26 minute read

ness concern where the engine loses power due to the loss of cylinder head fastener torque

Photo: Phyllis Ridings-Murawski

The loss of an aircraft, and survival of a dream. By Phyllis Ridings-Murawski, Photos: Steve Garvin Geared Drives, LLC 1510 South 3rd Conroe, TX 77301 (936) 827-5126

Advertisement

www.GearedDrives.com Bud@GearedDrives.com

CONTACT! Magazine readers may remember seeing this plane on the cover of our July-Aug 2007 issue, #89. Although the staff at CONTACT! is deeply troubled over the loss of such a beautiful plane, we can’t help but be elated that our friends on board survived the accident unharmed and are in the process of getting back into the game and, in a way, the accident has opened the door to new possibilities. ~Pat

To see the photos of the scene, it is easy to see how no one believed that we walked away. My father, Bud Warren, and I were looking forward to our flight in the Wheeler that Thursday afternoon, October 18, 2007. EAA Chapter 774 had previously invited us to give a presentation for their members and guests regarding the use of Chevrolet engines in experimental aircraft. They were expecting us to fly in that afternoon.

Of particular interest to the group was Bud’s Geared Drive, a straight-cut spur gear propeller speed reduction unit (PSRU) with its fully automatic centrifugal clutch and flywheel assembly. We were planning to arrive at the meeting early so that we could remove the cowling from the Wheeler to allow everyone to get a good look at the installation. They were all looking forward to a question and answer session in order to learn more about Bud’s engine and PSRU setup in his Wheeler Auriga. What better way would there be to accomplish this than to fly the aircraft in for an up close and personal look? We just met our new friend James at our local EAA Chapter 302 meeting the Saturday before and we invited him to join us on our trip to Brookshire, Texas, the home of Chapter 774. As our guest, I offered him my spot in the right front seat and I piled in the back with my laptop, big screen monitor and all the other magic electronic stuff that it takes to do a really thorough, professional and entertaining presentation for an EAA Chapter meeting. Within a few minutes we were cleared to taxi to oneniner at Lone Star Executive Airport, located in Conroe, Texas, for a departure to the west. Ten-mile visibility, weather was fine, winds were light and it looked like a nice afternoon for a flight to West Houston. We planned to fly back home later that night following the meeting.

GETTING OFF TO A BAD START

As we departed the pattern to the west and flew along just to the south of Lake Conroe, we pointed out landmarks to James. The air was really calm and stable and the flight was smooth. However, several miles out we encountered some haze so we dropped to about 1,500 feet in order to stay out of it. Moments later, Bud announced that his engine oil temperature was higher than normal. This alarmed us because he resolved all engine cooling issues years before, back when he first developed the engine package. Engine oil temperature indicating on the high side is never good news.

“The water temperature looks fine,” Bud said, “and the oil pressure is perfect. What the heck is going on?”

A second later, the engine coughed. “Now, this is not good”, Bud said. The engine coughed again. I noted to Dad that I thought the engine smelled like it was hot. I also thought it smelled like burning oil. The engine was losing power, and smoke began to fill the cockpit. Then those dreaded words were heard. “You guys help me find some place to land — we are going down.”

PICKING THE PLACE TO LAND

Bud immediately banked to the left to do a 360-degree turn and survey the area for possible landing sites, remembering that the closest and best place to put her down could be have been just behind us. There were no roads nearby we could land on. No smooth asphalt airstrips, nothing but piney woods all around. Then suddenly, about a mile in the distance was a beautiful hayfield. Believe me, to us there has never been a more beautiful hayfield!

On the right-hand side of this rather wonderful hayfield was a nice, long, smooth and level area between the fence line on the right and a long row of huge round hay bales to the left. We weren’t sure if we would make it far enough to clear the iron ore strip mine that stood between the hayfield and us. The iron ore mine was rough, with large holes and uneven pits all around and filled with water. At that point, the hay field seems so very far away. If we could make it there, it would be our grass landing strip, our only chance for a safe landing. Thank God for farmers, I thought as Bud trimmed for max glide and made for the hayfield. By now, the smoke was getting thicker and the engine was running weaker and weaker. The atmosphere in the cockpit was calm and matter-of-fact. This gave me a lot of peace and I was able to just relax and take what was to come. I remember thinking, If anyone can get us out of this safely, Dad certainly can.

