By Ruksana Hussain CEG CORRESPONDENT

The Virginia Department of Transportation’s (VDOT) Interstate 81 widening project impacting northbound and southbound lanes between mile markers 221 and 225 in Augusta County in Staunton, Va., is on track to be completed in 2027, reducing vehicular congestion and enhancing safety and capacity by adding a third lane and widening and rehabilitating five bridges. Work began in 2023 and includes extensive earthmoving; full-depth reclamation; paving; and bridges undergoing substructure repairs to support the expanded superstructure.

Specifically, there will be one additional northbound lane from the Route 250 (Jefferson Highway) on-ramp at exit 222 to the Route 262 (Woodrow Wilson Parkway) off-ramp at exit 225 and one additional southbound lane from the Route 262 onramp at exit 225 to approximately 1,200 ft. south of the bridge over the I-81 southbound ramp to eastbound I-64 at exit 221. Interstate 81 is a 325-mi. corridor that connects 13 counties and 21 cities and towns across Staunton, Bristol and Salem districts overseen by VDOT.

The Virginia Department of Transportation’s (VDOT) Interstate 81 widening project impacting northbound and southbound lanes between mile markers 221 and 225 in Augusta County in Staunton, Va., is on track to be completed in 2027.

By Lucy Perry CEG CORRESPONDENT

At last year’s national stand-down to prevent falls in construction, OSHA’s assistant secretary said citations alone won’t change the culture around construction. Doug Parker believes everyone in the industry is responsible for sustaining a strong health and safety culture. A group of researchers hopes to help with identifying and addressing safety and health challenges unique to the construction industry.

During the OSHA-hosted Construction Safety Week event last May, Parker urged contractors to refocus on a culture of safety. see TOOLKIT page 54

Florida

of single-family homes, apartment complexes and hotels are in the pipeline.

It was a record-breaking year for PCL Construction’s Special Projects Division, which secured nearly 270 new projects in 2024, amounting to approximately $500 million in new work — its highest ever.

During the high stakes period of a plant turnaround, Northwest Crane Service relies on a fleet of Liebherr cranes to complete a series of critical lifts — all while ensuring maximum safety and customer satisfaction.

Ring Power will now offer HIAB’s equipment and services to customers across the southeast, further enhancing its reputation for providing industry-leading products and exceptional customer support, the company said.

JCB, the official heavy equipment partner of Monster Jam, unveiled a bold, army-green special-edition teleskid at the Monster Jam event at Angel Stadium in Anaheim, Calif.

Tadano announced that it completed the acquisition of Manitex International on Jan. 2. Manitex is now a wholly owned subsidiary of Tadano Ltd., and, as a result, Manitex shares are no longer listed on Nasdaq.

28 MCCOY CONSTRUCTION & FORESTRY’S DILLON TO LEAD NASHVILLE BRANCH

McCoy Construction & Forestry (MCF) announced that Mark Dillon has been named general manager at the John Deere construction and forestry dealer’s Nashville, Tenn., location.

29 ACPA ANNOUNCES PRESTIGIOUS INDUSTRY AWARD WINNERS

The American Concrete Pavement Association (ACPA) announced the winners of several of its prestigious industry awards, presented during the association’s 61st annual meeting of the members held Dec. 4, 2024, in Phoenix, Ariz.

38 CIM ANNOUNCES DONATIONS FOR AUCTION AT WORLD OF CONCRETE

The CIM program announced that Alliance Concrete Pumps, Papé Kenworth and Kenworth Truck Company have generously donated to the auction fund for CIM’s annual fundraising auction at World of Concrete.

58 SUPPORT MENTAL HEALTH IN CONSTRUCTION WITH THESE STRATEGIES

Mental Wellness Month is a chance to prioritize the mental health of workers, highlight the stressors they face and implement strategies that foster healthier mindsets on and off the job site.

58 CATERPILLAR KICKS OFF ITS NEXT 100 YEARS OF INNOVATION

Caterpillar Inc. marked its 100th anniversary with celebrations throughout the United States that commemorate a monumental moment in the company’s history. The iconic manufacturing company officially turns 100 on April 15.

74 MANITOU GROUP WINS ‘GRAND PRIX IMPACT ENTREPRISE 2024’

Manitou Group has won the “Grand Prix Impact Entreprise 2024”. This award recognizes the group’s solid local

Lloyd Meekins & Sons Auction Co. held its 30th Annual Absolute Construction, Farm, Truck and Auto Auction Dec. 27, 2024, in Lumberton, N.C. Bad weather did not deter buyers from attending in person.

24 CONSTRUCTION EQUIPMENT DISPLAY EXPANDS AT SOUTHERN

Manufacturers exhibiting construction equipment and attachments at the show include New Holland, Kubota, Kioti, Fecon, Loftness, Loflin Fabrication, Southeast Attachments, WR Long, Carolina Attachments, and Utilitough.

68 E2 SYSTEMS OFFERS MATERIAL PLACEMENT SOLUTION

What began as a solution to a specific problem on a southeast Michigan concrete paving project has since evolved into a leading manufacturer of advanced material placers, serving clients across the United States and internationally.

Brevard County, Fla., on the state’s East Coast, has experienced a building boom lately, a trend likely to continue in the coming year.

Florida Today reported Jan. 5 that development there is expected to be robust in 2025, particularly in the residential sector, where a number of single-family homes, apartment complexes and hotels are in the pipeline.

Commercial and industrial projects also are proceeding throughout the county, as are projects at the Space Coast’s colleges.

Port Canaveral CEO John Murray said he saw record amounts of lumber and plywood coming through the port’s cargo terminals in November and December — an indication that the housing industry is about to rebound in the second quarter of 2025.

So, what is ahead for construction and development along the Space Coast in 2025? Following are examples from throughout the county.

A number of residential projects are under way in Palm Bay as Brevard County’s most populous city adds to its current population of just over 140,000.

Deputy City Manager Joan Junkala-Brown said that there are 9,264 housing units within Palm Bay that have been approved and are under construction. Another 21,133 units are currently going through the review process.

One of the big efforts that has been approved is Cypress Bay West, near Babcock Street and Mara Loma Boulevard in southeast Palm Bay, Junkala-Brown noted. It is a threephase project that is targeted to include 1,219 single-family homes, to be developed by Texas-based D.R. Horton, in

addition to 124 townhome units.

Another is the Palm Vista Everlands project, designed to be a mix of 854 single-family homes and 624 multifamily villas and townhomes, including some in age-restricted communities. The site is not far from St. Johns Heritage Parkway, north of Malabar Road, in northwest Palm Bay. There will be three subdivisions within Palm Vista Everlands in which Lennar Homes, located in Miami, is the developer.

Junkala-Brown said two high-tech companies are also in the midst of large expansion projects in Palm Bay.

L3Harris Technologies has two major projects currently under construction at its Palm Bay campus.

The first, Project SAMT, which is an acronym for “secure advanced manufacturing technology,” will be a 105,000-sq.ft. facility upon its completion. The project is projected to create approximately 100 jobs over three years, with private capital investment of $110 million, and $80 million in manufacturing equipment, Florida Today noted.

In addition, L3Harris’ Project LEO, or “low-earth orbit” facility, also is under way and will encompass 93,000 sq. ft. of manufacturing space. A total of 101 new jobs are likely to be hired there over three years, with private capital investment of $70 million in building construction, as well as $13.1 million in manufacturing equipment.

Each of the two projects received approval from the Palm Bay City Council for city property tax breaks over a 10-year period. The combined tax breaks are worth an estimated $1.14 million annually during each of the first five years, with reduced tax breaks later on, Junkala-Brown said.

Another firm to receive city property tax breaks was

Rogue Valley Microdevices, an Oregon-based semiconductor company that is developing a plant at 2301 Commerce Dr. in Palm Bay, with a grand opening tentatively scheduled for this summer.

Rogue Valley is renovating an existing 50,000-sq.-ft. facility and making an investment of about $25 million in private capital for equipment and facility improvements. Officials with the company project an addition of at least 75 jobs over a three-year period.

Work also is proceeding at Eastern Florida State College’s (EFSC’s) Melbourne campus on a new Center for Innovative Technology Education for the training of hightech workers.

The $20 million facility is scheduled to open in August, Florida Today reported, with programs that can lead to bachelor’s degrees, associate degrees and college certificates.

EFSC President Jim Richey told the Viera-based news source that the complex would “set a high standard in Central Florida to meet the surging workforce demands for local business and industry. As such, it will be a critical component in creating jobs and helping ensure the continued economic growth of the Space Coast.”

The 31,500-sq.-ft. building will feature labs that can be configured to provide students with access to software used by high-tech employers, as well as simulation labs, and collaboration areas where students can work together to solve problems in real time.

Students in various disciplines will be supported through the new center, including those studying engineering techsee BOOM page 60

It was a record-breaking year for PCL Construction’s Special Projects Division, which secured nearly 270 new projects in 2024, amounting to approximately $500 million in new work — its highest ever.

This achievement underscores the division’s pivotal role within one of North America’s largest general contractors, delivering specialized small-contractor services in the buildings, civil and industrial sectors.

Tackling projects valued between $10,000 and $15 million, the division’s guiding principle — “compact, complex, quick and competitive” — enables clients to leverage the resources and expertise of a major contractor,

tailored to the demands of smaller, fast-paced projects.

