Essential Farm

covering East Anglia and the Midlands

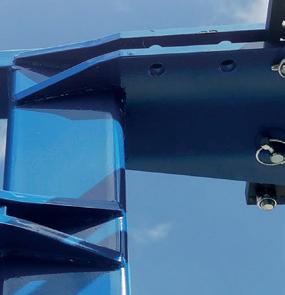

Twin hold roll pin blade removal system and backward leaning air borne upper blade for trash lift and ease of trash flow

Twin hold roll pin blade removal system and backward leaning air borne upper blade for trash lift and ease of trash flow

Seed depth tail 40mm deep holding the seed at correct depth and placing seed on either side of seed terrace

Seed depth tail 40mm deep holding the seed at correct depth and placing seed on either side of seed terrace

Triton launched its unique deep soil engagement direct drill in 2018 to give plough based yields from direct drilling. 6 years later we are consistently achieving higher yields from the Triton than from ploughed trials on our own land. The Triton is the only all weather seed drill on the market that gives the flexibility to grow maximum profit autumn sown crops whilst reducing blackgrass from late drilling... several manufacturers are now also claiming all weather capability... if these are false claims then the farmer’s new approach will be thwarted.

Downward facing upper blade does not hook grass weed seed up from below stale seed bed and field surface

Downward facing upper blade does not hook grass weed seed up from below stale seed bed and field surface

Triangular tungsten tiles for reduced draught and soil disturbance

Triangular tungsten tiles for reduced draught and soil disturbance

SOIL SURFACE

Drilling at 40mm depth

SOIL SURFACE

Downward facing upper blade holds field surface in place minimising soil eruption in the stale seed bed

Drilling at 40mm

Downward facing upper blade surface in place minimising soil eruption in the stale seed bed

holds field

Buying a blade drill is now an open and shut case. Why?

14cm deep lower blade takes blade deep below ground for air drainage and rooting

Because only the Triton drill has a slot closer

14cm deep lower blade takes blade deep below ground for air drainage and rooting

www.vanstomp.co.uk

Rogueing

Field workers

Tractor and FLT

Picking

Packing

Grading

Factory Staff

Livestock care

Hedging

Groundwork

Events staff

General labour

The People People

WE HAVE SKILLED AND UNSKILLED STAFF AVAILABLE NOW 40 years’ experience providing temporary and seasonal workers to farmers, growers and related businesses across the UK.

Committed to supporting our farming community through these terrible times

We can supply teams of staff or single workers throughout the year. Fully GLAA and HSE compliant. Transport and supervision available as required.

needs.

New powers aim to deter the theft and resale of all-terrain vehicles and quadbikes – a racket which costs farmers £2.8m annually.

It comes after the Equipment Theft (Prevention) Bill received Royal Assent following months of work by the NFU, rural insurer NFU Mutual, the National Rural Crime Unit and other industry organisations.

The act grants the government new powers to make regulations that deter quadbike theft – such as requiring ATVs to be fitted with immobilisers and forensic markings and ensur-

ing the owners details are reg istered on a database.

Combating crime

NFU vice president David Ex wood said: “Farmers across the country will be delighted that the government and police now have wider powers to tackle increasing incidents of equipment theft.

“Quads are often one of the main things that attract criminals onto farms which often leads to further thefts. But if these new powers can deter criminals in the first instance, I hope they will drive a reduction in further instances of rural crime.”

Editor:

Johann Tasker T: 07967 634971

E: johann@ruralcity.co.uk

Advertising sales:

Danny Lewis | T: 01502 725862

E: danny.lewis@micropress.co.uk

Advertisement production:

Jade Soanes | T: 01502 725840

E: jade.soanes@micropress.co.uk

Mr Exwood thanked Greg Smith MP, Lord Blencathra and the Home Office for working so closely with industry groups to get the bill through parliament. He added: “This legislation is a big step forward in protecting Britain’s farms.