I don’t believe that anyone really ever expects to have an engine fire or a forced landing, but a pilot had better be ready for one at any given minute. There was a moment of nothing but quiet in the cockpit. I think that the three of us were all going through our own emergency checklist in our minds. Suddenly I remembered something I could add, and I blurted out with a rather loud and forceful, “Pop the door, James!”

I had been watching my DVD’s and reading my books and, as a student pilot, this was a detail that was fresh in my mind. I wondered why I had not thought to say it sooner. I guess that you never really know how you are going to react in an emergency until it really happens to you. All I remember is that Bud was intent on getting this airplane and his passengers safely to the ground. James was busy with his own personal checklist and we were all busy watching the ground coming at us faster than we would have liked. It all happened so quickly.

TOTAL POWER LOSS

Dead sticking the Wheeler in itself was not a big deal but it certainly glides better while making at least some power than when it’s not. We prayed that we could stay in the air long enough to make it over the fence and into the hayfield; our survival depended on it. But just as we cleared the jagged open-pit mine, the engine quit altogether. With the subsequent increased rate of descent, we didn’t quite clear the farmer’s fence and the Wheeler clipped two large posts with the left wing. This destroyed the wing and ruptured the fuel cell. One fence post broke off and one was completely pulled out of the ground. I remember seeing a broken post and dirt flying past the left window just before we made contact with the ground, and thinking how very odd it looked. The aircraft made impact with the ground hard enough to punch the landing gear up through the wings. Striking the posts with the left wing sent us rotating in a counterclockwise motion, on the airplane’s belly, as we slid across the slick grass of the hayfield. While we were spinning on the ground, all we could see from the windows of the airplane was bright hot orange and red flame all around us. We must have looked like a pinwheel on fire until we came to a stop.

EGRESS

It was a surreal moment. I sat in the back seat stunned for what felt like minutes, but could only have been seconds when I heard Bud yell, “Get out of the airplane!” I don’t even remember actually seeing who made it out first, but I know it was James. He raised the right hand door that he previously unlatched and bailed out.

I made my quick exit from the back seat out the right side following James. Bud was the last one out of the airplane. The left side of the airplane was burning like mad, and it would have been impossible to escape through the pilot’s door. Thank God for cool heads and two doors on an airplane.

I ran a few steps away and looked up to see James and my father standing side by side. I thought that was the most wonderful thing I had ever seen; the two of them, safe and alive. I ran to them and gave them both a big hug, surveyed them for injuries, then turned to see the burning airplane for the first time. The sight of the Wheeler burning, with nothing we could do about it, made me feel sick. The reporter in me required that I reach in my handbag for my digital camera and get a shot of the scene, but by that time the entire cockpit was completely engulfed in flames.

VERY MINOR INJURIES

James suffered a bruised ribcage, a few scrapes and what looked like sunburn on his face from the heat of the fire. Bud had two large goose eggs on his head. The backs of his calves were burned, some of his hair was singed off, and his face was burned a bright pink from the heat of the flames. His seat belt buckle got so hot that it burned his fingers when he removed it. In a moment of complete gratitude, I realized that as a passenger, I survived an in-flight engine fire, a forced landing and total loss of an airplane with only a scraped elbow. My sense of elation was overwhelming.

We stood quietly in the hayfield, watching the airplane burn, wondering what to do next. We could not call anyone since we all left the aircraft so quickly that we didn’t grab cell phones or any of our electronics. I managed to grab my purse but on my way out, my cell phone must have fallen out. Bud wondered aloud how long it would take for someone to find us.

RESCUE

The black billowing smoke must have made it easy to track us because in a matter of moments the farmer and his friends showed up in their pickup trucks and they stayed with us until the emergency personnel got there. They were kind to us, offered us their phones, and we were able to contact our families, our FBO, and EAA Chapter 774 to tell them we would not make it to the meeting. I looked up to see a friend of mine, Leslie, running toward me, shouting “Phyllis, is that you?” She gave me a bear hug and said that she could not believe that I was alive. I told myself that maybe I lived in Montgomery County too long when the first person who showed up after we crash landed an airplane in a field is a friend of mine! What are the odds?

