A dverti $ er Component manufaCturing

Serving the Structural Building componentS induStry

S

“Precision Equipment Truss Trailer Manufacturing Adds Galvanized Rollers as an Option” Cover story on page 76

Advanced equipment for truss and wall components.

As a longtime partner to the construction industry, Simpson Strong-Tie continues to explore and invest in advanced equipment. Around the country, manufacturers and LBMs are already gaining speed and accuracy with our EasyFrame automated marking and cutting system for wall panels. Now with Monet DeSauw truss machinery — a full line of precision component and linear saws — you have all you need from one source. Along with industry-standard connectors, fastening systems, software and professional design services, our cutting equipment is available nationwide. It comes with fast, onsite installation and in-depth training to get your team up and running, plus expert support. Learn more at go.strongtie.com/cs or contact your sales representative.

A dverti $ er Component

Anna Stamm – Advertiser Forum: Always Remember to Soar

Joe Kannapell: Home Building Technology, Part II: Mass Production Technology

Wendy Boyd – Spida Machinery: Benefit from a Wall Line Solution That Fits Your Business!

Todd Drummond Consulting, LLC: The Sales Team’s Number One TimeWasting Activity

Glenn Traylor: What is the Risk of Using Incorrect Lumber?

Ed Lim – LimTek Solutions: Joint Detailing for Accurate Plate Placement

Ben Hershey and Thomas Griffin –4Ward Solutions Group: The Digital Revolution in Offsite Construction and Manufacturing

Dario Schmidt – Stiles Machinery: A Case for Manufacturing Execution Software (MES)

Bryan Shinn – Precision Equipment: Precision Equipment Truss Trailer Manufacturing Adds Galvanized Rollers as an Option

Carl Villella – Acceptance Leasing: Roof Truss Industry Outlook: Navigating Challenges and Seizing Opportunities

Steph Karlstad – LFT Strategies: A Core Artery of Your Truss Plant

Thomas McAnally – TheJobLine: Reasons Why Truss Designers Leave Their Jobs

Geordie Secord – Design Connections: Complex World of Truss Design Access

Carolina Structural Systems Team: Growth and Accolades for Component Manufacturing

Lesko Financial Services Team: Starting 2025 with Reserved Optimism

MiTek Staff: MiTek Trimmable End Details

Simpson Strong-Tie Staff: Scabs on Webs & Parapets

Joe Kannapell – The Last Word: Building Companies and Building Teams

111,113,115,119,125,134,138,139,143

Publisher Thomas McAnally twm@componentadvertiser.org

Editor Anna L. Stamm

800-289-5627 x 3 anna@componentadvertiser.org

Distributed FREE Via e-mail subscription Download PDF or Read on line at www.componentadvertiser.com

News of Interest and Advertising inquiries can be submitted to: anna@componentadvertiser.org An Open Forum for many sources.

Deadline 20th of each month. Articles, Trade Names, and Logos are the property of their respective owner or creator unless otherwise noted

Disclaimer: We reserve the right to refuse any advertisement or material that we deem not in the interest of the industry or the Advertiser. Permission to use content is the responsibility of the contributor including permissions to use any likeness of persons.

The Advertiser is provided “As Is” including typographical errors, omissions, and mistakes both intentional and unintentional.

Believe it at your own risk!

Copyright 2008-2025

Component Manufacturing Advertiser

The Advertiser 7586 Becks Grove Road Freetown, Indiana 47235 no reproduction in whole or in part without permission from the component manufacturing advertiser Archive Copies Available On Line www.componentadvertiser.com

Anna L. Stamm Director of Communications and Marketing Component Manufacturing Advertiser.

AAdvertiser Forum

Always Remember to Soar

s I read replies to notices I posted of her death, I was impressed with how many of Susan’s friends and colleagues mentioned the joy my sister brought to their lives. Be it authors she helped throughout the last three decades or classmates she has not seen since junior high and high school, the remembrances spoke of her cheerful spirit, helpfulness, and sense of humor. She would have been surprised, overwhelmed, and touched by the outpouring.

I’ve also been asked why a charity in Boise was chosen for donations in her memory. The answer is simple. On a business trip many years ago, she had the opportunity to visit The World Center for Birds of Prey, which is the headquarters of The Peregrine Fund, a non-profit founded in 1970 that conserves endangered raptors around the world. The beauty and majesty of the birds spoke to her, and the center’s hands-on commitment to education and conservation left a lasting impression.

In 2021, we had the opportunity to “buy a brick” during an expansion to construct a new education center, landscape-based peregrine falcon and hawk exhibits, a family-friendly courtyard, and an outdoor classroom. With elements of play and exploration built into their facilities, children engage in hands-on STEM-based learning, and visitors of all ages have the opportunity to see themselves as scientists and, through the lens of raptor conservation, learn how we can all play a role in conserving our wildlife and wild places. For our brick, we were able to write our own message. That too was a simple decision: Always Remember to Soar.

Pursue Your Dreams

Great tragedy is a time to reflect on what we have lost. It can be devastating and truly be The Hardest Days of Our Lives. But through the darkness, we must find our way and keep moving forward. And in so doing, we must remember to honor those we have lost by living the lives they would want us to have. We must remember to act with purpose. We must remember to value our time with others. We must always act with kindness, generosity, and a caring spirit. And we must always remember to soar.

Monet DeSauw FWA 500 Floor Web Cutter

• Push Button Powered Blade Angulations

• Single Push Button Setting for 2 Blades per Side

• Electronic Digital Readouts

• Backup Mechanical Indicators

• Cuts 4 Angle Webs, Cantilever Webs (2 piece webs) & Square Blocks

• Magazine Lumber Feed for 3x2, 4x2 and 6x2 Lumber 12 1/2” to 48 1/2” Length Capacity (7” Minimum on Square Blocks)

• 60 Pieces per Minute

• (4) Internal 16” Blades & (1) External 16” Cut-Off Blade

• Pneumatic Blade Brake on External Blade

• Dust Hoods

• Belt Waste Conveyor (under saw)

• Add $4,300 for 12’ Incline Waste Conveyor (adjacent to saw)

• Add $2,100 for Extra Set of Blades

• 480 Volt / 3 Phase FOBMO Call For Pricing

• Automated (Truss Design Software Download) or SemiAutomated (Touch Screen Entry) Operation

• All Movements are Computer & PLC Controlled

• Comprehensive Setup Screens Display Each Piece with Setup Data

• 22” x 40 Tooth Blade on PAE Cut 1 or 2 Boards up to 20’ (2 Second Plunge Cut)

• Cut Chords, Webs, Rafters, Wedges & Stair Stringers

• Cut Long Scarfs by MultiPlunging

• Servo Positioning on Infeed, Angle & Outfeed Pusher

• Over Travel Protection

• Ink Jet Printer

• Lumber Optimization Program

• Belt Waste Conveyor

• 480 Volt / 3 Phase / 60 Amp

• Includes 5 Day Onsite Installation & Training

• Optional Monet DeSauw Live Deck, Bunk Feeder & Incline Belt Waste Conveyor FOB MO Call For Pricing

• Touch Screen User Interface with Backup Mechanical Controls

• 3 Operating Modes: Auto, SemiAuto & Manual

• All 20 Axes of Movements are Computer & PLC Controlled

• Comprehensive Setup Screens Display Each Piece with Setup Data

• Anti-Collision & Optimizing Programming

• Auto Calibration Productivity & Time Tracking

• Maintenance Diagnostics

• Variable Speed Conveyor (0-50 Flights per Minute)with Powered Hold Downs

• (1) 30” x 80 Tooth Blade (27 3/4” Scarf on PAE)

• (4) 16” x 40 Tooth Blades (13 1/2” Scarf on Centerline)

• Pneumatic Blade Brakes on all 5 Blades

• 16 1/2” to 20’ Length Capacity (11” Minimum on Square End Blocks)

• Vibrating Waste Conveyor Under Saw

• 480 Volt / 3 Phase

• Includes 4 Day Onsite Installation & Training

• Add $2,900 for Extra Set of Blades

• Optional Live Deck, Label Printer, Ink Jet Printer, Catcher Display & Incline Belt Waste Conveyor.

