Issue 1, 2024

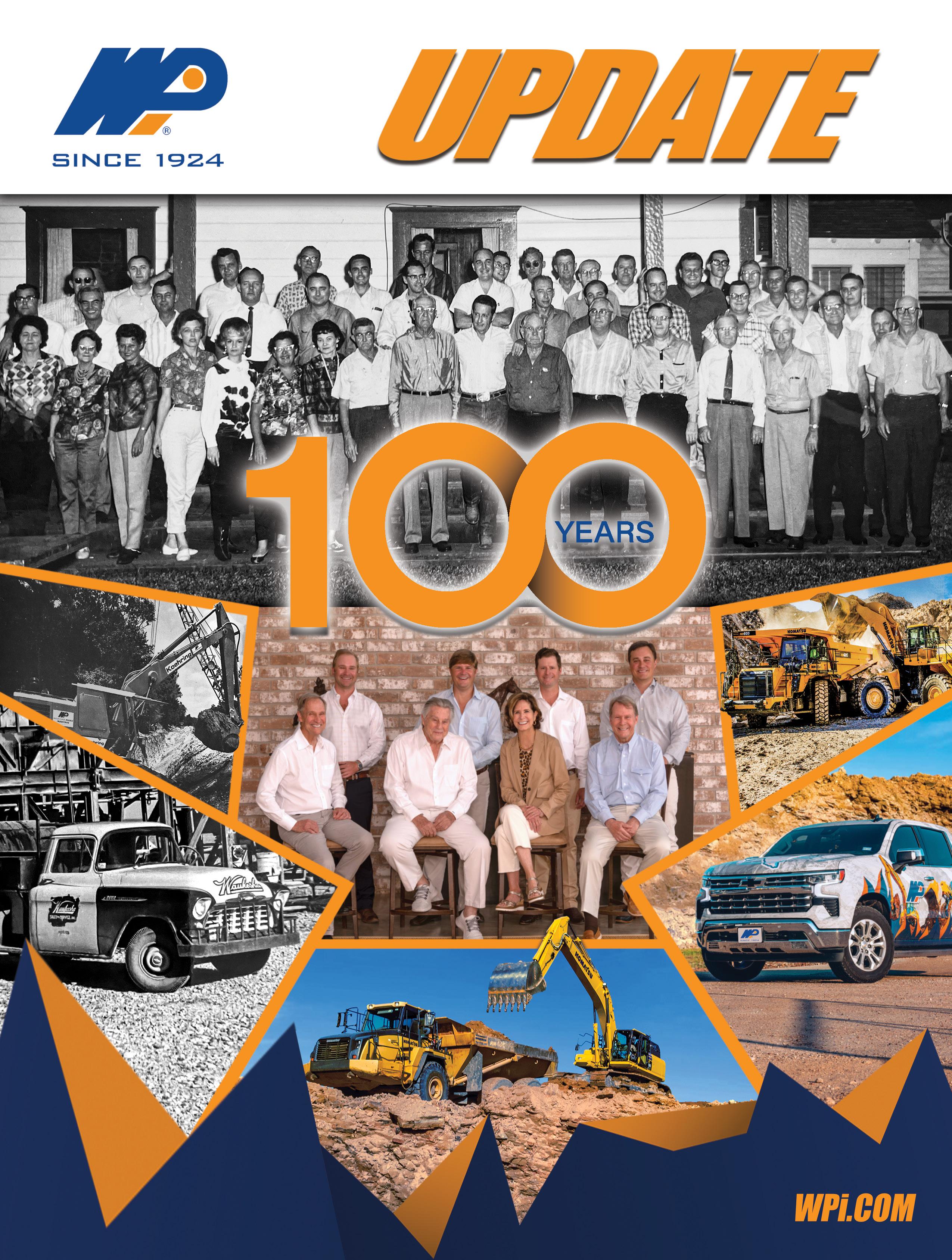

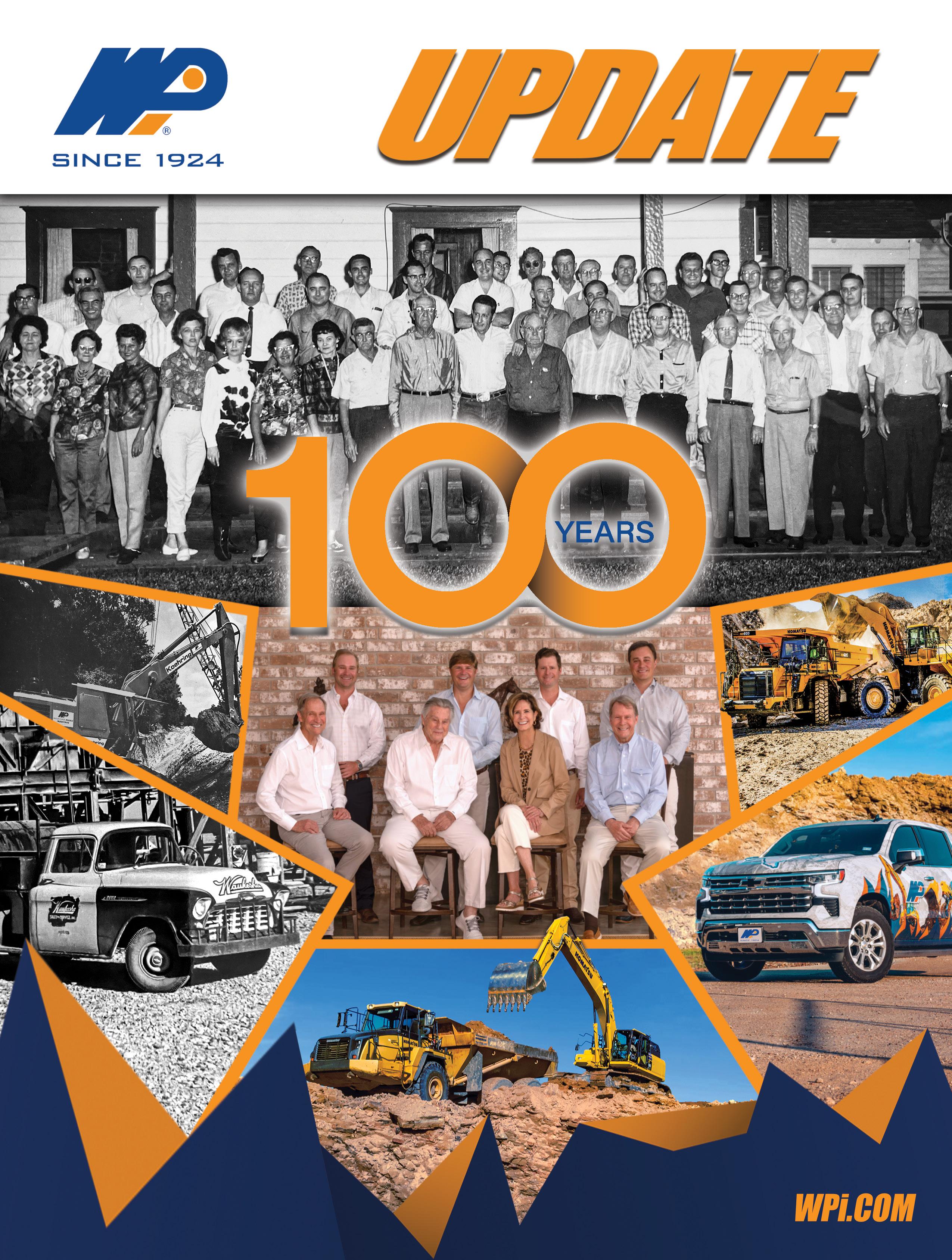

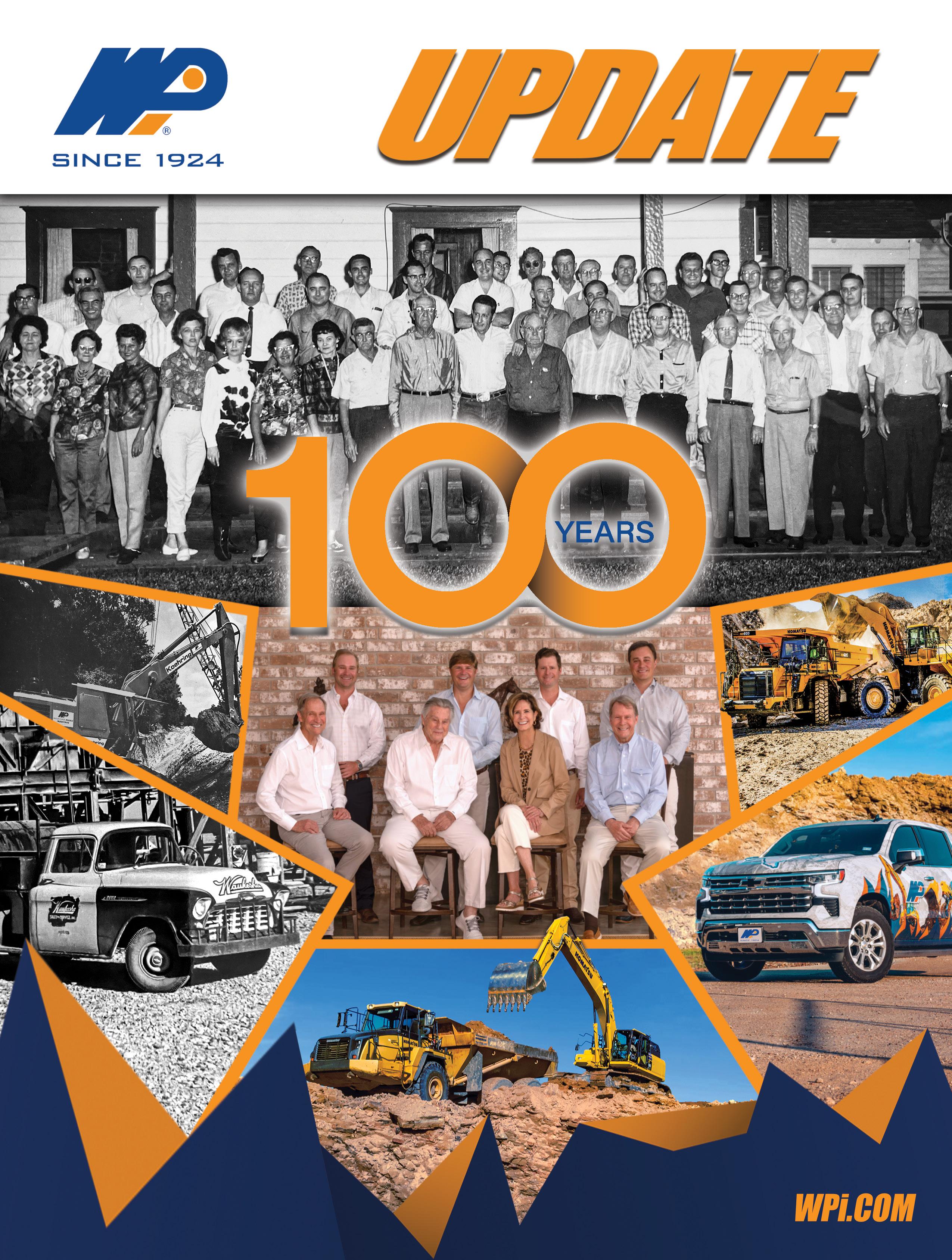

celebrates its 100th anniversary

Dear Valued Customer:

I hope 2024 is off to a great start for you. The forecast looks promising across most sectors of the construction industry, and my hope is that your year is filled with numerous projects.