FAA

The next few days were gut wrenching for Bud. Friday was FAA day, that dreaded day when you must interview with the feds and submit your report. Then the NTSB gets involved, makes their notes and you go away nervous, not knowing what they are going to do or say. Following the interview, Bud was told that the scene had been released, and he could go ahead and begin clean up and salvage operations. The following day, Saturday, Bud took truck and trailer to the site and cut the airplane into pieces, removing the wreckage from the hayfield. Sunday was spent cleaning up the hayfield and repairing the farmer’s fence that we destroyed. I felt so bad for my father; it must have been sickening for him to have cut up into little pieces the charred and burned wreckage and then to haul it away.

THE AFTERMATH

That airplane was a dear friend; Bud could hardly speak about it afterward but once the pieces were home, he disassembled the engine and PSRU. Close inspection revealed that the engine caught fire along the right side due to the failure of a braided steel fuel line near the fuel pump. Apparently the lining failed, allowing fuel to spray back along the right side of the engine, igniting it on the headers, burning the distributor completely off and leaving the spark plug wires looking like wire mesh. The fire burned a hole in the aluminum firewall; the smoke we were seeing was in part due to the insulation burning between the firewall and the cockpit. We did not know how very close we were to having fire in the cockpit during descent until we saw that hole in the firewall. Thank God for the haze that appeared, requiring that we fly lower than we would have otherwise. We didn’t have any extra time to descend from a higher altitude.

Thank God that this fire did not happen on our way home that night. I am pretty sure that no one would be able tell a hayfield from the piney woods at night, not even my Dad. And thank God for Dad’s unwavering and decisive piloting skills. Never did I doubt that he could get us down safely. I was not afraid. My friends asked me if I would ever fly again. My answer: any time, any day, with my Dad.

The postscript to this story is that Bud’s Geared Drives PSRU escaped the impact, prop strike and fire completely unscathed. Inspection of the unit on the bench following the accident (with witnesses in attendance) revealed absolutely no damage to the aluminum case, shaft, gears, flywheel, clutch assembly, or any of the other components. We were both stunned and humbled at the same time.

Bud’s PSRU performed far beyond his expectations and under the worst of circumstances. One of our friends joked that we could now tell everyone that we literally “test run ‘em into the ground!” Sometimes laughter is what gets you through.

The unscathed internals of Bud’s charred PSRU.

The Monday following the loss of his aircraft Bud continued on in typical style, fulfilling his obligation to attend and participate in the COPPERSTATE Regional Fly-in, and conducting several forums on automotive conversions. Bud is currently making plans to build his next airplane and is leaning heavily toward building an RV-10. He has already begun plans to build his firewall forward package for this aircraft and plans to have an LS-1 engine with a Geared Drives PSRU on an engine stand to demonstrate at Sun ‘n Fun, 2008. Of particular interest, he has just delivered three PSRU’s to customers in New South Wales, Australia, for installation in their scaled P51s. One is for use with a Chevy V-8 and two of them are set up for use on BMW V-12 engines. Bud has delivered another PSRU which is currently undergoing testing for possible use in a Reno air racer. His agreement with this customer is that if they can blow it up in testing, he will do what it takes to beef it up so that they can race it at the 2008 Reno Air Race!

Several other interesting projects are underway, not the least of which is the one-of-a-kind Mooney experimental that Bud has been working on for part of the last year. This airplane has a Supercharged Ecotec 2.0 L Chevrolet engine installed with the Geared Drives PSRU, and at 205-hp it is really expected to be a super performer. We also have a customer in Canada who is flying a Chevrolet V-8 with a Geared Drives PSRU installed in his Cessna 182. The progress of these and additional projects will be posted on at www.GearedDrives.com.

Note: The intense personal nature of the loss of our Wheeler has made it difficult to write about or to tell others about. However, the fact remains that we experimental aircraft enthusiasts can learn from one another’s trials and tribulations, successes and failures. Our hope is that perhaps someone will benefit from us sharing our experiences.

We humbly offer a special thank you to our experimental aviation family for your support and good wishes throughout this time, which has been difficult for us, but know that it will take more than the loss of an aircraft to destroy our vision and dampen our determination. See you all at Sun ‘n Fun and Oshkosh in 2008!

