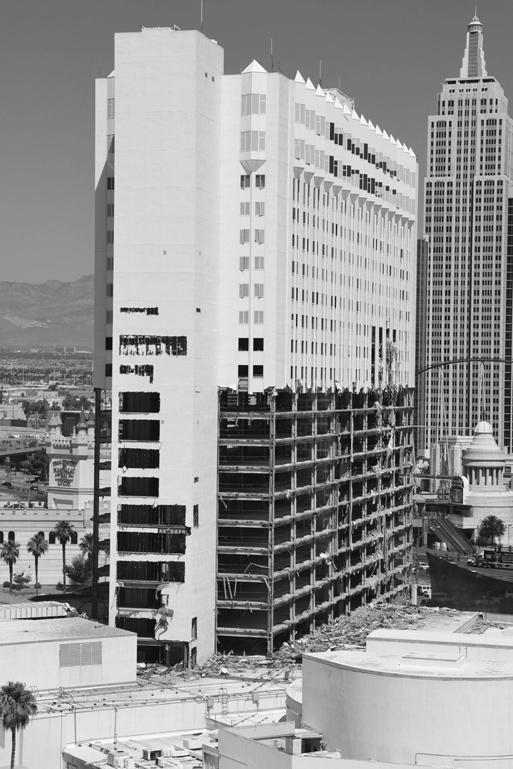

A piece of Las Vegas history is disappearing from the city’s “Just Off the Strip” landscape. The Tropicana Hotel complex, once a hub of Las Vegas betting and nightlife, is being systematically demolished to make way for a stadium that will house the city’s newest professional sports franchise.

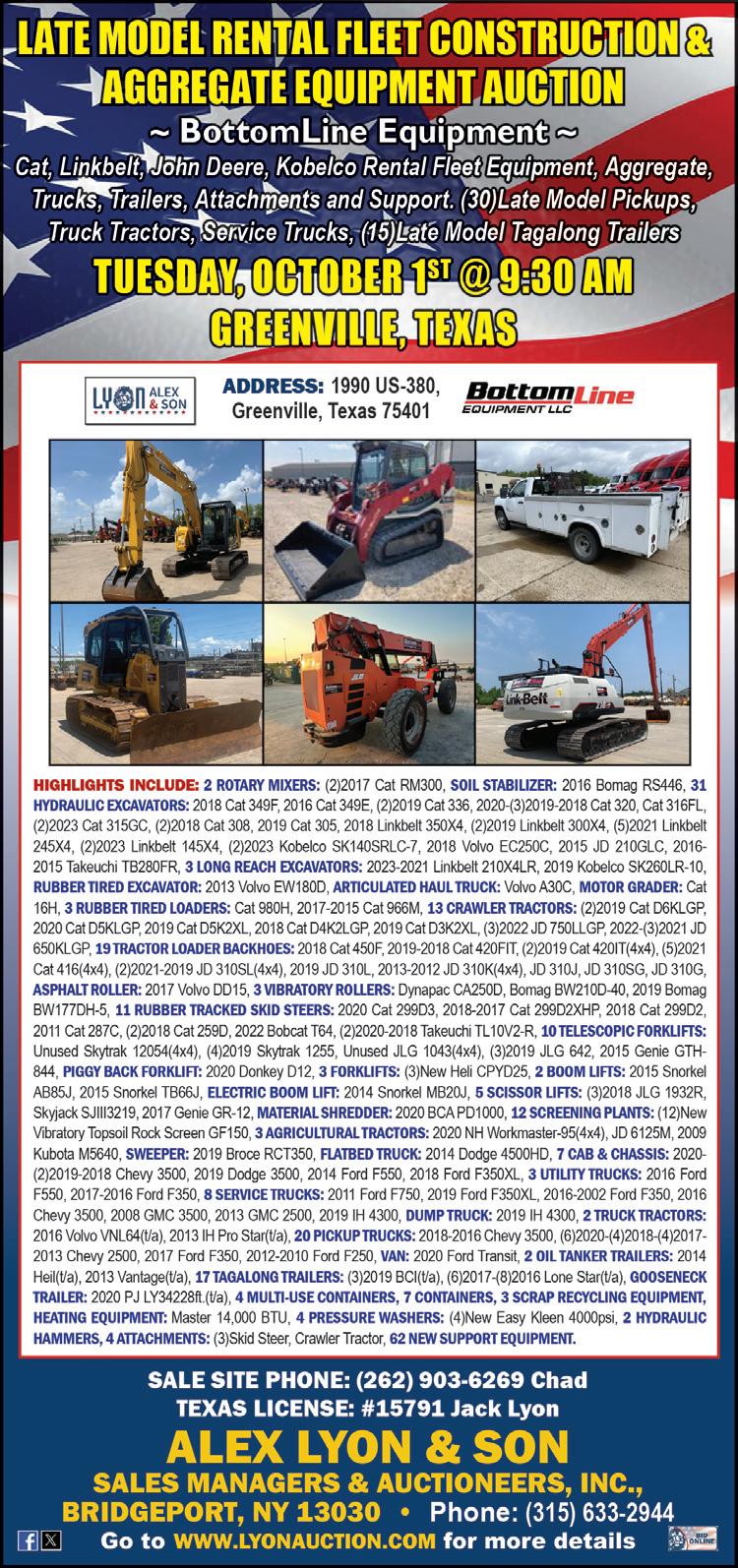

Heading the effort to level nine structures — including a pair of 22-story towers — on the 34-acre site, Miller Environmental Inc. (MEI, Orange, Calif.) has assembled an armada of equipment, including no fewer than 10 Link-Belt excavators, a host of attachments, support equipment and a crew of more than 100 skilled personnel.

As the phrase “Drop the Trop” enters the vernacular, Miller is helping usher in a new era for Las Vegas.

By Las Vegas standards, the Tropicana Hotel is ancient. First opened in 1957, it was, at the time, the most expensive Las Vegas resort ever developed, with a price tag of $15 million. Over more than six decades, despite expansions, multiple owners and several rebrandings, the Tropicana failed to keep up with the more popular and elaborate offerings on The Strip.

Another Link-Belt excavator removes a chunk of the former Tropicana Hotel

By Lucy Perry CEG CORRESPONDENT

The construction industry is no stranger to hard work. So, when it comes to workforce shortages, instead of throwing up their hands contractors are rolling up their sleeves. Companies have gotten clever in their strategies to overcome workforce issues. Not wasting time pointing fingers at the federal government’s preference for higher education over craft training, the industry instead is opting to develop a culture that invests in workers for the long haul.

In its annual workforce survey, the AGC finds its members are carving away at the “significant” impact of federal workforce policies. see WORKERS page 26

2020 Komatsu D61PX-24, Stk#: 13536, EROPS, A/C, 3,625 hrs., 6 Way Blade,80% U/C, 34" Pads, 12' 7"

2016 Kobelco SK140SRLC-3, Stk#: 13546, EROPS, A/C, Heat, Radio, 4,463 hrs., 34" Bkt, 24" Pads, Aux Hyd, Back-Up Camera $48,500

2018 John Deere 450K LGP, Stk#: 13610, OROPS, 2,399 hrs., 6 Way Blade, 24" Pads, 10' 4" Wide $59,500

2013

1,007

lbs

2014 Laymor SM400, Stk#: 12756, EROPS, A/C & Heat, 594 hrs., Water System, 8 ft. Broom, 225x75Rx15 Tires, 4 Cy. Kubota Eng .. $24,500

JLG Industries Inc. announced that Oshkosh has completed the acquisition of

S.L., adding the brand’s compact all-terrain machines for the transportation and material handling to the company’s Access segment.

Takeuchi-US hosted the Association of Equipment Manufacturers (AEM) Manufacturing Express national tour at its compact track loader production facility in Moore, S.C., on Aug. 27, 2024.

PacWest Machinery, a heavy-equipment distributor based near Seattle, Wash., announced on Sept. 10 that CEO Andy Wold is retiring and will transition his duties to Jolene Logue, the company’s president.

Nearly 221,800 U.S. bridges need major repair or replacement, an American Road & Transportation Builders Association (ARTBA) analysis of recently released federal government data shows.

The Design-Build Institute of America (DBIA) announced the 2024 National Design-Build Project/Team Award Winners. Sixty-three projects from across the United States were submitted for consideration across 10 categories.

Staff gathered to celebrate the milestone Sept. 12 in conjunction with a visit from the “AEM Manufacturing Express” bus tour. Festivities included a cookout, yard games and sharing stories from the last five decades.

Kansas Speedway announced that its NASCAR CRAFTSMAN Truck Series race on Sept. 27, will be named the Kubota Tractor 200. It will serve as the final race in the NASCAR CRAFTSMAN Truck Series Playoffs.

24

Kubota Corporation, Osaka, Japan, through its North American subsidiary, Kubota North America Corporation, has acquired Bloomfield Robotics Inc., a Pittsburgh-based company.

24

DEVELON celebrated the grand opening of the North American Customization Plant in Brunswick, Ga., on Sept. 4. Executives from DEVELON headquarters and North America and Wallenius Wilhelmsen attended the ceremony.

39 TOUGH SEATS TOUTS HEAVY MACHINERY SEATING EXCELLENCE

In 2010, Nick Kemnitz established Tough Seats, which has since become a leader in the heavy machinery seating industry. Kemnitz launched the company drawing from his industry experience post-college.

45 VOLVO ANNOUNCES PLANS TO LAUNCH HYDROGEN-POWERED TRUCKS

Trucks that run on green hydrogen instead of fossil fuels provide one way to decarbonize transport. Volvo will begin customer tests with trucks using hydrogen in combustion engines in 2026.

46 FORD EXPANDS SUPER DUTY PRODUCTION IN NORTH AMERICA

Ford Motor Company announced plans to assemble F-Series Super Duty pickups at its Oakville Assembly Complex in Ontario, Canada, starting in 2026, boosting production of one of the company’s most popular vehicles.