On a celebratory note, this year is Waukesha-Pearce Industries LLC's 100th anniversary. Thank you for your business and support over the past century. To mark this special occasion, a couple of fourth-generation members of the Pearce family have been promoted into key leadership roles, including Louis M. Pearce IV to Division President of the Engine Division and myself to Division President of the Construction Mining Division (CMD). We look forward to the many exciting opportunities ahead of us.

Recently, Komatsu's Quarry Days took place at Komatsu's Arizona Proving Grounds. Quarry Days offered attendees a chance to see and operate more than a dozen machines, including a Komatsu PC2000-11 surface mining excavator and Komatsu’s new GD955-7 motor grader with a standard 18-foot blade. In addition to equipment, Komatsu representatives from its Smart Quarry solutions and My Komatsu teams were available to show customers the advantages of incorporating technology into their operations. In this issue, you can read all about the equipment and products that were on display at the event.

No matter your machinery or fleet size, My Komatsu can help you manage it better. Now even easier to navigate, My Komatsu lets you get the critical information you need in fewer clicks. You can also see manuals and order parts, including Reman items that could potentially provide you with significant savings.

Additionally, you can access Komatsu’s Smart Construction solutions through your My Komatsu account. Smart Construction solutions can help you maximize productivity and efficiency, and you can incorporate them at practically any stage of the construction process, from pre-bid to production to final closure. Be sure to check out the article on how to choose the best solution for your business.

There are several other articles that I believe you will find valuable as you work on projects now and look to the future.

As always, if there is anything we can do for you, please feel free to contact us.

Division President, Construction Mining Division

Division President, Construction Mining Division

Message from the Division President 2

A

Lloyd R. French IV

WPI

In this issue

D2 Excavating Inc. pg. 4

www.wpi.com

Senior Leadership

Louis M. Pearce III, Chief Executive Officer

Louis M. Pearce IV, Division President, Engine Division

Delve into how this Austin-area contractor focuses on providing quality earthwork in Texas.

Larry Loyd Construction Co. Inc. and Casco Contracting LLC pg. 8

Discover how these two companies team up to complete big jobs.

Choosing the Right Fit pg. 12

Figure out which Smart Construction solution is right for you.

Marking a Milestone pg. 16

Celebrate WPI’s 100th anniversary.

Optimized Experience pg. 20

Learn about My Komatsu’s new features and updates.

Demo in the Desert pg. 22

Explore Komatsu’s Quarry Days.

Investing in the Future pg. 25

Understand the AED Foundation’s Vision 2025 initiative.

Top Honors pg. 26

Find out which Komatsu excavators were featured on a list of top new products.

Timber Talk pg. 29

Take a look at Komatsu’s S92 harvester head.

Serving You Better pg. 31

See how WPI was named the new full-line BOMAG Americas dealer in Louisiana.

Houston 12320 S. Main St., Houston, TX 77035 (713) 723-1050

San Antonio 3740 S.E. Loop 410, San Antonio, TX 78222 (210) 648-4444

Corpus Christi 5226 Interstate I-37, Corpus Christi, TX 78407 (361) 884-8275

Edinburg 5934 U.S. 281 Business, Edinburg, TX 78542 (956) 386-0107

Pflugerville 16029 Interstate 35, Pflugerville, TX 78660 (512) 251-0013 Kilgore 3106 Texas 42, Kilgore, TX 75662 (903) 984-2011

Buffalo 2077 N. Craig Dr., Buffalo, TX 75831 (903) 322-7150

Tomball 1720 Hicks St., Tomball, TX 77375 (281) 351-9016

Port Arthur 8903 Memorial Blvd., Port Arthur, TX 77640 (409) 721-5305

Bryan 5956 E. State Hwy. 21, Bryan, TX 77808 (979) 314-1191

Lufkin 4006 Ellen Trout Dr., Lufkin, TX 75904 (936) 243-6056

Brownsville 7700 Padre Island Hwy., Brownsville, TX 78521 (956) 474-8199

Alexandria 5732 S. MacArthur Dr., Alexandria, LA 71302 (318) 408-3099

Baton Rouge 7502 Pecue Ln., Baton Rouge, LA 70809 (225) 800-3711

Kenner 125 E. Airline Hwy., Kenner, LA 70062 (504) 467-5906 Broussard 5407 Hwy. 90 E., Broussard, LA 70518 (337) 362-4331 Bossier City 5908 Industrial Dr. Ext., Bossier City, LA 71112 (318) 746-5272 Sulphur 2320 Louis Alleman Pkwy., Sulphur, LA 70663 (337) 287-9455

Lloyd R. French IV, Division President, Construction Mining Division

Bruce Truesdale, Executive Vice President & COO

Bobby Slay, Senior Vice President, Earthmoving

Jackie Haney, Vice President, Operations

Scott Smith, Vice President, Sales

Frank Pagura, Vice President, Major Accounts

Ben Sitton, Vice President, Service

Byron Blair, Vice President, Parts Operations

Jeff Cox, Vice President, Commercial Strategies

www.wpi.com

Published for Waukesha-Pearce Industries LLC. © 2024 Construction Publications Inc. Printed in the USA.

3

Austin-area contractor D2 Excavating Inc. focuses on providing quality earthwork in Texas

FFocusing strictly on earthwork has been a major factor in D2 Excavating Inc.’s success during nearly two decades in business. That strategy also appealed to Vice President Jonathan Clarkson and Vice President Eric Houdek, who both joined the company about two years ago.

“I came from general contracting, managing multifamily projects that involved multiple scopes of work,” said Clarkson. “Dealing with one is challenging enough, let alone 20. I really like that D2 focuses just on the earthwork portion, and it’s a lot of fun.”

D2 Excavating is currently solely owned by Nancy Heaton, who helped found the company in 2005. Based in Leander, Texas, D2 Excavating serves about a 100-mile radius of the area and prefers to stay around Austin. Clarkson oversees D2 Excavating’s commercial side, while Houdek oversees its residential. Both operations offer similar services to general contractors throughout Central Texas.

“The initial step is taking care of any clearing,” explained Houdek. “From there, it’s heavy

earthmoving and excavation, embankment, road grading, flex base installation, and getting prepped for curb and gutter and paving. We self-perform anything related to the earthmoving and subgrade, and we sub out the rest such as utilities and asphalt.”

Significant growth

In the relatively short time Houdek and Clarkson have been on D2 Excavating’s team, it has nearly tripled.

“When Jonathon and I started, there were roughly 25 employees, and now we’re up to about 70,” said Houdek. “The growth has been based on client needs as well as good management, operators and machinery. We have developed a list of repeat customers because we’re there from the start to the finish of the project. Our clients call us back because we put out a good finish product, and we take pride in what we do and what we’re selling at the end of the day. We’re also working with new customers and building relationships with them.”

An operator digs and piles dirt with a Komatsu PC290LC-11 excavator.

Eric Houdek, Vice President

An operator digs and piles dirt with a Komatsu PC290LC-11 excavator.

Eric Houdek, Vice President

A Salute to a Customer 4

Jonathan Clarkson, Vice President

D2 Excavating typically has 15 to 20 active jobs in various stages of progress at any one time. Its projects range in size from approximately 3,000 yards of excavation up to about 200,000 yards. A recent 150-lot residential subdivision included road improvements, roughly 50,000 yards of excavation, and about 30,000 yards of embankment for pond building and home development. Additional crews worked on smaller sites, moving 3,000 to 4,000 yards with embankment and putting in select fill as part of school renovations in the Austin area.

“Our people make the company successful — from our estimators to our management to our field staff,” stated Clarkson. “It also comes down to good planning. We set up our jobs so that everyone is on the same page going in, knows exactly what needs to be done ahead of time, and there are no questions when we get on-site.”

Savings with IMC, WPI service

No matter the size of the job site, D2 Excavating uses Komatsu dozers, excavators and wheel loaders that were acquired from Waukesha-Pearce Industries LLC (WPI) with

the help of Austin-based Sales Specialist Cory Webb. Houdek noted that the company prefers to run machines that are three years or newer to help limit the amount of maintenance needed.

“Cory is always ready to answer questions and help with any need we have,” said Clarkson. “We rely on his expertise to choose the right-sized machines so that we get maximum efficiency and production. For many years, that’s primarily been Komatsu because of Cory and WPI’s service, as well as the machines themselves. We have practically no issues with Komatsu, and that reliability is essential to us.”

Webb and WPI have helped coordinate financing through Komatsu Financial and service through Komatsu Care.

“They are with us every step of the machine purchasing and leasing processes,” said Houdek. “We like Komatsu Care because we know the services are done on time, and it frees up our mechanic to work on other things.”

Recently, D2 Excavating added Komatsu D61EXi-24 and D71EXi-24 Intelligent Machine Control (IMC) dozers with factory-integrated GPS to help increase efficiency.

Discover more at WPIUpdate.com Continued . . . 5

On a job site in the Austin area, an operator pushes material with a Komatsu D61EXi-24 Intelligent Machine Control (IMC) dozer. Vice President Eric Houdek commented, “The dozers eliminate a significant amount of surveying, staking and grade checking, which further reduces downtime.”

‘They

. . . continued

are versatile machines’

“We use the D61 on smaller sites and the 71 on larger residential sites; both from rough cut to finish grade, so they are versatile machines that get us through the whole life cycle of a project,” said Houdek. “The dozers eliminate a significant amount of surveying, staking and grade checking, which further reduces downtime. When you can show up to a job site with the model loaded into the machine that gives the operator all the information they need

WPI’s Cory Webb

talks with D2 Excavating’s Eric Houdek

and Jonathan Clarkson at D2 Excavating’s office in Leander, Texas. “Cory is always ready to answer questions and help with any need we have,” said Clarkson.

to move dirt, you can get to work and move dirt a lot faster. The savings we get with the IMC dozers compared to traditional methods are significant.”

D2 Excavating also utilizes standard Komatsu PC210LC-11 and PC290LC-11 excavators for digging, large building cuts and loading trucks, as well as Komatsu WA320 wheel loaders for a variety of tasks.

“Like the dozers, the excavators and loaders fit well on our smaller projects, and we can put them on larger sites and still get the same mission accomplished,” said Houdek.

Fine tuning

Having come from larger companies, Houdek and Clarkson are more than satisfied with the growth D2 Excavating has made in the last few years.

“I think the goal for D2 Excavating would be to continue to operate at a similar size but to fine tune the operation even more so that we can do better for our clients,” stated Houdek. ■

*The opinions expressed here are from the end user as quoted. The results described herein are those of these end users under certain conditions. Individual results may vary.

D2 Excavating uses Komatsu WA320 wheel loaders to move dirt and load trucks.

D2 Excavating uses Komatsu WA320 wheel loaders to move dirt and load trucks.