“We now urge the government to pass secondary legislation to widen the scope of the Equipment Theft (Prevention) Act to include other agricultural equipment, especially GPS systems after the stark rise in thefts this year.”.

Combating crime

NFU Mutual rural crime expert Bob Henderson said: “We know the role measures such as forensic marking, registration and immobilisation play in preventing crime and we have a huge opportunity to protect farmers and tradespeople.

“The Equipment Theft Bill receiving Royal Assent comes at a

time when we are seeing an increase in theft of vital equipment and machinery.”

Latest theft claims figures from rural insurer NFU Mutual show a 26% annual increase in the cost of quad theft – bringing the total value to £2.8m in 2022. A continued increase in thefts this year has prompted a warning to farmers to ramp up their security.

Quad thefts at busy times can leave farmers struggling to look after crops and livestock when they are at their most vulnerable. NFU Mutual says extra security measures should be implemented where possible.

Farmers across the country will be delighted

Yamaha has announced a trade-in bonus of £1750 against the purchase of its side-by-side all-terrain vehicles.

The trade-in bonus applies to the Wolverine RMAX 4 1000, Wolverine RMAX 2 1000 SE, YXZ1000R SS and Viking EPS models. It applies to part ex change of any recreational offroad vehicle regardless of make, model or year.

Yamaha power products man ager Gareth Sloane said: “This trade-in bonus scheme is aimed at helping more drivers enjoy and benefit from the features of our latest side-by-side vehicles.”

The scheme will be supported by all participating members of the Yamaha dealer network.

Farmers looking to benefit should contact their local dealer for more details. The trade-in bonus will be provided in addition to the

part exchange value offered by the dealer.

The offer applies to all off-road vehicles, regardless of brand, be-

ing traded in against a new Yamaha recreational off-road vehicle (ROV). It is valid until 31 August 2023.

KRM have a full range of solutions to suit all situations budgets and crop types from cereals to vegetables including sugar beet and maize.

Our Econet range of inter row hoe’s are available with camera guidance and full auto section control via ISObus.

With chemical costs rising and environmental pressures, growers are increasingly choosing alternative methods of weed control.

•

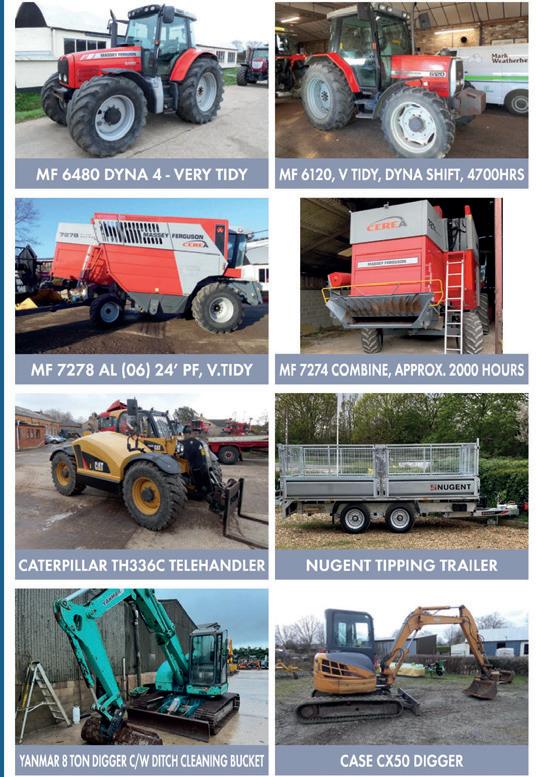

Dyna 4, v tidy.

• Kv Taarup 4232 3 2 trailed mower.

• New Holland 377 baler.

Other Equipment

• Dowdeswell DP7F, 7f, v tidy.

•

• MF 6120

v tidy, Dyna shift, 4,700hrs.

• New Holland TOSO & loader -5,900hrs.

• Caterpillar 407 ag telehondler (20091 • tidy.

• Various forks & grapples.

• MF 7278 AL combine (20061 • 24' PF, v tidy.