Bud Warren and daughter, Phyllis Ridings-Murawski

...and probably not the last.

The following is a reprint of an article that appeared in the October, 2007, issue of the Winnipeg Area Chapter of RAA Canada monthly newsletter (Winnsock), written by one of our loyal subscribers. ~Pat

By Harry Hill

hhill56@shaw.ca

I may not have been thinking too well when I suggested an article on this topic for your Winnsock. And your editor Bob Stewart, being hard up for articles, wasn’t too choosy and gave the go-ahead. I was probably influenced in making my suggestion by my experience as an investigator and as a pilot. It seemed to me that occurrences involving carburetor icing (carb ice) kept happening despite all that is said and taught on the subject. Thanks to Google.com it’s easy to see that carb ice related incidents and accidents are still rather commonplace. So maybe there is some sense in trying again to understand this phenomenon and its proper handling. In this, my part of the discussion, I will try to concentrate on icing in the carburetors of the smaller types of engines that most of us will fly. And I will not give much time to other than carb heat as a means of combating carb ice. Other ideas or thoughts will find a way in of course.

WHY IS THERE AIR?

Although I couldn’t find it on the records (LPs) that I have, I feel quite sure that the question was the title of a stand-up bit by Bill Cosby and with him, I feel equally that the answer was something like “to blow up basketballs.” That makes sense to a kid growing up in a big city in the USA, but those of us involved with aviation might have a similar tongue-incheek answer, “so that we can fly.“

So let us have a quick look at air because it is, of course, essential to our enjoyment of flying and, at times, gives us problems in flying. I expect that we all were supposed to learn something about air when we were learning to fly. If you know it all, please forgive me this review.

The major components of air are nitrogen and oxygen, about 78% of the former and about 21% of the latter according to one weather related text that I have. There are small amounts of other gases including water vapor. Near the surface of the earth, natural processes keep the two main gases in balance near the values given. However, the amount of water vapor in a sample of air can vary from a high of about four percent in tropical areas to a small part of one percent in the Arctic. The other Gases don’t mean much to our use of air but the water vapor certainly does.

There is a maximum amount of water vapor that a sample of air can hold at any given temperature and pressure. For our use, we express lesser amounts of water vapor as a percentage of the maximum and we call such percentages “relative humidity.” Air containing the maximum amount of water vapor is said to be saturated.

If a sample of air that contains water vapor but is not saturated is cooled down sufficiently, a temperature will be reached at which the same amount of water vapor becomes the maximum amount that the sample (at the new lower temperature) can hold. We call that lower temperature the “dew point”. And in normal circumstances, the vapor condenses and becomes visible in the forms of cloud, fog or ice crystals, or maybe something else that I haven’t thought of at this time.

Aviation weather reports usually include the temperature and dew point and we call the difference between the two the “spread.” When the spread is small, a small amount of cooling can cause the air to become saturated. And a small spread also means a high relative humidity of course. A large spread indicates a low relative humidity and what we call dry air. It is worth noting that very cold air, say –30° C (-22° F), can have a high relative humidity but contain only a very small amount of water vapor. When that air enters our homes and is heated to say, 20° C (68° F), it then has a very low relative humidity.

Thus ends the lesson on air.

ICING IN GENERAL

Discussions of carb icing frequently start with at least mention of induction system icing and three types of icing that can happen: impact icing, throttling icing and fuel evaporation icing. The first can happen when supercooled water or wet snow contacts surfaces such as air filters and intake ducting that are below freezing temperature. Of course, when that happens ice will also accumulate on the airframe and stress levels will rise in the pilots and knowledgeable passengers. In our kinds of airplanes, we don’t usually have the means of getting rid of airframe ice so we better have means and knowledge that will allow us to keep the engine running so that we can get out of the conditions causing the puckers.