Looking ahead to next year and the anticipated uptick in smaller-scale projects — spanning various market sectors, including hospitality, education, nonprofit organizations, civil infrastructure and data centers — PCL plans to strategically expand its Special Projects Division in 2025 across the United States. To support this anticipated growth, the company plans to expand its Special Projects workforce by at least 25 percent in the next three to five years.

“Our network of close to 20 local offices and over 4,000 employees across the United

States equips us to offer the specialized attention and flexibility of a ‘local contractor,’ while also leveraging the extensive resources of a major construction company,” said Sean Barnes, vice president of special projects of PCL. “This unique combination allows us to handle the intricacies of phasing and working within occupied spaces, ensuring that business continues as usual for our clients.”

As the economic landscape remains uncertain, PCL’s Special Projects Division has emerged as a key contributor to the company’s success. These smaller projects not only allow for quick-turnaround work but also provide vital infrastructure to local communities. Whether it’s performing seismic upgrades at a university or renovating a nonprofit to better serve the community, PCL ensures each project is both impactful and efficiently executed.

Some of PCL’s notable Special Projects awarded in 2024 include:

• Four Seasons Maui upgrades: Nordic PCL Construction is enhancing the Four Seasons Resort Maui with a new sushi bar and lobby, as well as upgrades to two model rooms and the Maile Presidential Suite in Maui, Hawaii.

• The University of California, Los Angeles (UCLA) Mid-Wilshire Parking

Structure seismic upgrades: Seismic upgrades and code-required corrections will take place for UCLA’s Mid-Wilshire parking structure in Los Angeles.

• Minnesota Indian Women’s Resource Center renovation: Renovations include remodeling the third and fourth floors and adding an ADA-accessible tenant entrance on the second floor in Minneapolis, Minn.

• Flexential Chaska Data Center upgrades: Phase five of the project will accommodate increased demand and includes significant upgrades to the heating, ventilation and air conditioning systems and electrical infrastructure in and around the facility. It is located in Chaska, Minn.

• Lake Mary Water Treatment Plant Sedimentation Basin Improvement: Rehabilitation, removal and replacement of the major mechanical and electrical equipment associated with the sedimentation and flocculation basins will take place at the plant in Flagstaff, Ariz.

Looking ahead to 2025, PCL’s Special Projects Division is well-positioned to continue addressing the needs of communities across the United States, delivering projects that are lean, flexible and designed to meet the needs of local communities.

For more information, visit PCL.com.

In total, Northwest deployed 10 Liebherr cranes that were operated, rigged and supervised by a 56-member team. Working day and night, the project took place more than 57 days and 12,357 man-hours.

During the high stakes period of a plant turnaround, Northwest Crane Service relies on a fleet of Liebherr cranes to complete a series of critical lifts — all while ensuring maximum safety and customer satisfaction.

A plant turnaround, often called an outage or shutdown, is a scheduled period when a facility conducts maintenance on equipment and utilities.

Northwest Crane Service was chosen as the crane service provider for a plant turnaround in fall 2023 at a site in Kansas. Utilizing Liebherr equipment and backed by months of planning, technical engineering and ongoing communication with the customer, Northwest Crane Service maintained high productivity, kept the turnaround on schedule, and ensured the project’s safe completion.

At Liebherr USA, Co., safety is not just a buzzword, every crane has a sophisticated safety concept. With these safety features in mind, crane selection played a critical role in the timely completion of this project as there were several complex lifts.

The most difficult lift included a 220,000-lb. ammonia converter. This lift not only required a large crane, but one that could meet the customer’s ground bearing pressure requirements.

Northwest had the ideal solution by utilizing the Liebherr LR1600/2-W, narrow track crawler crane. As the only LR1600/2-W in the United States, it was clear that Northwest’s utilization of the Liebherr crane was the ideal solution for this job as it could easily lift and maneuver in a tight space.

The Liebherr LR 1600/2-W excels in heavy lift applications across a wide variety of industries, according to the manufacturer. The crawler offers both standard and narrow travel gear allowing it to move on tracks between tight erection sites. The LR 1600/2-W also provides class lifting capacity with numerous enhancing attachments.

“Safety, innovation and teamwork are in the DNA of how we operate at Northwest Crane

The most difficult lift included a 220,000pound ammonia converter. This lift not only required a large crane, but one that could meet the customer’s ground bearing pressure requirements.

Northwest operated and maintained the fleet of mobile cranes to provide rigging and hoisting support for a variety of technical components, tools, and pipe during the mechanical shutdown of the plant. Due to the tight timeframe, it was essential that Northwest personnel stay on the customer’s schedule and meet their lifting needs in an efficient manner.

Service. And we use these same parameters when selecting our equipment — which is why we have a fleet of exclusively Liebherr cranes,” said Andy Hodges, owner of Northwest Crane Service.

In addition to the LR 1600/2-W crawler crane, Northwest utilized a fleet of Liebherr mobile cranes including the LTM 1650-8.1, LTM 1230-5.1, LTM 1130-5.1, LTM 1110-5.1, LRT 1100-2.1 and LTM 1070-4.2.

Northwest operated and maintained the fleet of mobile cranes to provide rigging and hoisting support for a variety of technical components, tools and pipe during the mechanical shutdown of the plant. Due to the tight timeframe, it was essential that Northwest personnel stay on the customer’s schedule and meet their lifting needs in an efficient manner.

Not only are Liebherr mobile cranes efficient for the plant turnaround, but they offer powerful, long telescopic booms that can reach incredible heights quickly and easily. As flexibility is a high priority for Northwest, the mobile cranes also can be configured quickly using functional lattice extensions, folding jibs, fixed and luffing lattice jibs.

“Liebherr’s commitment to producing the safest and most innovative machinery on the market coupled with the collaborative nature of our relationship allows Northwest to provide the industry leading service we are known for day in and day out,” said Hodges.

In total, Northwest deployed 10 Liebherr cranes that were operated, rigged and supervised by a 56-member team. Working day and night, the project took place over 57 days and 12,357 man-hours. Northwest successfully completed multiple complex and tandem crane lifts with zero incidents, owing to Liebherr’s excellence.

(All photos courtesy of Liebherr.)

Cat 320 – 2021 MYK Series, 1,428 Hours, Auxiliary Hydraulics, Hyd. Coupler, 48” Bucket

Cat 323 – 2022 NDL Series, 1,558 Hours, Auxiliary Hydraulics, Hyd. Thumb, Hyd. Coupler, 48” Bucket

Cat 330 – 2020 WCH Series, 1325 Hours, Auxiliary Hydraulics, Hyd. Coupler

Cat 335 – 2021 XBE Series, 2,551 Hours, Auxiliary Hydraulics, Hydraulic Coupler, 54” Bucket

Cat 815B – 1988 17Z Series, ROPS Canopy, Leveling Blade with Tilt, Good Feet and Cleaner Bars

Cat 926M – 2019 LTE Series, 905 Hours, GP Bucket, Fusion Coupler, 20.5R25 Tires

Cat CP56B – 2019 Model, 2,119 Hours, Cab, Heat, 84” Padfoot Drum

Cat D3 – 2022 XKW Series, 616 Hours, EROPS, Screens, Sweeps, Reach Winch

Cat D6 – 2022 HNK Series, 4,100 Hours, S/U Blade, Rear Ripper, Trimble Earthworks

Cat D6T XW – 2019 JNM Series, 1,929 Hours, EROPS, Sweeps, VPAT Blade, Rear Drawbar

Cat D8T – 2022 AW4 Series, 650 Hours, S/U Blade, Trimble Earthworks

Deere 544P – 2022 Model, 2,575 Hours, GP Bucket, Coupler, Forks

Dynapac CA30PD – 2023 Model, 328 Hours, ROPS Canopy, 84” Padfoot Drum

Dynapac CA30PD – 2023 Model, 863 Hours, Cab, A/C, Heat, 84” Padfoot Drum

Komatsu WA270 – 2023 Model, 582 Hours, Coupler, G.P Bucket, Forks

$Call

$184,500

$252,500

$Call

$89,500

Ring Power Utility, Tru and digger derricks to loaders, hydroexcava t

uck & Crane specializes in ever our vocational line of equipme ion trucks and contractor truc

rything from bucket trucks nt, including grapple ks.

RingPowerUtilityTruuck&Cranespecializesineverrythingfrombuckettrucks

We can handle all you truck mounted, rough

r lifting and rigging needs wit h terrain and industrial cranes.

lattice boom, crawler,

JCB — the world’s largest privately-owned manufacturer of construction and agricultural equipment and the official heavy equipment partner of Monster Jam — unveiled a bold, armygreen special-edition teleskid at the Monster Jam event at Angel Stadium in Anaheim, Calif.

This exclusive debut marks the launch of an ambitious campaign to raise $1 million for U.S. military veterans through a partnership with VetsAid, a national 501(c)3 non-profit veterans organization founded by rock legend Joe Walsh of the Eagles. The partnership will raise awareness and funds for U.S. veterans through the power of rock and the transformative process of rebuilding.

For each teleskid sold in the United States, JCB will donate a percentage of the proceeds to VetsAid, which directly supports veterans service groups across the United States that provide myriad types of care for veterans and their families. Adding to the excitement, the teleskid loader made its debut on the field to the U.S. premiere of “Dig It” — an original song by Joe Walsh which debuted in London in July during Monster Jam. This powerful anthem, also featuring Ringo Starr on drums, is the soundtrack for JCB’s DIGatron, and serves as an uplifting call-to-action to support the vital mission of VetsAid.