• MF 7280 AL combine (2012124' PF, v tidy.

• MF 7274 combine (20041 • 22' table, 208hrs.

• MF 30- 14' FF-v tidy.

• MF 40 RS -20' PF-v tidy.

• Vicon RV2160 Round Boler, v tidy.

• Krone 1270 Big Boler (20121, 44,389 boles.

• Krone 1290 HOP Boler-tidy.

• New Holland 940 Square Baler.

• New Holland 980 Big Bale.

• Lely 280 MC combi mower.

• Claas Liner 3100 twin rotor rake 10m.

KRON.

• KV LOBS Sf & 4f.

• Flat Lift Force • 2 leg HD buster.

• Knight Raven 3 leg combination, vgo.

• Vicon PO-EDW weightcell, vgo.

• Vicon RO-EDW extension hopper.

• Kuhn Axis 30. 1 spreader extension hopper.

• Cousins 6.2m hyd rolls.

• Cousins 1Om hyd rolls with rings.

• Richard Western 121 dump trailer.

• Armstrong & Holmes 14.51 trailer, vtidy.

• Bamford 9' topper.

• Major 1,600g vacuum tanker.

• 80" mounted rotovator.

• 450 & 600 workshop heaters.

• A full range of Nugent trailers.

Excavators

• Yanmar St & 3 buckets

• Case CX, 5 ob, St & 3 buckets

The all-electric front loader has a lifting height of 3.10m

Kubota has extended its baler range with the arrival of the FB1000 – a non-stop round baler wrapper combination that integrates a pre-chamber, main chamber and wrapper.

Machinery giant JCB used a Somerset dairy farm to debut its allelectric compact wheel loader.

The JCB 403E compact wheel loader was demonstrated at Neil Baker’s dairy farm in Haselbury Plunknett during the Down to Earth regenerative farming event earlier this summer.

Mr Baker is one of Arla’s re-

generative pilot farms, focusing on reducing emissions from his herd of 1,800 Holstein cows.

The JCB 403E was developed for various farming enterprises, including livestock and arable units. With a lifting height of 3.10m, it includes an integrated charger to connect to various power sources and comes with a starting price tag of €79,900.

Designed and developed by sister company Kverneland Group, the FB1000 uses two bale chambers arranged in series so a number of rollers can be shared. Operating as a pre-chamber, the front half of the FB1000 produc es two-thirds of the bale.

As the pre-chamber reach es its preset density, crop flow is diverted into the main bale chamber, allowing baling to con tinue non-stop. The pre-cham ber is then opened, moving the pre-formed bale into the main chamber, where it is increased to 1.25m in size.

Once bale formation is com plete, crop flow is switched back

to the pre-chamber without stopping, allowing round baling to continue as a non-stop process. Netting is then applied to the completed bale in the main chamber.

After this, the tailgate is opened and the finished bale is transferred onto the wrapper.

The FB1000 was designed and developed in Italy, says Kubota

ple, reliable and fuss-free, the FB1000 uses a wrapper frame mounted on a parallel linkage. This enables the wrapper to be lowered from its working position to collect the completed bale as it rolls from the main chamber. This avoids the need for a complex mechanical transfer system. With the bale collected, the wrapper is raised to allow twin satellite arms to rotate around the bale. Unlike traditional wrapping mechanisms, these arms

Two Essential Farm Machinery readers each won a 205-litre barrel of Agrimax UTTO 10w-40 universal tractor transmission oil – each worth about £1000.

The competition was organised by Morris Lubricants – and each barrel of oil was signed by TV presenter, former motorcylcle racer and celebrity mechanic Guy Martin.

It coincided with a series of videos to give farmers and contractors working in the agricultural sector with an insight into how oil is made – and the factors that should be considered when choosing a lubricant supplier.

The two competition winners each received a specially signed barrel of lubricant. They were Norfolk farmer Charles Clarke, of Micklehaugh Farm, Barnham; and Essex farmer James Strathern, of Park House Farm, Layer Marney.

