23 minute read

News from around Asia and the world

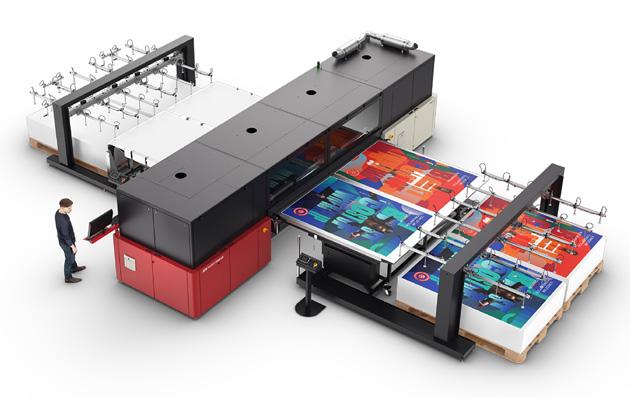

Canon introduces new Colorado ProCare After Sales Service Programme

Targeted for Colorado 1650 users, the programme increases productivity with minimal downtime.

Advertisement

Canon has launched its new ProCare after-sales service programme in South & Southeast Asia, designed for users of the Colorado 1650 rollto-roll wide format printer series powered by UVgel technology. With the objective of offering a consistent service concept for customers with production in multiple region, Colorado 1650 owners can now benefit from maximised uptime through access to spare parts, preventive maintenance and remote software application support.

ProCare contracts are available on the basis of three to five years, with the option to extend support after the initial contract has ended. Additional premium support options include next business day onsite response and print head replacement. Colorado ProCare is available via Canon Appointed Partners or directly from Canon for customers across Singapore, Malaysia, Thailand, Hong Kong, Indonesia, Taiwan, Sri Lanka and Pakistan.

Performance You Can Rely On Colorado series printers are designed for optimal productivity with minimal operator intervention and manual maintenance. The ProCare service programme extends this philosophy, backed by a skilled team of service technicians, strong global logistics network as well as state-of-the-art communication and diagnostic tools.

This means print service providers can focus on what matters most - exceeding client expectations on quality, delivering within tight turnaround times, growing their business and increasing profits.

“With more than 1,500 installations of Colorado printers worldwide, it is clear that our customers see the benefits that UVgel technology brings to their business – the perfect balance of productivity and quality at a reduced Total Cost of Ownership. With Colorado ProCare, we look to further complement the impeccable features of the Colorado printers, so our customers can experience the full value of their investment. They know they have a technology they can rely on and a solutions partner who will always be at their side to ensure that,” said Steve Ford, Managing Director, Production Printing Asia, Canon.

Kornit Digital Appoints Ilan Elad to Lead Asia-Pacific Regional Expansion

Kornit Digital a worldwide market leader in digital textile printing technology, announced the hiring of Ilan Elad as incoming President of the company’s Asia-Pacific (KDAP) division.

Based in Tokyo, Elad has served Daimler Trucks Asia since 2013, most recently as Vice President of Sales— Africa, SAARC, Oceania. Previously,

he was Founder and CEO of Vision India, as well as Regional Managing Director NEU with telecommunications company Ciena. Elad has successfully spearheaded go-to-market strategy and execution across multiple continents, with a specific focus on Asia and Oceania in the past 12 years, accumulating vast market insights and leadership instincts that will serve Kornit’s commitment to growth and industry leadership in Asia-Pacific territories—particularly Japan, the world’s fourth-largest e-commerce market.

In recent months, Elad has served as a consultant to Kornit Digital in support of several expansion opportunities, allowing him to become acquainted with Kornit’s global business, in addition to giving Kornit full confidence in Elad’s qualifications as an executive leader.

“I’ve been aware of Kornit’s growing position as a tech leader for several years, and was genuinely moved by the opportunity to join such an inspiring and disruptive organization,” said Elad. “Mature and ready to grow, Kornit checked all the boxes for me. It’s a creative brand that clearly invests in growth, offering precisely the kind of culture and diversity I’ve been looking for, and one where I’m certain I can create new opportunities from the first days.”

“Efficient, sustainable, digitized production capabilities are essential to businesses moving from traditional retail cycles to the web-driven, on-demand economy, and nowhere is truer than in Asia-Pacific, where a

great deal of the global textile supply chain begins,” said Ronen Samuel, Kornit Digital CEO.

