3 minute read

and distribution project

LATTICE-TYPE TOWERS - FOR POWER TRANSMISSION AND DISTRIBUTION PROJECT S tructa Group has proved that self-supported monopole masts can replace lattice-type towers in a large-scale power transmission and distribution project in Ethiopia. The company’s top mechanical engineer in charge of designing masts relates to Construction Review how this feat was accomplished and prospects for the project in Africa. Visibly elated, Erasmus Cilliers, the senior mechanical engineer of Structa Group is revelling in the successful delivery of the company self-supported tubular monopole masts to a power transmission project in Ethiopia. The ongoing project forms part of a large-scale electricity infrastructure upgrade for Ethiopia and focuses on the transmission and distribution of electricity from various substations to surrounding areas of Addis Ababa. These distribution networks convey electricity with high voltages from 132 kV up to 230 kV and span through tough terrains, city centres and densely populated informal settlements. Taking the mast into Africa transmission pole solutions to clients in other African countries. And already, there are encouraging prospects. “We are continuously receiving requests for mast designs, and we strive to optimise these masts in conjunction with the project requirements and scope. In terms of using self-supported masts, some projects have been identified for which these masts will be a highly suitable product,” reveals, adding: “However, the use of towers is never eliminated but rather added as an additional avenue. Structa is always ready to take on the task of designing and manufacturing optimised sustainable products for their clients.” Structa was able to deliver the first batch of masts within 15 months from the initial contact. What made the project a different kind of a beast was that the monopoles were for the Ethiopian project were beyond the size that the company normally delivers for clients. Structa manufactures standard masts and towers for voltages of 11kV up to 220kV. But Cilliers is content that it was delivered to client’s expectations – on time, to exact specifications in terms of size and quality.

Building on experience from the project in Ethiopia, Structa is looking forward to providing its know-how in power and telecommunication

Advertisement

Currently, Structa has three masts product categories: light masts, communication structures, and the utility and transmission towers marketed as Electrotowers.

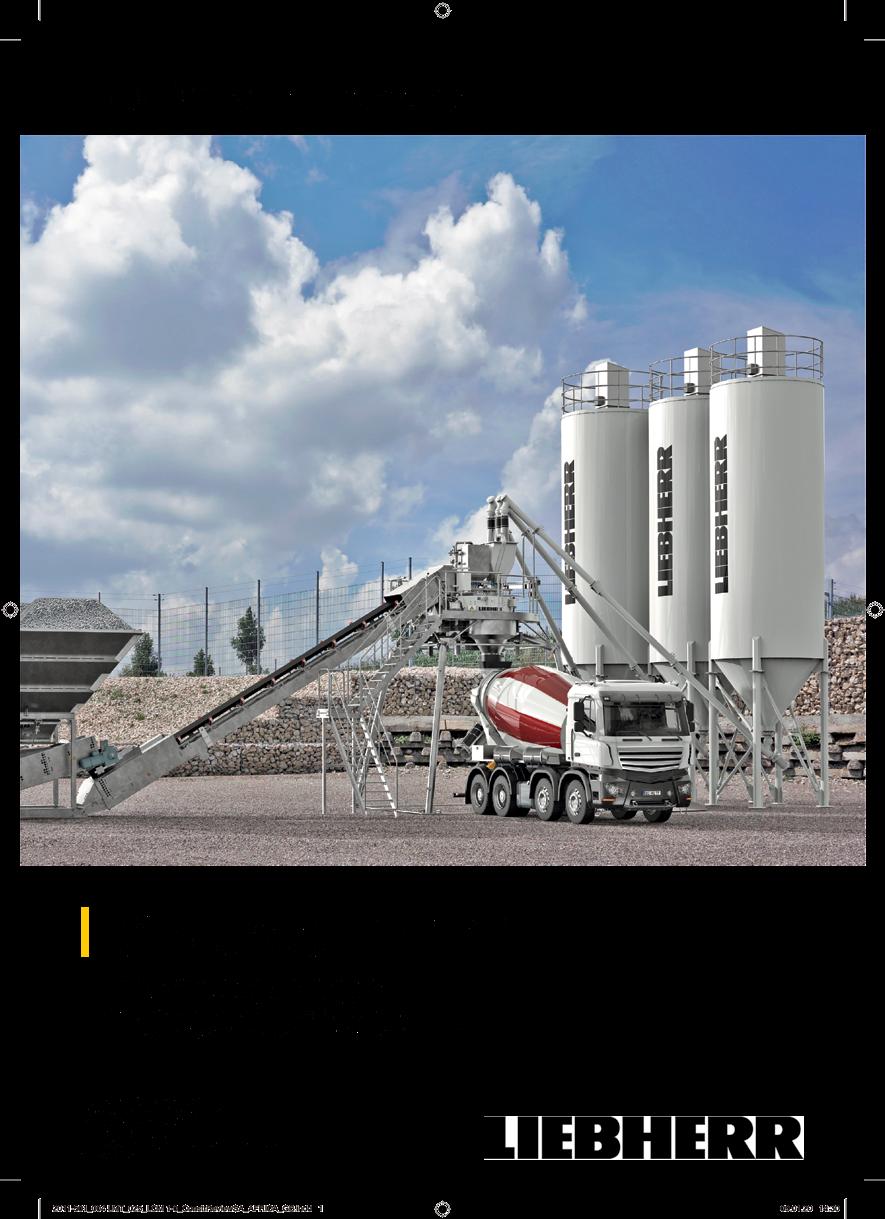

Rhombus, one of the leading manufacturers of premixed concrete in Kenya, has recently installed another batching plant in Athi River, the Southern part of the capital city Nairobi. The batching plant supplied by Liebherr, a renowned manufacturer from Germany, has a capacity to produce 120 cubic meters of concrete per hour.

According to Rhombus Managing Director, Mr. Solomon the plant is meant to serve Nairobi’s southern market as the company looks to consolidate its position in the Kenyan market. He also added that Rhombus chose Liebherr as its supplier because of their impeccable after sales service. “Liebherr is the best when it comes to quality, efficiency. They also provide technical support and ensure the plant is being well utilized for maximum productivity,” he added.

26 CR | Jan - Feb 2020 Liebherr representatives echoed the MD’s sentiments and also added that Liebherr concrete mixing plants enable concrete to be manufactured economically: “We supply our plants in different sizes and stationary or mobile concepts. We can meet individual customer requirements in a short space of time,” he said.