VISION MADE SIMPLE

•

3D SMART CAMERA

• ON-BOARD IMAGE PROCESSING

• COMPANION APP (iOS/ANDROID)

The Smart 3D Camera : Advanced Technology for Quality Checks and Inspection

Our Smart 3D Camera, featuring Time-of-Flight technology and QVGA resolution, is designed for highly accurate quality checks and inspections of medium- to large-sized objects. Smart Camera is ideal for industries that rely on costly manual inspection routines. With onboard image processing, it's not only powerful but also highly cost-effective.

• SIMPLE NO-CODE CONFIGURATION

• ALGORITHM LIBRARY

USE CASES

The Smart 3D Camera communicates directly with our no-code iOS/Android companion app, allowing you to use predefined algorithms tailored for specific use cases. It’s intuitive and requires no coding expertise, avoiding dedicated staff overhead. With just 5-10 sample images, you can easily train the Smart Camera to meet your unique application needs, ensuring fast and reliable results every time.

LIBRARY OF USE CASES FOR EASY CONFIGURATION

QUALITY CONTROL

Verifies that the captured image of the object envelope corresponds to the pre-taught reference image.

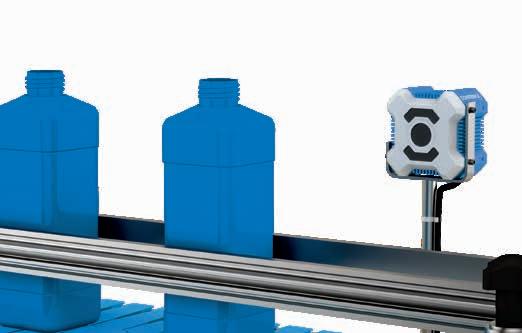

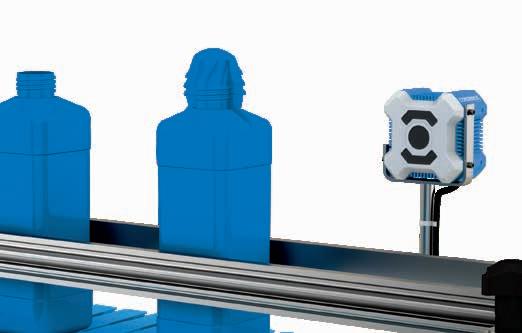

AUTOMATED BLOW MOLDING

QUALITY CONTROL

CUSTOMER APPLICATION

Thin flaps of plastic, or flash, that escape from a blow-mold tool during the production of plastic bottles, typically form on the top of a molding. In-line trimmers ensure that finished moldings are flash-free and fit for purpose.

CUSTOMER SOLUTION

CUSTOMER BENEFITS

• Reduced operating costs with flexible, localized vision systems for in-process quality control using 3D Smart Cameras

• Affordability and convenience of self-contained product inspection with on-board image-processing capability and industry-standard connectivity

CONFECTIONERY MANUFACTURING

FILL-LEVEL MEASUREMENT

CUSTOMER APPLICATION

When molding hollow chocolate confectionery, accurate control of the amount of liquid chocolate in the mold is vital, as this determines the weight and wall-thickness of the finished product.

CUSTOMER SOLUTION

CUSTOMER BENEFITS

• 3D Smart-Camera system reduces cost of quality in low- and medium-volume production, offering affordable automated control of mold fill-level in real time

• Self-contained, easy-to-install operation with on-board image-processing and top-down viewing capability

Calculates the actual filled volume and compares it to the pre-taught reference volume.

Output FILL-LEVEL MEASUREMENT

PACKAGING – FLAP POSITION

Verifies if cartons have been closed correctly.

Output

Output : (i) Reference volume reached (ii) Displays calculated volume (IO-Link or app only)

(ii) Displays measured flap angle

3D Smart Cameras from Contrinex, using Time-of-Flight (ToF) technology, inspect moldings for the unwanted presence of residual flash and unwanted variations in shape, triggering an alarm if a defective part is found. Smart Cameras, featuring on-board image-processing, require no coding to configure and set-up via a dedicated iOS/Android companion app.

MOBILE APP

Predefined Smart-Camera algorithms include visual inspection and feature detection.

During configuration, real-time images of the target show clearly the presence of any residual flash or other defect in product formation. Here, the right-hand image on the app, highlighted in light blue, indicates a defective molding.

In routine operation, Smart Camera communicates directly with local control systems via SIO or IO-Link.

• Quick and easy configuration with no extra staff costs for businesses with little or no coding resource

• Tangible cost savings by replacing laborious manual inspection with Smart Cameras

The Contrinex 3D Smart Camera monitors the fill-level in real time, triggering an alarm in the event of an incorrect fill. This innovative instrument features Time-of-Flight (ToF) technology with on-board image-processing, yet requires no in-house coding capability for configuration and set-up, thanks to its dedicated iOS/Android companion app.

MOBILE APP

The companion smartphone app gives access to a library of predefined algorithms, including fill-level control.

During configuration, the app displays real-time images of the target, showing clearly any instances of under- or over-filling.

Here, the right-hand image on the app, highlighted in light blue, indicates an underfilled mold cavity. Once configured, Smart Camera communicates directly with local control systems via SIO or IO-Link.

• No additional staff cost for smaller businesses with little or no coding expertise

• Immediate cost savings arise from Smart Camera’s ability to replace time-consuming manual inspection