“We could not ask for a more knowledgeable, capable, proven candidate than Ilan Elad to lead Kornit’s charge towards innovation leadership and market dominance in this critical region. His appointment reflects our high standards for giving fulfillers and brands the partner they need to generate new business, expand their operations, and elevate the textile industry to be the model of eco-consciousness, versatility, and profitable expression it’s capable of being.”

EFI unveils new suite of cloud applications

EFI introduces EFI IQ, a new suite of free and paid cloud applications that enables smart, data-driven decisions for cut-sheet operations. EFI IQ is designed to operate with Fiery Driven™ cut-sheet digital printers. To access IQ’s free applications, businesses can simply open an EFI IQ account online. Additional paid applications in the suite, including EFI ColorGuard and the new EFI Manage, extend users’ capabilities. Driving value from data

The free applications in this cloudbased suite help printing businesses extract value from data to minimize bottlenecks, optimize equipment utilization and increase profit.

EFI IQ Dashboard provides a personalized view of a user’s digital printing operation and is the launching pad for all EFI IQ applications. Users can monitor the status of any printers, consumables and job status on their Fiery Driven printers. Printer groups as well as role-based permissions allow for managing more sophisticated environments with many printers or users.

EFI Insight provides users with deep historical data in an interactive environment to help users transform print production data into actionable analytics that drive business improvement. Insight displays trend analytics, including shift and other comparisons. Print users can use this intelligence to make data-driven decisions to increase shop floor productivity, or import a job log to perform extensive analysis.

EFI Notify allows users to get production-blocking alerts, as well as establish timing for automatic distribution of production reports.

Customers can also get IQ capabilities such as dashboard metrics, notifications and more on their mobile phones via the EFI Go app.

Extended capabilities for in-depth quality and production control

The suite has paid applications as well, including the EFI ColorGuard, a winner of 2019 SGIA Product of the Year Award for colour enhancement software. This cloud-based software helps automate and standardize colour verification and calibration processes to help ensure printers get the best colour output. By ensuring consistently accurate colour, users can win more business, reduce waste and eliminate rejected jobs.

Sites with many Fiery digital front ends will benefit from subscribing to the EFI Manage application, which remotely monitors Fiery DFEs to keep

production running at its best, syncing print devices and setting compliance targets for the best print production outcomes.

“Print operations generate an overwhelming amount of data, and it can be difficult to transform that volume of data into actionable business insights,” said Toby Weiss, senior vice president and general manager, EFI Fiery. “Our objective with the EFI IQ suite is to make data readily available in a form that makes it easy for users to take action. That way, customers can optimize production in real time with a goal of creating the most efficient and effective digital printing operation possible.”

A suite of applications, a wealth of benefits

In summary, the EFI IQ Suite helps businesses of all sizes: • Make informed decisions to grow their businesses using EFI IQ data and analytics; • Leverage past production data to improve future performance with production analytics from EFI Insight; • Boost shop floor productivity with status alerts using EFI Go; • Satisfy colour-critical print buyers with consistent, accurate colour with EFI ColorGuard; and • Keep print production running smoothly with EFI Manage.

Future enhancements to the EFI IQ suite will bring many of its capabilities to wide and superwide-format inkjet printers as well. Fiery users can create an EFI IQ account or find more information at https://iq.efi.com.

Durst acquires digital printer manufacturer s

Durst acquires majority stake in US printer manufacturer Vanguard Digital Printing

Vanguard Digital is a leading manufacturer of printing systems for the signage, decoration, corporate, industrial and packaging sectors.

With the acquisition, Durst adds new printer classes to its large format portfolio while Vanguard now has a global distribution and service network and technical resources to continue developing robust solutions.

"Vanguard Digital Printing Systems is a rapidly growing and very successful company in a customer segment in which we are currently not active," said Tim Saur, President of Durst North America. "Through the combination of high-quality products, a strong management team and absolute customer orientation, both companies are a perfect match."

As part of the agreement, the new company will operate as Vanguard Durst Digital Printing Systems with effect from October 1, 2020. David Cich remains CEO while Jim Peterson continues to serve as Vice President of Sales. will now be a part of the world class industry leading Durst Group,” said David Cich, CEO of Vanguard Digital Printing Systems. “Becoming part of the Durst Group Family, provides Vanguard Digital the opportunity to expand its portfolio of innovative market leading UV Printers to the entire world."