“VetsAid isn’t just about raising money and awareness for America’s veterans and their families,” Walsh said. “It’s also about finding common

ground amongst music lovers of all backgrounds and coming together to build and rebuild communities around a shared love of country. It’s a privilege for us at VetsAid to expand upon this vision with Alice, and Ann, and our friends at JCB, and keep the party going with this kick-ass new song, special edition teleskid, and exciting partnership.”

As a family-owned company, JCB is committed to supporting American families, particularly those with ties to the military. Monster Jam is the perfect partner, with 25 percent of its audience coming from families with veteran connections. This collaboration reinforces shared values of resilience, innovation, and giving back, while allowing JCB to connect with key audiences, including farmers, builders and small business owners.

“JCB is a family company with an expanding manufacturing base in North America, and we have always been committed to supporting the veteran community,” said Alice Bamford of JCB North America. “At our North American headquarters in Savannah, 10 percent of our workforce are veterans, and we will continue this commitment with our new $500 million factory in San Antonio. I’m thrilled that JCB can further support veterans through this special edition Teleskid loader and our partnership with VetsAid.”

For more information, visit www.jcb.com, www.vetsaid.org and www.MonsterJam.com.

Ring Power Utility | Truck | Crane announced its new partnership with HIAB, a globally recognized leader in smart and sustainable load handling solutions.

As an authorized dealer, Ring Power will now offer HIAB’s equipment and services to customers across the southeast, further enhancing its reputation for providing industry-leading products and exceptional customer support, the company said.

This partnership marks a significant mile-

stone for both organizations, combining HIAB’s loader cranes with Ring Power’s extensive network and strong salesforce.

“This partnership represents an exciting new chapter,” said Mike Beauregard, SVP and director of Utility Truck & Crane at Ring Power. “By combining HIAB’s products with our established infrastructure and unwavering commitment to customer satisfaction, we’re confident in a bright future together.”

HIAB loader cranes are known for their reliability, quality and industry-best safety features. With more than 700 service points nationwide, HIAB’s service network will further bolster Ring Power’s ability to provide comprehensive support to customers.

“HIAB is looking for future growth, and an important part of that is to further expand our leading position in the growing North American markets. The cooperation that we now embark on with Ring Power Utility | Truck | Crane will greatly support our ambitions in this,” said Pauliina Kunvik, SVP of sales & services, HIAB USA.

“Ring Power Utility | Truck | Crane is strategically very well positioned in the U.S. and their sales and services organizations are well-known for their enthusiasm and expertise.”

“The geographical coverage of Ring Power Utility | Truck | Crane is excellent and from HIAB growth point of view very attractive. Both teams Ring Power and HIAB show 100 percent commitment to the cooperation, and are excited to head towards joint growth together,” said Bob Cannady, VP of sales, HIAB US.

The addition of HIAB equipment to Ring Power’s portfolio followed a rigorous New Product Integration (NPI) process. Andrew Kurz, VP of Sales, described the process: “We sought a knuckle boom manufacturer that met our standards for quality and partnership. Through factory tours and in-depth discussions with HIAB’s leadership team, it was clear their innovation and customer focus align perfectly with our values. We’re eager to deploy this product offering immediately, leveraging our team of more than 20 account managers across multiple industries.”

Dan Leach, VP of aftermarket product support, added, “HIAB’s aftermarket footprint complements ours beautifully. Together, we’re positioned to deliver even better coverage and support for customers across the southeast, providing a seamless experience throughout the lifecycle of their equipment.”

(Photos courtesy of Ring Power.)

Tadano announced that it completed the acquisition of Manitex International on Jan. 2. Manitex is now a wholly owned subsidiary of Tadano Ltd., and, as a result, Manitex shares are no longer listed on Nasdaq.

On Sept. 12, 2024, Tadano announced its plans to acquire all the remaining shares of Manitex that it did not previously own. Tadano first invested in Manitex in 2018 and held 14.5 percent of the outstanding common shares of Manitex at the time of the September announcement.

Tadano’s Mid-Term management plan outlines the company’s growth strategy and the objective to venture into new areas. The Manitex acquisition is a significant step in implementing this strategy to further diversify the Tadano product portfolio while remaining 100 percent committed to the lifting equipment industry.

In addition to other crane models, the strategic move adds mobile truck cranes and aerial work platforms to the Tadano portfolio to help expand the company’s global presence in these markets.

Commenting on the Manitex acquisition, Toshiaki Ujiie, president, CEO and representative director of Tadano, said: “We welcome Manitex as the newest members of the global Tadano team. Tadano enjoys a strong global market share in large cranes. In Japan, we are market leaders in truck loader cranes and aerial work platforms but have not yet been able to duplicate this success outside of the country.

“Combining the engineering, sales and service expertise of both companies allows us to rapidly expand Tadano’s global presence in these areas, so we can better support our customers’ lifting needs and further innovate. Together, we will work hard, grow strong, achieve great things and reach new heights.”

Hiroshi Nishizaki will assume the position of chairman of the board of Manitex International, bringing extensive experience in managing construction machinery businesses in the United States. Dean Barley, current president and CEO of Tadano America Corporation and Tadano Mantis Corporation, will take on the role of president and CEO of Manitex International in addition to his current responsibilities.

The former executives — Dave Langevin, chairman of the board; Michael Coffey, CEO; and Joseph Doolan, CFO — are stepping down but will remain with the organization for a transitional period as interim advisors to the new management and the Tadano team before their departure.

Serving the infrastructure, heavy industry and general construction markets, the acquired product line includes Manitex mobile truck cranes, PM knuckle boom cranes, Valla small electric cranes and Oil & Steel aerial work platforms. Tadano also gains five engineering and manufacturing locations throughout North America and Europe.

Additionally, this acquisition includes Rabern Rentals. For more information, visit www.tadano.com.

Alabama Heavy Machines Inc.

www.heavymachinesllc.com

THEODORE (251) 653-5955

BIRMINGHAM (205) 323-6108

DECATUR (256) 898-0550

Arkansas LiftTruckServiceCenterInc

Lift Truck Service Center, Inc.

www.lifttruckservicecenterinc.com

LITTLE ROCK (501) 568-3330

Florida Heavy Machines Inc.

www.heavymachinesllc.com

PENSACOLA (888) 366-9028

Great Southern Equipment, LLC. www.gsequipment.net

T

AMPA FT. MYERS

(813) 248-4971

ORLANDO (407) 859-9160

JACKSONVILLE (904) 268-4400

OCALA (813) 248-4971

Georgia Heavy Machines Inc.

www.heavymachinesllc.com

COVINGTON (770) 788-0888 (239) 334-6063

Louisiana Heavy Machines Inc.

POMPANO BEACH (954) 327-8808 MIDWAY (850) 574-0892

www.heavymachinesllc.com

SHREVEPORT (318) 621-0854

State Machinery & Equipment Sales, Inc. www.statemachineryco.com

KENNER (504) 464-0431

North Carolina

Liebherr r Equipment Source libh www.liebherr.com

RALEIGH (919) 329-0080

RECO Equipment, Inc. www.recoequip.com

CHARLOTTE (704) 399-7555

Tennessee Heavy Machines Inc. www.heavymachinesllc.com

MEMPHIS (901) 260-2200

RECO Equipment, Inc. www.recoequip.com

LaVERGNE (615) 610-7326

VIRGINIA Liebherr r Equipment Source www.liebherr.com

MANASSAS (703) 392-0111

(757) 240-4250 LOUDON (865) 686-8686 material handling equipment and technology in th components are developed and manufactured in-h or in close collaboration with our partners to ensu possible quality standards.These components inc drive and controltechnology, diesel engines, and a components for hydraulics, gearboxes and electro Reach out to your local Liebherr distribution partne nformation. e USA Main ouse by Liebherr re the highest lude the entire variety of nic systems. rfor more

The 2025 Southern Farm Show, scheduled for Feb. 5-7 at the NC State Fairgrounds, continues to expand its offering of grading, excavating and land clearing equipment.

Now the largest annual display of construction equipment in the Carolinas and Virginia, this section of the agricultural show attracts professionals from across the region.

Manufacturers exhibiting construction equipment and attachments at the show include New Holland, Kubota, Kioti, Fecon, Loftness, Loflin Fabrication, Southeast Attachments, WR Long, Carolina Attachments, and Utilitough. The show also is gaining international attention with Italy’s VF Venieri and Spain’s TMC Cancela participating for the first time this year.

