By Cindy Riley CEG CORRESPONDENT

To better prepare inmates for reentry into the community, a new correctional facility is being built in Painesville, Ohio. The $205 million Lake County Sheriff’s Office and Public Safety Center will be just north of the existing jail on East Erie Street and include more than 500 beds and three-and-a-half floors.

“The current facility has no room to accommodate an expanding jail population,” said Lake County Sheriff Frank Leonbruno. “In the past 30 years, the jail has grown from 100 Lake County Court inmates per day to 385 or more inmates. This 400 percent increase highlights that a new facility must be

modate future inmate growth over the next 40 years.

“Although the county has performed routine maintenance over the years, many of the overall physical building system components, such as plumbing, mechanical, electrical, security and fire protection, have reached the end of their

Work on the new nine-story OhioHealth Women’s Center is under way in Columbus, Ohio.

ALL Crane Rental Corp., a member of the ALL Family of Companies, is currently supplying two tower cranes for the project, with other heavy lift equipment arriving at the site soon.

The standalone medical center, which will total almost 590,000 sq.-ft., will become one of the leading facilities of its type in the country. It is being constructed on the southeast corner of the existing OhioHealth Riverside Methodist hospital campus.

ALL provided two Potain MD569 tower cranes for this phase, both erected in June 2024 and expected to be on site until the end of 2025. One is located on the east side and the other on the west side of the current project site. Both have a capacity of 25,000 lbs. and jib lengths of 262 ft. The taller of the two will have a final hook height of 258 ft., with the other at 209 ft.

“The towers are handling a variety of materials,” said Richard Randall, general manager of ALL Crane Rental Corp. “Steel for the main structure, precast concrete

panels and assisting with pouredin-place concrete features.”

Randall credits the work of Chris Kirk, sales and rental specialist of ALL, for collaborating with contractors to deliver a package of heavy lift equipment beneficial to efficient construction.

Currently being built is a conventional concrete patient tower, with a five-level post-tension concrete parking garage to follow. The garage will be topped with a medical office building made of structural steel and metal decking. Two

additional tower cranes from ALL will be delivered to the site during that phase of construction.

The facade of the main building will consist of architectural precast, curtain-wall glazing and metal wall paneling.

Brian Duffy, project manager of Lithko Contracting, said the tower cranes from ALL have formed the nucleus of work being done by his company and other trades on the site.

“They are the logistical heartbeat of everything we do here,

from unloading trucks to setting and placing materials,” said Duffy.

“Beyond structural work, the tower cranes will play key roles in the installation of the building services equipment and the exterior facade.”

When façade work begins, ALL will be called upon to supply multiple additional cranes from its yard.

“I anticipate needing rough-terrain cranes, hydraulic truck cranes and potentially even crawlers,” said Christopher J. Hall of Ben Hur

Construction.

The equipment will help erect more than 550 architectural precast panels on the exterior facade, weighing between 5,000 and 45,000 lbs.

“This is a complicated project,” said Hall. “It has a variety of access challenges, vastly diverging material weights, and extremely tight site conditions, especially on the north elevation. It’s a good project for everyone involved. I prefer the professionalism ALL Crane offers at every stage of the process.”

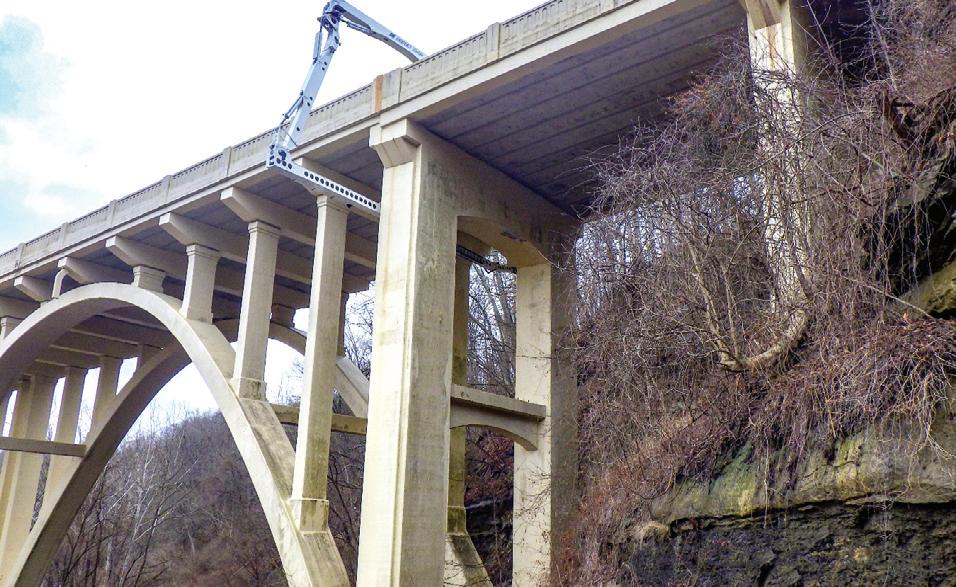

ODOT crews have completed preliminary work on the Blaine Bridge, sealing off bridge joints to meet necessary environmental requirements before starting construction.