"Vanguard's printing systems have rightly achieved rapid growth and high customer acceptance in the North American market," said Christoph Gamper, CEO and co-owner of the Durst Group. “Despite the global pandemic, we are positioning ourselves for the long term and are determined to invest in the large-format graphics market. In addition, with our technical expertise, Vanguard will continue to ensure that its products and services are industry-leading and a wider customer base will understand what it is like to be part of the Durst family. "

Fuji Xerox’s online event focuses on navigating the ‘new normal’

Industry leaders and analysts share perspectives and solutions to build business resiliency post-pandemic Fuji Xerox Singapore presented the third edition of its flagship event; Innovation Re:Mix Forum Work Reimagined 2020. This year, the event took place online on IDC’s proprietary platform, IDC Arena.

With approximately 80% of organisations in Asia Pacific expecting a decline in 2020 revenue, the Innovation Re:Mix Forum is particularly timely as it explores the many facets businesses face in their accelerated digital transformation journeys to ensure business continuity in the current climate.

Aligned with Fuji Xerox Singapore’s corporate practice ‘Genko-Itchi’, a Japanese concept of walking-the-talk, Fuji Xerox Singapore leads this charge,

with the agenda of the three-day conference set by new Chief Executive Officer Koh Ching Hong, who assumed his role amid the pandemic.

“As Fuji Xerox innovate within to meet the new demands in the marketplace, we are also enabling our customers with new ideas in transforming how their processes work in new digital world, how their distributed workforce collaborate more effectively, and how they are able to re-connect and re-engage their customers and stakeholder as we go into the next normal,” said Koh. “This is emphasised in our annual Innovation Re:Mix Forum as we explore how organisations, big and small, can pivot their business and future-proof operational resiliency and customer engagements amidst current challenging times.”

A fireside chat with Sandra Ng, Group Vice President, Practice Group, IDC Asia/Pacific brought to focus the significance of redefining, rethinking and refreshing workplace collaborations to ease into the ‘new’ normal and enhance business outcomes with Internet of Things (IoT), Artificial Intelligence (AI) and a sturdy Application Programme Interface (API).

The Work Reimagined edition explored three themes with a lineup of business and thought leaders from sectors across banking and finance, insurance, healthcare, retail and logistics: ‘Reboot Your Workplace in the New Normal’, ‘Digital Disruption: Pivoting Your Business for a Strong Future’ and ‘Building Resiliency with Digital Acceleration’.

The Innovation Re:Mix Forum Work Reimagined 2020 concluded with an on-demand Solutions Showcase where delegates were offered various types of solutions tailored to their organisation’s needs to view and

experience at their convenience. In addition to corporate motto of ‘Genko-Itchi’, Fuji Xerox Singapore believes in a bespoke approach in empowering their customers’ digital journey.

The company’s dedication is also reinforced as it launched 19 new models from its digital multifunction printer ApeosPort and DocuPrint series recently, to support customers in accelerating efficiency while enhancing security, document management and remote working capabilities.

Next generation in its 3D printing product line

BCN3D, a leading 3D printer manufacturer, announced the next generations in its 3D printing product line, the Epsilon W27, the Smart Cabinet, and the Sigma D25. With the new product introductions, in addition to recent investment in the business and significant new appointments, BCN3D unlocks a new era in its growth and demonstrates its commitment to providing an innovative and expansive product portfolio, cementing its position as a major player in 3D printing.

At the height of the global coronavirus pandemic BCN3D succeeded in securing a funding round led by industrial Group Mondragon, CDTI (Centre for Industrial Technological Development) and Danobatgroug. The 2.8 million euros will allow the Spanish manufacturer to continue to innovate and expand its range of 3D printers further to help innovators and creatives.

“With new integrated solutions in the both the desktop and workbench segments, BCN3D has a range of products that will take the business to a new level. We are also working more closely than ever with an unparalleled network of sales and support partners to ensure the best possible experience for our customers on a local level,” explains Xavier Martínez Faneca, BCN3D CEO.

With the new Epsilon Series, BCN3D provides industrial power for the seamless daily operation of applications such as low volume production, functional end-use parts, and manufacturing aids in the workbench segment.

The flagship model Epsilon, announced last November, is now renamed as Epsilon W50, and is joined by the new Epsilon W27, providing the same functionality but with a smaller build volume (50 liters vs. 27 liters) and competitive pricing.