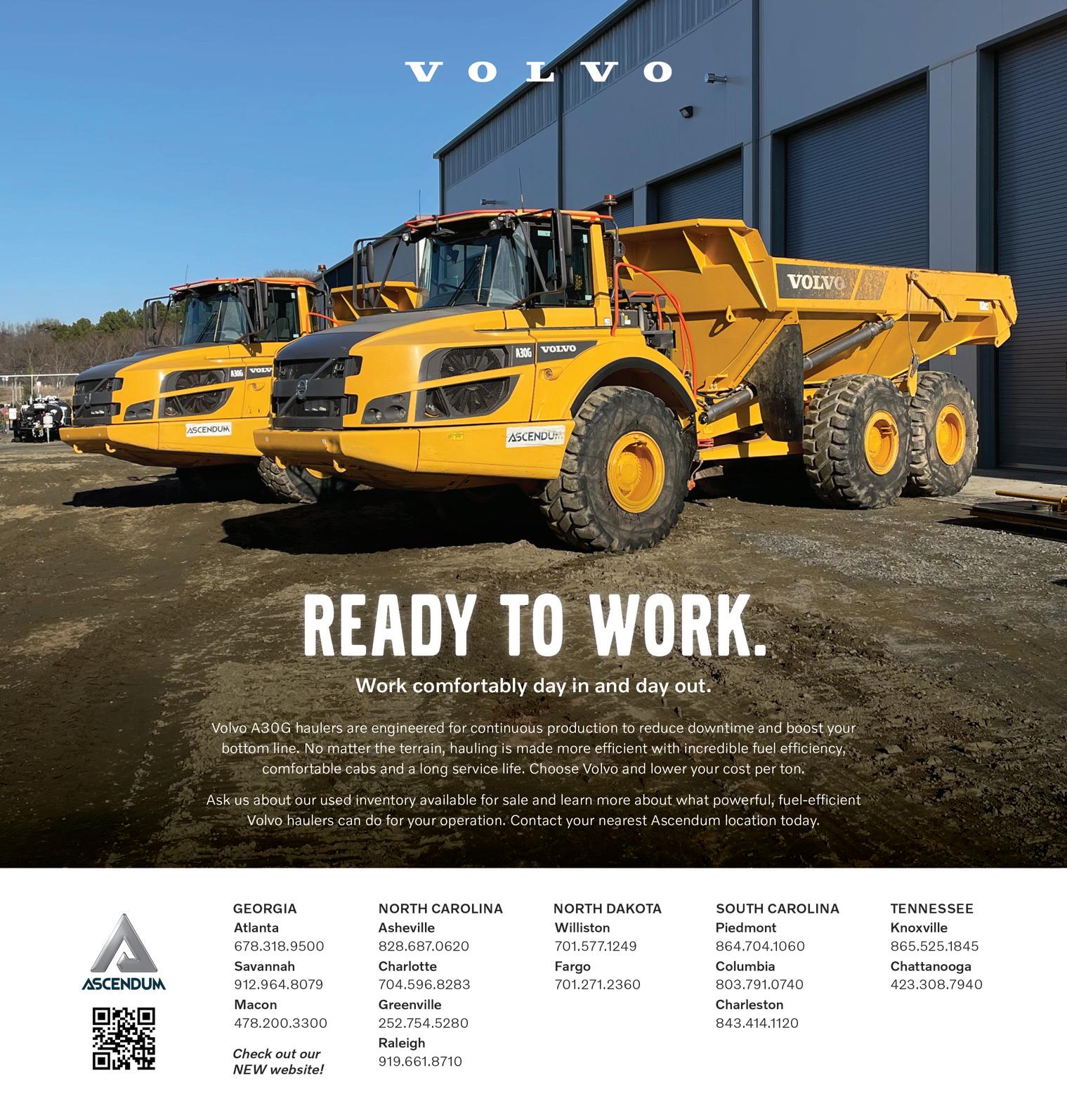

Dealers and distributors to be on hand include Ascendum with its Volvo, Doosan and Bergmann lines; Asheboro JCB; Company Wrench showing JCB, Kobelco and Pinroth; Triangle Equipment Group with Bobcat; James River Equipment and Quality Equipment with John Deere; National Equipment Dealers with ASV, Brush Wolf, Denis Cimaf, Hyundai, Manitou, Shearex, Werk Brau and Yanmar; Sound Heavy Machinery showing AUSA, ASV, Kobelco, Rubble Crusher, Loftness, Blue Diamond, Geith and Strickland; Implement Sales with Baumalight and Construction Attachments; Jesse Rast with Gyro-Trac; Cummings and Bricker with Wallenstein; and CCS Equipment Sales showing Blue Diamond, CID, FAE, Liugong, Multiquip, Takeuchi, Toro, Virnig and Wacker Neuson.

GF Equipment Sales is greatly expanding its presence at the 2025 show and plans to display Lane, Rubble Crusher and Sunward equipment.

Company Wrench is returning to the show with its popular area that allows show guests to operate Kobelco excavators. Kolbeco factory representatives will be on hand to help those 21 and older understand how the excavators operate. There also will be a skills challenge with prizes for the best operators. Look for the large inflatable Kobelco robot to sign up.

Company Wrench also will have an additional exhibit area this year dedicated to Prinoth mulching and other equipment. Both carrier vehicle and attachment models will be in the display.

The Southern Farm Show is the largest annual agricultural exposition in the Carolinas and Virginia. Filling the NC State Fairgrounds, the show also includes a large selection of professional landscape equipment. Show hours are 9 am to 4 pm on Wednesday and Thursday and 9 am to 3 pm on Friday. Admission and parking are free. For

The largest annual display of construction equipment in the Carolinas and Virginia

HYUNDAI•JCB•KOBELCO•NEW HOLLAND KUBOTA•JOHN DEERE•TAKEUCHI•DANSUER DOOSAN•VOLVO•BOBCAT•ASV•KIOTI BERGMANN•SUNWARD•VERNIG•YANMAR MANITOU•LIUGONG•WERK BRAU•FAE FECON•PRINOTH•BLUE DIAMOND BAUMALIGHT•VF VENIERI•CID•DENIS CIMAF AUSA•SHEAREX•LOFTNESS•BRUSH WOLF SHOULE AND MORE

Plus a great selection of construction attachments, forestry equipment, and trailers.

February 5-7

McCoy Construction & Forestry (MCF) announced that Mark Dillon has been named general manager at the John Deere construction and forestry dealer’s Nashville, Tenn., location.

“I am confident in Mark’s ability to bring a winning culture into, not only Nashville but also our region,” said Brad McCoy, a vice president of sales and operations of MCF. “Mark has a proven track record, and I am excited for his ability to lead in our company’s largest market.”

Dillion’s promotion to lead the Nashville operation took effect on Jan. 6. Previously, Dillon was the general manager at MCF’s Foristell, Mo., dealership. He also served as the regional training and safety director of Erb Equipment, prior to MCF’s acquisition of eight Erb Midwestern-based locations in 2021.

Dillon also has experience working as a technician in the quarry industry, prior to transitioning to managing trucks and intermodal fleets.

The American Concrete Pavement Association (ACPA) announced the winners of several of its prestigious industry awards, presented during the association’s 61st annual meeting of the members held Dec. 4, 2024, in Phoenix, Ariz.

The Hartmann-Hirschman-Egan Award is the most coveted of the ACPA service and achievement awards. First presented in 1968, this award was originally named in honor of Harold W. Hartmann, the association’s secretary-treasurer from 1964 until 1974. In 1987, Robert E. Hirschman’s name was added in recognition of his term as the association’s chairman (then president) in 1967, as well as his tenure as secretary-treasurer from 1975 to 1987.

In 2007, the name of Edward A. Egan was added for his service as ACPA’s chairman in 1986, as well as secretary-treasurer from 1988 to 2007.

The award recognizes individuals or organizations for unparalleled commitment, dedication, participation and leadership in the concrete pavement community.

industry,” said Laura O’Neill Kaumo, president and CEO of the American Concrete Pavement Association.

“The more than 40 years of contribution, value and fantastic personality that Glenn has brought to the entire concrete paving industry make him more than deserving of this award. Glenn and I worked together at different times across our careers, my first interaction with him being at Ersco, where I was his salesman from Dayton Superior. Throughout my career I have considered Glenn a mentor, and our business relationship has grown into a personal friendship,” said Ron Meskis, CEO, American Highway.

The 2024 HartmannHirschman-Egan Award winner is former ACPA Board member Glenn Eder.

The 2024 Hartmann-Hirschman-Egan Award winner is former ACPA Board member Glenn Eder. Eder retired as American Highway’s vice president of technical sales in 2022. Prior to American Highway, Eder owned and was the president of Contractors Steel & Accessories from 1986 to 1998. After his company was purchased by Ersco Corporation in 1998, he served as the vice president & division manager of paving supplies until 2007.

Eder went on to work for another load transfer manufacturer, Block Heavy & Highway, from 2007 until 2011, when that company was acquired by Dayton Superior. Eder made his name within the Dayton Superior organization from 2011 to 2015, where he served as the sales manager of paving products.

In 2015 he transitioned from Dayton Superior to JC Supply, growing its business as the vice president of marketing & business development until JC supply was purchased by American Highway in December 2020.

“Glenn was a valued member of the ACPA board of directors for many years and is considered a trusted advisor and friend. Once again, the members have chosen to honor a gentleman and a legend in our

The Harold Halm Presidential Award is named in honor of ACPA’s first president, and this prestigious recognition is awarded at the discretion of ACPA’s president to an individual who has made significant contributions to the concrete pavement industry.

The 2024 recipient is Matt Zeller, concrete promoter at the Concrete Paving Association (CPAM) of Minnesota. Zeller has more than 30 years of experience in the concrete paving industry, serving as CPAM’s executive director from 2004 to 2024.

During his tenure at the Minnesota Department of Transportation, Zeller was a key architect of the water/cement ratio specification, which has resulted in concrete pavements that drastically outperform the concrete pavements built without it. Zeller is widely known as an expert on concrete pavements pushing for early opening strength research, leading to ideas that are currently being adopted worldwide.