EZ-SET AUTO JIGGING EXCLUSIVE & PATENTED DESIGN

Automatic Truss Jigging System to drastically reduce setup times. Allows for 100% embedment on the table, with top & bottom chord pucks in the same slot. TopSider or standard configurations available for conventional kick-leg, walk-thru, or our new trackless 8' and 10' continuous table systems. Systems for other roller & hydraulic gantries are coming soon. Available in new machine installations or for retro-fitting your existing table. The TopSider is exclusively applicable for “kick or flip leg” style truss presses such as the Tri-Axis & Lumbermater®

FEATURES / APPLICATIONS

• Capable of 100% On-Table Nail Plate Embedment

• Two Pucks Per Slot

• 24", 26", and/or 30" Spacing

• Compatible with all current major design software

• Multiple Simultaneous Layouts

That'sallthetimeittakes todrillstudsforrunningRomexorotherelectricalwireinthewallpanels

Motor: HeavyDuty5HP-3phase-220vor440v(Pleasespecifywhenordering)

MotorcarriagebearingandspindleassemblymountedonBlanchardgroundsteelplate

LinealmotionishardenedandgroundVbearingsandrails

BlockSizes: 2x4through2x12infiniteheightsettingtocenter

AirSupply: 100psi10CFM

Drills: 2wing3/4'”CarbideTippedcanaccommodatesmallerorlarger

Spindles: AlloySteelpolishedandgroundprecisionshafting

Frame: 2"SteelWithPowderCoatFinish

Covers: 10Gauge(1/8"Thick)Aluminumremovable

Dimensions: Height-60inches,Width-33inches,Depth-33inches

Shippingweight: 750lbs.-(Includingcrate)

MADEINAMERICABYAMERICANS

By Joe Kannapell

Home Building Technology, Part II: Mass Production Technology

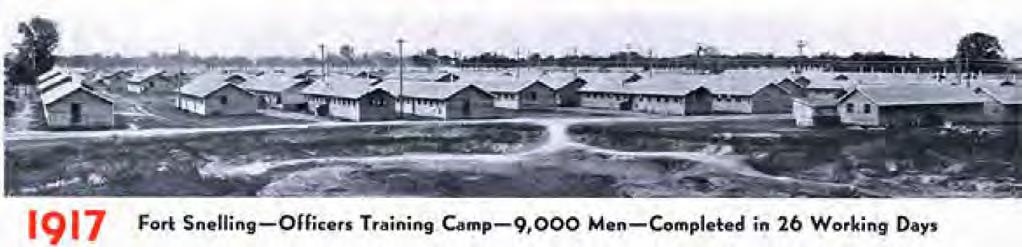

While Sears had stolen the spotlight on precut technology, their lesserknown rival, Aladdin Homes, helped usher in prefabrication, but not initially. For many years, Aladdin fought the concept of preassembling parts of homes in their factory, asserting that their precut packages took “one-half the number of cubic feet that the same building would require in panels.” This certainly was a relevant factor very early in the 20th century, before trucks could haul large volumes of cargo. Sears, for example, shipped via rail, and it took up to three railcars to ship one of their precut homes. So, using Aladdin’s analysis, Sears would have incurred twice the shipping expense if they panelized their Honor Bilt Homes. Aladdin also asserted the same rationale that prevails in many corners today, that their “Readi-cut buildings can be erected as with practically the same rapidity as prefabricated panel type buildings.” And they demonstrated this on a large barracks project that was built incredibly fast in the frenetic war year of 1917. Even though Aladdin’s owners didn’t use panels on this project, when the next war was imminent 20 years later, they recognized that the dramatic improvements in transport and material handling would make panelization feasible. What they probably didn’t realize going into that war, however, was the immense scale of the military bases that would have to be built.

Sears also took on a large development in 1917, but of a different character – it was 192 units that Sears shipped to house workers for a Standard Oil refinery. Observing the rectangular footprints of these houses would suggest that panelization was feasible, but not in that day and age. Even if trainloads of boxcars could be marshalled, the difficulty of loading and unloading wall panels by hand would be overwhelming, as the modern forklift wasn’t yet widely available, having only been introduced in 1917 too.

Yet, even without the availability of more modern material movement capabilities, Aladdin, Sears, and Hodgsons panelized smaller buildings because all of the panels could fit onto one of the early delivery vehicles (for more on Hodgsons, see Home Building Technology, Part 1: Wall Panel Beginnings). As noted in the page shown from the 1925 Sears catalog, these were known as sectional structures. Hodgsons used six-foot sections/panels, because they were light enough to be manhandled, lacking interior finishes. However, Sears used three-foot panels to ease handling concerns, since they were usually finished on both faces, and because window and door panels fit nicely into modules of this width.

Wall panels were far from the minds of the dozen precut home suppliers as their businesses grew steadily throughout the 1920s. However, they suffered mightily in the depression years of the 1930s. Montgomery Ward quit selling homes in 1931. But Sears, with its massive resources, could artificially boost sales for several years by liberalizing its lending policies. In 1937, Sears received a government contract for 18 prefabricated Civilian Conservation Corps Camps that were built as sectional units. And to supplement lagging sales during the mid-1930s, Sears began selling lumber, just as Trussway would do at the bottom of the Great Recession in Texas in the 1990s. But, just as Trussway would discover, the low margins on lumber sales could not support any level of manufacturing infrastructure. Consequently, the losses occurred by Sears in their operations were compounded by the huge loan write-offs they sustained when they ceased catalog sales in 1940.

Fortunately for Aladdin Homes, its owners could not afford to embark on that kind of aggressive but ultimately imprudent survival strategy. Also unlike their much larger rival, they did not have to answer to shareholders. Instead, Aladdin was able to scrape by until the massive military contracts started being offered for bid in the late 1930s. From their prior experience, Aladdin was able to anticipate what it would take to become the best facilitator of the mass production of the repetitive structures involved. To be successful, they realized that they would have to adopt panelization, and also, for the first time, figure out how to include roof trusses.

Next Month: Prefabricated Trusses Debut

DESIGN SOLUTIONS

DESIGN

Elevate Your Wall Panel, Floor Truss or Roof Truss

Manufacturing with 4Ward Design Solutions’

Precision Component Design Services!

When you work with us, you get: and

Speed and Scalability

Adjustable Hours

No Need for Training

Reduced Regulatory Burdens

Reliable Timelines

Excellence

Extend your existing capabilities with 4Ward's design expertise. Without the hassle and expense of training your own designers, partnering with us guarantees that each wall panel, floor truss or roof truss will be designed for structural integrity and production and field efficiency.

Achieve cost efficiency without compromising on excellence. Our costsensitive approach ensures maximum value for your investment.

Leverage our expertise, ensuring every component is attentively designed for optimal performance and durability.

We understand that every component project is unique. At 4Ward, we create custom designs, tailored to your exact specifications. Contact us today for a complimentary consultation.

SCALE YOUR BUSINESS

Get the industry-leading software and automation technology you need to scale your business. Overcome market challenges, boost productivity, and confidently meet demand when you choose MiTek as your solution partner.

Are you ready to scale your success?

EXTENDABLE TRUSS TRAILERS

Wendy Boyd Chief Customer Officer Machinery Group Spida Machinery

Benefit from a Wall Line Solution

That Fits Your Business!

When it comes to wall frame lines, they aren’t all made equally. At Spida Machinery, we pride ourselves on providing solutions that are comprehensive, innovative, and most importantly, designed for your manufacturing needs and budget.

The beginning of the year is often a time to reflect and plan for the months ahead and where you want your manufacturing operations to be. With recruitment and retention of labor continuing to be challenging, alongside increasing costs, streamlining your processes and automation are key areas for you to consider in 2025.

Wall Frame Solutions That Start and Stop Where YOU Choose

When talking with customers about wall lines, they often share with me that they can’t afford a “full” line or they don’t have space for a line of machines, so they don’t feel they need such a solution. But, what I convey to them is that our solution is being able to design a wall line explicitly for their business. With a Spida solution, you can start and stop where you wish, ranging from a complete line to just adding a Wall Extruder or Raked Wall Extruder to your current process.

A typical wall frame line at Spida starts with the Major Sub Assembly Table which allows for construction, assembly, and transport of major sub-components. You then have the ability to add relevant machines based on your needs and budget, down the line to complete the building of the wall frame, ending up with the Wall Stacker Outfeed which is a station that accumulates the finished frames as a bundle or stack, ready for the forklift for loading.

You can have as much or as little as you want in this wall line process. A hero within our wall frame line is the Raked Wall Extruder. The operator places the top and bottom plates into the Extruder, clamping in place, followed by feeding the first component of the wall between the plates, and the nails are fired automatically through the plates into the component. The process is repeated until the wall frame is completed. The Raked Wall Extruder is powerful, fast, accurate, and versatile – from this one machine, you can produce both common walls and raked walls!

Some customers opt for the Wall Extruder instead, due to their factory only producing common walls and/or budget considerations.

We can supply a Curved Conveyor that turns the component 90° and allows components to be staged and moved parallel to the line to save space.