The new Smart Cabinet completes the Epsilon ecosystem, offering seamless integration with the BCN3D Epsilon printer and boosting its performance. Its filament humidity control keeps materials in optimal condition, and an Uninterruptible Power Supply (UPS) protects the print job at all times, eliminating the risk of losing a print job due to power outages. The Sigma Series now consists of the Sigma D25, the next generation of the Sigmax R19, replacing the acclaimed Sigma and Sigmax 3D printers.

Known for the IDEX (Independent Dual Extruder) system, unique to BCN3D desktop 3D printing technology, and large build volume, the Sigma D25 takes up the mantle of the Sigma series whilst offering improved functionality.

Re-engineered with state-of-the-art features, the new Sigma D25 provides full accessibility for easy workflow. Developments include enhanced heat distribution, a refined calibration process, new embedded electronics, a refined extrusion system and reinforced axes. It is engineered to provide maximum productivity for applications such as design prototypes, functional prototypes, and for educational and research purposes.

“I see it as our job every day to make every aspect of the customer experience better. With the launch of this new portfolio, I strongly believe we have done just that. The new fully integrated product offering means customers can find the quality and productivity they need at the pricepoint they can afford, making it easier than ever for users around the world to innovate and create faster,” says Eric Pallarés, BCN3D CTO.

The Epsilon W27 and Sigma D25 are available for pre-order now and will be available locally via BCN3D sales partners worldwide on October 19th, 2020. The Smart Cabinet will be available from spring 2021.

BOBST launches new gravure printing press for flexible materials: the EXPERT RS 6003

BOBST has launched oneINSPECTION, a set of quality control solutions to proactively meet the needs of brand owners and converters. The solutions aim to make zero-fault packaging a reality in the labels, flexible packaging, folding carton and corrugated board industries, while also providing value to packers, retailers and consumers as part of the packaging value chain.

oneINSPECTION ensures an endto-end data driven quality process specifically tailored for each industry, which can be deployed in both new and existing production lines. It is a core enabler of the BOBST vision to shape the future of the packaging world and a core component of BOBST CONNECT, an open architecture cloud-based platform delivering solutions for pre-press, production, process optimization, maintenance and market access.

“Brand Owners and converters are faced with increasingly tight margins and timelines, which places huge amounts of pressure on quality control,” said Alexandre Pauchard – Group R&D Head. “We have launched oneINSPECTION to alleviate these pressures. Most companies no longer have the luxury of quality control personnel carefully checking their packing and filling processes. That is why our solutions are highly digital, automated, completely reliable, inline and offline. They offer peace of mind for converters and brand owners alike.”

The current solutions for each industry are as follows:

Labels • Print Tutor Max – a system specifically designed to measure and control color for DigiColor. • iQ 500 – a 100% inline quality control system checking each individual label for quality, color, codes, text and register.

Flexible Packaging • HAWKEYE – an optical density and pinhole detector monitoring system. • Digital Inspection Table – a quality center that enhances the operator’s skills with augmented reality overlays while gathering photographic evidence for audit; ensuring trust and top production quality for flexible packaging production.

Folding Carton • New ACCUCHECK – a 100% inline quality control system checking each individual blank for quality, color, codes, text and register. • iQ 400 – a 100% inline quality control system for web-fed folding carton production.

Corrugated Board • iQ 300 – a 100% inline quality control system for corrugated production • PREMIUM GAP CONTROL – a system controlling the folding process of all finished boxes at full production speed. • Digital Inspection Table – a quality center that enhances the operator’s skills with augmented reality overlays while gathering photographic evidence for audit; ensuring trust and top production quality for corrugated

packaging production.

Ultimately, oneINSPECTION will provide a range of end-to-end quality control solutions, which will close the loop from artwork design to the final product through BOBST CONNECT, resulting in reduced production recalls and waste.

“oneINSPECTION moves quality control into the digital age,” said Pauchard. “It perfectly reflects our vision to shape the future of the packaging world through four key pillars of connectivity, digitalization, automation and sustainability, in this instance by aiming at delivering a new range of equipment and solutions that leverage digital intelligence, software and cloud-based platforms.”

For converters, oneINSPECTION means complete peace of mind, enabling them to deliver the highest possible quality products to brand owners, while simultaneously improving efficiency and profitability. It puts guaranteed quality control at their fingertips, making zero-fault packaging a reality.