6

(center)

(left)

Hydraulic Hammers

Houston, TX • (713) 723-1050

San Antonio, TX • (210) 648-4444

Corpus Christi, TX • (361) 884-8275

Edinburg, TX • (956) 386-0107

Pflugerville, TX • (512) 251-0013

Kilgore, TX • (903) 984-2011

Buffalo, TX • (903) 322-7150

Tomball, TX • (281) 351-9016

Port Arthur, TX • (409) 721-5305

Bryan, TX • (979) 314-1191

Lufkin, TX • (936) 243-6056

Brownsville, TX • (956) 474-8199

Alexandria, LA • (318) 408-3099

Baton Rouge, LA • (225) 800-3711

Kenner, LA • (504) 467-5906

Broussard, LA • (337) 362-4331

Bossier City, LA • (318) 746-5272

Sulphur, LA • (337) 287-9455

Scan the QR code to explore our site for more information. Providing the productivity you want and the reliability you need! PH Series: 150-1,300 ft. lb. Impact Energy Class Scan the QR code to explore our site for more information. npkce.com NPK MANUFACTURES AND MARKETS THE GREATEST SELECTION OF: Hydraulic Hammers • Compactors • Sheet Pile Drivers Concrete Crushers • Material Processors Demolition Shears • Demolition Grabs • Pedestal Breaker Systems Scan the QR code to explore our site for more information.

Providing the productivity you want and the reliability you need! PH Series: 150-1,300 ft. lb. Impact Energy Class / Carrier Range 1-8 Metric Tons Scan the QR code to explore our site for more information. npkce.com NPK MANUFACTURES AND MARKETS THE GREATEST SELECTION OF: Hydraulic Hammers • Compactors • Sheet Pile Drivers Concrete Crushers • Material Processors

Shears • Demolition Grabs • Pedestal Breaker Systems

Demolition

construction.wpi.com

Larry Loyd Construction Co. Inc. and Casco Contracting LLC team up on large sitework projects

Chad Hambacher, President/Owner, Larry Loyd Construction

Chad Hambacher, President/Owner, Larry Loyd Construction

Jerrett “Buster”

Casadaban, Operations Manager, Casco Contracting

BBy its nature, the earthmoving industry is competitive with companies bidding against each other to get coveted projects. There are rare exceptions, such as when Louisiana contractors Larry Loyd Construction Co. Inc. and Casco Contracting LLC team up to complete big jobs.

“We have been working together for probably 12 years or more and have developed a good relationship,” said Chad Hambacher, President/Owner of Abita Springs-based Larry Loyd Construction. “The job we are currently doing near Ponchatoula is a great example. We sat down and developed a plan of how much equipment and how many people we needed and went at it.”

Larry Loyd Construction serves as the general contractor for the sitework on the approximately 60-acre project with Covington-based Casco Contracting as a subcontractor. Both are performing a similar scope of work that includes everything from clearing to finish grade for a new water bottling facility.

“We work really well together, and we don’t really view ourselves as being competitors,” stated Jerrett “Buster” Casadaban, Operations Manager for Casco Contracting. “On these larger projects, it’s easier on both of us. They bring part of their staff, and we bring part of ours, and we do the job.”

Casco Contracting operators use Komatsu D51PX dozers for mass material movement. “The D51 is a great in-between dozer because it will push a lot of material, but it’s small enough to work on some more compact sites,” said Operations Manager Buster Casadaban. “The Komatsu dozers with the slant-nose are the best on the market because the visibility to the blade is great.”

The two companies began the project in March and expect it to last about a year. Located next to the Tangipahoa River, the site was formerly wooded and privately owned. Casco Contracting and Larry Loyd Construction teamed up on clearing before commencing bulk earthwork operations.

“The site was fully wooded with a lot of massive trees,” said Casadaban. “After we had those taken care of, we could start moving dirt. It was a low-lying area, so it had to be built up. We hauled in about 100,000 yards of red clay for structural fill, and there will be about 350,000 yards of on-site material that has to be moved.”

Larry Loyd Construction Supervisor Jessie Stewart is overseeing the project and said it’s going as expected.

“The building pad is about 400,000 square feet, and in addition to putting that on grade, we’re building ponds, putting in subsurface drainage, and constructing the subgrade for parking,” said Stewart. “We don’t view anything as strictly Casco’s or Larry Loyd’s. Whatever needs to be done, we get after it together.”

A wealth of experience

Both companies have a wealth of experience to draw from to get projects like this done on schedule. After several years of working for other companies, Hambacher purchased Larry Loyd Construction about 20 years ago to be closer to home because he was starting a family.

At the time, Larry Loyd Construction had been in business for nearly 30 years and was focused on residential subdivision work with about a dozen employees. Today, the company continues to serve southern Louisiana with approximately 40 staff members — including Stewart, who is Larry Loyd’s nephew.

“I actively sought growth, specifically branching out to do more commercial work in an effort to expand,” said Hambacher. “That helped us go from doing about $3 million per year to about $20 million today. We typically have six to eight projects going at one time, and those range from $500,000 up to $10 million in size.”

Casco Contracting is owned by Casadaban’s wife, Jennifer. The company was formed about 15 years ago when he dissolved the business he

Discover more at WPIUpdate.com

8 A Salute to

Customer

a

owned and joined forces with Jennifer. Casco Contracting has a staff of about 20 and typically has four to five jobs on the books at any one time.

“I’ve been moving dirt since I was 17 and bought my own skid steer, so I’ve been doing this kind of work for about 27 years,” said Casadaban. “When we got married, Jennifer was running a truck parts company and wanted to start her own business. I decided to go work for her and run the field operations. Like the business I owned previously, it started out small. I graded yards with a tractor for residential contractors. They asked me to do more work, so we added on services and just kept growing.”

Dealer service leads to loyalty

Casco Contracting and Larry Loyd Construction both rely on Komatsu equipment to complete jobs efficiently. For the water bottling project, the companies are using PC210LC and PC360LC excavators as well as D39PX, D51PX and D61PX dozers. They also rented HM300 articulated trucks from Waukesha-Pearce Industries LLC (WPI) with the help of Sales Representative Philip Derbins.

“We have run Komatsu ever since I can remember; my uncle Larry used it when

he owned the business,” said Stewart. “It’s good-quality machinery that lasts and is dependable. We have worked with Philip for a long time, and we were happy to see him stay on board when WPI took over the territory. If we need anything, he’s right on top of it.”

Casadaban added that product support is a big reason Casco Contracting continues to use Komatsu as well.

“We have really good reps here in Louisiana,” said Casadaban. “They take care of us. Phil will do anything for you. He’s helped me determine the proper size of machines to maximize productivity. That high level of service keeps us loyal. We made our first purchase through WPI with his help a few months ago — a D51PX. It’s the latest of several pieces we have bought in the last 12 to 15 years. We get great life out of the machines. For instance, we have a PC210 with 5,500 hours that’s still tight and has its original pins and bushings. All my operators love Komatsu equipment.”

Casco Contracting and Larry Loyd Construction maintain their older machines, and WPI takes care of scheduled services on newer units, including the rented trucks, under the Komatsu

Continued . . . 9

Casco Contracting and Larry Loyd Construction operators move mass amounts of dirt with Komatsu equipment, including a PC360LC excavator and rented HM300 articulated trucks.

Jessie Stewart, Supervisor, Larry Loyd Construction

Travis Delatte, Superintendent, Casco Contracting

‘The

. . . continued

machines are strong and reliable’

Care program for the first three years or 2,000 hours.

“That helps us a lot because it ensures those are done on time,” said Casco Contracting

Operator Braeden Cooper pushes dirt with a Komatsu D61PX dozer. “I can see the corners of my blade without any problem," said Cooper. “It has good versatility too, because I can go from stripping to finish grade with one machine. It’s the best machine I’ve run by far.”

(L-R) Larry Loyd Construction

Supervisor Jessie Stewart, WPI

Sales Representative Philip Derbins, Casco Contracting Operations

Manager Buster Casadaban, and Casco Contracting Superintendent Travis Delatte talk shop on a job site.

Operator Matthew Nolan sorts and loads logs with a Komatsu PC210LC excavator equipped with a thumb. “It has plenty of power to do this type of work; I can pick up to three or four logs at a time,” said Nolan. “The hydraulics react really well, which is beneficial to grabbing and holding the logs or trash or whatever I need to pick up. It’s got plenty of room in the cab too, which is great for a big, tall guy like me.”

Superintendent Travis Delatte. “WPI is tracking them and calls when it’s time for service. They set it up so that it minimizes our downtime, which is helpful on projects like this where we need maximum production.”

Hambacher said Komatsu equipment has always given Larry Loyd Construction outstanding production.

“I was introduced to Komatsu when I bought the company,” noted Hambacher. “The machines are strong and reliable, so our uptime is great. Combine that with good service, and that’s why I have stayed with Komatsu.”

More joint projects

Due to the excellent work that Larry Loyd Construction and Casco Contracting have done at the water bottling facility, additional work has been added, including running sewer force main from the site and tying it in with the city of Ponchatoula utilities.

“That’s typical for us because we focus on doing work on time and on budget, which has led to a lot of repeat customers,” said Hambacher. “We are typically a turnkey site contractor who likes to control the schedule. Teaming up with Casco on some key jobs like this really helps.”

Moving forward, the two companies’ mutually beneficial relationship will continue to grow, as they already have more joint projects in the works, including some subdivisions and retention ponds. ■

*The opinions expressed here are from the end user as quoted. The results described herein are those of these end users under certain conditions. Individual results may vary.

10

What if YOUR material handler’s purpose is a little different from the OTHER material handler’s purpose?

When you want purpose-built, only SENNEBOGEN purpose-builds one machine at a time to meet your goals. Think of the possibilities!

• Diesel and/or electric-drive

• 44,000 to 900,000 lbs.