Component builders always face the time-consuming and troublesome process of nailing C corners and L studs. Our Stud Extruder helps expedite the process with its placement at the foot of the conveyor. This machine nails together a variety of combinations including C’s and L’s, double studs, triple studs, and fire and cabinet blocking. Also computer controlled and driven by the same file on the Extruder, this is a marriage made in heaven, ensuring accuracy of the components both in construction and staging order.

Some manufacturers need to add door and window openings, and we have these covered as well. The Build Table allows individual components to be added to the wall panels in one workstation within the workflow process, removing any bottlenecks that may otherwise occur.

The Sheather 5 Gun 2 Saw is another option for inclusion in your wall frame, operating on the same file as the Extruder. “Set and forget” with one touch automation means the operator loads each frame and lets the machine do the rest. With the capability of shooting up to 10 nails per second from all 5 guns and clamping and straightening studs from the underside to prevent shiners, this machine delivers a perfectly sheathed wall in minutes!

Another option to add to your wall line is the Ball Castor Table which allows for one-hand operation, to easily rotate the frame on the table for either a common wall or a raked wall.

When it comes to adding a wall frame solution, we’ll work with you to understand what you’re wanting to achieve and recommend the best machine or machines to allow you to achieve this. Continued next page

Benefits of Adding a Wall Frame Line

There are many advantages from adding a frame line to your manufacturing, including how it

• Streamlines your wall manufacturing process and provides consistency,

• Reduces manufacturing costs and increases production,

• Adds innovation and automation, which is not only good for you but also your employees as in most cases the machinery, not the worker, is doing all the heavy lifting,

• Provides excellent ROI, and

• Remains simple to operate due to its intuitive software.

Our robust and reliable machinery is built for the production environment it works in, and we’d welcome the opportunity to talk with you more about what other benefits you can expect when adding a Spida wall line.

Common Concerns When Considering Adding a Wall Frame Line

I’ve been fortunate to talk with many customers about adding a wall frame line, so I’ve heard what the common concerns are. We have answers for these too, so please let me put your mind at ease on these items.

• Is the cost prohibitive? – No, because as I mentioned earlier, we design the wall frame line solution for your needs and budget. One customer said to me, “I don’t have millions to spend on this,” and my answer was, “you don’t have to.” The cost is reflective of the solution you choose, which may be only one machine or multiple machines, that are tailored to your budget, your needs, and your future plans. The great thing about our machinery and how we structure our lines is that you can start off small and add machinery to the line as and when you’re ready. Or, for those who have the need and budget now, they can add a complete line from the get-go – we’re very flexible and will work with you.

• Will this be too big of a change to our manufacturing process? – Change of any type can be daunting and potential customers have shared with me that this move from heavily manual labor towards automation with adding a frame line just seemed like a step too far. But, what I impress upon people is that our machinery has been cleverly designed, with intuitive software making it simple to operate. At Spida, we also provide onsite specific training for you at your factory, which means your employees will learn how to properly frame a wall in a day or two, as the majority of the thinking is done by the machinery

Also, we work with you on an installation and training plan to ensure minimal downtime to your operations.

• Is there enough space in my factory? – Well, that really depends on the solution, doesn’t it?! Given we customize the solution for your needs, we’ll work with you to provide something that makes sense for you and optimize the footprint you have. We will even work with you to develop a layout that suits your factory, material handling, and all the available space for your new line.

• Will it be difficult to service the machinery? – Service is not a challenge with Spida! We have a dedicated service and support team locally who provide reliable and responsive service, support, and parts to our customers in the U.S. and Canada. We don’t outsource installation or servicing, so you can rest assured you’ll be well looked after by a member of the Spida team.

Reach Your Growth and Automation Goals

The manufacturing sector will continue to look at ways to improve throughput and reduce costs in 2025. We encourage you to consider how automation within your workflow will help you achieve these goals.

Here at Spida, we don’t offer a “one size fits all wall frame line” but instead are committed to partnering alongside you to bring a customized, fit-for-purpose solution to your production floor. When recommending such a solution, we take into account your manufacturing needs and objectives, your pain points, and of course your budget, to bring this solution to life. When you’re ready to take the next step and learn more about how a wall frame line solution (of any size) can benefit you in 2025, please reach out to me or one of the Spida team.

Custom Cutting & Material Solutions For Your Plant

ProCut™ UC Linear Saw

ProDeck™ Linear Infeed Material Handling

The ProCut™ UC Linear Saw Series is your perfect cutting soluti on for roof, floor, and wall panel components—from webs, chords, sliders, and wedges. Its 6-position clamping squares and holds lumber securely, ensuring spot-on accuracy for up to four boards high.

Pair your ProCut UC Linear Saw with the ProDeck™ Lumber Infeed for a steady flow of lumber, accumulating and dispensing materials seamlessly to the sawyer for processing. Customize your setup with our range of Material Handling Options, eliminating carts and reducing plant congestion. Our products streamline operations and deliver perfectly cut materials directly to your assembly stations!

Cut, deliver, and build with ProCut™ UC Linear Saw Series—designed to meet the demands of modern component manufacturing.

• Automated Cutting with Software Download to Operator Console/ Computer

• 20' Capacity Loading Conveyor System

• Automated Infeed Wheel

• Automated Clamping & Positioning System

• Angle & Bevel Drive for Truss Cutting

• 20' Capcity Outfeed Table with Ink Jet Printer

• 6 Arm Storage Deck (adjacent to saw outfeed table)

• Waste Conveyor (under saw, waste/ small parts to the rear)

• Incline Waste Conveyor

Waste Conveyor (under outfeed conveyor)

Extra Programmed Computer

New L1 and L2 Belt

2 Extra Blades

The Enventek Collated Plate Dispenser

Truss Plate Specifications

12 inch Maximum Plate Width

20 inch Maximum Plate Length

20ga, 18ga, 16ga and High Strength Plates

Expandable and Customizable

16 Truss Plate SKUs per Module

8 SKUs per Side

Customizable in Multiples of 16 SKUs Includes Touchscreen Computer (left end), Overhead Status

Displays (each side), Label Printer and Hundreds of Bins

Customizable Bin Exits

Plates Dispensed to Bins in Layers Based on Number of Joints per Truss

Plate Dealing Schemes: Left-Right, RightLeft, Top Joints then Bottom, Bottom Joints then Top, By Truss Table Quadrant, etc.

Build More Trusses On Your Million Dollar Tables

Distribute Truss Plates Around Every Truss Build

Table Just Like Dealing Cards

Speed Up Truss Build Crews, and Ensure Quality

Standardize Truss Plate Organization and Distribution With the Enventek Plate Dispenser

That’s How You Feed The Beast!

F1 Pit Stop Each Truss

Employee-owned

√

√

√

√

The Sales Team’s Number One Time-Wasting Activity

When it comes to the sales team, the very group that provides the lifeblood of the entire company, there is often one blind spot for wasted efforts. Why do so many companies allow their sales team to jump through so many hoops to find need-to-know-right-now information? Why must the sales members so often have to call someone within the company, interrupting the work of those they are calling, to obtain the critical needed information? Often, each sales team member wastes at least two to three hours daily. The amount of wasted hours is enormous.

Too Much Time Calling Someone Internally — The number one excuse for this daily time-wasted exercise is the sales team not utilizing existing application programs, such as accounting or specialized component management software. As my clients have stated, “They just need more training or the ERP system needs a little more development.” But, then I will ask in reply, “If they have not been using your existing system, which has been in place for years, why do you expect different results?”

Best of the Best Projection Management Communications — The gold standard to eliminate these wasted hours for the sales team, and every other group looking for project information within your company, is set by one application, AppWright. Proof that AppWright can work for any company in our industry is the fact that one of the largest LBM companies in America uses AppWright to consolidate all the project information into one application to tie all the various divisions and various applications together. It does not matter what specialized application a department, such as door or wood components, uses for their task because they can link them to AppWrigh via API. (More on linking programs below)

Instant

Information Retrieval — Whether it is project information or task assignment related, everyone is held accountable because it is difficult to argue with someone when they know they can instantly see the live status and retrieve any information about any project from their cell phone. For example, if a customer states something is missing on the jobsite, the salesperson can instantly retrieve the picture(s) of the delivered items the driver has uploaded to the project, which was extremely easy for the driver. Any salesperson, department manager, or individual needing information about a project has access via any browser. Of course, everything is based on users’ access rights.