• Apply online for eq

• A/B/C credit and so

• Depend On uipment up to $500,000 le proprietors welcome

FI • SCAN NANCIAL RELATIONSHIPS SINCE 2011 TO LEARN MORE

At Blue Diamond Attachments, all we do is manufacture attachments that make you better at all you do. From excavators, skid and track loaders to tractors and more, our commitment to quality shines through in every weld and every design. Crafted with precision and innovation, our complete attachment solutions redefine durability and performance.

So, whether you’re breaking ground or finishing a project, trust the experts who focus on one thing, and when it comes to your equipment, demand the attachments that excel. Choose Blue Diamond –where all we do is elevate everything you do.

Scan the QR code or go to www.AllWeDoBDA.com to find your nearest dealer. It’s time to take your projects to a whole new level.

JLG Industries Inc., an Oshkosh Corp. business and a global manufacturer of mobile elevating work platforms (MEWPs) and telehandlers, announced that Oshkosh has completed the acquisition of AUSACORP S.L. (AUSA), adding the market-leading brand’s compact all-terrain machines for the transportation and material handling to the company’s Access segment.

Following the acquisition of Hinowa in 2023, the AUSA acquisition further supports the Oshkosh accelerated growth strategy and strengthens the JLG equipment portfolio.

Established in 1956, AUSA specializes in designing, manufacturing and selling wheeled dumpers, rough terrain

forklifts and compact telehandlers for the residential, civil and road construction industry and the transportation and handling of industrial and agricultural materials. The acquisition included AUSA’s 250,000-sq.-ft. manufacturing facility in Barcelona, Spain, approximately 350 team members and access to 200 equipment dealers worldwide.

“AUSA’s culture of innovation and quality matches the same standards we hold,” said Mahesh Narang, president, JLG, “and our shared core values around safety, productivity and sustainability position us well for the future. Together, we will work diligently, as both companies always have, to meet the needs of our customers.”

JLG and AUSA have collaborated since 2020, bringing the SkyTrak 3013 to market together. With the acquisition, AUSA products will enhance JLG’s line of telehandlers and complement Hinowa’s line of tracked dumpers and forklifts. Both acquisitions help accelerate JLG’s growth into the specialty equipment, agriculture and landscaping markets while providing its construction and materials handling customers with an even broader array of products — all backed by JLG’s robust training, support and service infrastructure.

“Our combined capabilities, market leadership positions and complementary product offerings provide a more comprehensive solution to address market needs, expand our operational footprint and unlock growth opportunities worldwide,” said Narang. “The acquisitions of AUSA and Hinowa help JLG create an organization that

better serve customers

Takeuchi-US hosted the Association of Equipment Manufacturers (AEM) Manufacturing Express national tour at its compact track loader production facility in Moore, S.C., on Aug. 27, 2024.

AEM recognized Takeuchi-US and its employees as industry leaders for their contributions to the local community and manufacturing industry. At the event, Takeuchi-US also celebrated the production of its 10,000th compact track loader, a TL12 model, at the Moore facility, which opened in September 2022.

Takeuchi’s employees signed the interior of the TL12’s rear cover, and soon, this unique, one-of-a-kind 10,000th machine will be delivered to a Takeuchi customer.

Congressman William Timmons, 4th District, South Carolina spoke at the event, noting the importance of manufacturing in Spartanburg County and thanking Takeuchi-US for putting its faith in the Moore community by locating its compact track loader production facility there two years ago.

Several other dignitaries also were on hand for the festivities, including:

• David Britt, Spartanburg (SC) County council vicechairman

• Allen Smith, president and CEO, OneSpartanburg Inc.

• Kyle Sox, VP of Industrial Development, OneSpartanburg Inc.

• Katherine O’Neill, chief economic development officer, OneSpartanburg Inc.

• Dwayne Hatchett, director of existing industries, OneSpartanburg Inc.

• Cole Alverson, administrator, Spartanburg County

• Carter Smith, advisor, OneSpartanburg Inc.

“As proud AEM members, we believe in the importance of American manufacturing, and we were pleased to host the AEM Manufacturing Express tour,” said Jeff Stewart, president of Takeuchi-US. “We enjoyed celebrating our employees and the Moore community while highlighting our contributions to the local, regional and national economies.

“We’ve only been open for business in Moore for two years, but we’ve already manufactured 10,000 machines and now employ more than 150 people here. We thank our local policymakers for joining us at this celebration and learning more about how we’re helping drive innovation and eco-

nomic growth in this region.”

Takeuchi-US was the 43rd stop on the AEM Manufacturing Express tour, which will visit 80 manufacturers across 20 states. The tour showcases the cutting-edge technology and innovations that power modern equipment, as well as the innovative technologies, processes, people and products revolutionizing this industry across America.

“We were thrilled to join so many community leaders and supporters of Takeuchi-US at this amazing opportunity to highlight the importance of American off-highway equipment manufacturing in Moore, South Carolina,” said AEM President Megan Tanel.

“The AEM Manufacturing Express is more than just a bus tour; it is an opportunity to tell the stories of the men and women of our industry in the Greenville area and highlight how their grit, determination and can-do spirit has contributed to the American way of life.”

For more information, visit www.takeuchi-us.com and www.manufacturingexpress.org.

(All photos courtesy of Takeuchi.)

PacWest Machinery, a heavy-equipment distributor based near Seattle, Wash., announced on Sept. 10 that CEO Andy Wold is retiring and will transition his duties to Jolene Logue, the company’s president.

Logue will assume her new post as CEO on Oct. 1, 2024, and will retain the title of president.

“I would like to personally thank the PacWest employees, customers, suppliers and other stakeholders for their many contributions over the past nine years,” Wold said. “Together, we broadened our product mix with new suppliers, built an efficient branch network and completed three successful acquisitions. The company more than doubled its business while delivering on important customer service, training, safety and profitability metrics.”

Logue brings to her new role considerable experience leading sales, service and corporate teams at Ingersoll-Rand, Volvo

“The PacWest mission is to support our customers so they can build and maintain our communities...”

Jolene Logue

PacWest Machinery

Construction Equipment and, since 2016, PacWest.

“I’m looking forward to the challenge,” Logue said. “The PacWest mission is to support our customers so they can build and maintain our communities, and every day our team pursues that overarching goal.”

“Over a short period of time, the PacWest team has created a leading equipment business while developing a company grounded in honesty, integrity and fair dealing,” said Stan McCammon, the president, CEO and board chairman at Joshua Green Corp., the majority owner of PacWest Machinery. “On behalf of our board, we thank Andy Wold for his leadership through the challenges of a new startup, and we congratulate Jolene Logue on her much-deserved promotion.”

PacWest Machinery distributes heavy construction equipment across the Pacific Northwest including Washington, Oregon, Idaho and Hawaii. The company offers sales, rental and aftermarket support for a full equipment lineup from quality companies including Volvo Construction Equipment, Metso Minerals, Ponsse, Blaw-Knox, Yanmar and others.

The Joshua Green Corp. is a Seattle-based family company founded in the 1890s with interests in banking, energy, consumer goods, real estate, equipment distribution and other industries.

For more information, visit www.pacwestmachinery.com and www.joshuagreencorp.com.

The Design-Build Institute of America (DBIA) announced the 2024 National Design-Build Project/Team Award Winners. Sixty-three projects from across the United States — and one in Antarctica — were submitted for consideration across 10 categories.

Submissions were evaluated by a distinguished panel of industry experts. Merit Award winners will now compete for a National Award of Excellence, “Best of” categories and Project of the Year.

“As design-build approaches nearly half of all construction spending, we continue to see extraordinary projects that raise the bar for design-build teams across the country, pushing the limits of high performance and optimizing triple-bottom line success,” DBIA Executive Director/CEO Lisa Washington said.

Merit winners will be recognized and additional winners announced at DBIA’s Design-Build Conference & Expo Awards Ceremony Nov. 7, 2024, in Dallas, Texas.

Aviation

• Nashville International Airport Terminal Lobby and International Arrivals Facility (Nashville, Tenn)

Civic/Assembly

• Colorado Convention Center (CCC) Expansion (Denver, Colo.)

• Millbrae Recreation Center (Millbrae, Calif.)

Commercial/Office Buildings

• General Motors Design Studio (Warren, Mich.)

• One Platte (Denver, Colo.)

• Wake Technical Community College, Central Energy Plant, Site Work and Infrastructure (Wendell, N.C.)

Educational Facilities

• Applied Research Building (Tucson, Ariz.)

• Prince George’s County Public Schools (Prince George’s County, Md.)

• University of California, Irvine Verano 8 Graduate Student Housing (Irvine, Calif.)

Federal/State/County/Municipal

• County of San Diego Southeastern Live Well Center (San Diego, Calif.)

• Queens Borough Hall Municipal Garage and Community Space (Queens/Kew Gardens, N.Y.)

Health Care Facilities

• Grady Memorial Hospital Bed Expansion (Atlanta, Ga.)

Industrial/Process/Research Facilities

• Holt Watters Field Camp (Livingston Island, Antarctica)

• NREL Research and Innovation Laboratory (RAIL) (Golden, Colo.)

• Santa Monica City Yards Modernization (Santa Monica, Calif.)

Rehabilitation/Renovation/Restoration

• Large Diameter Sewer Rehabilitation Project (Louisville, Ky.)

• Replacement of Tower Elevators & Misc. Rehab at the Marine Parkway-Gil Hodges Memorial Bridge (MP-09) (Brooklyn, N.Y.)

Transportation

• Central 70 Design-Build-Finance-Operate-Maintain (Denver, Colo.)

• Fern Hollow Bridge Emergency Replacement Project (Pittsburgh, Pa.)

• Hwy 52 Zumbrota to Cannon Falls (Zumbrota and Cannon Falls, Minn.)

• I-270 North Design-Build (St. Louis, Mo.)

Water/Wastewater

• Cornish Creek Water Treatment Plant and Water Supply Facilities Improvements (Covington, Ga.)

• Headworks Facility at the San José-Santa Clara Regional Wastewater Facility (San José, Calif.)

• Regional Surface Water Supply Project (Hughson, Calif.)

