By Andy Gotlieb CEG SENIOR EDITOR

The Tropicana Hotel stood, in some form or fashion, for 67 years, but it took just 22 seconds to level the famed casino’s two 23-story hotel towers in Las Vegas on Oct. 9, although it required months of preparation since its April closure.

GGG Demolition Inc. of Orange, Calif., completed all the pre-demolition work, removing smaller buildings on the property and handling interior pre-demolition. It also will handle the post-implosion debris removal and other site preparation, including removing building foundations and grading the property.

Controlled Demolition Inc. (CDI) of Phoenix, Md., handled the implosion of the two

see IMPLOSION page 44

The Big Dig of Northern Colorado had one of its most successful years ever in 2024, raising $125,841 in support of pediatric cancer research for the American Cancer Society.

This year’s event, which took place on Sept. 7 at Richie Bros. Auctioneers in Longmont, Colo., sold out for the first time. The strong backing from the community allowed such a feat to become possible.

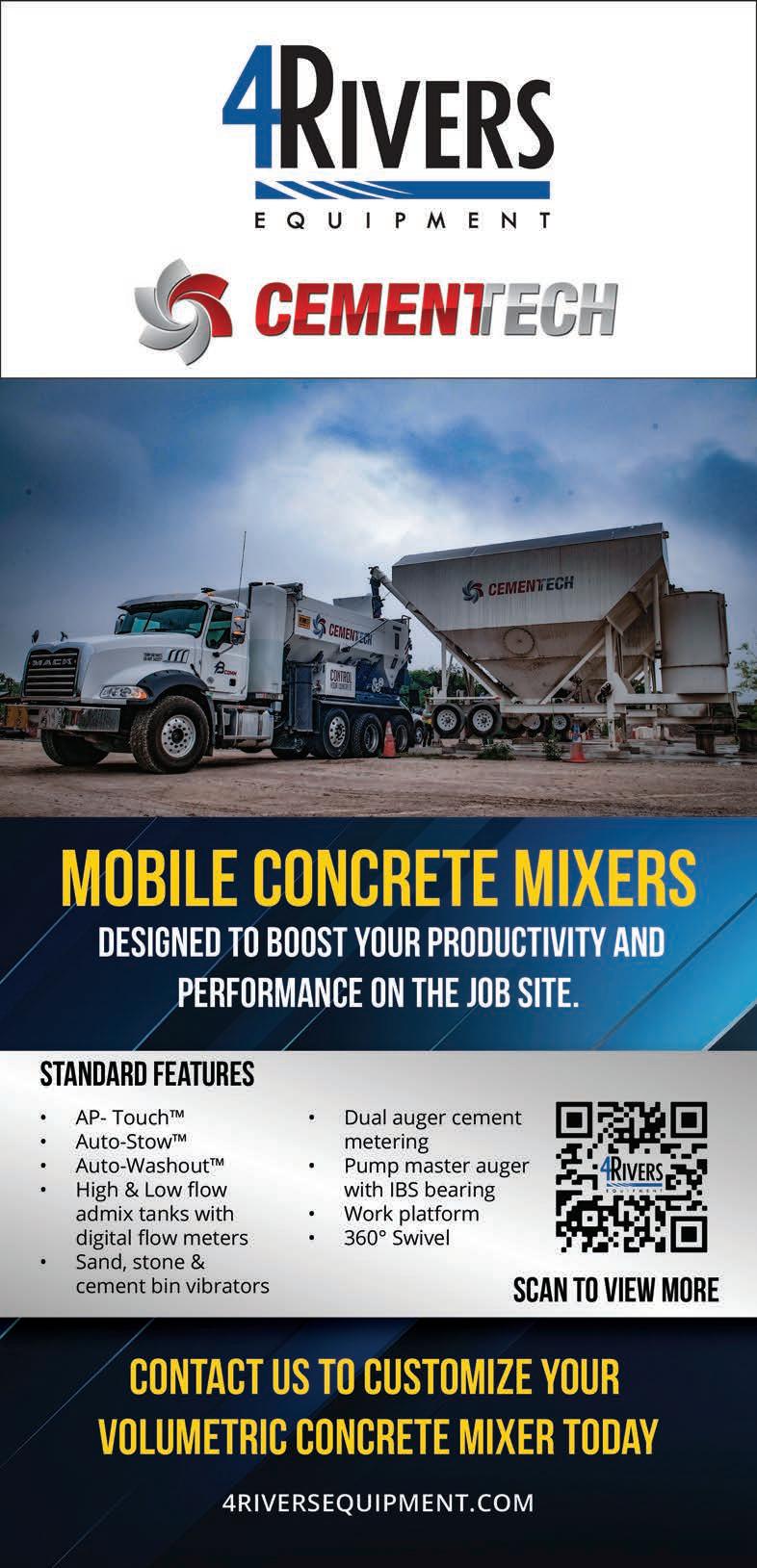

4Rivers Equipment was one of the key sponsors of Big Dig of Northern Colorado 2024 and brought a 70-ft. obstacle course and 12 mini-excavators for children to enjoy. The event offered a fun, hands-on experience for kids while supporting the fight against childhood cancer.

There were 2,569 attendees to the event, which generated see DIG page 32

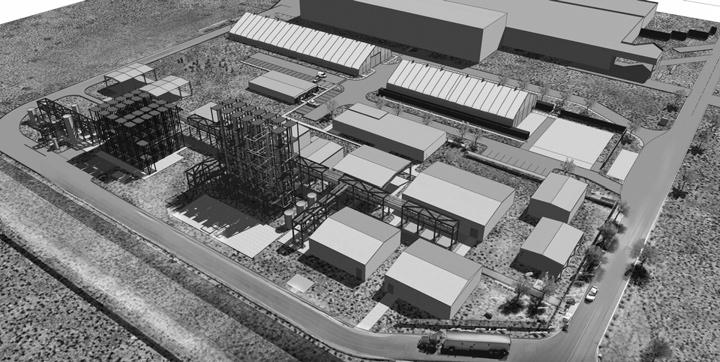

The U.S. General Services Administration (GSA) announced on Oct. 3, 2024, that it awarded a $274,716,965 design-build contract to Hensel Phelps Construction Co. for the new Douglas Land Port of Entry.

The Phoenix, Ariz.-based company will provide design-build services for the new commercial port which will be built approximately 5 mi. west of the existing Raul Hector Castro Land Port of Entry in Douglas, Ariz.

This critical infrastructure development project, which received $180.3 million in Bipartisan Infrastructure Law funding and $92.2 million in Inflation Reduction Act funding, will increase capacity and facilitate lawful trade and travel between the United States and Mexico.

Construction of the new port is set to begin in fall 2025, with completion slated for fall 2028.

At the current Castro port, both inbound and outbound trucks maneuver within the same undersized commercial vehicle inspection compound, which slows traffic and poses safety hazards. Once complete, the U.S. Customs and Border Protection will relocate commercial operations from the existing Castro port to the new port.

This change will increase the number of commercial vehicle inspection lanes from one to four, and the number of commercial vehicle inspection docks from 12 to 36 while also allowing for the processing of oversized mining equipment too large to cross at the Castro port. The existing Castro port also will be modernized and expanded.

“These strategic upgrades are a triple win — generating high-quality jobs that fortify our economy and national security, reducing taxpayer expenses through energy efficiency, and paving the way for a more resilient and thriving future for our communities,” GSA Administrator Robin Carnahan said.

GSA said it will design a facility that will not only enhance security and spur regional economic activity but enhance sustainability through the implementation of sustainable design, technology and materials.

The port will be all-electric, meeting the Federal Building Performance Standard, and will incorporate photovoltaic solar panels which will generate clean renewable energy to achieve net-zero energy. It will feature water-saving fixtures, energy-efficient building systems and low-embodied carbon construction materials such as concrete and steel.

“The new Douglas Land Port of Entry

will significantly increase our ability to inspect commercial vehicles and process goods more efficiently, all while supporting economic growth in the region,” said CBP Senior Official Performing the Duties of the Commissioner Troy A. Miller. “This project represents a critical investment in both the security of our nation and the prosperity of our border communities. By leveraging advanced technologies and sustainable design, we are also building a smarter, more resilient port of entry for the future.”

The construction of this project furthers the goals of President Biden’s Federal Sustainability Plan, which directs federal agencies to lead by example and achieve net-zero emissions by 2050, including netzero emissions from all federal buildings by 2045.

“These investments to construct the Douglas Land Port of Entry and modernize the existing Castro Land Port of Entry are crucial for Arizona’s security and economic prosperity. I’m proud to deliver this win for Douglas and our entire state,” Arizona Sen. Kyrsten Sinema said.

“This new commercial port in Douglas will not only increase processing and inspection capacity, strengthening supply chains and facilitating hundreds of millions of dollars in trade, but it will also expand the ability to screen for illicit drugs more effectively, Arizona Sen. Mark Kelly said. “This is a win for Arizona’s economy, a meaningful step towards a two-port solution and a major effort to secure our border.”

This project not only addresses current needs but also sets the stage for future innovations in border management and environmental sustainability, said Sukhee Kang, regional administrator of GSA’s Pacific Rim Region.

The Bipartisan Infrastructure Law includes $3.4 billion for GSA to build and modernize land ports of entry on the country’s northern and southern borders. The investments will improve commerce and trade, enhance security, create good-paying jobs and incorporate innovative sustainability features.

The Inflation Reduction Act includes a separate $3.4 billion for GSA to use its buying power to promote the development and manufacturing of low-embodied carbon construction materials and to make federal facilities more sustainable and cost-efficient. GSA’s Inflation Reduction Act projects will implement new technologies and accelerate GSA’s efforts toward achieving a net-zero emissions federal building portfolio by 2045.

2016 Kobelco SK140SRLC-3, Stk#: 13546, EROPS, A/C, Heat, Radio, 4,685 hrs., 34" Bkt, 24" Pads, Aux Hyd, Back-Up Camera $48,500

2018 John Deere 450K LGP, Stk#: 13610, OROPS, 2,534 hrs., 6 Way Blade, 24" Pads, 10' 4" Wide $59,500

12756, EROPS, A/C & Heat, 594 hrs., Water System, 8 ft. Broom, 225x75Rx15 Tires, 4 Cy.

The U.S. General Services Administration (GSA) announced on Oct. 3, 2024, that it awarded a $274,716,965 design-build contract to Hensel Phelps Construction Co. for the new Douglas Land Port of Entry.

NAWIC President-elect Rita Brown joined innovators on Sept. 5 at the U.S. Department of Labor’s Lansing, Mich.-area Good Jobs Principles Roundtable, and signed a national initiative designed to support the creation of quality jobs.

Construction theft is not new, but criminals are getting bolder in their efforts to make a buck on anything they can grab quickly at a job site, from the rig itself to the fuel and parts inside it.