LBMs, CMs, and Home Builders — Over two decades, AppWright has gradually emerged as one of North America’s leading cloud-based project management communications software, trusted by LBMs, CMs, and Builders. Thousands of users are leveraging AppWright in every aspect of their business. Many have found that AppWright is a seamless fit, simplifying the integration of diverse departments regardless of the department’s vendor applications. In addition to the testimonials and case studies on the AppWright website, consider this statement from a home builder:

“AppWright is a one stop shop for scheduling, payment, document storage, and data collection. By assisting in the delivery of greater productivity from the accounting, purchasing and design departments, it allows our builders to spend more time on the actual jobsite; thus, creating a more efficient and timely process. AppWright is truly a program that benefits every department at Newmark Homes Houston and our partners.” — Rodney Mican, Product Development Manager, Newmark Homes Houston

Ease of Use and Customization — It is not just the sales team that benefits, but every department within your company can use this one project management application. Regardless of who is using AppWright, the ease of training is a snap. The user interface is tailored to look like your existing forms, so new users immediately have familiarity with the forms. Furthermore, those forms can be upgraded to an easy step-by-step user interface that allows for “If Statements” selection that then easily walks the user through complex options. For example, if the user selects one of multiple options, another pop-up UI displays the next user selection based on the previous selection. Best of all, this customization is included with AppWright’s services with just a few exceptions.

Customer Portals — You have the option to create customer portals, too. Create a new project request, or check on existing projects, it is totally up to your company what you provide to your customers with AppWright.

Information Grouped by Projects — No matter which department or division of a company, AppWright will combine all the various project information. With a multitude of features that have been highly refined over the past two decades, it will provide the following:

• All emails are linked to individual projects. No more searching for which person sent that missing email because all emails have embedded links to attach them to individual projects. This feature has saved countless hours of searching for needed information.

• All documents are linked to individual projects. Everything can be linked to projects, from job site photos to engineered drawings. Fast, easy retrieval and updating are all available via the cloud.

• All schedules and assigned tasks are identifiable for every department. You can instantly know the progress of all the assigned projects. Capacity displayed with linked dependencies for any department, workstation, vehicle, or individual is always right at any manager ’s fingertips.

• Automated alerts and reminders of any scheduled tasks. What and who is alerted is totally user-configured, which includes alert emails sent to customers failing to meet a deadline for much-needed information.

• There are so many other features that are too numerous to list.

Link Data with Other Applications to AppWright — AppWright provides a rich array of integration using Application Programming Interface (API). You can integrate with other systems, including your existing accounting systems, via our best-of-breed workflow and job management tools, which include BisTrack™ and other line-of-business applications. AppWright’s staff has decades of experience in system integration, so if you can dream it, they can make it happen.

When your company is ready to stop wasting countless hours for your sales team and so many others within your company, take the next step in communications improvement, go with what thousands of users do daily and contact AppWright.

Do not let unwholesome [foul, profane, worthless, vulgar] words ever come out of your mouth, but only such speech as is good for building up others, according to the need and the occasion, so that it will be a blessing to those who hear [you speak]. — Ephesians 4:29

The TDC team is your best source for learning about proven and practical lean manufacturing best practices combined with industrial engineering principles to keep your company at the leading edge of competitiveness. No one is better at providing your team with proven results for good employee practices, pricing, truss labor estimation, and so many other best-in-class practices. TDC’s tailored solutions are for the client’s specific needs. Go beyond the typical software and equipment vendor recommendations for your operations and do what many have dared to do. Embrace the Drummond Method, and your company can experience cost savings and net profit gains that usually take months or years. These gains can be accomplished in weeks or months, resulting in an average of 3 to 6 point net profit gains for CMs. All areas are addressed, not just manufacturing. Please do not take my word about TDC’s services, though. Read the public testimonials many current and past clients with decades of expertise and experience have been willing to give.

Website: www.todd-drummond.com • Phone (USA): 603-748-1051

E-mail: todd@todd-drummond.com • Copyrights © 2025

HUNDEGGER

lnnovationen fur den Holzbau

HUNDEGGER

Hundegger leads the way in automation innovation for the truss component industry. Our advanced CAMBIUM software offers cutting-edge automation and digitalization solutions, revolutionizing operations, boosting productivity, and driving sustainable growth for manufacturers like you.

We go beyond standard mechanization; we champion true Automation. The Hundegger TD-II isn't just a saw-it's a transformative, comprehensive solution designed to streamline your production process. From retrieving lumber to optimizing, nesting, stacking, destacking, sorting, buffering, and precise delivery, our system ensures peak efficiency and productivity, tailored specifically to truss component manufacturing.

REVOLUTIONIZE YOUR TRUSS MANUFACTURING WITH THE HUNDEGGER TD-II

Harness the power of data with Hundegger's advanced CAMBIUM TACTICAL software. It meticulously tracks and optimizes your production, ensuring more automated operations and significant productivity gains.

We provide state-of-the-art automation and control solutions that set the industry standard. Our focus on industrial automation and robotics positions Hundegger as the leader in enhancing performance and efficiency in truss component manufacturing and beyond.

Hundegger products are essential for future-proofing your business. Elevate your productivity and secure your competitive edge with our advanced technologies and automation solutions, meticulously designed to meet the unique demands of component manufacturers today and tomorrow.

Don't get left behind. Invest in the future with true automation from Hundegger and see your business thrive.

TRUSS JIGGING TABLES

• Servo Controlled Single Blade Linear Saw

• 7.5 HP Motor (230 Volt/3 Phase) with 20" Blade

• Touch Screen Computer

• Ink Jet Printer

• Powered Infeed Roller Tables & Outfeed Queue System

• (2) Manual Bunk Feeders (saw can be used with or without bunk feeders)

• Waste Conveyor (includes new belt which needs to be installed)

• 240 Volt / 3 Phase

• Motion Control Upgrade in 2018

• New Computer with Touch Screen in 2019

• T1 Axis Rod and Pillow Bearings replaced in 2023

• (4) T1 Linear Bearings replaced in 2023

• (4) Z1 Linear Bearing replaced in 2023

• (8) Belt Drive Linear Bearings replaced in 2023

• Several Belt Drive Wheels replaced in 2023

• New Z1 Actuator in 2023

• Spare Parts: 2 White Drive Belts, Spare Power Cable, Rebuilt Z1 Actuator

• Video available upon request

BCE-MASTER

A dverti $ er

SAWS

2003 Alpine AutoMill RS Component Saw, Model 344

Computer controlled saw sets up in 2 to 19 seconds and downloads from a network or by using a touch screen for ease of operation. Five-head automated component saw works in both automated (downloading files) and semi-automated control via touchscreen input. It has [23] axes of automated movement, enhanced diagnostics, auto management reporting. The RS cuts from 13″ to 20′ long material in size ranging from 2×3″ through 2×12″, includes [3] 18″, [1] 22″ and [1] 32″ blades with air brakes, shaker pan waste conveyor to incline scrap conveyor, one set of spare blades and any available spare parts. (Infeed conveyor needs electrical service). 480v/60Hz/3Ph power.

$17,997 FOB AZ

Wood Tech Systems

765-751-9990

www.woodtechsystems.com

Striebig Optisaw, model Optisaw Automatic (Type # 5164) vertical panel saw station, with angled frame supporting material being cut: Max. cutting height (vertical) 5′-4″, max. cutting length (horizontal) 15′-1″, max. cutting thickness 2.36″. Both vertical and horizontal analog measuring scales on frame. Cutting head manually rotates from ve rtically t o horizontally for rip vs. cross-cutting, adjustable spacers for repetitive cuts, 5.25 HP saw motor, 9.84″ diameter blade, guide bearings for travel , push button controls, e-stop button and dust extraction hose (no vacuum included). Overall footprint of station 19′-1″ wide x 4′7″ deep x 7′-10″ height. Sold for $36,000 new. 208 volt, 3 phase electrical required.

$14,490 FOB AZ Wood Tech Systems 765-751-9990

www.woodtechsystems.com

2000 Alpine AutoMill Component Saw 2000 Alpine AutoMill model 343H, (5) blade component saw, cuts lumber from 2×3 through 2×12, from 18″ to 20′, 4-angle floor webs from 18″. Includes powered length and angulation, digital readouts, (1) 32″, (3) 18″ & (1) 20″ blade, shaker under-saw scrap conveyor, incline, PC with Windows 98 o/s, and outfeed conveyor. Decommissioned in 2018. Stored indoors. 480 volt ,3 phase electrical required.