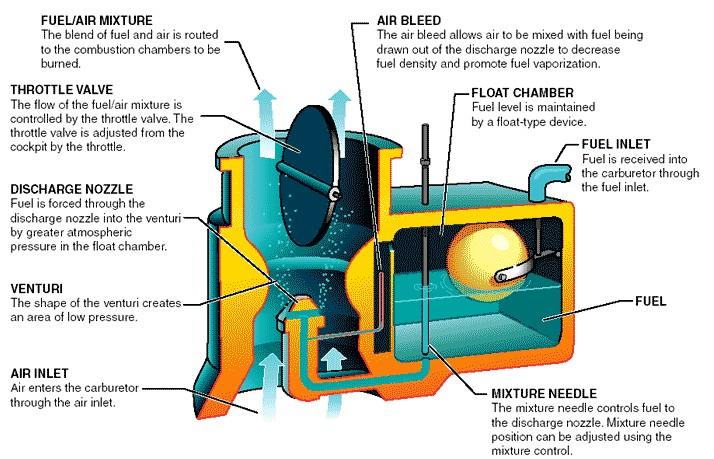

The effects of impact icing are sometimes taken care of by “suck-in” doors in the induction system located ahead of the carb. In the second type of icing previously mentioned, throttling refers to the reduction in flow area in the throat of a carburetor caused by the venturi or by the throttle plate. Both of these situations (impact and throttle) cause a reduction in pressure and a consequential cooling in the throat of the carb.

We have all probably felt fuel evaporation cooling because we have all probably spilled gasoline on our hands. The cooling effect is immediate and quite noticeable and results from our body heat being used to evaporate the fuel. In the research that I did for this article, I was unable to find estimates of the amount of cooling in a carb that was attributable to each of those cooling elements. I did find that it is estimated that the total cooling can reach about 40° C (104° F)! Consider a nice summer day, with a temperature of 20° C (68° F) and relative humidity of 50%. If I have correctly read the small psychometric chart in a handbook that I have, it would take only about 11° C of cooling to raise that air to 100 % RH. So carb ice happens.

UNDER WHAT CIRCUMSTANCES CAN IT HAPPEN?

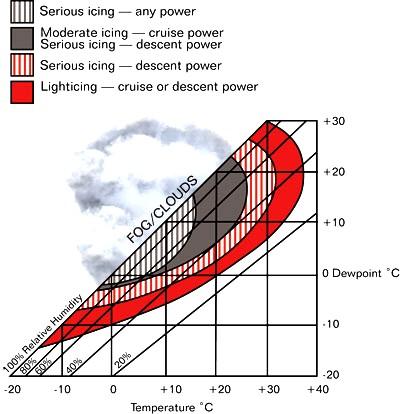

First, consider the conditions of the air in question. You can find lots of words about the weather conditions in which carb ice can happen but I think that the information is much better presented in a temperature and dew point forecast. The graph will enable you to estimate the severity of icing that might happen while in flight under those conditions.

Carb icing can be more severe with closed throttle or reduced throttle settings. I would surmise that is a result of the tighter restriction in the throat of the carb and resulting greater cooling effect. At the same time, less power and less heat under the cowl are generated with lower throttle settings. And smaller throttle openings result in smaller gaps for ice to bridge if it starts to develop. Things could get ugly in a hurry. This may help explain the “serious icing with descent power” area shown in the carb ice graphs.

So carb ice happens in various flight conditions. Also, the use of mogas can lead to carb icing at higher ambient temperatures. Again, my 1993 info says, “In severe cases, ice may form at OATs up to 20° C (68° F) higher than with AVGAS.” I presume that that happens because mogas evaporates more readily than avgas and in so doing, causes greater cooling due to evaporation.

EARLY DETECTION

And how do we know if carb ice is happening? To simplify this discussion, let us look at cruise flight at a consistent altitude and throttle setting. When carb ice develops beyond a trace of ice, you can expect a power loss. With a fixed pitch propeller, there will be a loss of RPM. With a constant-speed propeller, there will be a drop in manifold pressure. In either case, the engine could start to run roughly. We can use carb heat to see if icing is the culprit, as we’ll discuss later in this article.

CAN CARB ICE BE PREVENTED?

In 1970, the Fuels and Lubricants section of the National Research Council of Canada issued a report titled “Aircraft Carburettor Icing Studies”. (Yes, they did spell it with two tees). The main purpose of the study leading to the report was to see if additives in the fuel or if surface treatments in the throat of the carburetor could markedly reduce or eliminate carb icing. In my judgment, the test was well set up and some good results, relating to icing in general, were obtained. For example, the test set up allowed quick disassembly of the intake after a test permitting good photographs of ice that had developed before melting could eliminate the evidence. It was found that a couple of glycols with fancy names could eliminate icing and that a Teflon coating of the throttle plate and carb throat would prevent ice from adhering to those surfaces. Neither of these practices were adopted, of course, and so we are left with carb heat as our defensive weapon.