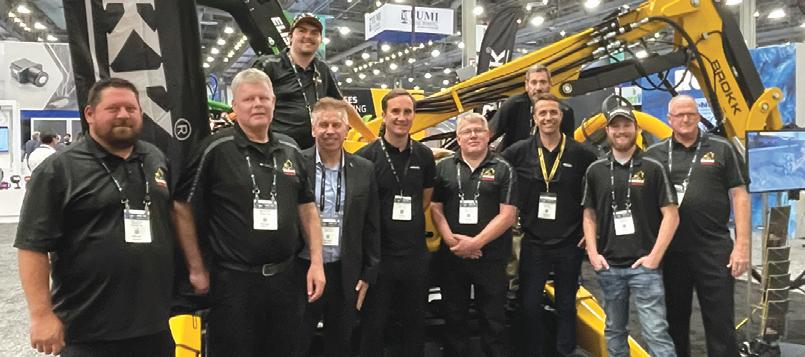

14 GLOBAL MINING INDUSTRY GATHERS AT MINEXPO 2024 IN VEGAS

Thousands of people involved with the global mining industry visited the Las Vegas Convention Center from Sept. 24-26 to attend the National Mining Association’s MINExpo 2024, the once-every-four-years trade show.

Kairos Power started construction on a new facility in Albuquerque, N.M., that will produce “Flibe” molten salt coolant for its Hermes reactor, the federal Office of Nuclear Energy announced.

16 NEARLY $9B APPROVED FOR OKLAHOMA HIGHWAY UPDATES

The Oklahoma Transportation Commission on Oct. 7 approved $8.6 billion in highway construction and safety projects in the newest edition of the Oklahoma Department of Transportation’s Eight-Year Construction Work Plan.

18 AED FOUNDATION BRINGS STUDENTS TO APPRENTICESHIP EVENT

High school students took significant steps toward careers in the equipment industry by learning essential diesel engine repair skills, operating equipment, polishing their interview techniques and connecting with industry leaders.

18 CATERPILLAR, TRIMBLE EXTEND LONGSTANDING JOINT VENTURE

Caterpillar Inc. and Trimble announced the extension of their long-standing joint venture. The agreement includes expanded distribution of grade control solutions in the construction sector to accelerate innovation and customer adoption.

19 STARTUP HB

REBRANDS AS TRUE ATTACHMENTS

Kelly Russell founded HB Attachments Inc. in 2023 to help excavator dealerships close more deals with higher profits. The startup designs, manufactures and distributes high-quality aftermarket excavator work tools.

24 BOBCAT COMPANY WINS PRESTIGIOUS RED DOT DESIGN AWARD

The Red Dot Design Award is one of the most respected design awards in the world, with its Design Concept category identifying and celebrating new design concepts and innovations.

24 YANMAR CONTINUES SUCCESSFUL CHARITY GOLF TOURNAMENT

Yanmar America continued its tradition of giving back to the community with its 3rd Annual Charity Golf Tournament. Held on Sept. 19, 2024, the event raised $15,400 for the Good Neighbor Homeless Shelter.

27 JOHN DEERE EXTENDS WESTERN SNOWPLOW AGREEMENT

John Deere has extended its allied distribution agreement with Douglas Dynamics, parent company of Western Products, to sell and support Western snow and ice removal products.

20 DIAMOND MOWERS’ EXCAVATOR BRUSH CUTTER CUTS INTO CHAOS

Designed to tame even the toughest overgrowth, Diamond Mowers’ excavator brush cutter Pro X cuts through chaos of any size. Available in 50, 60 and 72 in., it tackles dense brush and trees while getting more done in less time.

Cell 602/679-8759 e-mail dennishogeboom@cegltd.com

518/221-5159 e-mail khogeboom@cegltd.com

To expand its artificial intelligence (AI) capabilities and help customers optimize their mining operations, Komatsu announced its intent to acquire Octodots Analytics, a Chile-based digital solutions provider.

760-518-4336

sswanson@cegltd.com

jestrello@cegltd.com

pkiel@cegltd.com

The collaborative roundtable and signing event fosters workplace stability, inclusion and support for Lansing, Mich., workforce and the nation.

The National Association of Women in Constructions (NAWIC) President-elect Rita Brown joined leading innovators in Michigan’s workforce on Sept. 5 at the U.S. Department of Labor’s Lansing, Mich.-area Good Jobs Principles Roundtable, and signed a national initiative designed to support the creation of quality jobs that enhance stability, promote inclusivity and empower workers across the construction sector and beyond.

This initiative is led by U.S. Department of Labor Acting Secretary of Labor Julie A. Su and locally by Andy Schor, mayor of Lansing.

The Good Jobs principles were created to enhance communities and business competitiveness on a global scale with a framework of principles for workers, businesses, labor unions and governments to create a shared vision of job quality. Cities across the country are adopting these principles.

Brown’s insight on the construction industry as CEO of Brown Construction Collective Plus (BCC+), brings a nationwide perspective, based on her significant volunteer and corporate work in advocating and advancing women and underrepresented populations.

“The Good Jobs Initiative is important and tangible for our members [NAWIC’s] and for the growth and stability of the construction industry. The reinforcing principles of the Initiative speak directly to our NAWIC mission and vision. Connecting resources between employers, employees, unions, government and industry is intentional and resourceful. There isn’t a downside,” Brown said.

NAWIC was invited to participate in this significant initiative, marking a historic moment for this nationwide organization. Being part of this event spotlights NAWIC’s presence nationally and demonstrates the organization’s commitment to advocating for job quality, advancement, inclusivity; benefiting the industry and NAWIC members. NAWIC currently has 120 state-based chapters in eight regions, representing women working in all aspects of the construction industry.

The National Association of Women in Construction is dedicated to advocating for recognition of the value and impact women bring to these industry jobs and amplifying their relevance in all aspects of the construction industry.

For more information, visit nawic.org.

By Lucy Perry CEG CORRESPONDENT

Construction theft is not new, but criminals are getting bolder in their efforts to make a buck on anything they can grab quickly at a job site, from the rig itself to the fuel and parts inside it.

The pain of dealing with the theft is obvious, but other issues come into play, including damaged equipment leading to missed deadlines, increased insurance premiums and profits lost on a project.

One Oregon excavation contractor felt the burn this summer over two days of theft and destruction.

One morning, he discovered his skid steer had been stolen; the next, he noticed his compactor was damaged during a fuel theft.

“There’s a hole in the bottom of our fuel tank of our roller,” Veneta, Ore., excavation contractor Brian Sorensen, told news station kezi.com in late June.

“They drained all of the fuel out of it,” said Sorenson, adding that now he’ll have to fork out thousands of dollars to repair the compactor.

Fortunately, the skid steer was recovered just hours later, due to a GPS tracker he’d smartly installed on it.

“They started it and they drove it down the road, loaded it up and took it,” he said. “Luckily, we had GPS, so I was able to call the sheriff with the address of the machine and meet them out there.”

Sorenson said the worst equipment damage they’ve dealt with until now was stolen batteries.

“If the guys don’t lock a battery compartment, the battery might get stolen, it’s a couple hundred-dollar deal,” he said.

“But [we’ve] never had anything stolen like this, never any damage like that done to equipment before.”

Trackunit says construction theft is a growing concern, even with today’s asset equipment devices and software. Thieves simply exploit security gaps.

Theft is big business because of the resale value of machinery and relative ease of access to job sites, the equipment management service provider said.

Inadequate perimeter fencing, lack of surveillance systems and poor record-keeping also make job sites attractive for theft.

Nationally, heavy equipment theft costs the construction industry an estimated $400 million every year, according to National Equipment Register (NER).

Theft is a significant problem. Sites in Texas, California, Florida, North Carolina and Georgia are hit most often, said the

Adobe Stock photo

Loaders, excavators, tractors, generators, light towers, forklifts, utility vehicles and compressors are the most soughtafter types of equipment by construction machinery thieves.

“Thieves often strike during long weekends and holiday periods when job sites are less monitored and activities slow down,” said Trackunit. “Additionally, nighttime and early mornings are prime times for theft due to reduced visibility and fewer workers on site.”

Awareness of these common times can help in planning enhanced security measures during these vulnerable periods.

Equipment brands that offer the highest resale value and most widespread use across the construction industry are hit most often. They’re high in demand in both legitimate and illicit markets, said Trackunit, and their prevalence on job sites means they’re often readily accessible.

Plus, parts for these types of equipment are valuable and relatively easy to resell.

What frustrated Sorenson was the fact that no arrest was made in the recovery of his skid steer.

“When I was getting the skid steer, they were there speaking with the deputies,” the excavation contractor told kezi.com. “They had a ‘I don’t know how it got there, it’s not mine.’ And that was it. There were no arrests made; I got my skid steer eventually and left,” he said.

The local sheriff’s office said it can’t assume that the party that possesses the stolen vehicle is responsible for the theft.

Adobe Stock photo

With gaps in security and easily accessed machines, when it comes to equipment theft, criminals are getting bolder forcing contractors to get more inventive in their theft prevention methods.

national organization. They’re particularly vulnerable, said NER, because of their large construction industries and high volumes of equipment in use.

Though Sorenson in Oregon was able to recover his skid steer quickly, Trackunit and NER said recovery rates for stolen machin-

ery are alarmingly low.

“Even if your state isn’t listed among the top for construction equipment theft, it doesn’t mean you’re immune to the risk,” said Trackunit.

The National Insurance Crime Bureau reports only approximately 20 percent of stolen equipment is ever recovered.

Machinery most frequently targeted by thieves? Loaders, excavators, tractors, generators, light towers, forklifts, utility vehicles and compressors.

“These machines and equipment are prime targets owing to their high value,” said Trackunit.

Their ease of access and mobility also make them relatively simple to steal and sell on the black market, the company said.

Construction theft is never random, say security experts. Certain patterns can indicate when thefts are more likely to occur.

“Just because they’re behind the wheel doesn’t necessarily mean they are the person that stole it,” said Sergeant Tim Wallace. “Maybe they know it’s stolen, or maybe they don’t. If they’ve purchased it, that’s an investigative lead we have to consider, too.”

As Trackunit notes, construction site theft can have severe repercussions, significantly disrupting job progress and creating substantial financial losses.

“When vital equipment is stolen, operations can halt, causing delays and missed deadlines, leading to penalties and damaged client relationships.”

A contractor’s replacement costs are often coupled with increased insurance company premiums and additional security expenditures.

“Beyond the tangible losses, theft can demoralize the workforce and erode trust within the team, as well as among contractors and clients,” said Trackunit.

Construction sites are often expansive, with many people going in and out, proving difficult to secure fully, especially during periods of low activity.