$10,497 FOB ON Wood Tech Systems 765-751-9990 www.woodtechsystems.com

Idaco Webmatic Saw

• Roof & Floor Web Saw

• Four 5 HP Saw Motors

• Cuts 2x4, 4x2 and 2x6 up to 16'

• Manual Angulation

• Waste Conveyor (under saw)

• Incline Waste Conveyor (adjacent to saw)

$8,500 FOB CO Wasserman & Associates 800-382-0329 www.wasserman-associates.com

The truss industry relies on 3rd party quality assurance services to provide random visits to review the plants Quality Assurance program along with their operations. If your plant needs to comply with the IRC, IBC and to those who depend on solid, experienced QA expertise, we ask you to consider selecting Timber Products Inspection, Inc. (TP) as your choice for 3rd party inspections.

Proudly serving the forest products industry for over 50 years, TP brings the expertise you need to ensure your business is successful. As a responsible partner, TP delivers to clients, employees, and the industries we serve the confidence to drive value through the effective use of our diverse professional team.

TP would like to welcome the following authorized agents to our inspection team, each of whom have many years of experience in the truss industry!

Al Coffman

Jean Hart

Curt Holler

Chuck Ray

Glenn Traylor

Elliot Wilson

If you have questions about how you can make this selection, please contact your authorized agent above or Glenn Traylor at 919-280-5905 or trusguy@gmail.com. https://www.tpinspection.com/ https://www.tpinspection.com/auditing-services/truss

By Glenn Traylor

What is the Risk of Using Incorrect Lumber?

What is at risk when we fail to use the correct lumber? If you are not careful, it could cost you your business.

Several years ago, I received a call from a client searching for a solution to a problem. Unfortunately, their purchasing department got a “great deal” on some lumber, but in the process, there was considerable misunderstanding as to how this would impact their final product. First of all, Section 3.4.1 in ANSI/TPI 1–2014 states, “Truss lumber shall be the size, species and grade specified on the truss design drawing.” If substitutions are made, lumber must be substituted per Section 3.4.2.

This requirement means the substituted lumber must meet or exceed 8 specific values.

As a great reference, Timber Products Inspection has compiled design value comparison tables for several popular species and species groups. This is a helpful tool for truss manufacturers to determine if a lumber grade and/or lumber species substitution satisfies the original truss design. These charts are included in the April 2023 article by David Conner, “Truss Design Value Comparison Tables.”

One example of non-conformance would be using non-graded lumber. The lumber in the first photo has a “stamp,” but this is not a lumber grade stamp. It simply states that this lumber has been heat-treated. The stamp lacks a grade with species/species grouping.

Unfortunately, these alternative lumbers are being used in the manufacture of components – even though they shouldn’t be. In this case, the truss manufacturer has used this non-graded lumber in the floor webs.

Importantly, the lumber does not have a grade value. Even so, the fabricator is using the lumber where graded lumber is required.

Notice that the lumber in the second photo is called #4. The problem here is that there are no published values for #4. There is really no such thing as #4 – it’s just a name the lumber industry uses to say: “Does not meet #3 grading rules and requirements.”

In the situation of my client with the “deal” on lumber, the product they received was stamped as grade “Stand.” Note in the table that the value of “Stand” has Fb at 950 psi, which is less than the design requirement on a truss drawing for #2 where the Fb requirement is 1250 psi. In their situation, the substitution impacted over 120 units in a large collection of townhomes, half of which were already sheathed and some of which had C/O’s and were occupied.

The next photo is of several units of lumber purchased to be used as webbing in roof and floor trusses. It indicates the lumber is “Spec,” which according to the manufacture means “There is no grade.” In this case, there can be no comparison of values because none exist.

In a recent plant inspection for another client, it was discovered that they were substituting “Utility” for #3 southern pine. As the next chart shows, the difference in values is completely unacceptable. For southern pine, the value of Fb for utility is only 225 psi, significantly lower than the 650 psi of #3. Likewise, Ft is only 125 instead of 400. This egregious substitution has potentially occurred on hundreds of projects and will have to be resolved, impacting millions of dollars.

The requirements are clear in ANSI/TPI 1. Lumber must be graded. Substitutions must be of an equal or higher value – not just on fiber bending but all 8 values: Bending (Fb), Tension (Ft), Compression parallel to grain (Fc), Compression perpendicular to grain (Fc⊥), Shear (Fv), Specific Gravity (G), Modulus of Elasticity (E), and Modulus of Elasticity for stability calculations (Emin).

Know and Track Your Grades

After purchasing lumber, it’s also important to keep track of lumber grades at your plant, especially if you have pieces without specific stamps. How do you legitimately have pieces without grade stamps on them? First, after a truss manufacturer has received lumber into their inventory with a stamp on each piece, the standard allows the truss fabricator to crosscut this lumber. Second, it is not uncommon for a truss manufacturer to receive lumber shorter than 8’ from a supplying mill without a grade mark. This can be for assorted reasons but is often due to the automatic stamping process mills currently use. The pieces drop out of the conveyors due to their short length. The material still must be graded, but because the materials are often handled by hand, the units are segregated and labeled as a unit. The mill selling the shorts must provide qualification that this lumber meets the requirements of ANSI/TPI 1 Section 3.4.3. This certification must be issued by a lumber inspection agency accredited by the Board of Review of the American Lumber Standard Committee (ALSC). In all of these cases, it’s important that your plant has a reliable system for keeping track of this lumber by grade.

How to Remain in Compliance

• Non-graded materials cannot be used in structural components.

• Purchasing must be made aware of design requirements.

• Receiving procedures must be established and followed when receiving materials.

• Graded lumber can be crosscut by the truss fabricator without impacting the grade once the grade has been verified. This does not apply to a lumber manufacturer. (For more on this, see “When I Cut My Lumber, Do I Affect the Lumber Grade?”)

• Ripping lumber changes the lumber grade and would require a regrading step.

• The grade must be transferred by mark or segregation within the component facility.

• Non-marked but graded material must be handled by segregation or by the CM’s mark.

• Introduction of non-graded material will require the facility to track all materials to stipulate “Graded” and “Non-Graded.”

• There is no such thing as #4 lumber grade.

• Most often, the reason lumber is marked as #4 is because it does not meet #3 requirements.

• Grading lumber requires a certified lumber grader under an ALSC program.

• There is a significant liability involved if receiving anything less than #3 grade lumber into your truss facility.

The Bottom Line

Correcting mis-utilized lumber can result in replacement of components and re-evaluation of truss designs. Serious issues like lumber non-conformance can result in loss of reputation and thereby loss of customers. Obviously, this can result in millions and millions of dollars in lost revenue.

Most importantly, you can maintain the quality of your finished products when you remain in control of your raw materials. Don’t create a problem by introducing substandard material into your facility. Track lumber grades and your cutting process to ensure lumber is used appropriately. Pay attention when receiving lumber. Your customers will expect the best from you.

An ANSI/TPI 1 3rd Party Quality Assurance Authorized Agent covering the Southeastern United States, Glenn Traylor is an independent consultant with almost four decades of experience in the structural building components industry. Glenn serves as a trainer-evaluator-auditor covering sales, design, PM, QA, customer service, and production elements of the truss industry. He also provides project management specifically pertaining to structural building components, including onsite inspections and ANSI/TPI 1 compliance assessments. Glenn provides new plant and retrofit designs, equipment evaluations, ROI, capacity analysis, and CPM analysis.

Glenn Traylor Structural Building Components Industry Consultant http://www.linkedin.com/in/glenntraylor

WORKSHOP

IntelliVIEW Suite Manage. Design. Build.

The industry’s most powerful integrated component design, engineering, and management software for steel and wood-framed structures.

iCommand

Manage projects, customers, materials, pricing & inventory

iModel Design truss layout & profiles

iDesign

Optimize material usage & engineer trusses

iPanel

Design wall layouts, panelize, bundle, break & stack

eShop

Maximize crew productivity & improve manufacturing efficiency

The IntelliVIEW Suite is a fully integrated software solution for the layout and design of a building’s rough framing elements—including roof and floor trusses, wall panels, solid sawn, EWP, sheathing and various ancillaries.

The IntelliVIEW Suite provides the industry’s most complete analysis of the design, cost information and bill of materials—promoting increased profits by reducing plate and lumber use.

Ask those who know. They’ll tell you about the people at Alpine who make a difference.

• •

• • Automated Setup via Download or Semi-Automated Setup via Touch Screen Input

• 23 Axes of Automation

• Sets up in 2 to 15 Seconds

• Five

• Waste Conveyor (under saw)

• Excludes (adjacent to saw) and Live Deck (in

Hain Systems Framer

Safety Speed Cut Model 7000 Panel Saw

Safety Speed Manufacturing model 7000, vertical panel saw, 3 HP induction motor, 64 inch crosscut, 2 inch maximum thickness, accuracy within 1/64th of an inch, 10 foot welded steel frame with integrated stand and linear V-guides, enclosed counterweight system, adjustable vertical and horizontal rules. Quick changes from vertical to horizontal cutting. Includes machined aluminum material rollers, hold down bar, wheels, quick stop gauges and material hold downs. Dust collection ready. Options available include lower frame extensions, digital readouts, laser guide, stop bar, vacuum and midway fence. 208-230/460 volt, 3 phase electrical (208-230 single phase, 2 HP power optional +$100.00). $10,199 Base, FOB MN.