“Matt is an outstanding person who is passionate about concrete pavement. He is truly deserving of the acknowledgment and appreciation of his years of dedication to the industry,” explained Dan Labo, executive director, Concrete Paving Association of Minnesota.

The Marlin J Knutson Award for Technical Achievement is named in honor of the second chief executive of ACPA and recognizes individuals who

5710 Riverview Road SE Atlanta, GA 30126 (404) 696-7210

2238 Pinson Valley Parkway Birmingham, AL 35217 (205) 841-6666

15101 AL-20 Madison, AL 35756 (256) 536-9390

1797-A Fulton Springs Rd Alabaster, AL 35007 844-786-6373 800-239-2694 | COWIN.COM

www.stoneequipmentco.com

210 West Boulevard Montgomery, AL 36108 844-786-6373 334-625-6585

35 Schillinger Road North Mobile, AL 36608 (251) 633-4020

4325 Northern Blvd. Montgomery, AL 36110 (334) 262-6642 1501 Highway 78 East Oxford, AL 36203 (256) 832-5053

7950 Pittman Avenue Pensacola, FL 32534 (850) 479-3004

1800 Culver Road Tuscaloosa, AL 35401 (205) 848-4147

The Carlson CP100 II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100hp engine, an array of configurations and the class-leading EZCSS single slide screed, it’s time to see why the CP100 II has fast become the contractor’s choice for heavy-duty commercial paver platforms.

have made significant contributions to advancing the development and implementation of technical innovations — as well as best practices — for the design and construction of concrete pavements.

The 2024 recipient is Bernard Izevbekhai with the Minnesota Department of Transportation. With decades of experience in the concrete pavement industry,

Izevbekhai has been a leading voice in research, co-authoring and authoring more than 40 different research papers, primarily on concrete pavements. His work behind MnROAD was critical and his efforts have received worldwide recognition, contributing greatly to new innovations and applications of concrete paving ideas and technologies.

“Bernard is one of the most intelligent and

thoughtful researchers that I have ever known, and his integrity and character has always impressed me through the decades that I have known him. Without a doubt, his contributions to the concrete industry will be referenced by other researchers for decades to come,” said Dan Labo, executive director, Concrete Paving Association of Minnesota.

The Outstanding Promoter Award is given annually to a person who has made significant contributions through promotion efforts or programs to advance the awareness, specification, and/or placement of concrete pavements. This recognition is reserved for those who have been on the front lines making a difference for our industry.

Brent Burwell with the Oklahoma/Arkansas Chapter of ACPA is the recipient of the 2024 award. Burwell serves as the primary concrete pavement representative between contractors and the Departments of Transportation for Oklahoma and Arkansas. Burwell’s steadfast promotion of concrete pavement and concrete pavement technology, as well as his involvement in specification review processes, encourages decision makers to have confidence in choosing concrete. Burwell has

skillfully guided meetings between contractors and DOT representatives, providing rare forums where industry stakeholders can collaborate directly on concrete specifications and innovative ideas, effectively managing research and fostering open discussions.

“Brent’s expertise has become a valuable asset, not only to contractors, cement companies, and suppliers, but also to DOTs and municipalities who often seek his insights on concrete-related matters. His technical expertise and professional disposition have created a great deal of respect and trust in the industry, which has undoubtedly resulted in an increased use of high-quality concrete pavements in Oklahoma and Arkansas. Brent truly serves as the ‘cement’ that binds various stakeholders, ensuring cohesion and advancing standards across the industry,” said Don Weaver, president, Weaver Bailey Contractors.

The National Lifetime Pavement Recognition Award is presented to an agency/owner of an in-service concrete pavement that has demonstrated exceptional performance for its state and community,

page 36

Sandy and Jeff Eder accept the Hartmann-Hirschman-Egan Award on behalf of Glenn Eder.

and for local users.

The Dare County Regional Airport has served the Outer Banks Community in North Carolina from its Roanoke Island location since 1943 and is the recipient of the 2024 Lifetime Pavement Award. The airport’s concrete apron — also known as a ramp or tarmac — was in service for nearly 80 years, facilitating more than 32,000 landings and takeoffs each year before requiring renovation. While the renovations the airport were completed in 2022, this airport serves as a great story telling the benefits and longevity of concrete pavement.

“This project is worthy of an award for long-life pavement and the following should be recognized: Dare County, the North Carolina Department of Transportation and the FAA Southern Region for having the foresight to fund and award a concrete project to fix the long-life pavement that had been in service for 80 years,” said Greg Dean, executive director, Southeast Chapter, ACPA.

The Best in Show Sustainability Award is awarded to the organization and project that best showcase sustainable operations and construction practices. The 2024 recipient was the IDOT-Emmet County-Highway 9 project located in Emmet County, Iowa. Project contractor Cedar Valley believes that “being green” is cost effective and socially responsible and they have been recognized by the Waterloo-Cedar Falls Chamber of Commerce as a Leader in Sustainable Business. This project removed and recycled more than 34,000 sq. yds. of concrete, which was used as modified subbase under the new mainline pavement.

Additionally, the project used 1L cement, reducing the environmental impact of cement production by reducing the CO2 emissions in the manufacturing process. The first operation on this project was the installation of silt fences and ditch checks to prevent fugitive soil from entering the existing water ways. Likewise, disturbed areas were always stabilized if construction activity did not take place for 21 calendar days.

The project contractor is Cedar Valley Corp and the owner is the Iowa Department of Transportation.

The Best in Show Innovation Award is awarded to the organization and project that best showcase innovation in either the contracting process or during the construction phase to improve safety, cost to construct, value, quality, and performance.

The 2024 recipient is the Route 28 Interchange Improvement Project, located in Allegheny County, Pa. The project incorporated many innovative construction practices such as utilizing stringless paving and nondestructive paving.

Using stringless paving allows for the elimination of the labor-intensive aspect of setting up stringline for concrete slipform machines and concerns about limited workspace. Using non-destructive paving eliminated the need for nearly 30 concrete cores which would have been drilled into the new concrete pavement.

The project contractor is Golden Triangle Construction, the project owner is Pennsylvania Department of Transportation; and the engineer is Michael Baker International.

(All photos courtesy of the American Concrete Pavement Association.)

9000 Statesville Rd Charlotte, NC 704-596-6700

40 Interstate Blvd Asheville, NC 828-251-2500

Carolina Cat carolinacat.com

6215 Swiggett Rd Greensboro, NC 336-294-5240 1201 US-70 Hickory, NC 828-464-7045

Gregory Poole gregorypoole.com

151 Backhoe Road NE Leland, NC 28451 910-371-6301

53 Springs Rd. Washington, NC 27889 252-946-1081

8522 NW 58th Street Miami, FL 305-592-5360 2801 Reese Road Davie, FL 954-581-8181

500 World Commerce Pkwy St. Augustine, FL 904-737-7730

14300 Ponce De Leon Blvd Brooksville, FL 352-796-4978

401 N Tomoka Farms Rd Daytona Beach, FL 386-947-3363

4900 N Main St Gainesville, FL 352-371-9983

2070 Corporate Woods Dr Alabaster, AL 205-664-4833

121 Gilbert Ferry Rd SE Attalla, AL 256-570-1100

2401 Pinson Valley Pkwy Tarrant, AL 205-841-8601

5749 John Givens Rd Crestview, FL 850-682-6510

6969 US-31 Tanner, AL 256-353-7721

2211 Morgan Mill Rd Monroe, NC 704-292-1555

7394 Old US 421 S Boone, NC 828-268-9992

3041 Beechtree Drive Sanford, NC 27330 919-355-0511

4807 Beryl Road Raleigh, NC 27606 919-828-0641

400 Gregory Poole Lane Mebane, NC, 27302 919-568-7500

Kelly Tractor kellytractor.com

5460 Okeechobee Blvd. West Palm Beach, FL 561-683-1231

801 E Sugarland Hwy Clewiston, FL 863-983-8177

Ring Power ringpower.com

330 Pecan Park Road Jacksonville, FL 904-714-2600

390 SW Ring Ct Lake City, FL 386-755-3997 3425 Reynolds Rd Lakeland, FL 863-606-0512

5633 U.S. 301 Hope Mills, NC 28348 910-424-4400

324 U.S. 158 Camden, NC 27921 252-706-7354

9651 Kelly Tractor Dr. Ft. Myers, FL 239-693-9233

6200 North US 301/441 Ocala, FL 352-732-2800

9901 Ringhaver Dr, Orlando, FL 407-855-6195

415 Community College Pkwy SE Palm Bay, FL 321-952-3001

Thompson Tractor Company thompsontractor.com

118 Vulcan Way Dothan, AL 334-671-1040 6307 Co Rd 490 Hanceville, AL 205-283-0128

3600 Governors Dr SW Huntsville, AL 256-532-1776 30950 AL-181 Spanish Fort, AL 251-626-5100

10120 US-80 Montgomery, AL 334-215-5000

508 Columbus Pkwy Opelika, AL 334-749-3359

2300 AL-21 Oxford, AL 256-831-4104

4109 Cato Rd Panama City, FL 850-785-4007

7500 26th Ct E Sarasota, FL 941-359-6000

32000 Blue Star Hwy Tallahassee, FL 850-562-2121 10421 Fern Hill Dr Tampa, FL 813-671-3700

2670 W 9 Mile Rd Pensacola, FL 850-471-6700

2501 Joe Davis Industrial Blvd Thomasville, AL 334-636-0420

3550 Joe Mallisham Pkwy Tuscaloosa, AL 205-247-2800 1030 State Hwy 20, Tuscumbia, AL 256-381-2771

The Concrete Industry Management (CIM) program — a unique businessintensive program that awards students with a four-year Bachelor of Science degree in Concrete Industry Management — announced that Alliance Concrete Pumps, Papé Kenworth and Kenworth Truck Company have generously donated the proceeds from the sale of a truckmounted 38M concrete pump to the auction fund for the National Steering Committee for CIM’s annual fundraising auction at World of Concrete.

