to sell their surplus power in the power exchanges or allow, in advance, the sellers to sell in the power exchange. The amendment order is being looked at as a boost to renewable energy and a step forward in the direction of the government of India meeting its international obligations and climate change ‘commitment’. WWW.AUTOCOMPONENTSINDIA.COM

N

ewscast

TKM MoU with ACMA a commitment to share industry best practices for the future Toyota Kirloskar Motor (TKM) has signed a Memorandum of Understanding (MoU) with the Automotive Component Manufacturers Association (ACMA). Using its training arm Toyota Learning and Development India (TLDI), TKM has committed to sharing its knowledge pool including best practices with ACMA’s member companies. It will include imparting knowledge gathered on people development and lean management principles in line with the company’s objective to offer ‘Lifelong Learning’ to the stakeholders of the industry. Mentioned G. Shankara, Vice President, Human Resources and Services, TKM, “Toyota Production System which is a globally renowned approach for the auto industry helps in building lean and agile systems. We are happy to share Toyota’s know-

manufacturing with safety. Auto components manufacturers who will undergo skilling under this joint TKMACMA initiative will be endowed with skills and knowledge for creating a manufacturing ecosystem that can overcome disruptions and ensure business continuity,” he opined. As part of the MoU, TKM will impart 131 programs with a focus on a wide array of subjects including automobile and electrified vehicle technologies, industrial safety, environmental management systems, quality and supply chain management. It will also cover automobile welding, car painting, mechatronics, automation and robotics. To impart the training, TKM will deploy trainers certified by Toyota Motor Corporation (TMC), Japan and Toyota Asia Pacific Global Production Centre (AP-GPC), Thailand.

how and contribute to the human development of the auto components industry.” Averred Vinnie Mehta, Director General, ACMA, “The MoU between ACMA and TKM for people’s development is a step in the right direction to prepare our human resources for the future.” “The pandemic has led to the realigning of the shop floors to ensure sustainable

ZF four-point strategy for India ZF Friedrichshafen AG has renewed its focus on India by earmarking a Euro 200 million investment. The company is also looking at a strategic consolidation of its business domains with an eye on the next decade. In a company statement, Dr Holger Klein, ZF Member of the Board responsible for the Asia Pacific region and India mentions that despite the pandemic marred fiscal, the company is buoyant of the long-term growth potential in the country. “The refresh four-point strategy includes a plan to rapidly growing business in one of the largest automotive markets in the world,” averred Dr Klein. Centred on the need to ‘Readapt’, “Reinforce’, ‘Retain’ and ‘Restructure’, through the investment, he added, the company plans to aid WWW.AUTOCOMPONENTSINDIA.COM

this growth through product launches, manufacturing and engineering footprint expansions. It will also look at hiring and developments across other business domains. The focus areas of the company remain in e-mobility and next-generation technology through a global portfolio. It also includes using the racetrack as a test bed for power electronics, electric motor and transmission. Coming off its recent acquisition of Wabco, forming the ZF Commercial Vehicle Control Systems Division, the company expects to be able to increase its content per vehicle. At the same time, the company aims to bolster India as a global sourcing hub across software development, information technology, manufacturing and material sourcing, as per Dr Klein. AUGUST 2021 n AUTO COMPONENTS INDIA

7

N

ewscast

Ceat Partners TyresnMore for home fit services In an era of doorstep services, Ceat Tyres has partnered with TyresnMore to offer home fit services. With an aim to sell its range of tyres online and follow it up with home fitment, Ceat will pilot the new initiative in select cities. As stated, Amit Tolani, Chief Marketing Officer, Ceat Tyres Ltd., expects the company to tap into the growing customer inclination towards availing

services on a touch and in the convenience of their home. Available for Mumbai, Delhi-NCR, Bengaluru, Hyderabad and Pune, the tyre manufacturer aims to leverage its partner’s online marketplace for tyres and batteries to expand into other cities across the country. TyresnMore also offers tyre fitment, replacement, balancing, alignment among other maintenance services.

MTech in Defence Technology Mobile calibration lab services

The Defence Research and Development Organisation (DRDO) has launched a regular MTech program in defence technology in partnership with the All India Council of Technical Education (AICTE). Aero Technology, Communication systems and sensors, directed energy technology and high energy materials technology are among the courses on offer. Students can look forward to conducting their main thesis works in DRDO laboratories, Defence PSUs and across indistries. Babasaheb Neelkanth Kalyani,

8

AUTO COMPONENTS INDIA n AUGUST 2021

Chairman and Managing Director, Bharat Forge Ltd., congratulated DRDO and AICTE for initiating the program as he highlighted its importance for creating a talent pool for defence technology in line with the government’s ‘Atma Nirbhar Bharat’ programme. Aimed at motivating aspiring engineers, the program can be conducted at any of the AICTE affiliated Institutes and Universities, IITs, NITs or private engineering institutes. The program will be adapted for both online and offline mediums.

Godrej & Boyce of the Godrej Group has launched a mobile calibration lab service in the states of Tamil Nadu, Andhra Pradesh, Kerala, Telangana and Karnataka. Aimed at providing on-site calibration services to automobile, aerospace and manufacturing sectors, it will cater to the high precision requirements of these sectors. Xercsis K. Marker, Executive Vice President and Business Head, Godrej Lawkim Motors said, “On surveying our customers, we found out that a large volume of customers face problems in sending their instruments for calibration, and with this insight, we created the service.” The company will offer a high volume of measuring equipment with service provider Godrej Lawkim Motors, a NABL accredited, ISO 17025, calibration laboratory. The company will deploy a custom built van carrying calibration instruments to carry out 20 services on the go. With a claim of high vibrations dampening capability in the van, the company assures high precision calibration and instrument functionality. WWW.AUTOCOMPONENTSINDIA.COM

The best technicans demand the best parts

www.elring.com

With over 140 years of sealing expertise, Elring leads the industry in knowledge and innovation. Through our collaborative relationship with the world’s best engine designers, Elring assures quality and performance in every engine build using our gaskets. Use Elring and build with the best.

Your contact in India: Abhishek Bhagwani Country Sales Head IAM, India Mobile: +91 9156445474

Trust the OE-Expertise of Elring Germany!

Website

YouTube

N

ewscast

New leadership in key industrial ministries A major expansion as part of the Narendra Modi led BJP government’s cabinet reshuffle has translated to key ministries undergoing a change of leadership. Union minister Dr Mahendra Nath Pandey took charge of the heavy industries ministry. Dharmendra Pradhan assumed charge of the Ministry of Skill Development and Entrepreneurship as a cabinet minister. In another change, Rajeev Chandrasekhar, Member of Parliament, Rajya Sabha, from Karnataka,

took office as the Minister of State (MoS) of Ministry of Skill Development and Entrepreneurship. Both ministers resolved to create linkages between skilling and employment. Anupriya Patel took over the charge as

ION Energy Pre-Series A funding ION Energy has raised USD 3.6 million in a Pre-Series A funding round. The funding has been raised from Amazon’s Climate Pledge Fund, Silicon Valley-based Climate Capital, early-stage investor Yournest Venture Capital, Riso Capital, Venture Catalysts among other angel investors. Akhil Aryan, Co-founder and CEO of ION Energy mentioned, “Globally, we believe 2021 will be the inflexion point for the new energy transition as both companies and governments come together towards reducing carbon emissions.” “At ION, we’re confident that advanced electronics and software that help enterprises accelerate this transition will become mission-critical to meet our goals of a zero-carbon future,” he said. The fund raised will be used to grow the ION team from 70 to 150 plus. It will also be utilised for investments towards product development, expansion of the software business in North America and in Europe.