• Rubber tired, tracked or stationary

• Custom boom & stick configurations

www.sennebogen-na.com | +1-704-347-4910 See how SENNEBOGEN can purpose-build the right machine for you PURPOSE-BUILT FROM THE GROUND UP

Texas locations only

Choosing the Right Fit

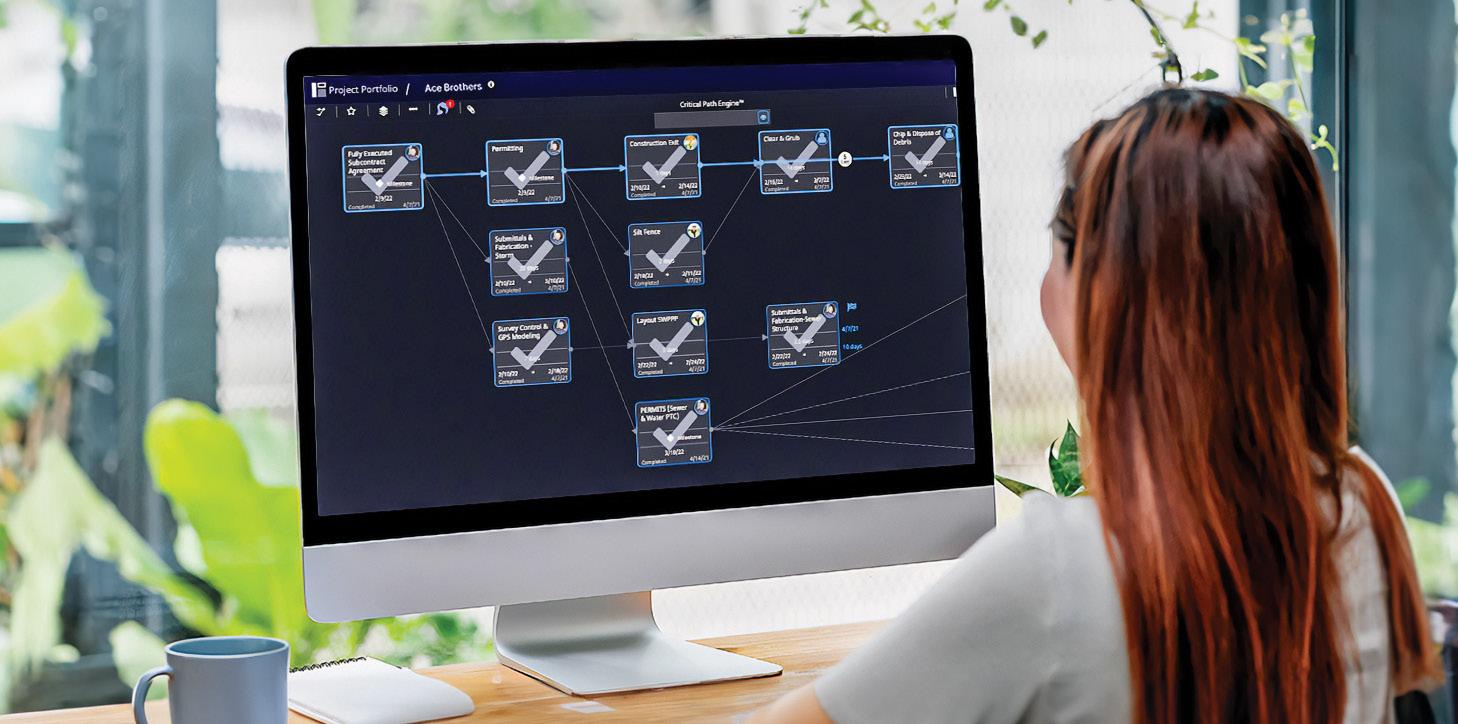

Smart Construction solutions can help you increase productivity, track it and make faster critical decisions

TTechnology use in the construction industry has grown rapidly during the past decade and includes both on-machine technology as well as software designed for each stage of project management. Choosing the right technology to move your business forward comes with many questions, and the correct answers depend on what technology your company has already adopted.

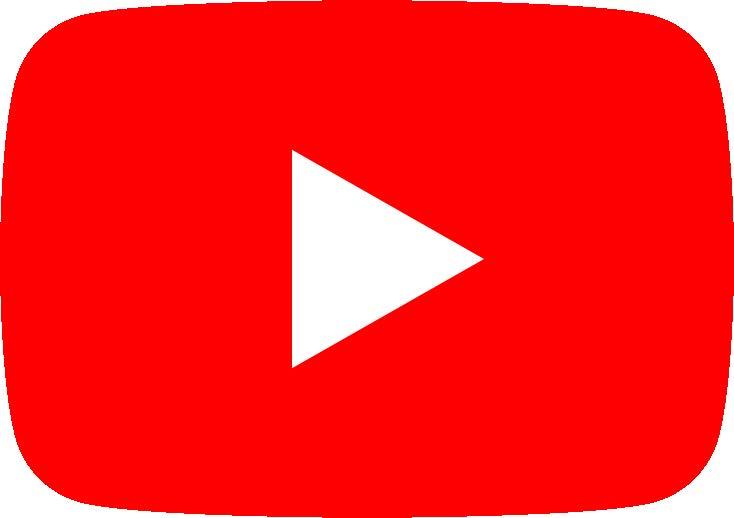

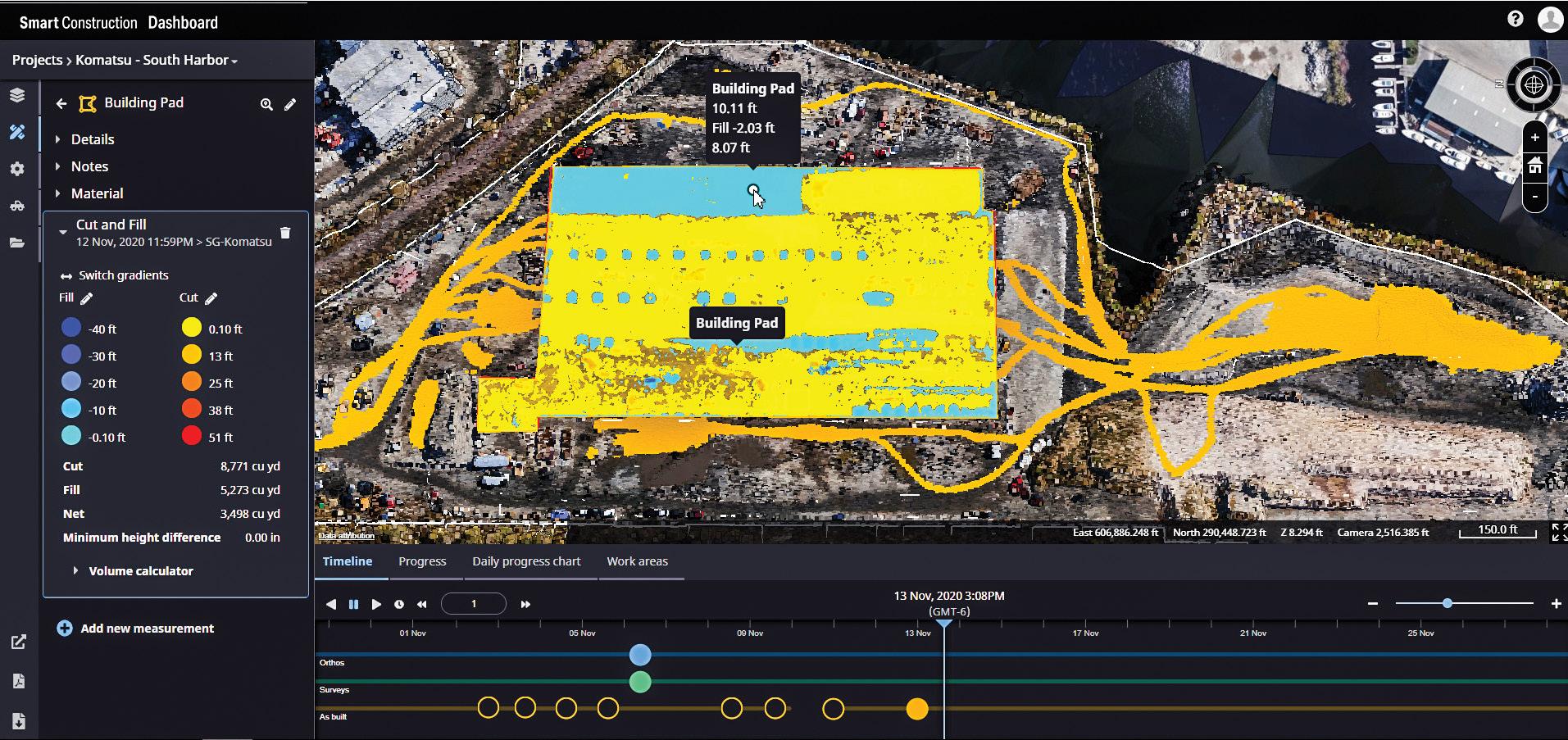

If you already have IMC equipment in your fleet, the next step may be to add solutions that help you better track and manage progress. Smart Construction Dashboard allows remote visualization of job site terrain progress with the aim to have a digital twin of the job site material movements.

Komatsu has long been a technology proponent. It was among the first manufacturers to incorporate telematics into its machinery, with its Komtrax remote monitoring system that enabled customers to monitor fuel usage, idle time, location and more. During the past two decades, Komtrax has expanded to include additional comprehensive information that helps with proactive fleet management, to help reduce downtime as well as owning and operating costs.

“For our customers, Komtrax was a great introductory option down the technology path, and it continues to be a great feature,” said Jason Anetsberger, Director of Customer Solutions, Komatsu. “On our new machines, it’s easily accessible through our My Komatsu platform and lets you monitor any piece of equipment.”

Anetsberger continued, “Now, the question is: what’s the next step that is right for you in this technological journey? Fortunately, we have many Smart Construction solutions depending

on where you are at the moment. We offer solutions that can support a small operation that is currently not using any technology, as well as solutions for large multinationals that have fully embraced machine control and project management systems.”

Anetsberger provided some helpful tips for how to determine which Smart Construction solutions could be beneficial and when the right time to add them is. All of the solutions can be accessed and viewed through your My Komatsu account.

No solutions? IMC is a good introduction If you are not using any of Komatsu’s Smart Construction solutions, Intelligent Machine Control (IMC) dozers and excavators may be a good starting point, according to Anetsberger. When Komatsu introduced its first IMC dozer more than a decade ago, it was the original Smart Construction solution. Several new models and next generation machines have been added that feature fully factory-integrated GPS machine control, which helps increase productivity and efficiency by reducing surveying and staking costs and eliminating the masts and cables of traditional aftermarket GPS add-on systems.

With seven sizes of IMC dozers, ranging from the 105-horsepower D39i-24 to the 354-horsepower D155AXi-8, there is a fit for

12

Jason Anetsberger, Director of Customer Solutions, Komatsu

Contact WPI’s Smart Construction Team

practically every construction site application. The IMC 2.0 dozers have advanced features such as proactive dozing that enables operators to cut/strip automatically from existing terrain as well as lift layer control, tilt steering control, and quick surface creation.

On the excavator side, there are IMC machines ranging from the 20-ton-class PC210LCi-11 to the 50-ton-class PC490LCi-11. All have semi-automatic functions that go beyond simple guidance to semi-automatically limit over-excavation and trace a target surface. Once target elevation is reached, even if the operator tries to move the joystick to lower the boom, the excavator doesn’t allow it, reducing wasted time and the need for expensive fill material.

IMC 2.0 excavators feature bucket angle hold control, which automatically holds the bucket angle to the design surface during arm operation. It’s less fatiguing for operators, so they can be more productive, and it produces a better finish-grade surface. Plus, auto tilt bucket control assists operators by aligning the bucket parallel with the slope, so that finish grading can be accomplished without needing to align the machine with the target surface. Testing has shown that these latest generation models help improve accuracy by up to 33% and efficiency

as much as 63% compared to conventional excavation and grading methods.

“We have more than a decade of proven success with IMC machines saving time and material costs, to help increase profitability,” said Anetsberger. “IMC was our first Smart Construction solution, and we have built a suite of additional beneficial solutions, including our Smart Construction Retrofit for standard excavators. This technology is a good entry-level system for someone who may be considering GPS but is not ready to fully commit to integrated machine control.”