The frequent movement of machinery between sites complicates tracking and recovery efforts. Additionally, stolen see THEFT page 32

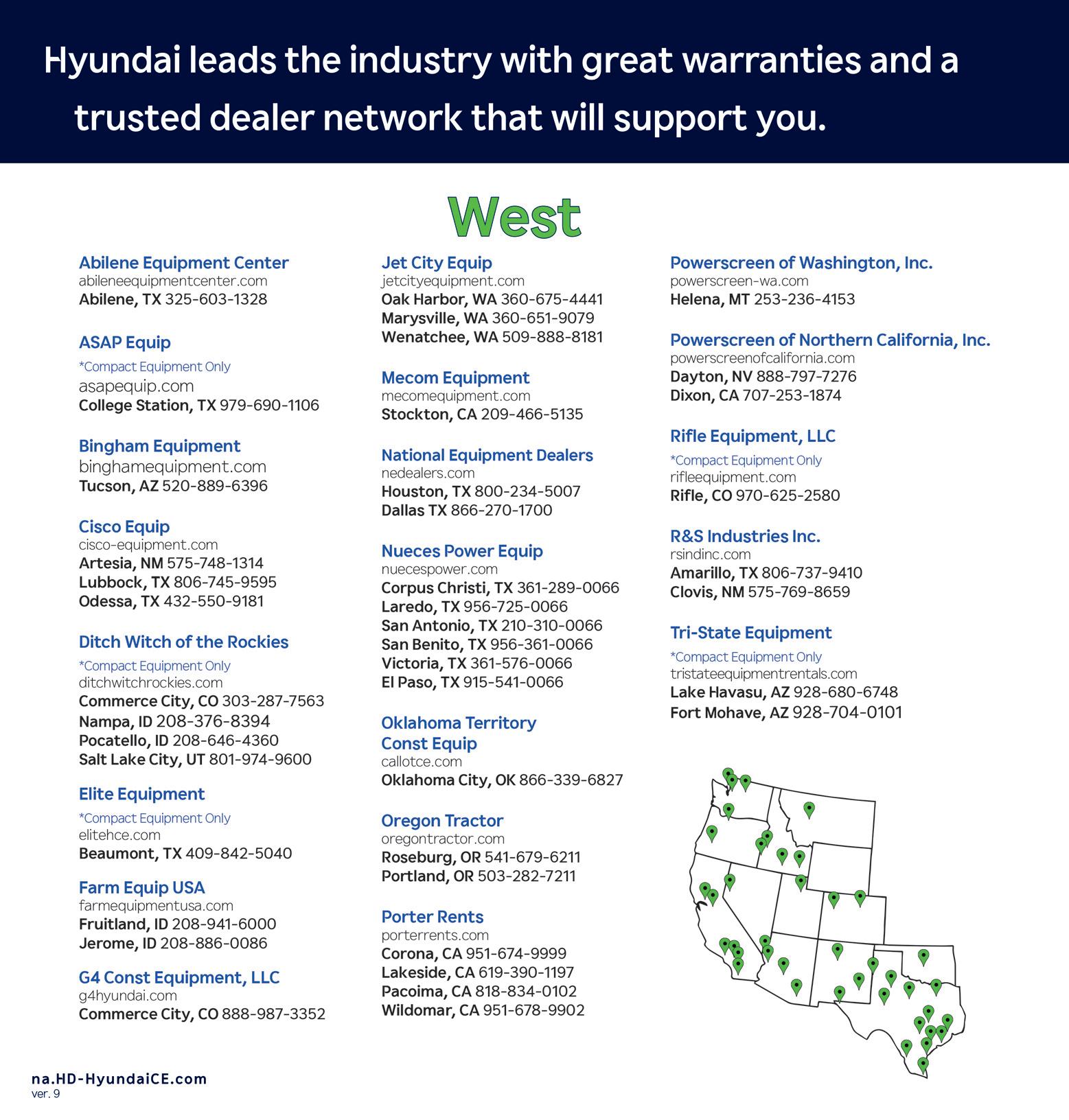

MAKE YOUR MOVE

Push

... more material with the new Hyundai HD100 crawler dozer's best-inclass power-to-weight ratio.

See ...more than ever with the unobstructed view to the blade.

Engage

...more accurately and more productively with standard 2D or optional 3D machine guidance.

Doze

...with confidence, knowing your new 115 hp Hyundai crawler dozer delivers the quality and value you expect from Hyundai, with the peace of mind that comes with our industry-leading warranty.

No wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, na.hd-hyundaice.com.

Thousands of people involved with the global mining industry visited the Las Vegas Convention Center from Sept. 24-26 to attend the National Mining Association’s MINExpo 2024, the once-every-four-years trade show.

Attendees and exhibitors explored three halls where hun-

dreds of exhibitors displayed equipment and the latest technology, including AI, robotics and sensors.

The opening day keynote speaker was Mike Rowe of TV show “Dirty Jobs” fame, while the second day featured former professional race car driver Danica Patrick and former Philadelphia Eagles player, magician and motivational

team

speaker Jon Dorenbos. The final day featured entrepreneur Kevin Leary, known as “Mr. Wonderful” on TV’s “Shark Tank.” CEG

(All photographs in this article are Copyright 2024 Construction Equipment Guide. All Rights Reserved.)

see MINEXPO page 29

(L-R): K-Tec representatives Paul Camasto; Dallas Foster of NDK Scrapers Inc., an authorized K-Tec dealer; and Chris O’Connell at their booth with a model of the ADT scraper.

Kaeser’s Michael Camber (L) and Al Moreno showcased a wide range of compressed air equipment for all types of mining operations.

Kairos Power started construction on a new facility in Albuquerque, N.M., that will produce “Flibe” molten salt coolant for its Hermes reactor, the federal Office of Nuclear Energy announced.

Hermes is one of several projects supported by the U.S. Department of Energy’s (DOE) Advanced Reactor Demonstration Program.

The low-power reactor is being built in Oak Ridge, Tenn., and could be operational as early as 2027.

The new salt production facility will be the latest addition to the Kairos Power Manufacturing Development Campus in Albuquerque.

Construction and operation of the new facility is anticipated to result in an additional 20-30 full-time, high-paying jobs. TIC-The Industrial Co. of Woodlands, Texas, a subsidiary of Kiewit Corp., will serve as the project’s general contractor.

Many Hermes components will be fabricated at the site, which includes facilities for component manufacturing, pressure vessel production, modular reactor construction, fuel fabrication process development and non-nuclear prototype testing.

The salt production facility will produce reactorgrade Flibe, which is a chemically stable combination of lithium fluoride and beryllium fluoride salts, that will be used to cool Hermes’ TRISO-fueled pebble bed design and allow it to operate near atmospheric pressure.

Kairos Power plans for the salt production facility to be operational and producing salt in 2026.

“The facilities we are building in Albuquerque will play a pivotal role in deploying Kairos Power’s clean

energy technology with robust safety at an affordable cost,” said Kairos Power CTO and co-founder Ed Blandford. “With the addition of molten salt coolant production, Kairos Power's Manufacturing Development Campus will soon have all the capabilities we need to deliver the Hermes reactor and establish a credible path to scale up production for the commercial fleet.”

“Kairos Power continues to make impressive strides towards demonstrating the Hermes reactor,” said acting Deputy Assistant Secretary of Nuclear Reactors Brian Smith. “DOE is pleased with the company’s progress on its Advanced Reactor Demonstration Program Risk Reduction project, and we look forward to seeing what Kairos accomplishes next.”

DOE is investing up to $303 million to support the design, construction and commissioning of the Hermes project.

Hermes is the first advanced reactor to receive a construction permit from the U.S. Nuclear Regulatory Commission.

Construction on the project started earlier this year in Tennessee and could be completed as soon as 2027. The company wrapped up molten salt testing on its first, large-scale non-nuclear prototype in July and is working to build a second iteration at the campus to demonstrate the reactor’s modular design.

Hermes is being built to inform the final design of Kairos Power’s commercial reactor which could be deployed in the next decade.

(Photos courtesy of Kairos Power.)

The Oklahoma Transportation Commission on Oct. 7 approved $8.6 billion in highway construction and safety projects in the newest edition of the Oklahoma Department of Transportation’s Eight-Year Construction Work Plan.

The plan contains transportation infrastructure improvements scheduled for fiscal years 2025-’32. The improvements are designed to enhance the safety and travel reliability of the interstate and highway systems across Oklahoma.

“Our Eight-Year Plan serves as a guide for the department’s construction and maintenance efforts and allows us to ensure we are addressing as many transportation needs as we can statewide,” ODOT Executive Director Tim Gatz said. “Our main focus continues to be safety and reliability, and we are working to enhance safety by improving interchanges, adding shoulders to rural twolane highways and addressing bridges statewide.”

In addition, the Four-Year Asset Preservation Plan was introduced, which includes nearly $500 million in investments for preventative maintenance aimed at extending the life of the state’s highway system in fiscal years 2025-’28.

Oklahoma, like many other states, has

The final three phases of the I-35 and I-240 interchange improvements are scheduled in the 2025-’32 Eight-Year Construction Work Plan.

taken inflation and the changing economic climate in supply costs into consideration and adjusted its plans accordingly.

Construction costs have increased more than 60 percent since 2022. While some projects were redistributed in the plan to accommodate these increases, no projects were removed.

The $8.6 billion will include 1,647 projects. That addresses 632 bridges, including 299 that are structurally deficient or are at risk. It also includes 3,755 mi. of roadway improvements; those projects feature 954

mi. of safety improvements on two-lane highways with deficient or no shoulders.

Some notable projects include:

• In the Oklahoma City metro area, the final three phases of I-35 at I-240.

• In the Tulsa metro area, widening U.S. 169 between 66th and 86th streets.

• In southeastern Oklahoma, U.S. 70/Roosevelt Bridge replacement over Lake Texoma advanced from 2029 to 2026.

• In south central Oklahoma, widening I35 to six lanes in Love County.

• In southwestern Oklahoma, new inter-

changes will be built along the Duncan Bypass in Stephens County, as well as along U.S. 62 and Goodyear Blvd. in Comanche County.

• In north central Oklahoma, the final phases of widening SH 33 to four lanes between Guthrie and Stillwater.

• In western Oklahoma, an interchange improvement project along I-40 at I-40 Business in Custer County.

• In northwestern Oklahoma, adding shoulders to more than 6 mi. of U.S. 412/U.S. 60 between Ringwood in Major County and the Garfield County line.

An additional area of special interest is the southern I-35 corridor. Throughout the plan, there are 14 projects totaling more than $377 million that will widen nearly 53 miles of I35 between the Oklahoma River in Oklahoma City and the Oklahoma-Texas state line.

Meantime, the Four-Year Asset Preservation Plan projects include pavement resurfacing, rehabilitation and bridge rehabilitation, painting and joint sealing. The $494 million plan has 276 projects addressing 81 highway bridges and will resurface 1,964 mi. of pavement.

(Photo courtesy of the Oklahoma Transportation Commission.)

On Oct. 8, high school students from across Chicagoland took significant steps toward careers in the equipment industry by learning essential diesel engine repair skills, trying their hand at operating equipment, polishing their interview techniques, and connecting with industry leaders.

Hosted by AEDF in collaboration with SkillsUSA Illinois and its Youth Workforce Development Foundation (YWDF), the Industry Pathways: Career Experience brought more than 500 students from 20 regional schools and career centers together with employers and unions. These young participants received firsthand insights into careers as diesel technicians and equipment operators, helping address the equipment industry’s critical workforce needs.