10

AUTO COMPONENTS INDIA n AUGUST 2021

the Minister of State in the Ministry of Commerce and Industry. Union Minister Narayan Rane assumed charge of the MSME. Ramchandra Prasad Singh took charge of the Ministry of Steel. Raj Kumar Singh

took charge of the Ministry of Power and Ministry of New and Renewable Energy. Bhupendar Yadav took charge of the Environment, Forest and Climate change, and the Labour and Employment ministry.

Tata Power rapid charger Tata Power has installed a fast DC Electric Vehicle (EV) charger next to the popular statue of unity at Kevadia, in Gujarat. Expected to serve as an important pit stop for EV users, it will be accessible through the Tata Power EZ Charge application. The installation is in line with the recent announcements made by Prime Minister Narendra Modi and the Statue of Unity Area Development and Tourism Governance Authority (SOUADTGA), Kevadia, on making the city, the country’s first EV city to run only electric buses, cars and twowheelers on its roads. Sandeep Bangia, Head, EV Charging, Home Automation & ESCO Tata Power committed to installing EV charging points at important highway locations and other such tourist destinations across the country. WWW.AUTOCOMPONENTSINDIA.COM

Mr. Issac J Kuttisseril +91 _ 7397484425 issac@titan.co.in

N

ewscast

Steep decline in operating profits of suppliers as per rating agency ICRA

Rating agency ICRA in its latest study estimates auto component suppliers to witness an over 70 per cent decline in operating profits during the first quarter of the current financial year (Q1FY22). Largely blamed on the second wave and associated lockdowns, the study expects challenges to be further compounded by the sharp increase in commodity prices. These price burdens are known to be passed on to the Original equipment manufacturers (OEMs) with a three to six-month lag. The study allayed fears by stating how most investment grade auto component suppliers are maintaining adequate liquidity to help them sustain and ensure continuity. Retail sales on the decline sharply during the last two months are said to indicate an inventory build-up in the system. Commodity prices could also remain high in the first half of the current fiscal. The shortage of electronic components and increase in semiconductor prices are known to have added to the woes, stated the report. “ICRA estimates a revenue loss of 30 to 40 per cent quarter-

12

AUTO COMPONENTS INDIA n AUGUST 2021

on-quarter. This will translate into a sequential decline in EBIDTA of over 70 per cent during Q1 FY22 for the industry,” Vinutaa S, Assistant Vice President and Sector Head at ICRA reportedly said. However, the overall industry revenue will still be almost double than Q1FY21 level, she opines. Drawing attention to exports coming to the industry’s rescue in the last few months with domestic demand known to have been negatively impacte, she

cited suppliers depending solely on domestic OE demand as the worst impacted. The domestic auto component industry is however expected to register a 20-23 per cent revenue growth in the current fiscal year, supported by doubledigit volume growth across most automobile sub-segments and with the impact of commodity inflation on realisations. Both aftermarket and export stability is expected to add to the industry’s revenue.

WWW.AUTOCOMPONENTSINDIA.COM

M Dual-Sided-Cooled Silicon Carbide Inverter obilised

BorgWarner’s dual-sided-cooled inverter is the first-to-market inverter using a silicon carbide-based power switch. Ashish Bhatia looks at the inverter designed for an 800V application.

D

14

riven by the climate change commitments made by the Indian Government during the COP21 Summit, Paris to reduce emission intensity by 33-35 per cent by 2030 from the 2005 levels, electric mobility continues to be high on the agenda for governments globally. The government’s the world over are relying on the technological prowess of automotive component manufacturers and their tier suppliers to achieve the ambitious goal of zero emissions by 2030. The industry together with the government is working towards reorienting businesses to meet modern-day needs and to do its bit to reverse climate change through such innovative and advanced next generation solutions. BorgWarner has taken it upon itself to improve upon the erstwhile generation of inverters used for electric vehicles. In electric vehicles, an inverter is a device that converts Direct Current (DC) power to the Alternating

AUTO COMPONENTS INDIA n AUGUST 2021

Current (AC) power known to be used in an electric vehicle motor. It has the capability to change the speed at which the motor rotates as it adjusts the frequency of AC.

First-to-market

With its ‘Dual-Sided-Cooled Silicon Carbide Inverter’, the company is claimed to have introduced the first-to-market inverter using a Silicon Carbide (SiC)-based power switch for an 800 volt application, The BorgWarner component is claimed to deliver increased efficiency for enhanced voltage flexibility, improved recharging times, better range and smaller battery size for cost reductions. For instance, the inverter’s SiC technology is claimed to extend electric vehicle range by c.5 per cent and enable faster charging times at 800 volt in comparison to the 400 volt systems. The Viper power module boasts of dualsided cooling for enhanced thermal management.

WWW.AUTOCOMPONENTSINDIA.COM

Mobilised The use of SiC helps extend PHEV and BEV besides contributing to the range extension and faster charging also delivering a better solution with more power. Its advantages include a smaller package that is also cost effective. The patented technology has won many accolades including being adjudged as the ‘Innovative E-Mobility Solution’ for which the company was adjudged as the ‘Supplier Of The Year’ at the Auto Components India 2021 Awards earlier this year. Notably, it eliminates the need for wired bonds or connections often blamed for the cause of quality and reliability issues. It also optimises switching and conduction to deliver up to 70 per cent reduction in power loss. In effect, the Original Equipment Manufacturers (OEMs) can look forward to room for creating more compelling consumer propositions for hybrid and electric vehicles. The additional room is believed to have the potential to lead to a broader acceptance of e-mobility in compliance with the government-mandated emissions targets. The patented capabilities are aimed at giving manufacturers the propulsion system design flexibility and performance in line with the strategy to capitalise on the market pull. The resultant vehicle mix and volumes could help meet the increasing emissions regulations. BorgWarner’s Bengaluru Technology Centre is known to have contributed to the design of the product under multiple competencies including systems, software, test and verification, electrical analysis and simulation, mechanical analysis and simulation. On the software front, critical features design and development confirming to the ASPICE model, for example, the bootloader, functional safety mechanisms, control WWW.AUTOCOMPONENTSINDIA.COM

Key Benefits Of 800 volt Silicon Carbide Inverter c c

c c

Viper power module includes dual-sided cooling for enhanced thermal management. SiC helps extend PHEV and BEV range by approximately five per cent and enables faster charging times - delivering a better solution with more power, in a smaller package and for less cost. Award winning, patented technology eliminates the need for wired bonds or connections that can be the cause of quality and reliability issues. Optimises switching and conduction to deliver up to 70 per cent reduction in power loss.