Smart Construction Retrofit is an add-on, indicate-only system that offers many of the benefits of IMC. It’s three-dimensional, so operators get the advantage of seeing where they are on a project, as well as their relation to target elevation. They can set audio alerts that change tone the closer they get to finish grade. That, along with the visual representation on the app, helps keep operators from digging too deep, saves time and lowers costs.

From site to office and vice versa

Additional Smart Construction solutions can help customers better manage their projects from pre-bid to final close out.

Continued . . . 13

Intelligent Machine Control (IMC) dozers can help increase productivity. For those looking for an introduction to Smart Construction, IMC equipment may be the best fit.

‘Easy to implement, user-friendly’

“Knowing which one to use is a matter of assessing your goals,” Anetsberger stated. “Do you want faster, more accurate mapping and progress tracking? Do you want to move to 3D digital plans and combine drone data with 3D design data to confirm quantities? Do you want better labor management and cost tracking and to be able to do it remotely?”

A couple of solutions Anetsberger suggested for those who now have IMC machines are Smart Construction Remote and Smart Construction Dashboard. Remote allows users to remotely send design files to targeted machines in the field and remotely support operators without driving to the job site, saving time and fuel expenses. With remote access, contractors can help their operators troubleshoot issues in real time by viewing the same visuals as in the machine.

To help users with tracking cut/fill progress, Dashboard allows remote visualization of job site terrain progress, with the aim to have a digital twin of the job site material movements. It combines data from multiple sources into one comprehensive picture and provides a 3D graphic visualization of all design, drone and machine data to measure cuts/fills, quantities and productivity. Users can confirm pre-bid and topographical map data, track site progress in near real time, document job site conditions as evidence for change orders, and quickly and easily measure quantities.

“Dashboard and Remote are complementing solutions to IMC,” said Anetsberger. “The visual representation and the ability to track job site progress more easily from practically anywhere, can lead to faster decisions and potentially better bottom-line outcomes. They are easy to implement, user-friendly,

and the cost savings have been significant for companies using them.”

Further building your solutions portfolio

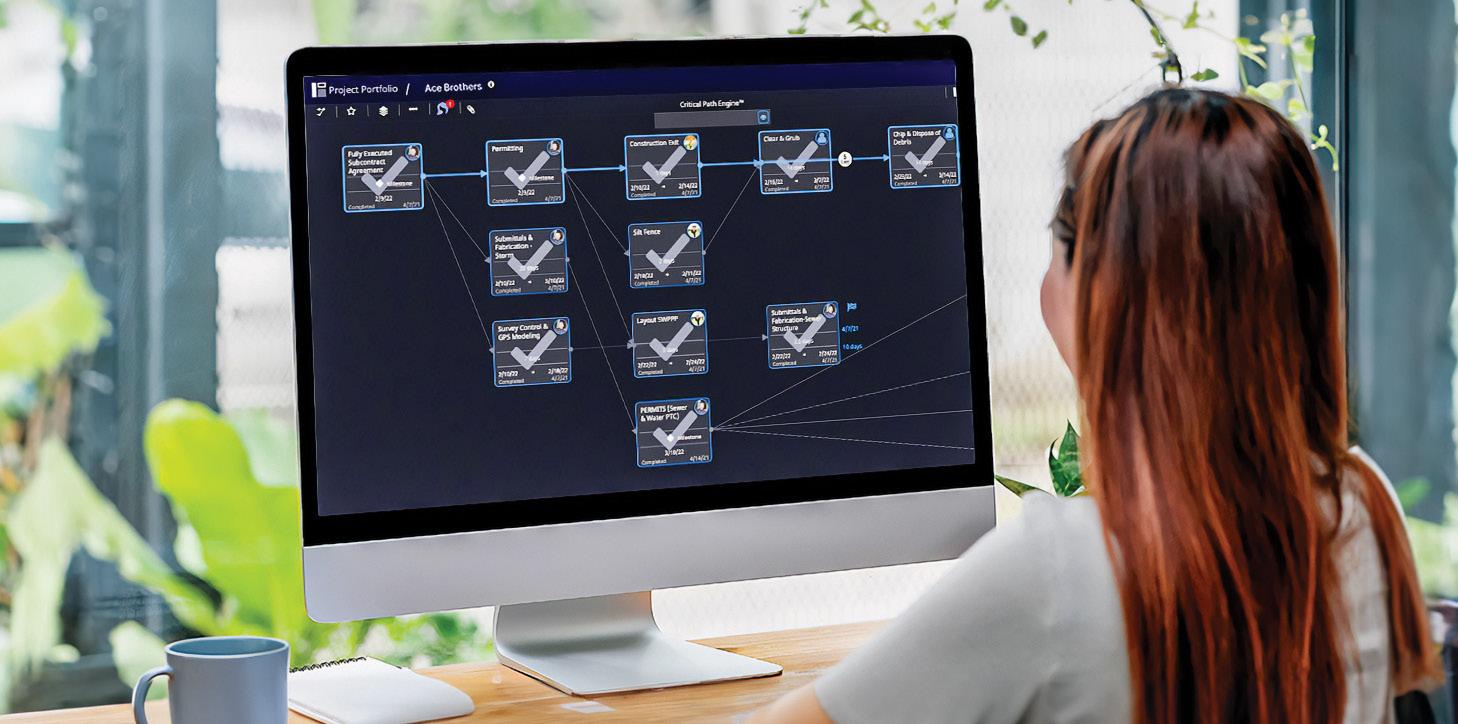

As any project manager knows, job sites often evolve and plans change, which makes staying on schedule and on budget a challenge. Smart Construction Office is a project scheduling and management solution that serves as a central hub for all your jobs and can help replace manual production and cost tracking with streamlined daily automation. It delivers timely updates, insights and auto-forecasting schedules, and cost estimates throughout a project’s life cycle.

“Office is a project management tool that gives you reliable forecasting and insight into budget versus actual costs,” explained Anetsberger. “Another consideration is Smart Construction Field, a mobile app that uses data to track spending and allows contractors to quickly view current conditions and progress. You can break it down by labor, equipment, materials, receipts, timecards, and much more. Both Office and Field are brand-agnostic, so they can be a great solution for contractors with mixed fleets.”

Additional Smart Construction solutions include Design, Drone and Fleet, which can help replace paper plans with digital files, accurately map job sites, and collect data for fleet optimization.

“There are so many easy ways to implement technology solutions into your operations,” concluded Anetsberger. “We encourage anyone who wants to streamline and optimize their operations to learn about Smart Construction solutions by talking to their distributor about how to get started.” ■

Cost tracking is essential. Smart Construction Office is a project scheduling and management solution that serves as a central hub for all your jobs. It can help replace manual production and cost tracking with streamlined daily automation that delivers timely updates, insights and auto-forecasting schedules, and cost estimates throughout a project’s life cycle.

14

.

. . continued

SMART CONSTRUCTION

On your job site, productivity is the key to success, and with Komatsu’s Intelligent Machine Control (IMC), you have a powerful tool to help you achieve maximum productivity faster. IMC incorporates advanced proprietary technology and cutting-edge job site design for sophisticated productivity-enhancing automation.

Contact

WPI’s Smart Construction Team

Marking a Milestone

Generations of the Pearce family look forward to WPI’s future while reflecting on 100th anniversary

IIn the midst of celebrating its 100th anniversary in 2024, Waukesha-Pearce Industries LLC (WPI) is also focusing on the future. Part of that focus included the promotion of fourth-generation members of the Pearce family into key leadership roles, including Louis M. Pearce IV to Division President of the Engine Division and Lloyd R. French IV to Division President of the Construction Mining Division (CMD).

“There are a ton of opportunities ahead of us, which is exciting,” said Lloyd R. French IV, whose great-grandfather Louis M. Pearce Sr. founded the Houston-based company.

“We believe there are further growth capabilities in expanding our footprint

physically, which in turn increases our service capabilities. There is potential to diversify into other markets and industries and potential for acquisitions.”

A forward-looking vision and a commitment to better help customers with more local service, along with several strategic acquisitions, have helped the Pearce family expand WPI’s footprint. During the past few years, WPI took over the Komatsu distributorship in Louisiana, which added six branch locations in the Pelican State. It also opened new Texas facilities in Lufkin, Brownsville and the College Station/Bryan area.

The new locations are part of WPI’s CMD, which started in 1955 as Pearce Equipment Company when it became the Texas distributor for Clark Michigan wheel loaders. Shortly thereafter, the company added Lima cranes, Koehring excavators, Bantam cranes and excavators, Blaw-Knox pavers, and Tampo rollers to its product offerings.

In the early 1980s, WPI acquired the Komatsu distributorship for West Texas and later the Dallas-Fort Worth area. Prior to the appointment as a Komatsu distributor, the earlier product agreements were terminated.

In 1986, WPI acquired Plains Machinery Company, giving it a full product line with Dresser/International Harvester for the entire state of Texas. The Komatsu contract was mutually terminated, but when the Komatsu Dresser Company was formed in 1988, WPI was once again in the Komatsu family. WPI acquired the Komatsu assets from Houston Heavy Equipment in 1990, giving it the Komatsu territory it has in the state of Texas today. From 1995 to 2007, WPI was also a dealer for Komatsu in Mexico with a division known as WPI del Mexico.

Today, in addition to Komatsu, WPI also offers a wide assortment of other equipment lines from leading manufacturers such as BOMAG, SENNEBOGEN, NPK, TimberPro, Gradall, Atlas, LaBounty and more.