This event, held at Johnsburg High School, was made possible by $8 million in federal funding that the YWDF and AEDF secured as part of the Apprenticeships Build America program earlier this summer. These funds support workforce development initiatives that engage youth across the country, demonstrating AEDF’s ongoing commitment to developing a skilled workforce that meets national demand. Throughout the day, students engaged in hands-on experiences, operating machinery, participating in mock job interviews, and building connections with potential employers actively seeking new talent.

“The AED Foundation is committed to equipping the next generation with skills and opportunities,” said Sean Fitzgerrel, vice president, AEDF. “We thank the Youth Workforce Development Foundation, the federal government and our industry partners for supporting our vision to bring real career opportunities to students across the nation. Together, we are raising awareness and building the essential connections that will strengthen and secure the future of a skilled workforce in our industry.”

For more information, visit www.aedfoundation.org.

Caterpillar Inc. and Trimble announced the extension of their long-standing joint venture. The agreement includes expanded distribution of grade control solutions in the construction sector to accelerate innovation and customer adoption.

Since 2002, the Caterpillar Trimble Control Technologies (CTCT) joint venture has led the industry in grade control solutions, delivering products that contribute to jobsite safety and productivity.

The renewed agreement will increase industry reach and provide customers broader availability of interoperable grade control solutions via a flexible platform for use by Caterpillar, Trimble and other technology providers and equipment manufacturers. With a strengthened partnership, this agreement enables both Trimble and Caterpillar to increase innovation and differentiation, develop new offerings and pursue new industry and geographic opportunities.

For Caterpillar customers, there are more ways to access the technology:

• Factory-fit grade options through Caterpillar

• Cat Grade 3D Ready options allow upgrading at any point within the machine lifecycle

• Expanded aftermarket and digital offerings directly through Cat dealers

Trimble customers also benefit from broader availability:

• Continued mixed-fleet support from trusted SITECH dealers

• Expanded distribution network to reach and meet the needs of mixed fleet customers

• Streamlined access to grade control through Trimble Construction One suite of digital solutions further extends Trimble’s construction technology ecosystem

“Trimble’s Connect & Scale strategy has created an ecosystem that empowers customers across both the physical and digital worlds. The next phase of our joint venture will drive innovation

Since 2002, the

in grade control technology to expand the industry opportunity with localized and differentiated solutions while improving technology interoperability,” said Rob Painter, president and CEO of Trimble. “This partnership underscores a joint commitment to connect the office and the field throughout the design-build-oper-

contribute to jobsite safety and productivity.

ate lifecycle of construction projects.”

“Caterpillar and Trimble have a long history of innovating together,” said Tony Fassino, Caterpillar Construction Industries group president. “We are proud of what we’ve developed to help customers optimize their operations, including grade control. Today’s

announcement is a continuation of this collaboration. With a focus on accelerating this leading-edge technology, we are committed to making it easier for customers to acquire and adopt our solutions across Cat and mixed fleets alike.” For more information, visit www.caterpillar.com and www.trimble.com.

Pages 19-23

In the post-pandemic economy, earth-moving equipment dealers struggle with tight competition and shrinking profit margins.

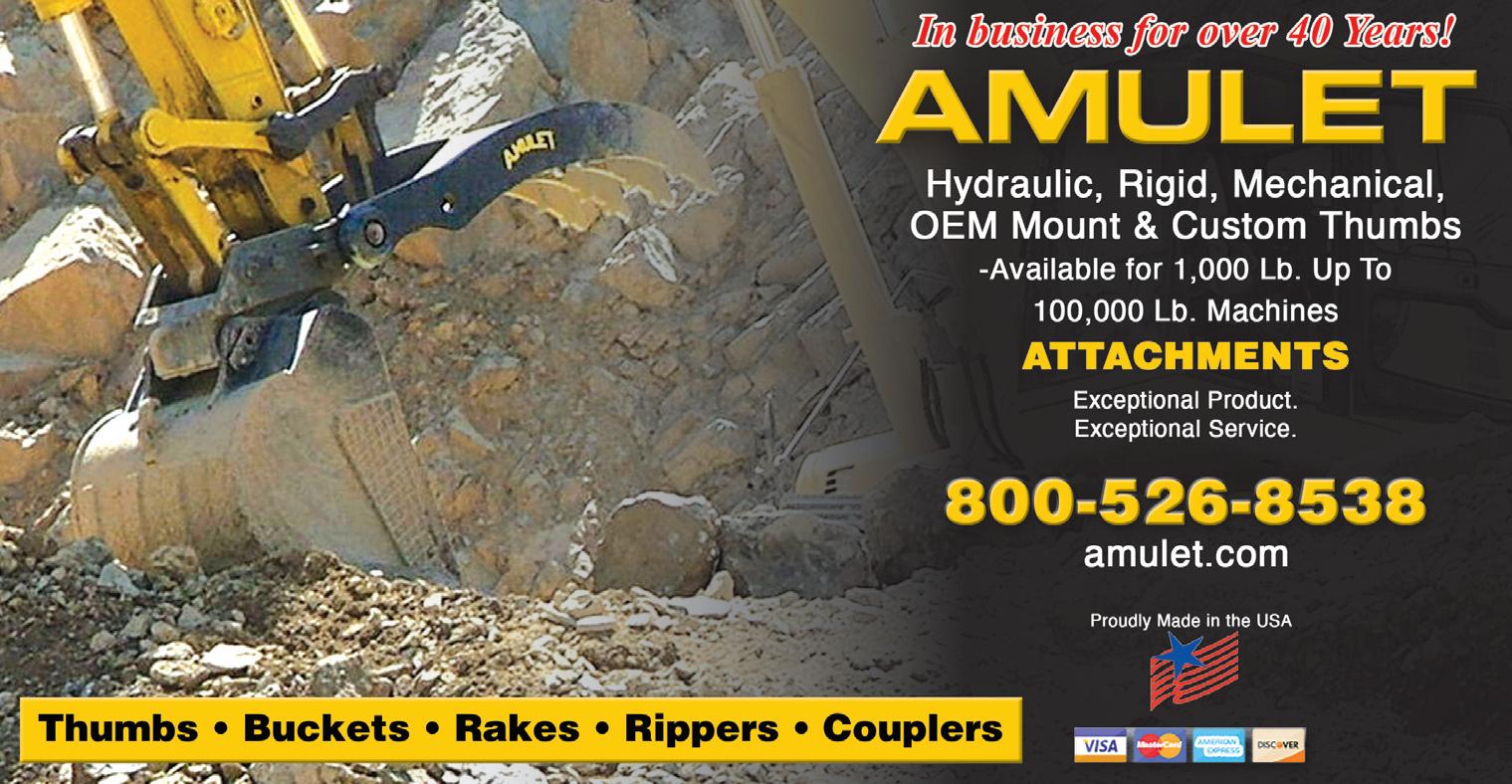

Industry expert Kelly Russell founded HB Attachments Inc. in 2023 to help excavator dealerships in the United States close more deals with higher profits. The startup designs, manufactures and distributes high-quality aftermarket excavator work tools, including buckets, rippers, quick couplers, rakes, thumbs and grapples.

In September, the family-owned business, based in Springfield, Mo., revealed its new brand name: TRUE Attachments.

The profit margin on a new excavator is quite small, so dealerships have very little room to negotiate with potential customers who are shopping based on price. However, sales are typically bundled with a package that includes several attachments designed for the machine’s boom arm.

Finding the right attachment wholesaler can greatly affect a dealership’s ability to craft a competitive yet profitable sales offer.

“I saw a need in our industry for a supplier of high-quality attachments — based in the central U.S. — offering wholesale products at a price that would give a dealer the slight edge they need to win more deals and increase the average margin per deal,” Russell said.

Russell launched the company with a team comprised of loyal family members and opened a warehouse in southwest Missouri. The company distributes its products to dealerships throughout the United States.

The attachments are designed to perform well in a variety of industries, including timber, quarry and mining, oil and gas, as well as construction and excavation, according to the company.

Kelly Russell founded HB Attachments Inc. in 2023 to help excavator dealerships in the United States close more deals with higher profits.

TRUE Attachments currently offers products to fit the following brands of excavators: Case, Kobelco, Komatsu, Kubota, Hitachi, John Deere, Volvo, DEVELON, Hyundai, Takeuchi, Yanmar and SANY.

The company began as HB Attachments — with a honey badger as the mascot — but recently consulted with Midwest marketing

agency Henderson Media LLC on a rebranding package that included the new TRUE Attachments brand name, logo design, domain name registration and upcoming website launch.

HB Attachments Inc. remains the legal entity, doing business as (DBA) TRUE Attachments. For more information, visit TRUEattachments.com. (All photos courtesy of TRUE Attachments.)

Designed to tame even the toughest overgrowth, Diamond Mowers’ excavator brush cutter Pro X cuts through chaos of any size.

Available in 50, 60 and 72 in. cutting widths, it tackles dense brush and trees while getting more done in less time — no matter the difficulty, according to the manufacturer.

The attachment can cut up to 10 in. diameter trees and brush and has flow rates ranging from 16 to 46 gpm to match your existing carrier.

The tri-hex disc on the attachment allows for greater inertia in tough conditions, and the discs are 50,000 psi-rate steel for unparalleled durability and easy blade maintenance. Additionally, the hex blade bolts and hardened inserts

provide the disc with the toughest blade retention in the industry.

These large brush cutters also are designed with three

in. thickness that are built to swing and break away upon contact with rock.

ABILENE, TX • 877-577-5729

AMARILLO, TX • 800-283-1247

DALLAS, TX • 800-753-1247

FT. WORTH, TX • 877-851-9977

HEWITT, TX • 254-261-1370

KENT, WA • 800-869-2425

POCATELLO, ID • 800-829-4450

PORTLAND, OR • 800-950-7779

COLUMBIA FALLS, MT • 800-434-4190

EUGENE, OR • 800-826-9811

LUBBOCK, TX • 866-289-6087 MCALESTER, OK • 918-310-1550 ODESSA, TX • 877-794-1800 OKLAHOMA CITY, OK • 800-375-3339 TULSA, OK • 800-375-3733 MISSOULA, MT • 800-332-1617 BILLINGS, MT • 800-735-2589 BOISE, ID • 800-221-5211

JEROME, ID • 800-221-5211

ROCHESTER, WA • 800-304-4421

SPOKANE, WA • 800-541-0754

Bobcat Company has been selected as a Red Dot Award: Design Concept winner for RogueX2, an all-electric, fully autonomous concept loader.

The Red Dot Design Award is one of the most respected design awards in the world, with its Design Concept category identifying and celebrating new design concepts and innovations as the precursors of tomorrow’s great products.

“We are honored to win the world-renowned Red Dot Award for Design Concept in recognition of the groundbreaking design of the RogueX2,” said Joel Honeyman, vice president of global innovation at Doosan Bobcat. “This award is a testament to the dedication of the Bobcat teams who are passionate about pushing design limits and advancing innovation to redefine the machines of tomorrow.”

