3 minute read

Going the extra mile for sustainability

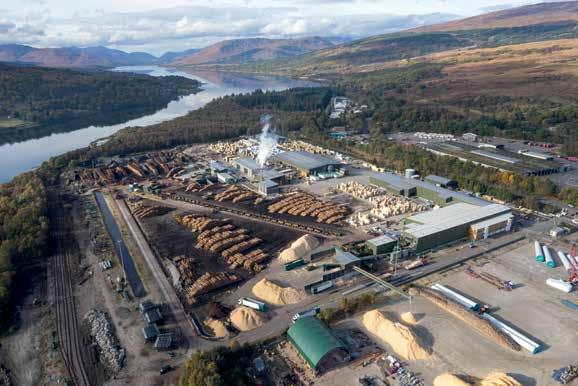

Tony Hackney, CEO of the BSW Group, highlights some of the firm’s most recent efforts to minimise the environmental footprint of their operations.

Over the last few years, sustainability has become a buzzword across industries and forestry is no exception. But while the word can sometimes be thrown around meaninglessly, it’s encouraging to see more companies committing to producing timber in a way that minimises environmental impact.

As the UK’s largest forestry business, at BSW Group we pride ourselves on innovating and implementing initiatives that go above and beyond industry requirements. We believe it’s the role of companies such as ourselves to push boundaries and set the standards when it comes to operating sustainably.

It’s great to see lots of businesses start to consider their carbon footprints, but the work of lowering emissions, reducing waste and improving the processes of reducing, reusing and recycling raw materials, can’t be something that is merely tacked onto the job description of department heads as a box-ticking exercise. Our approach is more holistic, it’s all of our responsibility not just the management team.

Alongside having individual sustainability targets for each part of the BSW Group, we have also recently created the new role of Carbon Manager to oversee management of carbon output across the entire group.

As a business that plays a part in every element of the timber industry, BSW is unique in its ability to develop this co-operation between stages of timber manufacture. Our wood waste, for example is used to create heat for drying timber in the kiln process, removing the need for burning fossil fuels. The heat generated from this process allows us to heat our buildings and offices, again limiting the requirement for traditional heat provision methods.

Having previously upgraded our mechanical handling vehicles to models with Tier IV diesel engines (which reduce harmful emissions by 85%), we have recently taken the decision to switch to a Tier V powerplant producing zero emissions and which also help to eliminate the fine soot particles that can cause air pollution and have negative health effects.

Efficiency is also a key part of this journey. Of course, machinery is needed for the manufacturing of timber, but the industry needs to work on operating them in an effective and energy-saving manner.

We are determined to improve this at BSW. Alongside trialling new, more intuitive electric forklifts, we are also installing digital management systems and weighing scales to all new vehicles to guarantee that we can get the optimum efficiency every day.

Of course, alongside these energy saving measures, we are also continuing to explore more renewable energy sources.

THE KEY TO TACKLING SUSTAINABILITY IS HAVING THE WILLINGNESS TO CHANGE AND ADAPT – CONSTANTLY ASKING, CAN THIS BE DONE MORE EFFECTIVELY AND SUSTAINABLY? THIS MEANS CONSTANTLY INNOVATING AND TAKING ADVANTAGE OF NEW TECHNOLOGY.

Our Carlisle mill has a CHP (Combined Heat and Power) plant, and we are also investigating solar power at many of our processing plants.

Another element of timber production which can be improved is packaging. Reducing, reusing and recycling packaging, especially plastic, needs to be a key focus for us all.

We have partnered with Trioplast to make sure that all timber packaging used in our sawmills will be produced from 30% - 50% PCR (post-consumer recycled material) by 2022. After our use, it is then recycled itself, demonstrating a circular journey that reduces landfill plastic.

As an industry and as individuals, it is important that we are neither naïve nor complacent about our responsibility to work towards reducing our impact on the planet. The great strides that have been made in the last ten years alone show that the job, whilst difficult, is not impossible.

When you plant a tree, it is most likely the next generation that will be able to benefit from your hard work. With cooperation, innovation, and a willingness to adapt, we can all do our bit to ensure that our hard work is able to benefit generation after generation after generation.