• Yadkin Region Water Supply Project — Raw Water Infrastructure (Norwood, N.C.)

A full list of project winners, including photos and descriptions of each project, can be found at DBIA’s Project/Team Awards page.

Nearly 221,800 U.S. bridges need major repair or replacement, an American Road & Transportation Builders Association (ARTBA) analysis of recently released federal government data shows.

Placed end-to-end, these structures span over 6,100 mi., or the equivalent of every mile of urban and rural interstate in California, Florida and Illinois.

Of the bridges needing repair, 42,067 are rated in poor condition and classified as “structurally deficient.” That is 324 fewer than in 2023.

States with the biggest decline in the number of bridges in poor condition: Pennsylvania (down 90), Louisiana (down 87), Florida (down 85), West Virginia (down 74) and California (down 64).

Bridges in poor condition represent 6.8 percent of the 2024 U.S. bridge inventory — compared to 7.3 percent in 2020.

“Over the last five years we have seen significant progress in states like Oklahoma, Pennsylvania, Mississippi, Louisiana and West Virginia — reducing the number of bridges in poor condition,” said Alison Premo Black, ARTBA’s chief economist who conducted the analysis.

“While improvements can take time, every bridge repair increases the safety and effi-

ciency of our network for the traveling public.”

States have received $15.9 billion in the first three years of the IIJA’s new $27.5 billion formula bridge program and, to date, have committed 46 percent ($7.3 billion) of these resources to over 4,170 bridge projects.

The remaining 54 percent ($8.5 billion) of already released bridge funds — plus the $10.6 billion that will be provided in the next two years — will support needed bridge improvements well into the future.

• I-55 over Madison Street, Illinois

• I-95 over Route 608, Virginia Bridges newly rated in poor condition

states to the U.S. Department of Transportation, ARTBA estimates it would cost more than $400 billion to make all needed repairs to the 221,800 structures.

“While improvements can take time, every bridge repair increases the safety and efficiency of our network.”

Twenty-three states have committed at least half of their available bridge formula funds, with the top 10 being: Georgia (100 percent), North Dakota (99 percent), Indiana (98 percent), Florida (96 percent), Oklahoma (95 percent), Nebraska (91.5 percent), Idaho (91.5 percent), Arkansas (88 percent), West Virginia (85 percent) and Alabama (85 percent).

Bridges that have come off the “poor condition” list include:

• I-695 over U.S. 40, Maryland

• I-93 over Conley Street, Massachusetts

• I-680 over Capitol Avenue, California

Alison Premo Black American Road & Transportation Builders Association

include:

• I-90 over Canal to Stewart Streets, Illinois

• Interstate 680 over Monument Boulevard, California

• I-93 over Mystic Valley Parkway, Massachusetts

• I-95 North and Southbound over Thurbers Avenue, Rhode Island

• IH-35 over Grand Avenue, Texas

Based on average cost data submitted by

The data in the report is from the Federal Highway Administration’s National Bridge Inventory (NBI), downloaded on Aug. 20. Specific conditions on bridges may have changed because of recent work or updated inspections.

Bridges are classified in good, fair or poor condition based on their inspection ratings and definitions from U.S. DOT.

The definition of “poor” is when a key element of the bridge — the deck, superstructure, substructure or culverts, are rated in poor or worse condition. During inspection, the conditions of a variety of bridge elements are rated on a scale of 0 (failed condition) to 9 (excellent condition). A rating of 4 is considered “poor” condition.

For more information, visit www.artbabridgereport.org.

1090 W 2181 N Salt Lake City, UT 84116

801-322-1300

atlasmachinery.us

6565 Smith Avenue Newark, CA 94560 510-400-5024

1535 SE 25th Street Oklahoma City, OK 73129 405-310-8700

2035 W Mountain View Road Phoenix, AZ 85021

480-463-4999

Equipmentshare.com

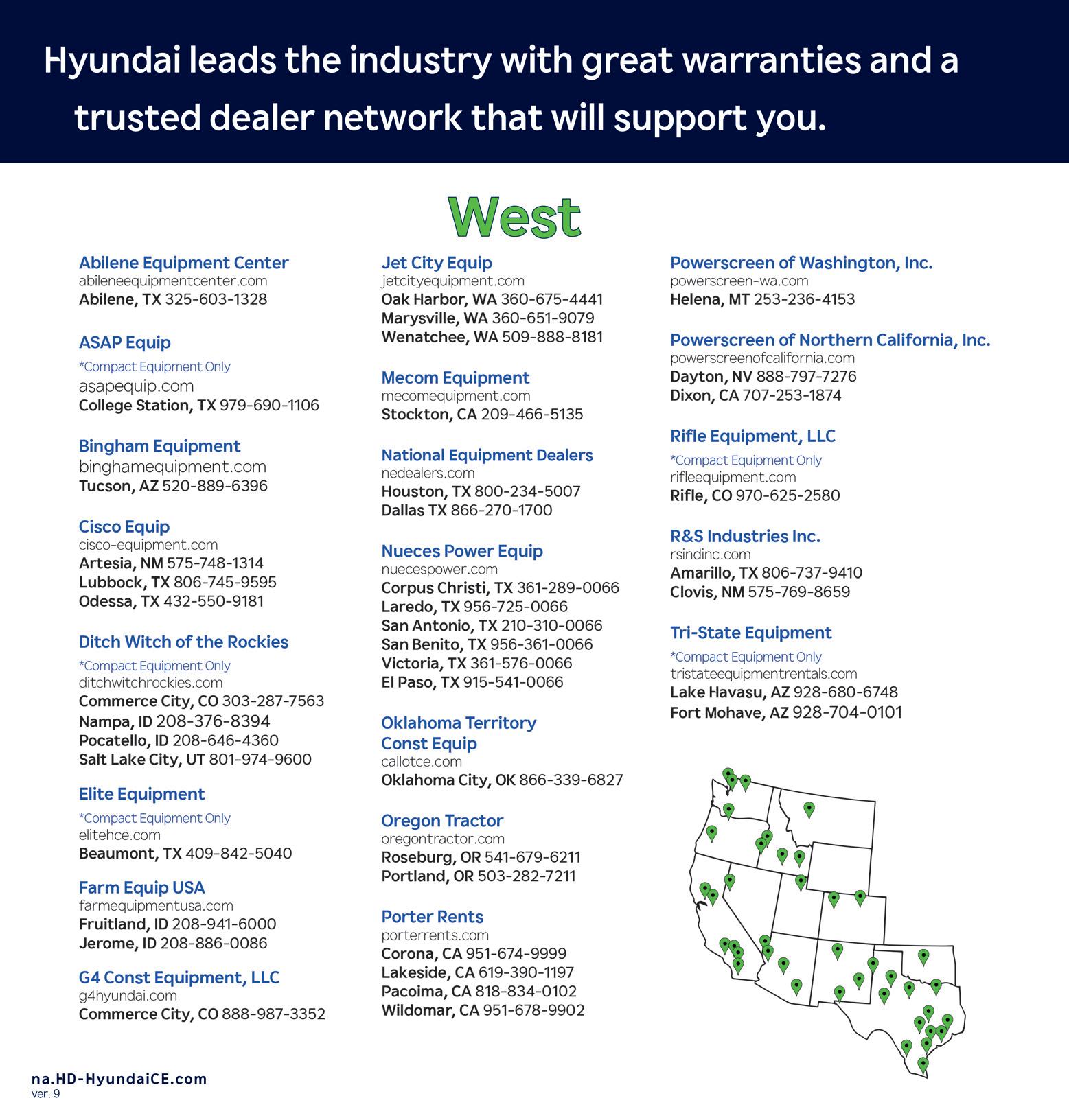

Loved for the features. Trusted for the performance.

Hyundai wheel loaders have the power and performance, not to mention top-notch interiors, accurate onboard weighing system, industry proven drivetrain durability, clear sightlines, and handy tech that make life on the jobsite easier. So you can do more without feeling it. No wonder so many first-time Hyundai users become longtime fans.

See the Hyundai difference yourself at your local dealer or na.hd-hyundaice.com.

1974: Construction equipment production begins with compaction products.

1980: A 46,000-sq.-ft. expansion upgrades machining, fabrication and welding capabilities.

1988: A 38,000-sq.-ft. expansion boosts assembly space.

1992: A 54,000-sq.-ft. expansion adds to assembly space again.

1993: The 49,000-sq.-ft. main office is built.

1998: A 21,000-sq.-ft. expansion provides more space for drum manufacturing.

2007: Volvo CE acquires the site from Ingersoll-Rand.

2010: A $30 million, 200,000-sq.-ft. factory expansion is completed.

2011: The Region Americas sales and marketing team relocates to the site.

2013: The wheel loader production line begins operation.

2013: A new office expansion is inaugurated.

2014: The Volvo Customer Experience Center opens.

2023: The Technical Training Center opens.

2024: Volvo and AEM celebrate 50 years of equipment manufacturing in Shippensburg.

It’s been 50 years since workers began building heavy construction equipment at a plant in Shippensburg, Pa.

Back then, the site was owned by Ingersoll-Rand and employed about 50 people. Today, it’s the North American headquarters of Volvo Construction Equipment and employs more than 650 people.

Staff gathered to celebrate the milestone Sept. 12 in conjunction with a visit from the Association of Equipment Manufacturers “AEM Manufacturing Express” bus tour. Festivities included a cookout, yard games and sharing stories from the last five decades.

“We have heavily invested in our facilities, our people and our services here in Shippensburg. The work done at this site has a significant impact on our customers, our industry and the local community,” said Gustavo Casagrandi, head of operations at the site. “It’s rewarding to gather today to reflect on all of that.”

Combining this celebration with AEM’s visit was natural.

“We’re proud AEM members, so this is a great way to celebrate our employees’ contributions to the construction and manufacturing industries,” said Casagrandi.

The “AEM Manufacturing Express” is an interactive mobile tour visiting 80 member manufacturers across 20 states. It’s the largest public engagement initiative in the association’s history, designed to celebrate the U.S. equipment manufacturing industry and the 2.3 million workers who help “build, power and feed the world.”

