3 minute read

Sixty Years of Machines Part XI: Auto-Jigging Innovations

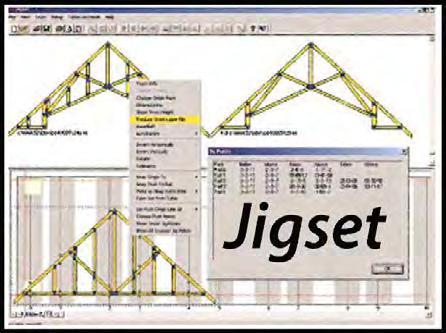

Joe Kannapell - P.E. Senior VP, MiTek USA www.mitek-us.com C lyde Fredrickson, a CM in the remote reaches of South Dakota, was determined to find a cheaper solution to the $250,000+ auto-jigging systems. So, he worked through several alternate ways to shorten setup times, like printing out Jigset coordinates, and moving pucks manually to designated locations. This worked okay until measuring tapes became too hard to read. In addition, his crews tended to waste time pouring over printouts, and then placing too many pucks. In the end, like most Jigset users, he soon went back to “string-lines and measuring tapes.” But he did figure out how he could extract the perimeter jigging locations from the MiTek Software, which made him think about other possibilities.

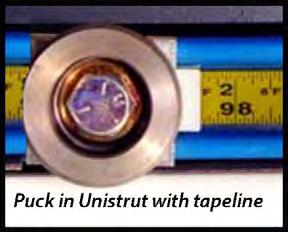

Most CMs agreed with Clyde and balked at the price tag. Some tried a non-automated, air-tool assisted version of auto-jigging. This method was much faster than Jigset, but still required operators to read a printout and decide where to place pucks. When the Unistrut channels were kept clean, this proved to be an effective solution.

In 1995, after auto-jigging had been deployed for over five years, BFS installed the Koskovich Jet Set System (see Part X of this series comparing it to the laser systems). This system consisted of large rectangular extrusions installed deep inside specially designed truss tables. Due to their high cost, Jet Set enclosures were deployed sparingly, approximately 30” to 48” on center. They performed well, but the minimal jigging they provided was insufficient for complicated trusses.

As we entered the new millennium, time was taking its toll on the above systems. All were fully enclosed: collecting sawdust, wood chips, and dirt from the surface of the table, without an easy cleanout. Even the simplest of these, the tape in a Unistrut channel, became unreadable, or the puck would become bound up in the channel. For the systems which enclosed a threaded rod in a channel, debris became an even bigger problem. The top of the rod was openly exposed on the surface of the table, and the threads of the screw easily picked up foreign material, especially when recently lubricated. Often the thin, 1/8” wall of the Unistrut was deformed by a misdirected hammer blow, putting the puck in a bind. Not finding a feasible resolution, BFS scrapped its Jet Set System. But there was a solution at hand, way up North in the middle of nowhere!

In their own plant, Clyde Fredrickson and his brother, Terry, tackled the two major drawbacks of existing systems: the exposed screw and the debris-catching enclosure. That their Britton, SD (population 1200) plant was several hours from supporting vendors in Fargo, ND or Minneapolis, MN didn’t hinder their efforts. And despite the dozens of patents protecting auto-jigging technology, some valid for over a decade, they progressed forward. By 2002, they had developed a way to protect the screws, and fashioned an open slot to allow table debris to drop through to the floor. They were ready to order 40 ft. of new tables without tops, so that they could fabricate and test a single setup. When their financial partner, John Kraft, asked them how much more they could build with such a system, Clyde speculated that he could double his production. John quickly surmised that they should order triple the length of table: 120 ft. This would be a huge stretch on the business’s resources: requiring a building addition, expensive PLCs, electronics and hardware, and the expense of a patent application. Fortunately, Clyde’s bankers went along, and the rest is history. In early 2003, the first of several patents was published, protecting the unique features of his invention.

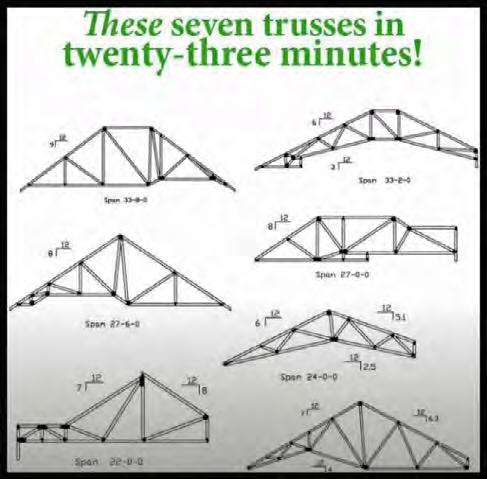

The Wizard PDS System reached the marketplace with proof of its efficiency embodied in the ad shown here. And over the past 15 years, it remains the autojigging standard of the industry. All this from American’s heartland; the greatest testimony to entrepreneurship so far in the component industry. Commendations to Clyde and Terry Fredrickson and team!