Written by Leslie Blaize Produced by Stephen Marino

Written by Leslie Blaize Produced by Stephen Marino

Formed in 2009, PLH Group is made up of eleven leading industry companies in the U.S. and Canada that provide services to the electric power line, pipeline, oil field electrical and industrial markets.

Through its pipeline division based in Houston, Texas, PLH provides quality pipeline construction, maintenance and inspection services throughout North America

Despite the challenges of a postpandemic construction industry, PLH has thrived by shifting from creating new pipelines to maintaining existing lines; extending the life of equipment whenever possible and building up a solid safety culture to attract and retain quality employees.

“We use consistent tools that we’ve invested in for safety,” says Peter Howe, president of the pipeline segment. “If we have an incident that incident gets reported within hours on our Industry Safe system. And we have a program called Good Catch where if someone is working on a site and they see an incident or practice that doesn’t look safe, they have the right to go up to the person and suggest a different way of doing it. We document that as a good catch.”

These incidents are reviewed

on a weekly basis so trends can be spotted and addressed at an annual safety conference. Employees who have worked without incident are recognized with awards for safety and professionalism. Maintaining safety and quality employees has been key to PLH’s success. The pipeline division has between 1, 000 and 1, 500 employees throughout the year with August and September being the busiest times. Many employees have been with them for decades.

“Most of our leadership has been with us for 12, 13, 14 years. Those guys are there long-term because they care about the staff. In this industry it’s a really small world. We look after our superintendents and they look after the foremen and those guys look after their craft resources; they come as a team. So we put a lot of effort into making sure we maintain that loyalty and that our people treat each other with respect.”

This loyalty, Howe says, is what first attracted him to the pipeline industry. “I’m a chemical engineer myself,” he says. “I grew up in engineering and construction and two years ago I got the opportunity to join PLH Group… Since then I’ve discovered the loyalty of the teams in this business is tighter than I’ve seen anywhere

else. That helps this to be a very enjoyable business.”

Maintaining this sense of loyalty among team players, he says, helps to ensure that projects are completed successfully. “If we have a tough project, we’re going to put our best people on it to face any issues as they come up,” says Howe.

Key to attracting quality employees

is offering competitive pay. “We make sure that our benefits are incentives and our base salaries are competitive,” Howe says. “People feel they’re respected here and they get paid for the work they’re doing.”

The construction industry has seen its share of challenges in recent years. Between stalled projects