“We’re thrilled to be part of this 50th anniversary celebration alongside community leaders and supporters,” said Megan Tanel, president of AEM. “This tour has been an amazing opportunity to tell the stories of the people of our industry.”

The AEM and Volvo teams invited local policymakers to the event to raise awareness of and support for bipartisan policies that support the equipment manufacturing industry and its employees.

Over the past 50 years, roadbuilding and general-purpose construction equipment has been manufactured at the

Shippensburg factory beginning with compactors, which have remained a focus.

Proximity to Interstate 81 — a major manufacturing and distribution corridor — and a highly skilled employee base made the area appealing to Volvo Group, which acquired the site in 2007 as part of its purchase of the road development division of Ingersoll-Rand.

Volvo has made significant investments in the site over the past 17 years, including a $30 million, 200,000-sq.-ft. expansion of its operations footprint in 2010. In addition to the production of wheel loaders, soil compactors and asphalt compactors, operations at the location include a regional excavator completion center and a rebuild center for used equipment. The site is the North American headquarters for sales and marketing, a hub for purchasing and supply management, and the design and engineering center for compaction equipment.

The Volvo Customer Experience Center and 40-acre proving grounds opened in 2014, housing a demonstration fleet of more than 70 pieces of equipment spanning the company’s full product portfolio. In 2023, a Technical Training Center wing added machine servicing bays and classrooms where dealer technicians and sales teams can learn about Volvo’s latest machines and technologies, including electric equipment. The venue hosts more than 10,000 Volvo CE dealers and customers annually.

Volvo CE collaborates with the Franklin County Career & Technology Center on a training program for industrial workers and has partnered with Shippensburg University to support a new engineering program. The company employs about 50 interns each year, and Penn State University is an Academic Preferred Partner of the Volvo Group. Volvo CE also works with the National and Pennsylvania chapters of SkillsUSA to support middle school, high school and post-secondary students and professionals enrolled in training programs for trade, technical and skilled service occupations.

“It’s an honor to work in such a storied place and continue sharing Volvo’s commitment to training, safety and sustainability with our community,” said Casagrandi. “I can’t wait to see what the next 50 years bring for our people and our industry.”

(All photos courtesy of Volvo.)

In addition to sponsoring the race and Chastain’s No. 1 Chevrolet and Rhodes’ No. 99 Ford F-150 at Kansas Speedway, Kubota also will be active in the Fan Zone with an equipment display and will have company representatives on-hand to discuss job openings at its Kansas facilities.

Kubota is partnering with Kansas Speedway for one of the most important races of the 2024 NASCAR CRAFTSMAN Truck Series season.

Kansas Speedway announced that its NASCAR CRAFTSMAN Truck Series race on Sept. 27, will be named the Kubota Tractor 200. It will serve as the final race in the NASCAR CRAFTSMAN Truck Series Playoffs’ Round of 10, with two drivers eliminated from championship contention by the end of the night.

“We’re thrilled to have Kubota playing such an important role in one of the most pivotal races of the season,” said Kansas Speedway President Pat Warren.

“Their commitment to Kansas City, the state of Kansas and to NASCAR racing overall is incredible, and we’re excited to partner with them to make this an event to remember.”

Kubota Tractor Corp. is based in Grapevine, Texas, and has a significant Kansas presence with its Midwest Division office and North American Distribution Center in Edgerton, manufacturing and assembly facilities in Salina and Abilene, and 17 dealerships across the state. Nationwide, there are more than 1,000 authorized Kubota dealerships and additional manufacturing, administrative and distribution facilities, with more than 7,000 employees who fabricate, weld and assemble compact equipment with domestic and globally sourced parts.

Since 2022, Kubota has been embedded within the NASCAR community and serves as the Official Tractor Company and a primary sponsor of Trackhouse Racing and NASCAR Cup Series driver Ross Chastain’s No. 1 Chevrolet, and ThorSport Racing and defending NASCAR CRAFTSMAN Truck Series champion Ben Rhodes’ No. 99 Ford F-150.

OEM authorized mining dealer www.coremachinery.com

Phoenix, AZ

480-545-2400

Phoenix, AZ 602-252-7121

Prescott, AZ 928-778-5621 Tucson, AZ 520-623-8681

Bakersfield, CA 661-695-4830 Mojave, CA 661-824-2319 Perris, CA 909-355-3600

*Formerly Road Machinery

www.wpi.com

In addition to sponsoring the race and Chastain’s No. 1 Chevrolet and Rhodes’ No. 99 Ford F-150 at Kansas Speedway next month, Kubota also will be active in the Fan Zone with an equipment display and will have company representatives onhand to discuss job openings at its Kansas facilities.

“Kansas is an important market for Kubota and we’re proud to partner with NASCAR and Kansas Speedway on this race in a region where so many of our employees, dealers, and customers call home,” said Todd Stucke, president, Kubota Tractor Corp. “We’re proud to continue investing in America, and particularly in Kansas, to respond to increased demand for our products — and to do that, we’re looking to fill more than 300 positions across our company to strengthen our operations nationwide.”

Kansas Speedway was the site of the closest NASCAR Cup Series finish in history in May when Kyle Larson edged Chris Buescher for the win in a photo finish for the ages. That sets the stage for the Hollywood Casino 400 presented by ESPN BET on Sept. 29, the opening race of the NASCAR Cup Series Playoffs’ Round of 12.

That race will cap an incredible weekend of racing at Kansas Speedway, featuring four races over three days. It begins Friday, Sept. 27, with a doubleheader featuring the Kubota Tractor 200 and the ARCA Menards Series’ Reese’s 150, and continues Saturday, Sept. 28, with the NASCAR Xfinity Series’ Kansas Lottery 300. And then on Sunday, Sept. 29, the NASCAR Cup Series returns to the site of the closest finish in series history with the Hollywood Casino 400 presented by ESPN BET.

Tickets for all seats are on sale and can be purchased at www.kansasspeedway.com.

12320 S. Main Street Houston, TX 77035 713-723-1050 Buffalo, TX 903-322-7150 Bryan, TX 979-314-1191 Corpus Christi, TX 361-884-8275 Edinburg, TX 956-386-0107

Kilgore, TX 903-984-2011

Lufkin TX 936-243-6056 Pflugerville, TX 512-251-0013 Port Arthur, TX 409-721-5305 San Antonio, TX 210-648-4444 Tomball, TX 281-351-9016

Cheyenne, WY 307-634-5149 Durango, CO 970-259-0455 Albuquerque, NM 505-345-8383 Bloomfield, NM 505-324-8601 Carlsbad, NM 505-485-1700

www.powermotivecorp.com Corporate Office 5000 Vasquez Blvd., Denver, CO 80216 303-355-5900 Colorado Springs, CO 719-576-5541 Grand Junction, CO 970-241-1550 Milliken, CO 970-587-1188

El Paso, TX 915-872-1001 Chandler, AZ 602-986-3003 Phoenix, AZ 602-463-3772 Tucson, AZ 520-649-2858

www.geehm.com

5461 S Nikita Avenue Fresno, CA 93725 559-834-3149

1164 Prestige Way Redding, CA 96003 530-229-3820

3650 Seaport Blvd. West Sacramento, CA 95691 916-375-3540

3350 Regional Parkway Santa Rosa, CA 95403 707-544-4147

45051 Industrial Drive Fremont, CA 94538 510-955-1170 NOW OPEN!!

OK 918-438-1700

Lubbock, TX 806-745-2112

Odessa, TX 432-333-7000

Abilene, TX 325-692-6334 Amarillo, TX 806-373-2826 Dallas, TX 214-371-7777 Ft. Worth, TX 817-378-0600

Waco, TX 254-261-1370 www.clairemontequipment.com San

858-278-8338

DEVELON celebrated the grand opening of the North American Customization Plant in Brunswick, Ga., on Sept. 4. Executives from DEVELON headquarters and North America and Wallenius Wilhelmsen attended the ceremony.

DEVELON opened its first North American Customization Center in July 2019 in collaboration with Wallenius Wilhelmsen. Due to the successes and growths within DEVELON, there is a need to expand the capabilities and capacities of the current site by relocating to a new, larger North American customization plant. DEVELON and Wallenius Wilhelmsen have had a long-standing relationship for 24 years and will continue by collaborating in the relocation and operation of this new customization plant. As a result, DEVELON dealers and customers will receive new machines faster and meet stricter quality standards due to the company’s larger modern customization facility in Brunswick.

DEVELON employees in coordination with Wallenius Wilhelmsen will manage the final assembly and configuration of construction equipment, ensuring the highest quality standards are maintained, the company said. The new facility is 50 percent larger than the current customization plant in Savannah, Ga., offering enhanced production capabilities, a dedicated machine storage yard and an expanded indoor warehouse.

Representatives of Wallenius Wilhelmsen and leadership of HD Hyundai group/DEVELON celebrated the opening of the new customization plant in Brunswick, Ga.

“Our new customization plant in Brunswick will allow us to expedite our services for our dealers and our customers,” said Chris Jeong, president/CEO at DEVELON. “It’s a much larger facility than the previous customization plant, with dedicated space for our machines, and will better meet the custom needs of our dealers and our customers with an array of final assembly options.”

The customization facility in Brunswick is located close to Interstate 95, allowing for convenient transportation once DEVELON machines are ready for shipment, optimizing

delivery lead times. DEVELON maintains its North American headquarters in Suwanee, Ga., including a parts distribution center for readily available DEVELON machine parts. Additionally, starting in August 2024, DEVELON operates a dedicated warehouse in Georgia.

For more information, visit na.develon-ce.com/en.

Kubota Corp., Osaka, Japan, through its North American subsidiary, Kubota North America Corp., has acquired Bloomfield Robotics Inc., a Pittsburgh-based company. Bloomfield provides a service that monitors the health and performance of specialty crops, one plant at a time, using advanced imaging and artificial intelligence (AI) to growers across seven countries and three continents.