TMotor: 1/4 HP, 110 VAC, Linear Actuator Highly Accurate: +/- .010 Inches

Stop Rail: 2 x 4 x 1/4 Aluminum Extrusion

he Hain Systems Framer (HSF) will help you build square and accurate wall panels for residential or commercial construction applications. It will help you cut building costs by saving time and improving your quality. It’s a reliable, efficient and proven system that features a ruggedly simple design. The HSF is based on a proven design with over 20 years of actual production use and maintenance experience. It comes fully assembled and is designed for portable job site framing or in-plant permanent installation. The table has many optional attachments and will support Mylar Tape wall layout or any other type of layout. The optional gun rails can also be retro-fit to any table.

Stops: Jig Bored Steel

Stop Blocks: Machine Billet Aluminum

Details:

Internal Components: Hardened, Ground and Polished Steel and Billet Aluminum

Dimensions:

Table Construction: Thick-wall Structural Steel Tubing, Jig Welded for Accuracy

Length: 5 feet (60”) to 60 feet (720”)

Height: 12 inches

Air Supply: 90 psi (10 CFM Air Flow Recommended)

Depth: 12 inches

Electrical Supply: 120 VAC

Powder Coat: Industrial Gray

Dimensions: Height: 43”

Length: 16’ or 20’

Width: Adjustable 8’ to 10’ or 8’ to 12’

Shipping Weight: 3000 lbs

If you are looking for the fastest, most consistent way to measure and cut your product, then the Hain Measuring System (MEA) is your answer. The MEA changes from one length t any length instantly, up to 60’, without changing the operator’s position on the line. It is also highly accurate (+/- .010) and quickly moves from one length to the next in seconds. The MEA is designed for quick and easy setup and is simple to use. Even a first time user will be productive with little or no training required. It can adapt to any saw and can be mounted to any surface so that you can integrate the MEA with your existing setup. The MEA is versatile allowing “left” or “right” handed operation and measurement in “feet and inches” or “inches” depending on your preference. The MEA is also available in a “Skid Mounted” version.

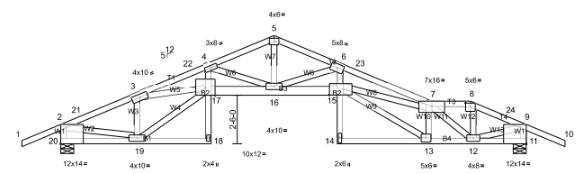

Joint Detailing for Accurate Plate Placement

Good joint detailing at the design stage can help truss builders accurately position truss plates, including the back plate which is essentially positioned “blindly.” Laser projection is excellent for positioning the top face plate, however, it is subject to the same limitations for the back plate and then some. (For more on that subject, see Glenn Traylor’s article, “Should We Follow Lasers Blindly?”)

Visual Plate Placement (VPP) is a technique of joint detailing specifically for the accurate placement of the back plate. With VPP, the designer reviews the computer-generated plate detail and re-positions and/or upsizes the plate so that at least one or two plate edges, and/or corners if needed, provide placement reference points for the back plate.

Shown in the first image is a 3x4 two-web joint that is fully symmetrical and the plate center matches the standardized joint center as depicted with the black dot. However, the back plate will have to be placed “blindly” by feel and will have a risk of angulation. The designer may want to upsize the plate to a 4x4 and position the plate to the edge of the green web’s vertical scarf, which can be spotted visually for accurate back plate placement. (For more on this issue, see Glenn Traylor’s article, “ How Important is Angulation? Why is It important?”)

Shown next is a good example of VPP. The back plate has an excellent chance of being placed accurately because three edges of the back plate can be visually positioned.

The next pair of images shows a 5x7 plate on a two-web joint that is fully symmetrical and the back plate can be positioned accurately. However, as shown in the image on the right, the software should be overridden and the plate re-positioned so the placement has better accuracy.

Good joint detailing enables Visual Plate Placement at the time of fabrication and quick QC visual verification during inspection by standardizing joint details with “rules of thumb” for VPP in the design office coupled with continuous education and continuous training of the truss assemblers. Many joints can be standardized with charts and rules of thumb. Training is further simplified if TVs are placed above the truss build tables for training. During fabrication, the truss builders only have to glance up at the screen to see how the plates should be positioned.

What’s more, proper use of a claw hammer will free up two hands to accurately place the back plate at the table:

Step One: Pry up the truss chord

Step Two: Rotate the hammer grip down to the table surface

Step Three: Release the hammer

Step Four: Use two hands to accurately position the back plate to match the position of the top plate

Unfortunately, I see the majority of truss assemblers stop at Step One and place the back plate with just the one hand. But, as shown in the photos, it’s easy enough to let go of the hammer and then proceed with the positioning! (For additional reference on this and other avoidable common mistakes, see Glenn Traylor’s “How Do Your Manufacturing Errors Rank on the List?”)

By implementing good joint detailing and visual plate placement, truss plants can improve production accuracy, reduce errors, and streamline the quality control process.

When you’re ready to Feed Your Beast and see these efficient and effective systems for yourself, let us know! Inside and out, LimTek Process Organization Technology will help you squeeze out more truss production and deliver quality trusses with shorter lead times to better service your customers by organizing your truss fabrication processes to maximize your investment in automation. https://limteksolutions.com/#solutions

and Auto-Nesting and Auto-Nesting

AutoFill button for Maximum Material Utilization

Labels parts as they cut. (printer optional)

Easy manual cuts and re-cuts

Import files from most major design suites

Industry-first sheathing saw that cuts angles.

Cuts OSB, CDX, Zip, Dense Glass and more.

Minimal airborne dust, even while cutting gypsum.

ACTUALLY, WE CAN SAY QUITE A LOT WITH LASER ACCURACY.

To see meaningful labor savings, quality improvement and production gains, SL Lasers with their easy-to-see green light are nothing short of illuminating. They enhance worker accuracy and productivity, regardless of experience or primary language. They can reduce tedious setup time by up to 70%. No complex training or costly service agreements are required. And SL Lasers integrate seamlessly with any component design software and are quickly installed over existing equipment. We’ve been trailblazers in wood component laser projection since its very beginning, and we’re still delivering more rapid ROI for roof truss, wall and floor panel producers every day. Contact our enlightening team at Wood Tech Systems to see how SL Laser can deliver for you.

productivity of any

SAWS

2021 Powermatic Model 511 Panel Saw 2021 Powermatic model 511 panel saw. Vertical panel saw features a powerful 3HP worm-drive motor which rotates in the carriage, adding the versatility to perform rip cuts. The solid aluminum rollers assure smooth feeding of stock and perfect 90° cuts every time. This saw will handle panels up to 5-ft tall in unlimited length. Includes horizontal and vertical scales and casters for mobility, the counterweight system keeps the saw carriage in the desired position when loading or unloading panels. Features dual 4″ dust collection ports with nylon brush surrounding the blade for superior dust collection from the front and the rear side of the panel. 115v, 1-phase electrical required.

$6,799 NOW $1,999 FOB AZ

Wood Tech Systems

765-751-9990

www.woodtechsystems.com

2023 Northfield Model 410 Upcut Saw NEW 2023 Northfield model 410 upcut saw available for immediate shipment. 90/90 degree cuts to 4″ x 10″ capacity (fence forward position) to 2″ x 14″ (fence rearward position). Saw is configured for material from left to right, with 3″ x 6″ air operated cylinder, filter, regulator, lubricator, 10 HP motor, enclosed steel base with cast iron table, magnetic starter and adjustable operating speed from 20 to 60 CPM. Includes optional two-palm controls, additional 4″ dust outlet, NEMA 12 electrics with fused disconnect and two 18″ diameter 60 tooth blades with 1″ diameter bore. 460 volt, 3 phase electrical required.