Key to the machine’s development was the Bobcat Global Design Studio, which supported the project in collaboration with the Bobcat Global Innovation team.

On display at CES 2024, the RogueX2 is a powerful, smart machine that produces zero emissions and features a lithium-ion battery, electric drive actuated lift and tilt kinematics with no hydraulics.

Specifically designed and built without a cab, RogueX2 explores the idea of how work machines of the future can be designed and optimized for new technologies and enable an entirely new work experience. Designed with wheels to optimize the electric battery run time, the RogueX2 features axial flux motors, which give the machine incredible tractive effort, the manufacturer said.

The RogueX2 was built as a proving ground to advance Bobcat’s innovation leadership and has garnered many new

The RogueX2 is a powerful, smart machine that produces zero emissions and features a lithium-ion battery, electric drive actuated lift and tilt kinematics with no hydraulics.

patents pending.

“To build a smarter, more sustainable and connected future, we must ask the questions no one else has thought to ask before and invent new solutions that previously did not exist,” continued Honeyman.

In the research and development stage, the award-winning RogueX2 is not commercially available.

The Red Dot Design Award is an annual international

competition that recognizes excellence in design and business. With around 20,000 entries per year, it is one of the biggest design competitions in the world. The Design Concept category features projects in varying stages of development ranging from concepts to prototypes, to almost or fully developed products which are ready for market.

For more information, visit www.red-dot.org.

Yanmar America continued its tradition of giving back to the community with the successful completion of its 3rd Annual Charity Golf Tournament.

Held on Sept. 19, 2024, at the Fields Ferry Golf Club in Calhoun, Ga., the event raised a substantial $15,400 for the Good Neighbor

Homeless Shelter.

A total of 17 teams participated in the tournament, competing for top honors and contributing to the charitable cause. The tournament featured a variety of contests, including a longest drive competition, a closest-to-the-pin contest, and a hole-in-one

challenge for a Yanmar UTV, which went unclaimed.

Following the golf tournament, participants gathered for dinner and an awards ceremony where prizes were distributed to the top-performing teams.

Before the presentation of the donation

check, Doug Belisle from the Good Neighbor Homeless Shelter highlighted the critical role the shelter plays in supporting individuals and families and the significant impact Yanmar America’s donation will make in the lives of those served by the shelter: “We are so thankful for Yanmar America and the sponsors for this tournament for their support in helping Good Neighbor assist the people in our community who are among the most vulnerable.”

Yanmar America would like to extend its sincere gratitude to the sponsors who made the tournament possible:

• Title Sponsor: Wells Fargo

• Awards Sponsors: Marsh McLennan and Ryder System Inc.

• Premium Sponsors: Ember Agency, Northpoint Commercial Finance, GreatAmerica Financial Services and OTR Engineered Solutions

“We are incredibly proud of the continued success of our Charity Golf Tournament,” said Jeff Albright, president of Yanmar America. “This event is a testament to the generosity and community spirit of our employees and partners. The funds raised will directly support the Good Neighbor Homeless Shelter, making a real difference.”

Stellar Industries, a 100 percent employee-owned and -operated manufacturer of high-quality mechanic trucks, cranes, tire service trucks, hooklifts, trailers and service truck and van accessories, announced the launch of the new Stellar TMAX 3T aluminum mechanic truck at MINExpo 2024.

This event marks the introduction of Stellar’s latest innovation ideal for mining and construction industries and beyond.

“We are so excited to unveil the aluminum version of the TMAX 3T mechanic truck,” said Tim Davison, vice president of sales and marketing at Stellar. “This lighter-weight, corrosion-resistant aluminum model exemplifies our commitment to delivering cuttingedge solutions that minimize downtime and enhance operational efficiency and reliability in challenging environments.”

Suited for the demanding conditions of mining operations, construction sites and more, this aluminum variation of the popular steel TMAX tandem axle mechanic truck combines the benefits of lightweight construction with enhanced durability. The TMAX 3T aluminum mechanic truck features increased payload capacity, superior corrosion resistance and an extruded top rail for convenient mounting. It also includes a robust steel crane compartment and a torsion box to withstand the toughest environments.

With a weight reduction of 1,587 lbs. compared to the steel model, the TMAX 3T aluminum mechanic truck maximizes payload and efficiency without sacrificing options or durability. This product launch underscores Stellar’s commitment to providing mining and construction profes-

sionals with a full range of aluminum mechanic truck options.

Stellar display the TM16160/28000 Large OTR tire service truck at MINExpo.

Engineered to meet the rigorous demands of large-scale mining and construction operations, this rugged tire service truck features a 20 ft. body for tire transport, ample compartments for tool storage and is equipped with the Stellar 110P, a two-stage, hydraulic-driven, aircooled compressor that delivers 110 CFM at 175 psi, providing the air power needed for any task.

Stellar’s modified A-frame stabilizer design combines the stabili-

ty of traditional A-frame stabilizers with the flexibility of out-anddown style outriggers. Dual cylinders and modified geometry provide enhanced stability at various widths, ensuring optimal performance on uneven terrain.

The TM16160/28000 features a highly versatile tire manipulator with +80 degrees to -24 degrees of articulation and 315 degree rotation. Continuous rotating pads and a clamping width of 158 in. allow it to handle tire and rim combinations up to 16,500 lbs., while its unique parallelogram design accommodates tires as small as 40 in.

For more information, visit stellarindustries.com.

(Photos courtesy of Stellar.)

Tucson, AZ

520-579-0261 Phoenix, AZ

602-437-0351 Spokane, WA

Richland, WA 509-578-5900

Petersandkeatts.net

John Deere has extended its allied distribution agreement with Douglas Dynamics, parent company of Western Products, to sell and support Western snow and ice removal products for its compact utility tractor and construction equipment lineups through the John Deere dealer network.

Through this newly extended agreement, participating John Deere dealers in the United States and Canada will sell and service Western equipment that is compatible with John Deere compact utility tractor models, as well as John Deere skid steer loaders, compact track loaders, compact wheel loaders and select mid-size wheel loaders.

“Following the success of our initial allied distribution agreement for our Gator line-up, we are thrilled to expand our partnership and offer our customers industry-proven Western solutions compatible with our compact utility tractors,” said Mark Davey, go-to-market

agreement ahead of another busy winter season.”

As it pertains to construction equipment offerings, in addition to the full line-up of compact wheel loaders, skid steer loaders, and compact track loaders, customers with select mid-size wheel loader models also will benefit from this agreement extension.

Western snow and ice control prod uct offerings are now available for the 444 G-Tier, 444 P-Tier, 524 P-Tier, 544 G-Tier and 544 P-Tier mid-size wheel loaders.

“Our construction equipment models, especially our compact equipment machines, are instrumental tools used in snow and ice management applications,” said Emily Pagura, product marketing man ager, John Deere. “With these new snow removal product offerings, our cus

“Our construction equipment models, especially our compact equipment machines, are instrumental tools used in snow and ice management applications.”

WESTERN from page 27

This agreement enables customers looking to expand their portfolio of snow and ice management solutions to purchase and service their John Deere machines and Western snow and ice removal products in one convenient location, streamlining support and getting customers back on the job sooner, the companies said.

“We are proud of our partnership with John Deere, which has developed over the past four years and has been well-received by dealers and customers alike,” said Michael Frank, manager of business development of Douglas Dynamics. “We continue to drive inno vation and expand our offering to include larger, commercial-grade snow and ice control equipment such as the PILE DRIVER line of pusher plows and Compact Tractor solutions that move massive amounts of snow and raise the bar on efficiency. We are pleased to build upon the success of our partnership with John Deere to include their compact utility tractors and construction equipment segments.”

Initial product offerings for compact utility tractor and construction models include the following Western snowplows and spreaders:

• IMPACT Heavy Duty Straight Blade Snowplow

• IMPACT Heavy Duty V-Blade Snowplow

• ENFORCER Hydraulic V-Blade Snowplow

• MVP3 Hydraulic V-Blade Snowplow

• PRO PLUS Straight Blade Snowplow

• PRODIGY Winged Blade Snowplow

• WIDE-OUT Adjustable Winged Blade Snowplow

• DROP 250 & 600 Stainless Steel Drop Spreaders

• LOW-PRO Broadcast Tailgate Spreaders

• PILE DRIVER Pusher Plow with TRACE Edge Technology

• PILE DRIVER XL Hydraulic Wing Pusher Plow with TRACE Edge Technology For more information, visit www.JohnDeere.com and www.westernplows.com.

Kirby Cline of Masaba talks with customers about Masaba’s conveyor systems and material handling equipment.

Representing Bedrock are Marcos Olivares (L) and Brian You. The company provides heavy machinery attachments for the construction, mining and forestry industries.

DIG from page 1

$28,570 in ticket sales.

Sponsorships raised $84,500, while a silent auction generated $2,968. Day of revenue enhancers such as hats, T-shirts and an equipment rodeo produced $2,125. The Childhood Cancer Champion brought in $1,625, while general donations accounted for $3,827 and credit card transaction fees added $2,327.

An estimated 9,620 children in the United States under the age of 15 will be diagnosed with cancer this year, according to the American Cancer Society.

Events like Big Dig of Northern Colorado seek to assist in the fight to find more — and better — treatments, uncover factors that may cause cancer and improve cancer patients’ quality of life.

For more information on the American Cancer Society, visit www.cancer.org.

(All photos courtesy of Big Dig of Northern Colorado.) A John Deere excavator provided by 4Rivers Equipment demonstrates its capacities.

machinery can result in additional security investments, further straining project budgets.

Another challenge in combating construction equipment theft is the lack of a standardized registration system, noted Trackunit.

“Unlike automobiles, heavy machinery does not typically have mandated registration akin to vehicle VIN numbers,” said the company. “Nor is there a centralized database for tracking ownership and theft across different jurisdictions.”

Stealing construction equipment is considered a low-risk crime because thieves often don’t get caught.

“This lack of significant consequences further encourages the proliferation of such thefts,” said Trackunit.

Preventing theft is challenging without security measures. Advances in technology and telematics can significantly boost a contractor’s recovery chances.

Mobile surveillance units are self-contained vehicles equipped with state-of-theart technology and tools to monitor locations.

Deploy Surveillance, a mobile unit provider, said these units are ideal for construction sites because they can be quickly deployed.

The units can be set up to monitor the site 24/7 via advanced analytics and an offsite monitoring center.

“If an event is ever triggered, everything is recorded in crystal clear video using combination HD, thermal and night vision cameras,” said the company.

Some units can record and read the license plate of a fleeing vehicle hundreds of feet away, said Deploy.

“The knowledge that the construction site is being monitored can dissuade thieves and vandals from attempting to break in or steal equipment.”

Alarms can be installed on the surveillance units to alert the company’s security team if there is an intrusion or other security breach. This, then, can help to quickly notify law enforcement or security personnel to respond to the site and prevent theft or damage.