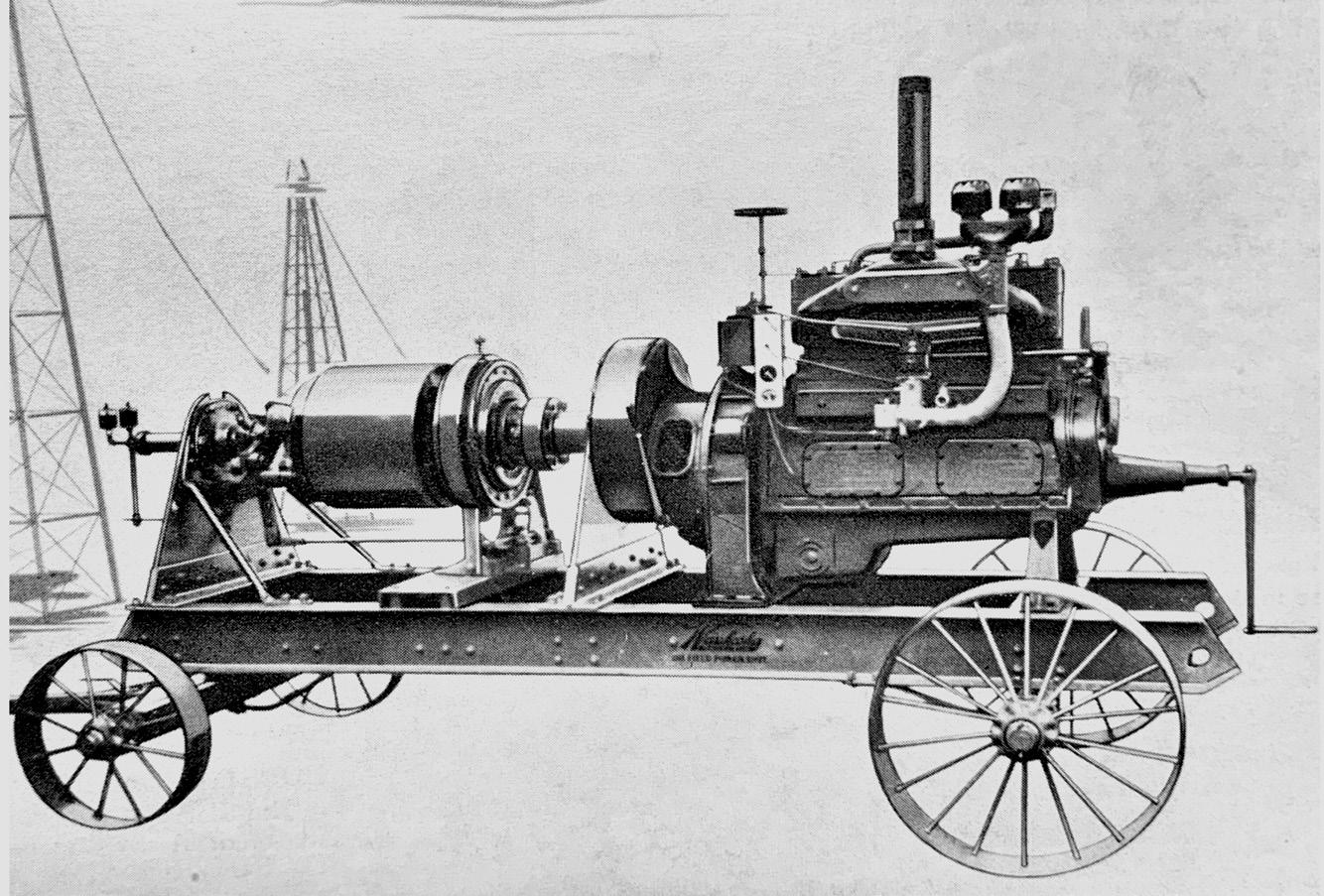

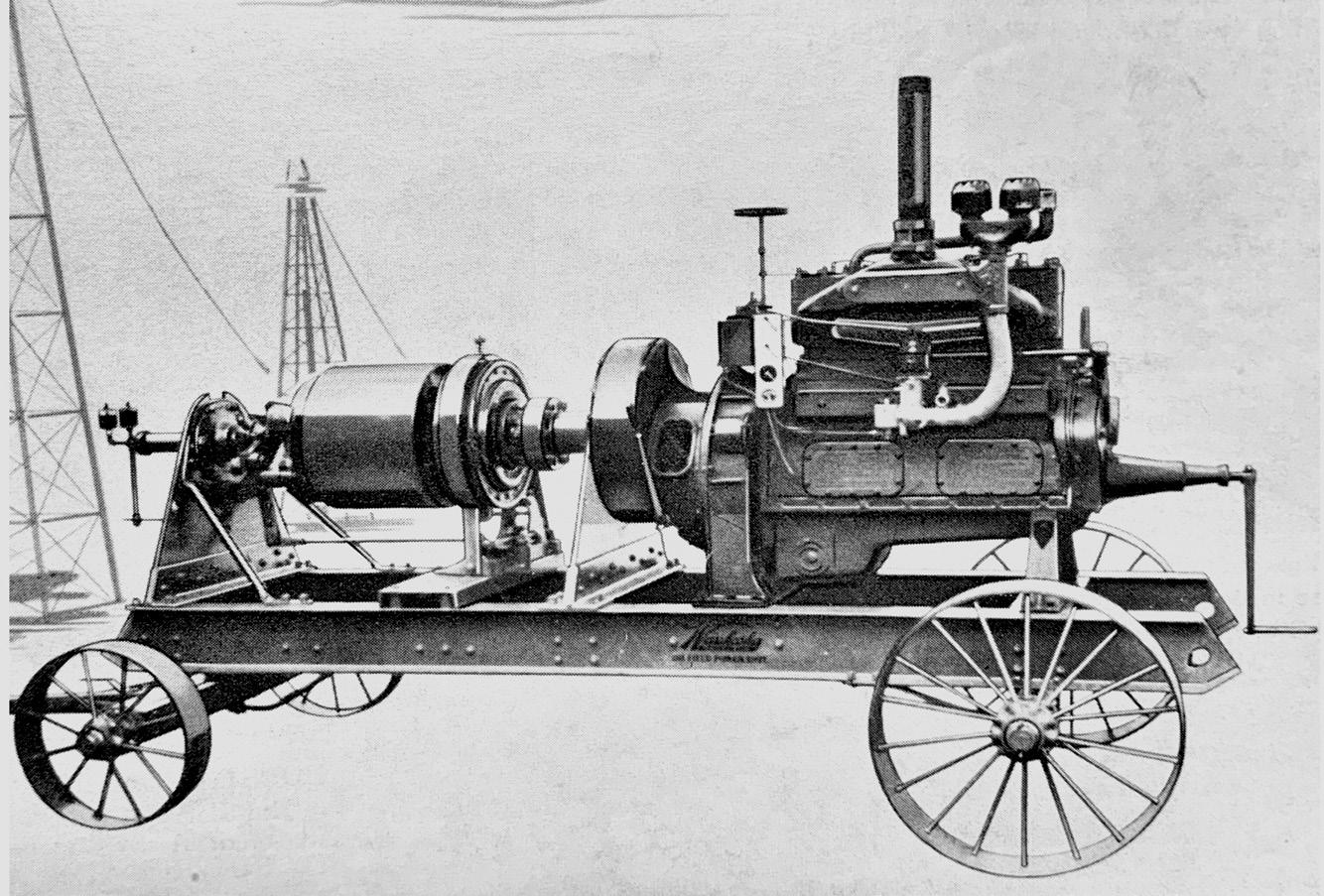

WPI’s origin traces back to 1924 when Louis M. Pearce Sr. started the Portable Rotary Rig Company to build steam-powered drill rigs. WPI added a Construction Machinery Division in the mid-1980s with the acquisition of a machinery dealership in Texas.

16

Always looking for opportunities

In addition to its CMD operations, WPI maintains its roots in the energy industry with its Engine Division. That division traces back to 1924 when Louis M. Pearce Sr. started the Portable Rotary Rig Company to build steam-powered drill rigs. In 1933, he acquired the Waukesha Engine distributorship for his drill rig business, and he and his son, Louis M. Pearce Jr., grew the business. Last year, the Engine Division expanded again with the acquisition of Memorial Machine, which specializes in remanufacturing engine components.

“We have always looked for good opportunities that made sense with our core products and services and are a natural fit, and Memorial is a good example,” said Louis M. Pearce IV. “That adds value to us as a company and gives us additional ways to better serve customers. I think there are other possibilities out there, and we are keeping our eyes open to them.”

He added, “A good example would be renewable energy. WPI can trace its roots back to the oil and gas industries when my great-grandfather started out. We are still firmly planted there, but we are also looking

at ways to expand. The wind power and solar sectors as they grow are prime examples.”

Focused on customer success

Louis M. Pearce III noted that surviving and thriving through 100 years and four generations is an accomplishment few companies achieve, but the formula for success is simple and has been passed down from the founder to today’s leaders and WPI team members.

“We have expanded quite a bit in the last few years, and our new areas are seeing the same commitment as we have always had to providing outstanding service,” said Louis M. Pearce III, who was recently named Chief Executive Officer after almost 50 years as WPI’s president and is a third-generation family member. “We have great products, but if you don’t back them up and keep customers’ downtime to a minimum, you don’t last. That’s been true for the past 100 years and will continue to be true forever.”

He continued, “That goes with caring about customers and their success. It’s an ideal that’s been instilled in every generation of the Pearce family that’s worked here, but it’s also been instilled in everyone who has, does and will work for WPI.” ■

17

Members of the third and fourth generation of the Pearce family who currently lead WPI include (front row, L-R) Gary Pearce Sr., Louis M. Pearce III, Anne French and Stephen Pearce, as well as (back row, L-R) Rex Pearce, Louis M. Pearce IV, Lloyd R. French IV and Gary Pearce Jr.

Maximize productivity on your job sites with advanced automation technology. Komatsu’s Intelligent Machine Control (IMC) can help you get the most from your machines, crew and carefully designed plans.

•Get new operators up to speed quickly

• Go from mass excavating to finished grading faster than ever

•Helps eliminate potential damage to design surface

• Empower operators to work efficiently, pass after pass

© 2024 Komatsu Ltd. or one of its subsidiaries. All rights reserved.

to help you work smarter

Technology

Discover more komatsu.com/imc

TEXAS

HOUSTON

Hollis Smith 936-433-9511 smithh@wpi.com

Justin Davis 713-569-9840 davjus@wpi.com

Brandon Simmons 979-285-7319 brandon.simmons@wpi.com

SAN ANTONIO

Mike Harris 210-391-8650 harrim@wpi.com

Chris Miller 210-749-3289 christopher.miller@wpi.com

CORPUS CHRISTI

Beto Estrada 361-429-1608 beto.estrada@wpi.com

KILGORE

Roger Sepaugh 903-522-0792 roger.sepaugh@wpi.com

BUFFALO

David Rodriguez 903-907-1020 david.rodriguez@wpi.com

TOMBALL

Jeremy Parkins 713-252-3588 jeremy.parkins@wpi.com

LUFKIN

Brian Vardeman 936-462-3719 brian.vardeman@wpi.com

AUSTIN

Allen Pavlica 830-377-7385 pavall@wpi.com

Jacob Young 512-769-0524 jacob.young@wpi.com

Tres Forester 832-654-3669 forest@wpi.com Harrison Stow 713-299-2091 harrison.stow@wpi.com

Jeremiah Sporn 832-296-5462

jeremiah.sporn@wpi.com

Jeffrey Smith III 318-955-8639

jeffrey.smith@wpi.com

ROUGE Travis Gilmore 225-888-5694 travis.gilmore@wpi.com

Michael Ventrello 504-463-6886

michael.ventrello@wpi.com

Greg Sanders 318-505-3598

greg.sanders@wpi.com

Jeff Choate 318-510-3203

jeff.choate@wpi.com

Meet WPI’s PSSR Team

ALEXANDRIA

KENNER

BATON

SHREVEPORT

AFTERMARKET

PSSR MANAGER

CORPORATE LOUISIANA

Product Support Sales Representatives

Optimized Experience

My Komatsu updates, new features improve fleet management to help

you get the critical information you want in fewer clicks

FFleet management is essential to maintaining your equipment’s health. Properly maintained equipment helps increase uptime and lower overall owning and operating costs. Staying on top of fleet management can be challenging, especially if you are still relying on end-of-day field reports or drives to the job site to check hour meters.

Digital solutions such as My Komatsu can change the game by giving you real-time machine data that can be accessed from practically anywhere, as well as tools that give you the capability to order parts and more. Recent updates make it easier to navigate, so you can quickly get the information you need to help make proactive fleet management decisions.