Mr Clarke said: “We have used Morris Lubricants for a number of years now on our small 35ha (85 acre) farm and their range of products suit our modern, classic and vintage tractors very well. It’s always good quality and the machines run well on it.”

l Order via our online shop for next day delivery

l Comprehensive range of hydraulic adaptors, BSP, JIC, ORFS, DIN 2353 tube fittings and many more available in stock.

l Stockist of premium quality Quick Release Couplings and hydraulic Test Point fittings

l Family owned UK manufacturers of premium quality hydraulic adaptors for over 55 years.

l In excess of 36,000 components manufactured every day

l ISO 9001 accredited

Crop cleaning and separation is easier on a Hertfordshire farm which has taken delivery of a vibrating sieve cleaner from McArthur Agriculture.

Groundswell co-founder John Cherry, of Lannock Manor Farm, near Hitchin, first saw the JK Machinery JCM VibroMAX 10133 when McArthur Agriculture exhibited the sieve cleaner at last year’s two-day regenerative farming event.

Mr Cherry said he recognised that the machine would prove an essential piece of kit as he and brother Paul increase the amount of intercropping as part of their regenerative and agroecological farming practices.

“After discussions with McArthur Agriculture, I took the decision to invest in a Vi broMAX,” explained Mr Cherry.

“We had previously been us ing an old two-sieve pre-cleaner to separate crops but we often had to put crops through it twice, and one of the crops would still not be as clean as we wanted.”

“Mono-culture does not hap pen in nature, so we are planning to increase intercropping into our crop rotations. This will help improve soil health by increasing water and nutrient utilisation, driving up pest and disease resistance and weed suppression.

“But with larger amounts of crops to separate it was clear that we needed to upgrade our cleaning and grading capabilities so that we could add value to harvested crops on-farm.”

‘Best

The JCM VibroMAX 10133 is a triple decked machine equipped with three vibrating sieves which clean and separate crops to a high standard in a single pass, each crop being aspirated individually, via twin aspirators, to ensure the best results.

The performance of the JCM 10133 range of cleaning and grading equipment can be controlled through the changing of sieves and adjustment of several process variables, including machine angle and vibration frequency.

Mr Cherry has been experimenting with intercropping for around eight years mainly growing peas and rape as both were relatively easy to separate and clean using the old pre-cleaner.

He is looking to grow twin crops of wheat and beans; oilseed rape and peas; and peas and beans – with the aim of reaching a stage where each field contains two or more combinable or noncombinable crops.

“Many farmers are looking at intercropping trials, which can add complexity to crop rotation. But it also allows savings to be made on inputs and the combination of potentially smaller yields of both crops can deliver a larger yield than one crop grown alone.”

The Cherry family have farmed for 31 years, converting to a zero-tillage production system in 2010. “Intercropping is the future as it becomes an integral part of regenerative farming,” explains Mr Cherry.

“We started Groundswell seven years ago out of frustration that no-one was putting on a summer show that we wanted to at-

tend,” he adds. “Its popularity goes from strength to strength and in 2022 we welcomed over

Groundswell’s growth reflects the snowballing of inter-

est in regenerative agriculture, says Mr Cherry – not only from farmers but also from policymakers attracted by the ‘public benefits’ of such systems, including carbon sequestration.

More farmers believe rodent control is becoming harder, suggests a survey. Some 40% respondents to the BASF survey said controlling rodents had become more difficult over the past year, with many reporting that they felt this was largely due to rodenticide resistance.

Promisingly, though, the data suggests that awareness of the issue is increasing, with the number of those unaware if their farm is in an area of rodenticide resistance having decreased by

25% compared to last year.

This follows the launch of BASF’s virtual digital pest control training portal Real Results Virtual Farm last year, which aims to encourage farmers to gain CPD points for pest control before completing the CRRU Safe Use of Rodenticides certification.

This year BASF launched Monitoring Paste, a palatable, non-toxic bait block designed to help farmers monitor rodent activity and detect early signs of an infestation.