“We are excited to announce the acquisition of Bloomfield Robotics, a natural evolution of our successful partnership through Kubota’s support of open innovation,” said M. Brett McMickell, chief technology officer of Kubota North America. “Combining AI-driven technology with our legacy quality products will enable Kubota to solve real issues facing agriculture. This acquisition is a key milestone for Kubota’s strategic vision to provide comprehensive smart agriculture solutions.”

Bloomfield’s cameras are the foundation for a new Software as a Service (SaaS) that provides plant-level health and performance assessments for growers of grapes (e.g., wine, table and juice), blueberries, and other specialty crops. Bloomfield’s purpose-built cameras are easily mounted on tractors and other vehicles common to farming and allow for the capture of detailed plant-level, geo-located images of the entire farm. These images are then translated into crop

data such as color, maturity and size of the fruit using Bloomfield’s AI. The result is unprecedented insights into harvest timing and yield, which enables meaningful operational efficiencies, better timed harvests, reduced labor costs and increased asset utilization, according to the company.

“The Bloomfield vision from our founding was to provide continuous plant-level knowledge to every specialty crop farmer around the world. This acquisition brings that vision forward at a scale and speed we could not have imagined. Fortunately, we’ve been working closely together for over two years, so we have a running start at achieving this vision. We’re truly excited for what’s to come,” said Mark DeSantis, president and CEO of Bloomfield Robotics.

The level of mechanization and automation in specialty crop farming, such as fruits, vegetables and tree nuts, lags behind advancements incorporated in the cultivation of row crops. Innovative solutions to integrate data with automated systems, operational robotics and other assets are needed. The specialty crop market overall has become a focal point of Kubota’s strategic attention and efforts to shape the future of agriculture.

For more information, visit KubotaUSA.com or Kubota.ca.

Though construction contractors are still having a tough time, finding and keeping qualified workers, they aren’t sleeping on the job.

WORKERS from page 1

In analyzing survey results, the association said the fed’s policies mean it costs more, takes longer and is less certain if a project will start on time.

However, the association outlined a range of steps construction firms are taking to build new workforce development partnerships.

“So too are AGC of America and its network of 89 chapters working to address workforce shortages,” said Jeff Shoaf, CEO of the AGC.

The group has partnered with member chapters to run more than a dozen targeted digital advertising campaigns designed to reach and recruit new workers.

Shoaf said they’ve created and shared recruiting resources, including a template recruiting website for chapters.

“Our Culture of Care program … available to the entire industry … is designed to help firms retain workers by teaching them how to create more welcoming and inclusive job sites.”

And, he said, “we regularly host virtual and in-person gatherings to share workforce development success stories and encourage their replication.”

Association chapters run a host of training and recruiting programs as well, partnering with local school districts to create new construction academies.

Pre-apprenticeship and registered apprenticeship programs have been built through a network of career and technical education teachers.

And members host dozens of construction career fairs each year, among many other

workforce efforts.

Shoaf is confident federal workforce policies will make a meaningful and lasting difference for the better for the nation’s construction workforce.

There is no denying that contractors are even more challenged to fill open positions this year than they were in 2023.

The AGC-Arcoro survey found that 94 percent of respondents reported having open positions for craft workers. In 2023 that number was 85 percent.

Likewise, for 79 percent, openings for salaried positions are plentiful. That compares to 69 percent a year ago.

The AGC reports that among those firms, 94 percent face challenges filling craft positions and 92 percent report difficulty in filling salaried openings.

“Nearly all craft positions are hard to fill,” noted the survey analysis. More than 60 percent of firms find difficulty filling craft trade positions.

AGC noted hiring mechanics and cement masons was the biggest challenge; 83 percent of firms that employ either occupation say workers are hard to find.

The most-mentioned hard-to-fill salaried position is superintendents, listed by 83 percent of the firms seeking those workers.

Project managers/supervisors are listed by 81 percent of firms and estimating personnel by 78 percent, according to the AGC survey.

Finally AI personnel/specialist, currently the least-mentioned salaried position, is rated hard to fill by 30 percent of firms.

“The candidates are mostly there, they just aren’t qualified to work,” said the AGC.

In fact, 62 percent of respondents reported that available candidates are not qualified to work in the industry for reasons such as a lack of skills.

Half reported that some new hires fail to show up or quit shortly after starting.

And 43 percent said potential employees lack required credentials, such as a driver’s license, work permit or clean background check.

Meanwhile, 37 percent list candidates’ failure to pass a drug test as a disqualifying factor. That is up from 33 percent in the 2023 survey. And 23 percent said potential employees list difficulty acquiring reliable transportation to and from a job site as a factor.

It’s notable that 22 percent stated some candidates report needing flexible work schedules or an option for remote work.

Despite all of the hardships in hiring qualified workers for the long haul, companies report trying innovative approaches to meet the needs of good workers.

The AGC survey found that 61 percent, more than half of responding companies, raised base pay for hourly craft workers even further than they had a year earlier.

And 42 percent initiated or increased spending on training and professional development in the past year.

“The industry is also looking to technological solutions to help overcome workforce shortages,” said the AGC.

In fact, one out of four firms has increased the use of learning programs with a strong

online or video component, such as holding classes using Teams or Zoom.

“Contractors have mixed expectations regarding the impact of technologies such as robotics and artificial intelligence [AI] on construction jobs,” AGC said.

A majority believes these technologies will positively impact jobs by automating errorprone tasks or improving job quality and making workers safer and more productive.

“But a third of respondents expects no effect on construction jobs and 10 percent believe the impact … will be negative, by eliminating jobs,” said AGC.

No one’s giving up, either. The survey found many are going where the workers are, starting with social media and targeted digital advertising.

The AGC reports that 57 percent of responding firms added online strategies to connect better with younger applicants.

Approximately half engaged with a careerbuilding program, at high schools, colleges or career and technical education programs.

Some 28 percent of firms used an executive search firm or professional employer organization. And 23 percent report using the services of a craft staffing firm or engaging with a government workforce development or unemployment agency.

A fifth of firms added or increased the use of sub- or specialty contractors or implemented software to distribute job postings and manage applications. Just 7 percent applied for employment-based visas, such as H-1B or H-2B. Those open-shop and union contractors using these visas was the same in 2023.

TROPICANA from page 1

This year, Bally’s, the Tropicana’s owner, agreed with the Oakland A’s baseball club ownership group to make available a huge portion of the site for construction of a new Las Vegas A’s stadium — setting the stage for the Trop’s planned demolition.

“When we first got on site in March, we dealt with some minor asbestos abatement,” said Gregg Miller, MEI’s president and owner. “Despite the Trop’s age, there had been so many additions and renovations over the years that the bulk of the asbestos had already been removed. We quickly moved to demoing 100,000 sq. ft. of smaller three- and fourstory structures that were part of the original Trop layout.”

Though dwarfed by most of the newer mega properties on The Strip, the Trop complex contains more than 1.7 million sq. ft. of structures, including the pair of towers (725,000 sq. ft., a pair of parking garages (one above ground, one below), a pool/spa area, a theater, the casino gaming area and 184,000 sq. ft. of support facilities.

Both in size and stature, there’s little denying that the pair of guest room towers are the center of The Trop’s profile. Though they will ultimately be imploded by Controlled Demolition Inc. (Phoenix, Md.), Miller has taken a different upfront approach to that facet of the project.

“Because we plan to recycle the concrete and steel from each structure, we are choosing to gut each structure before implosion,” he said. “If we were to simply drop the structures as they are, we would contaminate that valuable debris with all the building components: the walls, the ceilings, the carpet, furniture and so on. So, working from the ground up, we are tackling an interior demolition effort, three floors at a time. We have a dozen Bobcat loaders — two on each floor of each tower — gutting the rooms, punching a hole in the exterior wall, and pushing the debris to a pile below. There, we have a Link-Belt 350 X4 equipped with a grapple/thumb

loading out debris to end-dump trailers.”

On each tower, MEI is averaging six floors per week, after which each skid-steer is set onto a platform and lifted by crane to the next target level to repeat the process.

“This will allow us to have a relatively clean pile of steel and concrete after the implosions,” said Dave Anderson, MEI’s general superintendent for the project. “The concrete is being crushed on-site and will be repurposed, both as backfill and sold off for Class 2 base. The steel, on the other hand, is being taken to one of SA Recycling’s Vegas yards, less than five miles from the site. It’s really been an efficient operation right from the start.”

Different structures demand different demo techniques; The Trop’s mostly steel-constructed pool/spa area is a case in point. For it, MEI used another Link-Belt 350 X4, this one equipped with a Genesis GXT 335R mobile shear.

“The resort is a fairly large area, about 110,000 square feet in size,” Anderson said. “The shear is pulling double duty there — pulling the structure apart and then, when beams are freed up, downsizing them for transport. Another 350 X4 with a grapple/thumb is working alongside him and handling the loadout of that material.”

Despite the large acreage of the complex, Miller’s team’s focus is always on maintaining an orderly job site — hence the push to move material offsite as quickly as possible.

“Really, the only piles you will find out here for any length of time are concrete that is being hammered and pulverized (using a 490 X4 and 250 X4, respectively) for crushing and reuse,” Anderson said. “Everything else is hauled off fast.”

Miller prefers Link-Belt excavators. The company owns 33 of the red machines, many of which are at the Tropicana site.

Discover how MB Crusher is transforming excess concrete washout with innovative attachments for the construction industry. Turn hardened concrete into recycled aggregates for your next project.

MB Crusher jaw crushers provide contractors and readymix plants with the capability to turn leftover concrete into another revenue source.

Ready-mix concrete is a pre-mixed concrete that is manufactured in a batching plant or factory and delivered to the construction site in a ready-to-use form.

Excess concrete can come from concrete waste from equipment, tools and machinery used in the construction process. As a result, piles of leftover concrete continue to mount onsite.

Companies must provide a safe and proper way to clean and dispose of excess concrete known as washout. Washout ensures the excess concrete is removed and disposed of properly to prevent environmental factors such as runoff to storm drain systems. However, companies are left with limited options to deal with concrete stockpiles onsite.