In our type of airplanes, the carb heat system usually starts with a muff around some part of the exhaust system to gather heat. Heated air from the muff is ducted to a means of introducing heated air into the intake system before the carburetor. A manual control in the cockpit controls the diverter valve in the system. The carb heat system bypasses the intake air filter and so it is recommended that heat not be used on the ground except for check purposes.

For flyers of factory-builts or of amateur-builts with good operating instructions, the use of carb heat starts with an understanding of any instructions with respect to the topic. After that, I think that the use of carb heat starts with a check of the weather reports and forecasts before flight. A check of the spread will permit, with the carb icing graph shown on the opposite page, an estimation of the possibility and severity of carb icing. Some aircraft check -lists or handling notes call for a check for carb icing on run-up. Whether it is called for or not, I think it is a good practice, especially if the spread is not great. It is a simple check, usually done at an intermediate RPM used for other checks on the run-up.

GROUND CHECK

The throttle is prevented from moving and the RPM noted; full carb heat is applied and left long enough to ensure that any ice is removed; then the carb heat control is moved to full cold and the RPM noted. If there is an increase from that seen before the check, there was ice in the carb and it can be expected to occur again as the flight progresses.

Carb heat should not be used on take-off as power will be reduced by its use. If take-off is delayed much after the run-up, heat could be applied until just before take-off to ensure that no ice will develop during the wait. The routine of the check is the same. If icing is found, then the pilot can expect more ice build-ups as the flight progresses. The routine of the check will remove any new ice that may have formed. Some handling instructions suggest trying to find a setting of the carb heat control just high enough to prevent ice build-up. If that can be done, the mixture should be adjusted to suit the higher intake temperature that results. If the throttle is not wide open before setting the carb heat, it can be adjusted up to regain power before adjustment of the mixture.

If one is just punching holes in the sky when carb icing may be present, it would be prudent to occasionally level off, set the throttle and go through the icing check process to eliminate any ice and to prevent worsening of an icing situation. I seem to remember (from some 50 years ago) that, in Harvard training, we did a full “vital actions check” that included a check for carb icing before doing stalls, spins or aerobatics. If icing was present, we were not supposed to do spins as they were done with the throttle shut off and the engine at idle.

On descent with reduced power, exhaust and under-cowl temperatures will decrease. If a partial carb heat setting had been used while in cruise, a higher setting (during descent) should be selected to ensure the prevention of ice. Some handbooks call for full heat on descents and in the circuit. A note in a Cessna 172 manual, in a section on landing reads, “Carburetor heat should be applied prior to any significant reduction or closing of the throttle.” Sources seem to agree that if carb heat is on prior to landing and the landing is aborted, or if a touch-and-go is made, the throttle should be opened fully before the carb heat is removed.

CARB TEMPERATURE INSTRUMENTS

I am a fan of carburetor temperature gauges. I think it started with my introduction to the Beechcraft C-45 Expediter when I was flying in the RCAF (Aux) or reserve or whatever it was called. I was with 402 Squadron in Winnipeg and the Air Navigation School was also flying the bug-smashers from Winnipeg. There were some losses and someone decided that the problem was carb icing. The solution to the problem was to require that after take -off, all RCAF operators maintain 5 to 10 degrees C on the carb air temp gauge. The probe/sensor for the system was downstream of the carb and all of the engine cooling air so that maintaining carb temp in that range ensured that ice would not form. It was simple, it worked for me and many others, and I never noticed any performance loss during my fairly long experience in those airplanes. About the only thing a pilot had to remember to do was to add a little induction heat after reducing power for descent.

Adding a carb air temp gauge to a certified aircraft is not impossible, just expensive. I found the Web site of one supplier of a system. It would be easier and less expensive for an amateur builder to add a carb temp gauge for his power plant. A local “engine person” suggested that a Radio Shack temperature gauge could have its sensor epoxied into the intake system downstream of the carb and provide the vital information. I imagine there is someone out there with more elegant but still doable and not too costly solutions.