Agfa adds upgradable large format printer to Jeti Tauro range

Agfa has added a new model to its Jeti Tauro large-format inkjet printer family.

The latest member of the Jeti Tauro family is called the Jeti Tauro H3300 LED S (S for ‘standard’). It is a favorably priced entry model that will enable an even wider range of printing companies to benefit from one of Agfa’s flagship large-format printers.

This new hybrid six-colour printer, with optional white and primer, boasts award-winning quality at a top speed of 302 m² per hour, which can be upgraded to the even higher speed of the Jeti Tauro H3300. It shares the latter’s short start-up times and quick and easy maintenance, while also featuring the same automation options.

That means it will be available in six possible configurations. Four of these are dedicated to board printing, ranging from manual to fully automatic. The 3/4 automated version makes use of an automatic board feeder, which is particularly convenient for shorter runs and a fast, efficient changeover between various media sizes or types. The two remaining configurations focus on roll printing, with a master roll-to-roll and a light roll-to-roll model.

The Jeti Tauro H3300 S LED is powered by Agfa’s Asanti workflow software, which controls and automates the entire printing process from prepress to finishing, while guaranteeing colour consistency and optimizing ink consumption. The smart Asanti Production Dashboard displays ink and media consumption and printing time for each job and printer. is ready for installation as of this moment.

“We are committed to inkjet printing and we aim to support our customers by offering them complete and perfectly matched solutions that make their operations more efficient and productive,” said Reinhilde Alaert, Product Manager Sign & Display.

“The new Jeti Tauro H3300 S LED is built on the same platform as its bigger brother and marks another step in the expansion of our high-end large-format inkjet printer family. It covers a wide range of media sizes and types – for boards and sheets as well as rolls – and supports all print jobs with fitting automation options that ultimately enable operators to tend to multiple jobs and printing engines simultaneously.

The printer’s upgradability to the speed of the existing Jeti Tauro H3300 model makes it an ideal starting point for print service providers’ further growth in sign & display printing.”

Outstanding Innovation Award in Production Print

Keypoint Intelligence, the world’s largest business intelligence and testing provider for the digital imaging and business communications industries has awarded the revolutionary Tonejet Cyclone with an Outstanding Innovation Award in Production Print to reflect not just its innovative and unique design but the environmental value it brings users by replacing plastic shrink sleeves and labels.

The Tonejet Cyclone is an environmentally friendly alternative to shrink sleeves and pressure sensitive labels, a direct-to-shape, fully variable digital can printing system, decorating 60 cans per minute with the same feel and higher quality than traditionally printed cans.

“We’re delighted that the Cyclone has been recognized with an Outstanding Innovation award” comments Rob Day, CEO at Tonejet. “It’s important as it validates our mission to innovate and disrupt the status quo in beverage packaging, enabling craft brewers and global brands alike to realise the benefits of direct digital print productivity and short-run agility, while reducing their overall environmental impact.”

“The Tonejet Cyclone uniquely addresses the booming customized and personalized marketing segment with a system that prints directly onto beverage cans, at a lower cost than traditional decorating methods,” notes Marc Mascara, Director, Color Digital Labels & Packaging at Keypoint Intelligence. “Just as importantly, cans produced on the Tonejet Cyclone are 100% recyclable, so there are huge environmental benefits compared to add-on labels or shrink sleeves.” Also noted for its unique printhead technology, the Cyclone enables both mass customization and cost-effective short production runs.

Craft beverage producers like BrewBoard in the UK and Worthy Brewing in the USA are already reaping the additional marketing and branding opportunities made possible by direct-to-can printing technology from Tonejet. Tonejet pioneer SoluCan is doing some amazing things for their Canadian and US customers including Augmented Reality (AR) campaigns. The Cyclone technology is a truly versatile system that will benefit smaller craft beverage producers as well as larger global brands wanting to capitalize on shorter runs, limited-edition drinks, or marketing campaigns.

16 th

FREE ENTRY FORM DEADLINE 5PM NOVEMBER 3RD 2020 3 Windy Hill Drive, Mulgrave,3170 Victoria, Australia

SINGAPORE - THAILAND - INDIA - MALAYSIA - JAPAN - HONG KONG - CHINA - KOREA - TAIWAN - VIETNAM - INDONESIA - SRI LANKA - PHILIPPINES - CAMBODIA - MYNAMAR

The annual Asian Print Awards was founded to recognise outstanding achievement in the print and packaging industries across Asia. With more than half the world’s population represented in this fast growing area, communication in the form of printed matter links Asia’s diverse cultures. It is imperative that such print achievements do not go unrecognised, especially among the population base that Asia enjoys.