“Filtering capabilities have been updated to help users more quickly access the information they are looking for,” said Andrew Casey, Digital Solutions Analyst, Komatsu. “It’s more like a dashboard where you can get information in fewer clicks, which is something our customers wanted. Using their feedback, we made changes to make the interface more user-friendly. Customers who already have a My Komatsu account will see the updates automatically.”

Casey said one of the priorities based on customer feedback was a redesign of the My Fleet page, emphasizing that its substantially different look and easier navigation enable users to see their entire fleet of registered machines all on a single page without having to go through multiple tabs.

“We also expanded the ability to filter by idle time percentage, SMR range, model type, manufacturer, and much more,” Casey added. “A new sync map feature lets users zoom in on a particular territory, click the sync map to list button, and see machines just in that territory.”

Component tracking capability

Another major change is the addition of component tracking, according to Casey. The new functionality allows users to monitor component health, so they can more proactively plan for replacements.

“Users can set an interval based on last service date or SMR hours of the machine, then create an alert that notifies them when a component is due for replacement,” Casey explained.

Machine health and fleet monitoring are now easier, faster and more efficient with new alerting features, including additional alert types

My Komatsu updates include easier navigation, so you can access information more quickly.

My Komatsu updates include easier navigation, so you can access information more quickly.

20

Andrew Casey, Digital Solutions Analyst, Komatsu

for abnormality codes, coverage, Komatsu Oil and Wear Analysis (KOWA) samples, and more. Consolidated and customizable views of your alerts can be set with the alerting dashboard. With My Komatsu, you can choose how to receive notifications — by web, mobile app, email or SMS.

Telematics information (Komtrax) in My Komatsu remains a vital feature that works with Komatsu and other brands that you have registered in your My Komatsu account. You can view machine location, fuel consumption, and machine health, which includes maintenance history.

Additional features available in My Komatsu include:

• Publications – View parts and support manuals for your machines

• E-commerce parts stores – Easily order parts and solutions that you can pick up

in store, have shipped to your shop, or get delivered directly to your job site

• Digital solutions – Sign up for and access your Smart Construction accounts such as Dashboard, Design, Drone, Field, Fleet, Office and Remote

If you don’t already have a My Komatsu account, you can sign up for one by visiting https://mykomatsu.komatsu. Once you have an account, your dealer can help you get set up and work with you on how to best utilize the platform.

“Proactive fleet management results in less downtime because you have a clear picture of your equipment’s health at all times,” said Casey. “You can better plan for routine service and component changes, address excess idle time, train your staff, monitor job sites and machine performance, schedule part orders, and much more.” ■

21

My Komatsu lets users monitor their fleet from anywhere at any time and helps optimize fleet management — with real-time data that can help you make proactive decisions.

Meaningful conversations, ability to operate equipment stand out at Komatsu’s Quarry Days held at Arizona Proving Grounds

OOne of the highlights of Komatsu’s Quarry Days is the ability to get in the operator’s seat and put equipment to the test.

“I think it’s a very good thing for Komatsu to do for operators and businesses that are looking for equipment,” said Brad Disrud, an operator with North American Coal at its

Coyote Creek Mine in Zap, N.D. “I currently run an older PC2000 that we are looking to replace down the road, and the ability to get in the new one and make a comparison is valuable. It’s quieter, and the productivity is definitely there. The electronic over hydraulic controls is nice.”

The 1,046-horsepower PC2000-11 surface mining excavator was one of more than a dozen Komatsu machines that attendees could operate or see in action at Komatsu’s Quarry Days, an event that took place at Komatsu’s Arizona Proving Grounds. Among the machines was Komatsu’s new GD955-7 motor grader with a standard 18-foot blade.

“You can definitely tell the GD955 is a game-changer,” said Mauricio Vallejos with Titan America. “The palm steering is something completely different. In the long run, I think it’s going to benefit a lot of operators because it will cut down fatigue. Your hands are always on the controls. I think it has several uses — padding, the finishing touches, making sure our dragline shoes sit on the ground and don’t bend, and road maintenance for the haul roads our HD785s run on. It could allow us to do that in fewer passes.”

Popular PC900LC-11

In addition to the PC2000-11 and GD955-7, attendees were able to operate several other Komatsu machines, including a PC900LC-11 excavator; an HB365LC-3 hybrid excavator; WA900-8 and WA475-10 wheel loaders; a D475A-8 surface mining dozer; a D71PXi-24 Intelligent Machine Control (IMC) dozer; and HM400-5, HD785-8 and HD1500-8E0 trucks. A ZT44 drill and an RF-5 reclaim feeder were on display as well. Attendees could also talk with product experts from Montabert and Tramac about breakers and Hensley Industries about its Kprime tooth system. Montabert, Tramac and Hensley are all Komatsu-owned companies.

“We have solutions at Quarry Days that represent every application within a customer’s job site — from stripping, to loading and haulage, to drilling, blasting, breaking, processing, and dozing, it’s all here,”

22 Demo in the Desert

(L-R) WPI’s Frank Pagura explores Quarry Days with North American Mining’s Nick Haubruge, Michelle Lovland and Phil Berry, as well as Komatsu’s Todd Parks.

(L-R) WPI’s Mike Harris and Capitol Aggregates’ Justin Bradley, Scotty Gerbes and Steve Eckert check out all of the equipment on display.

said Joseph Sollitt, Director of Mining Support Equipment, Komatsu. “It gives customers a chance to put the machinery to the test and see firsthand what it can do in a real-world setting. The feedback has been overwhelmingly positive. These types of events are beneficial for the customer, as well as for us to learn more about them and what we can do to improve their operations.”

James Van Remmen with Interstate Earthworks specifically wanted to operate the recently introduced 204,148-pound, 543-horsepower PC900LC-11 excavator that’s designed for heavy construction, demolition, material handling, deep digs, large mass excavation and quarry/mining applications.

“We wanted to compare it to a competitive brand of a similar size,” said Van Remmen. “The speed was very fast for a machine that big.”

With more bucket and lifting capacity, the PC900LC-11 increases productivity up to 40% compared to its predecessor, the PC800LC-8.

Attendees test out Komatsu excavators at Quarry Days, including a PC2000-11, a PC900LC-11, and an HB365LC-3 hybrid model. Product Marketing Manager Casey Zbinden (right) answers a question about the PC900LC-11.

“The PC900LC-11 is ideal for those working in applications that involve moving large amounts of material efficiently,” said Casey Zbinden, Product Marketing Manager, Komatsu. “It’s been a popular attraction at Quarry Days because customers see so many potential uses for it. With an optional counterweight removal system, it’s more easily transported.”

Smart solutions

In addition to equipment, Komatsu representatives from its Smart Quarry solutions and My Komatsu teams were available to show customers the advantages of incorporating technology into their operations.

“Smart Quarry is designed to improve and optimize production, which includes site studies and our new Smart Quarry Site,” said Craig McGinnis, Senior Business Solutions Manager, Komatsu. “What’s great about Site is that it’s brand-agnostic, so it can be used with Komatsu and non-Komatsu equipment. It’s plugged into the machine and transmits actionable data that can be used to improve practices and increase productivity.”

the

Continued . . . 23

Watch

video

‘The

savings are significant’

McGinnis continued, “For example, we did a case study and identified that a quarry was only putting about 89 tons on a 100-ton truck during loading. We determined that if they added about six more tons that it would equate to more than 13,000 tons per month in added production with the same fuel burn and time. The savings are significant.”

Great conversations

The ability to network with other contractors doing similar work is another advantage

of events like Quarry Days, according to Moroni Wardell, who along with his three brothers owns and operates Wardell Brothers Construction in Morgan, Utah. The full-service construction company manages two gravel pits and currently runs several Komatsu loaders and excavators.

“Sharing information is very valuable because it gives us insight into how others are using the equipment and the production they get from it,” said Wardell. “All new iron looks pretty and runs really well — but talk to a customer that has 10,000 or 12,000 hours, and you will see where the results really are. We have been able to network with a lot of other customers that stand behind Komatsu equipment.”

Chad Mikulec, Regional Operations Manager with Permian Basin Materials, said the ability to talk with Komatsu personnel was another positive aspect of Quarry Days.

“The attentiveness of the people out here, wanting to talk to us and hear what we have to say and be actively engaged is very meaningful,” said Mikulec. “It makes me feel good as an end user that they listen to us. Our opinion matters, and what we say is taken into consideration for new products.” ■

*The opinions expressed here are from the end user as quoted. The results described herein are those of this end user under certain conditions. Your results may vary.

At Komatsu’s Quarry Days, attendees move material with a Komatsu D71PXi-24 Intelligent Machine Control (IMC) dozer and a Komatsu D475A-8 surface mining dozer.

24

Komatsu personnel provide information about technology such as Smart Quarry Site, which is designed to help increase efficiency and production.

. . . continued

Watch the video

Investing in the Future

Komatsu, Waukesha-Pearce Industries LLC donate to the AED Foundation’s Vision 2025 initiative

TThe current skills gap and workforce shortage facing the construction industry are daunting. To address these issues, the AED Foundation (AEDF) — an organization affiliated with the Associated Equipment Distributors (AED) — created Vision 2025, an initiative aimed at helping increase the number of qualified technicians entering the equipment distribution industry. Komatsu and its distributor network, including Waukesha-Pearce Industries LLC, have collectively pledged $1.45 million for the initiative.

“We recognize the imperative to build a talent pipeline for our distributors and the heavy equipment industry at large,” said Komatsu’s Rod Bull, Executive Vice President, North America Region. “Komatsu supports Vision 2025 and its focus on helping schools promote careers in the technical field to young people, who often aren’t aware of the great family-supporting jobs available in this industry. We’re excited to do our part to share this story of opportunity to join an industry that keeps our world growing and sustains our way of life.”

Research by AEDF has found that the industry needs to fill an anticipated 73,500 heavy equipment technician positions over the next five years, and that the technician shortage is compounded by a gap in required skills and available training. Vision 2025 aims to address these issues by growing AEDF’s impact to include a minimum of 120 accredited college programs (currently 71) and a minimum of 200 recognized high school programs (currently 36).

Create a talent pipeline

If successful, Vision 2025 has the potential to create a talent pipeline that includes an additional 10,000 skilled technicians

entering the workforce, 5,000 AEDF-certified technicians, and 500 AEDF-certified managers.

AEDF hopes to raise $10 million during the next five years, and funds will be directed toward:

• New college accreditation programs targeting underserved areas where an existing heavy equipment technology program is already in place

• High school recognition programs that will prioritize locations that can serve as a feeder system into current and anticipated accredited college programs

• Expanding the AED Foundation’s endowment to ensure Vision 2025 efforts are sustainable over the long term

“The AED Foundation is grateful for Komatsu’s leadership and investment in our Vision 2025 campaign,” said AEDF President Brian McGuire. “Komatsu’s support, in conjunction with nearly 75 other investors, brings our Vision 2025 campaign to over $6 million. These investments provide the foundation with the sustainability needed to continue to be the heavy equipment industry’s leader in workforce development.” ■

AEDF’s Vision 2025 initiative is addressing the current skills gap and shortage of technicians in the heavy equipment industry. Donations from Komatsu and distributors will help support new college and high school programs designed to build a pipeline of new technicians.