$18,630 FOB MN Wood Tech Systems 765-751-9990

www.woodtechsystems.com

Whirlwind Model 1000 Cut-Off Saw

• 5 HP Motor with 14" Blade

• 2 3/16" x 8 1/4" Capacity

• Pneumatic Blade Guard/Lumber Clamp

• Foot Pedal Control

• Dust Collection Outlet

• 460 Volt / 3 Phase

• 1 Left Hand & 1 Right Hand Model

Available

$3,500 NOW $2,800 Each FOB NC Wasserman & Associates 800-382-0329

www.wasserman-associates.com

GOOSENECK ROLL OFF TRUSS TRAILERS

26’, 32’ & 36’ sizes available, Split Rollers available too! 2 YEAR WARRANTY

Scan the QR Code to take you directly to our website. For more information or to request a quote Call or Email: 1-800-237-5161 sales@precisionequipmfg.com

1982 SpeedCut MetraCut

Centerline Saw

1982 Speed Cut Metra Cut, model SSA-11, centerline saw, 16″ blade, maximum cutting depth of 6″, maximum cut length of 31″, 164 deg. cutting range and 5 HP motor. Includes push-button on/off controls and analog angle measure on turntable with air stop, 20′ long infeed conveyor with OEM SpeedMeasure, 20′ long outfeed conveyor and one (1) spare blade. 208 volt, 3 phase electrical required (can be converted to 240v/440v).

$6,990 FOB WY Wood Tech Systems 765-751-9990 www.woodtechsystems.com

New Monet DeRobo Linear Saw

New, DeRobo linear saw by Monet organizes "fill" boards to increase optimization of each board, can produce unlimited scarf cuts, cuts 1 or 2 boards at a time and cuts webs, chords, wedges, rafters and open-stair stringers. Works with all major connector plate manufacturer's software. Features include 22 inch blade, left-to-right feed direction standard, lumber push and pull grippers for more accuracy, ink marking on the 1 1/2" face of the incoming boards and small piece capture and delivery to the front of the saw for easy access. Infeed deck and bunk feed are shown as options only. 480 volt, 3phase.

$239,000, FOB MO.

Reliable automated machinery, built to last for generations!

“The equipment is extremely durable to stand up to the beating it takes in a truss plant”.

$330,000

Location: MO

New, Monet DeSawyer 2000, computerized, five-bladed component saw, sets up in 15 to 17 seconds, can run in manual mode, downloads projects from a network or manually using display screen controls. Features all powered movements, cuts from 15" 90/90 cuts to 20 foot length, 2 x 3" to 2 x 12" lumber depths and internal brakes are standard. Options include enhanced servo controls featuring autocalibration, catcher's display and either shaker or belt scrap conveyor and incline. 440 volt, 3 phase electrical.

A multitude of products for one smart solution.

It takes all the right players to build a winning team. That’s why Simpson Strong-Tie provides truss and component manufacturers with a broad selection of versatile hardware products. Choose our code-listed truss connector plates, framing angles and straps, heavy-duty girder hangers and holdowns for strength and durability. Secure them with speed and ease using Strong-Drive ® structural fasteners, along with our Titen HD ® heavy-duty screw anchor and other mechanical anchors. Along with software, cutting equipment and professional design services, our hardware is widely available and backed by expert support. Learn more at go.strongtie.com/cs or contact your sales representative.

Lauderdale Hamilton 24" Up-Cut Saw with 24' TigerStop

• 10 HP (3 Phase)

• 6" x 13 1/2" Capacity

• Foot Pedal Operation

• Dust Outlet (excludes dust collector)

• 2015 TigerStop 24' Programmable Stop

• Automatic Positioning of Stop via Simple and Intuitive Controls

• Infeed/Outfeed Roller Conveyor with Stands

• Video available upon request $16,900 NOW $15,900 FOB WI Wasserman & Associates 800-382-0329 www.wasserman-associates.com

Safety Speed Manufacturing, model 7400 XL*, vertical panel saw, 3 HP induction motor, 64 inch crosscut, 2 1/8" maximum thickness, accuracy within 0.005 inches, 13 foot long welded steel frame with integrated stand and linear V-guides, enclosed counterweight system, adjustable vertical and horizontal rules. Quick changes from vertical to horizontal cutting. Includes machined aluminum material rollers, hold down bar, wheels, quick stop gauges and material hold downs. Dust collection ready. Options available include digital readouts for vertical cuts, automated length measuring, laser guide, stop bar, vacuum and midway fence. 208-230/460 volt, 3 phase electrical (208-230 single phase, 2 HP power optional +$100.00).

Clary Master Component Cutter

We are installing a

Inspired by ten years of intensive field experience and the ample and detailed feedback of numerous customers, we’re pleased to introduce the most advanced, most enhanced and high-performance Terminailer yet-Terminailer V.8. Drawing on invaluable time in the trenches closely evaluating Terminailer’s performance under varying conditions, our engineers have incorporated critical learning and insight to enhance simplicity, performance and operator control. Just part of what V.8 offers includes:

•Vastly enhanced operator control for even greater productivity

•A redesigned nail-feed supplying EverWin PN90-PAL industrial nail guns

•Simplified pneumatics featuring direct air-supply to all six nail guns

•Even more sub-component profiles for wall design flexibility

•Rugged durability with pharmaceutical grade assembly

Developed by people who know well the mechanics, safety considerations and business aspects of wall-panel production, Terminailer V.8 combines more enhancements & operator-friendly features than ever to take your productivity to the next level and beyond. Contact us to learn even more and to put the V.8 performance in motion at your facility.

2006 Alpine Speed Rafter Cutter

• Simplified compound cutting for hip, valley and jack rafters (double & single compound cuts)

• Two Worm-Drive Circular Saws (110 Volt / 30 Amps)

• Saw Turntable (for angle cutting)

• Saw Carriage (for up to 45 degree bevel cutting)

• Infeed & Outfeed Roller Conveyor with Stands

$4,900 NOW $4,250 FOB CA Wasserman & Associates 800-382-0329 www.wasserman-associates.com

Used - Metra Cut Radial Arm Saw (2x) Parts Machine

$500 – Make Offer

Eide Machinery Sales, Inc. 612-521-9193 www.eidemachinery.com

Used - 2005 Model 305 Infeed Conveyor Designed for use with all component saws. To include: Soft Start ~ Soft Stop Inverter System. Programmable load sensing; Overload / Jamb sensing shut down feature. Gear motor providing conveyor speed of 36' per minute. Forward and reversing controls for location at both ends of conveyor unit. Material capacity range - 4' through 24' lumber. Chain deck pedestals 20' long with cross bracing. Staging area at the saw independent of the live deck system. 30,000lb. Deck capacity. Call for pricing

Eide Machinery Sales, Inc. 612-521-9193

www.eidemachinery.com

New Monet FWA 500 Floor Web Saw

New, Monet five-head, floor truss web saw, cuts 4-angle, 4×2 floor truss webs from 13 inches and 90-90 blocks from 7 inches, to 4 foot long maximum length. Features 10-board magazine feed, powered, fixed-quadrant angulation, manual carriage standard, scrap conveyor and cut-off blade. Options available for longer carriage length, incline scrap conveyor, and choice of shaker or belt scrap conveyor. 440 volt, 3 phase, 60 Amp electrical. 50 PSI air at 5 CFM required.

$75,000 FOB MO

Wood Tech Systems

765-751-9990

www.woodtechsystems.com

2023 LM Equipment Portable Yard Saw 2023 LM Equipment model 200MP-7-SS portable yard saw, 20 HP, 4-stroke gas motor (no fuel mixing required), cuts to 48″ x 52″ profile bunks of lumber. Includes chain, clutch to stop saw chain at idle, 12″ tires, and tension take-up assembly.Only used twice since new.

$26,144 FOB UT

Wood Tech Systems 765-751-9990 www.woodtechsystems.com

New SpeedWorx Automated Sheathing Station

Price Based on Configuration FOB NM NEW!

New SpeedWorx Automated Sheathing Station by Safety Speed Manufacturing- Reduce labor and operator fatigue by taking advantage of the SpeedWorx automated vertical panel saw. This one-person station cuts wood sheathing sheets up to 50-inches x 10-feet, and up to 2-inch thickness, using a fast 1-button cutting setup with CNC accuracy to 1/32 of an inch (0.03125″). The photos of raw materials illustrate the drastic reduction of scrap material thanks to implementing the Rogworx saw station.

Visual user interface makes choosing the job and sheet cutting order easy to determine. Files are downloadable allowing for minimum waste. Saw station reads WBX file format (Alpine) or EHX file format (MiTek) or CSV files with manipulation.

Automated sequencing of sheets provides optimum usage of each sheet. The cutting chamber changes from ri to cross-cutting automatically. All this in a very small machine footprint, so it can fit easily into your existing building.