Without an efficient concrete washout recycling system, companies are wasting money and decreasing productivity.

MB Crusher helps contractors and ready-mix plants solve the problem of excess concrete by crushing and recycling hardened concrete onsite. Therefore, companies can use the recycled aggregate as backfill, materials for new construc-

Excess concrete can come from concrete waste from equipment, tools and machinery used in the construction process. As a result, piles of leftover concrete continue to mount onsite.

tion projects or create an additional revenue source by selling the aggregate.

One customer received the equivalent of two years of leftover concrete washout returned to his plant. Instead of continuing to spend lots of money on transportation and crushing services, the company purchased an MB Crusher BF 80.3 crusher bucket. The company used the BF 80.3 crusher bucket to transform their excavator into a mobile recycling center on site by crushing the leftover stockpile of concrete as recycled aggregate.

MB Crusher attachments are easy to mobi-

lize and fast setup on site. In fact, all MB Crusher attachments can be operated by a single person on any brand of heavy equipment, according to the company.

The MB-L160 crusher bucket can be utilized in multiple locations allowing companies to move the attachment from plant-to-plant.

Now, contractors and ready-mix plants can quickly and frequently crush concrete washout, as well as avoiding expensive transportation and service fees, and increasing profit margins from recycled aggregate sales.

For more information, visit mbcrusher.com/us/us/. (Photos courtesy of MB Crusher.)

FAE has completely updated its top tracked carrier, introducing the PT550 to replace the PT475.

The PT550 is the FAE tracked carrier for big challenges, ideal for major jobs in large, wooded areas and along oil and gas pipelines.

Capable of working on large areas of soft, uneven or swampy ground, this vehicle can handle longitudinal slopes up to 45 degrees and transverse slopes up to 32 degrees. All this due to a low ground pressure of 13 psi.

This new vehicle has many updated features, from design changes to technological upgrades, starting with the completely redesigned cab for added operator comfort and safety. The PT550’s Cat. 2 ROPS/FOPS/OPS approved cab has a new configuration and an integrated cabin pressurization system, an industry benchmark.

Other improvements for added operator comfort and productivity include large Lexan glass windows, ergonomic joysticks, a pneumatic seat, a large 10 in. touch screen display to control all operating functions, a 360-degree camera system and display, and a heated and refrigerated compartment with cup holder.

The Caterpillar C13B six-cylinder engine in the FAE PT550 guarantees strength, reliability and global support. Equipped with a turbocharger with after cooler, the Tier IV Final/Stage V engine delivers 536 hp. The combined diesel particulate filter (DPF), selective catalytic reduction (SCR) and diesel oxidation catalyst (DOC) guarantee compliance with Tier IV Final/Stage V.

The PT550 also is available with a Tier III/Stage III A engine for emission-free markets, rated at 475 hp. The large 12.5-L displacement and the electronically controlled proportional and reversible fan cooling system, designed specifically for the FAE PT550, guarantee superior performance for

heavy jobs and in tropical climates, according to the manufacturer.

The FAE PT550’s heavy-duty undercarriage is designed to provide enhanced performance and reliability, even in the most demanding conditions. The lubricated track chains last longer than conventional chains and provide a smoother ride. When combined with the reliable dozer-type rollers and oscillating undercarriage technology, the PT550 offers enhanced grip and comfort.

There are two roller guard options to adapt perfectly to different environments. The conventional geometry means a low center of gravity and optimal contact between the chain and the drive wheel, two fundamental elements that provide the best performance, even on slopes, according to the manufacturer.

The FAE PT550 wheelbase also extends the load distribution area, which means lower specific pressure against the ground. The undercarriage frames are designed to withstand major stresses and make maintenance easier.

The PT550 can be equipped with a forestry mulcher or a multitask head to crush stone and till soil. Each machine benefits from Active Power Management technology, which combines the Floating System function with the Load Control function, ensuring that the head always precisely follows along the ground and that power is managed effectively during operation.

Combined with the 300/U/SONIC and 500/U/SONIC forestry mulchers, FAE’s exclusive Sonic technology enables the head to work at maximum capacity at all times. Sonic technology adjusts the torque in real time according to the force required, for up to 30 percent higher productivity. For more information, visit www.fae-group.com.

Terex Washing Systems (TWS), a global leader with more than 60 years of expertise in the design and manufacture of washing equipment, celebrated five years of manufacturing filterpresses.

This milestone underscores the team’s commitment to environmental responsibility in quarry operations worldwide, with its filterpresses processing approximately 100 million tonnes annually across the globe.

“Our journey in the design and development of our own filterpresses began in 2019 and today, we stand as a global leader in delivering complete ‘Feeder to Filterpress’ solutions,” said Mark Fisher, business line director of Terex Washing Systems. “The evolution of our filterpress technology underscores our commitment to driving efficiency and sustainability in the quarrying industry.”

coarse screening plant locations and new operating conditions - making i range of screen linings, the MSS 802 EVO can eas Thanks to its robust

improved overall efficiency of the wash plant by streamlining the water treatment process. By effectively separating solids from liquids, they produce cleaner water for reuse and optimize the performance of downstream equipment.

Quality assurance is another significant advantage as filterpresses provide clean, recycled water to re-enter the washing process, improving the quality of washed sand and aggregates.

Since the inception of in-house filterpress manufacturing in 2019 at the Terex Washing Systems headquarters in Dungannon, Northern Ireland, the team has refined its filterpress technology and integrated it into its comprehensive “Feeder to Filterpress” washing solutions. These systems divert waste from landfills while recycling the water used during the process, significantly reducing environmental impact and improving aggregate production for quarry customers.

functions can be operat

The MOBISCREE system control that redu

changing

and extensive solution in natural stone

One of the key advantages of the Terex Washing Systems filterpresses is their efficiency in water recycling, which reclaim over 95 percent of the water used in the washing process, minimizing water consumption and reducing the need for freshwater input.

error.Andallrelevant features an intuitive t ideal for a wide ily

ed from a safe distance for EN MSS 802 EVO - the heav .wirtgewww uces the risk of operating e

and recycling.

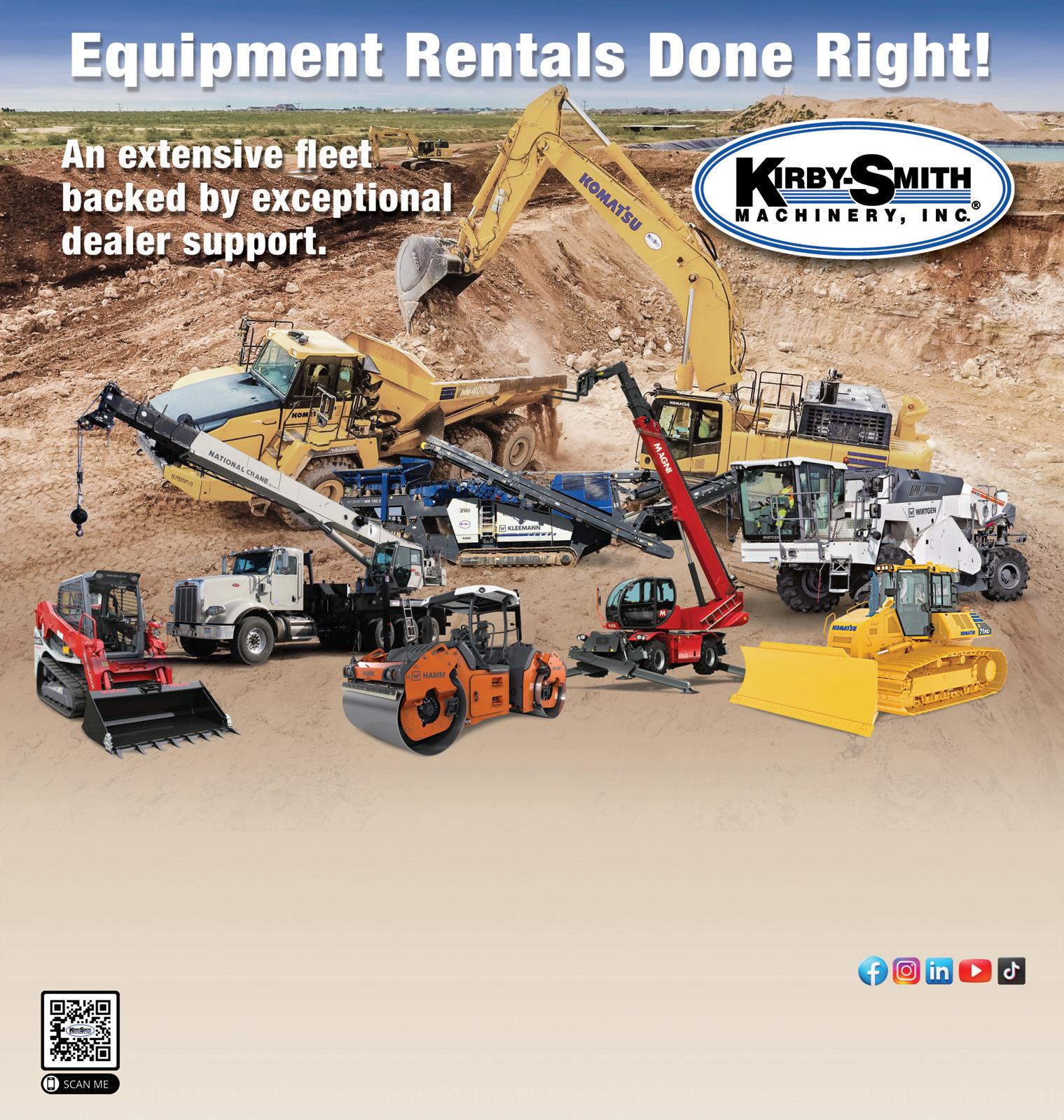

Oklahoma City, OK 405-495-7820 Tulsa, OK 918-438-1700 McAlester, OK 918-310-1550

TX 432-333-7000 Waco, TX 254-261-1370 www.kirby-smith.com

Abilene, TX 325-692-6334 Amarillo, TX 806-373-2826 Dallas, TX 214-371-7777 Ft. Worth, TX 817-378-0600

Lubbock, TX 806-745-2112

vydutyversatile increased work vy-duty, versatile

roup.com/klen-g error. And all relevant

TX 210-310-0066 www.nuecespower.com

Christi, TX 361-289-0066 Laredo, TX 956-725-0066 San Benito, TX 956-361-0066 Victoria, TX 361-576-0066 Vinton, TX 915-541-0066

Filterpresses also aid in waste reduction by producing a dry filter cake waste product. This dry cake is easily transportable and can be reintegrated into the quarry or used for other applications. By maximizing water recycling and minimizing waste generation, these systems help quarry owners meet environmental regulations and demonstrate a strong commitment to responsible quarrying practices.