features, diagnostics, cybersecurity – HSM etc were worked upon. The centre also contributed to the hardware and factory test software for testing the control board hardware besides being involved on the unit level software testing of all the features. On the systems engineering front, the centre is known to have contributed to the requirements definition and the algorithm development for key critical features for example critical temperature sensing and diagnostics of the SiC MOSFET. It is known to have been involved in testing and verification, software qualification, integration and regression tests on the test simulators for various key features referred to above. The process involved continuous integration and qualifying

the SW on the product against customer specifications. The team carried out continuously system test cases development on Motor sim and Dyne benches to confirm the superior performance of the SiC based Inverter product functionality. It also involved the automation of suite of software tests for most of the control features. In case of electrical analysis and simulation, the tech centre contributed to the worst case analysis and simulation of different electrical hardware circuit blocks aimed at the verification of hardware design for meeting the specified requirements. Multiple design and part changes were suggested to lower BOM cost and improve design. The EMI simulations were carried out to ensure emission outcomes were within specified standards. In case of the mechanical analysis and simulation, the centre contributed to ensuring that the product meets the customer specifications, both thermal and structural simulations by means of computed aided simulations known to have been performed for the product. The thermal and vibration characterisation studies were carried out on the modelled SiC MOSFET packages leading to the improvement of the overall performance under different loading conditions and hence adding to the reliability. ACI AUGUST 2021 n AUTO COMPONENTS INDIA

15

M Valeo Electric Powertrains obilised

Valeo partners has partnered with Omega Seiki Mobility. Prateek Pardeshi looks at the scope of the partnership involving electric powertrains for the latter’s vehicle range.

P

16

Powertrains are the building blocks of a vehicle. In line with the Omega Seiki Mobility (OSM) strategy to build a powertrain suited to the duty cycles of three-wheelers for cargo transportation, the Original Equipment Manufacturer (OEM)

AUTO COMPONENTS INDIA n AUGUST 2021

has found its powertrain partner in Valeo India (Valeo). Valeo has signed a Memorandum of Understanding (MoU) with Omega Seiki Mobility (OSM), part of the Anglian Omega Group, under which the company will provide electric

WWW.AUTOCOMPONENTSINDIA.COM

Mobilised powertrains for the OSM electric vehicle range. The two partners aim to deliver on the carbon emission reductions through the collaboration. Here, Valeo expects OSM to leverage its expertise deemed suited to the target segment of small commercial vehicles. Averred Jayakumar G, Group President, Valeo India, “Omega Seiki will benefit from our deep understanding of not only the electrification technologies but also the unique needs of integrating electric powertrain in the small mobility format of vehicles.” “I am positive that Valeo’s advanced technologies, our strong engineering combined with manufacturing expertise in India will help us to strengthen our partnership and succeed together in this rapidly growing segment,’ he stated.

48V e-powertrain

Valeo will provide its 48 volt electric powertrain system from its manufacturing plant, in Pune. The powertrain is known to constitute a reducer, an integrated motor and an inverter to go along with the Powertrain Control Unit (PCU) for

WWW.AUTOCOMPONENTSINDIA.COM

RAGE+ Powertrain Parameters

Specifications

Top Speed

45 kmph

Range

70-80 kms per charge

Battery Type

Li-ion 48V

Battery Capacity

7.5 kWh

Charging Time

3-4 Hours

Acceleration (Boost mode)

13 sec

Regen at IDC

15 per cent

Rated Power

4.8 kW

Battery Warranty

Three Years or 80,000 kms (whichever is earlier)

OSM’s cargo three-wheelers range comprising of ‘Rage+’ and ‘Rage+ Frost’. The vehicles under the Rage+ brand, for instance, have already been deployed by several major e-commerce and logistics companies in India. “We are thrilled to partner with Valeo. This association will allow us to address the core issue of reducing carbon load in the atmosphere, along with providing a sustainable solution for our product line-up,” stated Uday Narang, Chairman, Omega Seiki Mobility in the company release.

Rage+

The Rage+ three-wheeler cargo vehicle with a Gross Vehicular Weight (GVW) of 0.96-tonne and an open carrier box offers a range of 70-80 kilometres on a single charge as per company claims. It translates to a running cost of 0.50 rupees per kilometre Powered by an IP65 certified 7.5 kWh battery pack with a battery swap option, the vehicle is claimed to be charged in a time span of three to four hours using a fast charger. Range+ customers can look forward to a battery life of 2,000 cycles coupled with a three-year or 80,000 km warranty. On the safety front, customers can look forward to inclusions like regenerative braking, roller-cage support structure keeping in mind driver safety, a superior strengthened chassis claimed to be suited to Indian road conditions, and hydraulic braking. Both the front and the rear get are claimed to be fitted

with heavy-duty shock absorbers that include a damper plus helical at the front and independent suspensions and dampeners at the rear. The company also offers a reefer variant christened ‘Rage+ Frost’ unveiled earlier this year and aimed at pharmaceuticals and food delivery aggregators.

Go-to-market strategy

In addition, Valeo’s engineers will look to provide the technology integration support aimed at helping OSM accelerate the execution of its go-to-market strategy leading to faster commercialisation of the product offering. In relation to the technology used by OSM for their vehicles to be coupled with the Valeo e-powertrain, added Dr Deb Mukherji, Managing Director at Omega Seiki Mobility,

Jayakumar G, Group President, Valeo India

AUGUST 2021 n AUTO COMPONENTS INDIA

17

M

obilised

Uday Narang, Chairman, Omega Seiki Mobility

“With a global technology leader like Valeo on board, we would be providing our customers with new generation powertrains which are efficient, use latest technologies in motors, electronics and IoT, and at the same time are cost-effective too.” “That is the essence of any disruptive technology. We are very excited to be working with Valeo to introduce a new range of powertrains in the Indian market,” he expressed. The go-tomarket strategy of this collaboration entails Valeo offering quick charging and an efficient range. It also entails keeping the Total Cost of Ownership (TCO) low to maximise operator Return on Investment (RoI). To deliver on its promise, Valeo will fall back on its globally tested 48 volt affordable systems, known to have been launched in 2020. It expects the fully integrated compact

18

AUTO COMPONENTS INDIA n AUGUST 2021

48 volt electric powertrain system to aid in OSM’s requirement of building affordable small electric commercial vehicles. Besides three-wheelers, the Scops of the MoU extends to twowheelers aimed at both the first and last-mile connectivity requirements pan India. Going beyond the current scope Valeo and OSM will further collaborate for the latter’s upcoming vehicle models to be manufactured in India. “OSM is taking a holistic approach to not only provide innovative technology in the vehicles but also deliver high-performance vehicles at reasonable running cost through the claimed, state-of-the-art internal research and development and alliances put in place,” concluded Narang. ACI

Dr Deb Mukherji, Managing Director, Omega Seiki Mobility,

WWW.AUTOCOMPONENTSINDIA.COM

M

obilised

Kistler Measurement Systems Into dynamic pressure, force, torque and acceleration measurement technology, Kistler Group is banking on cutting-edge solutions. Team ACI looks at the modular and application-specific services.