“Not only that, but some units have builtin speaker systems that allow the agent to address the intruder live via the mobile surveillance unit,” said Deploy.

The video feeds and alarm systems can be

accessed remotely, and motion detection sensors can alert when there is movement on the site.

Business security system provider Safe and Sound suggests other ways to prevent construction site theft, starting with identifying marks on your assets. Simply engrave serial numbers or other identifying marks on tools and vehicles.

“Most construction materials around your job site are expensive and easily fenced, making them easy targets for potential thieves,” said Safe and Sound.

Copper tubing and wiring in particular demand a high price. Vehicles often lack standardized serial numbers, making them easy to strip for parts to sell.

“Engraving serial numbers or other identifying marks on your tools and vehicles is a great way to start if you’re concerned,” said the security provider. “As a bonus, it can also help keep your records more organized and smooth out your administrative process.”

Fully securing your site requires a construction site security system designed specifically for the construction industry.

That means video monitoring service, time-lapse or motion-activated surveillance cameras in strategic locations. Securing a commercial construction site is generally

done with temporary wireless cameras connected to a cellular network.

Hardwired security cameras are even more powerful than their wireless counterparts for projects that have access continuous power at the site.

“While they’re much more expensive, these edge-solution cameras are typically an entire surveillance system in themselves,” said the security provider.

Some systems are even capable of securing your entire site from a single vantage point. The downside is the power requirement, said the company.

“A cut wire will disable your surveillance, and it will be difficult to trace stolen equipment.”

Back in Oregon, Sorenson told kezi.com he was considering installing cameras or arranging for security patrols on the job site.

But since the two machines were not needed for the next phase of construction, they’d simply been moved away.

“Ideally, we don’t want to mobilize on and off a job site over and over again,” he said. “So, we’d leave the equipment here until the next phase begins. But with the damage that’s been done, it’s not worth the risk. So, we’ll haul it back to the yard and bring it back out.” CEG

For more information on crushing, screening and recycling equipment, visit CEG's Web site at www.constructionequipmentguide.com

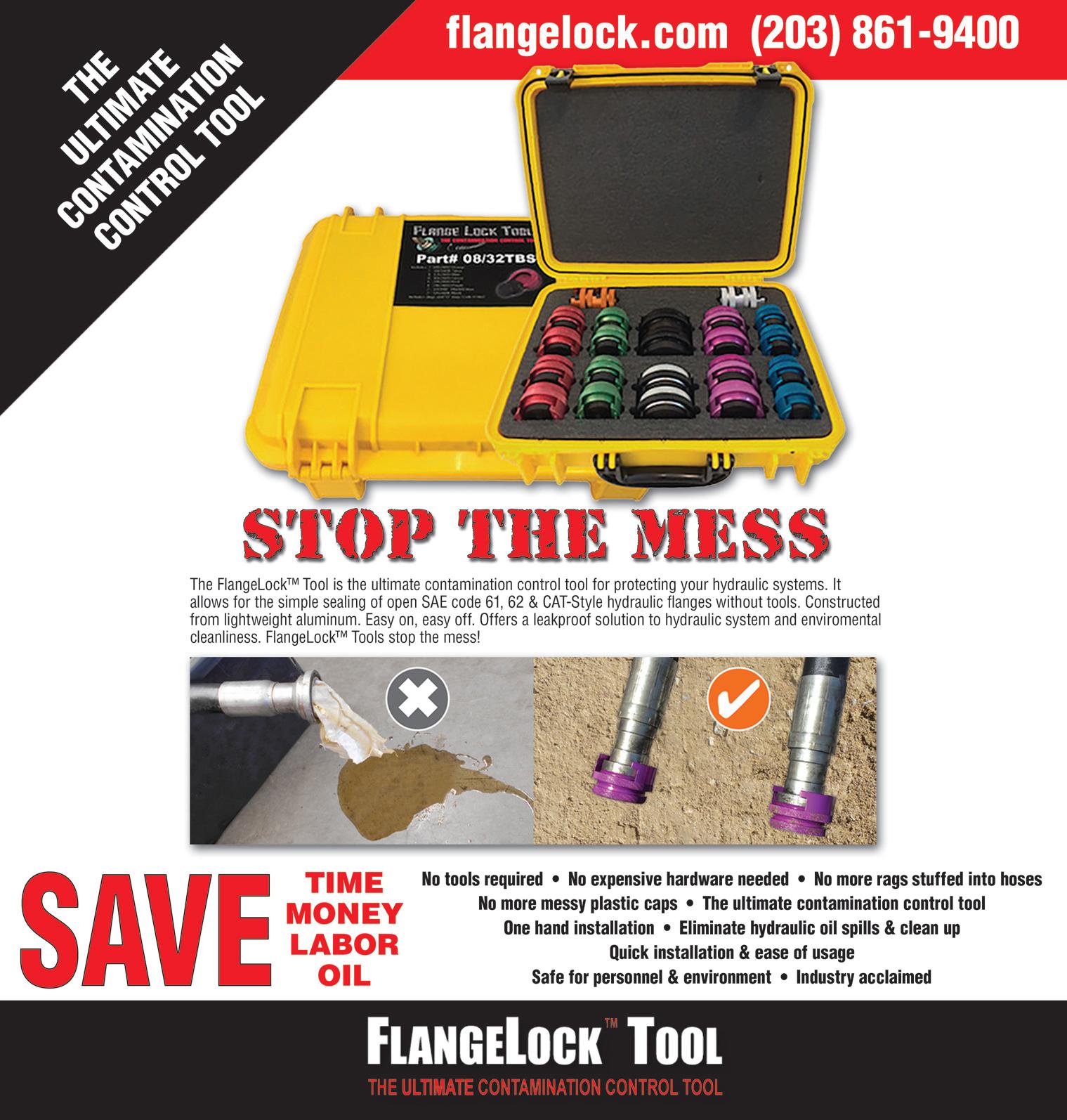

In response to the growing demands of its mining customers, Metso is strengthening its position as a supplier of innovative sustainable solutions with the introduction of its unique circularity process to the North American market.

The mill liner recycling service is a concrete example of how Metso can drive the mining industry towards more sustainable practices and a circular economy. With less unprocessed waste material sent to landfills, recycling helps to reduce CO2 emissions and improve environmental efficiency.

“Metso is expanding its recycling capabilities for the North American market by leveraging our experience with previous operations and customer cases in Europe and South America. Our service model in North America will be based on a modular solution, which gives us an interesting opportunity to bring the recycling process close to customer locations in the United States, Canada and Mexico. The availability of the service will be based on customer needs and demand,” said Giuseppe Campanelli, president North America market area, Metso.

Metso is committed to developing pioneering sustainable technologies and solutions for the global mining industry. Circular economy is one of the important areas of sustainability development throughout the industry. As part of Metso’s extensive mill lining offering, the company is developing ways to increase the use of recycled materials in liners to further close the circularity loop.

The recycling service is facilitated by an innovative technology that enables safe and efficient separation of different rubber and metal liner components, like cast inserts, wear plates and backing plates. Composite liners, like Megaliner and Poly-Met liners, can be processed using this solution.

“As a responsible supplier and partner for sustainable wear solutions, we have set ambitious targets to help our customers reduce the environmental impact of mining in the different stages of the production process. Metso’s unique solution enables the efficient separation of different liner materials so that the valuable components can be reused in the manufacturing of new products,” said Markus Marttiini, vice president, Optimized Mill Lining products, Metso.

The pioneering recycling service is a part of Metso’s Planet Positive offering.

Metso has a long history in solutions for mill liner recycling. The first feasibility studies were conducted back in 2009, with a formal recycling program initiated in 2015, and the important milestone of 1,000 recycled Megaliner liners achieved in 2016. After careful studies and customer pilots, in 2022 Metso launched a new separation unit for its customers in Europe, followed by its introduction in March 2024 to the South American market in Chile.

Metso also has an existing recycling process for metallic mill liners.

For more information, visit www.metso.com.

Metso highlighted its industry-leading sustainable technology and pit-toport aftermarket solutions including the revolutionary mill liner recycling concept at MINExpo INTERNATIONAL 2024, in Las Vegas.

The new PMM/RCU75 swinging hammer mulcher features a hydraulic hood for better control of the outflowing material, a support roller with integrated skids, a trapezoidal belt transmission and interchangeable protection chains.

The PMM/RCU75 is an efficient solution for mulching grass, brambles, twigs and small shrubs up to 3 in. in diameter.

FAE enhanced the versatility of its RCU75 remote controlled tracked carrier with the new PMM/RCU75 swinging hammer mulcher.

The PMM/RCU75 is an efficient solution for mulching grass, brambles, twigs and small shrubs up to 3 in. in diameter. This head features a hydraulic hood for better control of the outflowing material, a support roller with integrated skids, a trapezoidal belt transmission and interchangeable protection chains.

The PMM/RCU can be equipped with PMM hammers or Y/3 flails.

For more information, visit www.fae-group.com. (Photos courtesy of FAE.)

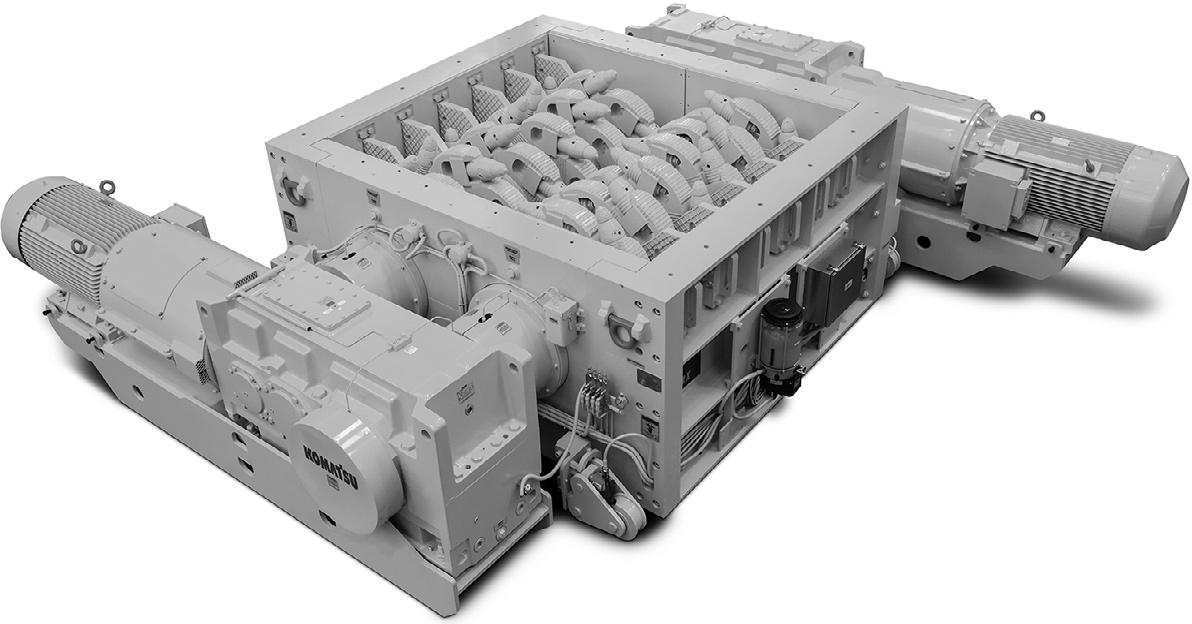

Komatsu announced the expansion of its hard rock crushing equipment portfolio with the introduction of the HRX800 sizer, an innovative solution designed to enhance efficiency and productivity while reducing waste.

