3 minute read

Raising the bar with embossing

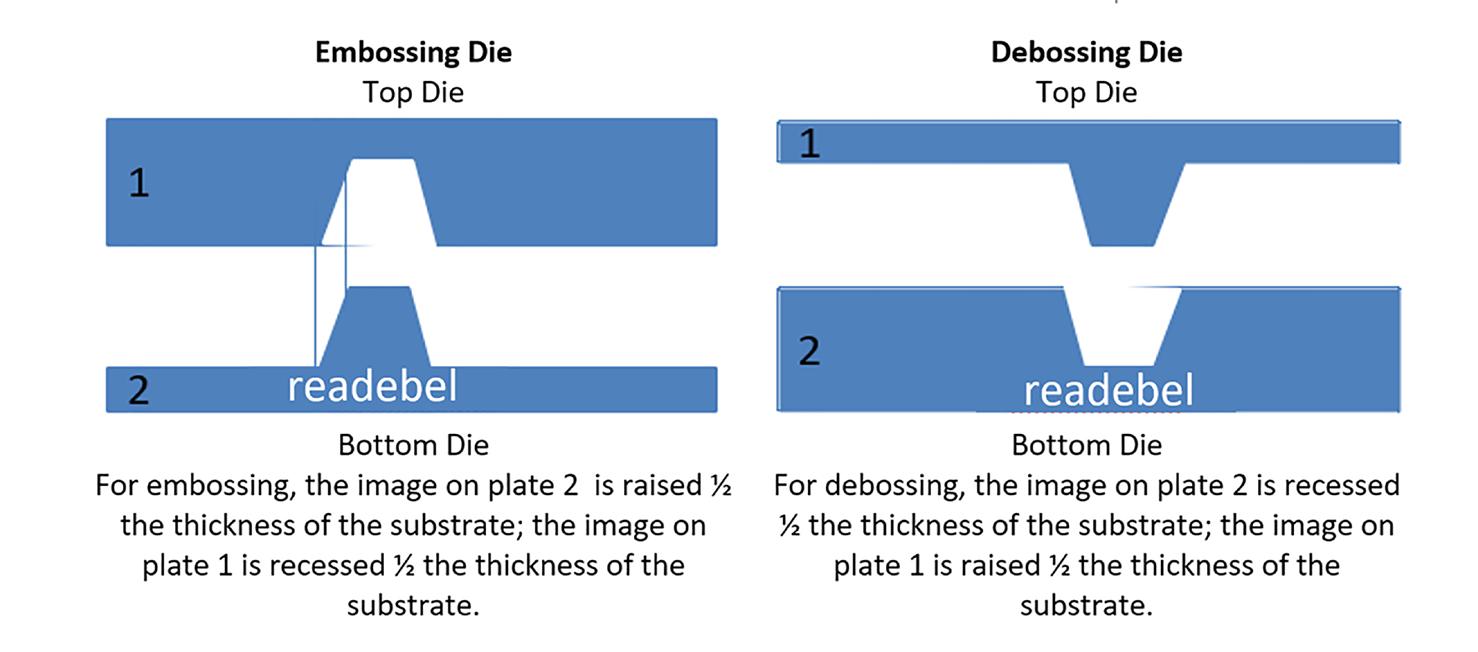

Embossing is one of many embellishment processes used in printing that gives labels a unique and appealing look with a raised image or pattern. There’s also the process of debossing that gives an opposite, relief effect.

Both applications can be done by rotary, semi-rotary and flatbed processes, with flexibility either online during printing or offline.

Advertisement

The processes explained Setting up the embossing plates is a very precise and critical step. When you engage the male and female dies for the first time, you want to prevent damage, potential flattening of the edges, and a poorly embossed image. If the dies are damaged and have to be remade (die making is usually contracted out), the delivery date will potentially not be met and extra costs are added to the job. When the two plates are engaged, the paper needs to be placed between both dies without being damaged. If the placement is incorrect you can get cracking on the edges or even a holepunching effect. Dies are manufactured from a range of materials depending on a number of factors such as: Nature of material to be embossed Complexity of image Depth of relief Perceived productive life Requirements specific to product use, e.g. food or pharmaceuticals Rotary embossing Rotary embossing can either use magnetic polymer dies (plates) used in a die unit, metal engraved solid cylinders dies used on longer running jobs, or polymer dies (plate) with an adhesive backing tape applied on a cylinder in a

dedicated embossing unit.

Semi-rotary embossing Due to the nature of the web movement, semi-rotary embossing units use between 50 to 80% of the cylinder depending on the system.

It’s more common that the embossing plate is magnetic or made of a polymer die. Depending on the complexity, the job will determine the press speed, but semi-rotary is generally slower that rotary.

Flatbed embossing Flatbed is the oldest method of embossing; in the past, a hard-set plaster product was sometimes used. This was premixed upon use and was called PragoPlast; it’s still used today not as common with current technology available.

The process only requires a top plate with a reversed image to press the image into the PragoPlast on the bottom plate. There are many types and plate combinations for a flatbed, and if the unit is used for foiling it’s also possible to apply heat for longerlasting embossing.

To prevent plate damage, sometimes the bottom plate can be made from brass and the top plate a polymer or thin brass plate. Flatbed has the longest contact-with-substrate time and the possibility of fine adjustment provides a high-quality embossed image.

Choice of die depends on a number of factors: Sharpness and depth of required embossment Complexity of image Area of material being embossed Type of material being embossed Construction and power of the press Size and volume of the product expected to be produced R&D for best results

As with choosing the die and other applications, it’s always good to do some R&D to determine what’s works best with your machine and types of jobs. The benefits of R&D outweigh any downtime of the press or other factors.

There are many benefits to having all the required information on what type of embossing plate to use, stepping information and anything else you may need to get the job running quickly and smoothly. Setting up a job only to discover something isn’t correct is costly and time-wasting. Therefore, especially when doing something new, R&D is critical.

Article by Kane Marsh

Regional Printing Instructor Asia Pacific with MPS Systems Asia.