K

nown for expertise in dynamic pressure, force, torque and acceleration measurement technology, Kistler Group is claimed to offer cutting-edge measurement solutions which form the basis of its modular and application-specific services. Finding applications in automotive development and industrial automation besides other emerging sectors, the Swiss corporation is focused on electrified drive technology, autonomous driving, emission reduction and Industry 4.0. Around 2,200 employees at more than 60 facilities across the globe are dedicated to the development of these new solutions and their localisation.

Test stands

The Test stands from the company are aimed at electrical drive systems and components on the development, production and quality assurance front. For instance, Kistler’s test stand systems are used in the development, quality control and production. The objective being to optimise the efficiency of test equipment and ensure that innovation can continue to advance. Claimed to precisely tailor to each customer’s requirements, the company takes special care to calibrate its measuring chains. The portfolio comprises test stand systems for electrical machines, generators and drive systems. Kristler has positioned itself as a one-stop

20

AUTO COMPONENTS INDIA n AUGUST 2021

solutions provider offering individual components to complete solutions in the spectrum.

Research and Development test stands

Aimed at Research and Development (R&D), the extensive range of electrical and mechanical characterisation methods offer a flexible platform. Through an open architecture, Kistler is claimed to facilitate an easy changeover of products. The test sequence on offer is adjustable and forms the base of a wide range of options to test different products like climate chambers. Kistler offers a large installed base at global certification and calibration laboratories.

End-of-line test stands

The end-of-line test stands are claimed to have been optimised for tact time, footprint, availability. It extends to the fully automated test cells including the loading process. A modular setup is said to aid in the scalability of capacity. High end measuring devices are claimed to provide superior speed and accuracy. Care has been taken to enable product tracking and complete documentation through the process. The end-of-line test stand is a certified QC tool for the end of the production line. The company has leveraged extensive experience in automotive electrical drive train production.

WWW.AUTOCOMPONENTSINDIA.COM

Mobilised

Benefits of Kistler test stand systems

The company’s test stand systems are claimed to offer a host of benefits to end customers as listed below: l Efficient quality control l Process reliability l The basis for developing high-quality products and boosting productivity l Enhanced efficiency and performance for electrical drive systems l Reduced testing costs l Flexible and modular customisable components, or complete systems from one single source Extensive range of services l Products that are simple to integrate.

done so with continuous collaboration with research and industry partners. The company is offering a wide range of high-precision torque sensors said to pave the way for innovative solutions in industrial measurement and system technology. To achieve a significant improvement on the fronts of safety, reliability and efficiency – in production, as well as R&D, the company has specially focussed on undertaking intensive testing of the mechanical and electrical characteristics of its electrical machinery. It has aligned the complete test bench with the latest

technological developments in an attempt to ensure maximum precision and reliability. Playing on its capabilities in measurement and system technology, Kistler is drawing on its wide range of torque sensors to cater to each and every application. Integrated Torque measurement in the production process, process monitoring to ensure zero-defect production are some of the benefits on offer. The company ensures controlled quality costs by detecting deviations at an early stage. Through flexible measuring equipment, it is claimed to optimise process efficiency. ACI

Measurement instrumentation

For the process monitoring and quality assurance coupled with test bench and drive technology, the company is said to have aligned with the increasingly higher standards for precision in industrial manufacturing. Aimed at addressing the rising time pressure, the company has taken special care to offer a reliable suite of measuring systems. It is said to have WWW.AUTOCOMPONENTSINDIA.COM

AUGUST 2021 n AUTO COMPONENTS INDIA

21

c

over Story

The esla Opportunity For More Indian Suppliers

Considered to be the flagbearer of EVs, Tesla, Inc has a strong supplier base supporting operations in each of its markets. Ashish Bhatia looks at this ecosystem and the underlying opportunities for more suppliers in India.

I

22

t is well known that Tesla Inc. is gearing to establish a base in India after the country rolled out a red carpet for the EV flagbearer. The inperson plant visits at the Tesla headquarters, in Palo Alto, California, by the top brass of the country led by Prime Minister Narendra Modi, in 2015, have since been followed by several state heads also extending an invite to Tesla Co-founder and Chief Executive Officer, Elon Musk for setting up the company’s India headquarters. States like Gujarat, Maharashtra, Andhra Pradesh, Tamil Nadu and Karnataka were among the front runners then giving hope to more domestic suppliers apart from the many that are known to supply to the company for its global markets. The speculations were put to rest only earlier i this year when in January, the company registered as ‘Tesla India Motors and Energy Pvt. Ltd.’ with the Registrar of Companies at Bengaluru, Karnataka. Now that Tesla is officially in India,

AUTO COMPONENTS INDIA n AUGUST 2021

the company, in phase one of its India strategy, is expected to import the Model 3 series. If it succeeds with imports and the sales strategy next year, it will want to establish a manufacturing plant in the next phase. The objective being to increase localisation of content per vehicle and succeed in this new market. More domestic manufacturers stand to benefit if it were to happen as envisaged. Musk, in a characteristic manner, took to social media platform Twitter to reiterate this intent in what was a reply to his follower asking to expedite the India launch. The reply was no coincidence and is believed to have followed an official note drafted to the concerned ministries. Citing the import duty in India as the highest in the world for a large country, Musk sought a tax cut even if it were to be granted in the form of a temporary relief to the new entrant. Calling out the treatment to clean energy vehicles as unfair, the tweet further read, “Moreover, clean energy vehicles are treated the same as diesel or petrol, which does not seem WWW.AUTOCOMPONENTSINDIA.COM

Cover Story Structural Batteries Improve Mass And Range

Revolution In Body + Battery Engineering

10% MASS REDUCTION

14% RANGE INCREASE OPPORTUNITY

370 FEWER PARTS

STORAGE

MODERN AUTOMOTIVE BATTERY

EXCESS STRUCTURE

STORAGE

FUTURE AUTOMOTIVE BATTERY

entirely consistent with the climate goals of India.”It remains to be seen though how the government responds to it though. If the company’s demands are met, however, and the company is able to localise eventually for sustenance and or building India as its global Research & Development (R&D), and manufacturing hub, Indian component suppliers could win big! The company last put in place a strong leadership team with automotive honchos and continues to hire for both blue and white-collar positions across the

WWW.AUTOCOMPONENTSINDIA.COM

country to get its execution right. It hints at wanting to be in the scheme of things for the long-haul.