“We are very appreciative of the continued support from Alliance Concrete Pumps, Papé Kenworth and Kenworth Truck Company,” said Ben Robuck, CIM auction committee chairman.

“Their continued support of the CIM program speaks volumes to their commitment to the concrete industry and the importance these leading companies place on CIM. The proceeds from the sale of this item will help ensure a successful CIM Auction at the 2025 World of Concrete.”

The modern design of the 38M concrete pump, with a robust rotec pedestal and streamlined side panels and outriggers, allows for less overall weight and makes this machine legal in more places while still providing simplicity, reliability and performance for the operator, according to the manufacturer.

Specifications for the truck-mounted 38M concrete pump include:

General Specifications

• Pipe Size (ID) — 125 mm (5 in.)

• Boom Control — Proportional (by HAWE)

• Radio Remote — Scanreco wireless dual transmitter system

• Vibrator — Standard

• Water Pump — Hydraulic Power 20 bar (290 psi)

• Water Tank — 800 L (211 G)

• Wear Parts — Carbide

Boom Specifications

• Number of booms — four sections

• Folding type — Z Fold

• Vertical height — 37.1 m (121 ft. 9 in.)

• Horizontal reach — 33.1 m (108 ft. 7 in.)

• Unfolding height — 8.9 m (29 ft. 2 in.)

• 1st Section — 8.98 m (29 ft. 5 in.)

Concrete Industry Management photo The modern design of the 38M concrete pump, with a robust rotec pedestal and streamlined side panels and outriggers, allows for less overall weight and makes this machine legal in more places while still providing simplicity, reliability and performance for the operator, according to the manufacturer.

• 2nd Section — 7.85 m (25 ft. 9 in.)

• 3rd Section — 7.94 m (26 ft. 1 in.)

• 4th Section — 8.33 m (27 ft. 4 in.)

• Outrigger — X-Style

• Front Spread — 6.3 m (20 ft. 8 in.)

• Rear Spread — 7.0 m (23 ft.)

Pump Specifications

• Output — Rod Side 164 m³/h (215 yd³/h)

• Output — Piston Side 102 m³/h (133 yd³/h)

• Pressure — Rod Side 72 Bar (1044 psi)

• Pressure — Piston Side 115‡ bar (1668 psi)

• Concrete Cylinder Diameter — 230 mm (9 in.)

• Concrete Cylinder Type — Hard Chromed

• Stroke Length — 2,100 mm (83 in.)

• S-Tube Size — 9 in. by 7 in.

• Main Oil Pump — Rexroth hydromatic A11VLO260

• Hydraulic System Pressure — 350 bar (5076 psi)

• Lube System (Hopper) — Automatic

• Switching System — Hydraulic

• Hopper Capacity — Easy Clean

600 L (158 G)

• Number of Strokes/Minute — 31

• Output Control Range — 10(13)~164m³/h (215yd³/h)

The Kenworth conventional chassis includes:

• Model — T880

• Wheelbase — 290 in.

• Engine — Paccar MX-13 455 hp

• Transmission — Allison 4500RDS 6-speed automatic transmission

• Front Axle — 20,000 lbs.

• Rear Axle — 46,000 lbs. Neway air suspension

• Base Warranty — 12 month/100,000 mile

Manufacturer’s Suggested Retail Price (MSRP) of the complete unit is $505,000.

“Alliance Concrete Pumps is excited to donate the proceeds of the sale of our most popular boom pump model to the CIM auction,” said Clayton White, president and CEO, Alliance Concrete Pumps. “We are also very proud to be part of procuring young and up-andcoming talent for the concrete industry.”

The annual auction will be held Jan. 22, 2025, in the North Hall Room N262 of the Las Vegas Convention Center.

For a full list of items, visit www.concretedegree.com/auction.

BLANCHARD MACHINERY www.blanchardmachinery.com/paving Columbia, SC 803-791-7100

Florence, SC 843.678.8520

Rock Hill, SC 803.324.9600

Simpsonville, SC 864.963.3645

Myrtle Beach, SC 843-399-2074

Summerville, SC 843.871.2001

Hilton Head, SC 843-784-6766

CAROLINA CAT www.carolinacat.com

Charlotte, NC 704-596-6700

Asheville, NC 828-251-2500

Greensboro, NC 336-294-5240

Hickory, NC 828-464-7045

Monroe, NC 704-292-1555

Boone, NC 828-268-9992

Chattanooga, TN 423-698-6943

Crossville, TN 931-484-4040

Knoxville, TN (East) 865-546-1414

and assist you.

Knoxville, TN (West) 865-218-8800

Sevierville, TN 865-595-3750

Tri-Cities, TN 423-323-0400

www.richmondmachinery.com

2350 Greystone Ct. Rockville, VA 23146 (804) 359-4048

www.reynoldswarren.com

1945 Forest Parkway Lake City, GA 30260 (800) 875-5659 (404) 361-1593

180 Thunderbird Drive Richmond Hill, GA 31324 (912) 445-2880

The project was awarded in April 2023 and is executed by the design-build team of Kokosing Construction Company and Rinker Design Associates. Construction commenced in November 2023 with the initial phase focusing on shoulder strengthening to facilitate traffic shifts necessary for median widening. Kokosing’s earthmoving operations actively progressed in the median.

Westerville, Ohio-based Kokosing Construction Company serves as the prime contractor for the project, deploying four crews on-site. The design-builder’s responsibilities include completing design of the project; acquiring any right of way and easements as needed; relocating utili-

ties; acquiring any environmental permits necessary; and constructing the final project.

The design-build team includes several subcontractors: Rinker Design Associates for project design; Haley & Aldrich Inc. for geotechnical services; H&B Surveying; Fairfield & Echols LLC for bridge construction; CES Consulting for signing and electrical; Slurry Pavers Inc. for full-depth reclamation; B&S Contracting Inc. for paving; Mullen’s Markings for pavement markings; and Long Fence Company Inc. for guardrail installation.

(844) 4 MY DOBBS www.dobbsequipment.com

2730 Falkenburg Road HQ Riverview, FL 33578 (813) 620-1000

4343 Northwest 77th Ave Miami, FL 33166 (305) 592-5740

3933 Martin Luther King, Jr. Blvd West Palm Beach, FL 33404 (561) 848-6618

4333 North John Young Pkwy Orlando, FL 32804 (407) 299-1212

3005 Hanson Street Fort Myers, FL 33916 (239) 334-3627

4618 Scarborough Drive Lutz, FL 33559 (813) 995-0841

1730 N. Nova Road Holly Hill, FL 32117 (407) 299-1212

1705 Columbia Lane Melbourne, FL 32904 (321) 234-3344

2710 Falkenburg Road Riverview, FL 33578 (813) 621-4902 - Parts

1751 Copans Road, Unit 8 Pompano Beach, FL 33064 (954) 977-9541 - Parts

6265 E Sawgrass Road Sarasota, FL 34240 (941) 960-2004 - Parts

www.tec1943.com

150 Piper Lane Alabaster, AL 35007 (205) 621-2489

5336 Messer-Airport Hwy Birmingham, AL 35212 (205) 591-2131

800 Church St. N.E. Decatur, AL 35601 (256) 355-0305

4307 Reeves Street Highway 431 North Dothan, AL 36303 (334) 678-1832

243 South Jackson St. Grove Hill, AL 36451 (251) 275-4158

108 Skylab Drive NW Huntsville, AL 35806 (256) 851-2222

2100 East I-65 Service Rd. North Mobile, AL 36617 (251) 457-8991

3285 Selma Highway Montgomery, AL 36108 (334) 288-6580

309 Hamric Drive West Oxford, AL 36203 (256) 831-2440

3820 Greensboro Ave. Tuscaloosa, AL 35405 (205) 752-0621

3305 Highway 77 Panama City, FL 32405 (850) 763-4654

9036 Pine Forest Rd. Pensacola, FL 32534 (850) 505-0550

www.powerequipco.com 3300 Dozer Lane Knoxville, TN 37920 (HQ) (865) 577-5563

4295 Bonny Oaks Drive Chattanooga, TN 37406 (423) 894-1870 1487 Rock Springs Road Kingsport, TN 37664 (423) 349-6111 320 Waldron Rd. LaVergne, TN 37086 (615) 213-0900 3050 Ferrell Park Cove Memphis, TN 38116-3502 (901) 346-9800 1545 Highway 45 Saltillo, MS 38866 (662) 869-0283

beardequipment.com 6870 Philips Highway Jacksonville, FL 32216 (904) 296-5000

2578 SE Baya Drive Lake City, FL 32025 (386) 752-9544

4539 NW 44th Avenue Ocala, FL 34482 (352) 732-4646

356 N. Hwy 17 Palatka, FL 32177 (386) 326-6268

3033 US Hwy 27 E. Perry, FL 32348 (850) 584-9200

7566 W. Tennessee St. Tallahassee, FL 32304 (850) 575-5600

“In 2019, the Virginia General Assembly adopted legislation creating the Interstate 81 Corridor Improvement Fund, which receives revenues through the Interstate Operations and Enhancement Program and a regional fuels tax along the corridor that was signed into law by Gov. Ralph Northam in April that year,” said Dave Covington, I-81 program delivery director. “VDOT is utilizing federal Transportation Infrastructure Finance and Innovation Act [TIFIA] loans to advance projects along the corridor more quickly with lowinterest rate loans.”