The Awards are judged on a wholly quality-oriented set of criteria to ensure that fair play is enacted at all times.

The Independent Judging Panel comprises highly qualified personnel from within Asia and around the world. The independent judging panel has no knowledge of the actual entrants details. ALL ENTRIES ARE NUMBER-CODED. Entries must be commercially produced work.

The Asian Print Awards is the only regional print quality competition of its kind in Asia. Supported by leading industry-supply companies, any progressive quality print house should enter and prove that they are the best - by winning the Gold, Silver or Bronze award. Proving pride in quality awareness is what customers love to see. It’s not just empty words, you can prove it.

Categories 1-8 : Offset Printing Only

1. Calendars – any format

2. Sheetfed Magazines

3. Book printing – less than 4 colours

4. Book printing – 4 or more colours

5. Limited Editions & Artwork Reproductions (under 1000 print run)

6. Web Offset – Coated stock 70gsm and above

7. Web Offset –LWC (light weight coated) 65gsm or less

8. Offset Packaging products

Categories 9 - 21 : Digital Printing Only

9. Book Printing

10. Calendars

11. Personalised photo books – any format.

12. Posters

13. Showcards & Point-of-Sale material

14. Digital Magazines

15. Gold, Silver and Special colours 20. Digital Labels

21 Digital - Outdoor Billboard

Categories 22-26 : Specialty Categories

22. Multi–Piece Productions and Campaigns

Any substrate or print process: Multi–piece Production must be 3 or more items such as folder, leaflets, ring binders, inserts, envelopes including their contents.

Campaigns must be 3 or more items with a consistent theme produced during the year by the same printer for the same client.

23. Embellishment

Any substrate – any combination - for example: embossing – diecutting – foil stamping –laminating - coating.

24. Innovation / Specialty Printing

The entry must exhibit any innovative and/ special application of machinery, process, substrate or finishing.

A short description must be provided for the judges, detailing reasons for entry into this category.

25. Company Self Promotion Any item printed to promote a product or company involved in the graphic arts industry. Self promotion cannot be entered into any other Category.

26. Judges Special Award (A job that catches all the Judges’ attention)

16. Restaurant Menus

17. Limited Editions & Artwork reproductions (under 500 print run)

18. Digital Proofing (must supply the digital proof and the prinnted product)

19. Digital Packaging Best in Digital Award

Best in Offset Award

Best Use of Colour Award

SECTION A (This will not be shown to judges). Please fill the form in capital letters.

Entered by (company name): ______________________________________________________________________________________

Contact Person: ________________________________________________ Email______________________________________________

Address: ___________________________________________________________________________________________________________

Telephone: __________________________________ Country________________________________

Category entered __________________________

Title of entry (ie: " Paul's Ice Cream" ): ____________________________________________________________

Printed by (Printers name): ________________________________________________________________________________________

Client name: ________________________________________________________

Designer Pre Press House: ___________________________________________________________________________________________

Brand of Printing Machine used: _____________________________________________________________________________________

Stock supplied by (Merchant’s name): ______________________________________________________________________________

Brand name of stocks Coated Uncoated: ____________________________________________________________________________

By signing here you accept the rules and conditions of the Asian Print Awards

Signature over printed name_____________________________ Name_____________________________________________________

SECTION B Production information to be shown to judges ( tape this securely to the back of your entries)

Category entered (Same as above): __________ Entry number (Administrative use only] ____________

Title of entry (ie: " Paul's Ice Cream" )__________________________________________Print method: _______________________

Number of ink colours (4-6-8 etc) ________ Any Embellishment (foil stamping etc) __________________________________

Quantity produced (Print run copies): ___________ Other technical details (finishing processes etc) ________________________ This Year due to COVID-19 the Judging will be done in Australia ____________________________________________________________________________________________________________________ The Awards will be held in December in Asia

16th Asian Print Awards 2020 ENTRIES SUBMISSION CLOSES 3rd NOVEMBER 2020, 5pm Send all entries to: APAM Pte Ltd, 3 Windy Hill Drive, Mulgrave,3170 Victoria, Australia