Visual user interface with standard ‘Auto Fill’ feature makes choosing the job and sheet cutting order easy to determine. System offers full optimization and sequence panel parts looking ahead through the job based on your specification. The cutting chamber changes from rip to cross-cutting automatically. All this in a 100 square foot footprint, approximately 25′ long x 4′ deep, so it can fit within existing facilities.

Includes advanced dust collection. Integrated Printing for labeling parts is available as an option. 208-230V volts, 3-Phase, 25 Amp electrical required, 5 CFM at 100 PSI air required.

By Ben Hershey and Thomas Griffin

The Digital Revolution in Offsite Construction and Manufacturing

The offsite construction industry is undergoing a transformative era, driven by the advent of digital technologies. This evolution is not only revolutionizing how projects are managed but also addressing fundamental industry challenges. As more firms embrace digitization, understanding its advantages, challenges, and solutions is pivotal for businesses aiming to stay competitive.

The Offsite Dynamic: A Paradigm Shift

Offsite construction differs fundamentally from traditional, on-site methods. Under the shelter of a factory, entire building components are fabricated, eliminating weather-related delays, and enhancing control over materials and processes. Unlike traditional construction, where project management oversees subcontractors across various scopes, offsite integrates production and project management under one roof. This integrated approach necessitates the efficient orchestration of tools, materials, and manpower to meet condensed timelines and high-quality standards.

Key benefits of offsite construction include reduced project timelines and greater control over production. However, these advantages introduce unique challenges, particularly in material planning, communication, and managing accelerated schedules.

The Challenges and Digital Solutions

Digitization presents a solution to several challenges plaguing the offsite industry. The five major hurdles and their digital remedies are:

1. Project vs. Production Management: Traditional project management software often falls short in addressing offsite needs. Solutions like manufacturing resource planning (MRP) tools integrated with project tracking features bridge the gap. For example, Moducore, an offsitespecific platform, offers an all-in-one solution that combines project budgeting, scheduling, resource planning, and analytics, ensuring seamless alignment between production and project requirements.

2. Lead Time Optimization: Offsite projects face tighter pre-production timelines, requiring overlapping processes such as design, procurement, and permitting. Digital platforms like Moducore streamline these workflows, enabling real-time collaboration on designs, automatic updates, and data sharing. By providing features such as 3D modeling and integrated design tools, Moducore helps mitigate risks associated with incomplete designs and delays in material procurement.

3. Communication and Information Silos: Communication breakdowns are a critical issue in offsite environments, where diverse teams work in varying locations. A unified digital ecosystem integrates all stakeholders—from production floor workers to project managers— ensuring seamless communication. Platforms like Moducore address this challenge by consolidating all communication, approvals, and workflows into a single dashboard, reducing dependency on emails and manual coordination.

4. Data Utilization: Analog methods fail to provide actionable data insights. Advanced software like Moducore collects and analyzes data from production processes, delivering metrics that inform decision-making, optimize workflows, and enhance productivity. By integrating realtime reporting and analytics, businesses can proactively address inefficiencies and increase throughput.

5. Evolving Industry Dynamics: The offsite industry is still finding its footing, requiring tools that adapt to its evolving nature. Digital solutions provide the flexibility to refine metrics, track new processes, and manage changes dynamically. Moducore, with its adaptable and scalable design, ensures businesses remain at the forefront of industry advancements, addressing evolving needs with tailored solutions.

Moducore: Driving the Digital Revolution

As an industry-specific software, Moducore meets the diverse needs of offsite construction with unparalleled precision. Its all-in-one platform integrates project management, resource planning, production scheduling, and analytics, enabling companies to manage their operations seamlessly. By combining the best of manufacturing and construction management, Moducore not only bridges gaps in communication and data utilization but also ensures a scalable, user-friendly interface that grows alongside businesses. For offsite companies looking to maximize ROI and streamline their operations, Moducore is a vital tool in navigating the complexities of digital transformation.

The Path to Successful Digitization

Despite its benefits, implementing digital solutions poses challenges, including managing multiple software systems, training workers, and navigating costs. Key strategies to overcome these barriers include:

• Adopting Unified Solutions: Choosing comprehensive software platforms minimizes the complexity of integrating disparate systems. Solutions tailored to the offsite industry, such as Moducore, consolidate functions like project management, production scheduling, and resource planning.

• Effective Onboarding and Training: Industry-specific software providers often offer dedicated onboarding support, simplifying adoption and ensuring usability across all employee levels.

• Scalable Investments: Modern Software-as-a-Service (SaaS) solutions are cost-effective and scalable, making them accessible for businesses of all sizes. Moducore exemplifies this approach, offering flexibility and robust functionality without overwhelming resources.

Conclusion: Building the Future Digitally

Digital transformation is no longer optional for offsite construction companies—it’s essential. The integration of tailored software solutions not only enhances operational efficiency but also empowers businesses to navigate the complexities of modern construction. By embracing tools like Moducore, the offsite industry can overcome its unique challenges, leading to a more efficient, scalable, and profitable future.

Whether it’s optimizing material flows, streamlining communication, or leveraging data analytics, the digital revolution promises to elevate offsite construction to new heights. For companies ready to embark on this transformative journey, the message is clear: the time to digitize is now.

Ben Hershey is the CEO and Founder of 4Ward Solutions Group and Past President of the Structural Building Components Association.

Thomas Griffin is the Project Manager for Moducore, a building solutions platform for the offsite industry.

2016 Alpine AutoMill HP Component Saw

Alpine AutoMill HP, model 349C component saw. Servo controlled computerized saw sets up in 2 to 19 seconds and downloads from a network, or by using a touch screen for ease of operation. Five-head automated component saw works in both automated (downloading files), semi-automated control (via touch-screen input) or manual mode. It has (23) axes of automated movement, enhanced diagnostics, and auto management reporting.

The HP cuts from 2′-6″ to 20′-0″ long material in size range from 2×3″ through 2×12″, and 4-angle floor webs from 2′-0″. Includes [3] 18″, [1] 20″ and [1] 30″ blades with air brakes, Windows 7 o/s and under-saw scrap conveyor. The Windows 7 o/s can be upgraded to a version of Windows 10 that will be supported until 2032, at an additional expense.

Also includes over $8,000 in spare parts. 480 volt, 3 phase, 100 Amp electrical required. 90 PSI @ 69 SCFM air required.

$129,997 - FOB OR

“Over the years Alpine ensured our quality and production kept improving. Working with Alpine has been a 22 year friendship as well as a partnership!”

— Roy Bedient Manager/

Production Manager, Warman

Truss

Alpine has it all—the right equipment, user-friendly software and dependable hardware to improve your teams efficiency. Alpine delivers the complete package for success—including comprehensive support and service that sets us apart within our industry.

Ask those who know. They’ll tell you about the people at Alpine who make a difference.

Used Hain Quick Rafter Cutter

• Reconditioned in December 2020

• Board Sizes: 2x4 and 2x6

• Motors: Two 1 HP / 220 Volt or 440 Volt / 3 Phase

• Saw Blades: 7 1/4" Carbide Tipped (set at 45 degrees)

• Angle Adjustment: Manual Rotation with Air Brake

• Air Supply: 90 PSI

• Carriage: Steel Rails with Steel Dual V Rollers

• Pedestal: 3/16" Formed Steel

• Saw Housing: 1/2" Billet Aluminum

• Covers: 10 Gauge (1/8" thick) Steel

• Fully Enclosed for Safety

$12,500 NOW $9,900 FOB AZ Wasserman & Associates 800-382-0329 www.wasserman-associates.com

In answer to the demands of high-volume customers comes the Monet DeSauw FWA 500 CA (Automated Controls) floor web saw. The 500 CA is perfect for component manufacturers who routinely run floor trusses in high volumes with variable web geometry. Another primary feature is enhanced safety through automation which eliminates the need to open the saw motor cabinets other than for periodic service. The 500 CA includes automation for all blades, including the fixed cut-off blade for minimal waste. Lumber infeed speed is variable up to sixty (60) boards per minute, while the powered carriage utilizes rack and pinion drive with airlock for set accuracy throughout the production run. Your operator will easily download batches to the 500 CA saw from your design software via an ethernet connection to a MS Windows 10 industrial PC with a 17″ monitor housed in a stand-alone console. If you frequently batch floor web cutting, and if enhanced safety with increased productivity are a concern, then an automated Monet FWA 500 CA may be the right selection for you. More information Here

Motor: HeavyDuty5HP-3phase-220vor440v(Pleasespecifywhenordering)

MotorcarriagebearingandspindleassemblymountedonBlanchardgroundsteelplate

LinealmotionishardenedandgroundVbearingsandrails

BlockSizes: 2x4through2x12infiniteheightsettingtocenter