The program began with a corridor study completed in 2018 identifying the different improvements required as part of the project.

Given the project's location at the busy I-81/I-64 Interchange and the presence of three other active projects nearby, safety is a top priority.

“To protect construction workers, traffic barriers have been installed and speed limits have been reduced. All detours, whether planned or due to incidents, will utilize the Route 262 bypass around Staunton,” said Joe Duquette, construction manager.

The project involves placing approximately 190,000 cu. yds. of fill and about 110,000 tons of asphalt. Around 105,000 sq. yds. of full-depth reclamation will be conducted between the northbound and southbound lanes using reclaimers and bulk spreaders. All other construction aspects will utilize conventional equipment.

“The greatest challenge of this project is maintenance of traffic [MOT] due to its phased nature, which includes the reconstruction of five bridges,” said Duquette. “While the median grading is relatively straightforward and the site is mostly balanced, there have been no significant environmental or historical impacts.”

Construction phases involve installing stormwater BMPs (best management practices); drainage pipes; full-depth reclamation; paving; bridge demolition and reconstruction; overhead sign structures; and new signage. Challenges anticipated during that time are the transitioning and scheduling

of work as the project moves through different phases. Duquette added that the area has sufficiently rebounded from the pandemic and not encountered any issues with materials or labor on this project as a result.

The estimated project value is $140 million, with Kokosing Construction Company awarded the contract for $100,831,000 as the design-builder. The contract includes a 6 percent DBE (disadvantaged business enterprise) participation goal. The three northbound lanes on I-81 are scheduled to open on Nov. 24, 2026, with substantial completion of the three southbound lanes by May 10, 2027. Final project completion is set for May 21, 2027. The Improve81 website (Improve81.org) has all the latest news including video and podcast updates. CEG

Construction

Work began in 2023 and includes extensive earthmoving; full-depth reclamation; paving; and bridges undergoing substructure repairs to support the expanded superstructure.

www.richmondmachinery.com

2350 Greystone Ct. Rockville, VA 23146 (804) 359-4048

www.reynoldswarren.com 1945 Forest Parkway Lake City, GA 30260 (800) 875-5659 (404) 361-1593

180 Thunderbird Drive Richmond Hill, GA 31324 (912) 445-2880

beardequipment.com

6870 Philips Highway Jacksonville, FL 32216 (904) 296-5000

2578 SE Baya Drive Lake City, FL 32025 (386) 752-9544

4539 NW 44th Avenue Ocala, FL 34482 (352) 732-4646

356 N. Hwy 17 Palatka, FL 32177 (386) 326-6268

3033 US Hwy 27 E. Perry, FL 32348 (850) 584-9200

7566 W. Tennessee St. Tallahassee, FL 32304 (850) 575-5600

150 Piper Lane Alabaster, AL 35007 (205) 621-2489

5336 Messer-Airport Hwy Birmingham, AL 35212 (205) 591-2131

800 Church St. N.E. Decatur, AL 35601 (256) 355-0305

4307 Reeves Street Highway 431 North Dothan, AL 36303 (334) 678-1832

www.tec1943.com (844) 4 MY

243 South Jackson St. Grove Hill, AL 36451 (251) 275-4158

108 Skylab Drive NW Huntsville, AL 35806 (256) 851-2222

2100 East I-65 Service Rd. North Mobile, AL 36617 (251) 457-8991

3285 Selma Highway Montgomery, AL 36108 (334) 288-6580

309 Hamric Drive West Oxford, AL 36203 (256) 831-2440

3820 Greensboro Ave. Tuscaloosa, AL 35405 (205) 752-0621

3305 Highway 77 Panama City, FL 32405 (850) 763-4654

9036 Pine Forest Rd. Pensacola, FL 32534 (850) 505-0550

www.dobbsequipment.com

2730 Falkenburg Road HQ Riverview, FL 33578 (813) 620-1000

4343 Northwest 77th Ave Miami, FL 33166 (305) 592-5740

3933 Martin Luther King, Jr. Blvd West Palm Beach, FL 33404 (561) 848-6618

4333 North John Young Pkwy Orlando, FL 32804 (407) 299-1212

3005 Hanson Street Fort Myers, FL 33916 (239) 334-3627

4618 Scarborough Drive Lutz, FL 33559 (813) 995-0841

1730 N. Nova Road Holly Hill, FL 32117 (407) 299-1212 1705 Columbia Lane Melbourne, FL 32904 (321) 234-3344

2710 Falkenburg Road Riverview, FL 33578 (813) 621-4902 - Parts 1751 Copans Road, Unit 8 Pompano Beach, FL 33064 (954) 977-9541 - Parts

6265 E Sawgrass Road Sarasota, FL 34240 (941) 960-2004 - Parts

Autonomous 9RX tractors for large-scale agriculture feature 16 individual cameras arranged in pods to enable a 360-degree view of the field so farmers can step away from the machine and focus their time on other important jobs.

John Deere revealed several new autonomous machines during a press conference at CES 2025 to support customers in agriculture, construction and commercial landscaping.

Building on Deere’s autonomous technology first revealed at CES 2022, the company’s second-generation autonomy kit combines advanced computer vision, AI and cameras to help the machines navigate their environments.

While each of these industries experiences their own set of challenges, a commonality across all is skilled labor availability.

• Agriculture: the American Farm Bureau Federation also estimates there are roughly 2.4 million farm jobs that need to be filled annually.

• Construction: 88 percent of contractors struggle to find skilled labor.

• Commercial Landscaping: 86 percent of landscaping business owners can’t find labor to fill open positions.

Quarries supply the essential raw materials vital for building roads, buildings and infrastructure, and it’s a complex process to mine, process and transport materials. Using the second-generation kit, the ADT will handle the repetitive tasks of transporting material around the quarry to facilitate different steps in the cycle.

“Our agriculture, construction and commercial landscaping customers all have work that must get done at certain times of the day and year, yet there is not enough available and skilled labor to do the work,” said Jahmy Hindman, chief technology officer at John Deere.

“Autonomy can help address this challenge. That’s why we’re extending our technology stack to enable more machines to operate safely and autonomously in unique and complex environments. This will not only benefit our customers, but all of us who rely on them to provide the food, fuel, fiber, infrastructure and landscaping care that we depend on every day.”

• Autonomous 9RX Tractor for LargeScale Agriculture: Tillage is one of the busiest times of the year for farmers. With the second-generation autonomy kit, featuring 16 individual cameras arranged in pods to enable a 360-degree view of the field, farmers can step away from the machine and focus their time on other important jobs. The advanced autonomy kit also calculates depth more accurately at larger distances, allowing the tractor to pull more equipment and drive faster.

• Autonomous 5ML Orchard Tractor for Air Blast Spraying: Protecting crops

through air blast spraying is a challenging and repetitive job. Featuring the latest autonomy kit with added Lidar sensors to address the dense canopies found in orchards, the initial machine will be offered with a diesel engine. A battery electric tractor of comparable size and capacity to existing diesel 5M/ML models on the market today will follow.

• 460 P-Tier Autonomous Articulated Dump Truck (ADT) for Quarry Operations: Quarries supply the essential raw materials vital for building roads, buildings and infrastructure, and it’s a complex process to mine, process and transport materials. Using the second-generation kit, the

ADT will handle the repetitive tasks of transporting material around the quarry to facilitate different steps in the cycle.

• Autonomous Battery Electric Mower for Commercial Landscaping: Commercial landscaping is a highly competitive industry and having the staff to support different bids is essential. The autonomous commercial mower leverages the same camera technology as other Deere autonomous machines, but on a reduced scale since the machine has a smaller footprint. With two cameras on the front, left, right and rear, 360-degree coverage is achieved, and staff can focus on other aspects of the job. Select machines will be autonomy ready from the factory and the second-generation perception system will be available as a retrofit kit for certain existing machines, providing customers with multiple paths to adoption based on where they are in their technology journey.

The machines are managed via John Deere Operations Center Mobile, the company’s cloud-based platform. By swiping left to right to start, the machine can be started once placed in the appropriate spot. Through the app, users also have access to live video, images, data and metrics, and the ability to adjust various factors like speed. In the event of any job quality anomalies or machine health issues, users will be notified remotely so they can make necessary adjustments.

For more information, visit www.deere.com.

(Photos courtesy of John Deere.)

imble®Tr The L

s u t acCont o p e t war t sof d o n n a l o too

The construction industry is undergoing a significant transformation as it embraces electric and hybrid equipment to reduce emissions on job sites. This shift is driven by stricter environmental regulations, rising fuel costs and a growing commitment to sustainability.