This product line extension underscores Komatsu’s commitment to providing customers with robust, high-performing machines that drive production growth and add value to their mining operations, according to the company.

Komatsu’s comprehensive crushing lineup includes feeder breakers, reclaim feed ers, mobile crushers and sizers, all engineered to meet the demanding needs of modern mining operations.

The HRX800, launching at MINExpo 2024, represents the next step in Komatsu’s evolution of crushing technology. Designed for hard rock applications, the HRX800 is a smaller-scale alternative to the HRX1000, providing the same high capacity and efficiency in a more compact form. This sizer is ideal for both underground and surface installations, offering the benefits of fines reduction in demanding applications of hard abrasive minerals or wet and sticky material.

Komatsu photo Designed for hard rock applications, the HRX800 is a smaller-scale alternative to the HRX1000, providing the same high capacity and efficiency in a more compact form.

“We are excited to introduce the HRX800 to our

Brandon Phillips, global product manager of sizers and feeder breakers at Komatsu. “The HRX800 is designed to push the envelope on where sizers can be successfully applied, delivering the power and performance our customers expect from Komatsu while offering the flexibility needed in

The HRX1000 is designed to accept run-of-mine materials and crush them to a size suitable for conveyor transport, making it a crucial component in mining operations that demand high production capacity. The HRX1000’s innovative pick technology efficiently breaks down minerals in tension, reducing the need for multiple crushers and lowering operating costs. Its versatility makes it an invaluable asset in a wide range of mining applications.

For more information, visit www.komatsu.com.

Terex Campsie, the manufacturing center for leading Terex brands including Terex Ecotec, Green-Tec, and ProStack, celebrated its 5th anniversary since opening in 2019. Over the past five years, the facility has become a key engineering and manufacturing facility for Terex, playing an essential role in advancing its brands across the waste management, recycling and bulk material handling industries.

Jonathan Hanna, general manager of Terex Campsie, said, “These past five years

have been a testament to the dedication, innovation and passion of our team at Terex Campsie. From the very beginning, our goal was to be at the forefront of the waste management, recycling sectors and conveying sectors, and today we are proud to see how far we’ve come.

“Our team has made significant strides in production capacity, product development and safety, and we look forward to many more years of success.”

In its first year, the facility quickly became

home for Terex Ecotec and Terex Conveying Systems. Just a year later, in 2020, a 30,000sq.-ft. expansion was completed, allowing for the addition of the ProStack product line. Production has seen substantial growth, with the facility reaching its 100th machine in 2020, 500th in 2022, and its 1,000th machine— the TDS 815 Slow Speed Shredder—in 2024.

Throughout this growth, the site has maintained a strong commitment to safety, celebrating 1,000 days without a lost-time inci-

dent in September 2024.

Employment at Terex Campsie expanded from 15 employees in 2019 to over 150 today, reflecting the site’s ongoing development and investment in local talent.

Terex Campsie’s expansion has not only facilitated the production of industry-leading products but also enabled the site to drive a proactive product development strategy. This approach has resulted in a 50 percent expansion of operations since 2019, and output has tripled compared to its early years. Terex Campsie continues to serve global markets, exporting machines worldwide and reinforcing Terex’s position as a leading manufacturer of advanced environmental and conveying equipment.

“The last five years have been an incredible journey and reaching our 1,000th machine production milestone was a proud achievement for the entire team,” Hanna said. “While current market conditions have presented challenges, we remain committed to focusing on innovation, safety, and operational efficiency. As we navigate these times, our focus is on building a resilient foundation that positions the site for future growth and continued leadership in the waste management, recycling and conveying sectors.”

An updated jaw pin is included on all future Lippmann models and can

ted on most current models in the field.

to its robust

systemcontrolthatreducestheriskofoperatinge variety of applications. The coarse screening plant locations and new operating conditions - making i range of screen linings, the MSS 802 EVO can eas

error.Andallrelevant features an intuitive t ideal for a wide ily adapt to changing design and extensive solution in natural stone safetyTheMOBISCREE functions can be operat safety The MOBISCREE system control that redu

ed from a safe distance for EN MSS 802 EVO - the heav .wirtgewww uces the risk of operating e

and recycling.

www.kirby-smith.com

TX 806-373-2826

TX 214-371-7777

Worth, TX 817-378-0600

Abilene, TX 325-692-6334

Hewitt, TX 254-261-1370

Lippmann, a manufacturer of aggregate processing equipment, announces its newly enhanced jaw safety pin. Underscoring the company’s dedication to advancing workplace safety, the pin is designed to lock the pitman securely in the forward position during maintenance or repair and is now available for retrofit on select existing jaw models and comes standard on future jaw crushers.

roup.com/klen-g error. And all relevant

www.nuecespower.com

956-725-0066 San Benito, TX 956-361-0066 Victoria, TX 361-576-0066 Vinton, TX 915-541-0066

The jaw safety pin is designed to prevent accidental pitman movement, a critical safety feature during servicing. With features such as a pinned locking mechanism and vertical storage location to prevent damage, Lippmann’s latest design aims to enhance safety while offering ease of use.

“We’ve prioritized safety in all our designs, and the jaw safety pin is no exception,” said Danny McElchar, director of engineering of Lippmann. “While safety pins exist on other jaw crushers, we’ve responded quickly to customer feedback to make this feature available not just for future models, but as a retrofit kit for existing customers as well.”

The updated design includes a new hole on each side of the jaw box, a boss and a brace added to the jaw box rib. Some models also will incorporate a modified cheek plate or side liner to accommodate the new locking pin system, which allows for safe pitman positioning during service. Additionally, decals provide clear instructions on proper usage of the pin, ensuring operators are aware of the safety features.

For more information, visit LippmannMilwaukee.com.

3100 N 1st Street Bloomfield, NM 87413 505-324-8601

4304 Monica Lane Carlsbad, NM 88220 505-485-1700

1181 Burgundy Drive El Paso, TX 79907 915-872-1001

25015 S McQueen Road Chandler, AZ 85249 602-463-3772

3300 E. Michigan Street Tucson, AZ 85714 520-649-2858

towers, which was preceded — in true Las Vegas fashion — by a seven-minute fireworks and 555-drone show.

“It was a remarkable end result for everyone to watch and see. … This definitely set a standard for whoever is doing the next one,” said Vince Gutierrez, the on-site senior project manager of GGG. “It’s a nice way to say goodbye to an iconic standard like the Tropicana.”

The site will be redeveloped into a $1.5 billion, 33,000-fan capacity domed baseball stadium for the relocating Oakland A’s. The stadium will encompass about nine of the 35 acres on site, with Tropicana owner Bally’s Corp. planning to build a future resort on the remainder, according to the Las Vegas Journal-Review.

CDI has plenty of familiarity with Las Vegas, having leveled 32 other buildings there, with company President Mark Loizeaux on site for every strip property, including the Dunes in 1993 and the Riviera in 2016.

Loizeaux said the implosion went off without a hitch and the company maintained a perfect record.

“There was not a single window broken,” he said, adding that the post-blast report showed less than expected levels of resulting dust. “It went exactly per plans. … They have two well-broken piles of debris.”

Although both the Paradise Tower closer to Las Vegas Boulevard and Club Tower were imploded simultaneously, different methods were used, Loizeaux said. The two towers combined housed 917,400 sq. ft. and required 22,000 ft. of detonating cord.

And while the blast itself was routine, the contractor,

whose company debuted in 1947 by felling a chimney, was surprised at how well the two towers were built.

The Club Tower was concrete framed, so dynamite was used to knock it down. Certain pillars were blasted with dynamite to weaken them. Those pillars, therefore, couldn’t support the building’s weight, prompting a collapse.

“It had more rebar in it per yard of concrete than I had ever seen,” Loizeaux said, adding that the 1,130 boreholes drilled into it required diamond core bits instead of the usual pneumatic drills.

Gutierrez noted that the diamond core bit drilling took a lot longer than pneumatic drilling, stressing the project’s timelines.

Meantime, the Paradise Tower was steel framed, prompting a different method.

“It was a very robust, well-built structure,” Louizeaux said, noting that commercial facilities don’t often use that level of construction.

To topple the Paradise Tower, a charge sent copper into the steel, weakening it. Linear-shaped charges that created 3 million pounds per square inch of pressure were placed on five different floors, Loizeaux said. There were 220 cut-point locations in the tower.

“To use an overused analogy, if you have a soft stick of butter and you put a knife through, it doesn’t melt the butter. It doesn’t vaporize it. It just shoves it sideways. That’s what the copper does,” Loizeaux told fox5vegas.com before the implosion.

Las Vegas is known for spectacles and this implosion was no exception, but Loizeaux explained why the implosion occurred at 2:30 a.m. local time on a Tuesday.

“Clark County says there’s the least activity on Las Vegas Boulevard at that time,” he said. “Also, historically, the lowest winds are at night, keeping the dust from moving around.”

IMPLOSION page 50

OEM authorized mining dealer www.coremachinery.com

Phoenix, AZ 480-545-2400

Bakersfield, CA 661-695-4830 Mojave, CA 661-824-2319 Perris, CA 909-355-3600 www.wpi.com 12320 S.

Phoenix, AZ 602-252-7121

Prescott, AZ 928-778-5621 Tucson, AZ 520-623-8681

*Formerly Road Machinery

Corpus Christi, TX 361-884-8275

Edinburg, TX 956-386-0107

Kilgore, TX 903-984-2011

Lufkin TX 936-243-6056 Pflugerville, TX 512-251-0013 Port Arthur, TX 409-721-5305 San Antonio, TX 210-648-4444 Tomball, TX 281-351-9016

Cheyenne, WY 307-634-5149 Durango, CO 970-259-0455 Albuquerque, NM 505-345-8383 Bloomfield, NM 505-324-8601 Carlsbad, NM 505-485-1700

www.powermotivecorp.com Corporate Office 5000 Vasquez Blvd., Denver, CO 80216 303-355-5900 Colorado Springs, CO 719-576-5541 Grand Junction, CO 970-241-1550 Milliken, CO 970-587-1188

El Paso, TX 915-872-1001 Chandler, AZ 602-986-3003 Phoenix, AZ 602-463-3772 Tucson, AZ 520-649-2858

www.geehm.com

5461 S Nikita Avenue Fresno, CA 93725 559-834-3149

1164 Prestige Way Redding, CA 96003 530-229-3820

3650 Seaport Blvd. West Sacramento, CA 95691 916-375-3540

3350 Regional Parkway Santa Rosa, CA 95403 707-544-4147

45051 Industrial Drive Fremont, CA 94538 510-955-1170 NOW OPEN!!

IMPLOSION from page 1

Speaking of dust, Loizeaux praised GGG for its advance work.