Crews completed the work using equipment that included ODOT's snooper truck. A lift was used to access areas of the bridge with deteriorating conditions.

The project was due to sell on April 24, 2025, and construction will begin in May 2025. The completion date for the project is expected by early summer 2026.

Crews completed the work using equipment including ODOT's

useful life cycles. Additionally, the building envelope was improperly installed and needs to be completely removed and reinstalled to stop the water infiltration throughout the building. The jail would require $30 million to restore it to its intended condition.”

Featuring red brick, limestone and gabled roofs, the 250,000-sq.-ft. structure is being promoted as an investment in the future of public safety. Leonbruno said the new facility will focus on rehabilitation, providing staffers with the resources needed to help inmates become productive members of society once their time has been served.

“What has changed dramatically in county jails since the facility was built in the 1980s is the more complex medical issues of today’s inmate population, the rise in drug and alcohol addictions and the reliance on jails and prisons to handle the mental health populations of our nation. In the current facility, there’s no adequate space for medical care, no space designed for handling the mentally ill and no programming space for drug and alcohol treatment.”

The new facility will have an enhanced area for medical care with large exam rooms and a pharmacy designed to handle medications for both medical and mental health needs of the inmate population. It will include housing areas to serve the mental health population and rooms for counseling and group therapy.

The new physical plant will provide increased camera systems to monitor all aspects of jail operations. This includes reduced inmate movement by having outdoor ranges attached to each range; reduced exterior movement through video arraignments and court hearings; new body scanning systems to control contraband; and a secured security perimeter around the jail. To meet the growing needs of patrol, the structure will include new evidence storage facilities, SWAT bays and training areas, as well as a conference room and interview areas.

Construction began in January 2025. The project should be completed by spring 2027, with a move-in date that summer.

Leonbruno said it’s exciting to see construction taking place, acknowledging that a lot has changed over the past 35 years.

“When our current facility opened in January of 1990, computer systems were not designed into the facility, camera systems were basic and antiquated and the medical area was designed to be the equivalent of a nurse’s station in an elementary school. Inmate treatment programs for drug addiction and mental health services were not planned, staff training areas did not exist, and no thought was given to staff health and workout areas to prepare for the rigors of the job.

Chief Deputy Bob Izzo said, “The process has given us the opportunity to investigate our past and see where our problems existed and correct the physical plant moving forward, so we can be more effective. Shaping new concepts in physical design to go with our programs and concepts in offender management and advanced policing will help us to ensure that Lake County is the community where you want to live, raise a family and grow your business.”

The design-build project includes the team of Gilbane Building Co., Lakeland — The Construction Group and architectural firm K2M Design.

“With this being a secure facility, there’s a lot of coordination required,” said Sean Noble, Gilbane senior project manager. “The walls are predominantly masonry or prefabricated steel cells, and there are many secure ceilings, which means

every single conduit, outlet, device, light, etc. needs to be coordinated to perfection up front.

“There are no opportunities for rework if a device isn’t installed properly the first time. There also is an abundance of security electronics [cameras, intercoms, access control, etc.] that are above and beyond other types of construction. These devices require detailed coordination for all device locations, pathways and cabling. We’ve developed a robust BIM coordination plan to 3D model all MEP systems, with the goal of identifying any potential clashes, so they can be resolved in the 3D space prior to becoming an issue in the field.”

The project is mostly a cut site, with more soil export than import. The storm system involves a 48,000-cu.-ft. storm detention system that collects and stores the site’s runoff prior to it exiting the site.

Two county buildings, a fast food restaurant and several houses were demolished prior to Gilbane commencing work. The building pad is established, site grading is finished and construction haul roads have been installed.

The underground utilities are roughly 50 percent complete. The focus has been prioritizing the utilities that are adjacent to the building pad to make space for follow-on trades. The installation of aggregate piers is ongoing, with foundations now under way.

“Building any facility begins with a pre-construction effort,” said Noble. “We work through the design with the owner to validate budgets and programming. During construction, the Gilbane/Lakeland team will consist of 10 personnel ranging from project managers, project engineers, superintendents and safety professionals. The workforce will peak at about 250 daily.