13’ X 9’ MODULAR TOILET BLOCK, SEPARATE MALE & FEMALE, 230V HOOKUP, TOILETS, URINALS, SINKS, LIGHTING, HEATING, HOT & COLD WATER OUTLETS, INSULATED CONSTRUCTION, JACK LEGS, LIFTING EYE POINTS, DRY CONDITION, £3,450

32’ X 10’ MODULAR CANTEEN OFFICE UNIT, 230V HOOKUP,

POCKETS, X2 OUTLETS, £750

• High-quality proven reliability

• Tried and tested technology

• Aimed at smaller arable units

Claas is extending its combine harvester product range below the Trion and Lexion series with two new fivewalker machines.

Equipped with modern Cummins six-cylinder engines and the Cemis 700 control concept, the Evion Classic is aimed at family farms and contractors operating across smaller field sizes.

The arrival of the Evion completes the restructuring of the entire Claas combine harvester range which began with the new Lexion in 2019. These three five-walker combine harvesters round out the lower end of the range below the Trion.

“The Evion is a very important product for Claas”, explains Claas chief executive Jan-Hendrik Mohr, who is responsible for the Grain Business Unit.

Affordable machine

“We are able to offer modern, yet affordable machines for smaller-scale farms which want their own grain harvesting equipment. We’re a family business and we want to continue to offer the right machines for smaller farms across all segments.”

Evion technology is based on the same modular system which is used to build almost 40 ver sions of the Lexion and Trion. “For the Evion, we are drawing on tried and trusted technology which has proven itself in thousands of machines,” says Mr Mohr.

Straightforward threshing with a large drum and maximum operating reliability

As well as focusing on using high-quality, proven components, delivering uncompromising threshing quality and ensuring operating reliability, even under difficult harvesting conditions, the development team have ensured that the Evion is easy to use.

It is therefore equipped with a single-drum tangential threshing unit with a large, 600 mm threshing drum and a synchronised impeller combined with five 4.40-metre-long straw walkers and a feeder housing width of 1,420mm.

This results in an impressive threshing concave area of 0.95m2 and a separation area of 6.25m2

provided by the straw walkers. Standard preconcave flaps under the threshing drum enable high throughput while also delivering excellent grain quality.

The threshing drum speed in the Evion Classic is infinitely adjustable over a range of 480 to 1,150 rpm using the Cemis 700 terminal. Concave adjustment is performed hydraulically from the cab and features integrated overload protection to prevent blockages..

Threshing concave is a Multicrop unit, so conversion measures are only needed rarely, if ever, when switching between common threshing crops. When conversion is required, the concave segments can be swapped out through the stone trap.

To provide more effective secondary separation and greater throughput, the centre risers of the straw walkers have been redesigned to loosen the crop mat even more effectively and to enable a faster transfer to the next

Another important factor –in addition to the threshing concave overload protection – in ensuring operating reliability is the sensor-based monitoring of the crop flow on the straw walkers.

As soon as any blockages begin to develop there as a result of difficult harvesting conditions, the operator receives early warning both in the form of an audible alarm and as a visual alert on the terminal display.

In addition, the optional Cemis AutoCropFlow automatically deactivates the front attachment and the feeder unit in the event of any imminent risk of blockages on the threshing drum or serious belt slippage so no more crop is fed in.

The sieve pan works with the upper and lower sieves moving in opposite directions and has a total sieve area of 4.80m2. The sieve design features frogmouth openings with optimised flow characteristics.

The grain tank integrated behind the cab Evion combine harvester holds 5,600 litres in the 410 version and 6,500 litres DCin the Evion model. Sensors alert the operator when the fill level reaches 70% and again when it is 100% full.

A grain tank inspection window gives the operator a direct, comprehensive view of the fill level and grain quality.All three Evion models have a 330mm diameter grain tank unloading auger and an unloading rate of 90 litres per second.

The 105-degree pivot angle of the grain tank unloading auger ensures that the operator always has a perfect view of the offloading process. An optional pivoting unloading spout provides high-precision control of the grain outflow.