The supplier base

A look at Tesla’s global supplier base and country-specific strategies reveal how the company has put in place a robust ecosystem and built a strong supplier base to succeed in each of its markets. For starters, the company has always been discrete on who it partners with. But with first hand knowledge, we know of Indian suppliers catering to the company for

years now. The secrecy, understandably is a means to retain the perceived early mover’s advantage by protecting its Intellectual Property (IP) to stay ahead of the competition. The IP referred to includes electric powertrain and the expertise in

AUGUST 2021 n AUTO COMPONENTS INDIA

23

c

over Story

developing self-driving technologies. The Tesla powertrain also consists of power electronics, motor, gearbox, and control software. The company credits its pool of powertrain variants to years of R&D undertaken behind the scenes of all the attention it gets. On the flipside, teardown exercises by competition means maintaining secrecy around its supplier base was and will never be an easy task. Besides the battery pack, electric motor and charger that the company is known to manufacture itself, its core vehicle technology competencies also include battery and powertrain engineering and manufacturing. The company takes pride in its ability to design vehicles claimed to utilise the unique advantages associated with an electric powertrain. On the front user interface, the company designs in a manner to incorporate the latest advances in consumer technologies, such as mobile computing. Indian technology companies in the space could leverage the opportunities if Tesla were to look at both established and new entrants out of the mix. Tesla currently depends on component suppliers from across the United States, Europe and Asia including many homegrown suppliers of India to meet its other needs. Its supplier list includes AGC Automotive for windshields, Brembo for brakes, Fisher Dynamics for power seats, Inteva Products for the instrument panel, and Modine Manufacturing Co for the battery chiller. Sika supplies the acoustic dampers with Stabilus providing the liftgate gas spring. ZF Lenksysteme supplies the power

24

AUTO COMPONENTS INDIA n AUGUST 2021

steering mechanism. Continental provides the air conditioning lines while Magnetic Marelli provides the headlamp LEDs. NSK provides the wheel bearings and Wabco provides the twin compressor. Mumbai-based GoldSeal-Saargummi, for instance, supplied to Tesla Model X for some of the most complex products like the falcon wing doors. Sandhar Technologies, Bharat Forge, and Sona BLW are also known to be in the mix. The list goes on to include other suppliers like ADAC, ABC Group, Angell-Demmel, Argent, Gentex, Harada, Hitachi Cable America, Hope Global, MacLean-Fogg, Magna International, Methode Electronics, Multimatic, Panasonic, Plastomer, PSM International, Riviera, T1 Automotive, Zanini Auto Group, TXU Corp., Universal Logistics Holdings, Inc., Affinia Group Intermediate Holdings Inc., Lithium Exploration Group, Inc., U.S. Lithium Exploration Group, Inc., Niocorp Developments, Ltd., Rare Element Resources, Ltd., Burlington Northern Sante Fe Corp., Cooper Industries, Ltd., Clarcor, Inc., Dana Corporation, Delphi Corporation, Flowserve Corp., NextEra Energy, Inc., Harman International Industries Inc., Lightwave Logic, Inc., Molex Inc., Metaldyne Performance Group Inc., Nortek, Inc., Rohm And Haas Company and Searchlight Minerals Corp.

Cost optimisation

Musk has admitted to cars getting increasingly complex compared to the Model T. The supply chain for battery’s, he tweeted, doesn’t exist at

the desired scale and must be built in parallel. No wonder, he deems ideation as easy and production harder. Cost optimisation plays a key role here. Earlier in September 2020, Asian suppliers of Tesla were in the news after Musk is known to have pushed for lowering the cost of batteries. Batteries are estimated to account for 50 per cent of the total cost of an EV like is known to be the case with the Model 3, on its way to India. To put its point across, the company hinted back then at considering, producing its own cells to gain greater control over ballooning costs. The move is known to have compelled suppliers LG Chem Ltd., Contemporary Amperex Technology Co. Ltd. (CATL) and Panasonic Corp counted among the top tier battery suppliers to reevaluate their strategies. Prospective Indian battery technology company’s and suppliers are sure to have noticed the development and taken a cue to pace themselves right. USA based electric vehicle and clean energy company CATL, for now, has signed on an extension deal with Tesla to supply batteries until 2025 as per a stock exchange filing. To be able to optimise the vehicle cost from USD 37,990 to USD 25,000 by 2023, the company will have to work out ways to bring down battery costs in line with Musk’s objective made public on the company’s ‘Battery Day’ event. Until Tesla can ramp up its own production, however, the company will have to rely on its existing supplier pool. In India, Indian battery pack manufacturers like Gemopai, Benling India, Okinawa Autotech and Ampere Electric, Amara Raja Batteries, Epsilon WWW.AUTOCOMPONENTSINDIA.COM

Cover Story Advanced Materials Pvt. Ltd., and Green Evol Pvt. Ltd. (Grevol) among others in the pool must leevrage their low-cost, quality solutions to capitalise. Both established and new entrants looking to break into the Tesla supplier pool are required to carefully assess and meet the quality benchmarks set by the company. to succeed in their endeavour.

Quality Assessment

A battery solutions supplier, for example, will have to achieve high energy density at decreasing costs while also maintaining safety, reliability and long life in the extremely challenging and dynamic automotive environment like Tesla is claimed to have mastered. Highdensity energy storage, cooling, safety, charge balancing, structural durability, and electronics management are some of the other areas that need to be focused on. Tesla is open to evaluating new battery cells and optimising battery pack system performance to gain better control over the costs of its current and future vehicles. Indian suppliers are well equipped to step up their ga me and capitalise on the intent. Suppliers in power electronics need to match up to Tesla’s ability to drive large amounts of electrical current in

WWW.AUTOCOMPONENTSINDIA.COM

a small physical package with high efficiency and low cost. It must also enable a recharge on a wide variety of electricity sources including at the company’s ‘Superchargers’. Motor manufacturers must benchmark with Tesla’s design, making use of two electric motors to maximise traction and performance in an all-wheeldrive configuration. It is said to pave the way for digital and independent control over torque to the front and rear wheels. In effect, the claimed, near-instantaneous response of the motors, combined with low centres of gravity, provide drivers with controlled performance and increased traction control. The company is also working on the development of vehicle powertrain technology featuring three electric motors to improve overall performance. Supplier manufacturers into steel, aluminium, copper and rubber besides alternative materials for body and chassis also stand a chance to associate with the company as it looks at ways to benefit from the use of a variety of materials and production methods for optimising vehicle weight. A testimony to existing suppliers coming good on all counts is the manufacturer’s warranty on all new and

used Tesla vehicles in global markets. A new Tesla vehicle comes with a four year or 50,000 miles ‘New Vehicle Limited Warranty’ to give a perspective on what the global consumer gains. This is further subjected to separate limited warranties for a supplemental restraint system, battery and drive unit, and body rust perforation. In the case of the battery and drive unit on the new Model 3 and Model Y vehicles, the company offers an eight-year or 100,000-mile limited warranty for its ‘Standard’ or ‘Standard Range Plus battery’ and an eight-year or 120,000mile limited warranty for its ‘Long Range’ or performance battery. The extended Service plans cover the repair or replacement of vehicle parts for up to an additional four years or up to an additional 50,000 miles after the expiration of the New Vehicle Limited Warranty. It will be interesting to see the fine print of these nitty gritties in the Indian context and how more Indian suppliers capitalise on the prospects of a Tesla association. The company, for now, is content with setting up an assembly plant for CKD and SKD units in India as all the stakeholders look to test the waters before committing to the long haul. ACI

AUGUST 2021 n AUTO COMPONENTS INDIA

25

I

nternational

Simulation Applications Streamline The Development Of Electric Vehicle Motors Volkswagen Kassel accelerates the design process for electric motors by building and distributing simulation applications that evaluate the strength of rotor laminations, writes Thomas Forrister.

A

s more consumers express concern for the environment, electric vehicles are on track to outpace conventional internal combustion engine vehicles as the transportation mode of choice. In response to this growing demand, leading auto makers are doing their part to pave the way for EVs, revving up the development of electric and hybrid motors alongside the manufacturers of combustion engines. One such auto maker is Volkswagen, whose Kassel plant in Germany specialises in the development, planning, and production of electric drives. It has a production output of 150 electric and 300 hybrid drives daily. As essential components in electric drives, rotors need to be tested for durability, since they must endure a very large number of revolutions at varying speeds and torque during drive operation.