25

Komatsu PC130LC-11, PC490LCi-11 and PC900LC-11 excavators named among best new products

TThree Komatsu excavators are featured on Construction Equipment magazine’s annual list of top new products, including the PC130LC-11, the PC490LCi-11 and the PC900LC-11.

According to Construction Equipment, its Top 100 New Products list is the longest-running awards program of its kind in the industry. Each year, editors evaluate products introduced during the previous months and choose those considered most innovative based on four criteria:

• Is it an advancement in technology?

• Is it a new product line?

• Does it offer significant improvements to an existing product?

• Does it increase competition in its category?

Increased lift capacity

Komatsu’s upgraded PC130LC-11 features a longer undercarriage with 8% more track length, which provides greater stability and increased operating weight. That contributes to increased lift capacity over the front and side — up to 20% compared to the previous model.

With an operating weight of 28,440 to 29,101 pounds, the PC130LC-11 is highly transportable and can be moved with a tag trailer and still have capacity to spare for additional support equipment.

Innovative bucket angle hold control

With Intelligent Machine Control (IMC) 2.0, the PC490LCi-11 offers sophisticated productivity-enhancing automation, making it an excellent match for excavation, trenching, slope work or fine grading. The excavator helps minimize over-excavation, empowering operators of all skill levels to dig straight to grade quickly and accurately.

The PC490LCi-11 features bucket angle hold control that automatically holds the bucket angle to the design surface during arm operation, enabling operators to perform

The Komatsu PC490LCi-11 Intelligent Machine Control (IMC) 2.0 excavator is excellent for excavation, trenching, slope work or fine grading. It helps minimize over-excavation, empowering operators of all skill levels to dig straight to grade quickly and accurately.

26 Top Honors

Quick Specs

Model PC130LC-11

PC490LCi-11

PC900LC-11

finish grading using only arm input. It also has a new 10.4-inch IMC monitor with increased memory capacity, processing speed, and pinch-to-zoom functionality.

Up to 40% greater productivity

The PC900LC-11 is ideal for those working in applications that involve moving large amounts of material efficiently. Productivity was a major driver of its design. It’s a mass excavator with the ability to handle a wide variety of jobs and materials, and can perform compound operations.

Designed for heavy construction, demolition, material handling, deep sewer, water, large mass excavation and quarries/mining, the PC900LC-11 provides increased bucket and lifting capacity for higher performance compared to its predecessor, the PC800LC-8. Major structures, booms and arms as well as a redesigned revolving frame were engineered to increase longevity.

The PC900LC-11 can deliver up to a 40% increase in productivity, 25% more arm

The Komatsu PC900LC-11 excavator can deliver up to a 40% increase in productivity, 25% more arm crowd force, and 12% more swing torque compared to the PC800LC-8.

With more track on the ground than its predecessor, the PC130LC-11 has greater lift capacity.

crowd force, and 12% more swing torque compared to its predecessor. It also features the KomVision camera monitoring system as standard. ■

27

Horsepower 97.2 hp 359 hp 543 hp Operating Weight 28,440-29,101 lbs. 105,670-107,850 lbs. 204,148 lbs. Bucket Capacity 0.34-0.78 cu. yd. 1.47-4.15 cu. yd.

3.7-8.0 cu. yd.

Major upgrades to popular harvester head improve reliability, productivity in the forest

AA popular and established harvester head with a reliable and service-friendly design, the Komatsu S92, has been upgraded with several new functions and improvements to make it even more productive. These upgrades, which include a brand-new Constant Cut saw unit, were made based on input from customers.

“Continuous improvement is part of our DNA,” stated Mikael Forsberg, Product Manager, Harvester Heads, Komatsu Forest.

Constant Cut now standard

A major new feature now standard on the S92 is the intelligent saw motor controller, Constant Cut. The motor controller ensures that the head can maintain a constant and high chain speed without the risk of overspeeding.

To extend the service life of the head, the find end function and the mechanical stops at the rear knife have been redesigned.

Komatsu’s S92 harvester head has an intelligent saw motor controller, Constant Cut, that ensures the head maintains a constant and high chain speed without the risk of overspeeding. The harvester head also has improved measurement characteristics designed to enable the measuring wheel to follow the contours of the stem more closely.

The upgraded feed system reduces energy loss and enhances the head performance, while improved hose routing simplifies servicing the feed system. All lubrication points can now be easily accessed with the head in an upright position.

The color marking tanks have been redesigned to provide easier access for filling, and the multi-tree handling function has a new, more durable design, providing a lower and more agile head. The upgraded S92 also enables the measuring wheel to follow the contours of the stem more closely, for excellent measurement characteristics.

“The response from customers who have tried the upgraded S92 has been positive,” said Forsberg. “They told us that the feed speed is really good, and that the geometry of the saw box and the position of the saw bar make cutting faster and help increase production significantly.” ■

29 Timber Talk

Learn more

TEXAS

Houston 12320 S. Main St. Houston, TX 77035 (713) 723-1050

San Antonio

3740 S.E. Loop 410

San Antonio, TX 78222 (210) 648-4444

Corpus Christi

5226 Interstate I-37

Corpus Christi, TX 78407 (361) 884-8275

Edinburg

5934 U.S. 281 Business Edinburg, TX 78542 (956) 386-0107

Pflugerville 16029 Interstate 35

Pflugerville, TX 78660 (512) 251-0013

Kilgore 3106 Texas 42

Kilgore, TX 75662 (903) 984-2011

Buffalo

2077 N. Craig Drive

Buffalo, TX 75831 (903) 322-7150

Tomball

1720 Hicks Street

Tomball, TX 77375 (281) 351-9016

Port Arthur 8903 Memorial Boulevard Port Arthur, TX 77640 (409) 721-5305

Bryan 5956 E. State Hwy. 21 Bryan, TX 77808 (979) 314-1191

Lufkin 4006 Ellen Trout Dr. Lufkin, TX 75904 (936) 243-6056

Brownsville 7700 Padre Island Hwy. Brownsville, TX 78521 (956) 474-8199

LOUISIANA

Alexandria 5732 S. MacArthur Dr. Alexandria, LA 71302 (318) 408-3099

Baton Rouge

7502 Pecue Ln. Baton Rouge, LA 70809 (225) 800-3711

Kenner

125 E. Airline Hwy. Kenner, LA 70062 (504) 467-5906

Broussard

5407 Hwy. 90 E. Broussard, LA 70518 (337) 362-4331

Bossier City

5908 Industrial Dr. Ext. Bossier City, LA 71112 (318) 746-5272

Sulphur

2320 Louis Alleman Pkwy. Sulphur, LA 70663 (337) 287-9455

Watch the video

Serving You Better

Waukesha-Pearce Industries LLC named new full-line BOMAG Americas dealer in Louisiana

FFor a century, Waukesha-Pearce Industries LLC (WPI) has been a trusted provider of heavy equipment options, services and unmatched support for the construction, mining, infrastructure, forestry and energy industries. The fourth-generation family business strives to lead the industry in customer satisfaction and supports every function within these channels with rental and sales of new and used units, service, parts and technical support.

To better support its customers in Louisiana, WPI added the full BOMAG product line of compaction, paving, milling and recycling/stabilizing equipment to its six Louisiana locations. WPI has successfully represented BOMAG soil machinery in its Texas branches for decades.

“The complete BOMAG product line allows WPI to fulfill and service the needs of our current and future customer base, and it makes perfect business sense for both companies to expand our partnership to better support dirt and asphalt contractors throughout this territory,” said Bruce Truesdale, Senior Vice President of Operations and Chief Operating Officer, WPI. “BOMAG’s unrivaled knowledge in compaction, milling and paving combined with the experienced WPI team will enable us to build deeper partnerships with our existing customers and help forge new business relationships.”

Cole Renken, Vice President of Sales and Marketing for BOMAG Americas, stated, “Our relationship with WPI in Texas spans more than 35 years, and their philosophy of putting the customer first aligns with ours. We are excited to expand the partnership to include our asphalt, waste and light compaction equipment in addition to the soil line in Louisiana. The talented team they have in place and their previous success with BOMAG soil equipment made appointing WPI an easy decision, and we look forward to working with WPI to better serve customers throughout this new territory.”

A wide range of machinery

The BOMAG range of cold planers includes models with milling widths of 20 inches to 87 inches, while versatile

recyclers/stabilizers deliver fast and efficient full-depth reclamation of roads and soil stabilization for a variety of projects. The broad BOMAG paver line spans from the compact BF 200 C-2 for paths and small construction sites to the 10-foot highway-class CR 1030 Series pavers. More than 40 models of heavy tandem and pneumatic tire rollers deliver compaction widths from 36 inches to 84 inches and integrate exclusive BOMAP, ECONOMIZER and ASPHALT MANAGER technologies.

More than 30 single drum and high-speed soil compactor models include smooth and padfoot drum designs that offer compaction widths of 47 inches to 84 inches. The extensive BOMAG range of light equipment features vibratory tampers, single and reversible plate compactors, multipurpose compactors, and small single and double drum rollers. BOMAG’s purpose-built landfill compactors range in size from 57,000 pounds to more than 124,000 pounds with an exclusive wheel design that delivers superior compaction results. ■

The full BOMAG product line includes compaction, paving, recycling/stabilizing and milling equipment, such as this BM 2200/65 cold planer.

31

WPI now carries the full BOMAG product line at its Louisiana locations.

Celebrating 100 years

On April 24, 2024, Waukesha-Pearce Industries celebrated its 100th anniversary. We extend our deepest appreciation to all our dedicated employees and customers as we embark on the next 100 years.

Houston, TX • (713) 723-1050

San Antonio, TX • (210) 648-4444

Corpus Christi, TX • (361) 884-8275

Edinburg, TX • (956) 386-0107

Pflugerville, TX • (512) 251-0013

Kilgore, TX • (903) 984-2011

Buffalo, TX • (903) 322-7150

Tomball, TX • (281) 351-9016

Port Arthur, TX • (409) 721-5305

Bryan, TX • (979) 314-1191

Lufkin, TX • (936) 243-6056

Brownsville, TX • (956) 474-8199

Alexandria, LA • (318) 408-3099

Baton Rouge, LA • (225) 800-3711

Kenner, LA • (504) 467-5906

Broussard, LA • (337) 362-4331

Bossier City, LA • (318) 746-5272

Sulphur, LA • (337) 287-9455

C.P.I. P.O. Box 1689 C.R., IA 52406-1689 Presorted Standard US Postage Paid C.P.I. 24 no1

Division President, Construction Mining Division

Division President, Construction Mining Division

An operator digs and piles dirt with a Komatsu PC290LC-11 excavator.

Eric Houdek, Vice President

An operator digs and piles dirt with a Komatsu PC290LC-11 excavator.

Eric Houdek, Vice President

D2 Excavating uses Komatsu WA320 wheel loaders to move dirt and load trucks.

D2 Excavating uses Komatsu WA320 wheel loaders to move dirt and load trucks.

Chad Hambacher, President/Owner, Larry Loyd Construction

Chad Hambacher, President/Owner, Larry Loyd Construction

My Komatsu updates include easier navigation, so you can access information more quickly.

My Komatsu updates include easier navigation, so you can access information more quickly.