Another benefit of filterpresses is

Beyond innovation, Terex Washing Systems offers comprehensive global support and service. With 40 distributors worldwide and regional offices in the United States, Europe, Asia-Pacific and Australia, Terex Washing Systems provides localized expertise and service.

Supported by a dedicated technical team and advanced laboratory facilities, Terex Washing Systems ensures optimal equipment performance and sustainability throughout its customers’ operations.

For more information, visit www.terex.com/washing.

(Photo courtesy of Terex)

Pages 39-44

In 2010, Nick Kemnitz established Tough Seats, which has since become a leader in the heavy machinery seating industry.

From its humble beginnings in Kemnitz’s rental unit with an $8,800 inventory, the company has become a significant player in the equipment seating market.

Kemnitz, the visionary behind Tough Seats, launched the company drawing from his industry experience post-college.

“I had worked for a supply company out of college, and it felt right to start my own business focusing on what I knew best,” Kemnitz said.

He started Tough Seats at 29, beginning the business alone in a rented 1,200-sq.-ft unit.

Today, the company operates from a 15,000-sq.- ft. facility, which has expanded several times.

Tough Seats, which is based in Trevor, Wis., has seen significant evolution.

“We’ve created the versatility to be the one-stop shop for seats for nationwide shoppers,” Kemnitz said.

The company now stocks top-rated brands such as Grammer, KAB Seating and Sears. This wide-ranging inventory includes seats for backhoes, dozers, excavators,

off-highway trucks, skid steers, scrapers, wheel loaders and tractors.

“Dozer seats tend to be our best seller because of the open cab,” Kemnitz said. The seats range in price from a few hundred dollars to $2,000.

The growth of Tough Seats is mirrored in its team expansion. From a one-person operation, it has grown to a robust team of 10 employees. Key team members, like Sarah Saucerman, Tony Saucedo and Ted Gogolewski, have been instrumental in the company's success. Several of Kemnitz’s family members also are employed by the company.

One unique aspect of Tough Seats is its ability to customize and engineer mounting plates and brackets to meet attachment designs from older to modern-day seats.

“The third-party seat companies do not make the brackets to fit the seats into the machines, so we have had to engineer our own solutions which makes our company unique,” Kemnitz said, explaining that the process has evolved over the years, adding a distinctive edge to the offerings.

Customer service is a cornerstone of Tough Seats’ operations. The company prides itself on quick turnaround times.

ABILENE, TX • 877-577-5729

AMARILLO, TX • 800-283-1247

DALLAS, TX • 800-753-1247

FT. WORTH, TX • 877-851-9977

HEWITT (WACO), TX • 254-261-1370

LUBBOCK, TX • 866-289-6087 MCALESTER, OK • 918-310-1550 ODESSA, TX • 877-794-1800 OKLAHOMA CITY, OK • 800-375-3339 TULSA, OK • 800-375-3733

MISSOULA, MT • 800-332-1617

BILLINGS, MT • 800-735-2589

BOISE, ID • 800-221-5211

COLUMBIA FALLS, MT • 800-434-4190

EUGENE, OR • 800-826-9811

JEROME, ID • 800-221-5211 KENT, WA • 800-869-2425

POCATELLO, ID • 800-829-4450

PORTLAND, OR • 800-950-7779

ROCHESTER, WA • 800-304-4421

SPOKANE, WA • 800-541-0754

Blue Diamond Attachments has announced the launch of a new line of rubber tracks.

Available for compact track loaders, mini-excavators, mini-loaders and multi-terrain loaders, and with the four most common track patterns (Block, C-Lug, Multi-Bar and Zig-Zag), the new line provides excellent performance under a wide range of working conditions, according to the manufacturer.

Ideal for use in the construction, agriculture, landscaping and rental industries, Blue Diamond’s rubber tracks are custom manufactured with a blend of tough rubber compounds, combining unique resistance features with outstanding durability. The abrasion-and-wear-resistant materials also provide a comfortable and safe ride for operators, reducing fatigue and vibration-related equipment issues.

A continuous steel cord structure with solid steel forged links and a reinforced roller path minimize the risk of track breakage by distributing the tension forces along the entire track instead of just small areas of the track. This significantly reduces downtime and maintenance costs.

Application-specific lug patterns offer enhanced traction, as well as chunk and tear resistance

“Our new line of rubber tracks are built to withstand heavy jobsite use while still giving a comfortable ride for operators,” said Drew Truan, chief operating officer at Blue Diamond Attachments. “Our products are compatible with most OEMs and have a similar wear lifespan at a fraction of the price, making them the perfect choice when tracks need to be replaced — and all are supported by Blue Diamond and our dealer network.”

The new line of rubber tracks come with the Blue Diamond Satisfaction Guarantee and are backed by a 2-year warranty.

For more information, visit www.bluediamondattachments.com.

"We can usually get a new sea” shipped out the door to a customer within one business day,” Kemnitz said.

Additionally, its return rate has been less than 1 percent over the last two years, indicating success in delivering the right product consistently.

"We do it right the first time,” Kemnitz said.

The service facilities in Trevor are wellequipped to meet various customer needs, ensuring consistent and fast delivery. This commitment to prompt service is a critical component of its customer satisfaction strategy.

Tough Seats has earned multiple awards for its contributions as a large distributor of several major seat manufacturers, according to the company.

“We’ve earned five significant recognitions for our distribution capabilities,” Kemnitz said, highlighting awards from Grammer for largest growth, highest sales value, and sales growth over multiple years.

As Tough Seats looks to the future, Kemnitz envisions continued growth and innovation.

“We’re always looking at the future and how we can better serve our customers,” he said. “In the future, we would like to expand further into small OEMs and into the joystick aspect of seats. This is a vision we see many years ahead in the future.”

This forward-thinking approach is essential as the company navigates industry challenges and seeks new opportunities. With a strong foundation and a clear vision, Tough Seats is positioned for continued success in the heavy machinery seating industry.

Tough Seats will be at Mine Expo 2024 at the Las Vegas Convention Center in September.

“Come visit us,” Kemnitz said, offering an opportunity for attendees to learn more about their products and services.

For more information, visit www.toughseats.com.

(Photos courtesy of Tough Seats.)

Trucks that run on green hydrogen instead of fossil fuels provide one way to decarbonize transport. Hydrogen trucks will be especially suitable over longer distances and in regions where there is limited charging infrastructure, or time for, recharging of batteries.

Volvo will begin customer tests with trucks using hydrogen in combustion engines in 2026, and the trucks will be commercially available towards the end of this decade.

gas and HVO (Hydrotreated Vegetable Oil).

Already, testing in labs and in vehicles is ongoing. The hydrogen-powered combustion engine trucks will complement Volvo’s offering of other alternatives, such as battery electric trucks, fuel cell electric trucks and trucks that run on renewable fuels, like bio-

“Trucks where the traditional internal combustion engine remains but runs on hydrogen will have the same performance and reliability as our diesel trucks, but with the added benefit of potentially net zero CO2 emissions well-to-wheel. They will be a valuable complement to our battery electric trucks, which have been on the market for

Volvo Trucks photo

Volvo will launch trucks with combustion engines that can run on green hydrogen. These trucks provide a significant step to decarbonize heavy transport.

several years,” said Jan Hjelmgren, head of product management and quality, Volvo Trucks.

Volvo trucks with combustion engines powered by green hydrogen have the potential to deliver net zero CO2 well-to-wheel when using renewable HVO as ignition fuel and are categorized as “Zero Emission Vehicles” (ZEV) under the agreed new EU CO2 emission standards.

“It’s clear that several kinds of technology are needed to decarbonize heavy transport. As a global truck manufacturer, we need to support our customers by offering a variety of decarbonization solutions, and customers can choose their alternative based on transport assignment, available infrastructure and green energy prices,” said Hjelmgren.

Volvo trucks with hydrogen-powered combustion engines will feature High Pressure Direct Injection (HPDI), a technology where a small amount of ignition fuel is injected with high pressure to enable compression ignition before hydrogen is added. The advantages of this technology include higher energy efficiency with lower fuel consumption, and increased engine power.

Volvo Group has signed an agreement with Westport Fuel Systems to establish a joint venture using HPDI technology.

• Hydrogen-powered Volvo trucks will have an operational range comparable to many diesel trucks, depending on the type of transport.

• Due to the low CO2 emissions from hydrogen combustion, these trucks are categorized as “Zero Emission Vehicles” under the agreed new EU CO2 emission standards.

• Hydrogen combustion engines will also emit very small amounts of nitrogen oxides and particles.

• Hydrogen also can be used to power fuel cell electric trucks, where electricity is produced on board the truck. Fuel cell electric trucks do not emit any tailpipe emissions, only water vapor.

For more information, visit www.volvotrucks.com.

XL Specialized Trailers announced the launch of a brandnew trailer model, the XL Knight 80 MFG. The Knight has an updated and improved mechanical, full-width gooseneck trailer design.

The 48-ft.-long detachable gooseneck lowboy has an overall capacity of 80,000 lbs. and a concentrated capacity of 70,000 lbs. in 16 ft. The trailer offers 29 ft. of main deck loading space and a loaded deck height of 18 in. for versatile hauling.