However, evaluating the strength of rotor laminations is time-consuming. VW Kassel is automating this test process for rotors, as well as reducing development costs and increasing product quality, by building simulation applications with the COMSOL Multiphysics® software.

Balancing electromagnetic and mechanical requirements In 2015, Volkswagen began developing a modular system to optimise EV design and make the manufacturing process more efficient, called the Modular Electrification Toolkit (MEB). The MEB accounts for the torque, power, and speed for the main rear-wheel drive and for the optional frontwheel drive that is used in all-wheel-drive versions

Figure 1. Schematic of the MEB, with the optional all-wheel drive (left, front of the vehicle) and the main drive (right, rear of the vehicle).

26

AUTO COMPONENTS INDIA n AUGUST 2021

WWW.AUTOCOMPONENTSINDIA.COM

International

Marie Hermanns (Simulation Engineer)

(Figure 1). Among other requirements, such as the ratios for the axles, drive units, weight, and wheelbases, the design and placement of the high-voltage drive battery play a major role in the overall MEB concept. While the MEB helps to optimise individual components and the system as a whole, balancing these requirements takes careful consideration on the part of the designer, especially when accounting for new technologies like digitalisation, autonomous driving, and electric drives. From the very beginning of the electric drive development process, there has been close cooperation between staff involved in the design, simulation, and testing at VW Kassel. First, the simulation experts review the performance specifications for an electric drive and use simulation to investigate how to best approach the design. For example, modelling the drive greatly reduces the number of variants, and distributing a simulation application based on this model enables the designers to then benchmark different variants and choose the best one. This collaboration is vital and beneficial to all, as simulation cannot cover all of the real-world issues. Hence, the test process plays an important role in the development process. In addition, the experimental test procedure helps to improve the simulation models. “In the development process of electrical WWW.AUTOCOMPONENTSINDIA.COM

machines, one has to fulfill many requirements,” explains Dr. Steffen Rothe, Simulation Engineer of component development at VW Kassel. “On one hand, the machine has to match electrical requirements for the torque and power. On the other hand, the rotor has to possess a certain durability, where the centrifugal force is the major load for the rotor,” he mentions. Further, balancing dual requirements can be challenging, as they are sometimes at odds. For example, while it is better to use thin, web-like structures for the electromagnetic requirements, thicker structures are preferable for mechanical durability. These requirements must begin early on in the development process. One way to do so efficiently is to simulate all of the load cases covering the requirements. “Simulation,” Rothe says, “plays a major role in accelerating the design process.” “Many industrial simulation programs are designed as a black box, whereas COMSOL Multiphysics® is unique in its transparency. It enables users to view and modify the implemented equations, or even add your own,” says Rothe. Furthermore, the software is designed as a multiphysics tool from the beginning and enables users to simulate different physical fields simultaneously. Hence, the user can combine different physical fields to do something completely new. However, analysing complex physical problems such as these can

Figure 2. A typical rotor setup with the rotor plates, shaft, and magnet.

be challenging, even for a simulation expert. The team needed a way to communicate with colleagues and enable nonexperts in mechanical simulations to test certain parameters. The designers were able to meet these needs by using the ‘Application Builder’, a built-in tool in COMSOL Multiphysics®, to create simulation applications that predict the stresses in a rotor.

Improving EV production with specialised applications

To design an application for colleagues to evaluate the strength and durability of rotor laminations, simulation experts Marie Hermanns and Steffen Rothe considered which part of the model could be automated, which model parameters were variable, and which results the application should show. For a typical rotor setup (Figure 2), the simulation experts concluded that

Figure 3. An example of the simulation application’s user interface. AUGUST 2021 n AUTO COMPONENTS INDIA

27

ntstsininddi ia. een nn po po mm coco uto .ato wu 20 2020 rilh20 ch ararc Ap MM

01 0201 Issue ssue 7

0 100 ``010 ` 10

I

om .com diaia.c innd tssi ennt pon pone om om ococ .aut wut w.a ww ww 20 2020 ril 20 rch rch Ap Ma Ma

S T N E N O P E M N O O C P M O C

IA DIA IND

IN

ERS SUPPLIER LI S AUTOMOTIVE OICE OF THE TOMOTIVE SUPP

CE OF THE AU

02 Vol 7 Issue 01 nternational Vol 7 Issue 01

OO20 PP 220020ent AAUUTTOOEEXX em

CCOOMMPPOONNEENTS

nag in CrisisIAMa

Supply Cha

IND INDIA S

ChaiV6nalue Chain 6 r o F s n r o o i F s n o i Decis s i c e D TomorrowTomorrow

6 alue V th

nag

in Crisis Ma

Supply Cha

PPLIERS TOMOTIVE SU ER ICE OF THE AU MOTIVE SUPPLI

VO E AUTO VOICE OF TH

hANNIVERSARYY

OO20 PP 220020ent AAUUTTOOEEXX em

th

thANNIVERSARRYY

NNIVERSAR

ANNIVERSA

Now read your favourite magazine wherever you go...

Available on PC... Mac... Tablet... or any other handheld device! Figure 4. Standardized stress results for the rotor.

Dr Steffen Rothe (Simulation Engineer).

100 `` 100 ` 100

they could automate the load testing to user co does not have includes a strength rating for laminated m to learn the details of .com dia.co tsin sindia en ent on on mp mp uto utoco w.a w.a ww ww include interference, temperature, and how the simulation works.” rotor sheet sections and helps to operating speed. These are parameters standardise the report summaries across Standardising that colleagues in other departments teams (Figure 4). development to serve would benefit from being able to change Through the stress analysis of S 20 T 20 N E PO PO 2020 AU EX COMPON and INDIA TOEX nt AUTO geme INDIA company customer themselves. General variable parameters rotor laminations using simulation Crisis Mana ain Ch ly Supp SUPPLIERS AUTOMOTIVE VOICE OF THE needs include geometry, area, interference, applications, engineers at VW Kassel In addition to automating the contacts, number of active magnets, and are able to save time and money during th RY Acquisition thANNIVERSARY olding 6 SA ER Sharehthe NIV development process among departments materials. These considerations helped development process of electric CO AN AB W ZF l ren g on Sp ion lydiinng ntsqu isditsimulation Re itio ne quee ishe a: pong AcSp diKassel, m In atOeVW specialised Hermanns put together an intuitive user Bros drives. The applications also contribute Ac Co h ol is di rk eh ol Tu ar eh e ThABCO Shar C Sh el ianc ZF W pl mSp l Co dph eed l3)ZF WAB applications VI ee re Sp help the engineers interface for the application (Figure to increasing product quality e dia.comby helping BS r on sin fo nt on S ng n ne g ts n po yi io in n io ly el at om e gr ong Acquisit te a:hRe In di mldpin India: R o www.autoc In C e se os ro is B Br dia rk o sin h nt Tu e ne e ar po their benchmarking that colleagues could use to automate theW simulation experts and nonexperts alike ThABstandardise utocom CO Sh /aprocess ZF ll edce @ACImagazine ponentsindia.com SinVgI CoonmSppliean reB fo cial nneeded. oia ti m of rotor The application calculations automate the lengthy model construction diaoffilaminations. ly ra co sin g to R nt : au te ne w. po In d w om w In /autoc Brose dia omponentsin /autocshortens the time it takes to perform “The idea was to create Im anagapplication process and standardise models and e in az @AC l ciaenable common tasks such as applying for colleagues an easy and fast results, shortening the distance it takes ntsindiaoffito ne po om oc ut /a boundary conditions, materials, and way to benchmark different designs,” to get from model to concept vehicle to loads, and is standardised and combined Hermanns says. “Additionally, one can commercially available EV. ACI H C A into a user interface. A further benefit is create a tool for a specific problem with ---------------------------------------------O R P P A D EGRATTEreport, OACH Courtesy: Mobility Engineering R P AN INTgenerated P A which an intuitive user interface. In this case, the an automatically D E A R EG

