12 minute read

carb ice, this time by Harry Hill of the Winnipeg Area RAA

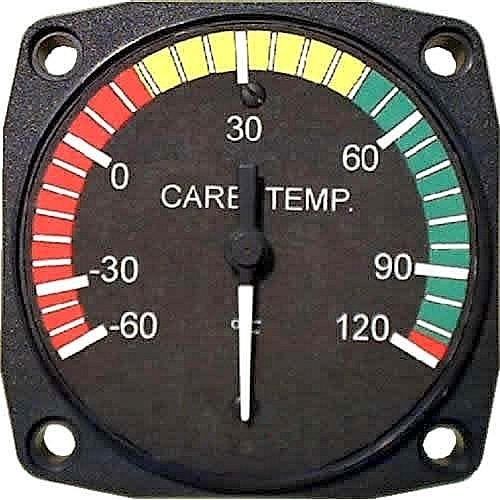

There are many instruments available that can give the pilot carburetor temperature information, many of which are non-TSOd “stand-alone” units for the amateur-builder, in addition to these single instruments (such as those made by Westach) there are several engine information systems (EIS) such as those offered by Grand Rapids, Rocky Mountain and Dynon that offer the option to monitor carb temperature and even include alarms.

One thing more about the use of a carb heat system— I was in the right seat of a DC-3 when we were about to take off into a temperature of –40° F or maybe even colder. I remember thinking that if I were captain, I would have added some carb heat before take-off. Not because carb ice might happen but because I was sure the engine would not like having such cold air pushed into its vitals. As confirmation of this, I am sure that one engine at least made one quick burp as we rolled out for the take-off run. No harm was done but I felt sorry for those poor engines. Not many of us are likely to go flying at –40° F in our little aircraft, but if the occasion arises, may I suggest the addition of some heat for take-off. There will still be lots of power and the wings will develop bags of lift in such cold air.

Advertisement

As I review the above, I am not impressed. I apologize for its shortcomings and hope that it will at least lead to some discussions that will lead to greater enlightenment on the subject.

Harry Hill

hhill56@shaw.ca

Jim Smith of Wichita, KS, has been doing true airspeed (TAS) tests of his ELIPPSE-designed, Fred-Felix-made, three-blade prop on his stock 150-hp, Vans RV-6.

His best speed was at a density altitude of 7,000' where the four-run, GPS-derived, TAS average was 191.6 MPH at 2,741 RPM, with high and low speeds of 193 MPH and 189.5 MPH. His average ROC from takeoff at 1,350' to 10,000' was 800 ft/min at 95 MPH IAS at 1,440 lbs., and a recent ROC test yielded an average of 1,032 ft/min from 2,000' to 10,000' at RPM ranging from 2,300 at 3,000' to 2,175 at 10,000', 1,440 lbs and 95 MPH IAS.

His previously installed two-blade 68-72 prop gave him 191.5 MPH at 3,880' D-Alt at 2,800 RPM in February of last year, and 181 MPH average of two runs at 11,200' D -Alt, 2,700 RPM. elippse@sbcglobal.net ~Paul Lipps

“Low” Altitude performance

Average Speed D-Alt RPM

Old two-blade Prop 68 x 72 191.5 MPH 3,880’ 2,800

Elippse three blade Prop 191.6 MPH 7,000' 2,741

“High” Altitude performance

Average Speed D-Alt RPM

Old two-blade Prop 68 x 72 181 MPH 11,200' 2,700

Elippse three blade Prop 180.3 MPH 11,000' 2,655

Don Parham RFI Power Systems P.O. Box 263 Indianola, Ok 74442 Phone: 918-823-4610

rfi@oklatel.net

By Don Parham

These three engines have an individual displacement of A true pioneer in experimental aviation, Don Parham only 1,000 cubic centimeters each, (about 61 cubic inchhas been developing and building auto conversions es) and rev at two-stroke speeds to develop their powfor gyroplanes and fixed-wing aircraft for many er—well over 6,000 RPM. The 914 is good for 115-hp for years. An experimenter with particular interest in only three minutes and then it has to be throttled back to gyroplanes and frequent contributor to CONTACT! 100-hp continuous.