For contractors aiming to stay competitive and environmentally responsible in 2025, understanding the benefits and challenges of this transition is crucial.

Transitioning to electric and hybrid construction equipment offers substantial environmental advantages. Electric machinery produces zero on-site emissions, significantly improving air quality and reducing the industry’s carbon footprint. For example, studies have shown that electric construction equipment can reduce emissions by up to 95 percent compared to diesel counterparts.

In addition to environmental benefits, electric equipment operates with lower noise levels, enhancing worker safety and minimizing disturbances in urban areas. Operationally, electric motors provide instant torque, improving machine responsiveness and efficiency. Moreover, electric equipment often has fewer moving parts, leading to reduced maintenance requirements and downtime.

Major manufacturers are leading the charge in developing electric and hybrid construction equipment. Volvo Construction Equipment, for instance, has committed to

transitioning its entire product line to electric or hybrid power by 2030. Their Electric Site project demonstrated a 98 percent reduction in carbon emissions and a 70 percent reduction in energy costs during a 10-week trial. Similarly, Caterpillar has introduced the Cat Dynamic Energy Transfer (DET) system, which transfers energy to both diesel-electric and battery-electric mining trucks during operation, aiming to lower operating costs and reduce greenhouse gas emissions.

Despite the clear benefits, transitioning to electric and hybrid equipment presents challenges. The initial investment for electric machinery is typically higher than for traditional diesel-powered equipment. However, lower operating and maintenance costs can offset this over time. Government incentives and tax credits also are available in many regions to support the adoption of electric equipment.

Another challenge is the development of adequate charging infrastructure. Construction sites, especially in remote areas, may lack the necessary facilities. However, advancements in fast-charging technology and the increasing availability of portable charging solutions are mitigating this issue.

The construction industry is expected to reach a tipping point in 2025, with a significant shift from diesel engines toward more electric or hybrid equipment. This transition is

supported by advancements in battery technology, decreasing costs and increasing regulatory pressures globally.

Innovations such as hydrogen fuel cells and solar fuels also are emerging, offering alternative energy sources for construction equipment. These technologies can work alongside electric solutions to further reduce emissions and enhance sustainability on job sites.

• Assess Equipment Needs: Evaluate which machinery in your fleet can be replaced with electric or hybrid alternatives without compromising performance.

• Explore Incentives: Research government programs that offer financial incentives for adopting sustainable equipment to offset initial costs.

• Invest in Training: Ensure that your workforce is trained to operate and maintain new electric or hybrid equipment effectively.

• Plan for Infrastructure: Develop a strategy for charging infrastructure, considering the specific needs and locations of your projects.

• Monitor Technological Developments: Stay informed about emerging technologies and industry trends to make timely and strategic decisions.

By proactively integrating electric and hybrid equipment, contractors can not only comply with evolving regulations but also contribute to a more sustainable future for the construction industry. Embracing these technologies will enhance operational efficiency and position companies as leaders in environmental stewardship.

Launching its new humanitarian Jump Start Initiative, Fleetio has awarded a free subscription for its fleet optimization software to Shake-A-Leg Miami, a non-profit dedicated to providing watersports opportunities and activities for people with disabilities, veterans and their families.

With a preventive maintenance system in place to increase watercraft availability and uptime, SALM can more confidently create life-changing experiences through adaptive sports.

Aligned with the spirit of Giving Tuesday, the new annual Jump Start Initiative invites Fleetio customers to nominate deserving non-profit organizations within their communities to win a free subscription of Fleetio’s comprehensive solution.

Based in Miami, Fla., Shake-A-Leg Miami (SALM) is a beacon of hope and inspiration, bringing individuals with disabilities and those from disadvantaged backgrounds together with their families and friends to enjoy the therapeutic beauty of Biscayne Bay. Through activities like sailing, kayaking and paddleboarding, SALM fosters inclusion, connection and personal growth.

The organization also creates a supportive environment where participants and their

families can engage in recreational experiences, build new skills and even prepare for future careers through its unique vocational program.

“For nearly 35 years, we’ve strived to offer the best possible experience for our participants, but managing our fleet without an automated system in place was a challenge,” said Harry Horgan, co-founder and president at Shake-A-Leg Miami.

“Fleetio’s technology gives us the opportunity to operate on a whole new level. The ability to simplify and automate our maintenance processes lets us become more proactive in how we manage our resources. With this support, we can focus on creating meaningful opportunities and pushing our mission forward — making waves in Miami and beyond.”

Impressed by the efficiency and value Fleetio brought to its business, Freedom Boat Club, the world’s largest boat club operator, introduced the platform to the SALM organization. As a long-time customer of Fleetio, Freedom Boat Club has experienced significant operational improvements by utilizing Fleetio’s fleet maintenance software across its numerous locations. After learning about SALM’s challenges with manual processes, Fleetio

“Fleetio’s technology gives us the opportunity to operate on a whole new level.”

Harry Horgan Shake-A-Leg Miami

responded with an in-kind donation of their software subscription, empowering SALM to improve operations and focus resources on their mission of serving the local community.

“As a board member at Shake-A-Leg Miami, I witnessed firsthand the operational challenges they faced with their fleet and knew that Fleetio could make a real impact,” said Kevin Seelig, co-owner and president at Freedom Boat Club of Northeast Florida. “At Freedom Boat Club, we’ve seen how

Fleetio optimizes fleet operations and eliminates the burden of manual processes. For Shake-A-Leg Miami, this means more than just ensuring uptime — it’s about allowing them to grow and better serve those who rely on their services.”

Fleetio provides a comprehensive fleet management and optimization platform that helps businesses of all sizes effectively maintain their fleets. Its cloud- and webbased solutions make it easy for fleets to handle inspections, work orders, maintenance schedules and parts inventory. By integrating with telematics providers, fuel card services and maintenance shops, Fleetio turns critical fleet data into insights that enable informed, data-driven decisions.

“Fleetio’s technology is designed to solve real operational challenges, and for ShakeA-Leg Miami, it means freeing up their limited resources to focus on their mission over menial tasks,” said Jon Meachin, CEO of Fleetio. “As an organization, we’re committed to making a positive difference, and by helping Shake-A-Leg Miami keep their fleet in top condition, we support their ability to continue the meaningful work they do for their community.”

For more information, visit www.fleetio.com/jumpstart.

Having a screen that shows exactly where you are in real time when working with multiple material layers will make that work much easier and faster, preventing rework and removing the danger of having a person in the trench measuring depths.

ly accepted and used in a variety of machine types, and GPS functionality can elevate that accuracy and efficiency even further. So how does it work?

By Matthew McLean and Jenny Olsen SPECIAL TO CEG

It can feel intimidating to keep up with technology, especially when it comes to sophisticated heavy equipment. While many owners and operators are getting more comfortable with — and even dependent on — tech features in their machines, some may

still need a little help making sense of it all. Let’s break down how global positioning system (GPS) functionality, machine automation and assistive technology can make operators safer and more productive.

Machine control is becoming more wide-

Typically, inertial measurement unit (IMU) sensors are mounted to certain parts of a machine. These can tell the operator where the bucket tooth is and how close they are to a target grade or depth. Upgrades like satellite antennas and smart receivers, which make up GPS functionality, allow the entire machine to “know” where it is.

For example, on an excavator, the operator can use an in-cab interface (like a tablet) to draw the shape they want to dig. Let’s

say it’s a basement. Then they can put the bucket on the ground where one corner of the basement will be, move the bucket to a second spot, and that tells the machine to “draw” a wall between the two. Depth and slope can be factored in as well. Due to the sensors and satellite receivers, the machine will remember where every point is as it moves around the site.

Upgrading to 3D software like Trimble or Topcon takes GPS support one step further. These programs can import a computer-aided design (CAD) file for an entire job site (like a neighborhood of roads and water and sewer lines), and all GPS-equipped machines will know how far to dig no matter where they are located on that site.

Some GPS software allows operators to create layers as well. Maybe you’re putting in a water line that involves multiple material layers with specific requirements for each. Let’s say you want 6 in. of sand as your base, 3.5 ft. of gravel, 2 ft. of fill soil and then 1 ft. of topsoil. Having a screen that shows exactly where you are in real time will make that work much easier and faster, preventing rework and removing the danger of having a person in the trench measuring depths.

Another safety-boosting feature is swing control (or swing fencing), which allows an operator to create an invisible “wall” so they cannot swing into traffic, other machines or people. Similarly, height or depth limits can be set to avoid clipping utilities. And to get even more specific, object detection does exactly what it says and alerts operators when something is in the way.

Perhaps one of the most exciting GPSrelated features still growing in functionality and adoption is jobsite mapping. This allows all equipped machines on a site to “see” where the others are, helping operators avoid traffic and safety concerns and improving jobsite (and fuel) efficiency.

Automating certain tasks can improve efficiency even more. To use another excavator example, many systems will “cut grade” on the final pass. But with automation technology, the operator controls only the arm while the computer controls the boom and bucket to ensure that the last pass is smooth and at the right depth.

Some articulated trucks and wheel loaders come with a speed limiter option that automatically regulates maximum speed. If you’re in a region that sets speed limits on work sites, this could help reduce the potential for fines while improving safety and managing site traffic.

Many compactors and pavers also have assistive technologies that show operators how many passes they’ve made, the temperature of the material and its density, and other important data that can improve their produc tivity.

Assistive technology can help operators make