ble on

SS C I N O R T A S H C I C E N MECHATROCOMM NPONIEECNCTSSHATERD OAPNPIRCOACH 02 e e 01 7 Issu 7 Issu Vol Vol

0 2020 l 202 ch ch Apri Mar Mar

01

M O AACTHED APPROACH R GR O T E R T A P N I H P A N C A E D E T M A AACT H aRin AN INTEGR ANAIN PeTPECRhGO VOICE OF THE

AUTOMOTIVE

SUPPLIERS

D6Valu ns For E T A R G E T N I N A Decisio Tomorrow

SS TTRROONNIC HA CH MEEC IC A

M

AN INT

Now read your favourite Available magazine wherever you go... Available on PC... Mac... Tablet... or any other handheld device!

on

diaofficial

tsin /autocomponen

@ACImagazine

/autocomponen

Digital Platform

Digital Platform

Digital Platform

/autocomponentsindiaofficial /autocomponentsindia

` 100

www.autocomponentsindia.com Vol 8 Issue 06

ition

olding Acquis

reh l ZF WABCO Sha ren Sphe ts uis itio Acq h Co ngen kisare ldion homp Tur TheBC O Sh el nc WA lia ZF mp l Co d com VI ee BS for g on Sp ion mponentsindia. lyin rat toco Re eg ia: w.au Int ww Ind Brose tsindia ying on Speed

Brose India: Rel

August 2021

#TRENDING

Available on Available on

COMPONENTS

INDIA

Digitisation In Manufacturing

VOICE OF THE AUTOMOTIVE SUPPLIERS

@ACImagazine Digital Platform

www.autocomponentsindia.com ACI Mag THE ESLA OPPORTUNITY FOR MORE INDIAN SUPPLIERS BEV GO-PARTS AND WEAR-PARTS

DuAl-siDeD-CooleD siliCon CArbiDe inverter @autocomponentsindiaofficial

28

@ACImagazine

t.me/acimagazine

International

Mobilised

Autonomous mobility theme DAy 2021

@autocomponentsindia

lAnxess ev ChArging inlets

www.autocomponentsindia.com

ACI Mag

t.me/acimagazine

/acimagazine

AUTO COMPONENTS INDIA n AUGUST 2021

/acimagazine WWW.AUTOCOMPONENTSINDIA.COM

Now read your favourite magazine wherever you go...

Available on PC... Mac... Tablet... or any other handheld device!

` 100

.com ponentsindia www.autocom August 2021

#TRENDING

Vol 8 Issue 06

COMPONENTS

anufacturing

Digitisation In M

INDIA

E SUPPLIERS

E AUTOMOTIV

VOICE OF TH

ORTUNITY P P O A L S E ERS THE I L P P U S N A I D FOR MORE IN D WEAR-PARTS AN BEV GO-PARTS International

Mobilised

lAnxess ts ev ChArging inle

Autonomous mobi theme DAy 2021

lity

eD DuAl-siDeD-Cool rter siliCon CArbiDe inve tsindiaofficial

@autocomponen

Available on

@ACImagazine

tsindia

@autocomponen

nentsindia.com

www.autocompo

ACI Mag

e

t.me/acimagazin

/acimagazine

Digital Platform

T

rending

Digitisation In Manufacturing Dassault Systemes has launched DELMIAWorks in India. Sumesh Soman looks at the potential of the ERP and MES solutions suite to digitise automotive manufacturing.

D

30

assault Systemes (Dassault) has introduced DELMIAWorks (DW suite) in India. Joining a host of 3D modelling and simulation applications from Dassault, the DW suite extends to automotive manufacturing operations with a pan India potential for growth. Dassault aims to deploy the Enterprise Resource Planning (ERP) and Manufacturing Execution System (MES) solutions as part of the DW suite. The initiative is said to be in line with the larger vision of digitising every aspect of manufacturing at automotive plants. Speaking at the launch conference, averred PM Ravikumar, India Management Director, Dassault Systèmes, “DW suite exemplifies our commitment for our manufacturing customers in India. Alongside SolidWorks, the suite provides a connection between engineering and manufacturing for small to large enterprises.” “It complements our strategy in India to be a trusted solution partner for the discrete manufacturers in the

AUTO COMPONENTS INDIA n AUGUST 2021

entire value chain, from engineering design to manufacturing, production and shipment of the customers’ product,” he expressed. The DW suite brings with it an array of applications claimed to make use of real-time data for the ERP and MES solutions. The end objective is to multiply the operational efficiency at manufacturing plants manifold. It is achieved by capabilities that include monitoring the end-to-end operational cycles of different business verticals. It is also tangible to functions like finance, design, planning, scheduling, production, quality or warehousing operations. Through the DW Suite, Dassault aims to empower manufacturers to gain a better hold of business with control over functionality and transparency in the value chain. Tailor-made for industries like transportation and mobility, constituting 52 per cent of its customer base, the suite also extends functions to realms like life sciences, industrial equipment, home and lifestyle, aerospace, defence and marine among others.

WWW.AUTOCOMPONENTSINDIA.COM

Trending

The digital transition will accelerate processes and introduce transparency to the workflow.

DELMIAWorks

Automotive and transportation customers account for up to USD 20 million in revenue. The company caters to customers with single sites to global companies with multiple sites, claimed Ramakrishnan Venkatraman, Director, SolidWorks and DELMIAWorks India, Dassault Systemes. Aimed at tackling manufacturing end-to-end and at scale, from order processing to shipping, the DW suite broadly covers ERP, MES, QMS and SCM. Within ERP, it eliminates the data silos to streamline the front office and factory operations to drive efficient utilisation of resources and attain customer satisfaction levels. In MES, detailed production data is captured to deliver big data. The big data spans actionable insights used to control costs, help improve quality and aid in proactive decision making. QMS facilitates compliance with ISO standards, for instance. Through SCM communication of business activities is made seamless in the entire supply chain, he exclaimed. To elaborate further, the DW suite brings to the table, a means to digitise customer relationship management, estimating and quoting sales order management, and capacity planning. It also facilitates advanced supply chain management, WWW.AUTOCOMPONENTSINDIA.COM

finance and accounting, accounts receivable and payable, planning and scheduling. Manufacturers can also hope to digitise job and process costing, inventory control, labelling, shipping and distribution, quality management and production control. Other offerings include MS interfaces, automated workflow, IQAlert activity monitoring and business intelligence among the core activities. The DW suite is notably claimed to tackle accessibility issues associated with the overlapping data being amassed by individual stakeholders in the business. Ravikumar drew attention to the suite connecting businesses to the existing 3DExperience marketplace, in turn, offering access to a pool of companies equipped with engineering capabilities and capable of discharging services like contract manufacturing and on-demand part supplies, known to be crucial for manufacture.