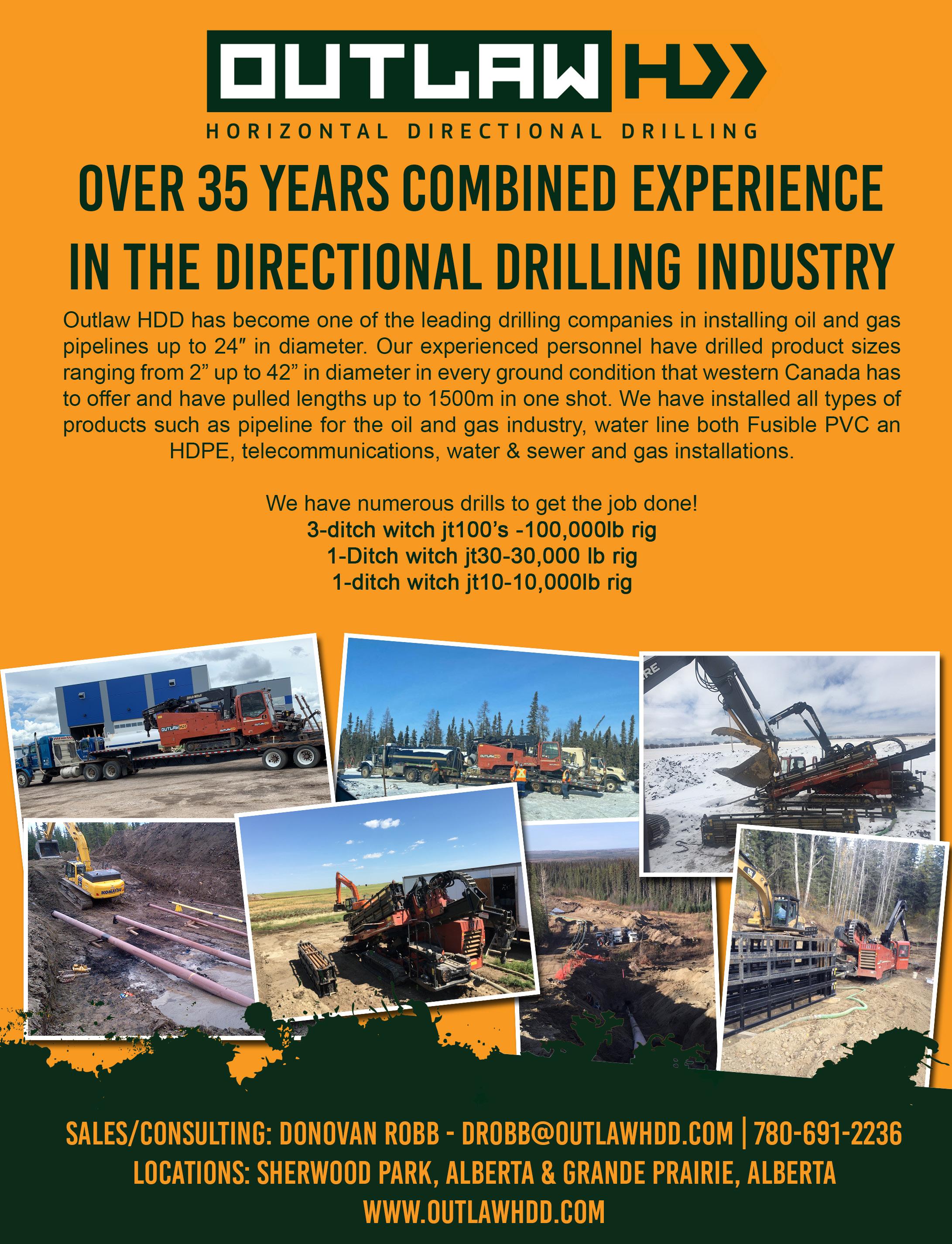

Outlaw HOD Ltd. began its venture into the Horizontal Directional world in 2011 , we started with 1 Brand new Ditch Witch J T 1 00 and a crew of 3 and myself and started our first job October 1, 2011. Myself and my crew weren't new to the industry but we were new to starting a business and having faith and confidence in each other that we will one day become a very successful and well known HOD company in western Canada and here we are today with 5 directional drills , and employees that have been with Outlaw HOD since day 1 .

We pride ourselves on our customer relations which takes us from the offices of our clients to the filed and have built many strong business and personal relationships over the last 11 years , we strive to be the best at our jobs in all fields and aspects of the industry such as safety with a zero incident record and SECOR certified , production -we do what it takes in the safest possible manner to complete each bore no matter what conditions may lay in front of us , we are firm believers that mother nature has helped us along this path of success as we do everything humanly possible to treat the environment that we work in as our own homes

Our clients have also believed in us as much as we have which has been able to help us through some crazy times , ups and down in the oilfield sector and our last challenge which was covid , but through it all we are here today and stringer than ever and for this I thank every single one of my employees and our clients that have supported us along this journey .

As this section in this journal we have be given this opportunity to showcase our company by Pipeworx and would like to thank Pipeworx and every single employee we have worked with from the laborers who stand in the snow and mud and help our crew to the hoe hands , welders, bore foreman , superintendents , project managers , construction managers , office staff in the field and in the office , the office managers , accounting departments , vice president and president of Pipeworx , I would love to name every employee we have worked with but I wouldn't have the room but you all know who you are in the Pipeworx world and without your belief in Outlaw HOD we wouldn't have been as successful as we have become today , so thank you from my self and every employee with Outlaw HOD and I wish everyone much success and good health each and everyday we are all out there doing our best to contribute in our own ways to this great opportunity we have all created as a team and family

Special thanks to my employees : Dane Bawdon-Operations ,driller and field manager, Colin Slobodian-Driller, Trevor Cooper-Locator , Micheal Christopher-mud man.

caused by the pandemic, rising costs of fuel and supplies and challenges in securing permits, it’s not been easy. The government canceling the Keystone pipeline and the fallout of that has had a ripple effect on the industry.

“There are significant environmental pressures against pipelines, mostly oil, but gas as well” says Howe, “There is a lack of understanding in the business that makes permits more difficult to get because environmentalists are fighting those permits, which causes significant delays.

Howe points out that large companies like Precision and MasTec that were taking on big projects just a couple years ago, are now struggling. To stay on top of the game, PLH has had to pivot from building new pipelines to maintaining existing pipelines. They’ve adapted to the equipment shortage by renting whenever possible and working to extend the life of existing trucks and machines they may have put out to pasture a few years ago.

As for ever-changing fuel costs,

and the rising cost of materials like concrete, Howe says PLH often copes by being upfront about extra costs with clients, who often split them.

“If there are struggles, we communicate with our clients early on and typically we can solve these problems together better than we can alone,” says Howe. “One of the most important things is being fully aligned with clients. We focus on making sure that we do what’s required to make them successful.”

To ensure success, PLH vets jobs carefully, choosing the best for their team and subcontracting

when necessary.

“We have close relationships with our subcontractors,” Howe points out. “We know their strengths and that they have the same safety culture as us… If we see a job that has high risks or there are huge safety concerns or we are not qualified to do it, we’ll say let’s not go after that; we’re just not going to be successful. That’s the first step. Identifying projects you should not go after before you go after them.

Despite the fluctuations in revenue that are par for the course in

construction, PLH seems poised to succeed in coming months; Howe is optimistic about the future.

“We spent a lot of time and money to form a consistent safety culture throughout each of our companies.. and a culture of accountability.” he says. “Our business leaders are accountable for what they do. We are a pretty well functioning machine right now.”

Howe measures his own personal success, he says, by how often he gets out every quarter to visit people in the field and have safety conversations about what’s working and what’s not. With the

lines of communication open, he feels confident about the team’s success.

And there are no shortage of projects in the pipeline.

Through one of its companies, Energy Services South, PLH Group is working on a project called the Navigator Borger Express, running 195 miles of pipeline through Oklahoma into the Texas Panhandle. Once completed this pipeline will be capable of transporting 90,000 barrels of domestic crude oil per day from Cushing, Oklahoma to a regional refinery.

PLH Group also recently finished a project in southern California, testing and replacing Line 1600, a 16-inch natural gas transmission pipeline owned by the San Diego Gas and Electric that had not been strength tested in 1949 when it was constructed.

And they are busy working on a Canadian project with another of their companies Pipeworx where they are executing a multiyear project with multiple spreads for a company called Keyera that will go through early 2023.

“It is a significant project for us,” says Howe. “The project is going well and the client is very satisfied.

We have had zero recordable incidents with safety. If you are aligned on the project plan with the client, and identify problems early on, 99% of those projects are successful.”

The construction industry is not for everyone, Howe points out.

“[Volatility] is a fact of life in this business that a lot of people can’t handle,” he says. What makes it worth it for him is the sense of loyalty and community that stems from working in a place where everyone is looking out for each other.

He reflects: “Nothing is more important than running a safe site. This is sacred.”