The XL Knight 80 MFG offers many new standard features and encompasses the most popular specs and options possible into a competitive offering. The detachable gooseneck features front connection plates with three height settings for added adaptability over various terrains.

The front of the main deck can go up or down 1.5 in., for a total of a 3-in. variance. The raise and lower valve in the rear allows for an adjustment of 1.5 in. The Colas-plus raise and lower valve is especially customer-friendly with its large and durable handle.

The Knight trailer has improved aesthetics with an aluminum logo decal at the front and MicroNova clearance lights. A battery backup with a four-way plug enables the lights to stay on even when the trailer is disconnected from the truck.

The 48-ft.-long detachable gooseneck lowboy has an overall capacity of 80,000 lbs. and a concentrated capacity of 70,000 lbs. in 16 ft.

The new trailer also features a convenient front storage area to stow chains or other materials. Swingout outriggers can be added to the main deck for hauling over-width loads. A 2 ft. by 2 ft. cutout in the rear transition provides additional space for equipment such as draw bars on tractors. The two-axle wheel area is prepped to accommodate a third axle if needed.

The Knight is our next product in a series of stock-style trailers, allowing the manufacturer to ramp up production of popular models to meet market demand. The XL Guardian 110 HDG was the first product in this program, released early in 2023.

Knights and Guardians are both now available on XL dealer lots.

In addition to its new Knight trailer, XL Specialized Trailers also recently launched its updated website. Designed with the customer experience as a top priority, the site offers simpler navigation and a sleek aesthetic.

For more information, visit xlspecializedtrailer.com.

Ford Motor Company announced plans to assemble F- Series Super Duty pickups at its Oakville Assembly Complex in Ontario, Canada, starting in 2026, boosting production of one of the company’s most popular and profitable vehicles.

The move to add production of up to 100,000 units of its best-selling Super Duty to Oakville expands Super Duty production across three plants in North America, including Kentucky Truck Plant and Ohio Assembly Plant, which are operating at full capacity. It also paves the way to bring multi-energy technology to the next generation of Super Duty trucks, giving customers more freedom of choice and supporting Ford’s electrification plans.

“Super Duty is a vital tool for businesses and people around the world and, even with our Kentucky Truck Plant and Ohio Assembly Plant running flat out, we can’t meet the demand. This move benefits our customers and supercharges our Ford Pro commercial business,” said Jim Farley, Ford president and CEO.

“At the same time, we look forward to introducing three-row electric utility vehicles, leveraging our experience in three-row utility vehicles and our learnings as America’s No. 2 electric vehicle brand to

deliver fantastic, profitable vehicles.”

In total, Ford plans to invest approximately $3 billion to expand Super Duty production, including $2.3 billion to install assembly and integrated stamping operations at Oakville Assembly Complex. When complete, Oakville Assembly Complex will be a fully flexible plant.

Boosting Super Duty assembly will initially secure approximately 1,800 Canadian jobs at Oakville Assembly Complex, 400 more than would initially have been needed to produce the three-row electric vehicle. Unifor-represented employees at Oakville Assembly Complex will return to work in 2026, a full year earlier than previously planned. The increased production also adds approximately 150 jobs at Windsor Engine Complex, which will manufacture more V8 engines for Super Duty.

print, and our investments will have a fast payback.”

Ford plans to hire new employees and add overtime at U.S. component plants that support Super Duty production.

• Sharonville Transmission Plant in Ohio

— $24 million investment and additional overtime

approximately 20,000 American workers.

Ford is a leader in producing and selling trucks in America, with two F-150 plants in Michigan and Missouri, two Super Duty plants in Kentucky and Ohio, and a Ranger plant in Michigan. Ford truck production directly and indirectly supports more than 500,000 jobs in America.

In the first half of 2024, Kentucky Truck Plant and Ohio Assembly Plant produced more than 200,000 Super Duty trucks. Order banks remain healthy since the launch of the new 2024 model year Super Duty, and demand from Ford Pro customers is higher than what Ford can produce now.

“This investment will benefit Ford, our employees in Canada and the U.S., and especially our customers who want and need Super Duty for their lives and livelihoods,” said Kumar Galhotra, Ford’s chief operating officer. “It is fully consistent with our Ford+ plan for profitable growth, as we take steps to maximize our global manufacturing foot-

• Rawsonville Components Plant in Michigan — $1 million investment and roughly 20 new jobs

• Sterling Axle Plant in Michigan — approximately 50 new jobs

Across powertrain, transmission, stamping and final assembly operations, 10 U.S. plants in five states support Super Duty production. Those plants directly employ

“There is durable demand for Super Duty from Ford Pro customers as spending on infrastructure and related construction activity remains high,” said Ford Pro CEO Ted Cannis.

“Many retail customers have not been able to get their trucks fast enough because of our production constraints. Unlocking Super Duty volume will also support businesses and tradespeople who rely on these trucks and first responders who serve their communities.”

Tucson, AZ

509-536-7300

El Cajon, CA

619-448-0770 Corona, CA 800-491-9004

Lewiston, ID 208-743-0866

Snohomish, WA 360-863-2552

Richland, WA 509-578-5900

Petersandkeatts.net

nixonegli.com

from page 28

“Because of the size of the job and the varied nature of all the work, we have 10 Link-Belt units at The Trop site,” Miller said. “Those include a pair of 750 X4s: three 490 X4s; three 350 X4s; one 250 X4 and one 145 X3. I’ve been a Link-Belt user since 2006 after I saw one of the larger demo firms in our area in California using it. I decided to follow their lead and it was a good move on our part. The equipment is extremely reliable, it performs well, our guys love it and I get the best level of support possible from both Link-Belt and our dealer, Bejac Corp.”

A feature Miller and Anderson cite is the X4 Series’ use of Isuzu engines. Because they do not use a diesel particulate filter — one of the biggest causes of machine failure — the company experiences fewer engine-related service problems. By instead using an exhaust gas recirculation (EGR) system, nitrogen oxide pollutants (NOx) are reduced without sacrificing fuel efficiency or engine horsepower. Harmful emissions are lowered even further by an SCR (selective catalytic reduction) system which removes pollutants to nearzero levels.

“Link-Belt excavators are also equipped with a proprietary control valve,” Anderson said. “That feature allows a particular machine to truly multitask — track, have bucket movement and swing — all without one action impacting the other. With project schedules getting tighter all the time, that really helps keep productivity up. And Bejac, which now also has a Las Vegas location, is excellent in seeing to our needs and minimizing the risk of any downtime.”

Other areas of the site MEI is tackling include 38,000 sq. ft. of the casino/gaming area and a broad expanse of concrete that served as an apron and parking areas for the various buildings. For the concrete removal, MEI called upon a Link-Belt 750 X4. The machine’s i breakout force coupled with an 84-inch bucket is making short order of both the removal and loadout. As the project progresses, Anderson foresees both 750s playing key roles.

“The underground and foundation facet of this job will probably be the most challenging,” he said. “The footers for the Club Tower are built on caissons that are 19 feet deep and

sitting on caliche rock. There are also three tunnels that connect some of the buildings — ranging in dimension from utility-sized to pedestrian — as well as additional underground infrastructure. For all that work, we will equip the 750s with Epiroc HB 7000 hammers; they’ll have no problem with any of it at all.”

The implosion of the towers is set for October, with a project wrap-up slated for April 2025. By project’s end, Miller

estimates they will recover about 180,000 tons of concrete and asphalt and 9,000 tons of ferrous/nonferrous metals.

“We are pleased with how well the Tropicana project is proceeding and are already getting set to begin work at the Mirage Hotel on the other end of the strip,” he said. “These are exciting times for both Las Vegas and Miller Environmental.”

(All photos courtesy of Miller Environmental Inc.)

The AGC’s annual workforce survey found that members are dedicating more resources to recruiting craft workers this year than they did in 2023.

The result of all this beating the craft trade bushes is a boon for those workers seeking employment in the construction field.

In fact, 61 percent of responding contractors increased pay rates or benefits even more for hourly workers this year; 45 percent did so for salaried employees.

“Contractors are rethinking how they operate to cope with and overcome labor shortages,” said AGC.

It bodes well for the industry’s future that even with the labor shortages most contractor firms expect to expand in the next 12 months, reported AGC.

In fact, 73 percent of firms, up from 69 percent last year, expect to add employees; 19 percent expect no change and 8 percent expect to drop headcount.

“If realized, such expansion would be more widespread than in the past 12 months,” said AGC.

In that period, roughly half of firms added employees, while 30 percent reduced headcount and 19 percent had no change, said the association.

“Unlike last year, when optimism was nearly uniform nationwide, there is more regional variation this year.”

The AGC found that firms in the Northeast express the most optimism — 83 percent expect to expand headcount in the next 12 months.

Those numbers were followed by the South, at 76 percent of firms; the West, at 70 percent and the Midwest, at 69 percent.

“Shortages of workers and certain essential equipment are still causing headaches for many firms,” said the association.

Materials shortages and delivery delays

are much less common, but a majority reports project delays from their own or subcontractors’ worker shortages.

And, longer lead times or shortages have delayed some projects for about half of firms, said the AGC.

In fact, 41 percent cite long lead times for electrical equipment such as transformers and switchgear as a source of project delays.

“Long lead times for mechanical equipment such as heating, ventilating and air conditioning gear is another source of delay,” as noted by 28 percent.

“About one-third list delays due to government, such as lack of approvals or inspectors, or delays due to an owner’s directive to halt or redesign a project.”

One source of delay that has improved is transportation or delivery delays, cited by 21 percent, compared to 36 percent in 2023 and 64 percent in 2022.

“Projects are still being canceled, postponed or scaled back for a variety of reasons,” said AGC. “Half of respondents cite increasing costs as a reason, while 40 percent report financing was unavailable or too expensive.”

One out of five respondents noted changes in demand or need as reasons for project cancellations, deferrals and scope reductions, similar to the 2023 survey.

But this year only 17 percent, down from 22 percent last year, list lengthening or uncertain completion times.

That’s another positive sign that availability of materials has improved over the past 12 months, said the AGC.