Magazine, Don has expertise and experience in us-

ing various Subaru engines which has helped lead to The Rotax engines have a very favorable power-totheir popularity among homebuilders around the weight ratio and they are quite fuel efficient. While they world. Aside from his business which converted are certified under the European JAR 22 regulations, a these engines for aviation use, including the manu- lot of the high price has to do with the value of the Euro facture of a successful belt reduction drive, Don over the American dollar. The Rotax 912S is FAR 33 published the popular monthly Homebuilt Rotorcraft certified and is currently the only aircraft engine apmagazine for more than fifteen years. His Current proved to utilize automotive fuel without a supplemental interests are with providing wiring harnesses to take type certificate. Practically all of the European-built lightadvantage of the stock electronics that feed fuel and sport aircraft utilize the 912 or 914 including all of the electricity to the Subaru engine. ~Pat new European gyroplanes.

The Rotax 912, 912ULS and 914 four-stroke engines are quite pricey for their 80, 100, and 115 respective horsepower ratings. The 80-hp 912 is over $12K USD, the 100 -hp model is in the $15K range or higher, and the 115-hp turbocharged 914 engine is in excess of $25K. There just isn’t much available that’s manufactured here in the USA that compares to the Rotax four-stroke engines in the 80 to 115-hp range except for the 80-hp Verner and a couple of versions of the Subaru EA81 and Raven Aircraft’s three and four cylinder Suzuki auto engine conversions.

We know of two companies that build EA81 Subaru engine conversions for aircraft use, they are Stratus, LLC and Ram Performance. Ltd. The Stratus EA81 conversion has been around for a dozen or more years and has been used in a number of light aircraft and several gyroplanes.

The Stratus EA81 develops 100-hp at around 5,000 rpm and has a good track record. Cost for a complete engine package is in the $8,500 range. The engine utilizes dual Bing altitude-compensating carburetors and a cog belt reduction drive with a 2.2:1 ratio. Propeller offset is close to 8 inches above the crankshaft centerline.

Rotax 914 Turbo

Rotax is an Austrian engine manufacturer, founded in 1920 in Dresden, Germany. Operations were moved to Wels, Austria in 1943 and finally to Gunskirchen, Austria in 1947. In 1959, Rotax merged with the Vienna-based Lohner-Werke, a manufacturer of automobile and railway wagon bodies. In 1970 Lohner-Rotax was bought by Bombardier, who uses Rotax engines in their motorBy the way, there is only one other cog belt drive available for Subaru engines and that is the Groen Brothers Aviation EJ22/25 Subaru engine for the SparrowHawk gyro. The prop is offset 7.75 inches below the crankshaft center on that reduction drive and may not be of much use to fixed-wing tractor applications.

cycles, personal water craft, and snowmobiles. The company constructed only two-stroke engines until 1982, when it started building four-stroke engines and aircraft engines. Other important dates include 1962, when a Rotax engine was first installed in a snowmobile and 1989, when Rotax received Type Certification for its 912-A aircraft engine.

Rotary Air Force is out of business as of the first of April, 2007 and we hear that Northwest Aero which built Subaru cog belt drives, is also out of business or doing business under another name.

We at RFI Power Systems discontinued building Subaru and Mazda reduction drives over two years ago although we do sell CAD plans for all Subaru engine models. See CONTACT! Magazine issue #90 for more on that.

As of this writing, we know of only one gear drive PSRU manufactured in the US for Subaru engines and none are built for the EA81 and EA82 engines.