“They did as good a job supporting CDI as any contractor I’ve worked with,” he said.

GGG “soft stripped” the buildings, removing things such as carpeting and drapes and also eliminated “dust creators” such as drywall. They also recycled concrete on site.

“Now, after the implosion, we will be getting the site clean, from the debris piles to removing foundations to grading the property,” Gutierrez said.

Gutierrez said he expects the process to take three or four more months.

The concrete will be cleaned, processed and crushed, then sold as a base material for roadways and parking areas. The steel and metal will be removed from the concrete and sold to a recycling center, Gutierrez said.

“The structures you see — 98 percent will be recycled,” he said. “There will be very little that will be required to be moved to a landfill.”

The sheer size of the project has created challenges for the contractors, Gutierrez said. One challenge was finding the specialty labor needed. While that labor is plentiful in GGG’s southern California home, it was less plentiful in Las Vegas, creating worries about safety, reliability and productivity.

“At our peak, between our labor and our subs. we had 120-130 guys on site,” he said.

In addition, there was a lot of coordination required between the contractors, Bally’s, government agencies and site neighbors.

“As much as we thought we were on top of talking to agencies and neighbors … there were last-minute issues that had to be dealt with,” Gutierrez said, adding that the contractor has a great relationship with Bally’s.

Heading the effort to level the nine structures originally on site, Miller Environmental of Orange, Calif. (the parent company of GGG) assembled an armada of equipment, including at least 10 Link-Belt excavators, a host of attachments and support equipment.

“When we first got on site in March, we dealt with some minor asbestos abatement,” said Gregg Miller, ME’s president and owner, in a previous Construction Equipment Guide article. “Despite the Trop’s age, there had been so many additions and renovations over the years that the bulk of the asbestos had already been removed. We quickly moved to demoing 100,000 sq. ft. of smaller three- and fourstory structures that were part of the original Trop layout.”

Though dwarfed by most of the newer mega properties on The Strip, the Trop complex contained more than 1.7 million sq. ft. of structures, including the towers, a pair of parking garages (one above ground, one below), a pool/spa area, a theater, the casino gaming area and 184,000 sq. ft. of support facilities.

“Because we plan to recycle the concrete and steel from each structure, we are choosing to gut each structure before implosion,” he said. “If we were to simply drop the structures as they are, we would contaminate that valuable debris with all the building components: the walls, the ceilings, the carpet, furniture and so on.

“So, working from the ground up, we are tackling an interior demolition effort, three floors at a time. We have a dozen Bobcat loaders — two on each floor of each tower — gutting the rooms, punching a hole in the exterior wall, and pushing the debris to a pile below.”

By project’s end, Miller estimated they will recover about 180,000 tons of concrete and asphalt and 9,000 tons of ferrous/nonferrous metals.

The Tropicana debuted on April 4, 1957, and closed on April 2, 2024, two days shy of 67 years, according to Las Vegas Weekly.

It opened with 300 rooms and cost a then-record $15 million to build, according to Newsweek. It was the city’s largest casino at the time.

When it debuted, it was known as the “Tiffany of the Strip,” attracting stars who visited and performed there. It was featured in movies including “Viva Las Vegas” and “Diamonds Are Forever,” according to Las Vegas Weekly. It

also hosted “Folies Bergere” for 50 years and jazz artists such as Benny Goodman and Louis Armstrong in its Blue Room.

In addition, Rat Packers Frank Sinatra, Dean Martin and Sammy Davis Jr. were all regular visitors.

And the Tropicana had ties to organized crime, according to Newsweek. Mobster Frank Costello had a financial interest in the property when it debuted. In the 1970s, federal officials explored Kansas City mobsters skimming money from the Tropicana and other casinos. Multiple convictions eventually occurred.

The Tropicana’s implosion leaves the Flamingo as the only mob-era casino remaining. CEG

ALASKA NC MACHINERY

www.ncmachinery.com

800-478-7000

Anchorage, AK • 907-786-7500

Dutch Harbor, AK • 07-581-1367

Fairbanks, AK • 907-452-7251

Juneau, AK • 907-789-0181

Prudhoe Bay, AK • 907-659-6900

Wasilla, AK • 907-352-3400

EMPIRE CAT

www.empire-cat.com

1725 S Country Club Mesa, AZ 85210

800-EMPIRE-1

CALIFORNIA HOLT OF CALIFORNIA www.holtca.com Pleasant Grove • 916-921-8969

NEVADA

EMPIRE CAT

www.empire-cat.com 3300 St. Rose Parkway, Henderson, NV 89052

702-649-8777

Elko • 775-738-9871

Reno/Sparks • 775-358-5111

TRACTOR AND EQUIPMENT

www.tractorandequipment.com Williston • 701-572-8377

WYOMING

TRACTOR AND EQUIPMENT

www.tractorandequipment.com

Worland • 307-347-4747

MONTANA TRACTOR AND EQUIPMENT

www.tractorandequipment.com

Billings, MT • 406-656-0202

Billings-Sgt. • 406-245-4426

Bozeman • 406-585-5800

Great Falls • 406-761-7900 Helena • 406-442-2990

TEXAS

MUSTANG CAT

mustangcat.com

Beaumont • 409-892-8412

Bryan • 979-775-0639

El Campo • 979-543-3389

Houston • 713-460-2000

Lufkin • 936-639-5551

WASHINGTON NC MACHINERY

www.ncmachinery.com

800-562-4735

Seattle • 425-251-5800

Chehalis • 360-748-8845 Fife • 253-896-0878

Monroe • 360-805-6000

Mt. Vernon • 360-424-4292

Wenatchee • 509-886-5561 Yakima • 509-248-2371

1090 W 2181 N Salt Lake City, UT 84116

801-322-1300

atlasmachinery.us

6565 Smith Avenue Newark, CA 94560

510-400-5024

1535 SE 25th Street Oklahoma City, OK 73129 405-310-8700

2035 W Mountain View Road Phoenix, AZ 85021 480-463-4999

Equipmentshare.com

To expand its artificial intelligence (AI) capabilities and help customers optimize their mining operations, Komatsu announced its intent to acquire Octodots Analytics, a Chile-based digital solutions provider.

The announcement comes as the company debuts its new Modular ecosystem, a bold vision for the future of mine site optimization and data sharing, at MINExpo 2024 in Las Vegas.

Building upon Komatsu’s DISPATCH fleet management system, the Modular ecosystem is a set of interconnected platforms and products designed to simplify existing workflows.

“Our ecosystem is designed to empower customers to optimize decision making at the machine, mine site and enterprise levels,” said Jason Fletcher, SVP Mining Technology Solutions, Komatsu.

“Octodots’ expertise and solutions map perfectly to what we’ve created and we are excited about the opportunities to incorporate their products and capabilities into our offering.”

Since 2017, Octodots Analytics has been developing and commercializing advanced digital solutions for industries including mining, construction, forestry, transportation and more. The company’s multidisciplinary team has particular expertise in three key areas: mining engineering, transportation and data science.

The Modular ecosystem will provide mining companies the ability to connect data used across their operations, including data from Komatsu products as well as third-party technologies and equipment from other manufacturers.

For more information, visit www.komatsu.com and octodots.ai/en/.

WANTED (US): TAKEUCHI SKID STEER LOADERS, ALL MODELS. TL150, MUSTANG MTL 25TH, GEHL CTL80 TURBO 2 OR CYCLONE AIR FILTER ASSEMBLY AND ACCESSORIES, PLUMBING FROM FILTER AND EXTERNAL SPINNER. EMAIL: AMATZEN@BROOKFIELDR3.ORG; PHONE: 660-734-0452

WANTED (NC): JCB 214E BACKHOE LOADER - HEAVY ROOT RAKE TO REPLACE FRONT BUCKET ON 214E BACKHOE LOADER

EMAIL: NORWOOD1310@GMAIL.COM; PHONE: 910-289-1310

WANTED (NC): JCB 214E BACKHOE LOADER – NEED HEAVY ROOT RAKE TO REPLACE FRONT BUCKET ON 214E BACKHOE LOADER.

EMAIL: NORWOOD1310@GMAIL.COM; PHONE: 910-289-1310

WANTED (NC): JOHN DEERE 12 INCH BUCKETS – LOOKING FOR A 12” BUCKET FOR A JOHN DEERE 310 G BACKHOE.

EMAIL: DANDHWORRELL@CHARTER.NET

WANTED (TX): CATERPILLAR EXCAVATORS, ALL MODELS. EMAIL: MMERRILL@WHEELERCAT.COM PHONE: 801-201-8655

WANTED (US): CASE 650L LGP CRAWLER DOZER – LOOKING FOR CASE 650LLGP BULLDOZER WITH OR WITHOUT ENC. CAB, MODEL YEAR 2010 – 2017, LESS THAN 900 HOURS TRUE HOURS METER AND FRAME, UNDER $35000 US. EMAIL: JEANMAURICEBOUTIN@VIDEOTRON.CA PHONE: 450-346-8975.

WANTED (US): CASE WHEEL LOADERS, ALL MODELS - 521D 521E 521F 621D 621E 621F 721D 721E 721F. EMAIL: FRANKHORAN@GTMIDATLANTIC.COM; PHONE: 800-654-USED

WANTED (US): JOHN DEERE 495D EXCAVATORS; WANT TO BUY JOHN DEERE WHEELED EXCAVATOR 495D & 595D. EMAIL: ILYAS.MTCPK@GMAIL.COM; PHONE: 346-484-0369

WANTED (WORLDWIDE): HITACHI ZW180-6 WHEEL LOADERS. EMAIL: SALMAN.MAYI@GMAIL.COM

WANTED (US): CATERPILLAR 140G MOTOR GRADER - 8000 OR UP SERIAL MODEL. EMAIL: ROYALMACHINERYTRADERS@GMAIL.COM PHONE: 0-33-6059-8261

WANTED (CA): CATERPILLAR WHEEL LOADERS, ALL MODELS. EMAIL: KARLOSZAC15@GMAIL.COM; PHONE: 657-274-8724

WANTED (OR): KOMATSU 3.0 YARD BUCKETS - NEED A 2015 KOMATSU WA270 LOADER BUCKET. QUICK RELEASE STYLE. EMAIL:

BRANDONDANLEY86@GMAIL.COM; PHONE: 1-541-213-4973

WANTED (US): JOHN DEERE 550K LGP CRAWLER DOZER - WANT TO BUY BULLDOZER 550KLGP OT 650KLGP 2021 AND UP. LOW HOURS (UNDER 600), ENC CAB, WINCH. UNDER $100,000 EMAIL:

JEANMAURICEBOUTIN@VIDEOTRON.CA PHONE: 450-346-8975