“The Gilbane/Lakeland team will work with trade partners to manage cost, schedule, quality and safety throughout the more than two-year construction process.”

Noble said the most time-consuming part of construction will be the masonry.

We are LeeBoy. The name behind the world’s m equipment: pavers, graders, distributors, maintai most trusted and requested around the world. B

d and r

e understand

m ost dependable and productive commercial asphalt paving ners and more. The LeeBoy family of products are among the ecause we understand what drives you and we deliver. Each u, day, lik e you we p q put it all on the line . It’s how w eeBoy ’reL e W e ’rebuilt. eL y . As depen d

y able as your day is long.

Ohio Gov. Mike DeWine on March 31, 2025, signed House Bill 54, the state’s $11 billion two-year transportation budget.

The budget, which goes into effect on July 1, includes funding for critical transportation infrastructure projects across the state.

“Transportation is vital to our state’s economy. It connects Ohioans to jobs, education, health care and entertainment. This budget reaffirms our commitment to providing our great state with a transportation system that is safe, reliable, and prepared for the future,” said DeWine.

“Ohio makes things and moves things,” said Lt. Gov. Jim Tressel. “The transportation budget that the governor signed today will ensure that we can deliver on the projects that get people and products where they need to go safely.”

This budget allows the Ohio Department of Transportation (ODOT) and local governments to maintain a safe highway network and pursue programs at their current funding levels over the next two years.

More than 90 percent of ODOT’s budget funding will be spent on maintenance, preservation and improvements to existing roads, bridges, culverts, signals, signs, lights

and all other critical components of Ohio’s roadway system, including snow and ice operations.

ODOT’s Highway Safety Improvement Program continues to be the largest per capita in the nation. This biennium budget increases funding for this important program from $185 million to $191 million in fiscal years 2026 and 2027.

The budget also includes $150 million to study and construct truck parking lots on state-owned land throughout Ohio. From 2015 to 2019, more than 460 truck crashes in Ohio were due to fatigued driving, resulting in six deaths and numerous injuries. Additionally, five people were killed in crashes involving trucks illegally parked on the shoulder of the road over the same period.

The new budget also supports ODOT’s work to create its new Division of Advanced Air Mobility (AAM). ODOT’s AAM Division will be co-located at the National Advanced Air Mobility Center of Excellence in Springfield with ODOT’s Uncrewed Aircraft Systems Center.

DeWine did not veto any items in House Bill 54.

Ohio Gov. Mike DeWine and Ohio Department of Development Director Lydia Mihalik announced Jan. 27, 2025, state support for nine mixed-use development projects expected to create more than $1.1 billion in new payroll and $2 billion in investments in Ohio.

During its monthly meeting, the Ohio Tax Credit Authority (TCA) approved a total of $100 million in tax credits through the fourth round of the Transformational Mixed-Used Development Program. Projects will support the construction or redevelopment of more than 7.4 million sq. ft. of transformational space to create housing, retail, dining, office, lodging and entertainment opportunities across the state.

“As our state grows, it’s more important than ever that we are creating communities where current and future Ohioans can live up to their fullest potential,” said DeWine. “By

prioritizing developments that transform neighborhoods, we’re making Ohio a place where people will want to be — now and in the future.”

“With new development and growth comes new possibilities for Ohioans,” said Mihalik. “Mixed-use developments create lively communities that attract residents and visitors, transforming empty lots into places where people can connect and thrive.”

The Transformational Mixed-Use Development program was created with support from the Ohio General Assembly. Major city projects must be located within 10 mi. of a corporation limit of Akron, Cincinnati, Cleveland, Columbus, Dayton or Toledo. Eligible costs include land acquisition, building acquisition, demolition, site improvement and new construction of the site.

Erie 22B Cable Backhoe,1:50 scale

Case 580D Backhoe/Loader, 1:35 scale

Case 580E Backhoe/Loader,1:35 scale ....................................................

Case 580SR Backhoe/Loader,1:50 scale

Case 850B Angle/Tilt Dozer,1:35 scale

Case 1845B Uni-Loader,1:35 scale ..........................................................