New to the market is a mounting kit to fit a Stocks Ag Turbo Jet 10 to a trailed Sky EasyDrill. The kit allows separate metering and accurate application of Avadex through an additional set of outlets behind the drill’s press wheel.

The mounting kit is designed to integrate with the Sky EasyDrill and consists of a loading platform, steps and guard rail to meet all safety regulations and maintain a safe environment for the operator.

Precise metering

The Turbo Jet was displayed at this summer’s Groundswell event. It is specified for the 6m Sky EasyDrill, has been colour matched, fitted with a 240-litre hopper and includes an Avadex feed block metering roller, 32mm seed hoses and 10 outlet spreader plates.

Stocks Ag aftersales director

Tim Farrow said: “With this new option, we aim to meet the needs of Sky EasyDrill owners look ing for an applicator that will precisely meter and accurately spread Avadex granules through a separate distribution circuit.

“Granules are applied direct ly to the seed bed behind the drill allowing for a consistent even spread pattern. The application accuracy of the Turbo Jet mount ed on a Sky drill has been inde pendently tested and exceeds NSTS requirements.”

The goal is for an even appli cation. The applicator fitting kit is also available for the 4m and 8m EasyDrill; 4m specified with a Turbo Jet 8 (8 Outlets), whilst the 8m EasyDrill is specified with the Turbo Jet 10 (20 outlets), with the option of a 400lt hopper.

For ease of operation, the Tur bo Jet 10 is fitted with the intui tive i-CON Control, which allows for rates to be automatically controlled in proportion to forward

kit allows separate metering and accurate application of Avadex

The

speed for ultimate accuracy.

When the Turbo Jet is not being used for Avadex application, it can be used as an addi-

Maschio Gaspardo has launched a new version of its high-speed Chrono precision drill – with a key option to woo growers and contractors.

The 500-series Chrono can be set up to run with variable row spacings and is equipped with either 8 or 12 planting units, making it suitable for sowing a range of crops with 45cm, 50cm, 70cm or 75cm row spacings.

This versatility makes it possible for the operator to switch from drilling sugar beet in the morning to maize in the afternoon, the conversion taking less than two hours.

Whether customers opt for the fixed row variant or the variable spacing option, the 500-series

shares all the common features with the other high-speed precision planters in the Chrono range.

“The Chrono was specifically developed for fast-paced precision drilling with unrivalled seed placement no matter what shape, size or seed type,” explains Maschio UK field sales manager Dominic Burt.

“Adding a version to the range that can swap between 50cm and 75cm row spacings in under two hours puts the Chrono further

ahead of the competition and provides the customer with a much more versatile machine capable of drilling multiple crop types.”

While conventional precision drills might run at 7-8kph, the Chrono has the potential to at least double these work-rates, at the same time improving the accuracy of seed spacing and depth placement.

This level of precision is all down to the design of the metering unit. Using a combination of traditional vacuum singulation and then pressure delivery down

the coulter tube, the moment the seed leaves the metering disc it is kept under control.

A venturi ensures seed ends up in the soil without bouncing. The 15-degree angle of each metering unit means drops off the disc and straight down the coulter tube without touching the sides. This means seed spacing is consistently uniform.

Prices start from £76,535 for a standard fixed width 8-row Chrono 508, while variable row spacing and four additional planter units adds £8,950.

a wide range of agricultural and farm tyres, Ascenso aims to provide long-lasting tyres that are specially designed for a variety of farming applications, keeping everything in mind including vehicle type, terrain, weather and user needs.

Bag Supplies specialise in the supply of net bags and ventilated FIBCs to the agricultural sector. We carry a wide range of stock of monofilament and leno woven nets, in a variety of sizes and colours.

We provide delivery within 48 hours of your order being placed.

Bag Supplies offer a free personalised print and design service, so your packaging can be customised with your company logo and additional product information.

Please contact Bag Supplies for further details.

We’ve got it in the bag!