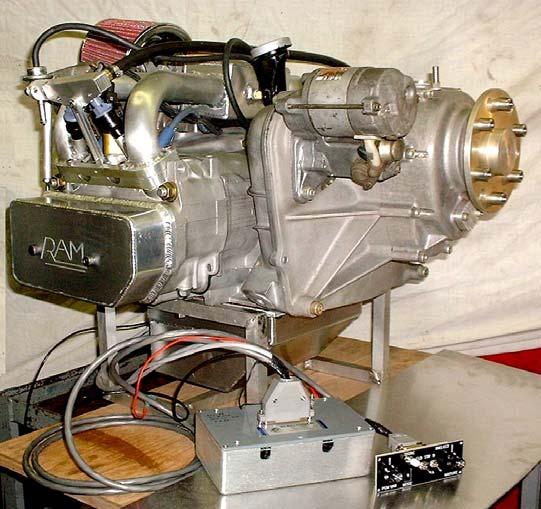

The other EA81 aircraft conversion offered in the US by Ram Performance Ltd., Clinton, Ohio, utilizes a gear reduction system built by Neil Hintz in New Zealand. Ram Performance offers components, short blocks, and complete engines and also complete packages that include custom fuel injection systems, performance headers and the Autoflight gear reduction drive from Neil Hintz. The drives are available in three different ratios: 2.2:1, 2.48:1, and 2.94:1 and are available with the offset up or down. Offset is around 3.5 inches.

The Ram engine packages are rated at 115 and 140-hp. The higher output version utilizes dual port heads with multiport fuel injection. Cost of the 115-hp version is $10,995 and the 140-hp model costs $12,995. That is pretty reasonable when compared to the cost of a Rotax 914 at $25,000 or more by the time the engine is shipped to the USA.

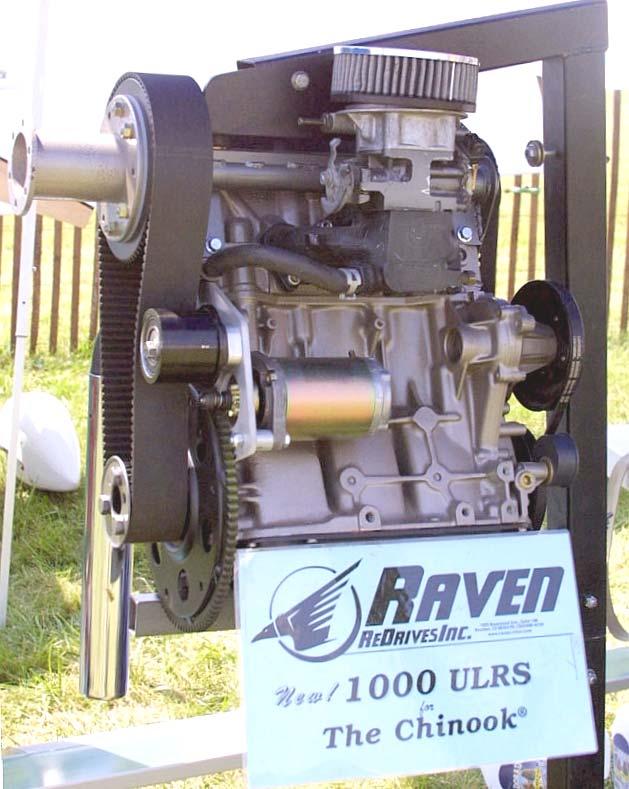

Ron Carr who operates Ram Performance has been building Subaru performance packages for over ten years and is an expert mechanic. Check out Ron’s website: www.ramengines.com for more details. I recently talked with Jeron Smith who operates RavenRotor, LLC in the Denver area and is a regular forum presenter at the CONTACT! Magazine forum tents at Sun-n-Fun and COPPERSTATE. He offers two basic engines: the 1,000cc three cylinder and the 1,300cc four cylinder Suzuki auto engines with cog belt reduction drives. The three-cylinder engine is offered with three different reduction drives and can be installed either upright, or at 20° as it is mounted in the car, or horizontally.

The four cylinder Suzuki engine is available in a flat (horizontal) configuration with a dry sump oil system and is offered in normally aspirated or turbocharged models.

Cost and weight of the engine packages is as follows: three cylinder normally aspirated, fuel injected, 62-hp is $5795. 75-hp turbocharged three cylinder engine is $7495. The 1,300cc four cylinder model normally aspirated develops 90-hp and weighs in at 168 pounds. It costs $8795 and the 115-hp turbocharged model which weighs the same costs $10,995.