The aftermath of the pandemic

In the aftermath of the pandemic, the DW suite is being positioned as a useful tool to address an array of issues. Be it enabling front office manufacturing workers to work from home or ensuring covid protocol compliance on the shop

The DW suite will aid in restart of operations and help sustain business continuity.

floor. It can be a critical aid to help the automotive industry restart operations and ensure business continuity. The suite facilitates precision planning, for instance, when there is a need to manage sudden shifts with volatility in product demand. It extends to the alignment of materials, forecast, and build strategy across Just in Time (JIT) and Make To Stock (MTS) strategies. It can also prove to be useful in revamping and reprovisioning the supply chains. With the suite, shop floor operations and quality checks can be managed and monitored remotely. It can also effectively minimise personal requirements. Besides enabling track and trace operations it is also claimed to help overcome most manufacturing constraints. Given that times are unprecedented, the acceleration of business is challenging, the DW suite is claimed to be a strong building block to build upon for the future of manufacturing. With intricate care and planning, such suites could help in a fruitful transition. Rossell Techsys of Bengaluru, known to supply to Boeing and Lockheed Martin and Amber Enterprises Ltd. a solution provider to air-condition OEM and ODM in Haryana are among the clientele of the company. ACI AUGUST 2021 n AUTO COMPONENTS INDIA

31

I

nternational

Autonomous Mobility Theme Day 2021 As part of the Continental ‘TechShow Around The World’ series, automated and autonomous mobility took centre stage. Ashish Bhatia highlights the technology portfolio designed for this future.

32

AUTO COMPONENTS INDIA n AUGUST 2021

WWW.AUTOCOMPONENTSINDIA.COM

International

T

he Continental ‘TechShow Around The World Theme’ progressed with a power-packed, exhaustive webinar. Under the theme, the company marked the ‘Autonomous Mobility Theme Day 2021’ with automated and autonomous mobility as the focal points of the discussions. The sessions highlighted the range and complexity of technical systems for automated and autonomous driving and deemed them huge. It was unanimously agreed that to accomplish the end objective, technology companies are required to plan a broad positioning as well as take a holistic approach. Continental claimed to partner with the stakeholders in driving forward the development of all manifestations of automated and autonomous driving to enable solutions to address the challenges of future mobility. The subjects of discussion were Artificial Intelligence (AI) enabled autonomous mobility, global AV regulation, automated driving for commercial vehicles, the road to driverless mobility, vision to perception, seamless mobility, LiDAR, and the Global AV regulation.

AI-enabled autonomous mobility

The session on AI-enabled autonomous mobility touched upon the state-ofthe-art AI solutions on embedded hardware. AI-enabled mobility and autonomous driving technology are known to have come a long way over the past decades and progressing steadily towards the future. Driverless capabilities have enhanced mobility systems as per leading journals researching the subject and claim it to have reached new heights. It has been cited as a key development, one that is inclusive to the older and disabled community with an end objective to offers legitimate, and affordable smart transportation. The future of transportation also depends on the

WWW.AUTOCOMPONENTSINDIA.COM

AUGUST 2021 n AUTO COMPONENTS INDIA

33

I

nternational

private sector-led initiatives on the front of offering new mobility services which will utilise autonomous vehicles.

Expected to contribute to the transformations of supply and demand, it is expected to influence

the developments in traffic congestion and the reduction in emission levels globally. Stakeholders at apex bodies have been urged to gauge the impacts of driving automation, more so when automation attains an influx of demand. Balázs Lóránd PhD Head of Location – AI Development Center Budapest and Regina DeákMeszlényi PhD Head of Deep Learning Methods explained the ingredients and challenges of AI-enabled autonomous mobility. They touched upon the complexity of environment perception, country-specific factors, high variability of traffic participants, and a few rare scenarios. If the software 1.0 approach resembles an ‘if-else flowchart driven algorithm, the 2.0 iteration entails feeding in real-world visuals for a solution with minimal lag. Weaved around machine learning and deep learning neural networks, the session highlighted the advancements reflecting in the increase of available computation. To give a perspective of the inhouse cluster, the deep thought platform comprises of 53 Nvidia DGX servers, 448 NVIDIA Tesla V100 GPUs, seven tonnes of hardware, over 600 cables with a total length of three kilometres known to have been labelled, connected and installed. The peak consumption of the entire GPU

Frank Petznick, Head of Business Unit ADAS, Continental

34

AUTO COMPONENTS INDIA n AUGUST 2021

WWW.AUTOCOMPONENTSINDIA.COM

International

Global AV Regulation Status Worldwide Type Approval Development Level 4 & 5 Region

2019

2020

2021

Safety Requirements & Validation Methods AD

(UNECE - GRVA)

› Simulation and Virtual Testing › Track and Real-World Test › Scenario Database › Audit and In-Use-monitoring

(EU COM)

2023

AD Type Approval Guidelines

› EU Regulation (EU COM) › AD Regulations China

1st skeleton by 12-21

(CARTAC)

› AD Regulations USA (NHTSA) European Type Approval Regulation

National Type Approval Regulation

(BMVI)

National Standards for ICV1) MIIT 2) : Access Rules for ICV Vehicles and Manufacturers

(CARTAC) (NHTSA)

2022

Self-certification without ODD3)/OEDR4) limitations based on

› “Automated Driving Systems 2.0: A Vision for Safety” with focus on 12 safety criteria › self-certification sales: the manufacturer needs a permission to deploy autonomous vehicles

1) ICV = Intelligent Connected Vehicle/Automated Vehicle 2) MIIT = Ministry of Industry and Information Technology

3) ODD = Operational Design Domain 4) OEDR = Object Event Detection Range

Worldwide type approval regulation is under process TechShow Around the World

is said to be ~360 kWh. The cluster operates on a 100 Gbps network. The project can be set up in a time frame of seven months with an assembly time of two weeks. Efforts have been made to provide automotive-grade embedded hardware with a high compute capacity made available with the use of low power.

Global AV regulation

As per the Center For Strategic and International Studies (CSIS), for Autonomous Vehicle (AV) developers to remain competitive against other countries and at the same time uphold strong safety standards, countries like the United States, for instance, are required to update their regulatory frameworks with the requisite standards. With the innovation of self-driving cars said to be at an inflexion point, the need of the hour is to formulate current standards in a manner that facilitate innovation and do not impede the growth, safety, consumer acceptance, and economic potential of AVs. Data and liability issues are known WWW.AUTOCOMPONENTSINDIA.COM

Heiner Hunold, Head of Regulatory Affairs AMS © Continental AG