Case DH4B Trencher,1:35 scale

Case 9030B Excavator,1:50 scale

Caterpillar AP-1000 Asphalt Paver,1:50 scale ......................................$100

Caterpillar C-591 Pipelayer,1:70 scale $70

Caterpillar CB534 Double Drum Roller, 1:50 scale $40

Caterpillar D3 Track-Type Tractor,1:50 scale ........................................$110

Caterpillar D4E Track-Type Tractor, new color,1:50 scale $60

Caterpillar D4E Track-Type Tractor, old color,1:50 scale $60

Caterpillar D6H Track-Type Tractor,1:50 scale ........................................$90

Caterpillar D9N Track-Type Tractor w/black Tracks,1:50 scale $100

Caterpillar D9N Track-Type Tractor w/yellow Tracks,1:50 scale $100

Caterpillar D8L Track-Type Tractor,1:50 scale ......................................$100

Caterpillar D7C Track-Type Tractor,1:50 scale $110

Caterpillar D10 Track-Type Tractor w/ ripper,1:50 scale $100

Caterpillar D10N Track-Type Tractor,1:50 scale ......................................$40

Caterpillar D11R Track-Type Tractor,1:50 scale

Caterpillar 438C Backhoe/Loader,1:50 scale ..........................................

Caterpillar 555D Log Skidder,1:50 scale

Caterpillar 631 Tilting Dumper,1:70 scale ..............................................

988B Wheel Loader,1:50 scale

988F Wheel Loader,1:50 scale

12G Motor Grader,1:50 scale ................................................

Caterpillar PR-450 Profiler,1:50 scale

Cedarapids 451 Greyhound Track-Wheel Paver, 1:50 scale ..................

HC-119 Soil Compactor,1:50 scale

Deere 470G LC Excavator,1:50 scale

John Deere 772BH Motor Grader,1:64 scale ............................................

John Deere 850C Dozer,1:50 scale

Kawasaki Wheel Loader,1:48 scale

Komatsu D155AX-5 Dozer w/ ripper,1:50 scale

Massey Ferguson 516 Skid Steer Loader,1:32 scale

“With this being a secure facility, there’s a large amount of interior masonry partitions. The secure walls have additional reinforcing, as well. There are two stair towers that are masonry, and the exterior façade is predominantly brick. Due to the sheer volume of masonry, our critical path runs through the masonry bid package.”

Regarding heavy equipment, site contractor Mr. Excavator will be using Komatsu PC360 and Komatsu PC138 excavators; Komatsu D71, Komatsu D61 and Cat D6N bulldozers; a Cat 563 roller; a Kubota SVL95 track loader; and a Komatsu WA200-7 wheel loader. Iron workers of Mull Iron will use a 110-ton Link-Belt crawler with a 140-ft. main boom and 40-ft. jib provided by ALL Crane.

Materials required include aggregate pier, concrete foundations and elevator shafts and structural steel frame with composite slab on metal deck. Brick, punched windows, curtain wall glazing,

storefront glazing, modified bitumen roofing and standing seam metal roofing also will be used.

The project calls for 17,000 cu. yds. of site excavation/export; 2,100 cu. yds. of site excavation/embankment; and 7,500 cu. yds. of utility excavation/export. The total amount of aggregate for the job, including utilities, is 16,630 cu. yds., with 13,050 linear ft. of underground utilities installed.

Noble said the chief concern when building a facility of this nature is the planning tied to jailspecific items.

“Coordination of detention doors and frames, detention ceilings, security ratings for walls, cameras, access control, etc. has been the biggest focus from a construction standpoint. There are many aspects to building a jail that are unique compared to other types of construction.”

He also noted that crews will be using pre-made jail units.

“The units are prefabricated as a five-sided box [four walls, a ceil-

Construction began in January 2025. The project should be completed by spring 2027, with a move-in date that summer.

ing and no floor], with all doors, hardware, lighting, furniture and plumbing preinstalled. They are shipped to the jobsite on a flatbed. We leave out a section of the enclosure to allow space to fly the pre-

fabricated units into the building.

“A scaffold is built on the exterior of the building. The units are craned onto the scaffolding and set on skates. They are then moved into place. Once a row has been set

in place, they are welded together. From there it is single point connections for all MEP systems to the back side of the units.”

As for winter weather, said Noble, “Thankfully, the major snowstorms hit the area just before we started construction, so we haven’t had much impact from snow. There have been a couple of cold snaps that stopped work because it was unsafe to be outdoors working in those temperatures.”

Despite the challenges, Noble is proud to play a role in the project and praised the sheriff’s team for their commitment and professionalism.

“They truly care about their community, and it shows every day with the thoughtfulness and due diligence they’ve put into planning this facility. They’ve shared many lessons learned about their current facility, and it empowers me to deliver a high-quality facility that will serve the sheriff’s office and the Lake County community for years to come.” CEG

the TB335R, TB350R, Compl ecent r

or eace o of mind is further prioritized