140-hp @ 5,700 140 FT/LBS @ 3,400 RPM EA81 MPEFI Real World Solutions EFI controller. 176 pounds as shown. Jeron Smith of Raven Rotorcraft and Redrives Inc., fielding Q&A outside the forums tent at COPPERSTATE, standing next to one of his direct-drive ultralight engines, mounted to the hood of his car as a test stand.

Raven Model 1300 SVS: 90-hp @ pounds. With turbo: 115-hp @ 190 pounds.

The majority of the offerings from Raven are geared more toward the Ultralight market, like this Model 1000ULRS 62-hp @ 130 pounds.

Jeron said that he has built around 220 engine packages and had experienced good success with them. The Suzuki three cylinder engines in the Geo Metro cruise at 3,950 rpm and are very reliable. The Geo Metro automobiles have been routinely used by courier drivers with only routine maintenance performed for over 150,000 miles of service.

If you want to build your own engine you can purchase components from Raven. Cog belt reduction drives for the three cylinder Geo engine run $2,095 to $2,695 depending on the model while the drive for the flat four version of the 1,300cc engine comes in at $3,295.

Turbo kits for the three cylinder run $1,695 and the four cylinder is $1,995. Raven also offers a detailed engine conversion manual for the do-it-yourself builder. For more information on the Raven engines check out www.raven-rotor.com.

THE ECONOMY OF AUTO POWER

One nice thing about auto conversions is that overhauls or engine replacements are inexpensive as compared to an aircraft engine. The Rotax 912 and 914 engine components are as expensive as Lycoming and Continental engine parts and aren’t any more reliable either.

If you need 80 to 115-hp as in a replacement for a 912 or 914 either a Ram Performance Subaru or a Raven-Rotor If you are building a centerline thrust gyroplane either Ram or Raven engines will provide a thrust line on or near the crankshaft centerline. The Autoflight gearbox is offset 3.5 inches above or below the crankshaft center. If you get the horizontal version of the 1,300cc Raven engine the prop offset is not too far above the crankshaft.

If you need 140-hp for a two place ship, the high output EA81 engine would do the job at a weight of around 200 pounds which is at least 100 pounds lighter than an EJ22 or EJ25. The dual port head EA81 should provide plenty of power for a typical two-place gyroplane and performance should be pretty impressive with the absence of a hundred pounds or so. Neil Hintz (Autoflight) also has a 140-hp engine that is a little over 200 pounds dry weight. That is the EA82 engine with custom dual port heads.

Airplanes and rotorcraft are very weight sensitive in the performance department, so the lighter you keep the total weight the better you can expect the performance and fuel economy to be.

A lighter weight engine means a lighter weight airframe and in the case of rotorcraft, smaller diameter blades to lift the same payload, and of course as mentioned earlier the less fuel will be burned. The high cost of fuel in Europe is one of the reasons why the Rotax four-stroke engines are popular there, plus the cost is less in Euros and there is less shipping costs.

The new, 2008 Subaru autos are up on the Subaru website. There isn’t much change in the engines for the new models except that horsepower has been reduced slightly. The 3.0 liter six cylinder is down to 243-hp from 250hp and the normally aspirated EJ25 is now rated at 170hp. According to Subaru, the reason for the reduction is that the new ratings are for use of regular fuel. We still haven’t heard anything on the new diesel boxer engine (see CONTACT! issue #86). Still don’t know displacement, weight or power rating but do know that it is turbocharged. It will probably come out for domestic Japanese and European autos first and it may not be available in the USA for some time, if ever, since we are not that keen on diesel engines in this country.

The newer Subaru engines should be a little lighter than earlier models because the 2006 and later engines have a plastic intake manifold which should knock ten or fifteen pounds off of the all up weight.

It is a shame that Subaru doesn’t have smaller engines available in North America. There are EJ15 and EJ16 engines built for the domestic Japanese market that are smaller versions of the EJ18, 20, 22, and 25 which have favorable power-to-weight ratios and develop around 100 -hp. In the meantime we will just have to be content with the EA81 and EA82 or the three and four cylinder Suzuki engines. Don Parham